Glue for cloth glue dispenser and preparation method thereof

A dispensing machine and glue technology, applied in the direction of adhesives, polyurea/polyurethane adhesives, adhesive types, etc., can solve the problems of worn leather clothing, poor product feel, insufficient bonding, etc., to ensure bonding Excellent fastness, excellent bonding strength, simple and beautiful products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment one cloth dispenser glue

[0035] A kind of glue for cloth dispensing machine in the present embodiment is made up of the raw material of following weight part:

[0036]

[0037] Wherein, the effective content of the blended resin ethylene vinyl acetate copolymer (EVA) is 25-30%, and DuPont EVA205W can be used. Calcium silicate may be substituted or mixed with calcium carbonate. Hydrogenated C9 petroleum resin can be replaced by hydrogenated C5 petroleum resin or hydrogenated C5 / C9 copolymer resin, or replaced by rosin resin, terpene resin, etc.

[0038] The content of NCO in the polyurethane prepolymer is 3.5%-4%.

Embodiment 2

[0039] Embodiment 2 Glue for cloth dispenser

[0040] A kind of glue for cloth dispensing machine in the present embodiment is made up of the raw material of following weight part:

[0041]

[0042] Wherein, the effective content of the blended resin ethylene vinyl acetate copolymer (EVA) is 25-30%, and DuPont EVA205W can be used. Calcium silicate may be substituted or mixed with calcium carbonate. Hydrogenated C9 petroleum resin can be replaced by hydrogenated C5 petroleum resin or hydrogenated C5 / C9 copolymer resin, or replaced by rosin resin, terpene resin, etc.

[0043] The content of NCO in the polyurethane prepolymer is 3.5%-4%.

Embodiment 3

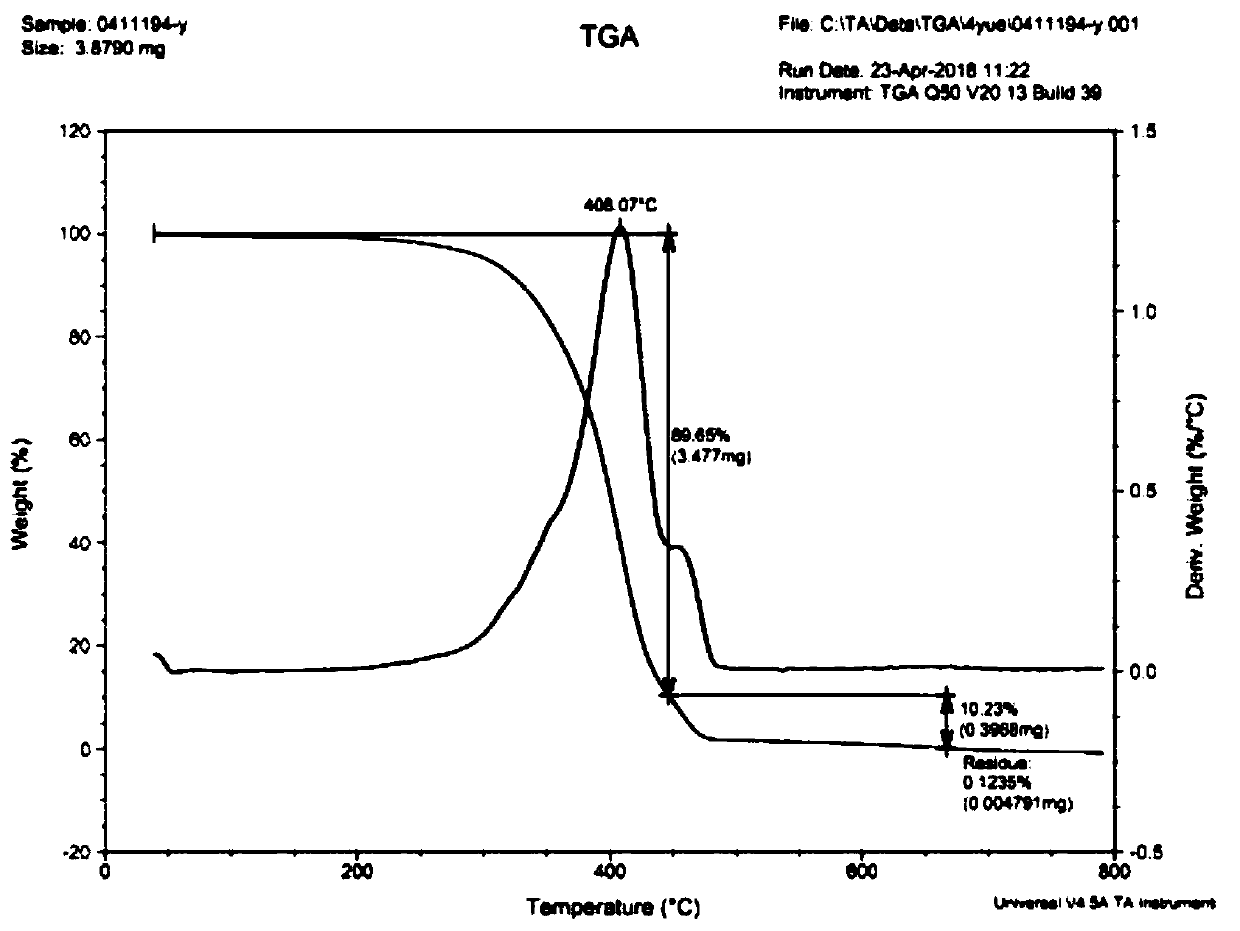

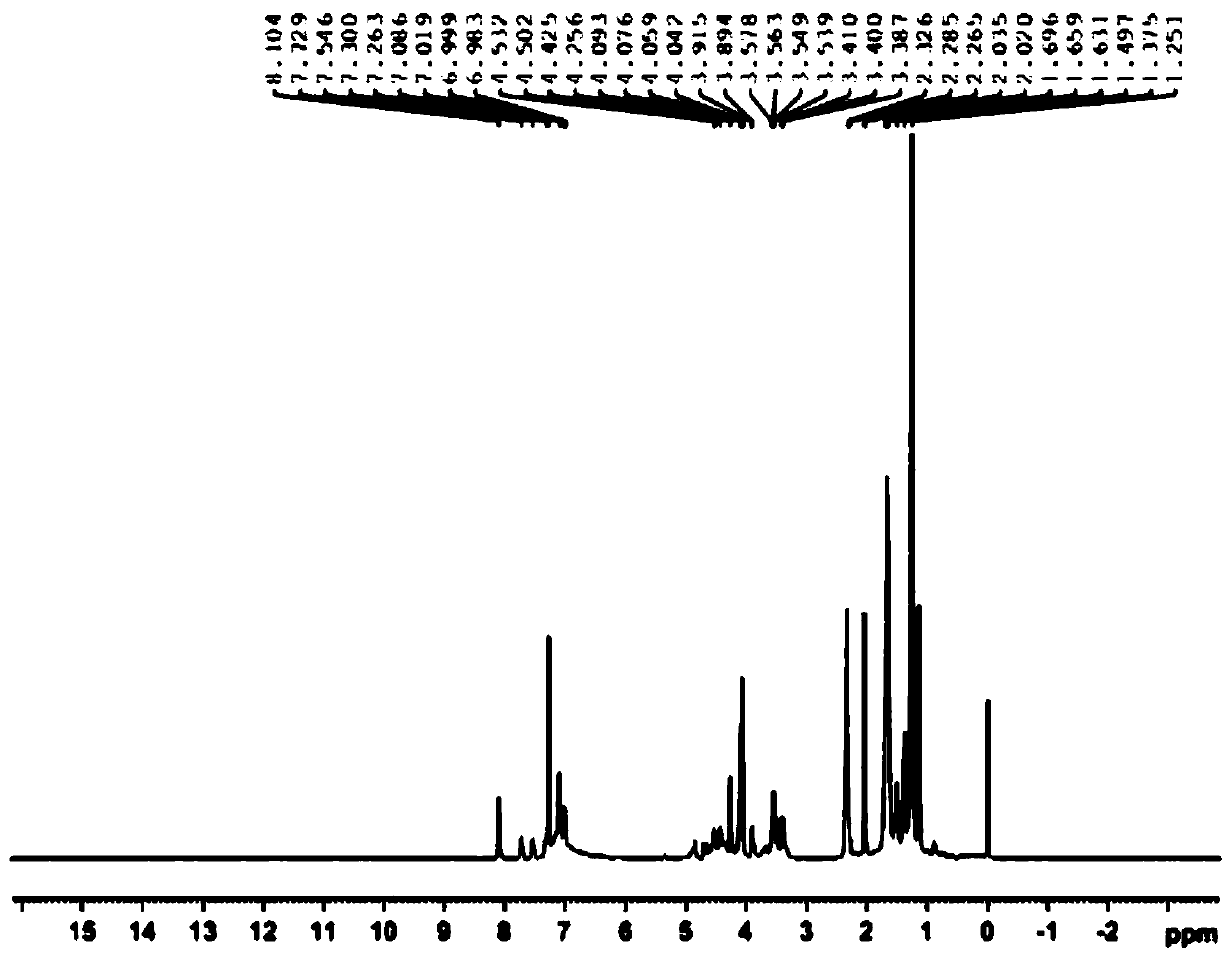

[0044] Embodiment three polyurethane prepolymer

[0045] The polyurethane prepolymer in embodiment one and two is prepared from the monomer of following weight part:

[0046]

[0047] Among them, polyether polyol 220, that is, polyether polyol has a functionality of 2 and a molecular weight of 1800-2200.

[0048] The molecular weight of polyester polyol is about 2000, and it is polymerized by dibasic acid and dibasic alcohol. The dibasic acid in this embodiment is terephthalic acid and phthalic acid, and the dibasic alcohol is diethylene glycol and ethylene glycol. Alcohol, n (terephthalic acid): n (phthalic acid): n (diethylene glycol): n (ethylene glycol) = 23:24:22:31.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com