Wearing-resistant super-hydrophobic fabric and preparation method thereof

A super-hydrophobic, fabric technology, applied in plant fibers, textiles and papermaking, ultrasonic/sonic fiber processing, etc., can solve the problems of complex preparation process of super-hydrophobic surface, incapable of industrial production and application, poor wear resistance of super-hydrophobic fabrics, etc. To achieve the effect of convenient and fast preparation process, small loss of breaking strength and strong superhydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

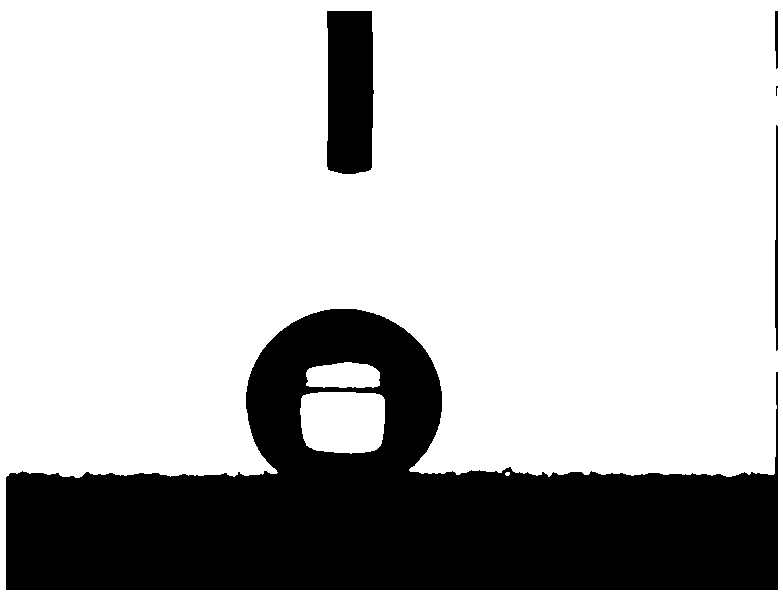

Image

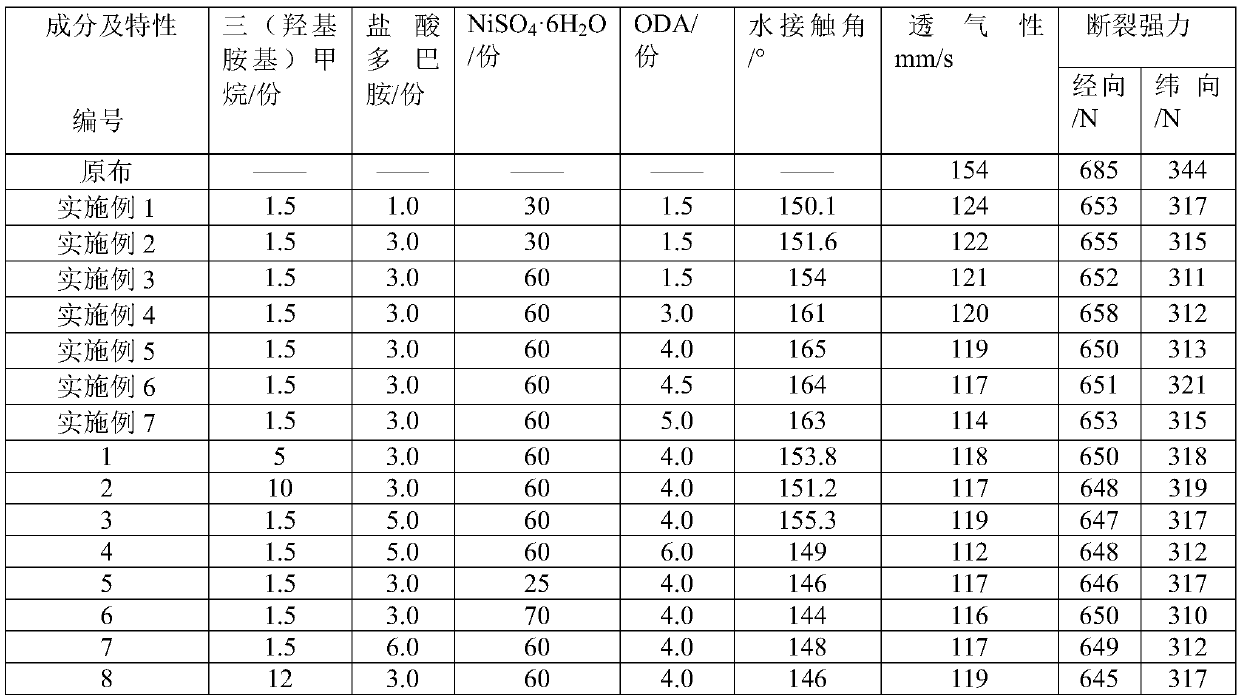

Examples

Embodiment 1

[0047] ①At room temperature, take 1.5 parts of tris(hydroxylamino)methane in a beaker, add deionized water to a total weight of 1000 parts, then add 1.0 parts of dopamine hydrochloride, stir with a magnetic stirrer until completely dissolved, and then add 2.0M hydrochloric acid Adjust its pH to 8.5.

[0048] ②Take 30 parts of NiSO 4 ·6H 2 O in a beaker, add deionized water to a total weight of 100 parts, then stir with a magnetic stirrer until completely dissolved.

[0049] ③Take 0.15 parts of NaOH in a beaker, add deionized water to a total weight of 300 parts, and then stir with a magnetic stirrer until completely dissolved.

[0050] ④ Take 1.5 parts of ODA in a beaker, add absolute ethanol to a total weight of 110 parts, then place the beaker in a constant temperature water bath at 60°C and heat until ODA is completely dissolved.

[0051] ⑤ Under the stirring of a magnetic stirrer, soak the clean raw cotton fabric in the dopamine buffer for 35 minutes, take it out, first...

Embodiment 2

[0056] ①At room temperature, take 1.5 parts of tris(hydroxylamino)methane in a beaker, add deionized water to a total weight of 1000 parts, then add 3.0 parts of dopamine hydrochloride, stir with a magnetic stirrer until completely dissolved, and then add 2.0M hydrochloric acid Adjust its pH to 8.5.

[0057] ②Take 30 parts of NiSO 4 ·6H 2 O in a beaker, add deionized water to a total weight of 100 parts, then stir with a magnetic stirrer until completely dissolved.

[0058] ③Take 0.15 parts of NaOH in a beaker, add deionized water to a total weight of 300 parts, and then stir with a magnetic stirrer until completely dissolved.

[0059] ④ Take 1.5 parts of ODA in a beaker, add absolute ethanol to a total weight of 110 parts, then place the beaker in a constant temperature water bath at 60°C and heat until ODA is completely dissolved.

[0060] ⑤ Under the stirring of a magnetic stirrer, soak the clean raw cotton fabric in the dopamine buffer for 35 minutes, take it out, first...

Embodiment 3

[0066] ①At room temperature, take 1.5 parts of tris(hydroxylamino)methane in a beaker, add deionized water to a total weight of 1000 parts, then add 3.0 parts of dopamine hydrochloride, stir with a magnetic stirrer until completely dissolved, and then add 2.0M hydrochloric acid Adjust its pH to 8.5.

[0067] ②Take 60 parts of NiSO 4 ·6H 2 O in a beaker, add deionized water to a total weight of 100 parts, then stir with a magnetic stirrer until completely dissolved.

[0068] ③Take 0.15 parts of NaOH in a beaker, add deionized water to a total weight of 300 parts, and then stir with a magnetic stirrer until completely dissolved.

[0069] ④ Take 1.5 parts of ODA in a beaker, add absolute ethanol to a total weight of 110 parts, then place the beaker in a constant temperature water bath at 60°C and heat until ODA is completely dissolved.

[0070] ⑤ Under the stirring of a magnetic stirrer, soak the clean raw cotton fabric in the dopamine buffer for 35 minutes, take it out, first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Longitudinal breaking strength | aaaaa | aaaaa |

| Weft breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com