Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Improve waxing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

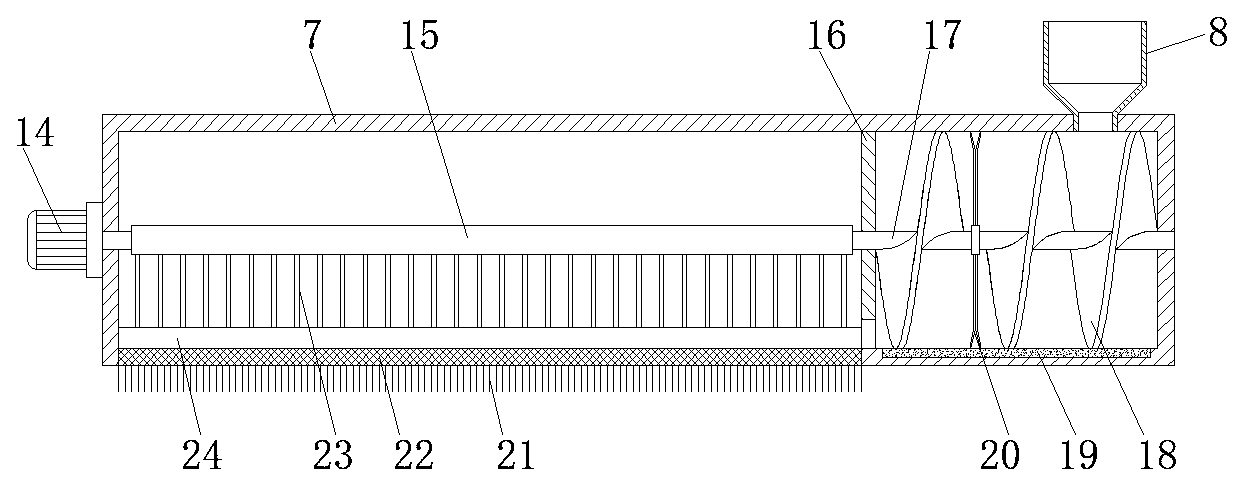

Seven-axis linkage numerical control polishing machine

InactiveCN101607380AImprove polishing qualityImprove stabilityPolishing machinesNumerical controlMechanical engineering

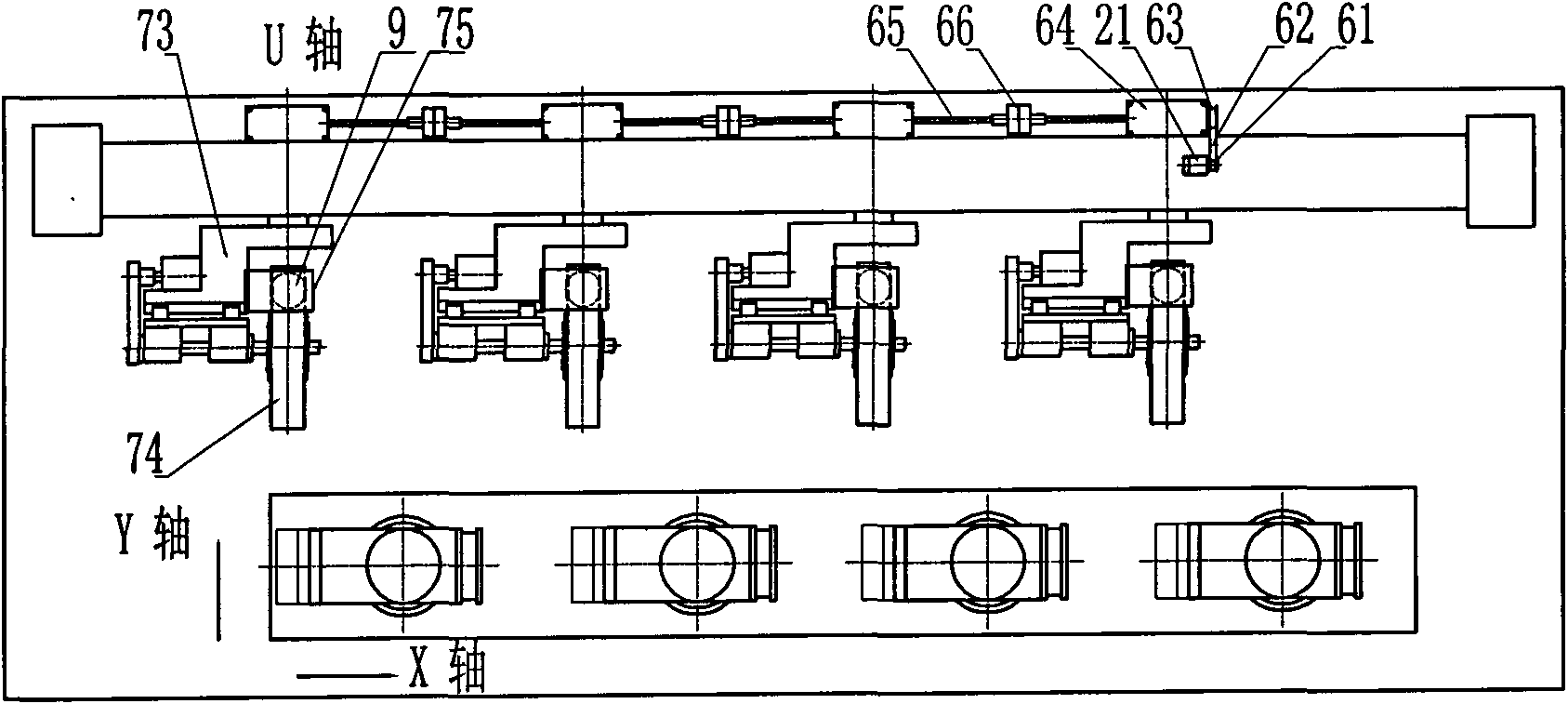

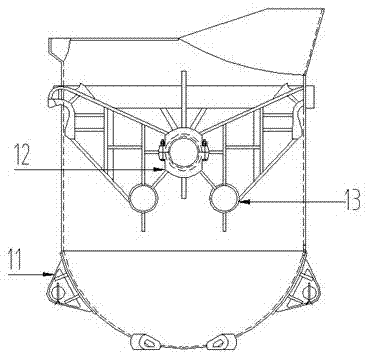

The invention relates to a seven-axis linkage numerical control polishing machine comprising a large base, a movable base, a worktable, a tee revolving base, upright posts, a beam and a head frame, wherein a polishing wheel is installed on the head frame; a working piece is installed on the tee revolving base; the movable base makes straight movement along the X-axis direction on the large base through a driving mechanism; the worktable makes straight movement along the Y-axis direction on the movable base through the driving mechanism; the tee revolving base rotates around a V axis on the worktable, and the working piece is clamped on the tee revolving base and rotates around a W axis; the beam arranged between the left upright post and the right upright post does straight movement along the Z-axis direction through the driving mechanism; the head frame for installing the polishing wheel rotates around a U axis; the movements in the six directions are all driven by independent servo motors and numerically controlled for the whole process by a servo system; the head frame is provided with an automatic wax-polishing device for polishing wax to the polishing wheel; and a wax rod arranged on the automatic wax-polishing device is driven by a feeding motor to rotate around an H axis. The polishing machine adopting the structure has stable processing quality and effectively improves the production efficiency and the economic benefit.

Owner:霍彩红

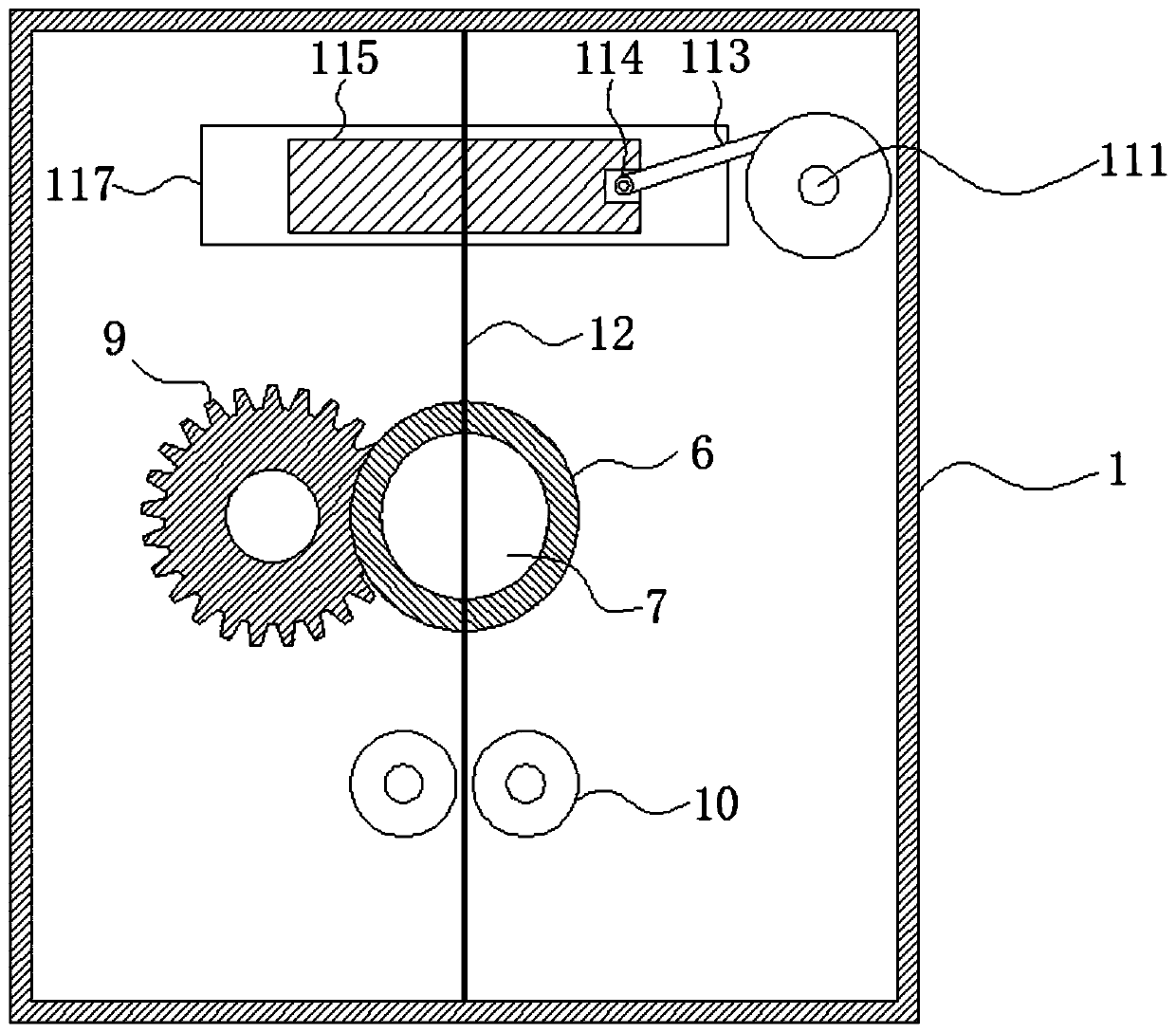

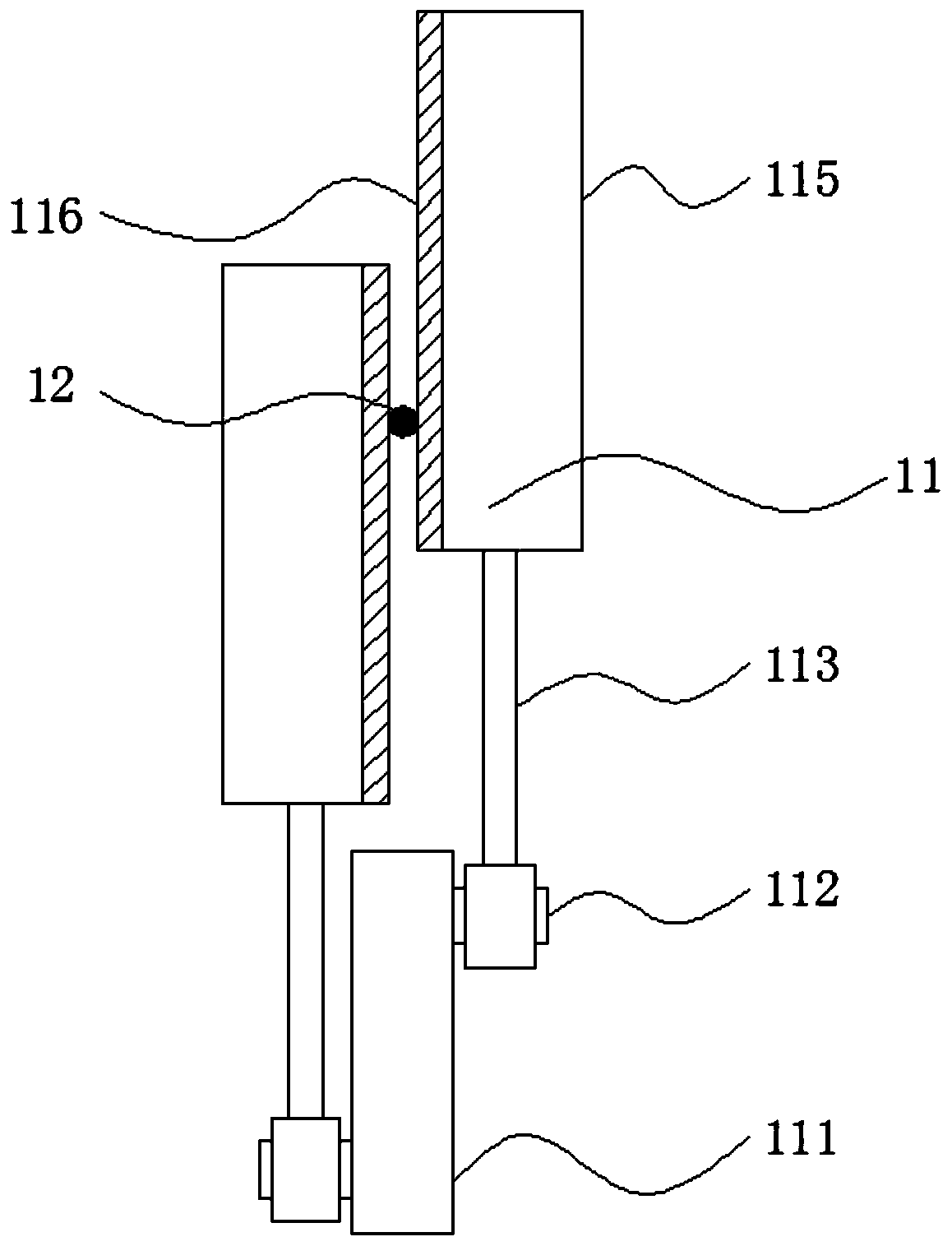

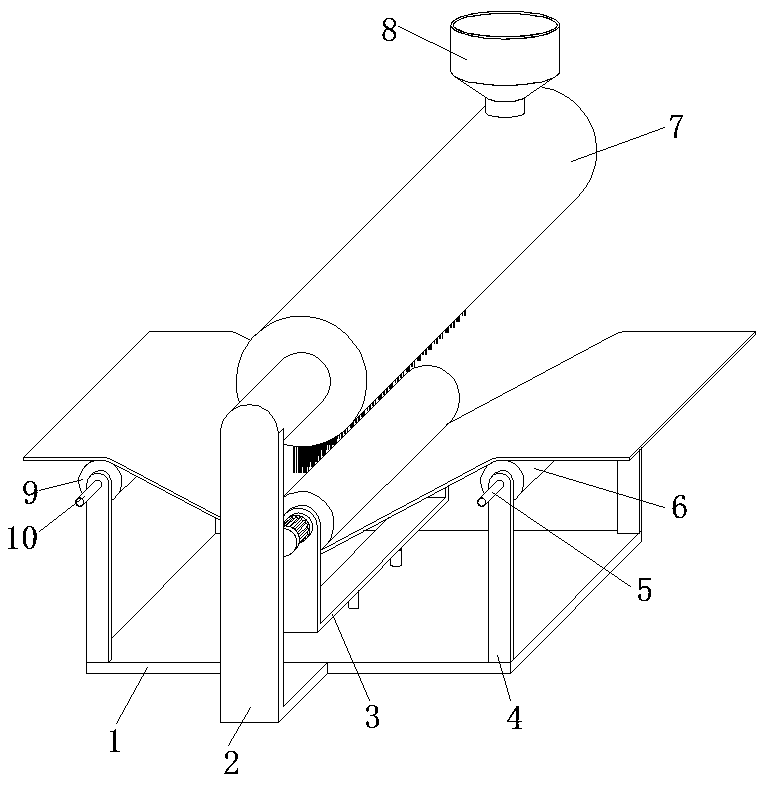

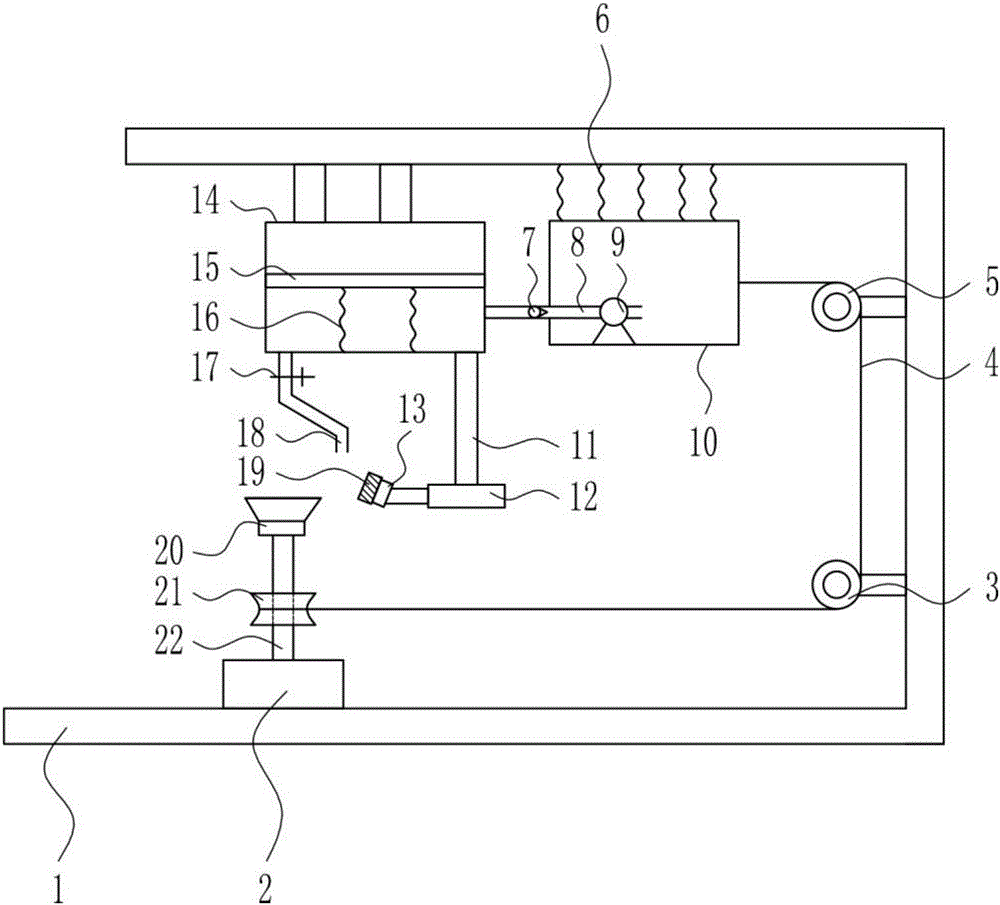

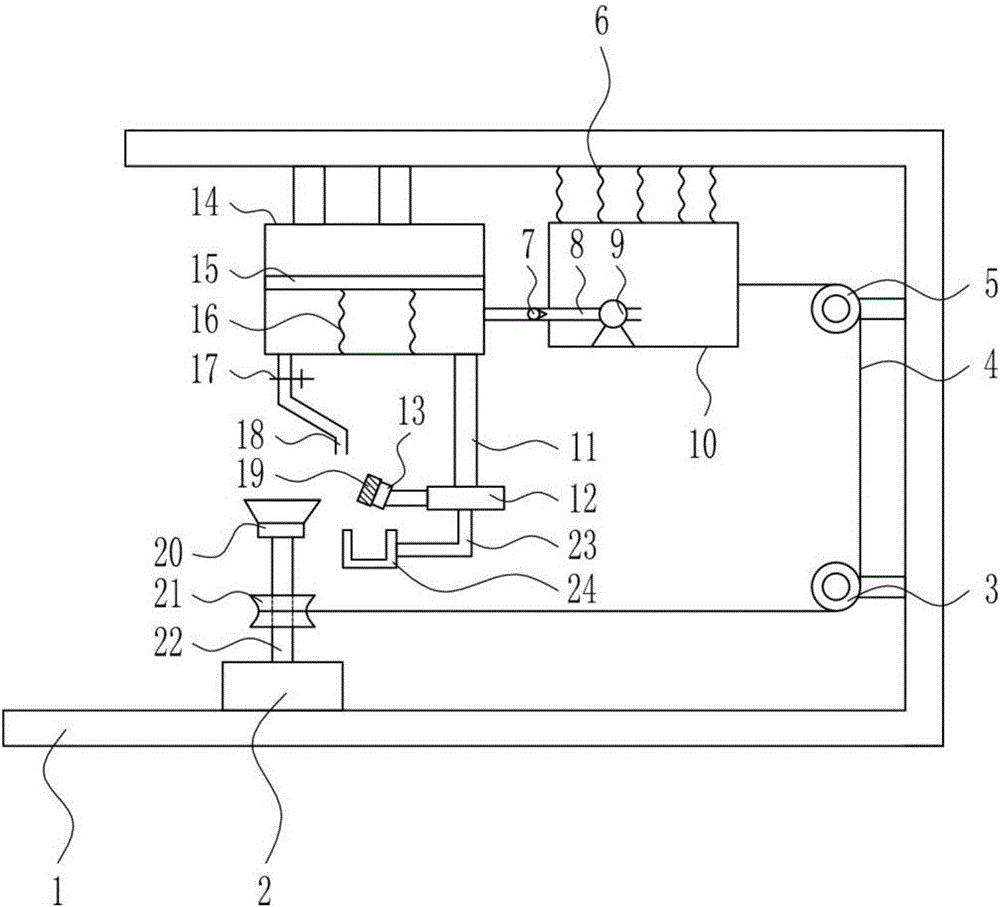

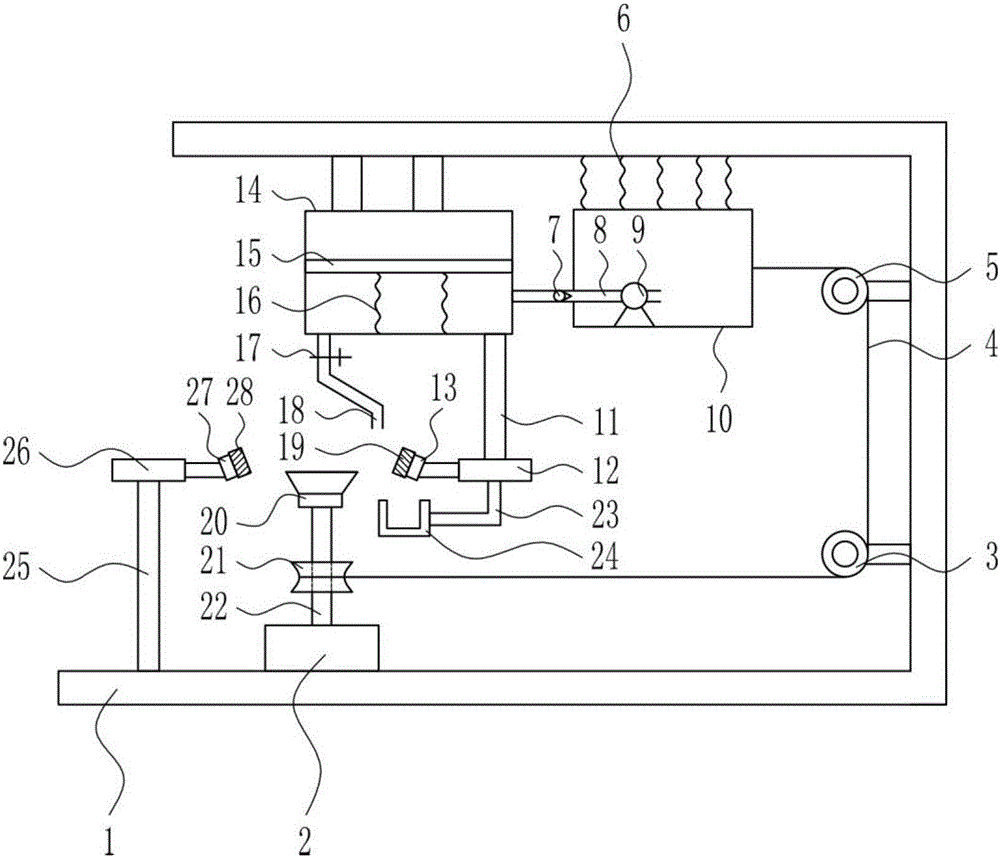

Uniform waxing device of mosaic tiles

InactiveCN106269411ASave energy on handlingConvenient for waxing workLiquid surface applicatorsCoatingsDrive wheelEngineering

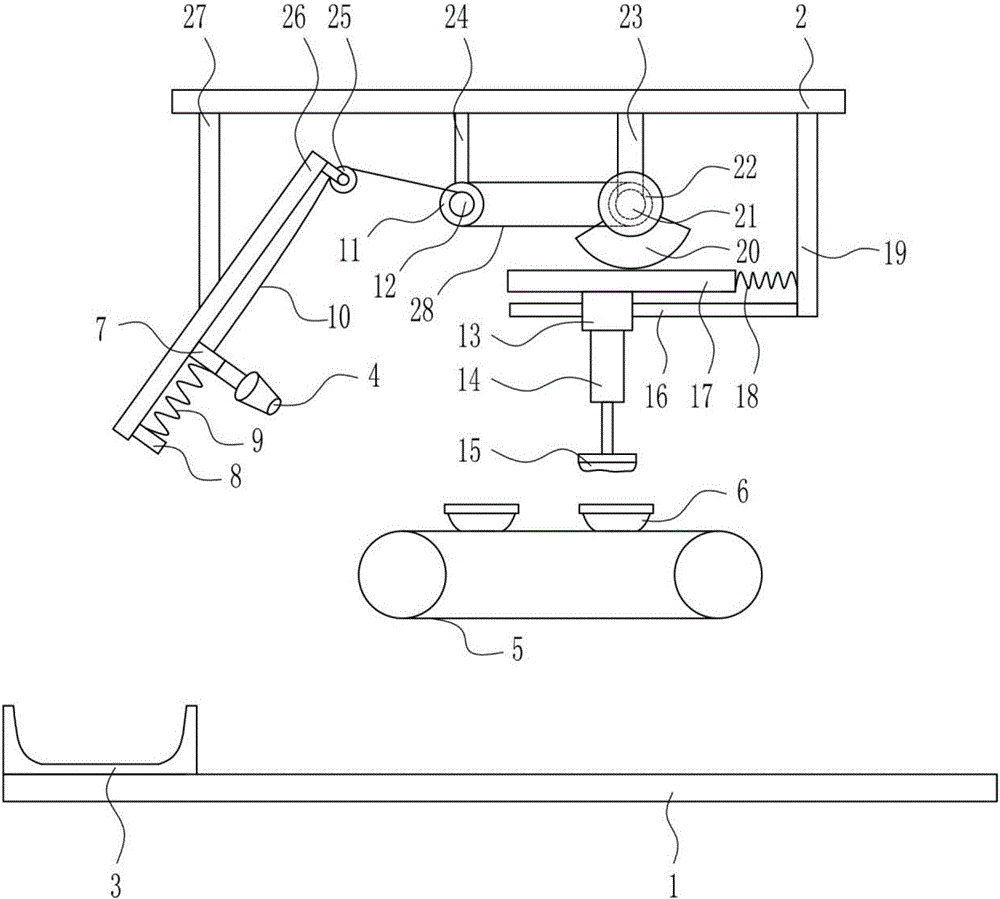

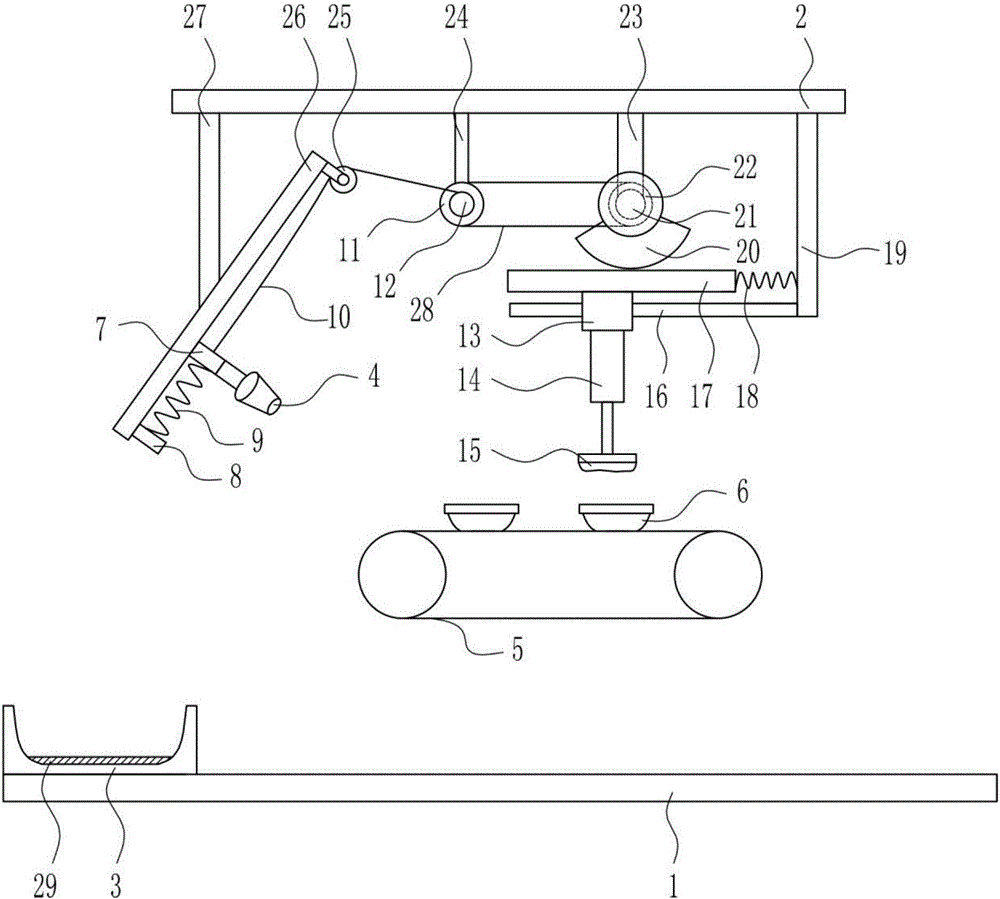

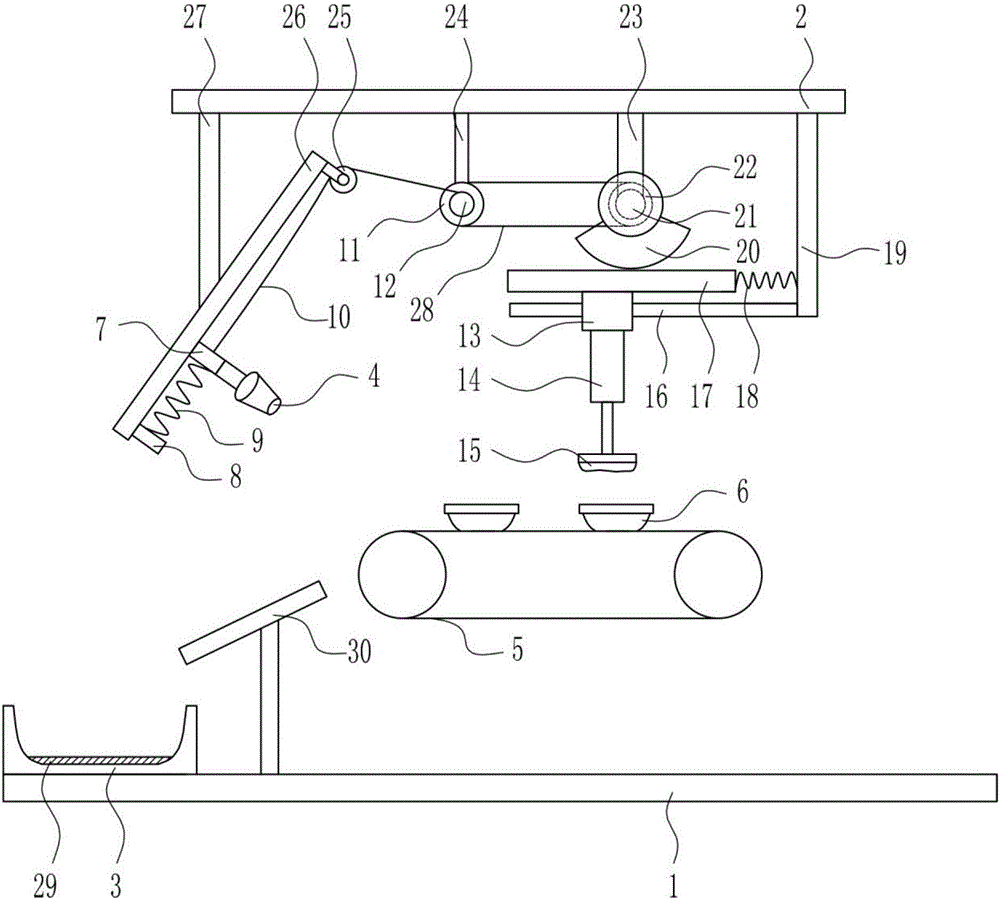

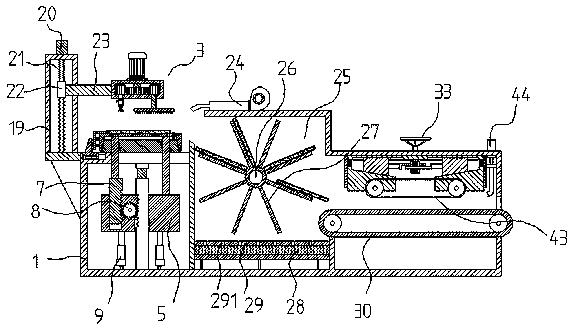

The invention relates to a waxing device, in particular to a uniform waxing device of mosaic tiles. In order to achieve the technical aim, the uniform waxing device of the mosaic tiles is uniform in waxing. To achieve the technical aim, the uniform waxing device of the mosaic tiles comprises a bottom plate, a top plate, a collecting tank, a draught fan, a conveying device, electric suction discs, a sliding block, a fixed block, a first spring, a pull wire, a driven wheel, a wire winding wheel, a sliding sleeve, an electric push rod, a rubbing block, a guide rod, a gear rack, a second spring, a fixed plate, a sector gear, a rotary motor, a driving wheel, a first supporting rod, a second supporting rod, a fixed pulley, a sliding rail, a third supporting rod and a flat belt. The collecting tank is arranged at the left end of the top of the bottom plate. The uniform waxing device achieves the uniform waxing effect, the device is used for waxing the mosaic tiles, the rubbing block moves more regularly through the rotating rule of the sector gear, and therefore regular waxing is carried out.

Owner:景德镇赛德陶瓷有限公司

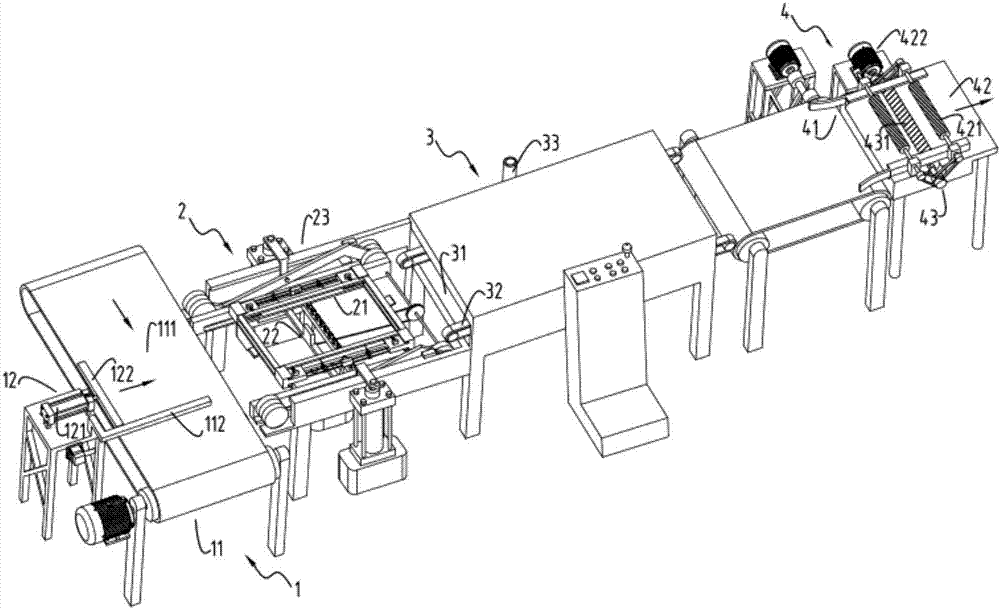

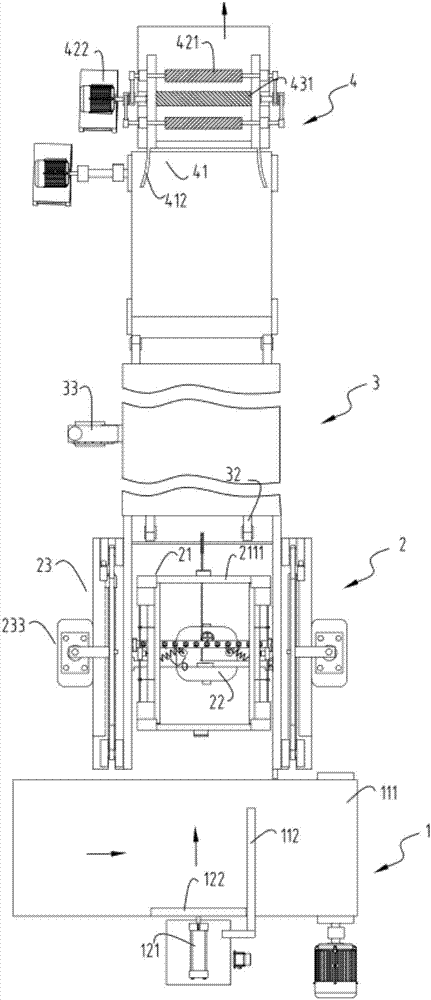

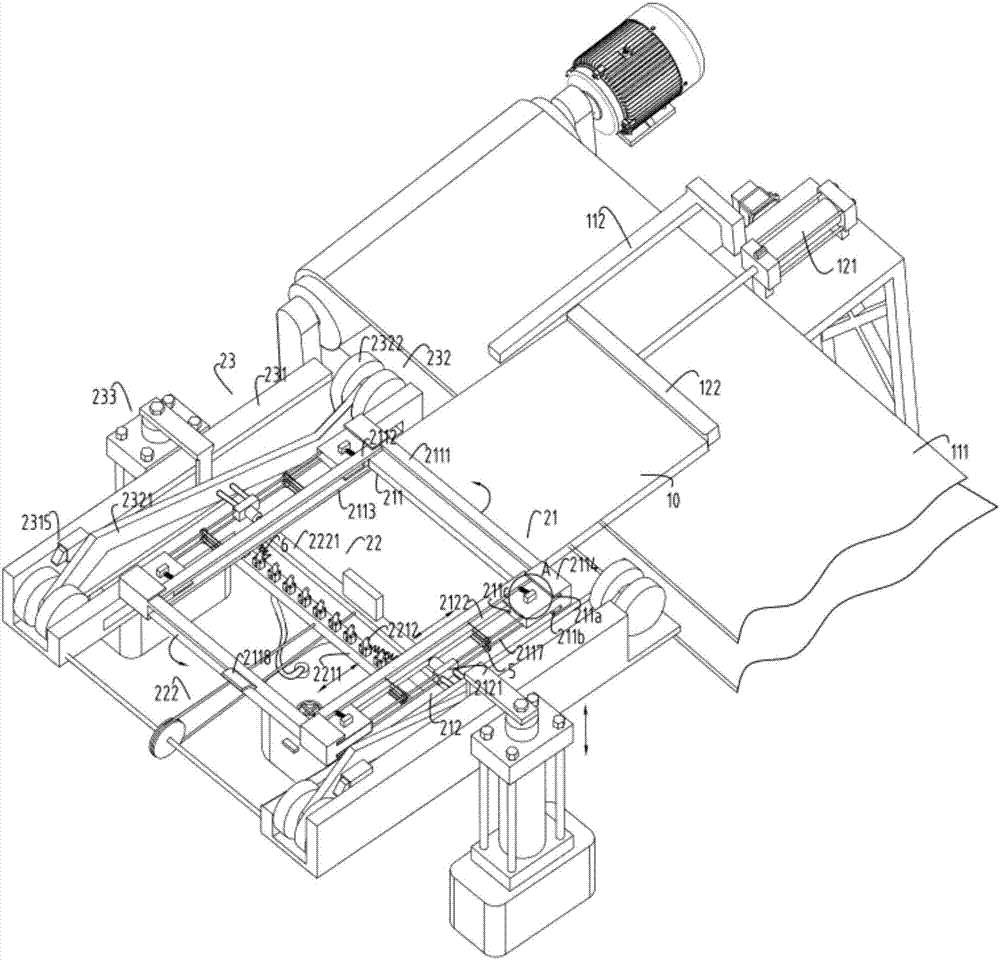

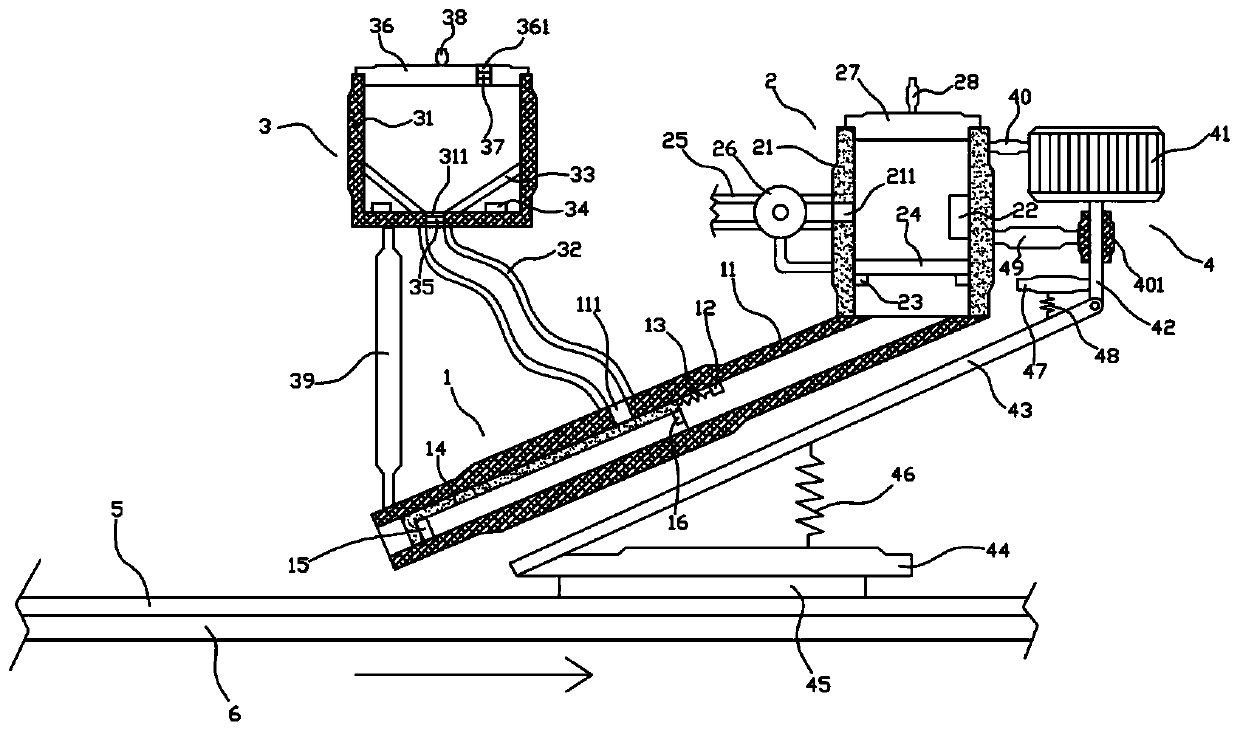

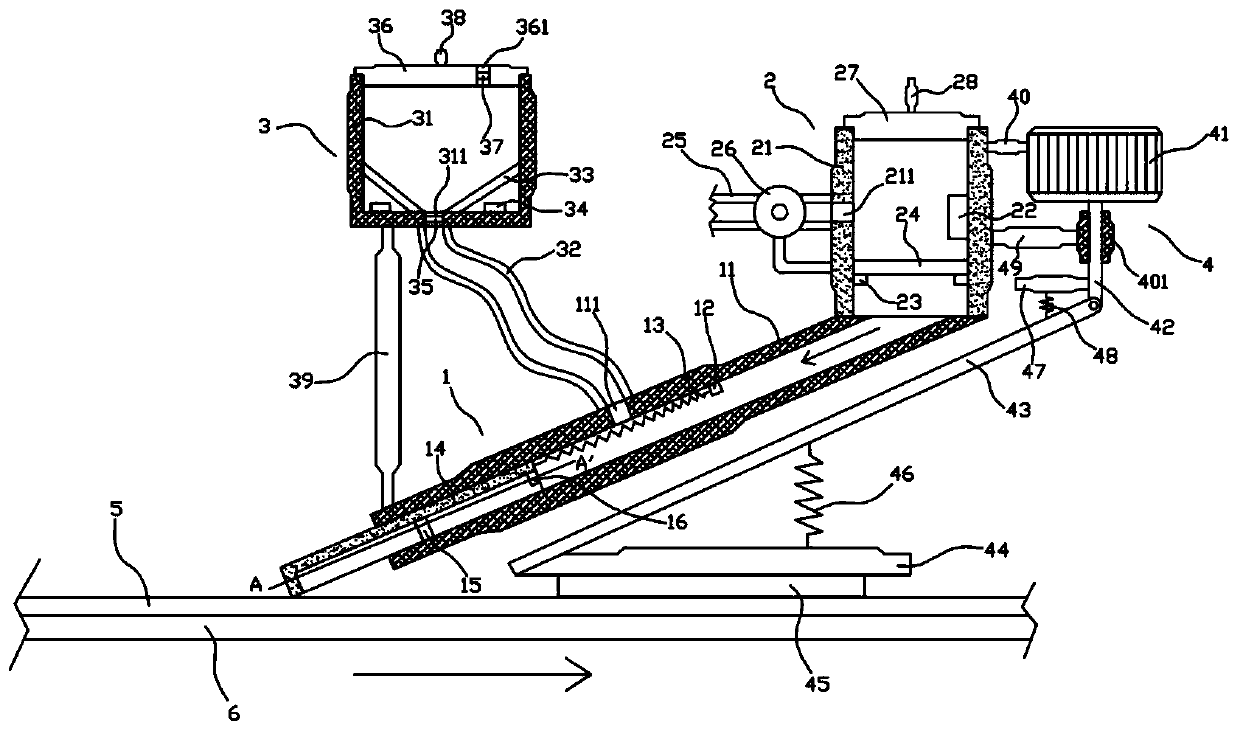

Ceramic tile surface waxing treatment production line

InactiveCN106938227AWaxes quickly and evenlyDry fastSpraying apparatusPretreated surfacesProduction lineWax treatment

The invention relates to a tile surface waxing treatment production line, which includes a positioning feeding part, the positioning feeding part is used to position and push the delivered tiles backward; a turning waxing part is arranged on the Positioning the rear end of the feeding part, the turning waxing part is used to wax the tiles pushed by the positioning feeding part; the drying part, the drying part is arranged at the rear end of the turning waxing part, and the drying part is used for It is used to dry the ceramic tiles output after being waxed by the turned waxing part; the polishing part is arranged at the rear end of the drying part, and the polishing part is used to perform surface waxing on the ceramic tiles output after the drying process of the drying part Polishing of the first layer; it overcomes the problems of tile waxing and wax surface polishing that do not have the function of integrated continuous processing, low efficiency and labor-intensive waxing process and uneven waxing.

Owner:湖州裕尚卫浴有限公司

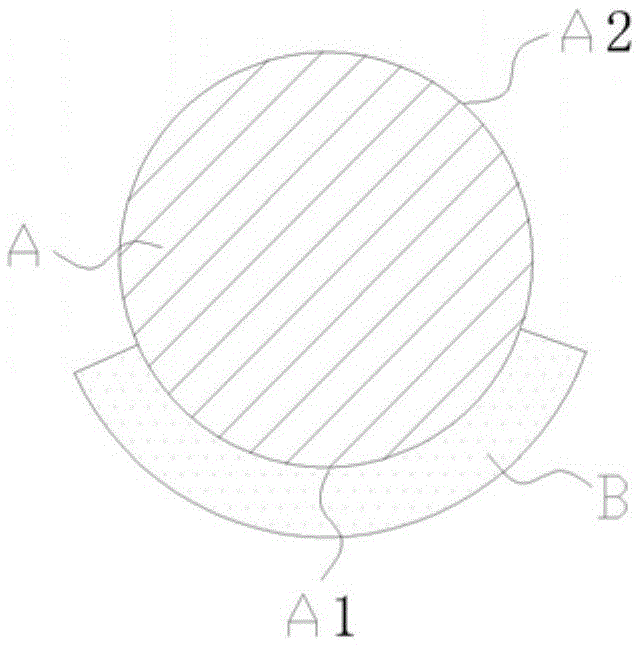

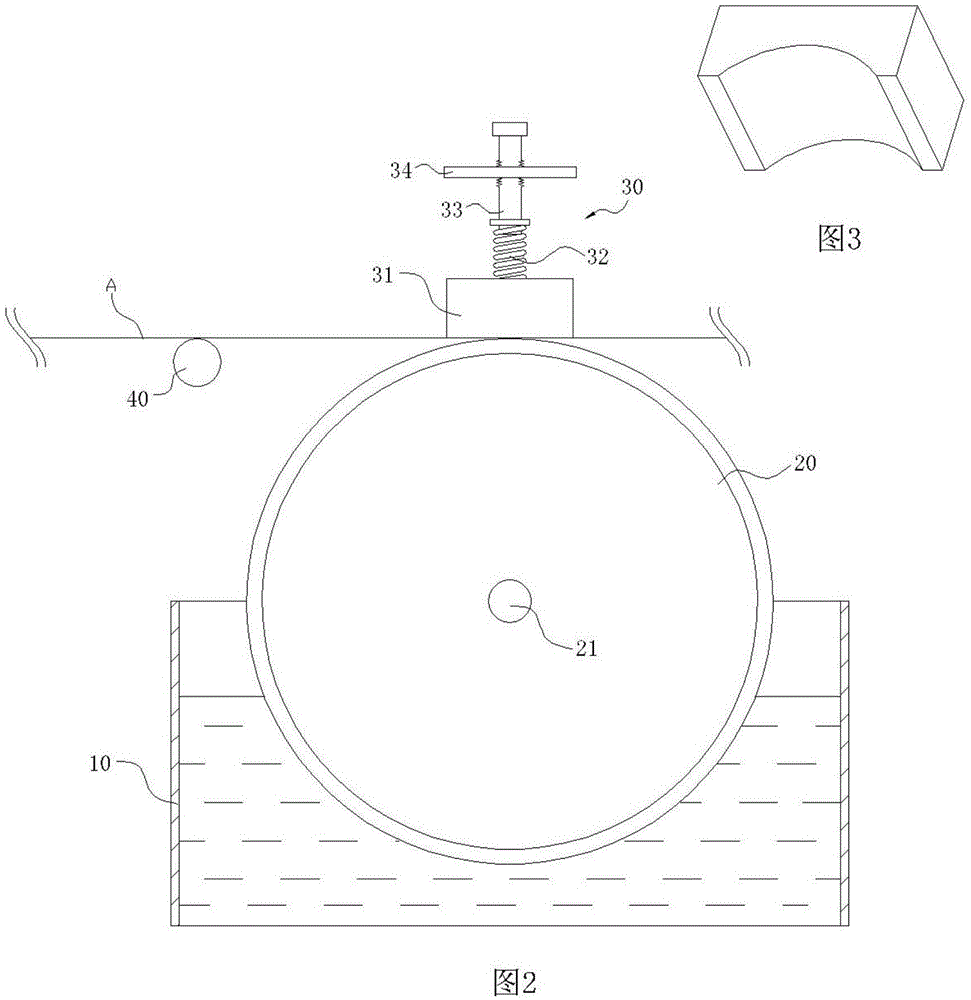

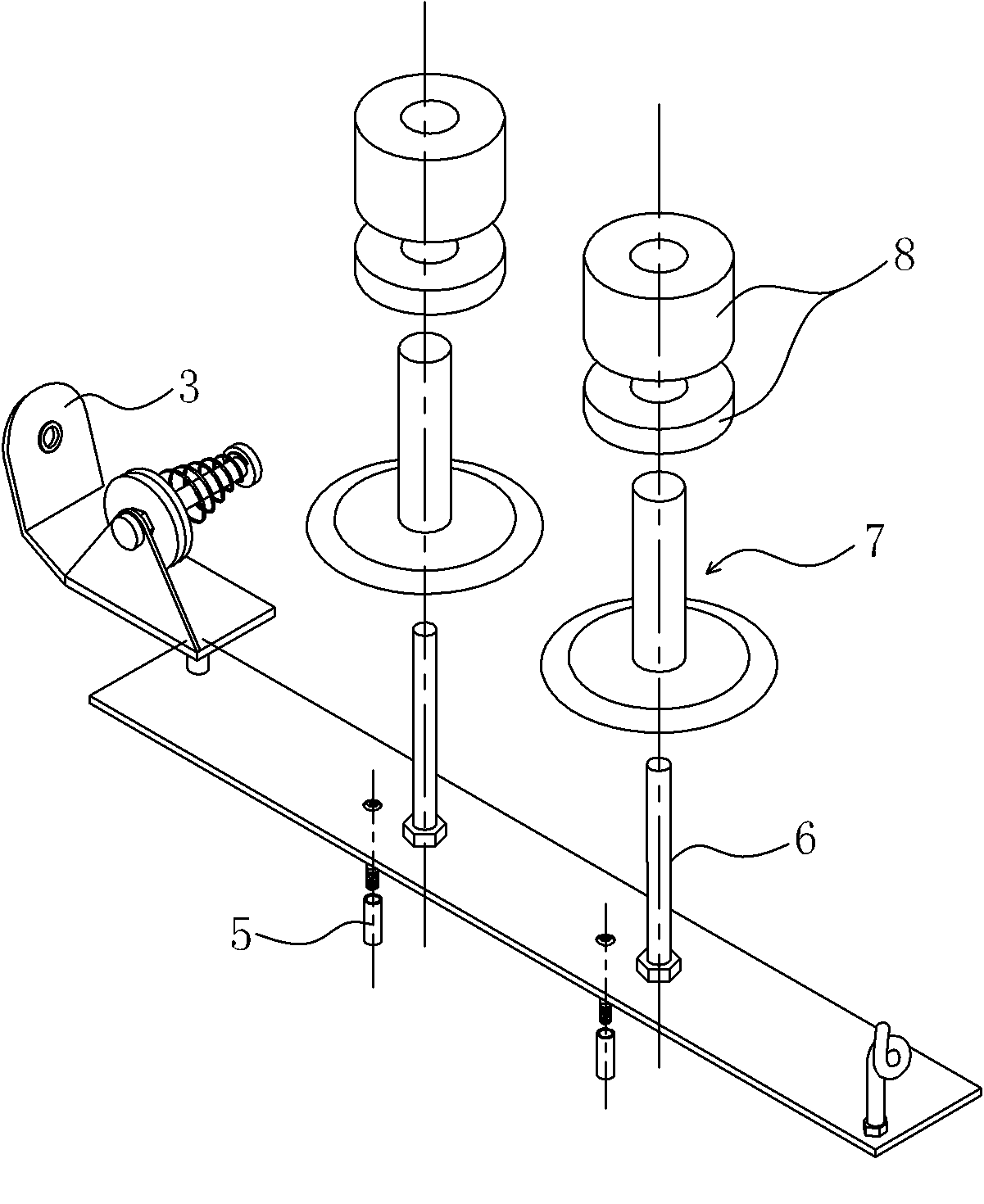

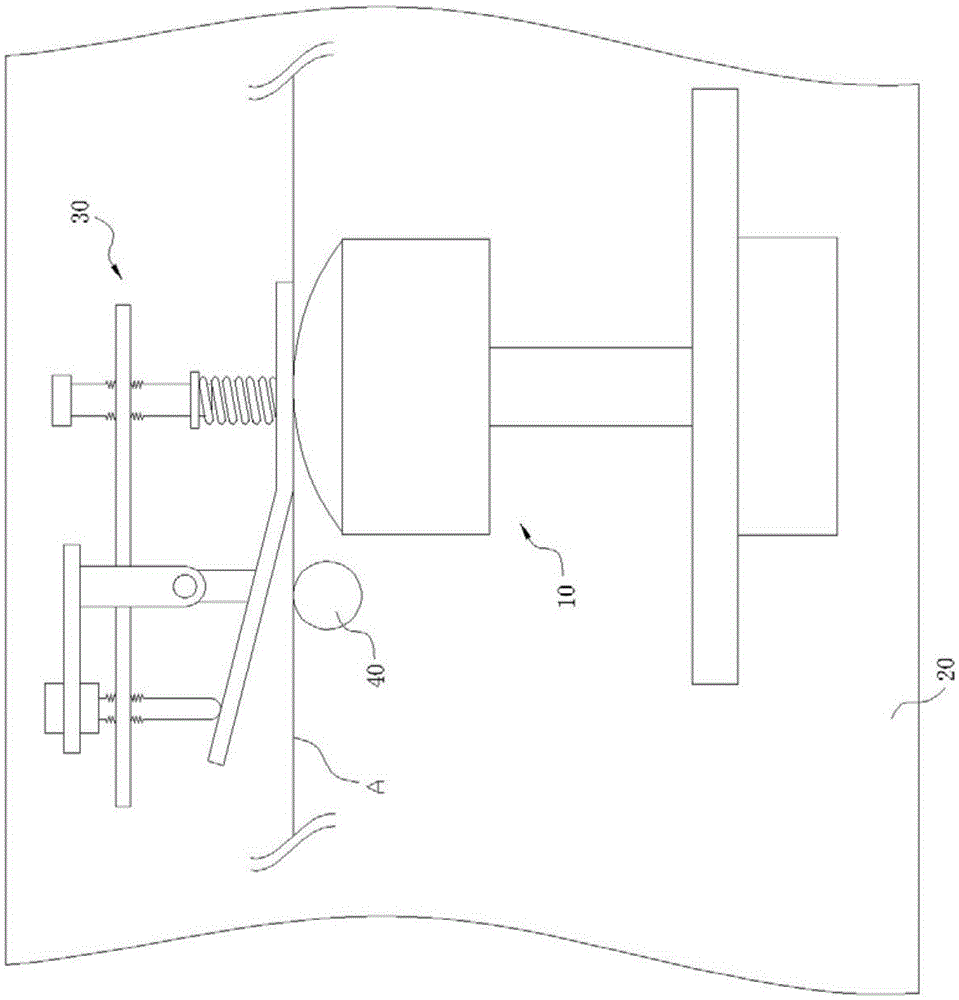

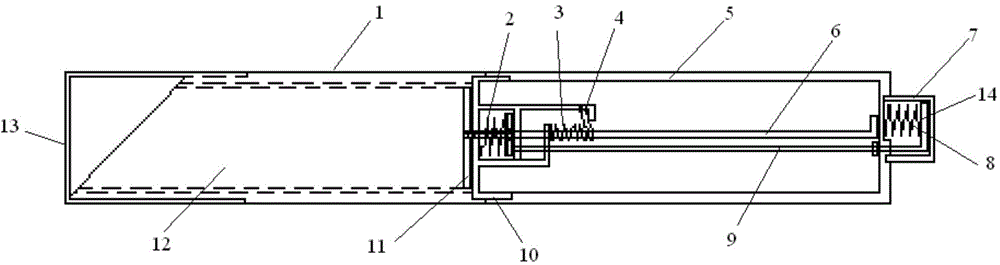

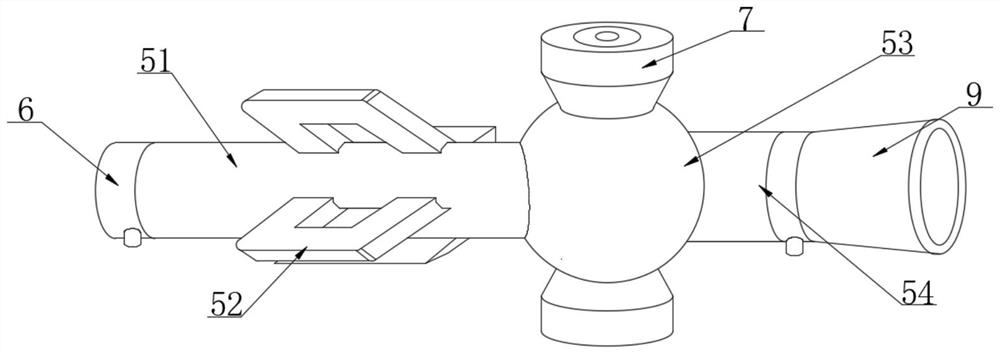

Waxing device capable of performing comprehensive waxing on yarn

The invention discloses a waxing device capable of performing comprehensive waxing on yarn. The waxing device comprises a wax oil tank and an oil guiding wheel partly immersed in the wax oil tank. The yarn passes through the circumferential surface of the oil guiding wheel, and the advancing direction of the yarn is perpendicular to the space of a center shaft of the oil guiding wheel. The waxing device further comprises a wax block device located above the oil guiding wheel, the wax block device comprises a wax block, and the yarn is clamped between the wax block and the circumferential surface of the oil guiding wheel through the wax block and the circumferential surface of the oil guiding wheel. By means of the above technical scheme, the part, making contact with the circumferential surface of the oil guiding wheel, of the yarn is waxed, meanwhile, the wax block in the wax block device located above the oil guiding wheel performs waxing on the part, not making contact with the circumferential surface of the oil guiding wheel, of the yarn, and therefore the waxing device can perform comprehensive waxing on the yarn, and accordingly the yarn waxing effect is improved.

Owner:SUZHOU LIAORUO ELECTROMECHANICAL TECH CO LTD

Ceramic waxing and polishing machine

InactiveCN108908023AIncrease contact areaReduce mechanical wear and tearLiquid surface applicatorsGrinding drivesSlide plateEngineering

The invention discloses a ceramic waxing and polishing machine. The ceramic waxing and polishing machine comprises a machine body, a workbench, a conveying mechanism, a waxing mechanism and a polishing device; the polishing device comprises an adjusting wheel arranged at the side end of the machine body and provided with a gear member; the two sides of the gear member are each engaged with one setof toothed plate blocks; an upper sliding table is arranged on the machine body; a set of upper pressing blocks are slidably arranged on the upper sliding table; the toothed plate blocks are connected with the upper pressing blocks correspondingly; the upper pressing blocks are trapezoidal bodies with tapered portions at the lower ends; two side sliding bases are arranged on the machine body; lower sliding plates are arranged on the side sliding bases; reset tension springs are connected between the lower sliding plates and the upper sliding table; the upper ends of the lower sliding plates are provided with tapered portions matched with the upper pressing blocks; the lower sliding plates are provided with polishing wheels; and the polishing wheels are provided with sheet polishing belts.The ceramic waxing and polishing machine is provided aiming at the problems, the polishing belts of the machine are arranged transversely, and the lower sliding plates are pushed by the adjusting wheel to press downwards, so that the polishing height is adjusted, mechanical losses during operation are small, operation is stable, and noise is low.

Owner:DONGGUAN UNIV OF TECH

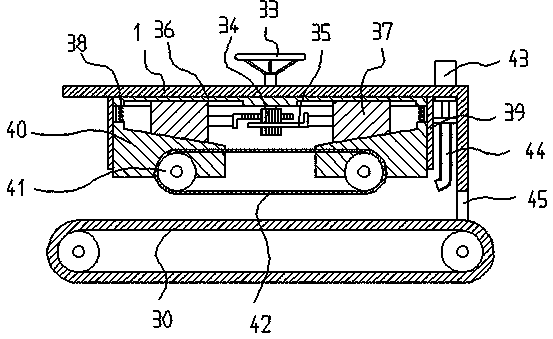

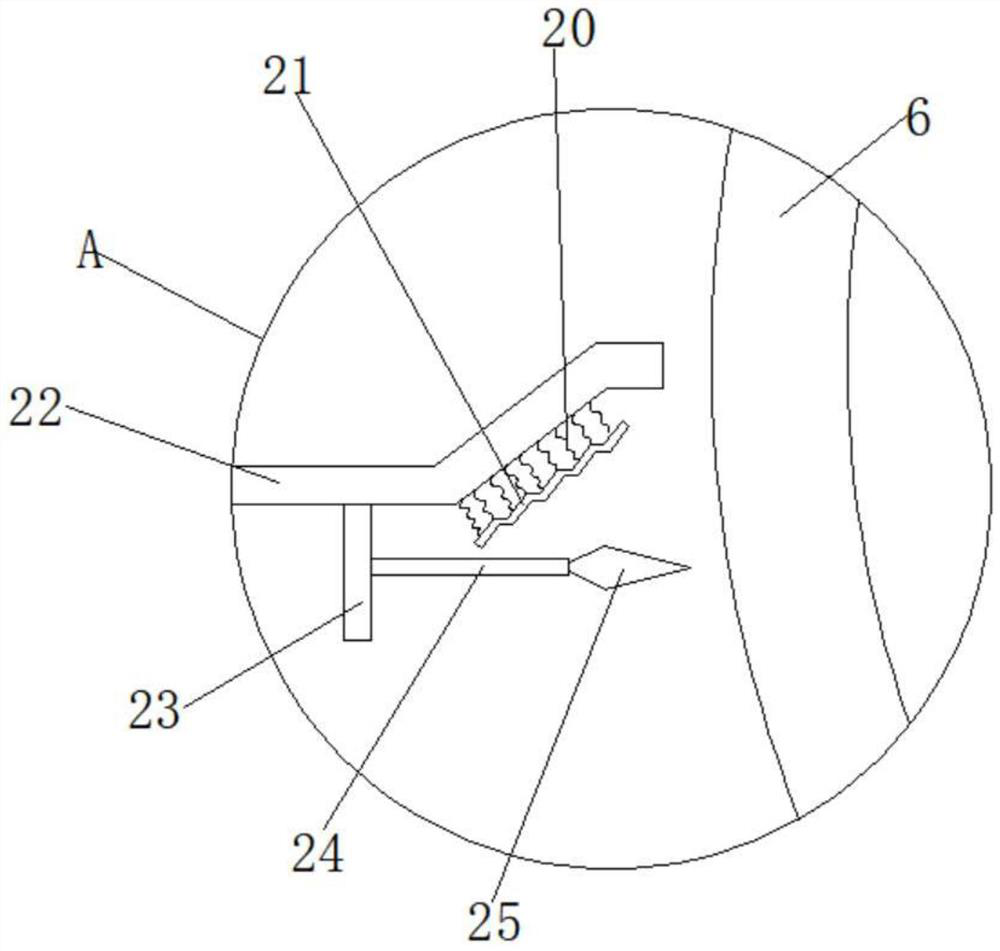

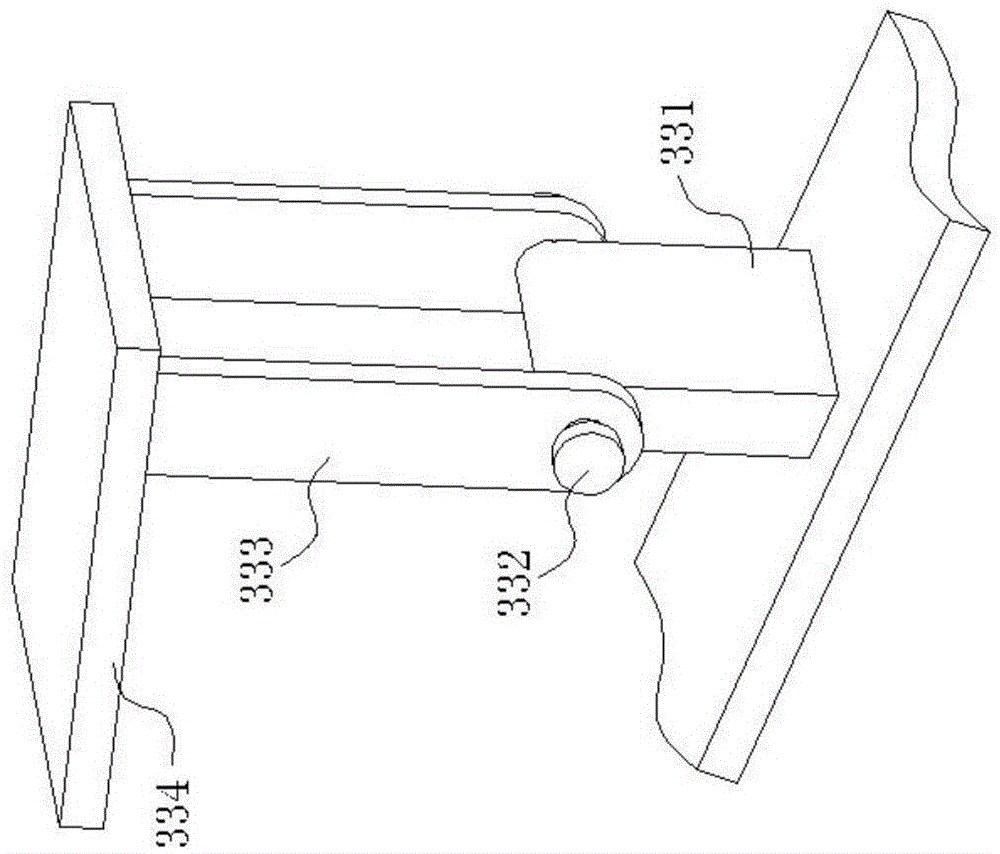

Rotary waxing device of spinning two-for-one twister

InactiveCN111155213AAvoid accumulationImprove waxing effectContinuous wound-up machinesYarnRotational axis

The invention provides a rotary waxing device of a spinning two-for-one twister, and relates to the technical field of spinning. The rotary waxing device of the spinning two-for-one twister comprisesa frame body, wherein the interior of the frame body is rotatably connected with a mounting seat through rotating shafts on two sides; a concave groove is formed in the side, close to the center of the frame body, of the mounting seat; a spring is fixedly mounted on the inner wall of the concave groove; a telescopic block is fixedly mounted at the other end of the spring; a wax disc is fixedly connected to the end, close to the center of the frame body, of a limiting block; a first gear is fixedly mounted at the other end of each rotating shaft; and a heating rotating shaft is rotationally connected to the lower part of the mounting seat in the frame body. According to the rotary waxing device of the spinning two-for-one twister, the surface of the wax disc can be ground more uniformly, itis guaranteed that yarn keeps a rotating state all the time when being in contact with the wax disc, and accumulation of fine hair on the surface of the wax disc is avoided, so that waste of paraffinis avoided, waxing on the periphery of the yarn is more uniform, and the waxing effect is improved.

Owner:曹超铨

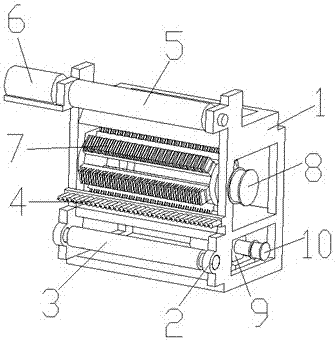

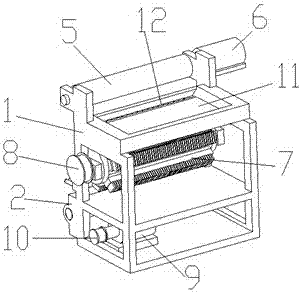

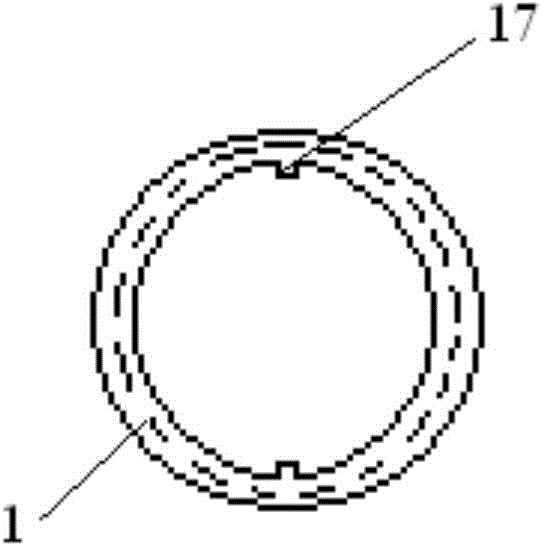

Automatic yarn waxing device of flat knitting machine

The invention relates to an automatic yarn waxing device of a flat knitting machine, belonging to knitting equipment. The device is designed to solve the technical problems that the existing yarn storage and supply equipment and the existing waxing equipment occupy large space and are relatively inconvenient in installation and operation in the operation pipeline of yarns. The key points of design are as follows: the upper end face of the body is connected with a waxing component that comprises a frame body, a shaft rod, a wax ring base and a wax ring; the body is connected with the frame body; the frame body is connected with the shaft rod; the shaft rod is connected with the wax ring base; and the wax ring base is connected with the wax ring. With simple structure and with the yarn storage and supply device and the waxing machine combined as a whole, the automatic yarn waxing device can synchronize the processes of waxing and yarn storage and supply, thus improving production efficiency. Besides, the automatic yarn waxing device is wholly small in occupied space, obviously better in waxing effect, stable in product quality and suitable for use as a structural improvement of the existing similar equipment.

Owner:厉力永

Waxing device capable of automatically feeding wax

InactiveCN106671949AAvoid too muchAvoid the problem of too fewVehicle servicing/repairingWaxArchitectural engineering

The invention discloses a waxing device capable of automatically feeding wax, and relates to the field of auto beauty maintenance devices. The waxing device includes a housing, a motor, a fixing plate and a waxing brush; the motor is positioned on the top of the housing; an output shaft of the motor is connected to the fixing plate; the fixing plate is connected to the waxing brush; the fixing plate is rotatably connected to the housing; a material storage cavity is formed in the housing; a handle is arranged on the left side of the housing; a telescopic air bag is arranged on the upper end of the handle; the telescopic air bag is fixed on the housing; an air inlet hole and an air outlet hole are formed in the telescopic air bag; the air outlet hole communicates with the telescopic air bag and the material storage cavity, and is positioned on the upper part of the material storage cavity; discharging holes are evenly distributed in the fixing plate; one-way valves are arranged in the discharging holes; and the material storage cavity communicates with the waxing device through the one-way valves and the discharging holes. The waxing device can rapidly feed wax in a waxing process, and can improve the waxing efficiency.

Owner:GUANGXI UNIV FOR NATITIES

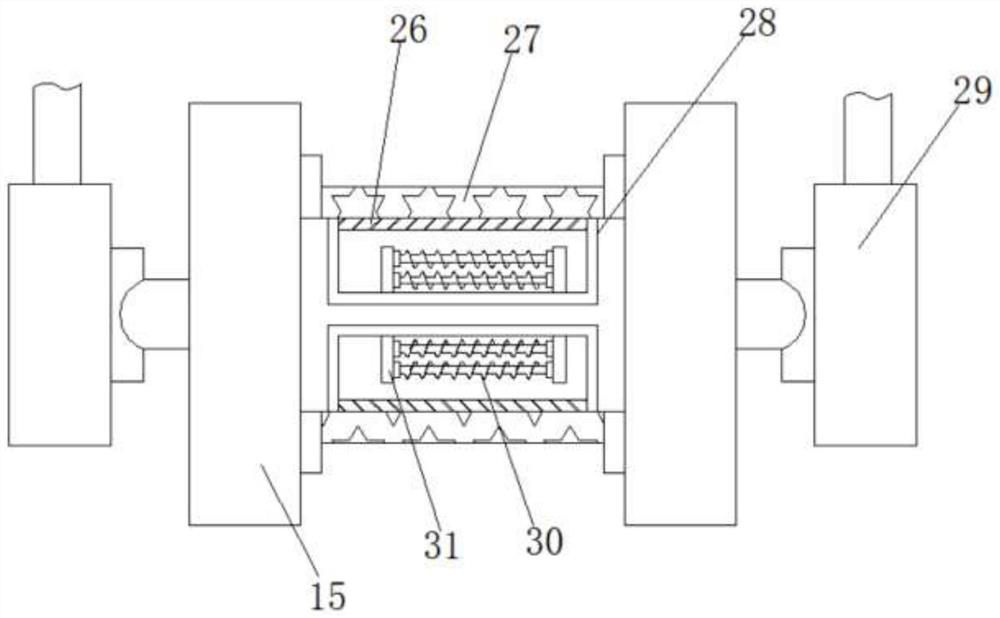

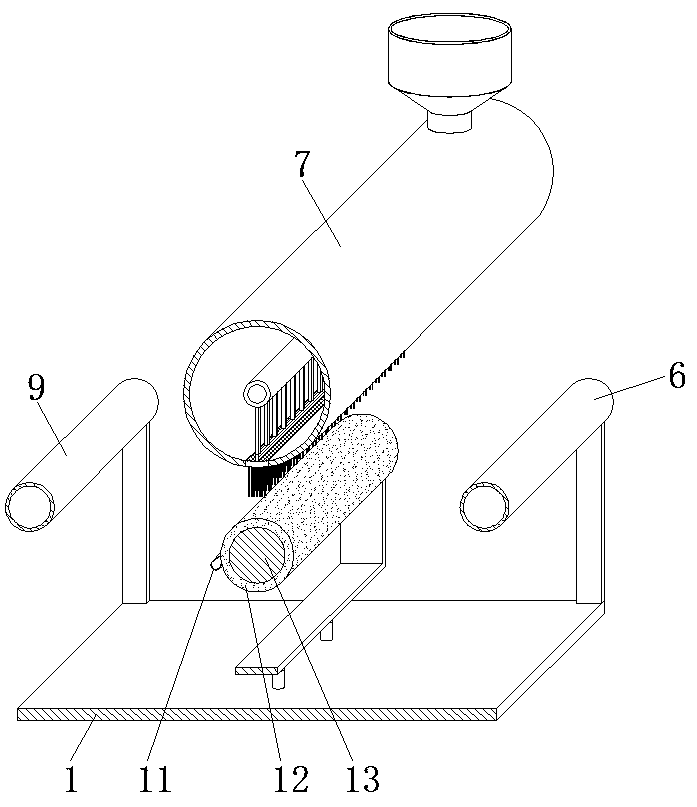

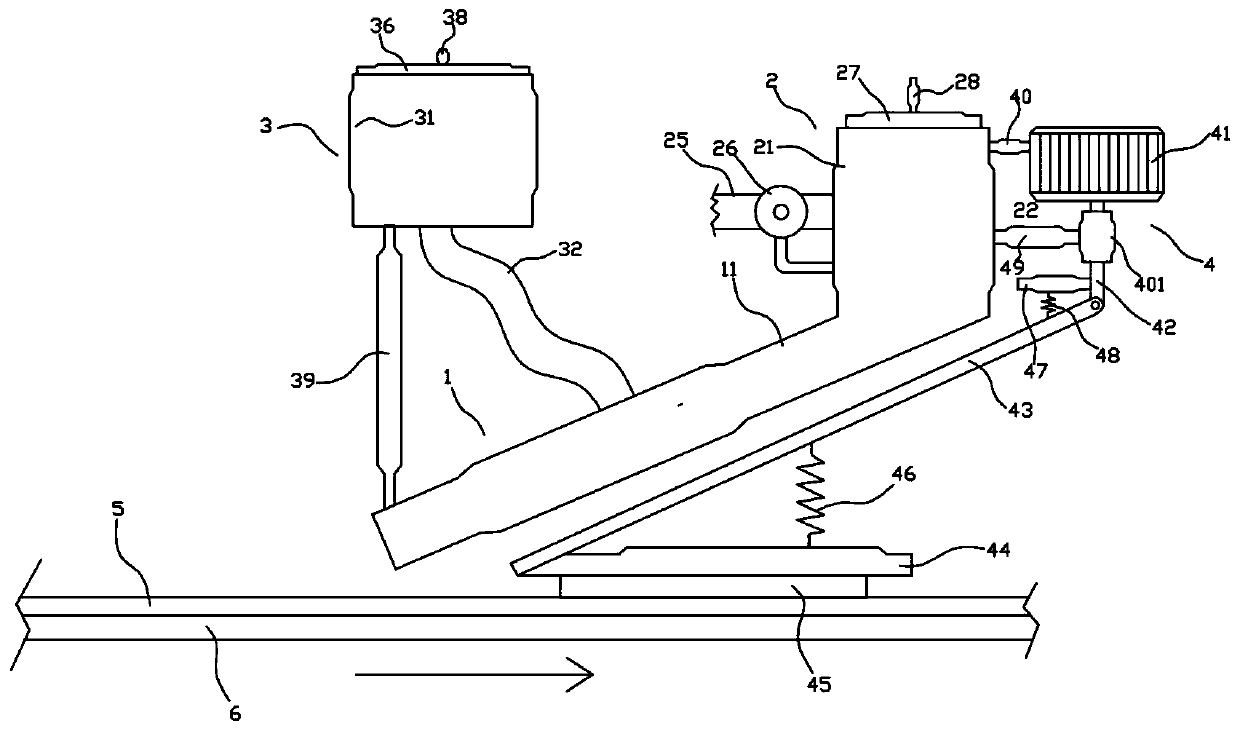

Efficient waxing device for textile machinery

InactiveCN107601171AImprove waxing effectGuaranteed waxing effectFilament handlingYarnPulp and paper industry

The invention discloses an efficient waxing device for textile machinery. The efficient waxing device includes a motor, an air cylinder, a wax block storing bin, a waxing roller and a height adjustingdevice. Upper layer wax blocks rotate in the direction opposite to the direction of yarn by using rotation of the motor, frictional force between the upper surface of the yarn and the upper layer waxblocks is further increased, the effect of yarn waxing is improved, meanwhile, the upper layer wax blocks are always in contact with the upper surface of the yarn by using the air cylinder to drive amoving rod to move on a sliding rail, separating of the upper surface of the yarn and the upper layer wax blocks is avoided, thus the effect of waxing of the upper surface of the yarn is ensured, frictional force between the waxing roller and the wax blocks is decreased by softening the wax blocks in the wax block storing bin, the purpose of waxing on the lower surface of the yarn is achieved byusing rotation of the waxing roller, the height of the wax block storing groove is adjusted by arranging the height adjusting device, so that the waxing roller is always in contact with the softened wax blocks in the wax block storing bin.

Owner:长兴宝诺纺织科技有限公司

Yarn wet-method waxing process

The invention discloses a yarn wet-method waxing process, which comprises the following steps: diluting molten wax with cold deionized water, adding acetic acid to regulate the pH value to 5 to 6, uniformly stirring, and adding into a cheese dyeing machine; performing post-treatment of yarns, dyeing, dehydrating and soaking the yarns in the cheese dyeing machine filled with the molten wax; and dehydrating and drying the soaked yarns at 100 to 120 DEG C. The process makes it is convenient to operate, and is applicable to processing of cellulosic fibers and blended yarns, particularly cotton yarns. The processed yarns can be directly used in weaving after being dried; and the dynamic friction value of the surface of the processed yarns is low, so that the hairiness phenomenon is eliminated effectively.

Owner:NANTONG UNIVERSITY

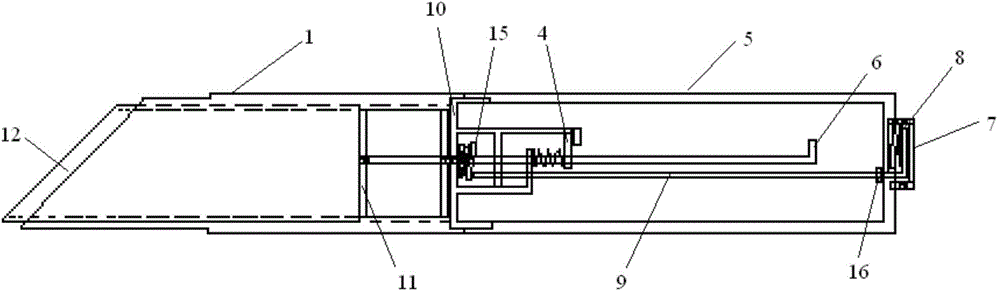

Waxing device capable of enabling wax block to be clung to yarn

The invention discloses a waxing device capable of enabling a wax block to be clung to a yarn. The waxing device comprises a waxing machine, wherein the waxing machine comprises a wax block device and a transmission device; the yarn passes through the end surface of the wax block; a rotational shaft of the wax block is perpendicular to a running direction of the yarn; the wax block device further comprises a cylinder and a telescopic device mounted in the cylinder; and through holes for pins to be inserted are formed in the wall of the cylinder and the telescopic device. In a yarn waxing process, the wax block on the waxing machine does a self-rotation motion under the action of the transmission device, and the rotational shaft of the wax block is perpendicular to the running direction of the yarn; and by continuously adjusting the position of the telescopic device, the wax block is clung to the yarn, so that the utilization rate of the wax block can be increased and the yarn waxing effect can be improved.

Owner:江苏新诚誉纺织科技有限公司

Production technology of waterproof wax-impregnated corrugated paper box

InactiveCN108277694AImprove anti-wear performanceImprove wear resistanceSpecial paperPaper coatingParaffin waxGroup control

The invention discloses a production technology of a waterproof wax-impregnated corrugated paper box. The production technology comprises six steps of putting a paper box on a hanging frame, pre-heating in a pre-heating drying channel, impregnating wax in a wax groove, leveling wax liquid in a leveling drying channel, drying wax and sizing, and taking off a wax box from the hanging frame, and is characterized in that the wax liquid for the waterproof wax-impregnated corrugated paper box is prepared from microcrystalline paraffin wax, oxidized polyethylene wax, amide wax, silicon dioxide nano powder, rosin, a surfactant and water. According to the production technology of the waterproof wax-impregnated corrugated paper box, disclosed by the invention, the used wax liquid is a wax composition, has excellent performance of water resistance, wear resistance and the like and has a long life cycle and good stability; in the production technology, heat preservation and heat insulation are carried out so that an energy-saving effect is realized; based on a PLC (Programmable Logic Controller) group control system, automatic flow line production can be realized and the production efficiencyis improved.

Owner:重庆融康彩印包装有限公司

Leather waxing device for leather shoe production

ActiveCN108315510AImprove waxing effectWon't wrinkleLeather/skins/hides/pelt chemical treatment apparatusLeather surface finishingEngineeringWaxing

The invention relates to a waxing device, in particular relates to a leather waxing device for leather shoe production and aims to solve the technical problem of providing the leather waxing device for time shortening and waxing for leather shoe production. To solve the technical problem, the invention provides the leather waxing device which comprises a bottom plate, a 7-shaped plate, first support rods, first arc-shaped clamping blocks, a waxing table, and the like, wherein the 7-shaped plate is mounted on the left side of the top of the bottom plate; the first support rods are mounted on the left side and the right side of the top of the bottom plate; the first support rods are positioned inside the 7-shaped plates; the first arc-shaped clamping blocks are mounted at the tops of the twofirst support rods; the waxing table is mounted in the middle of the top of the bottom plate; a coiling mechanism is arranged on the right side of the top of the bottom plate; the coiling mechanism is positioned on the right side of the waxing table. By adopting the leather waxing device, leather can be collected through the coiling mechanism, the leather can be waxed through the waxing mechanism, and the effects of time saving and sufficient and uniform waxing can be achieved.

Owner:嘉兴市南湖区余新振涛五金喷涂厂(普通合伙)

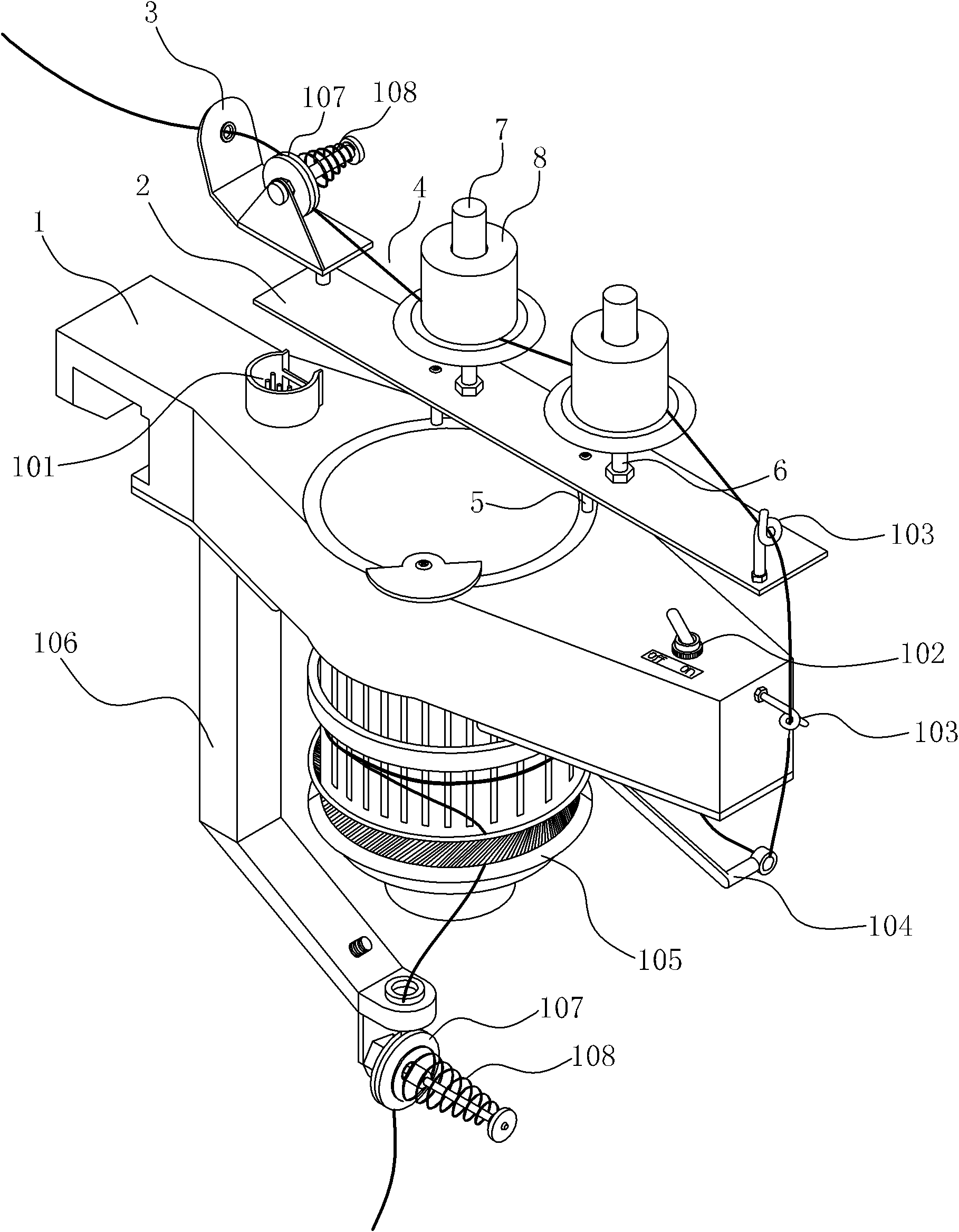

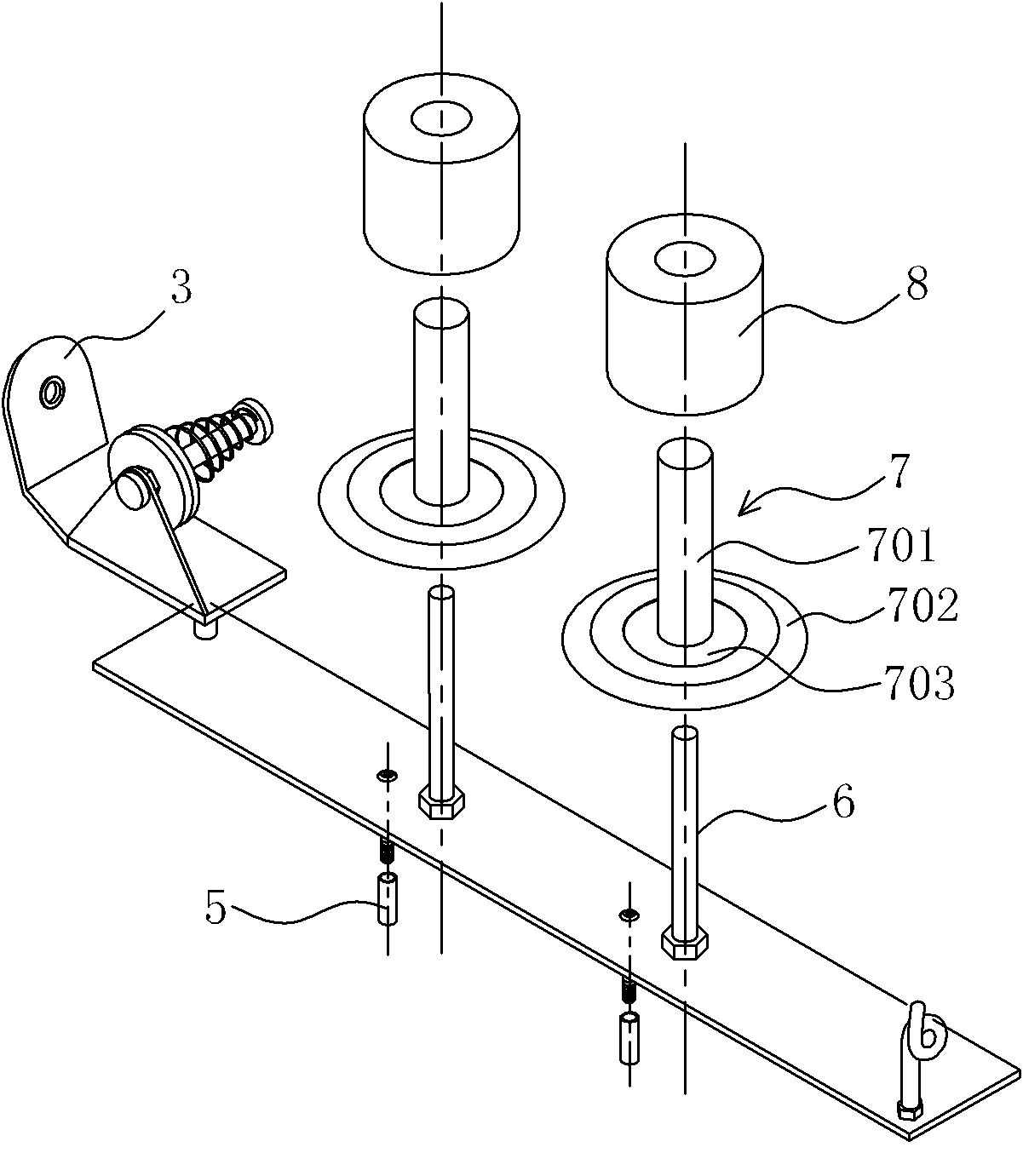

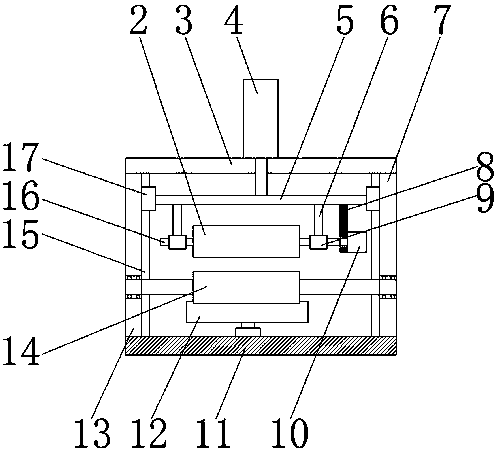

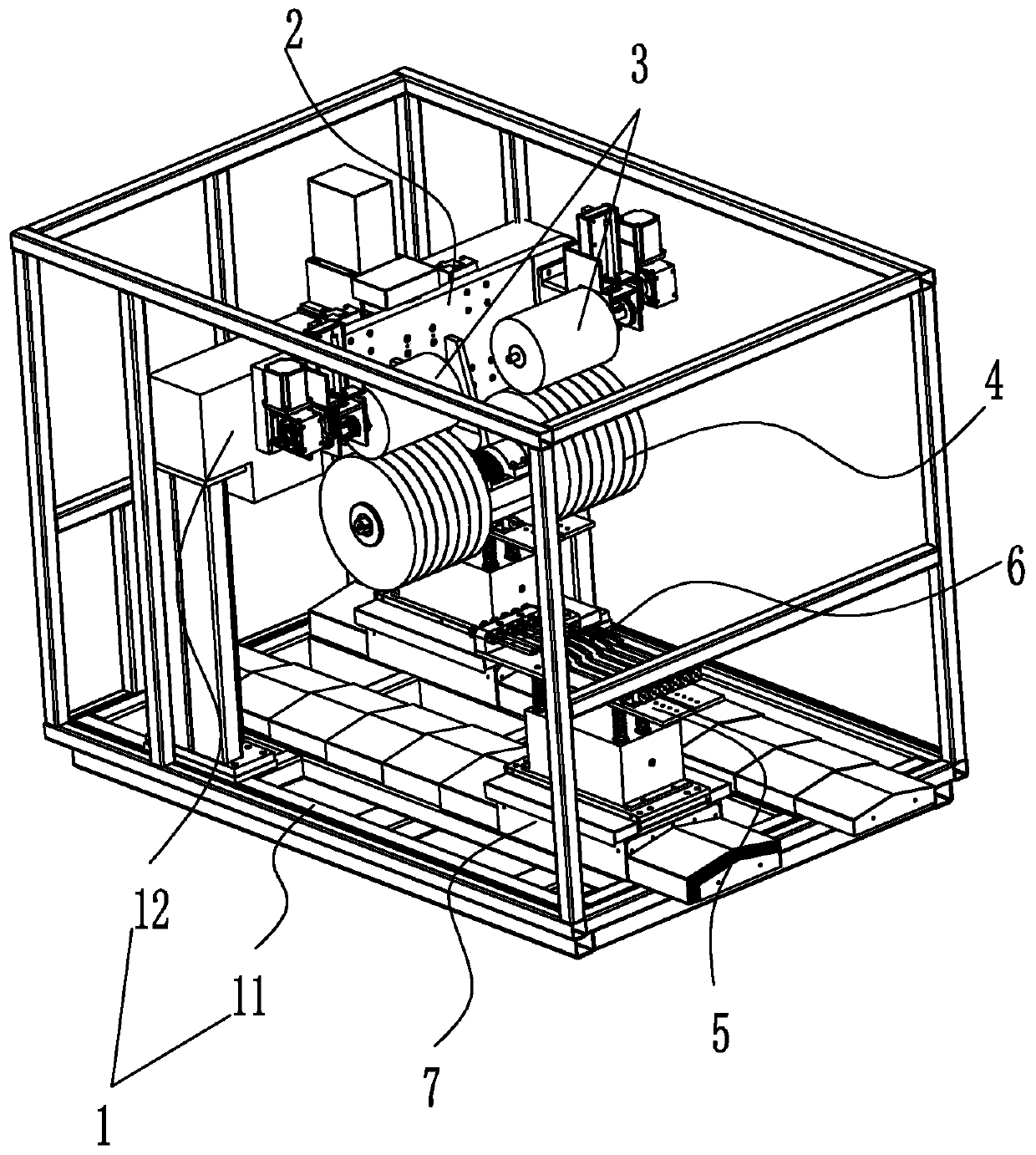

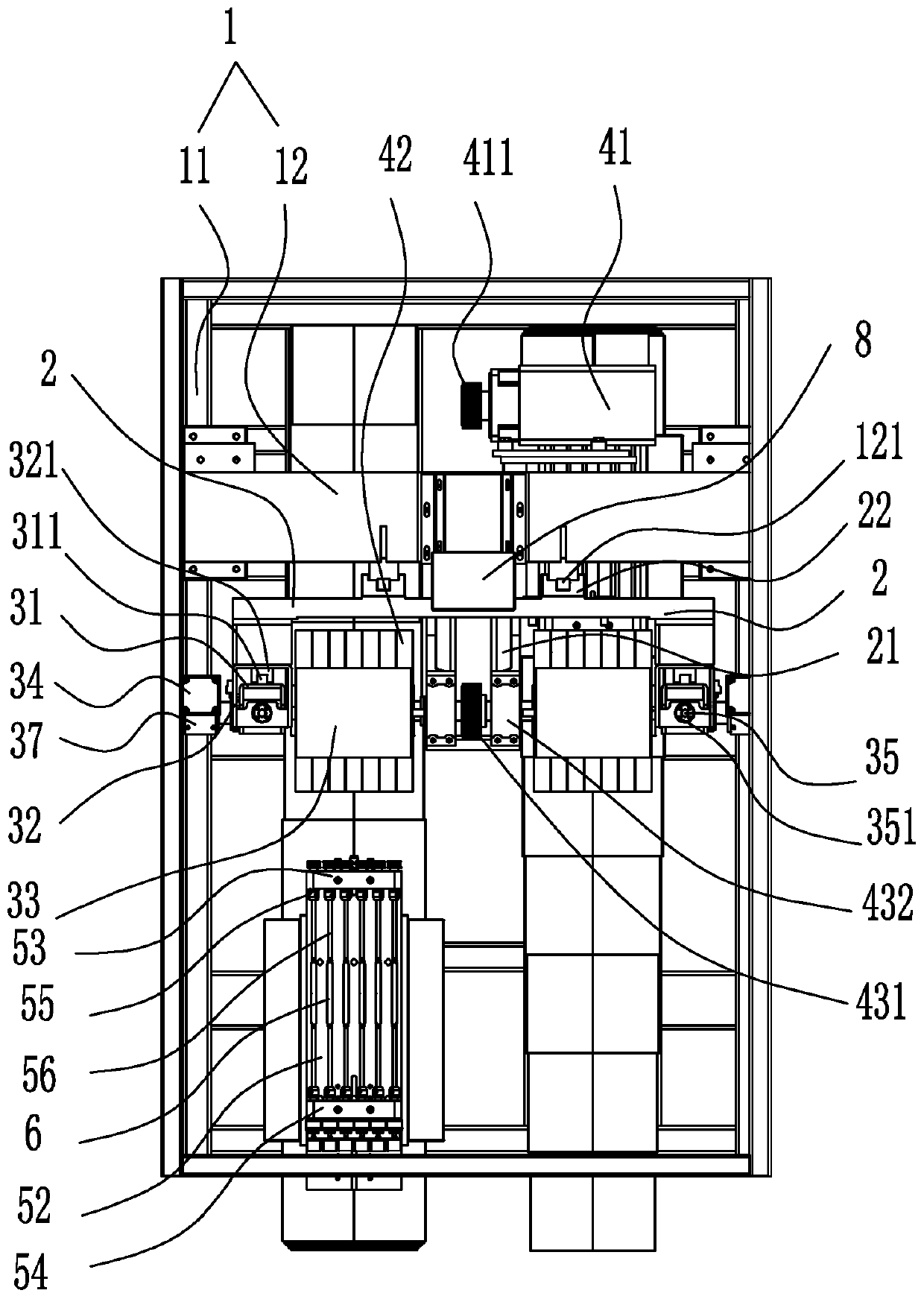

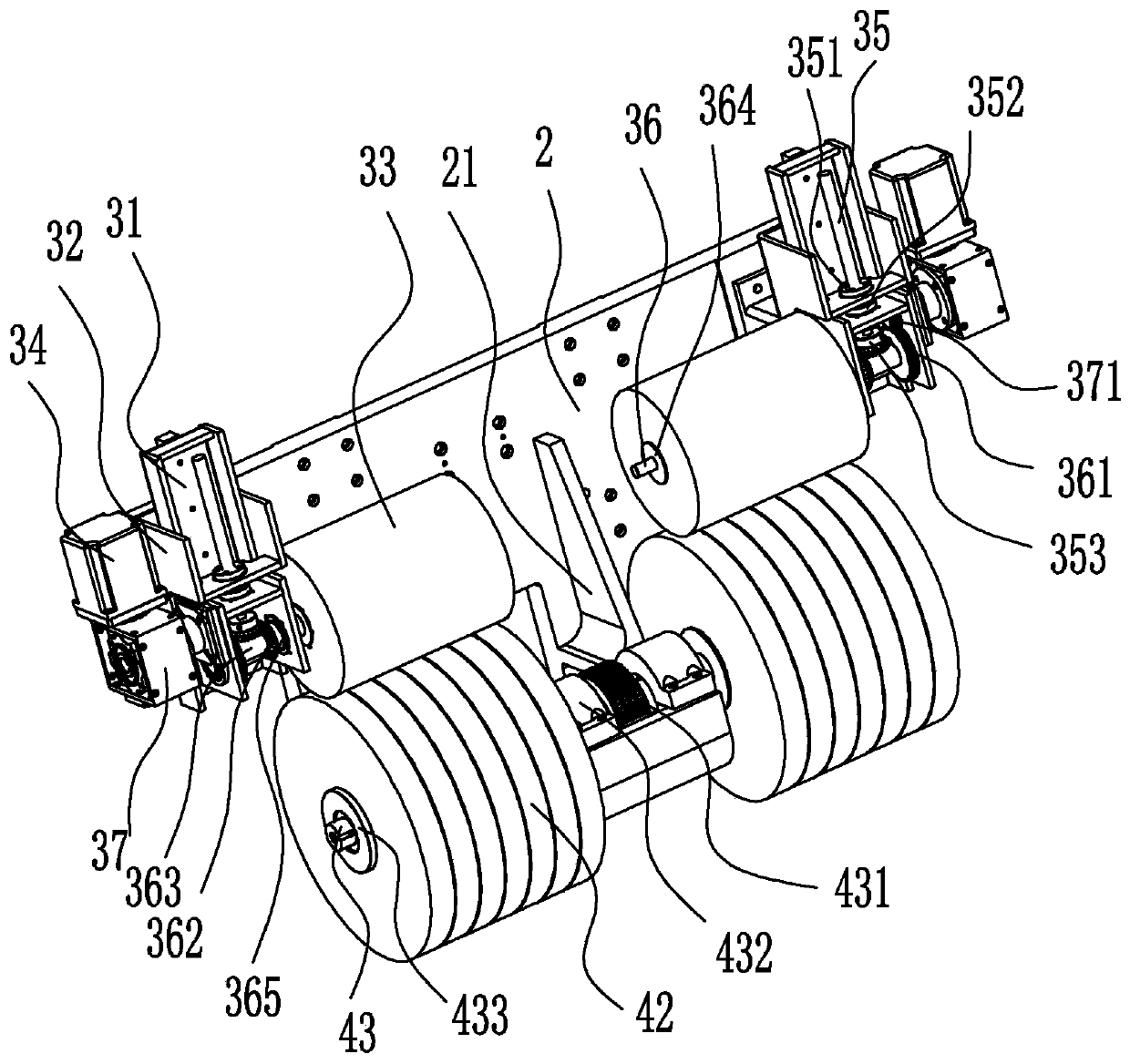

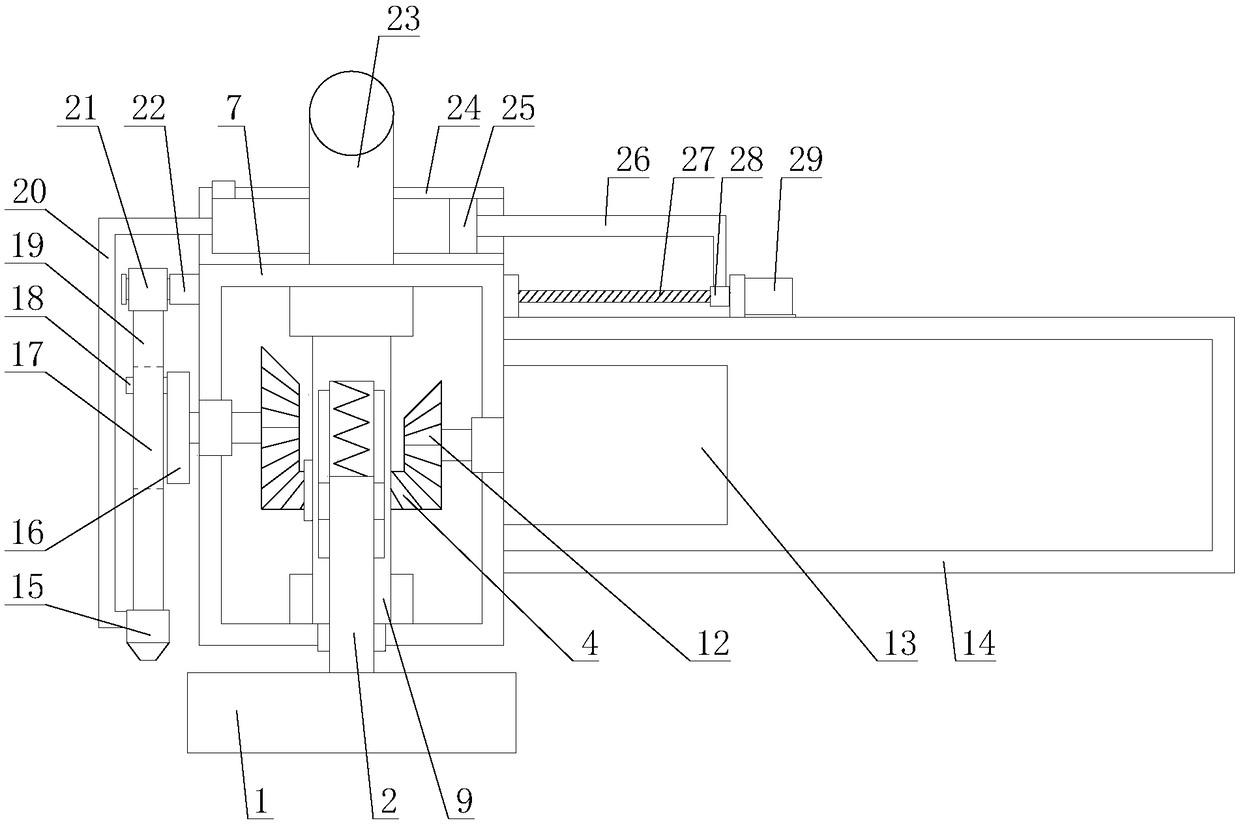

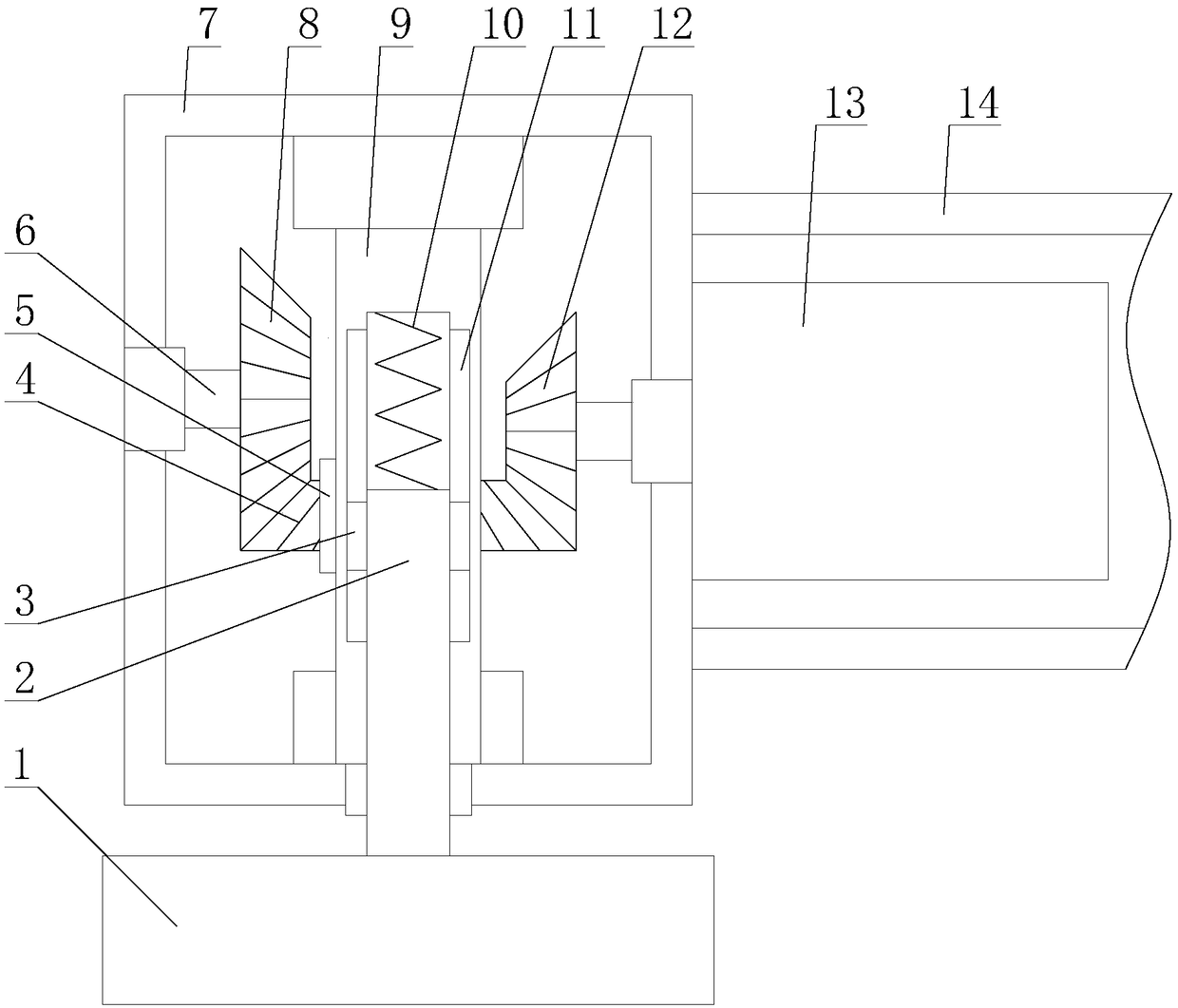

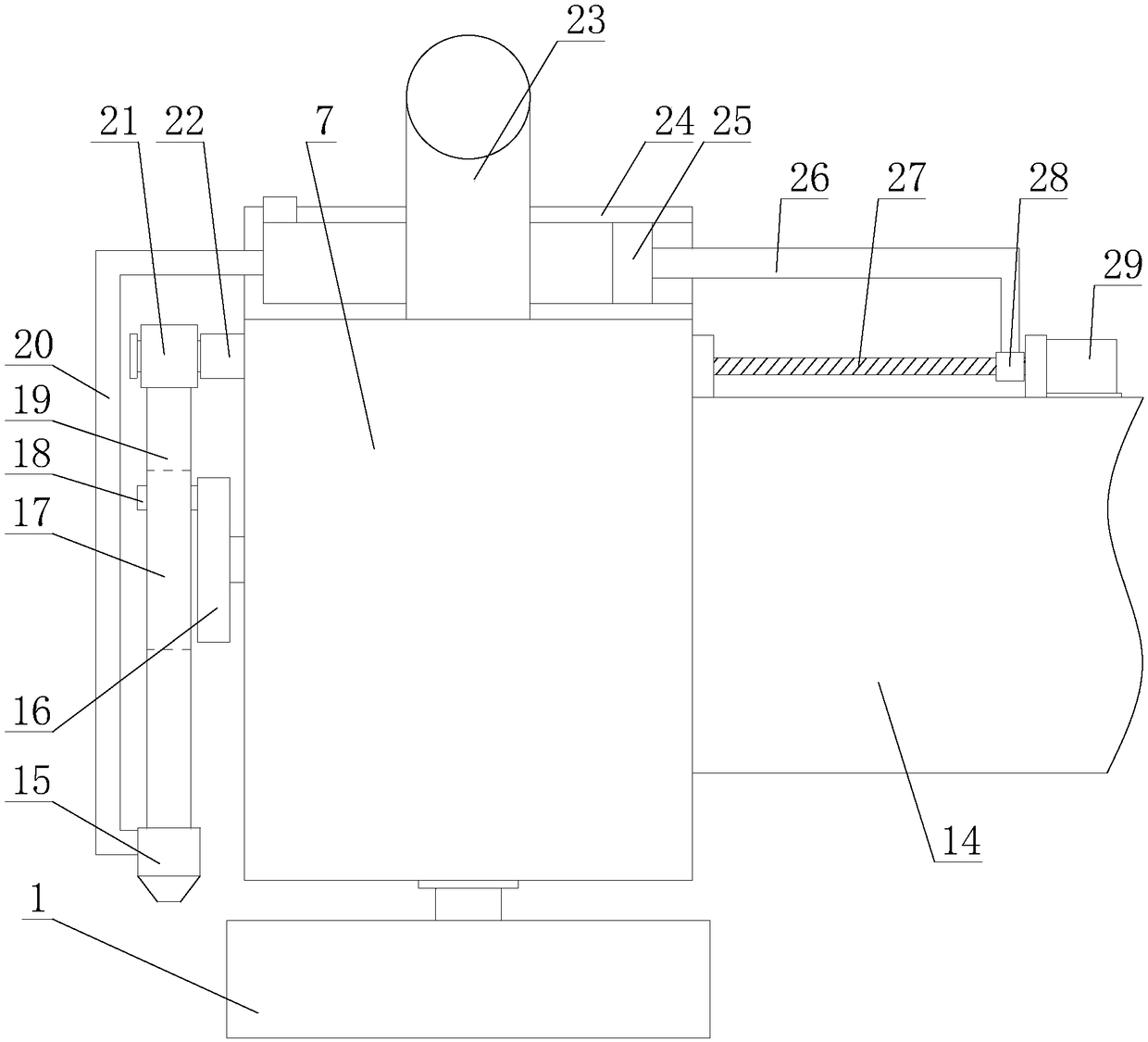

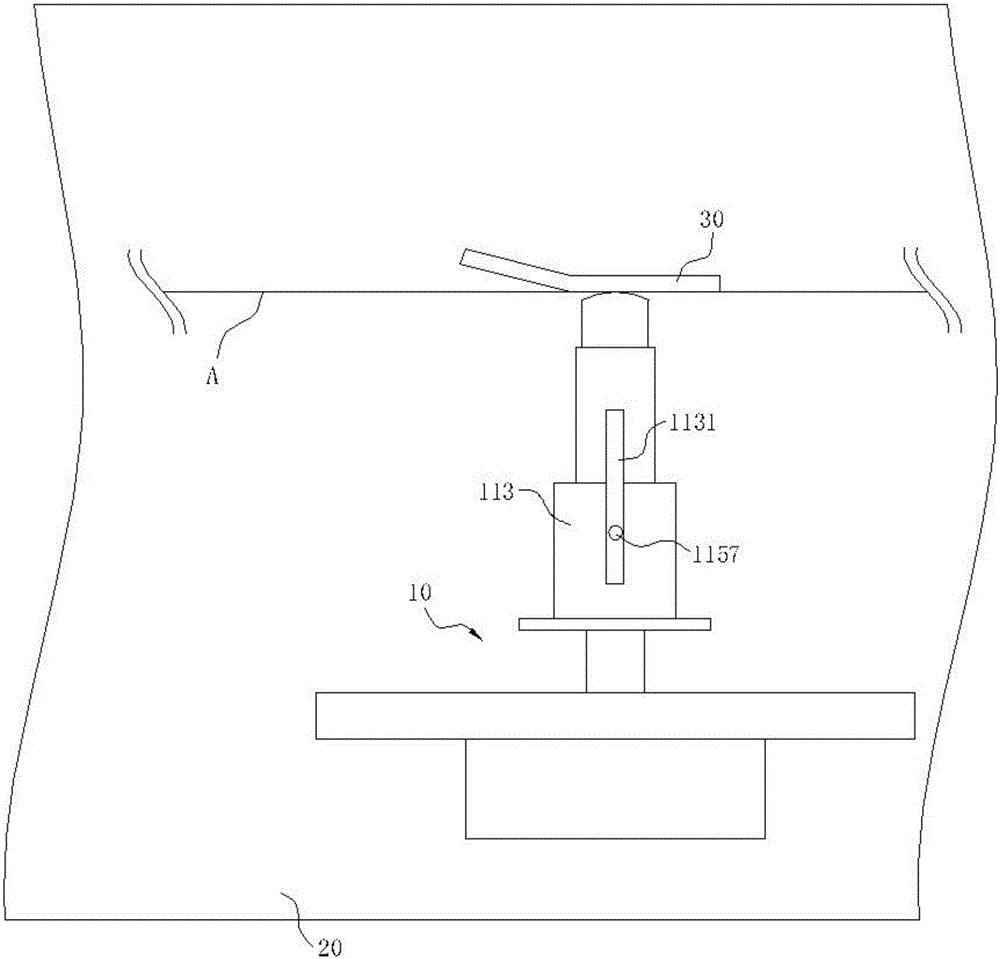

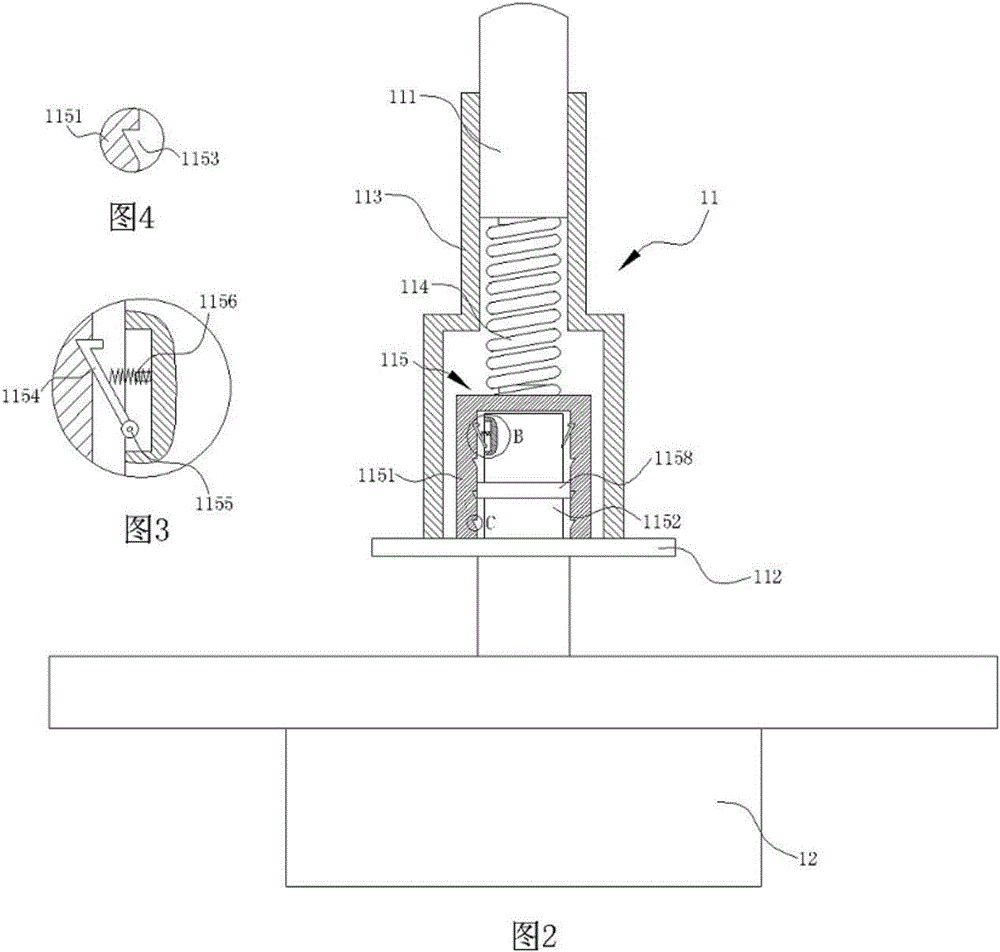

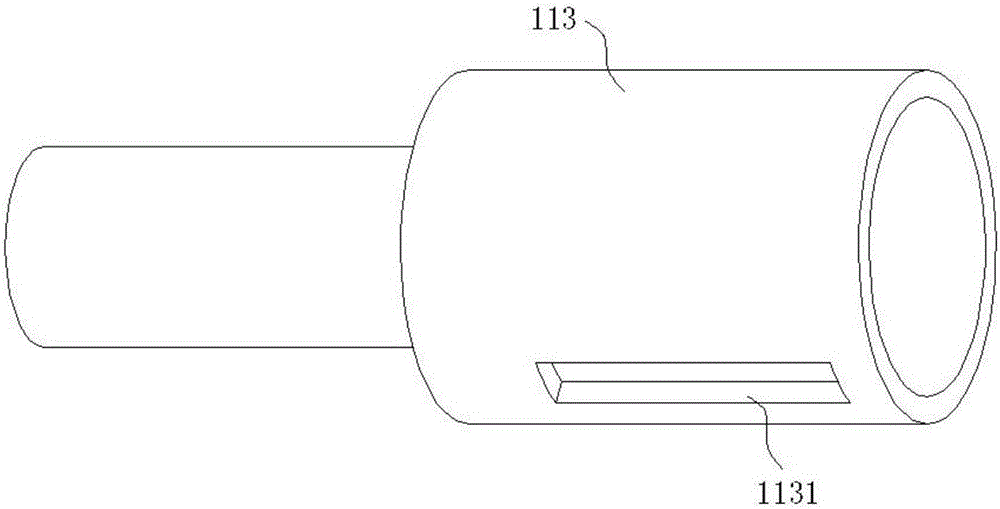

Automatic hardware polishing machine and using method thereof

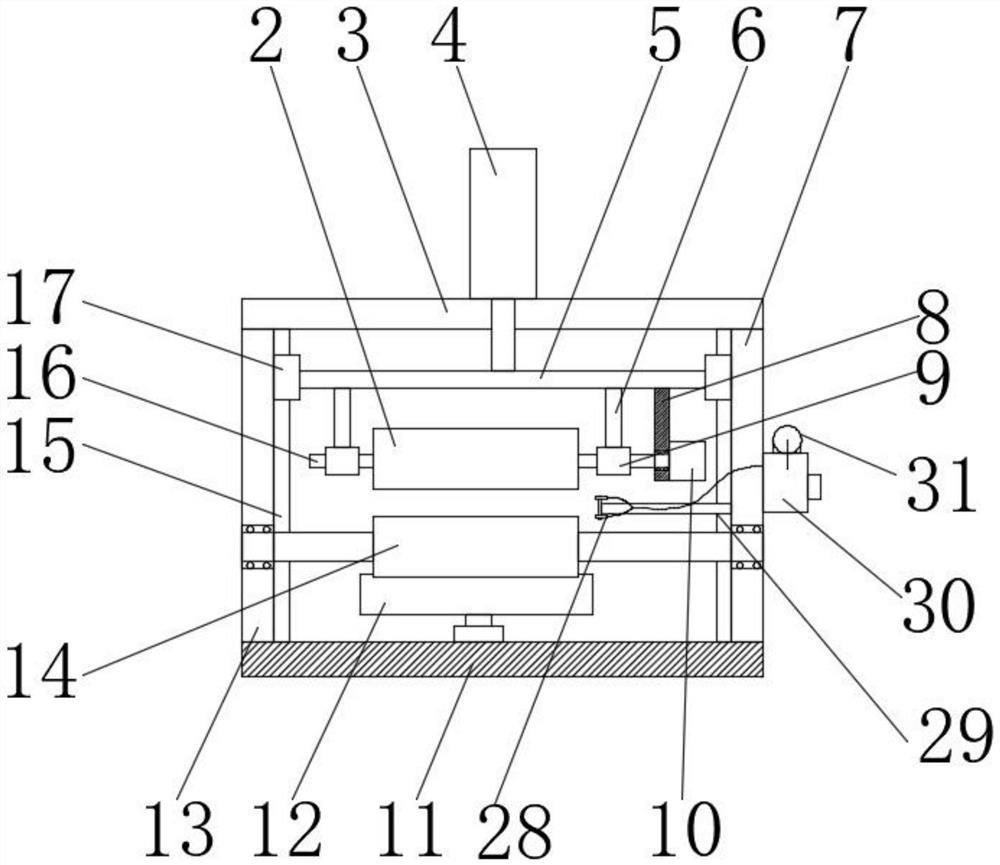

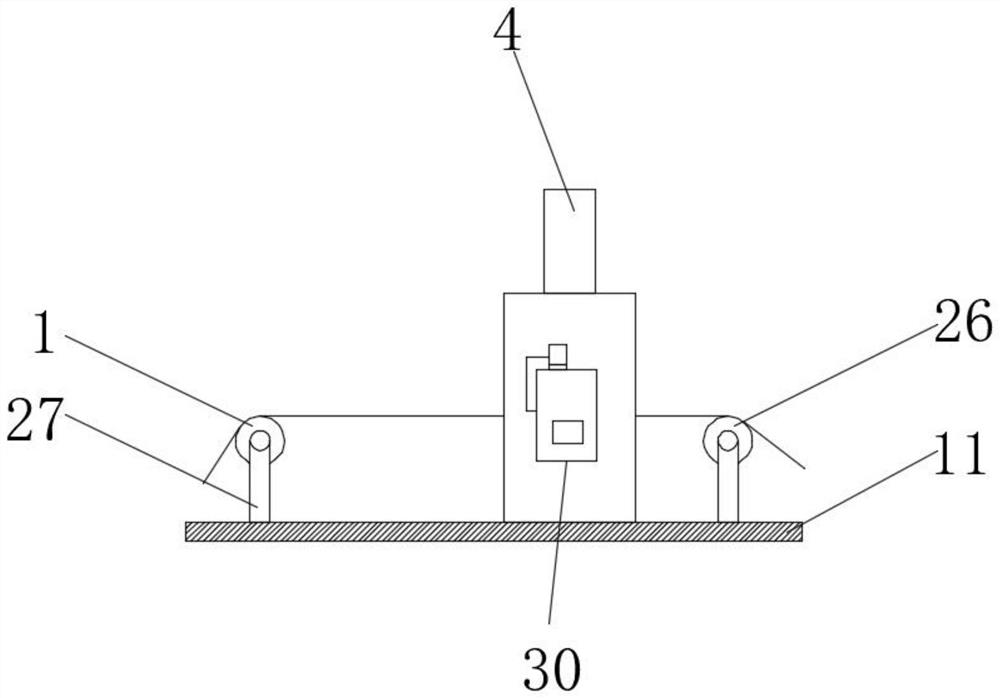

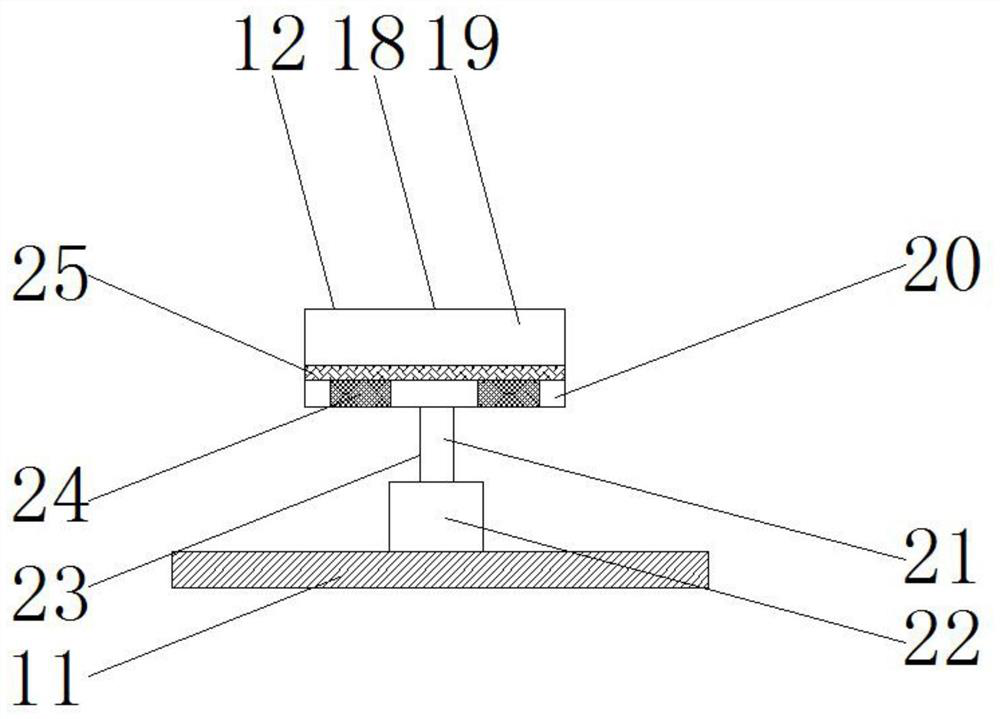

PendingCN110315422AImprove processing efficiencyShorten the production cyclePolishing machinesGrinding feedersWaxPulp and paper industry

The invention discloses an automatic hardware polishing machine and a using method thereof. According to the technical scheme, the automatic hardware polishing machine comprises a polishing machine frame, the polishing machine frame comprises a base and a transverse beam fixedly arranged on the base, the transverse beam is slidably connected with a mounting bottom plate, and two waxing mechanismsoppositely arranged left and right are arranged on the mounting bottom plate; and each waxing mechanism comprises a waxing sliding table sliding up and down and a waxing base fixedly connected with the mounting bottom plate, the two sides of each waxing sliding table are provided with cylindrical polishing wax and a waxing motor which are matched correspondingly, the middle of the mounting bottomplate is provided with a mounting base integrating with the mounting bottom plate, the mounting base is provided with polishing mechanisms matched with the two waxing mechanisms, the lower sides of the polishing mechanisms are also provided with clamping mechanisms matched with the polishing mechanisms, each clamping mechanism comprises a clamping base and a clamping substrate parallel to the clamping base, and the two sides of each clamping substrate are provided with a turning component and a clamping component. The automatic hardware polishing machine and the using method have the advantages of being high in processing efficiency, good in waxing effect, good in polishing effect and wide in applicability.

Owner:陈显青

Waxing device for textile processing

The invention discloses a waxing device for textile processing. The waxing device comprises a box; a feeding hopper is connected to the outer wall of one side of the box in an inserted mode, and a first connecting plate is arranged on the inner wall of one side of the box; a first mounting plate is arranged on the inner wall of the bottom of the box, and a first resistance wire is arranged on theouter wall of one side of the first mounting plate; a protective shell is arranged on the outer wall of one side of the box, and a motor is arranged on the inner wall of one side of the protective shell; a waxing roller is arranged at one end of an output shaft of the motor and located in the box; a second fixing plate is arranged on the outer wall of one side of the box, and a first fixing plateis arranged on the outer wall of the bottom of the second fixing plate; and the outer wall of one side of the first fixing plate is rotationally connected with an unwinding roller, and a textile thread is wound on the circumferential outer wall of the unwinding roller. Compared with traditional waxing by wax blocks, more resources are saved, and waste generated by the inability of the large numberof wax blocks to make contact with the textile thread is avoided.

Owner:李海燕

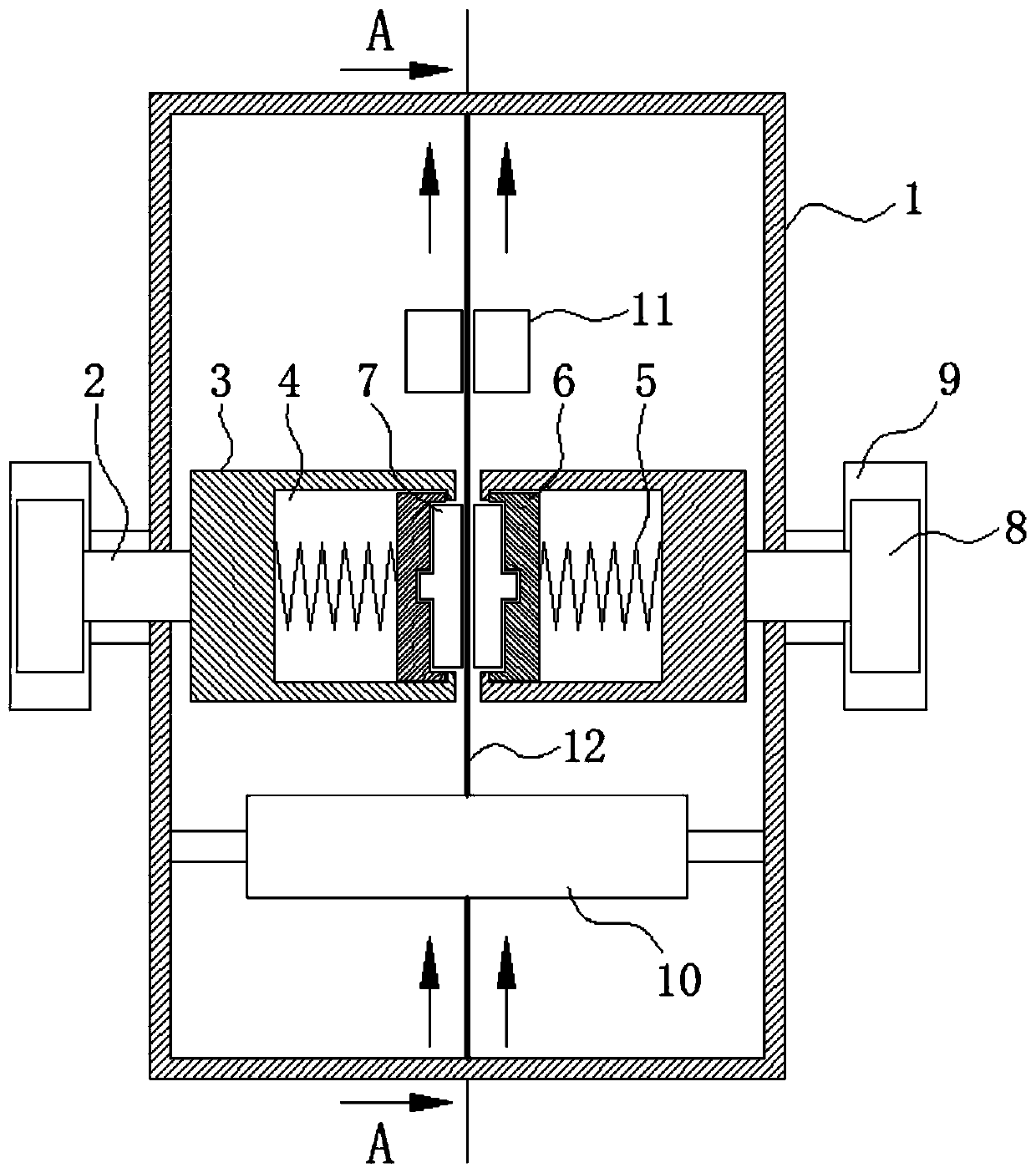

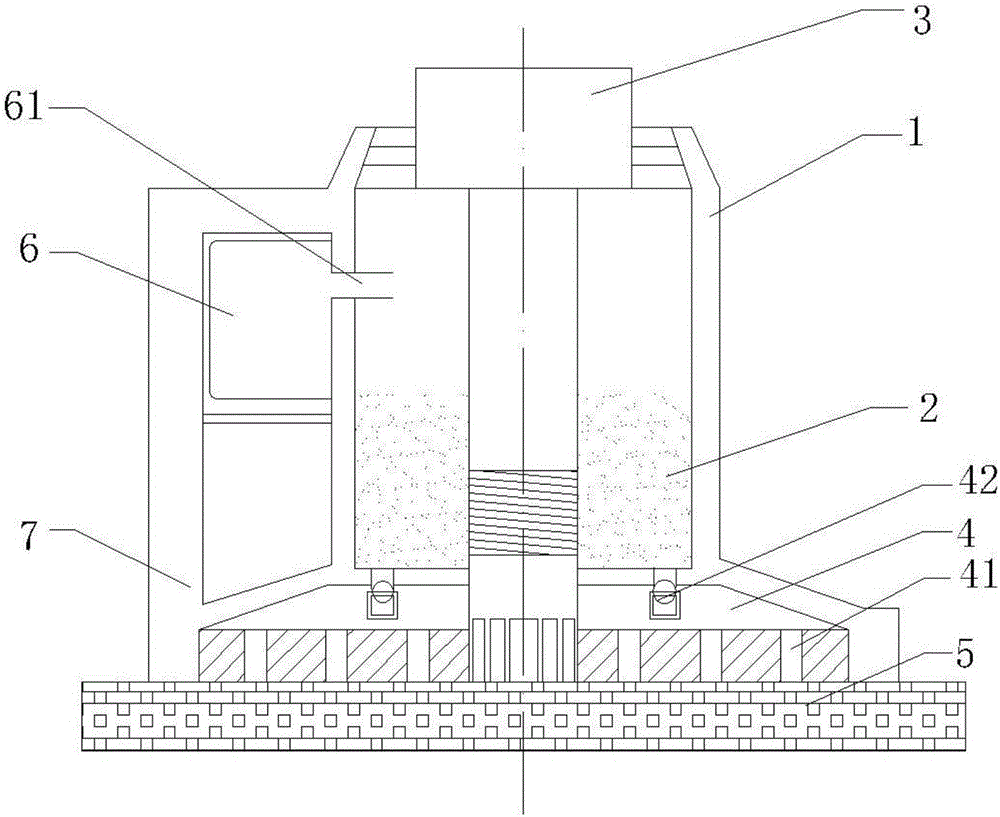

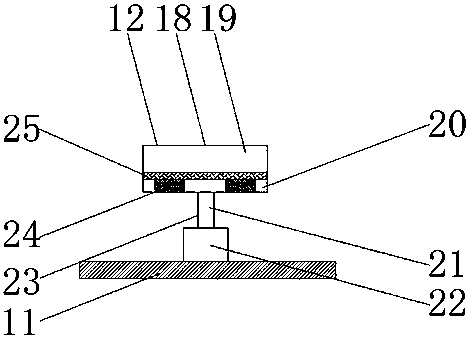

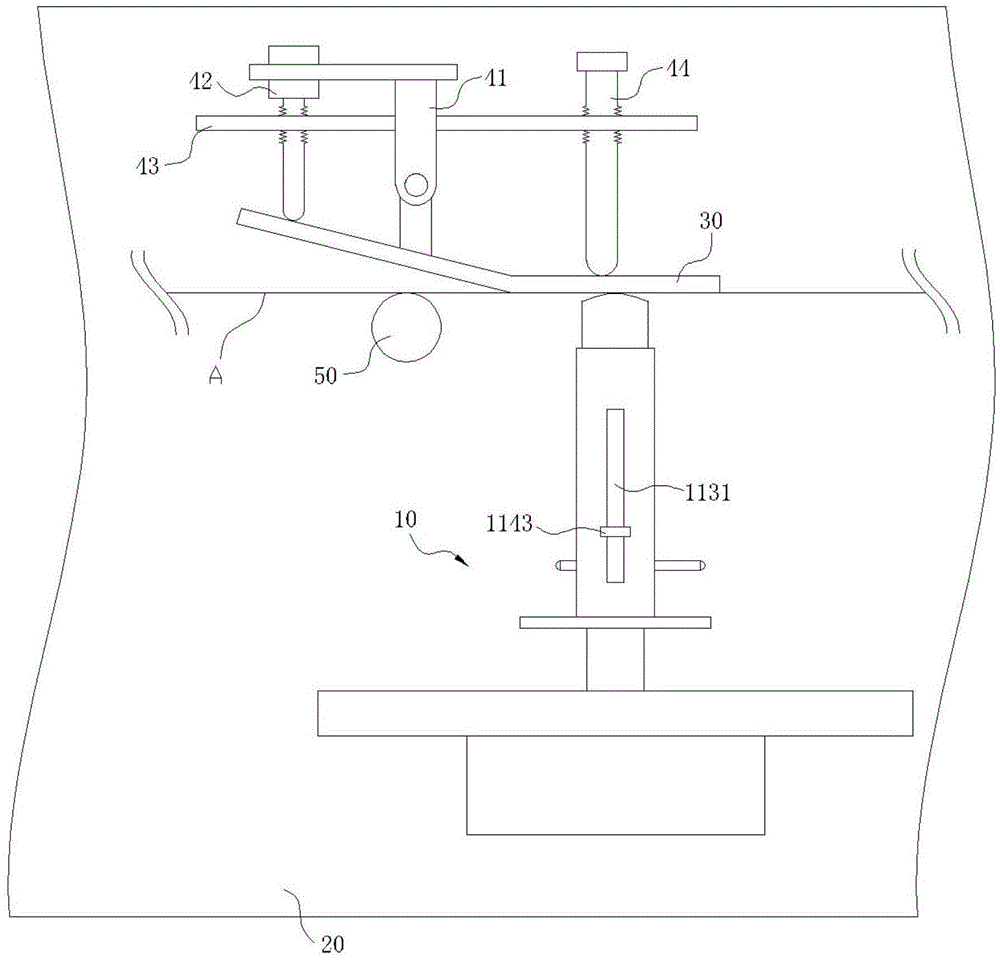

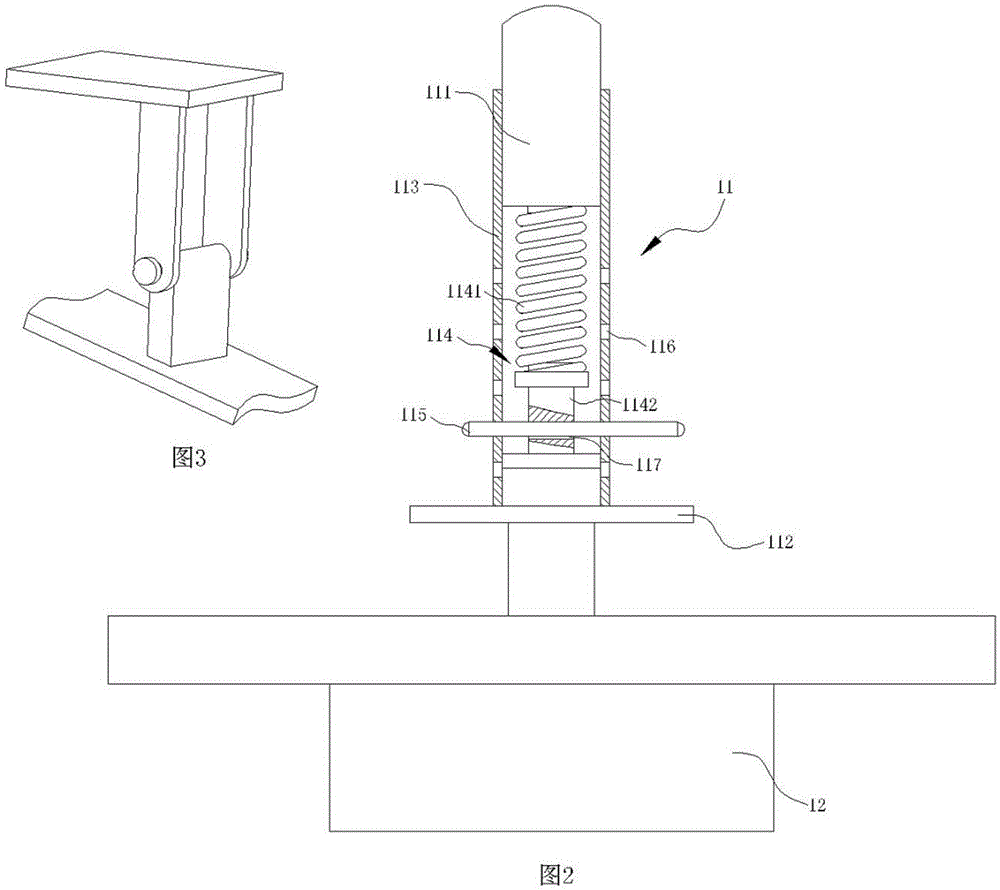

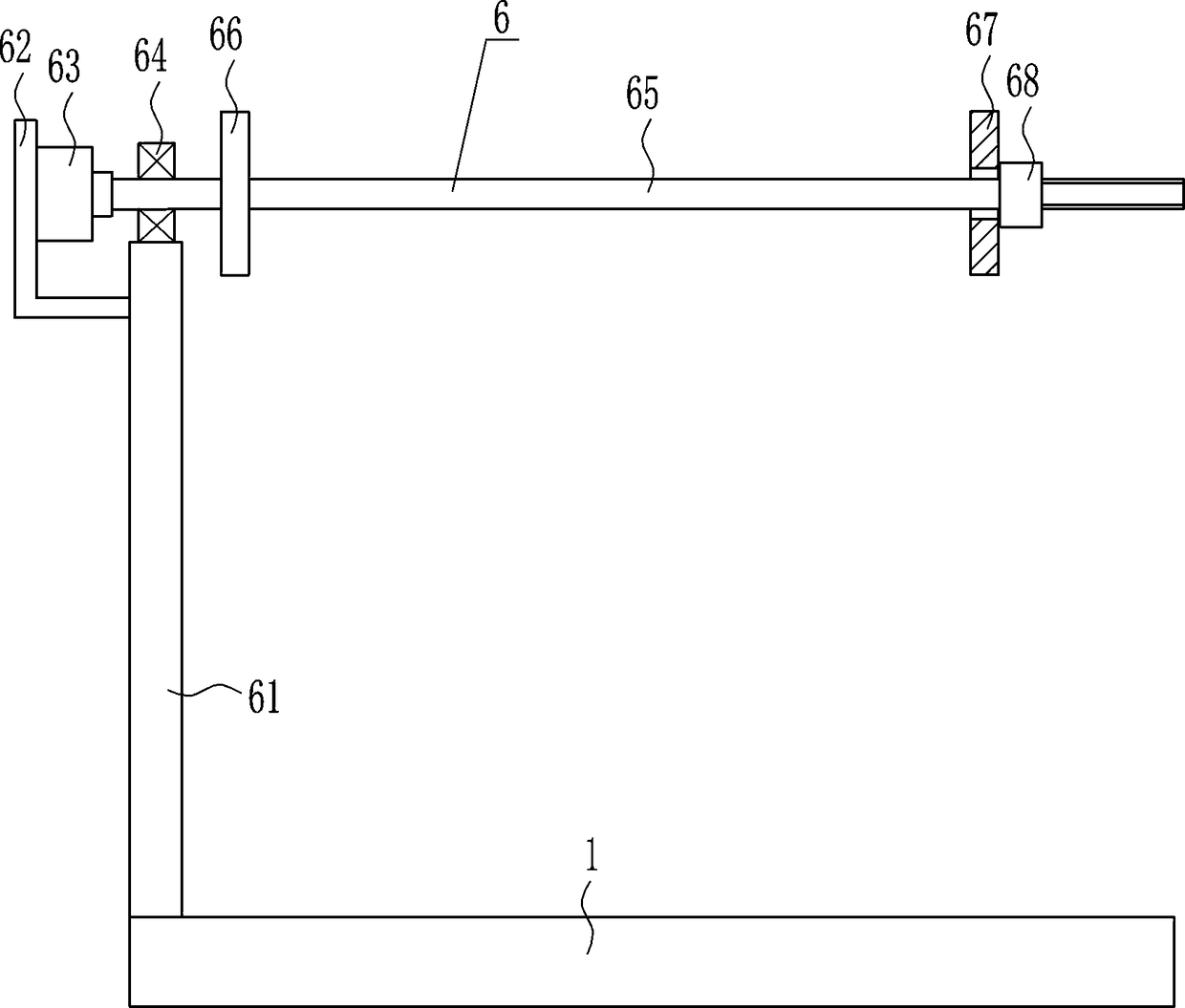

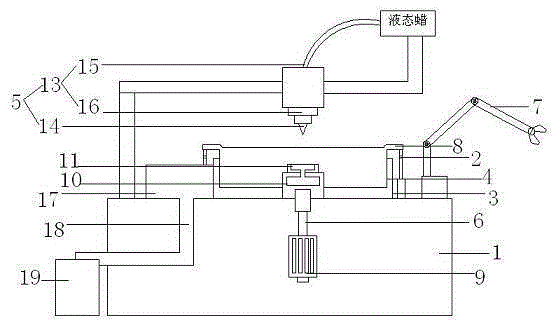

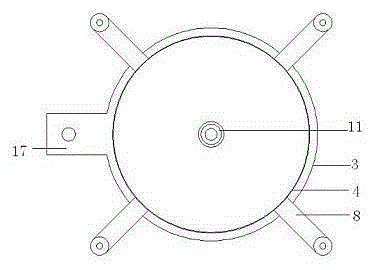

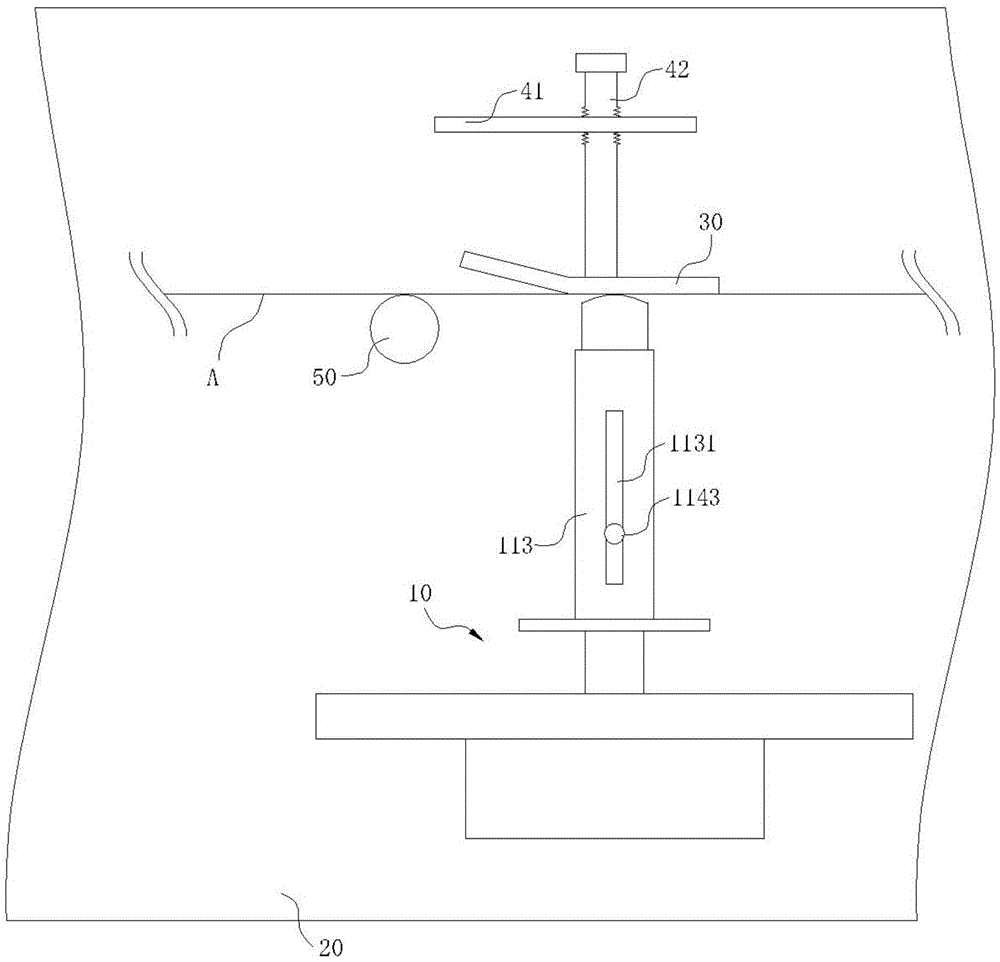

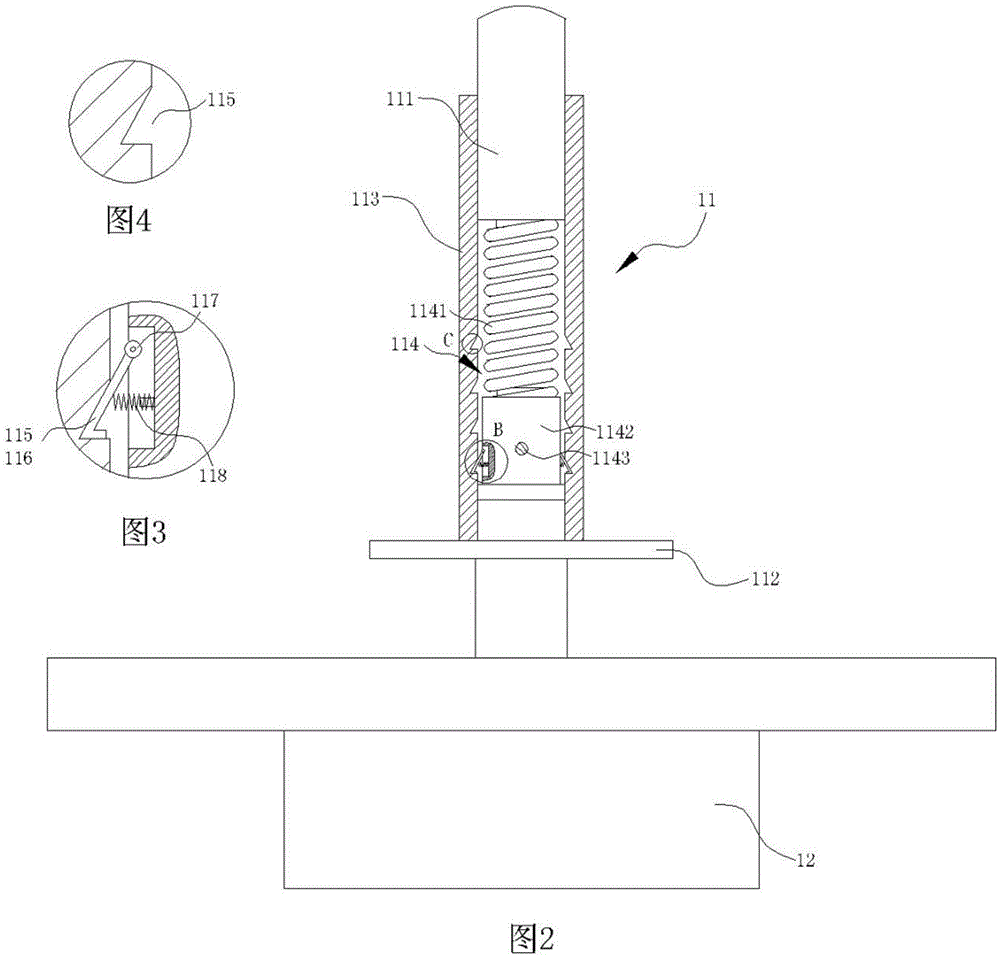

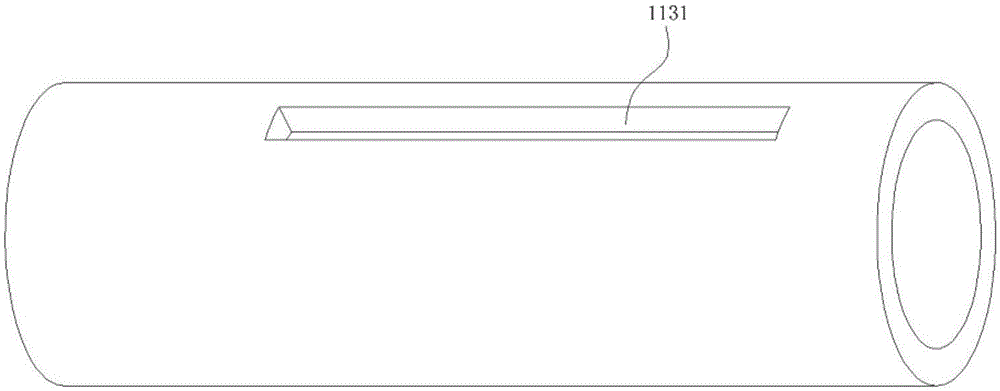

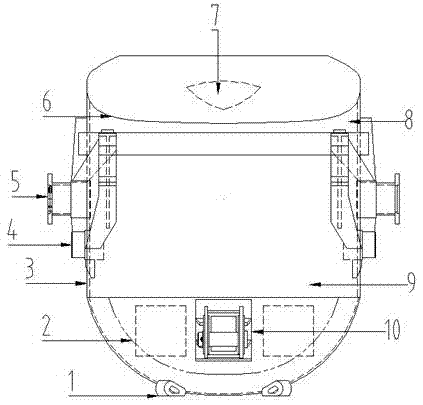

Liquid wax rotating device of wafer and waxing method

InactiveCN105214899ATTV value dropsReduce manufacturing costLiquid surface applicatorsCoatingsWaxLiquid state

The invention proposes a liquid wax rotating device of a wafer and a waxing method. The wax rotating device comprises a working table, an extension cylinder, an outer frame body, a baffle plate, a wax dripping device, a rotary absorbing mechanism and a mechanical arm, wherein the rotary absorbing mechanism comprises a rotating motor, a vacuum generator and a sucker; and the wax dripping device comprises a pneumatic valve and a needle. The wax rotating device is characterized by realizing a waxing technology of liquid wax of the wafer; compared with a traditional solid wax process, the waxing technology of liquid wax largely reduces the production cost by about 20%, and is excellent in waxing effect; and in subsequent polishing, a TTV value of an LED wafer is reduced by 10%, and a polishing exceeding proportion of the wafer is reduced from 5% to 0%, so that the problems of local pit caused by wax pasting and wafer break in the wax pasting process are totally eliminated.

Owner:江苏吉星新材料有限公司

Electric waxing machine convenient to use

InactiveCN109008854AImprove waxing qualityReduce maintenance costsCarpet cleanersFloor cleanersWaxDrive shaft

The invention relates to an electric waxing machine convenient to use. The machine includes a main body and further includes a waxing mechanism and a spraying mechanism. The waxing mechanism comprisesa housing, a driving component, a driving shaft, a connecting shaft, a spring, a first gear and a polishing plate. The spraying mechanism comprises a material conveying component, a fixed rod, a rotating sleeve pipe, a swing rod, a second sliding groove, a nozzle, a rotating disc, a driving block, a second gear and a rotating shaft. The material conveying component includes a drive unit, a storage tank, a material conveying pipe, a piston and a transmission rod. According to the electric waxing machine convenient to use, the connecting shaft rotates and meanwhile can move up and down along the drive shaft through the waxing mechanism under the action of the spring, under the action of the spring, a part of pressure is offset, thus the pressure applied by the polishing plate on a polishedobject is reduced, the waxing quality of the waxing mechanism is thus improved, through the spraying mechanism, the nozzle can be driven to swing left and right, the surface of the to-be-waxed objectthus can be uniformly coated with wax through the nozzle, and the working efficiency of the waxing machine is thus improved.

Owner:SHENZHEN ANSIKE ELECTRONICS TECH CO LTD

Waxing apparatus capable of maintaining sufficient friction between yarn and wax block

The invention discloses a waxing apparatus capable of maintaining sufficient friction between a yarn and a wax block. The waxing apparatus comprises a waxing unit, the waxing unit comprises a wax block device and a transmission device, a yarn passes through an end surface of a wax block, a rotary shaft of the wax block is perpendicular to a running direction of the yarn, the wax block device further comprises a barrel and a telescoping device mounted in the barrel, the inner wall of the barrel is provided with a position slot, and the telescoping device is fitted with a position block. During yarn waxing, the wax block on the waxing unit automatically rotates under the action of the transmission device, and the rotary shaft of the wax block is perpendicular to the running direction of the yarn; the position slot and the position block cooperate to continually adjust the position of the telescoping device so that the wax attaches tightly to the yarn, thus improving usage rate of the wax block and improving waxing effect of the yarn.

Owner:TONGXIANG SIYUAN TEXTILE

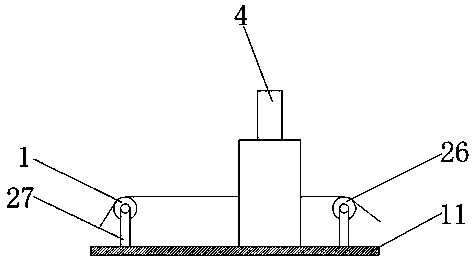

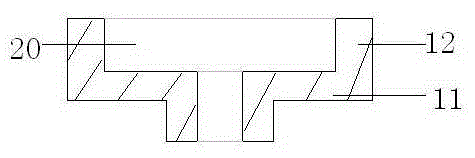

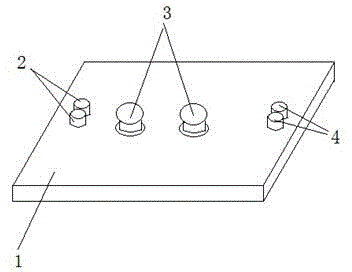

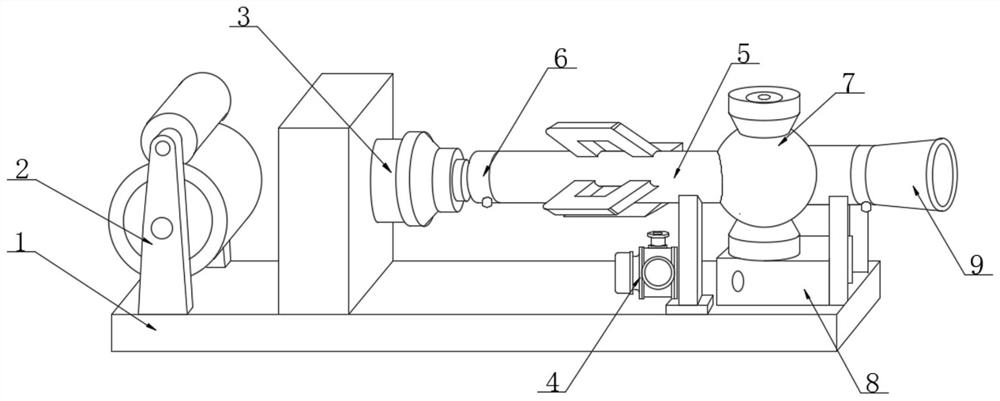

Waxing device for transmission machinery

The invention discloses a waxing device for transmission machinery. The waxing device comprises a base (1) and further comprises a friction wheel roller, a waxing wheel (3) and a polishing wheel roller (4), wherein the friction wheel roller (2), the waxing wheel (3) and the polishing wheel roller (4) are all installed on the base (1) and are located on the same horizontal line, and the waxing wheel (3) is arranged between the friction wheel roller (2) and the polishing wheel roller (4). The friction wheel roller (2) comprises two parallel cylindrical wheel roller bodies, and the surfaces of the wheel roller bodies are made of cotton cloth or rubber. The waxing device is simple in structure and can be used for evenly waxing yarn conveniently and effectively, hairiness of yarn is greatly reduced, and the quality of yarn is improved.

Owner:WUXI PRITEN TRANSMISSION MACHINERY

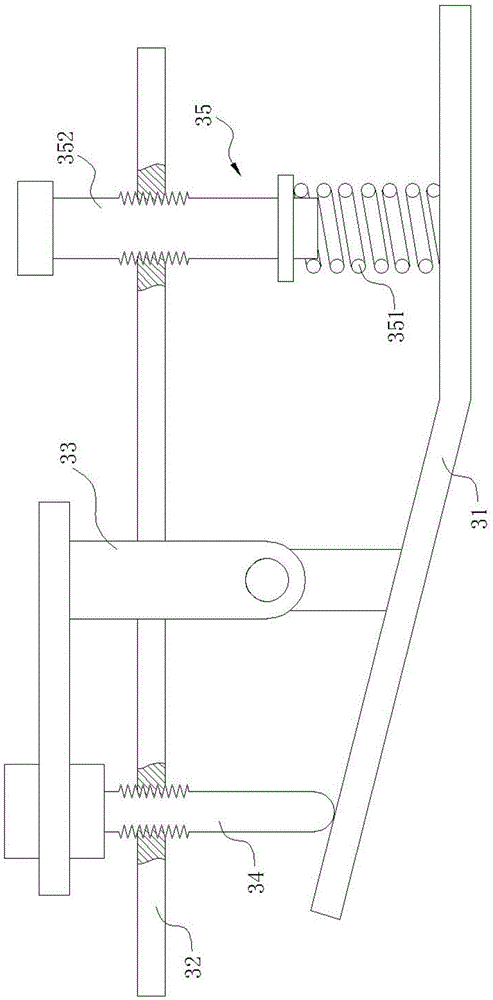

Waxing device capable of keeping enough pressure between yarn and wax block

The invention discloses a waxing device capable of keeping an enough pressure between a yarn and a wax block. The waxing device comprises a waxing machine, wherein the waxing machine comprises a wax block device and a transmission, the yarn passes through the end face of the wax block, and a rotary shaft of the wax block is perpendicular to the running direction of the yarn. The waxing machine further comprises a cylinder, an extensible spring installed in the cylinder and a gear device connected with the extensible spring. In the yarn waxing process, the wax block on the waxing machine performs spinning motion under the effect of the transmission, and the rotary shaft of the wax block is perpendicular to the running direction of the yarn. The position of the extensible spring is constantly adjusted through the gear position to make the wax block tightly adhere to the yarn, the using rate of the wax block can be improved, and a yarn waxing effect can be improved.

Owner:绍兴恒阳制线有限公司

Spinning thread wax brushing device

InactiveCN107354556AMeet the development requirementsGood waxing effectTextiles and paperWaxDrive shaft

The invention discloses a spinning thread wax brushing device which comprises a support. A rotating shaft is installed at the bottom of the support through a movable base. A wiring board is arranged above the rotating shaft. A driving shaft is arranged at the upper end of the support. One end of the driving shaft is movably fixed to the support, and the other end of the driving shaft stretches out of the support and is connected with a rotary shaft of a driving motor; a thread brushing roller is arranged between the driving shaft and the wiring board; one end of the thread brushing roller stretches out of the support, and a transmission wheel is installed; a rotating motor is further arranged at the bottom of the support; a rotating wheel is arranged on a rotating shaft of the rotating motor; the rotating wheel and the transmission wheel are connected through a belt; a wax inlet groove is formed in the portion, above the thread brushing roller, of the support; a flow guiding hole is formed in one end of the wax inlet groove; the flow guiding hole is formed over the thread brushing roller. Mechanical wax brushing operation is performed on spinning threads, the wax brushing effect is good, the production efficiency is improved, and the requirement for enterprise development is met.

Owner:湖州轶骏丝绸有限公司

Waxing device capable of making yarn tightly attached to wax block

The invention discloses a waxing device capable of making yarn tightly attached to a wax block. The waxing device comprises a waxing machine and a fixed plate. The waxing machine comprises the wax block and a transmission device. The yarn penetrates the end face of the wax block, and the rotating axis of the wax block is perpendicular to the running direction of the yarn. The waxing device further comprises a pressing device which comprises a pressing plate which can press the yarn on the end face of the wax block. In the yarn waxing process, the wax block on the waxing machine auto-rotates under the action of the transmission device, and the rotating axis of the wax block is perpendicular to the running direction of the yarn. The pressing device presses the yarn on the end face of the wax block through the pressing plate. By means of the technical scheme, the using rate of the wax block can be increased, production cost can be reduced, and the yarn waxing effect can be improved.

Owner:SUZHOU LIAORUO ELECTROMECHANICAL TECH CO LTD

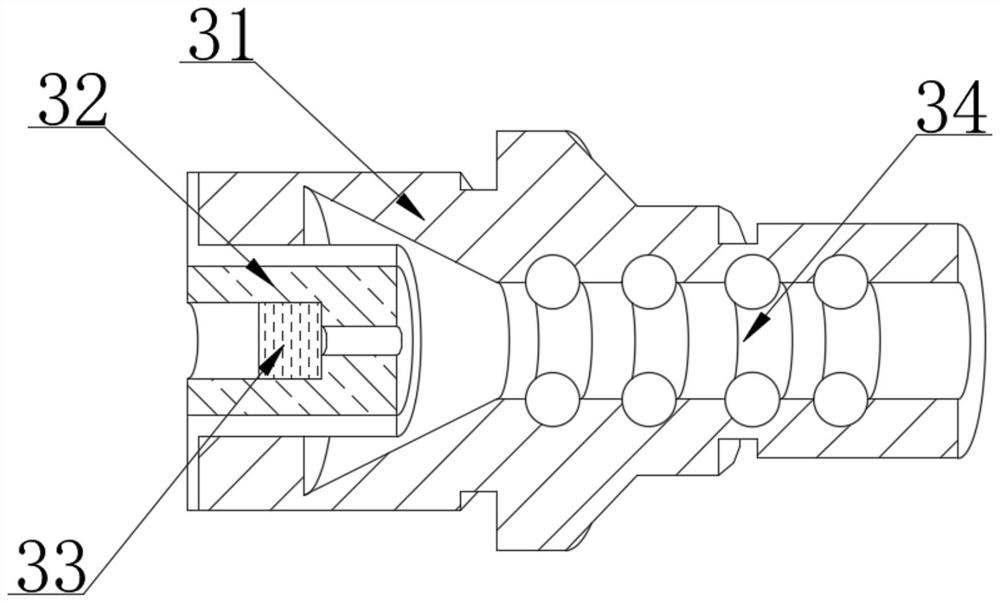

Bone wax coating device

InactiveCN104147687AEasy to applyImprove waxing effectSurgeryMedical applicatorsWaxBiomedical engineering

The invention relates to coating instruments, in particular to a bone wax coating device, and belongs to the technical field of medical instruments. According to the technical scheme, the bone wax coating device comprises a coating sleeve used for holding bone wax and allowing the bone wax to move; the coating sleeve comprises a first sleeve end and a second sleeve end corresponding to the first sleeve end, and the bone wax can penetrate out of the first sleeve end of the coating sleeve; the end of the first sleeve end of the coating sleeve is provided with a wedge-shaped outlet, a push plate used for installing the bone wax is arranged in the coating sleeve, and the push plate is provided with a bone wax push rod coaxial with the bone wax and capable of pushing the bone wax to move in the coating sleeve; the second sleeve end in the coating sleeve is provided with a bone wax push rod drive mechanism used for driving the bone wax push rod. The bone wax coating device is compact in structure, convenient to operate, wide in application range, safe and reliable and the wax coating effect is improved.

Owner:如皋薛窑医院

Waxing device for fabric production

PendingCN111321529AEnsure sufficientGuaranteed waxing effectTextile treatment machine arrangementsTextile treatment cleaning apparatusEngineeringMechanical engineering

The present invention belongs to the technical field of fabric processing equipment, in particular to a waxing device for fabric production. In view of the problem of poor wax coating effect on the fabric surface when waxing the fabric, the following solutions are now proposed, a base is included, a fixing frame is welded on the outer wall of one side of the base, a feeding box is fixed on the outer wall of one end of the fixing frame through screws, a support tube is welded to the middle of the top outer wall of the base, a sliding rod is slidably connected to the inner wall of the support tube, the same support spring is welded between the bottom outer wall of the sliding rod and the bottom inner wall of the support tube, a lifting frame is welded on the top outer wall of the sliding rod, a waxing roller mounting hole is formed in the inner wall of the lifting frame, and a waxing roller is connected to the inner wall of the waxing roller mounting hole through a bearing. According tothe waxing device for fabric production in the invention, sufficient wax liquid is guaranteed on the surface of a feeding brush, thereby facilitating ensuring the wax coating effect on the surface ofthe cloth, feeding can be continuously conducted, the wax melting speed can be accelerated, and improvement of the production efficiency is facilitated.

Owner:杨飞

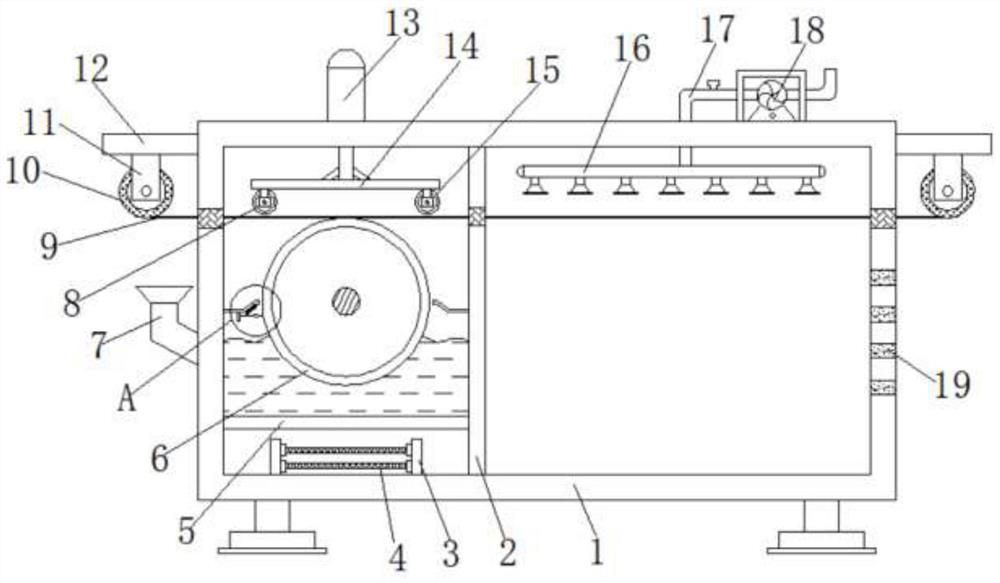

Hot-press waxing machine for fruit production

InactiveCN106858673AImprove work efficiencyStable jobFruits/vegetable preservation by coatingFood treatmentMicrocontrollerLow noise

The invention discloses a hot-press waxing machine used for fruit production, which comprises a base, a pressure sealer, a flat shaft and a driving wheel, a switch is installed above the base, and a heat conducting sheet is arranged above the switch , the heat conduction sheet is arranged between the switch and the pressure sealer, a wax dropper is arranged above the pressure sealer, a secondary drive wheel is installed above the wax dropper, and the secondary drive wheel A motor is arranged above the wheel, the motor is installed above the flat shaft, a chassis is arranged below the flat shaft, a thermal transformer is arranged below the chassis, a single-chip microcomputer is arranged above the walking driving wheel, and a A coupling is provided. Beneficial effects: the appearance and structure design conforms to ergonomics, beautiful and compact, adjusts the internal pressure through heat, integrates the current, improves the working efficiency of the motor, has little mechanical loss during work, prolongs the working time of the battery, works smoothly, and has low noise. The effect is good.

Owner:CHONGQING CHANGSHOU DISTRICT LUANXIANG AGRI DEV CO LTD

Mechanical waxing device capable of improving liquidity of wax liquid

PendingCN112442777AReduce frictionReduced deterioration of yarn hairinessTextiles and paperElectric machineryYarn

The invention discloses a mechanical waxing device capable of improving liquidity of wax liquid. The mechanical waxing device comprises a motor, an air cylinder, a wax block containing bin, a waxing roller and a height adjusting device, wherein an upper-layer wax block and yarn rotate in opposite directions through rotation of the motor, a friction force between the upper surface of the yarn and the upper-layer wax block is further increased, and then a yarn waxing effect is improved; meanwhile, the air cylinder is used for driving a moving rod to move on a sliding rail, so that the upper-layer wax block makes contact with the upper surface of the yarn all the time, the upper surface of the yarn is prevented from being separated from the upper-layer wax block, and thus the waxing effect ofthe upper surface of the yarn is guaranteed; a friction coefficient value of the surface of the yarn is reduced through waxing, so that friction between the yarn is reduced, and deterioration of yarnhairiness is effectively reduced; and a hot air system blows air to the waxing structure, so that the liquidity of the wax liquid can be improved, the waxing effect can be increased and the waxing efficiency can be improved.

Owner:武穴市宽创机电科技有限公司

Efficient yarn jet waxing equipment for textile processing and using method thereof

InactiveCN113401732AEvenly waxedAvoid the problem of uneven waxingFilament handlingYarnIndustrial engineering

The invention discloses efficient yarn jet waxing equipment for textile processing and a using method thereof, and particularly relates to the field of textile processing. The efficient yarn jet waxing equipment comprises an equipment base, a pay-off rack is fixedly installed on the top face of the equipment base, and a yarn fuzzing mechanism, a circulating air pump, an air distribution ring and a molten wax storage box are fixedly connected and installed on the top face of the equipment base. The yarn fluffing mechanism and a jet waxing mechanism are located on the same horizontal line, the two ends of the jet waxing mechanism are fixedly connected with the gas distribution ring and a wax liquid recycling mechanism respectively, and the end of the gas distribution ring and the end of the wax liquid recycling mechanism are communicated with the air outlet end and the air inlet end of the circulating air pump respectively. According to the scheme, the yarn waxing equipment adopts the molten wax liquid jet waxing structure, the atomized and diffused molten wax liquid is coated to the surface of the yarn through siphoning by utilizing the structure that airflow and the yarn are in the same direction, uniform and all-directional waxing of the yarn is achieved, the problem that waxing is not uniform during traditional contact is solved, and the waxing effect and the forming quality are improved.

Owner:嘉兴鼎澳纺织科技有限公司

Yarn wet waxing process

The invention discloses a yarn wet waxing process, wherein a yarn is sequentially subjected to dilution, PH value adjusting, impregnation, and dehydration drying to complete the waxing process. According to the present invention, the excellent and uniform waxing effect can be achieved by using the wet waxing of the liquid wax, the treated yarn has characteristics of low surface kinetic friction value, weaving enhancing, and hairiness reducing; and with the waxing process, the cohesion between the fibers is increased, the strength of the yarn is improved, the yarn is smooth and soft, and is easy to weave, the addition of the softener is not required, yellowing and discoloration cannot occur during the treatment and the drying process, the removal with the refining is easily performed, and the knitted fabric has characteristics of good hand-feeling and good electric resistance.

Owner:RUGAO CHANGJIANG SCI & TECHCAL IND CO LTD

Fabric waxing device for shoe processing

ActiveCN111482325AAvoid pollutionGood effectLiquid surface applicatorsCoatingsStructural engineeringManufacturing engineering

The invention discloses a fabric waxing device for shoe processing. The device comprises a shell structure, a heating structure arranged on the shell structure and a wax feeding structure. The shell structure comprises a shell with the upper surface and the lower surface communicating with each other, a fixed block arranged in the shell, a first spring arranged below the fixed block, a movable frame located below the first spring and a baffle arranged in the movable frame, a first through hole is formed in the shell, and the upper end of the fixed block is fixedly connected with the inner surface of the shell. The device can flatten the fabric during spraying of the fabric, molten wax can be evenly sprayed on the fabric after being scattered by a first filter screen, and the spraying quality is improved; and meanwhile, hot air flowing in the shell can enable the molten wax to continuously flow into the shell in a bent pipe, continuous and long-time operation of spraying is guaranteed,waste of wax resources is reduced, and comprehensive waxing treatment on the fabric is achieved through cooperation of spraying and smearing.

Owner:瑞锦鞋业集团有限公司

Stable waxing device for porcelain artworks

The invention relates to a waxing device, especially to a stable waxing device for porcelain artworks. The invention provides a stable waxing device for porcelain artworks and with uniform waxing effect so as to solve the technical problem. The stable waxing device for porcelain artworks comprises a support, a motor, a second guide pulley, a stay wire, a first guide pulley, a first spring, a non-return valve, a flexible pipe, an infusion pump, a second box, a first pole and the like. A first box is positioned at the left side of second springs. The second springs are symmetrically arranged at two sides of the bottom inside the first box. The upper ends of the second springs are connected to a piston which matches the first box. The bottom of the first box is provided with a drain pipe and the first pole. The effect of uniform waxing is achieved. With alternative-type clockwise rotation and anticlockwise rotation of porcelain, the porcelain is roundly waxed by sponge. Then, the porcelain waxing effect is better.

Owner:新昌县利拓科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com