Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86results about How to "Reduce work flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

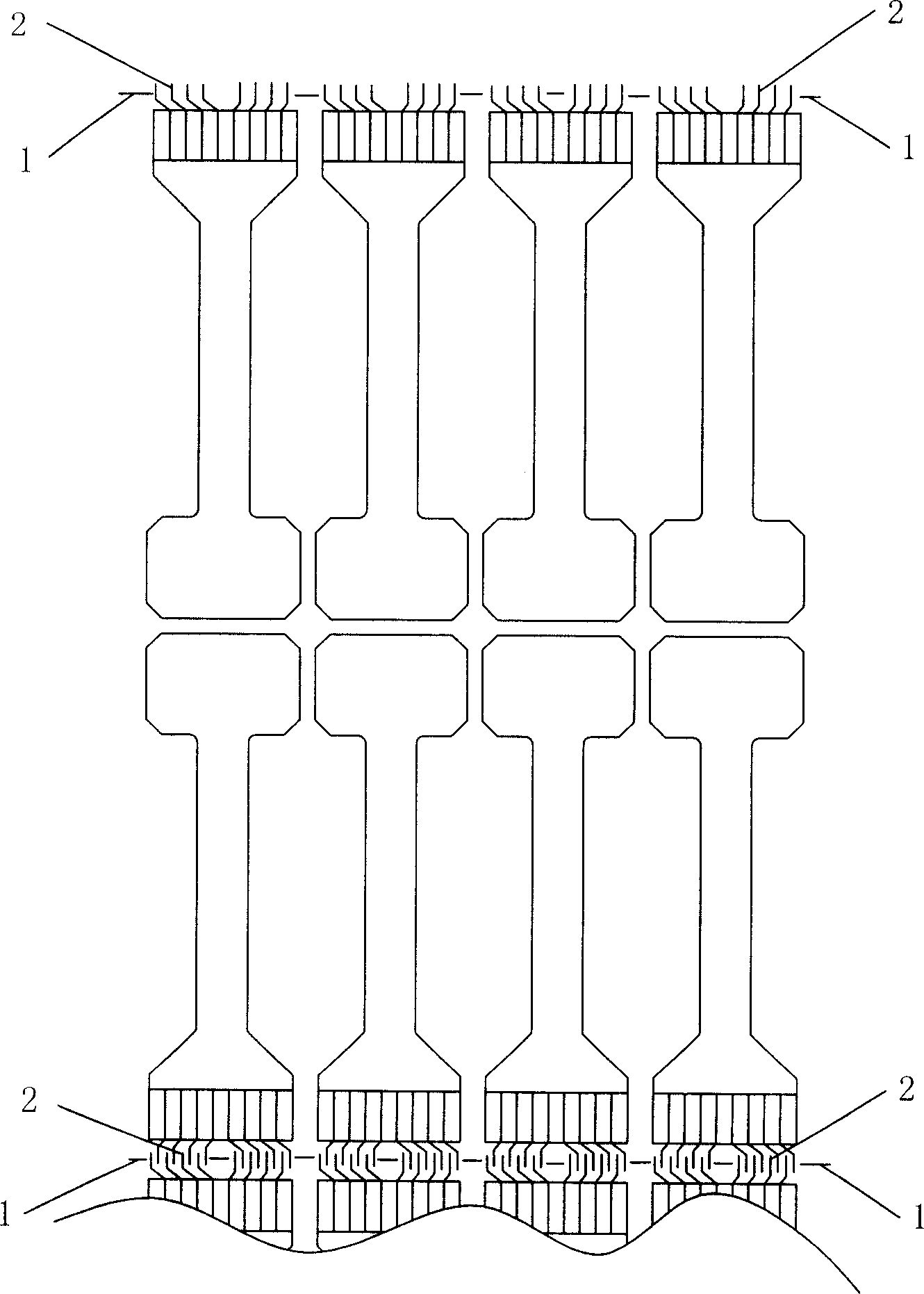

Production of flexible printing circuit board

ActiveCN1984534ALow costImprove plugging strengthPrinted circuit manufactureElectrical componentsTectorial membraneCopper

The method comprises: layout and wiring; cutting off; coating film; exposure; developing; etching; stripping film; covering tectorial membrane by hot press; surface treating; making location holes; cutting up into pieces. The layout and wiring step comprises: two wires to be located at the joint of flexible printed circuit (FPC) are crossed each other on same plane, and then are connected to the ground copper; making layout and wiring. The step of making location hole comprises: location holes are made at place exposed after etching. The step next to the step of cutting up into pieces comprises: testing and packaging the product.

Owner:靖江德方科技服务有限公司

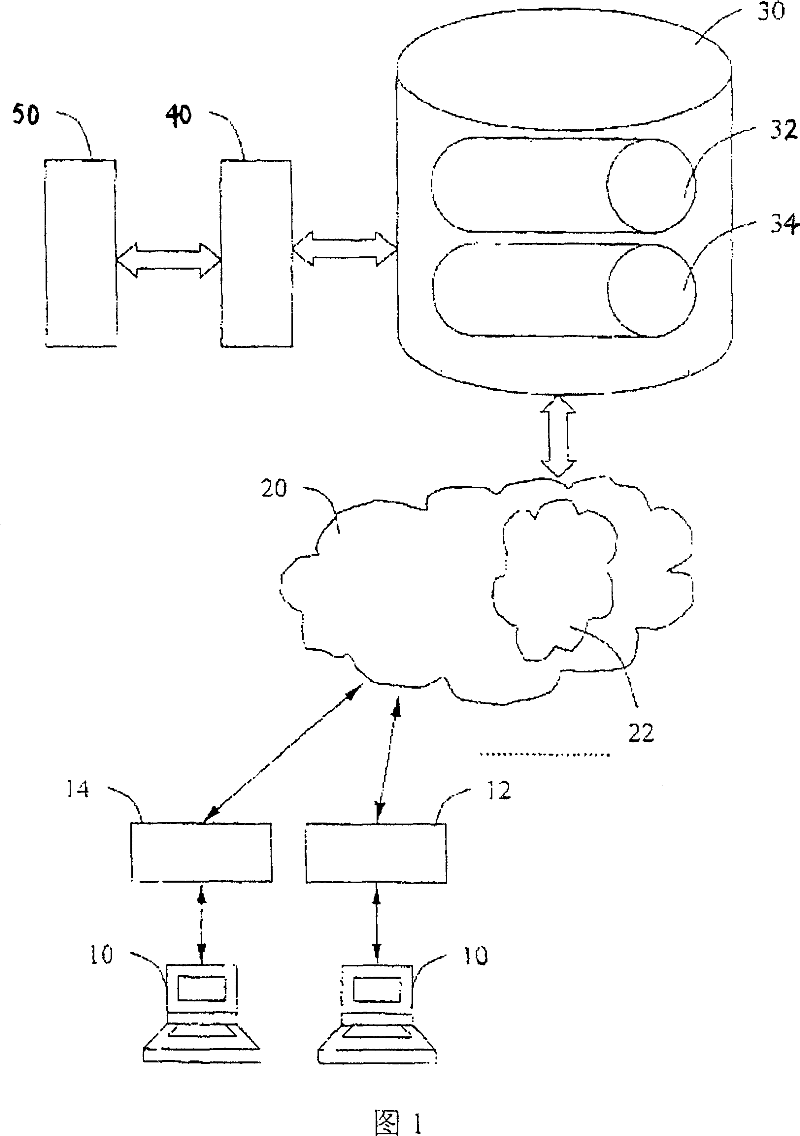

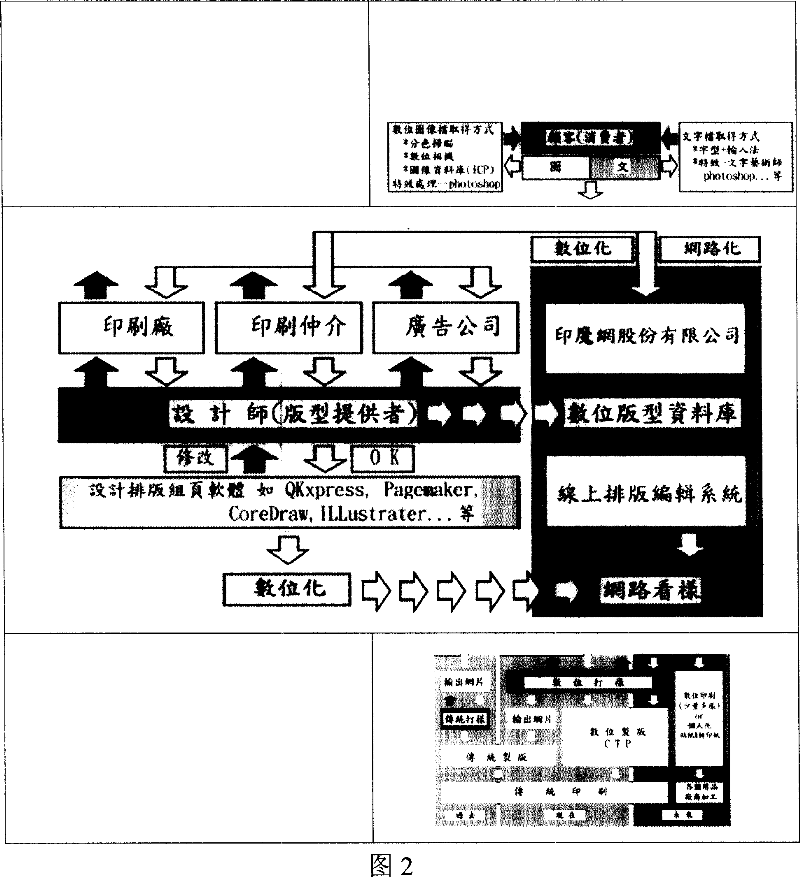

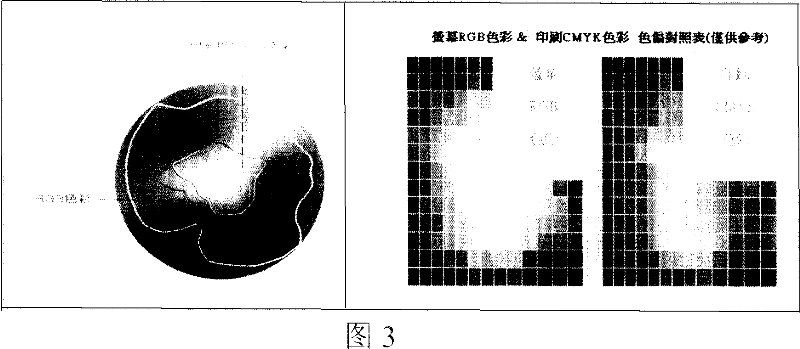

Network online instantaneous printing service system and method, and editor thereof

InactiveCN101038650AQuality improvementHigh speedTechnology managementCommerceManagement systemWorld Wide Web

An online instant printing service system, method and editor, comprise a service host, a servo host, a website providing edit typesetting and publishing service for a user, a database management system storing data of the edit typesetting and publishing service, in which the data can be accessed by a special website or the user, a network menu or named browser enabling the user to connect the website via the network menu, an online or offline editor enabling the user to execute various online or offline editting operations, so that the user can complete the edit typesetting and publishing service operation by the system.

Owner:全方位网路印刷科技股份有限公司

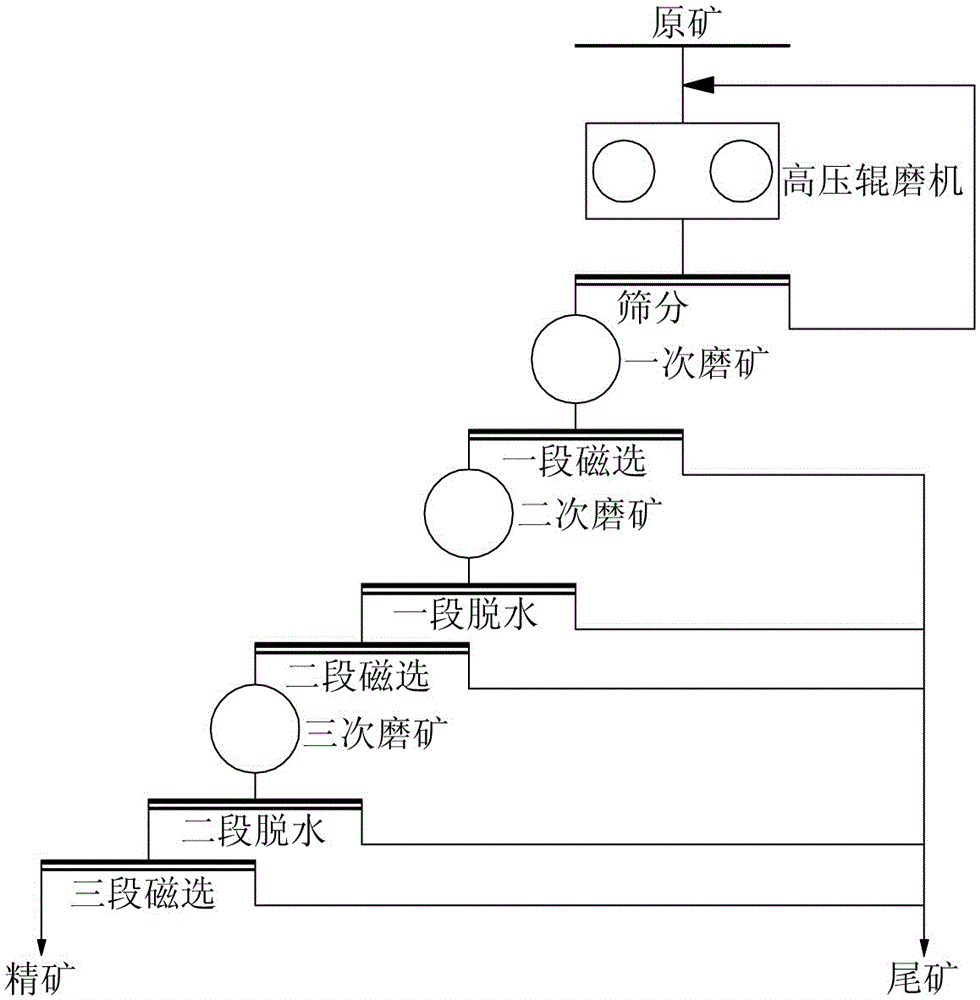

High-pressure roller selective comminuting and magnetic separating method for lean magnetite ore

The invention relates to a high-pressure roller selective comminuting and magnetic separating method for lean magnetite ore. According to the method, ultrafine crushing is conducted on raw magnetite with a grade of 28.59% by means of a high-pressure grinding roller, and three times of ore grinding, two-section dewatering and three-section magnetic separation are conducted on the crushed product to obtain concentrate with a grade of 68.23% and metal recovery rate of 82.35%. The method has the advantages that the recovery rate of the final concentrate can be increased, and efficient recovery and utilization of resources are achieved; the dissociation degree of the product is high, excessive grinding degree is low, follow-up magnetic separation effect is good, and the separation precision of equipment is improved; on the premise that the quality of the concentrate is guaranteed, concentrate recovery rate can be increased, iron ore resources can be recovered and utilized fully and reasonably, and resource waste is reduced.

Owner:ANSTEEL GRP MINING CO LTD

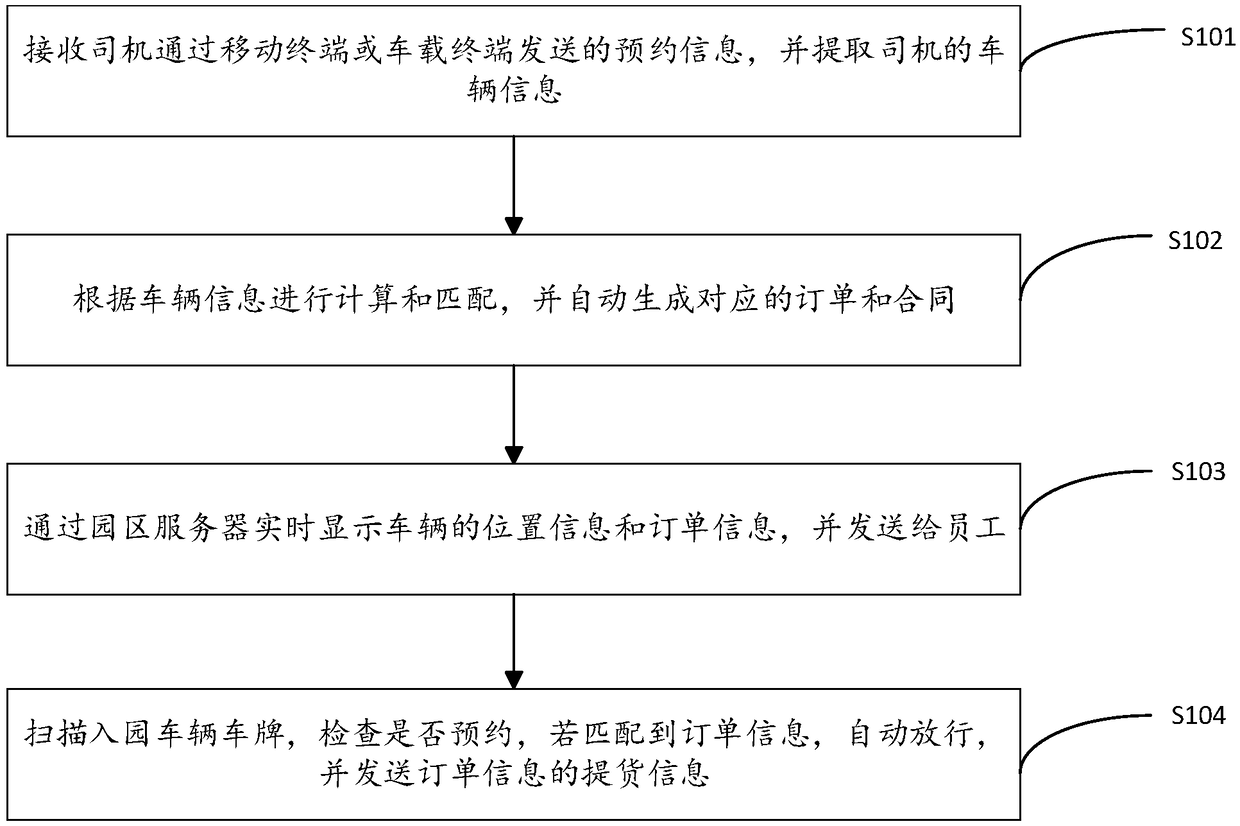

Garden vehicle management method and device

PendingCN108764766AOptimize admission proceduresImprove management efficiencyResourcesLogisticsLogistics managementManagement efficiency

The present invention relates to the technical field of intelligent logistics, especially to a garden vehicle management method and device. The method comprises the following steps of: receiving reservation information sent by a driver through a mobile terminal or a vehicle terminal, and extracting the driver's vehicle information; performing calculation and matching according to the vehicle information, and automatically generating a corresponding order and a contract; displaying the position information of the vehicle and order information in real time through a garden server, and sending the position information of the vehicle and the order information to the staff; scanning garden-entering vehicle plate numbers, inspecting whether the garden-entering vehicle plate numbers are reservedor not, if the order information is matched, automatically releasing the garden-entering vehicles, and sending goods pick-up information of the order information; and receiving reservation informationin advance to automatically generate orders and perform real-time location and garden-entering optimization so as to improve the garden vehicle management efficiency, save the human cost, understandvehicle information and positions in real time, optimize the vehicle garden-entering program, allow the garden to obtain efficient management and operation and improve the warehouse work efficiency.

Owner:SICHUAN HONGTU LOGISTICS +1

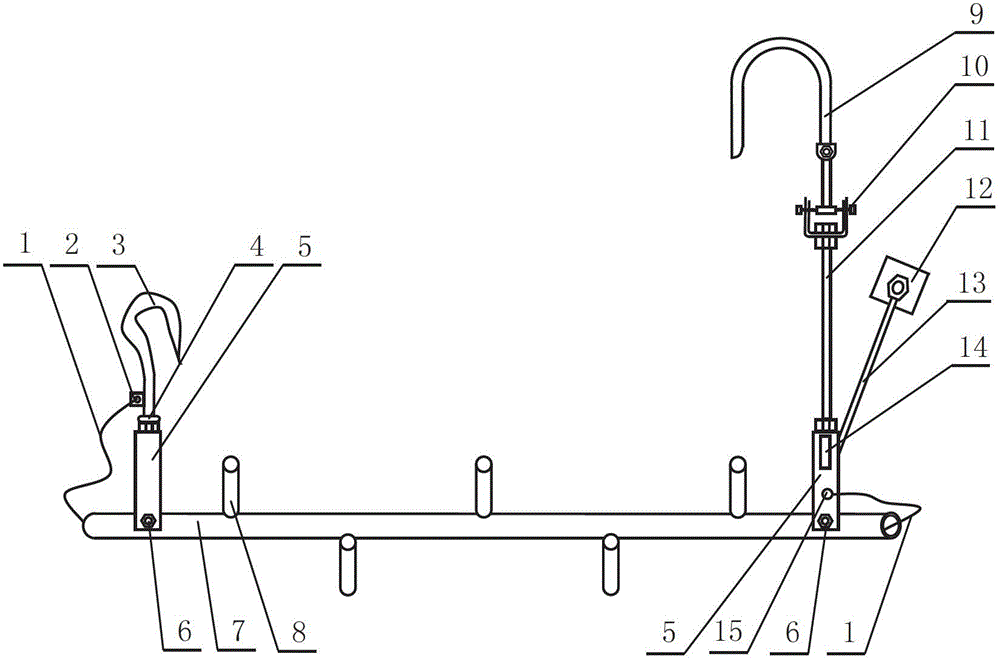

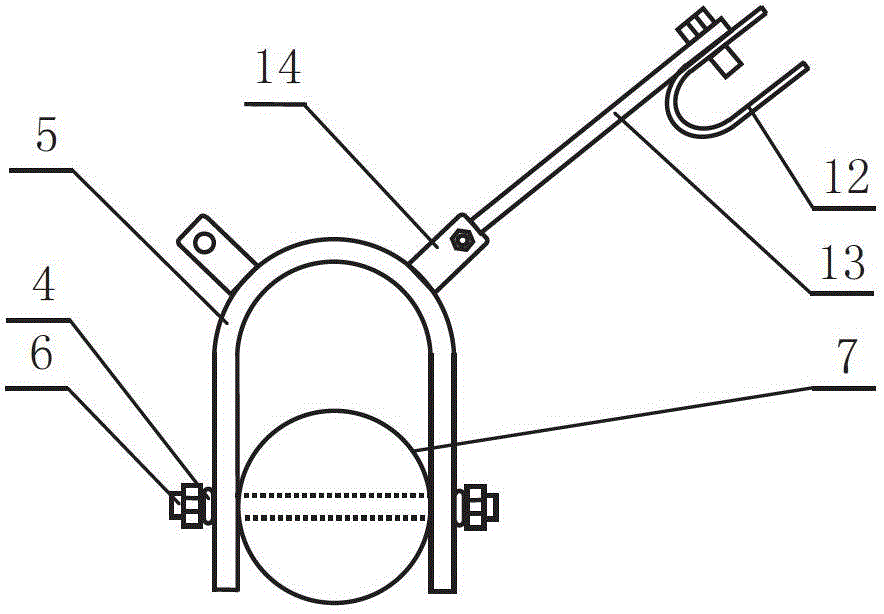

Portable tool for replacing tension wire shockproof hammer in power cut

ActiveCN102882157AEasy to replaceEasy to installApparatus for overhead lines/cablesSafety wireWasher

The invention discloses a portable tool for replacing a tension wire shockproof hammer in power cut, which solves the problems of high risk, complicated process and low working efficiency of the existing operation method. The tool is characterized by comprising a main insulation tube, a wire side universal hook, a cross arm side universal hook, U-shaped connection plates, a center-through fixing bolt and the like; the two ends of the main insulation tube are connected with the U-shaped connection plates through the center-through fixing bolt; spring washers are arranged in front of the nuts on the two sides of the center-through fixing bolt; and the U-shaped connection plate at one end is connected with the wire side universal hook, and the U-shaped connection plate at the other end is provided with a cross arm side safety wire connection hole and a support rod connection plate and connected with the cross arm side universal hook through a connection rod and a direction adjuster. The tool disclosed by the invention is safe to use, light in weight, convenient to transport, carry and mount, high in stability, flexible to use, convenient to operate and safe and reliable, reduces the labor intensity and operation risk of workers, improves the working efficiency, shortens the power-cut time of the line, and saves the expenses of the overhauling construction operation.

Owner:STATE GRID CORP OF CHINA +1

Operation method for replacing 10kV drop-out fuse in on-load manner

ActiveCN102931609ADoes not affect electricity consumptionAvoid investment and re-investment timeApparatus for overhead lines/cablesElectricityFailure rate

The invention relates to the field of a drop-out fuse in a distribution line of a power grid, and particularly relates to an operation method for replacing a 10kV drop-out fuse in an on-load manner. The operation method is characterized in that an insulation drainage wire bypass drop-out fuse is directly connected with the two ends of the drop-out fuse to be replaced for splitting current, and thus the 10kV drop-out fuse is replaced in the on-load manner and under the condition of continuously charging a load. Compared with the prior art, the operation method has the beneficial effects that the load on the lower end of equipment can be charged continuously in the operation period, and when the on-load operation is implemented by an electrified operation method, the delivery time and the redelivery time of the equipment can be avoided, the operation flow is shortened, and the electricity utilization of a user can not be affected in the operation period; the failure rate of 10kV primary equipment can be reduced greatly, and the power supply quality can be improved effectively; and the drop-out fuse is replaced in the on-load manner and with an insulation drainage wire, the operation is conducted by a double-man double-insulation bucket truck, the operation time is short, few tools are used, resources can be saved effectively, and the power supply reliability is improved.

Owner:ANSHAN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER COMPANY +1

Operation method for on-load replacing of 10kV pole-mounted disconnector

InactiveCN103001142ADoes not affect electricity consumptionAvoid investment and re-investment timeApparatus for overhead lines/cablesTruckLine current

The invention relates to the field of 10kV pole-mounted disconnectors, in particular to an operation method for on-load replacing of a 10kV pole-mounted disconnector. The operation method is characterized in that insulating current guiding lines are electrifiedly and directly connected, by an insulating glove operation method, to two ends of the pole-mounted disconnector for current shunting, and operations are performed through a double-man double-insulating-bucket-arm truck. Compared with the prior art, the operation method has the advantages that 1) by using the insulating current guiding line current shunting method for on-load replacing of the 10kV pole-mounted disconnector, power supply for lower-end load of equipment can be continued during operation, equipment launching and relanunching can be avoided during on-load operations utilizing an electrified method, operation process is shortened, power supply reliability is improved effectively, and power utilization of users is not influenced during the operation; 2) fault rate of 10kV primary equipment can be reduced greatly, and power supply quality is improved effectively; and 3) by the operation utilizing the double-man double-insulating-bucket-arm truck, operation time is short, few tools are used, energy is saved effectively, and power supply quality is improved.

Owner:ANSHAN POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER COMPANY +1

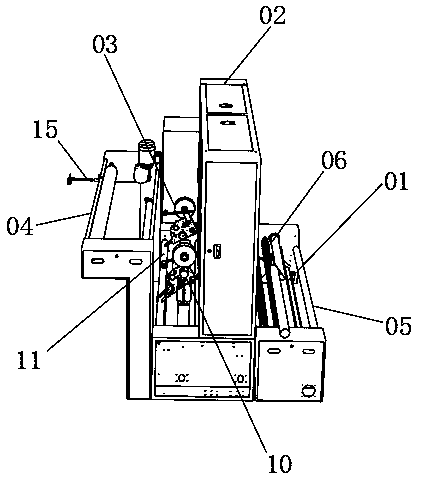

Silkscreen drying all-in-one machine

The invention provides a silkscreen drying all-in-one machine. The silkscreen drying all-in-one machine comprises an operating platform, a support, a fluorescent lamp, an intelligent electronic display board system, a drying mechanism, an electric cabinet, a screen printing device and a movable loading platform and is characterized in that the drying mechanism comprises a drying mechanism support frame, a dryer and a lifting mechanism; the screen printing device and the movable loading platform are arranged on the horizontal surface of the operating platform; the support is fixed in the vertical direction of the operating platform; the fluorescent lamp is arranged at the top end of the support, and the electric cabinet and the drying mechanism support frame are arranged in the middle of the support; the lifting mechanism and the intelligent electronic display board system are arranged on the drying mechanism support frame, and the drier is arranged at the bottom end of the lifting mechanism; the screen printing working angle of the screen printing device can be adjusted at random so that the screen printing device is very convenient to use, the operation strength is low, the operation procedure of products is greatly shortened, the production cycle of products is accelerated, manual labor and consumptive materials are saved, and the packaging frequency and the transfer frequency are reduced; the molding-machining-packaging integrated operation is implemented; and the machine platform is simple in structure and convenient to debug and jigs can be replaced conveniently.

Owner:ANHUI ECHOM SCI & TECH

Operation system and method for unloading from railway and waterway combined transportation railway harbour station to harbour district stacking yard

The invention provides an operation system and method for unloading from a railway and waterway combined transportation railway harbour station to a harbour district stacking yard. The system comprises a railway receiving and departure yard and a plurality of harbour districts corresponding to the railway receiving and departure yard; the railway receiving and departure yard is provided with at least one receiving and departure line; a dumping and loading yard arranged adjacent to the receiving and departure line is further included, and is provided with at least one dumping and loading line parallel with the receiving and departure line; the dumping and loading line communicates with the harbour districts; a plurality of track power flatcars run on the dumping and loading line; the railway harbour station is further provided with a container loading and unloading machine and tool; and the receiving and departure line and the dumping and loading line are located in an loading and unloading range of the container loading and unloading machine and tool. According to the operation system and method for unloading from the railway and waterway combined transportation railway harbour station to the harbour district stacking yard, the trace power flatcars serve as transferring carrying tools, transferring marshalling operation containers do not fall onto the ground for stacking, thusthe railway harbour station does not need a container stacking place, it is only needed to arrange the dumping and loading line, the container dumping and loading yard is small in occupied area, landfor use is saved, and station yard arrangement is flexible.

Owner:CREEC WUHAN SURVEY DESIGN & RES

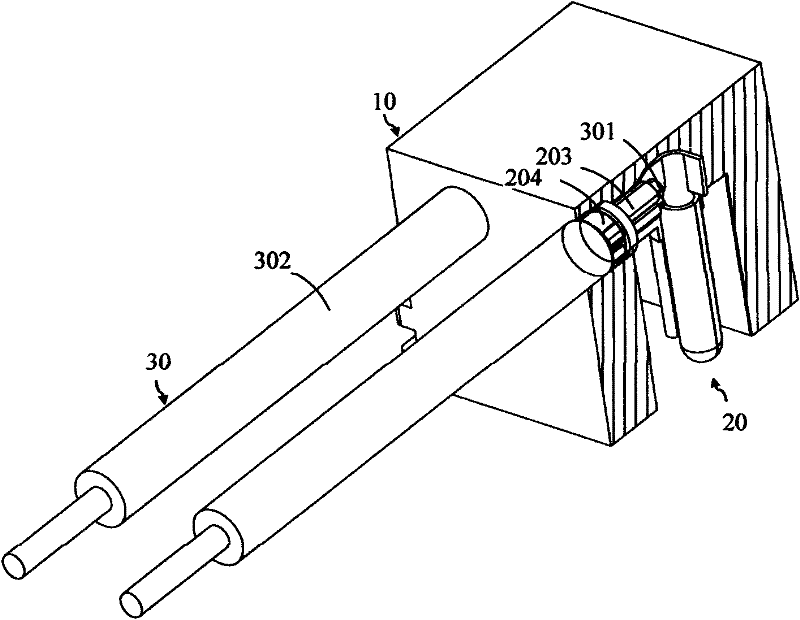

Manufacturing method and product of power connector with wires

InactiveCN102394410AQuick assemblySimplify the work processContact member manufacturingContact member cases/bases manufactureManufacturing cost reductionThin metal

The invention provides a manufacturing method and a manufacturing product of a power connector with wires. The method mainly comprises the following steps: first carrying out stamp molding on a plurality of hardware terminals by means of stamping on a thin metal material belt, and connecting the stamp molded hardware terminals with one another through combination parts to form a product material belt, wherein each hardware terminal is provided with at least one fixing ring, thus facilitating use of equipment such as a terminal crimping machine and the like to rivet connecting wires and continuously operating and being in favor of realizing automation; and then directly assembling the riveted hardware terminals and the connecting wires into an insulator or manufacturing the power connector with wires by means of embedding injection molding. By adopting the manufacturing method provided by the invention, while the production process and flow of the connectors are simplified, the reliability and production efficiency of the product are also improved, and the manufacturing cost is reduced at the same time.

Owner:SHENZHEN ZHITAI ELECTRONICS

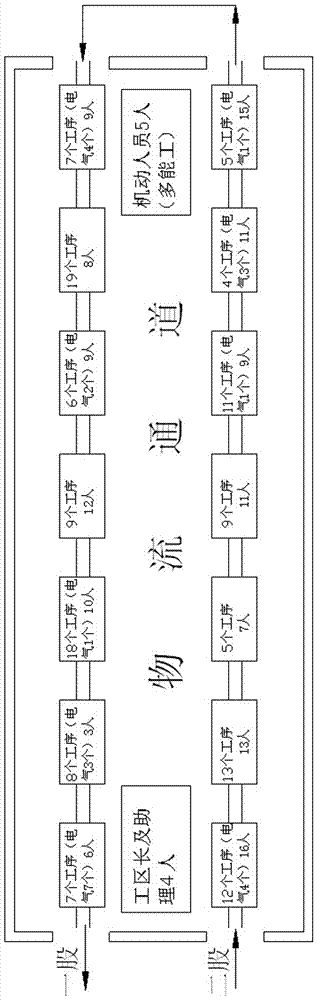

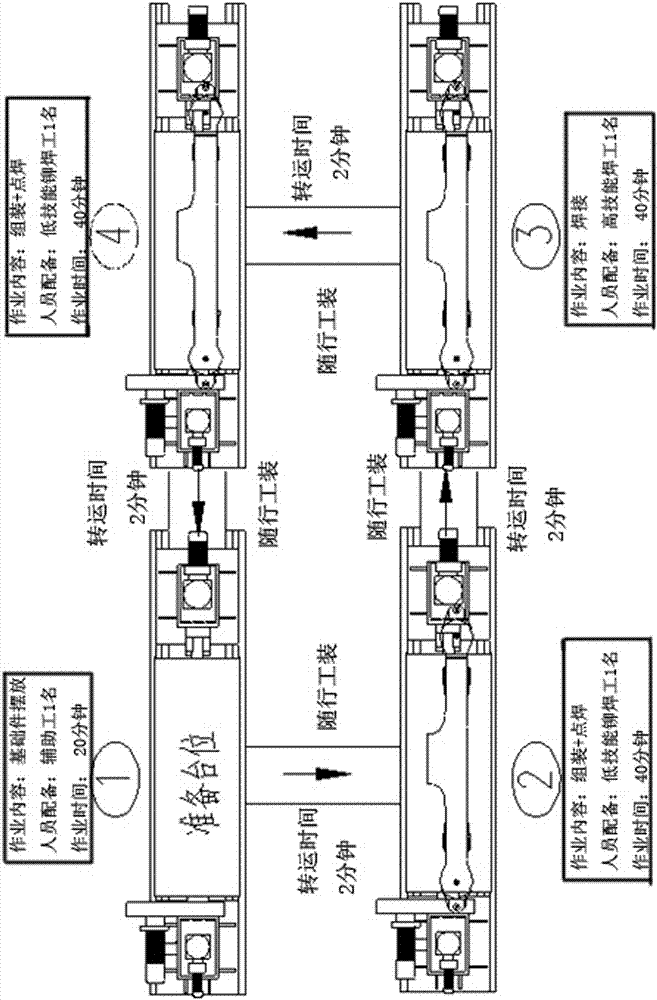

Method for constructing station-system beating type production mode of subway train

The invention relates to a production processing method of a subway train, particularly to a method for constructing a station-system beating type production mode of a subway train, so that technical problems that the application scope of the production line is small, the workers grouped based on skill types for working with high variability, the working management is confused, the production efficiency is low, various management measures can not be done truly, and the traceability is poor in the prior art are solved. The method comprises: standard stations are established, a production line of a whole subway train is cut into separate standard stations, when products flow on the production line, workers completes regulated working contents within one beat, and the workers and delivery men are separated by relative stay areas of the products; the time for completing two same products, two same services, or two same batches of products continuously is determined and thus the beat is determined; and then, with a standard station as a working organization unit, production is organized by assembly line work in a beating type balanced production mode.

Owner:CSR HANGZHOU RAIL TRANSIT

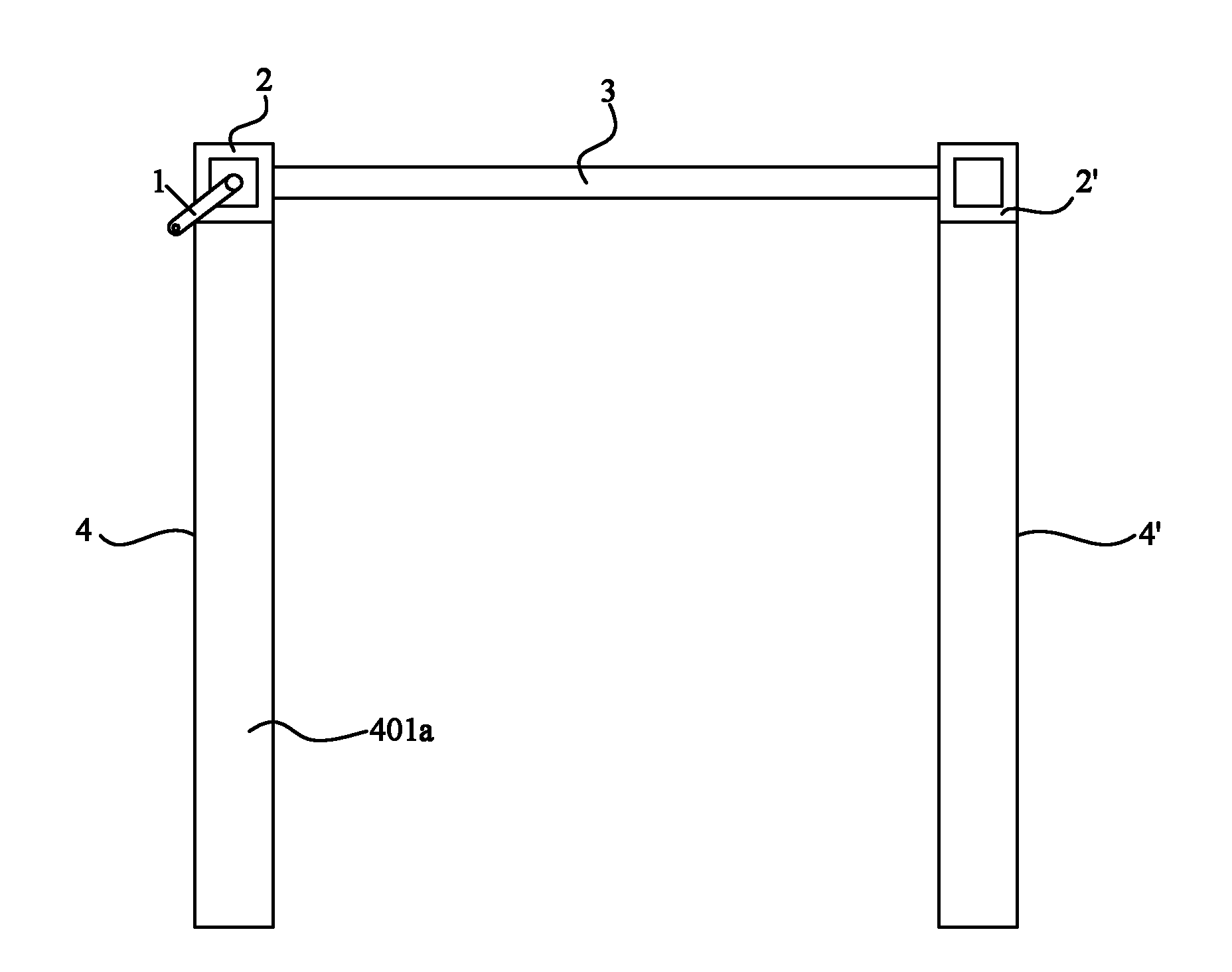

Online type automatic cloth inspecting machine at tail of setting machine and cloth inspection method

PendingCN111424413AStability checkReduce work flowMechanical cleaningPressure cleaningMachine visionDust control

The invention discloses an online type automatic cloth inspecting machine at tail of a setting machine and a cloth inspection method. The online type automatic cloth inspecting machine comprises a cloth expanding system, a cloth inspection system, a high speed labeling system and a cloth discharging mechanism, wherein the cloth expanding system is composed of a tension rack, a cloth expanding roller, a guide roller and a blowing and dust removing device. By combining an arranged photoelectric inductor with the arranged cloth inspection system, it can be effectively helpful for the arranged cloth inspection system to inspect cloth, so that the online type automatic cloth inspecting machine is high in detection speed, and the cloth inspection efficiency is improved as plant operation flows are reduced because the online type automatic cloth inspecting machine is mounted at the tail of the setting machine. The arranged blowing and dust removing device sucks air from an intermediate tube by a fan and air is diffused from the middle part to two sides through a silt opened at the lower end to eliminate impurities such as dust on the cloth surface, so that the problem of judging machine vision defects mistakenly as other impurities are brought in an environment is solved, and the device can operate more stably.

Owner:SUZHOU XIAOCREATE OPTOELECTRONICS TECH

Antireflective assembly and manufacturing method thereof, and flexible display device

InactiveCN108807463AReduce thicknessImprove bending resistanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringWork flow

The invention provides an antireflective assembly and a manufacturing method thereof, and a flexible display device; the antireflective assembly comprises the following parts: an antireflective film;a first protection layer formed on one side of the antireflective film; a touch control electrode layer formed on one side, departing from the antireflective film, of the first protection layer; a second protection layer formed on one side, departing from the first protection layer, of the touch control electrode layer; and a half wave-plate formed on one side, departing from the touch control electrode layer, of the second protection layer. The display module integral thickness can be reduced, thus improving the flexibility characteristics, reducing module segment work flow, improving the yield rate, and reducing cost.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

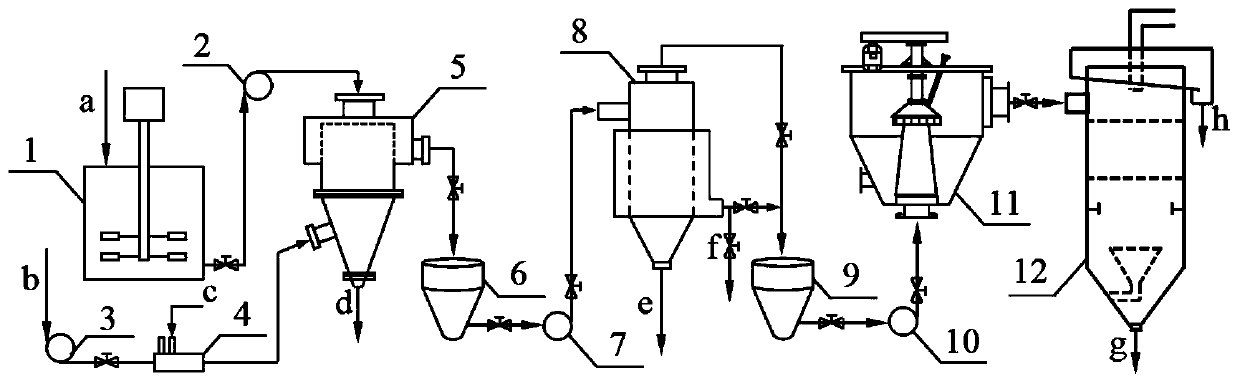

Separation recycling system and separation recycling process of wide size fraction coal slime

The invention relates to a separation recycling system and a separation recycling process of wide size fraction coal slime and belongs to the field of coal separation processing. The problems that theseparation recycling process of the wide size fraction coal slime in the prior art is complicated in technological process, and high in cost and energy consumption, and causes harm to the environmentare solved. The separation recycling system is provided with a stirring bucket, a hydraulic powder flotation machine, a three-product cyclone classification screen, an ore pulp preprocessor and a flotation column along a separation pipeline; a first buffering bucket is arranged between the hydraulic power flotation machine and the three-product cyclone classification screen; a second buffering bucket is arranged between the three-product cyclone classification screen and the ore pulp preprocessor; and the ore pulp preprocessor is connected with the flotation column. The separation recycling process includes the following steps that the coal slime in flotation is supplied into the stirring bucket, and is stirred and deployed into ore pulp to be supplied into the hydraulic power flotation machine; first time classification is performed; coarse particle concentrate, micro fine particle coal slime and fine particle coal slime are classified; and accurate separation of the fine particle coal slime is performed. The separation recycling system and the separation recycling process of the wide size fraction coal slime achieve wide size fraction and short process continuous coal slime separation.

Owner:CHINA UNIV OF MINING & TECH

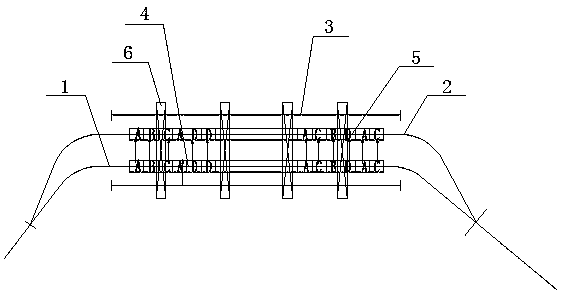

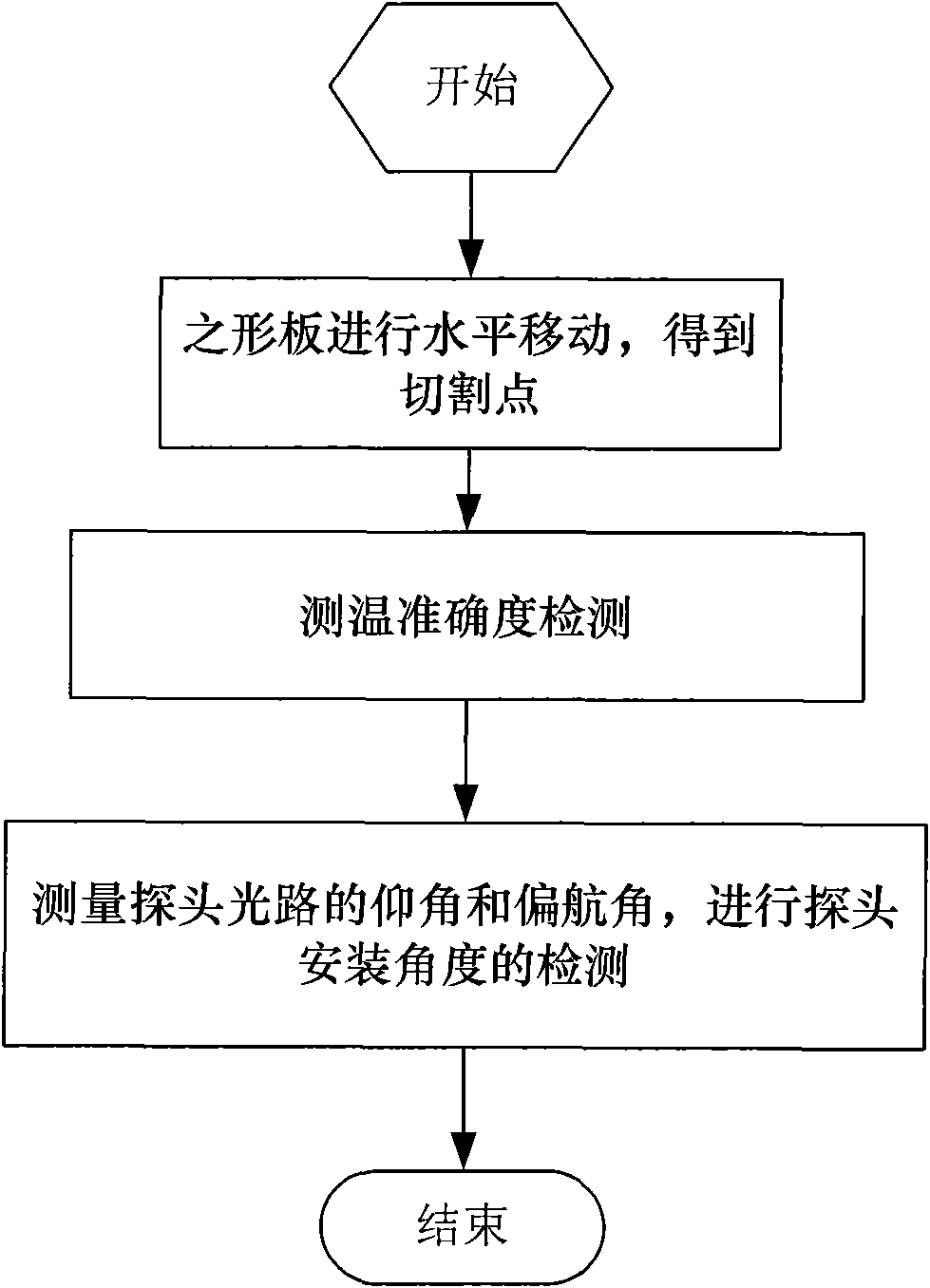

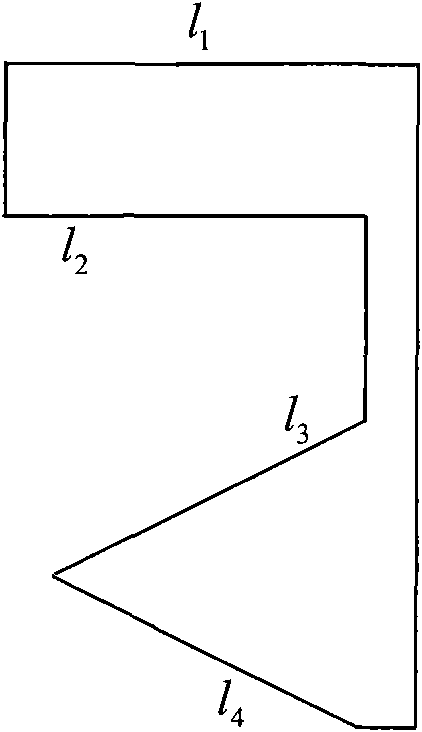

Method for calibrating infrared probe of shaft temperature detection system by adopting vertical zigzag plate

InactiveCN101832820AGuaranteed accuracyEnsure train safetyRadiation pyrometryRailway auxillary equipmentOptical pathTemperature measurement

The invention discloses a method for calibrating an infrared probe of a shaft temperature detection system by adopting a vertical zigzag plate, which can be used for simultaneously calibrating the installation angle and the temperature measurement accuracy degree of the double-probe infrared probe of the infrared shaft temperature detection system. The method comprises the following steps of: 1. horizontally moving the zigzag plate to obtain a cutting point; 2. detecting the temperature measurement accuracy degree; and 3. measuring an elevation angle and a yaw angle of an optical path of the probe and detecting the installation angle of the probe. The invention has the characteristics of easy operation, simple flow and short operation time, can be used for simultaneously detecting the installation angle and the temperature measurement precision of two probes of a double-probe device and provides specific parameters of the installation angle of the probe that needs to be regulated according to the detection result.

Owner:BEIJING CTROWELL INFRARED TECHN

Self-service automobile loading system and method for coal mine

InactiveCN107487644AReduce construction costsLow investment costLoading/unloadingControl circuitSelf-service

The invention discloses a self-service automobile loading system and method for coal mine. The system comprises a weighing automobile scale arranged on the ground surface. A material storage bin is arranged above the weighing automobile scale. A feeding port of the material storage bin is connected with a feeder of a washing center through a conveying belt. A discharging gate is arranged at a discharging port of the material storage bin. A controller box is further arranged above the weighing automobile scale through a suspending mechanism. Operation buttons are arranged on the controller box. A system server is connected with the weighing automobile scale and a control circuit in the controller box. The system server is connected and controls the discharging gate through a PLC. By means of the self-service automobile loading system and method for the coal mine, a driver can drive an empty automobile to run to an automobile scale weighing platform below a loading station, the driver does not need to get off the automobile after the automobile is parked in place, the driver stretches the hand to pick the wireless controller box, the rated load is input through the panel buttons, and discharging and loading are operated autonomously; and after the designated weight is reached, the discharging gate is automatically closed by the system, the drivers puts the controller box back and drives the loaded automobile to leave, and simpleness and rapidness are achieved.

Owner:TIANDI SCI & TECH CO LTD

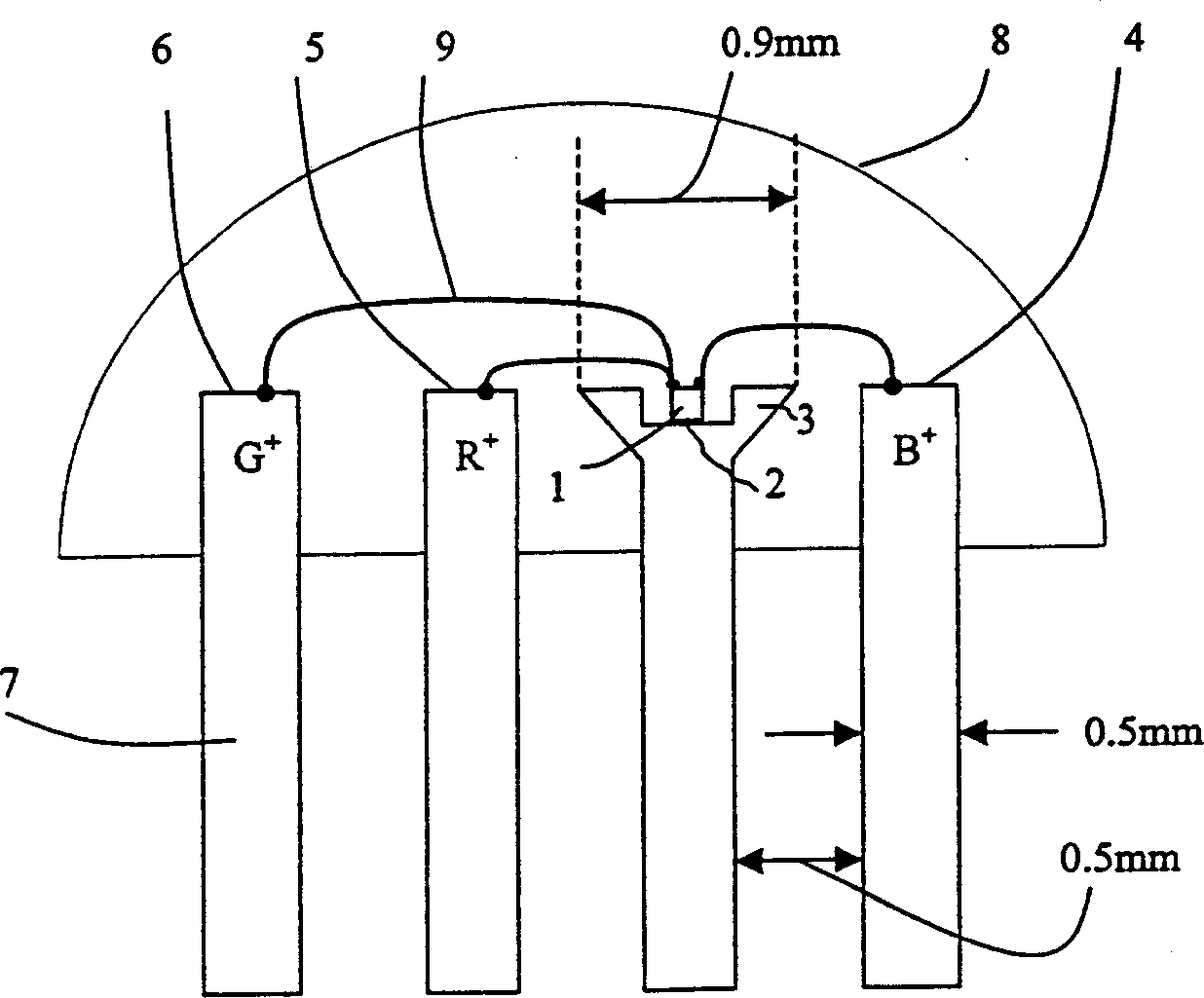

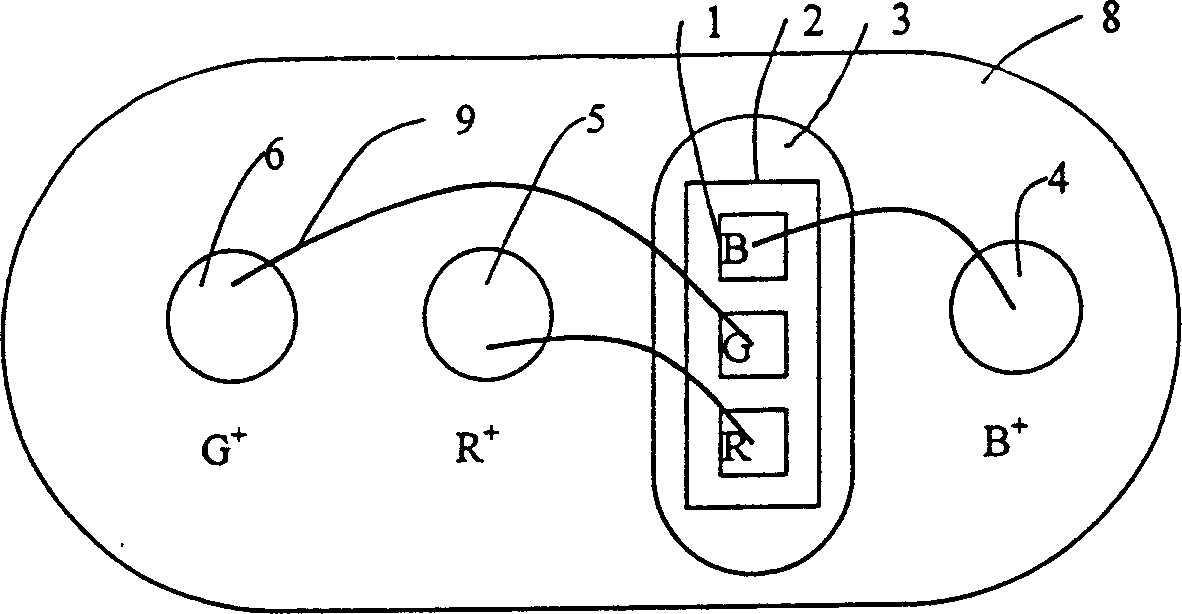

Structure of LED base and pins and producing method

InactiveCN1458699AReduce work flowSolid-state devicesSemiconductor devicesPrimary colorElectrical and Electronics engineering

This invention illustrates structure of three primary colors LED four plug pins and packaged base and its manufacturing method, among which one of the pins forms a grain base and a share negative connector base, the other three form positive connector base. The connector baser are placed at four corners of a square, two extend to the right, the other two to the left and they are formed by punch die, etching or coating. Multiple boses are formed in one run, then four pins are bent down by 90 deg. in one same direction from near the connector base to a standing state to be processed with grain welding and lining at first, then to be cut into a single structure and sealed with transparent plastic by moulding.

Owner:张修恒

Automatic labeling method for photovoltaic components

InactiveCN108516170AReduce mismatchReduce quality problemsLabelling machinesProduction lineTest flow

The invention discloses an automatic labeling method for photovoltaic components. The automatic labeling method comprises the following steps: (A) nameplate mold plates and frame barcodes of all pre-designed gears are stored in an exclusive labeling program root directory; (B) the components finishing IV test flow into a labeling station automatically by a production line and are fixed and stopped; (C) an automatic barcode scanning gun is automatically triggered, scans barcodes of the glass surfaces of the components, and transmits the scanned barcodes into an exclusive labeling program in a computer by a data line; (D) the exclusive labeling program automatically calls power and current data of the corresponding barcodes from a shared IV database, analyzes and judges the shifts of power and current automatically according to the data and transmits information to printers by the data line; (E) the two printers are respectively and automatically started after receiving printing commands, and print corresponding frame barcodes and nameplates. The automatic labeling method disclosed by the invention realizes full-automatic labeling operation, has higher automation degree and operationefficiency, and meanwhile has the beneficial effects that the labor can be reduced and the labor cost can be reduced.

Owner:格润智能光伏南通有限公司

Etching station aluminum anode oxidation component regeneration preparation technology

InactiveCN109161839AAvoid lossAvoid deformationAnodisationMolten spray coatingAluminum anodeSand blasting

The invention discloses an etching station aluminum anode oxidation component regeneration preparation technology. The etching station aluminum anode oxidation component regeneration preparation technology comprises the following steps: step one, carrying out ungrease treatment on an aluminum component; step two, putting the aluminum component into an alkaline liquor for alkali corrosion; step three, putting the aluminum component into an acid liquor for ash removal; step four, washing; step five, carrying out anode oxidation on the aluminum component; step six, cleaning and drying; step seven, using a tri-cathode plasma spray gun to spray a sizing agent onto an anode oxidation layer of the aluminum component, uniformly controlling the thickness of a sprayed coating to be 60 to 150 microns; step eight, drying and cleaning; and step nine, drying, cooling and packaging. Compared with the prior art, sand blasting pretreatment does not need to be carried out on the component, the anode oxidation layer also does not need sealing treatment, the operation procedure is reduced, the cost is reduced, the productivity is improved, simultaneously, the loss and deformation caused by a sand blasting technology for the component are avoided, and the number of times of repeated regeneration for the component is increased.

Owner:芜湖通潮精密机械股份有限公司

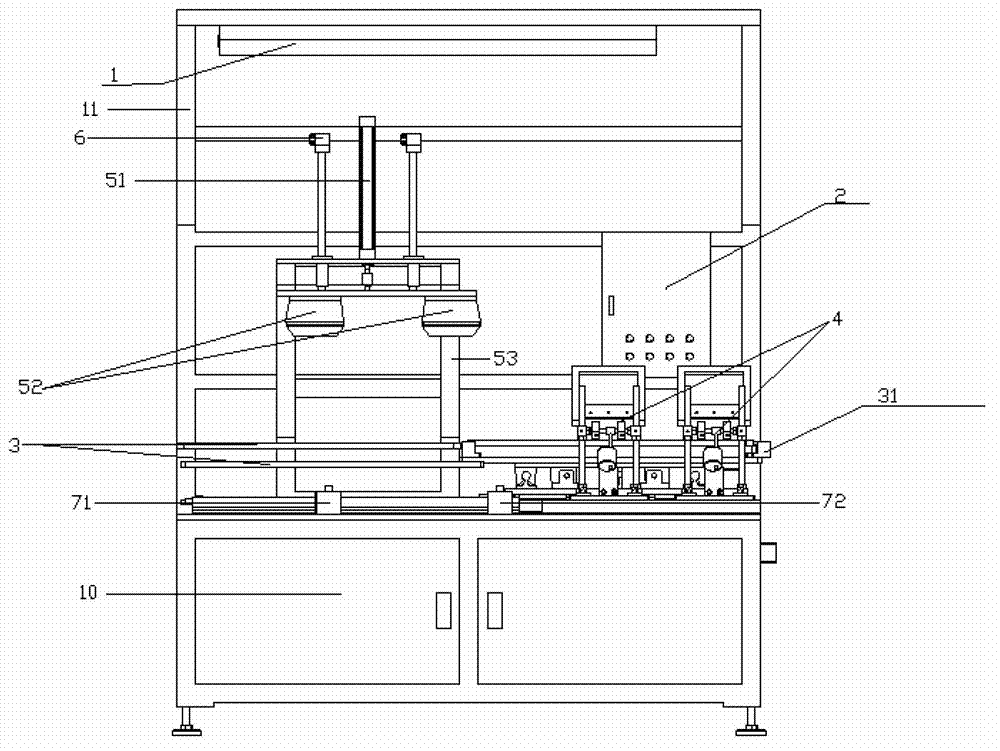

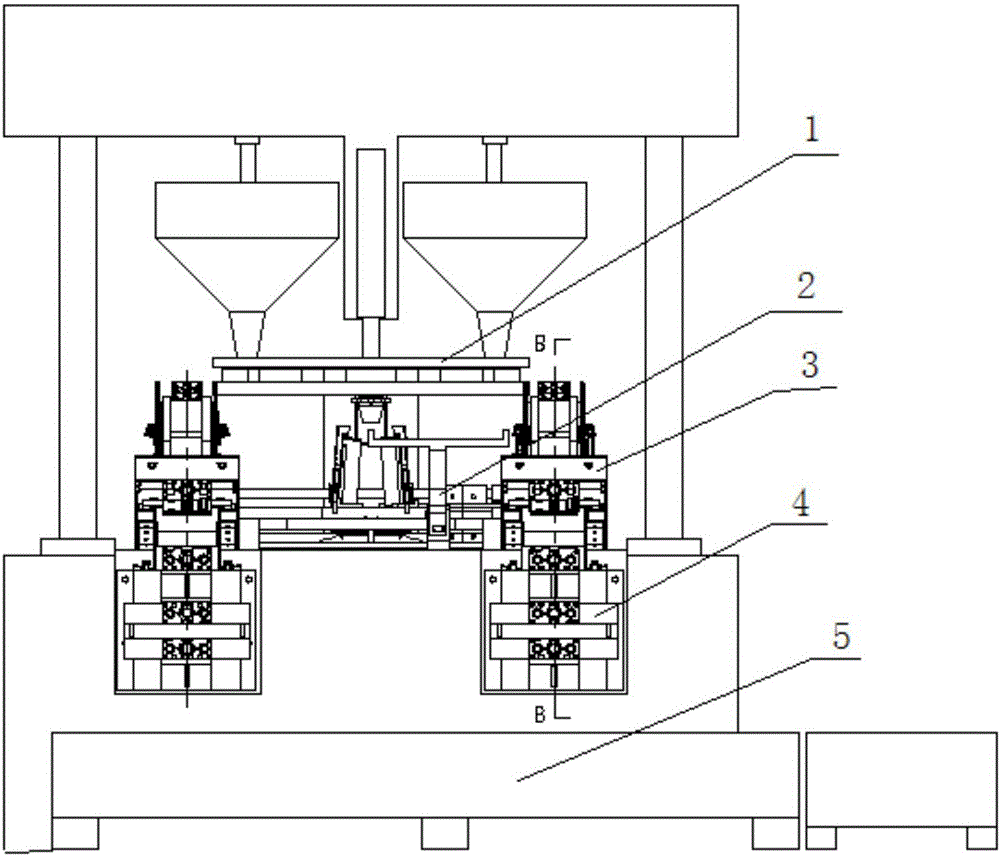

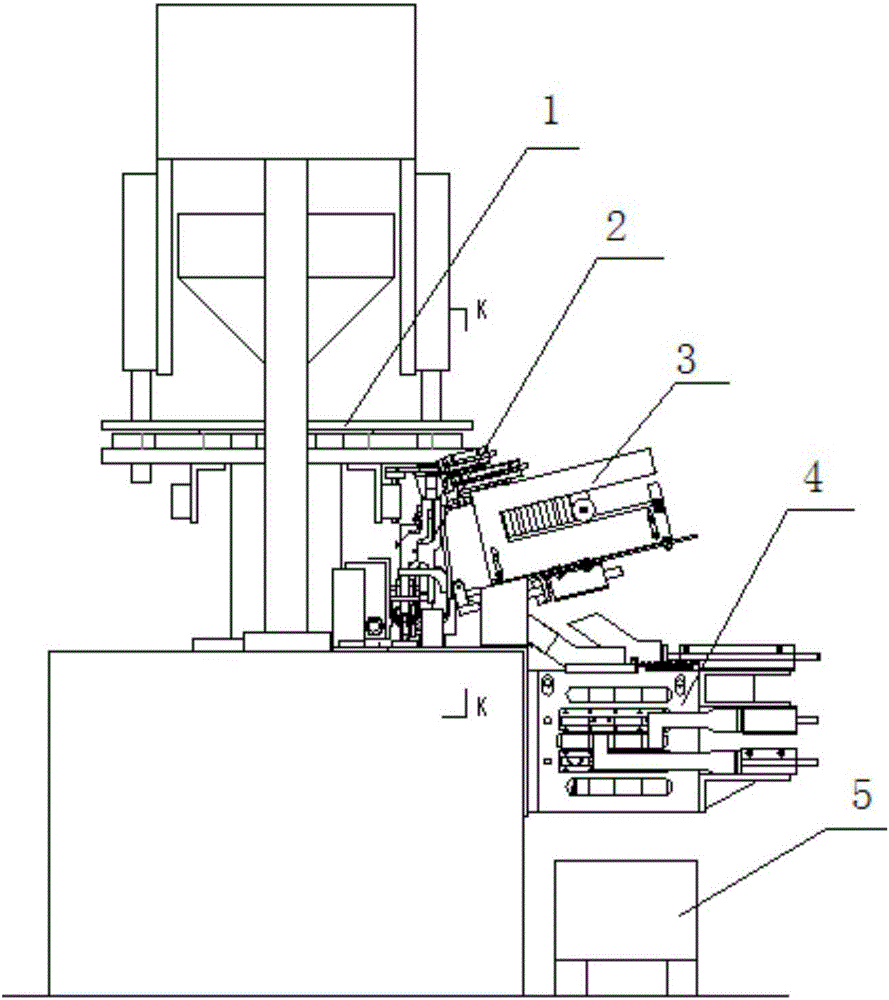

Automatic packaging equipment

ActiveCN105035415AReduce work flowSimple structurePackaging under vacuum/special atmosphereMechanical engineeringFeeding types

The invention provides automatic packaging equipment. The automatic packaging equipment comprises a filling machine, a packaging bag opening and conveying mechanism, a straight feed type loading mechanism, a vacuumizing and sealing mechanism, and a conveying belt, wherein the packaging bag opening and conveying mechanism is arranged below the filling machine; the straight feed type loading mechanism is arranged at the outer side of the packaging bag opening and conveying mechanism; the vacuumizing and sealing mechanism is arranged below the packaging bag opening and conveying mechanism; and the conveying belt is arranged below the vacuumizing and sealing mechanism. The automatic packaging equipment adopts a reciprocating oscillation conveying mode of packaging bags, so that the operation flow is shortened, the equipment structure is simplified, and the occupation volume is obviously reduced; and the automatic packaging equipment is joined with existing equipment to realize automatic modification of the existing equipment.

Owner:宁波智畅机器人系统有限公司

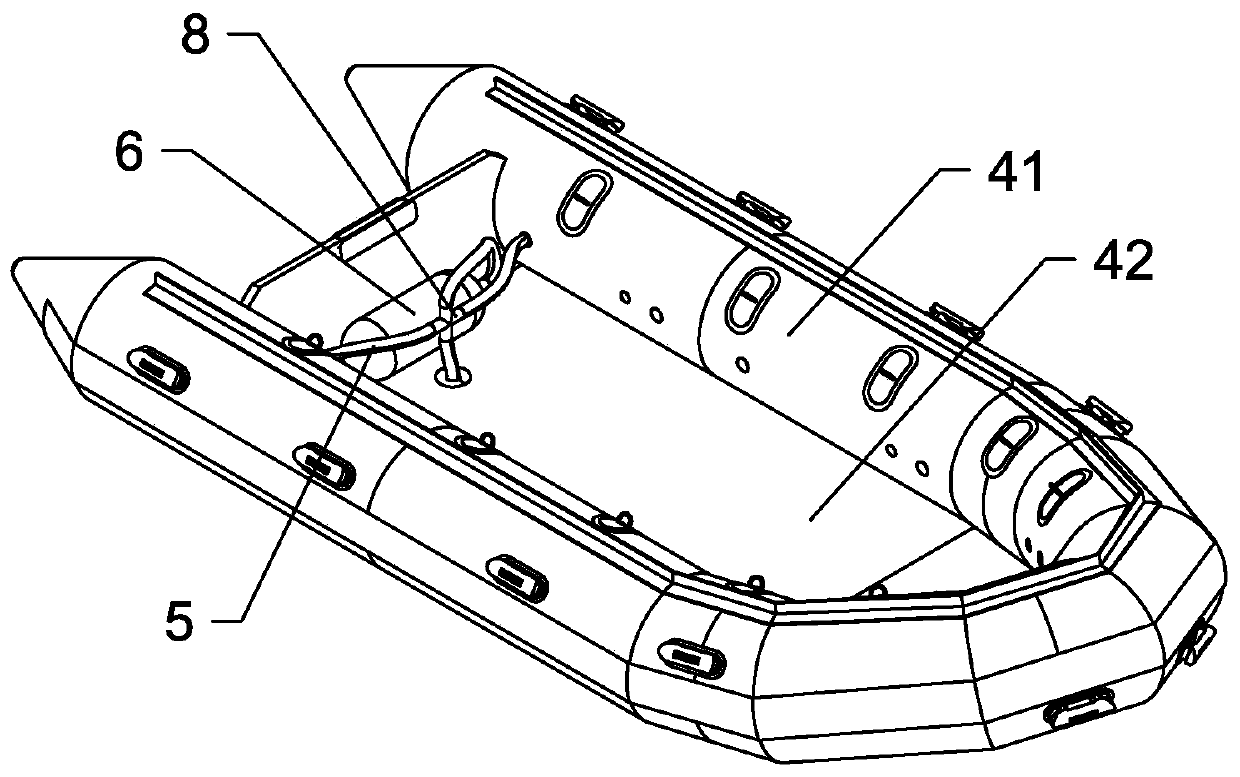

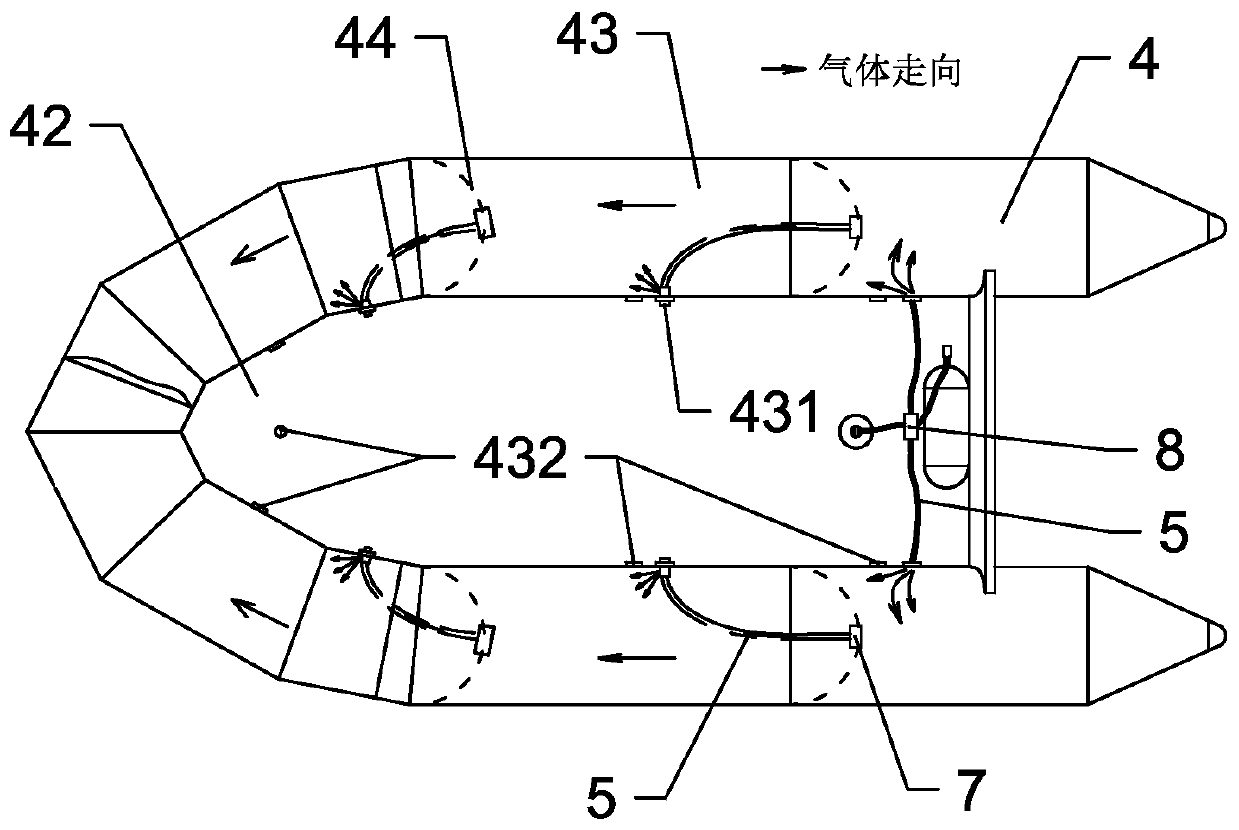

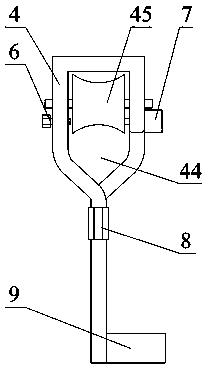

Automatic inflatable boat for airdrop

InactiveCN111204425ASimplify the inflation stepsImprove inflation efficiencyLife-raftsAir-sea rescue devicesInflatable boatMarine engineering

The invention provides an automatic inflatable boat for airdrop. The inflatable boat comprises a parachute and an inflatable boat body, wherein the inflatable boat body comprises a boat body, an air pipe and a high-pressure air bottle, the boat body is an air bag, the air bag is divided into a plurality of air chambers which are sequentially connected but not communicated, the air chambers are bulkheads and are separated by the bulkheads, check valves are arranged on the bulkheads, air chamber switches are arranged on the outer walls of the air chambers, and a high-pressure air bottle is placed on the air bag and communicated with the air chambers; the high-pressure gas cylinder is filled with compressed gas, and a release valve is arranged at a cylinder opening; a safety pin capable of triggering the release valve to open the high-pressure gas cylinder is installed at the end of the release valve, a release valve safety pin inhaul cable for pulling out the safety pin is connected to the safety pin, a guide wheel is fixedly arranged on the boat body, and the release valve safety pin inhaul cable penetrates through the guide wheel and then extends to be fixedly connected to a sling.The invention provides the automatic inflatable boat for airdrop, which is specially researched and developed for air drop operation, and is high in air transport efficiency, high in use efficiency,high in inflation speed, safe and reliable.

Owner:青岛哈文船艇有限公司

Suspension device for assisting in suspending rope ladder

ActiveCN110957669ASafe and stable useEasy to moveApparatus for overhead lines/cablesLaddersBrakeUncrewed vehicle

The invention relates to the field of power line maintenance and detection, in particular to a suspension device for assisting in suspending a rope ladder. The device comprises a traction piece for connecting an unmanned aerial vehicle; a traction rope is arranged on the traction piece; the traction rope is detachably connected with a ladder head; the bottom of the ladder head is connected with arope ladder; a pulley mechanism and a brake mechanism for limiting the rotation of the pulley mechanism are arranged on the ladder head; the operation process that a worker climbs to hang the ladder head is reduced, suspension workload is reduced, and suspension safety is improved, meanwhile, according to actual conditions, the ladder head is moved along the hanging position, so that the ladder head can be conveniently moved to a proper working position, meanwhile, the rotation of the pulley mechanism can be limited through the brake mechanism arranged on the ladder head, the ladder head is limited at the hanging position, the ladder head is prevented from moving under the influence of the inclined state or gravity action of the hanging position, and the stable and safe use of the hangingdevice is ensured.

Owner:DEYANG POWER SUPPLY COMPANY STATE GRID SICHUAN ELECTRIC POWER

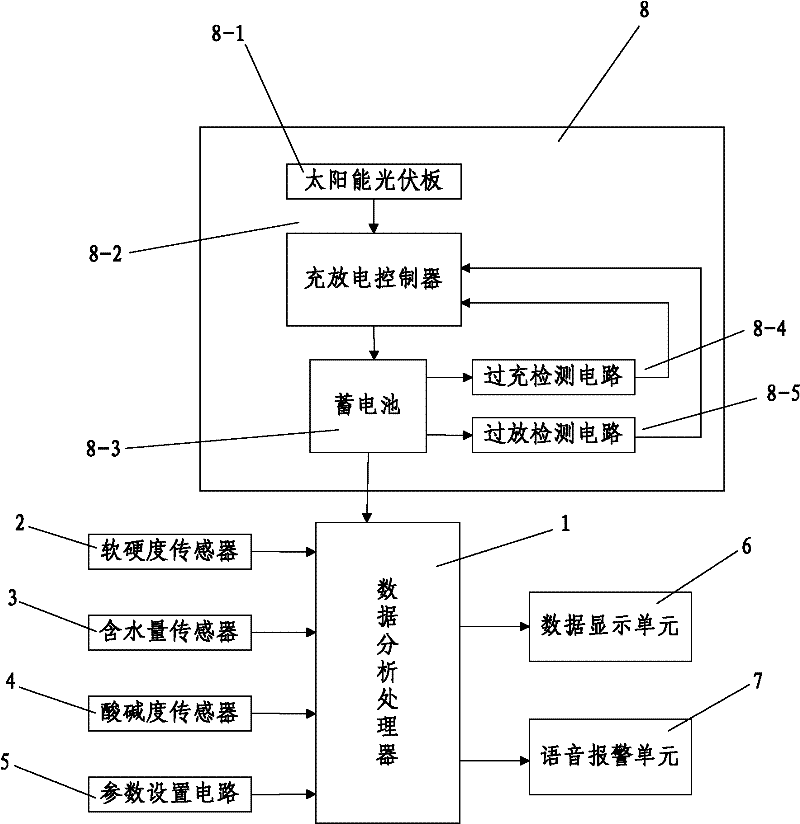

Soil texture determination analysis system

InactiveCN102539648AReasonable designEasy to implementEarth material testingData displayMeasurement cost

The invention discloses a soil texture determination analysis system, which comprises a data analysis processor, a softness and hardness sensor, a moisture content sensor, a potential of hydrogen sensor, a parameter setting circuit, a voice alarm unit, a data display unit and a power supply unit, wherein the power supply unit supplies power to the data analysis processor, the softness and hardness sensor, the moisture content sensor, the potential of hydrogen sensor, the parameter setting circuit, the data display unit and the voice alarm unit; the softness and hardness sensor, the moisture content sensor, the potential of hydrogen sensor, the parameter setting circuit and the power supply unit are respectively connected with an input end of the data analysis processor; and the data display unit and the voice alarm unit are respectively connected with an output end of the data analysis processor. The soil texture determination analysis system is reasonable in design, convenient to implement, easy to use and operate, and high in practicability, internal data of soil texture to be measured can be effectively acquired, and analysis can be performed according to the acquired data, so that measurement accuracy is ensured, and measurement cost is reduced.

Owner:XIAN CENTN TECH

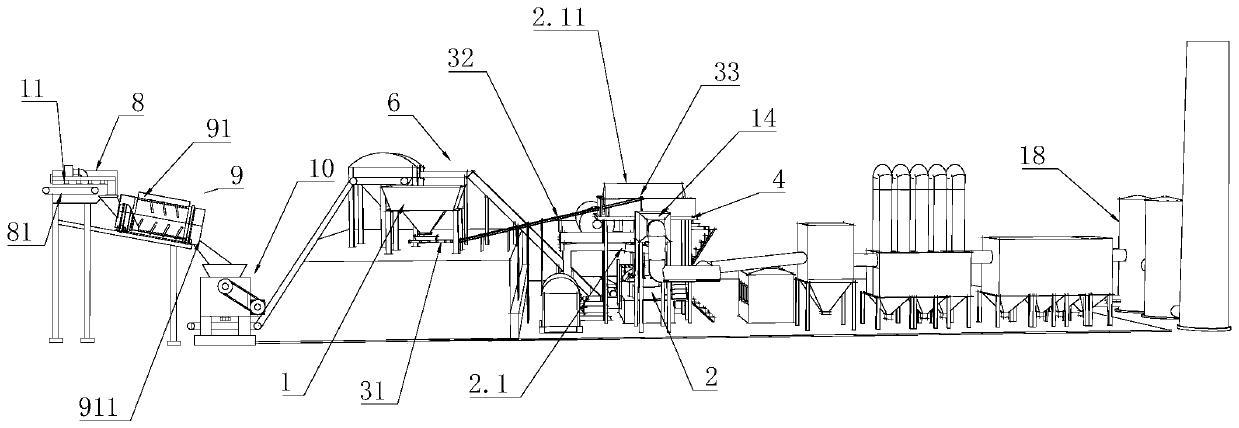

Hazardous waste recovery processing production line

ActiveCN110804699AReduce consumptionIncrease contact areaCombination devicesSludge treatment by de-watering/drying/thickeningWater useProduction line

The invention discloses a hazardous waste recovery processing production line which is reasonable in flow layout and capable of improving the production efficiency, saving energy and reducing emissions. According to the technical scheme, the hazardous waste recovery processing production line is characterized by comprising a smelting device, a collection tank and a slag fishing device; the smelting device comprises a smelting furnace arranged on the right side a storage tower; a feed port of the smelting furnace receives electroplating sludge coming from the storage tower through a conveyor belt, and the electroplating sludge is made into a melt through roasting; a water jacket for cooling a furnace body is arranged on the outer side of the smelting furnace; the water jacket is connected with a water tank through a pipeline; the water tank is arranged on a mounting rack erected on the outer side of the smelting furnace; the collection tank is arranged on the lower side of the smeltingfurnace and used for receiving the smelted melt coming from the smelting furnace; the upper end of the collection tank is provided with a slag discharge port used for discharging waste slag on the upper layer of the melt; and the slag fishing device is arranged on one side of the collection tank and suede for collecting waste slag discharged from the slag discharge port. The hazardous waste recovery processing production line is suitable for the technical field of environmental protection production lines.

Owner:宁波双能环保科技有限公司

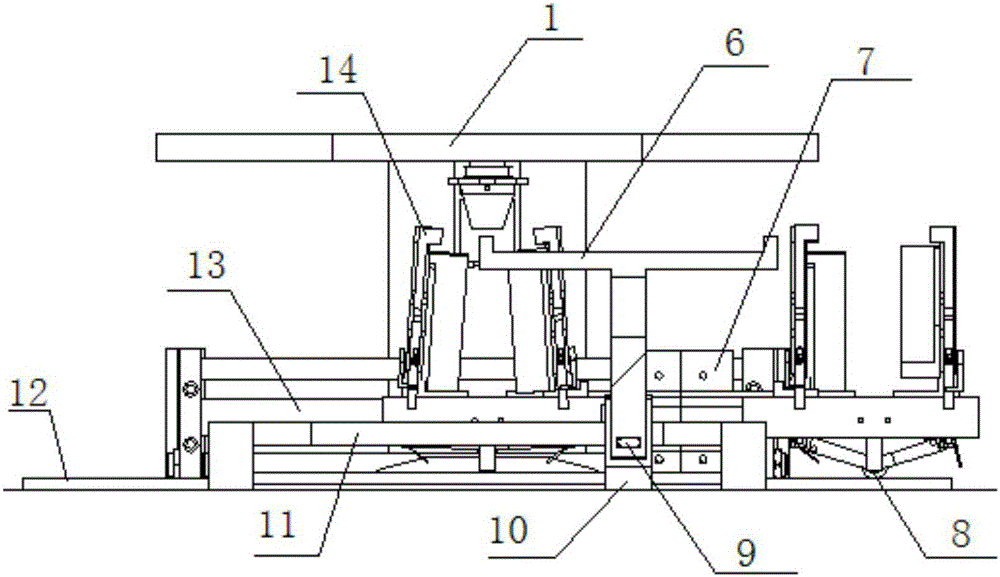

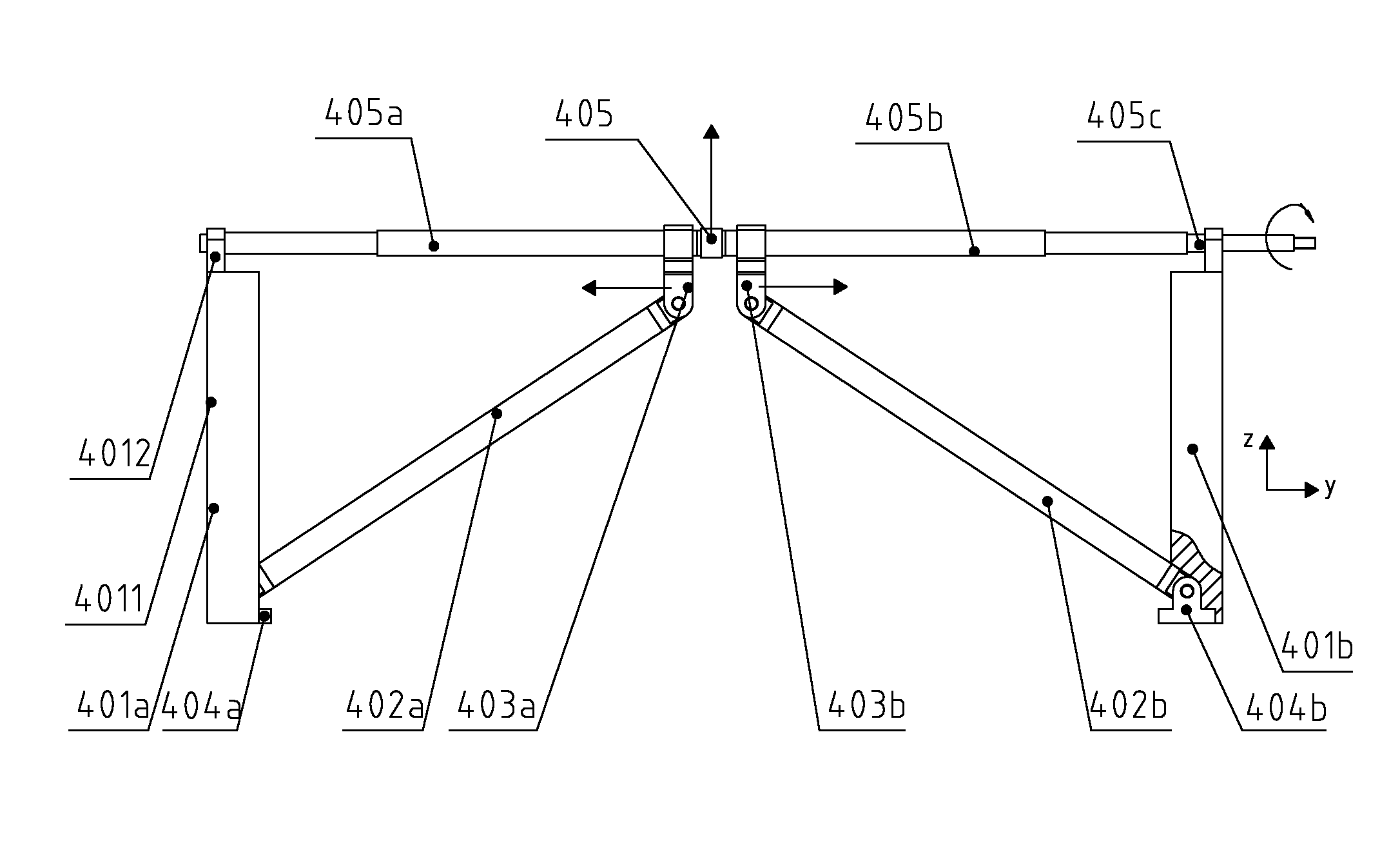

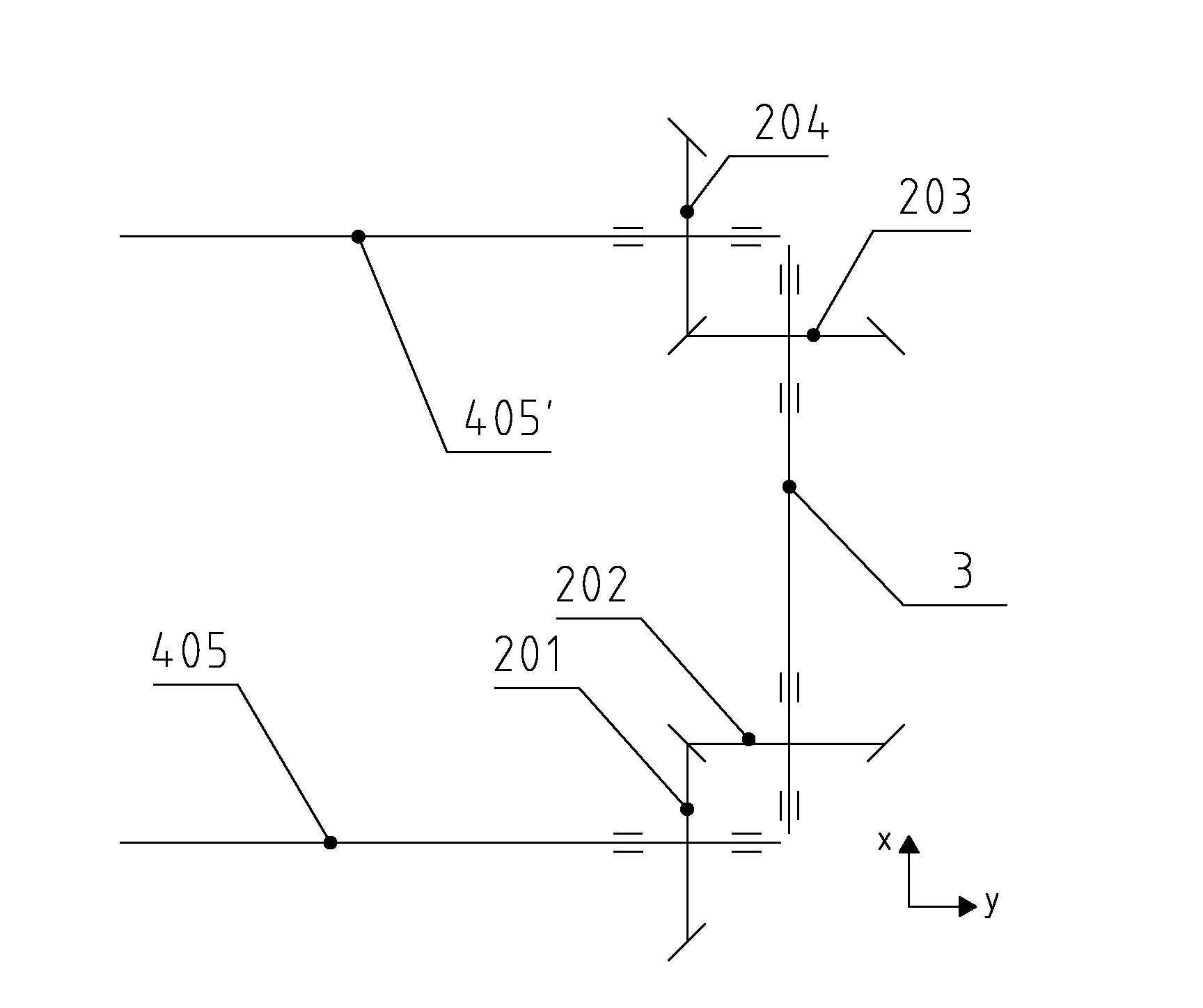

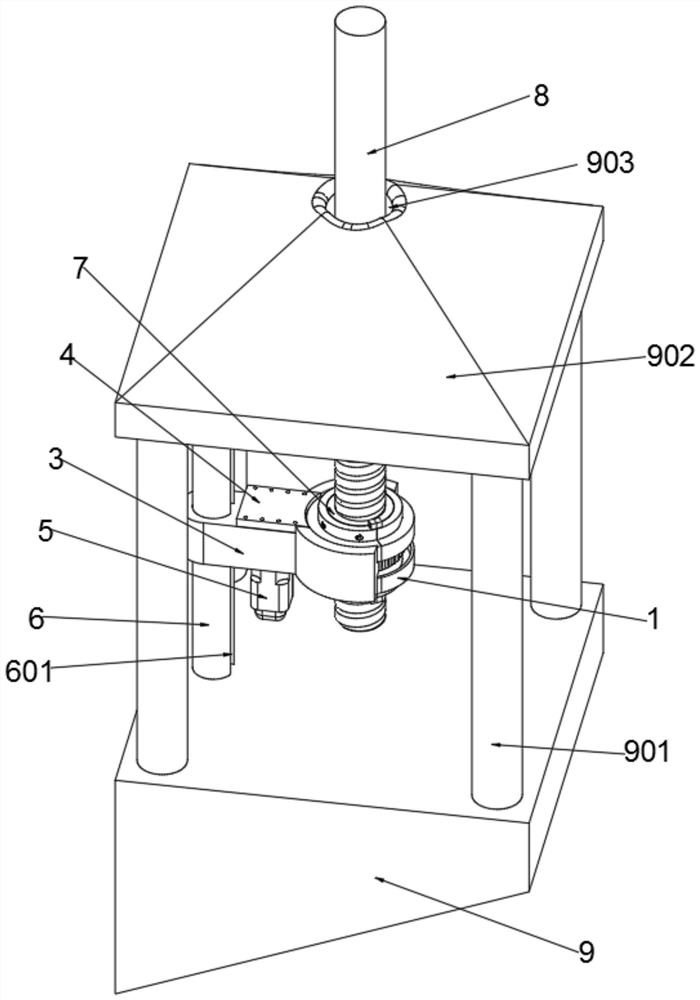

Synchronous lifting component and synchronous lifting and horizontal moving mechanism

InactiveCN102485636AImprove synchronicityLow costToothed gearingsLifting devicesDrive shaftEngineering

The invention relates to a synchronous lifting component and a synchronous lifting and horizontal moving mechanism. The synchronous lifting component comprises a telescopic lifting unit, a handle, a gear box and a transmission shaft, wherein the two ends of the transmission shaft are meshed with the lifting unit through the gear box; the handle is arranged at one end of the lifting unit; the lifting unit connected with the handle is stretched or retracted by the rotation of the handle; and the stretching or retraction movement of the lifting unit is transferred to another lifting unit through a transmission unit composed of the gear box and the transmission shaft so as to realize synchronous ascending or descending of the two lifting units. In the synchronous lifting component and the synchronous lifting and horizontal moving mechanism provided by the invention, a transmission unit composed of two gear boxes and a transmission shaft realizes synchronization of two lifting units to ensure the stability of the lifting process; a pure-mechanical structure is adopted to lift an object; and each component has a simple structure, and the cost is low.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

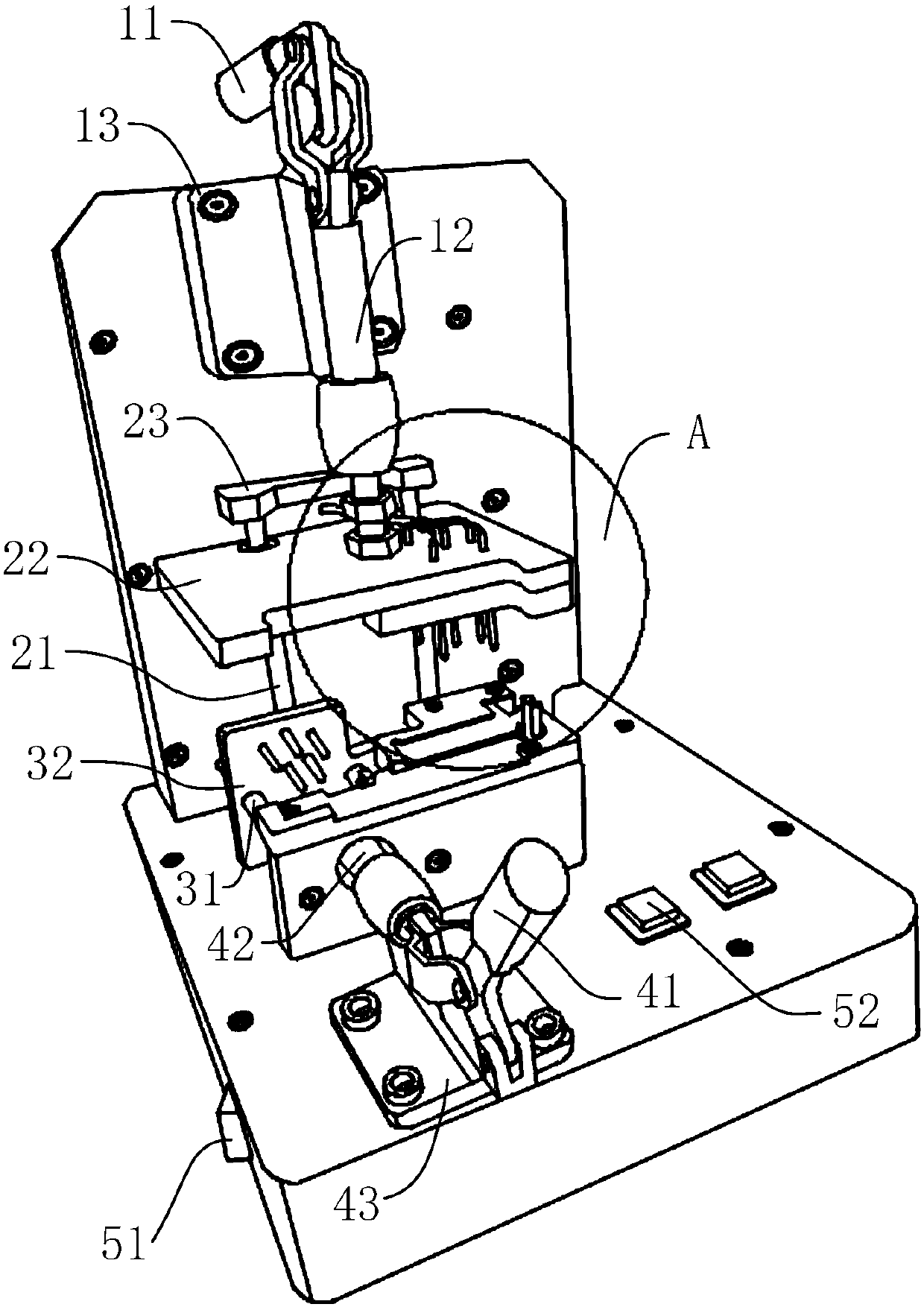

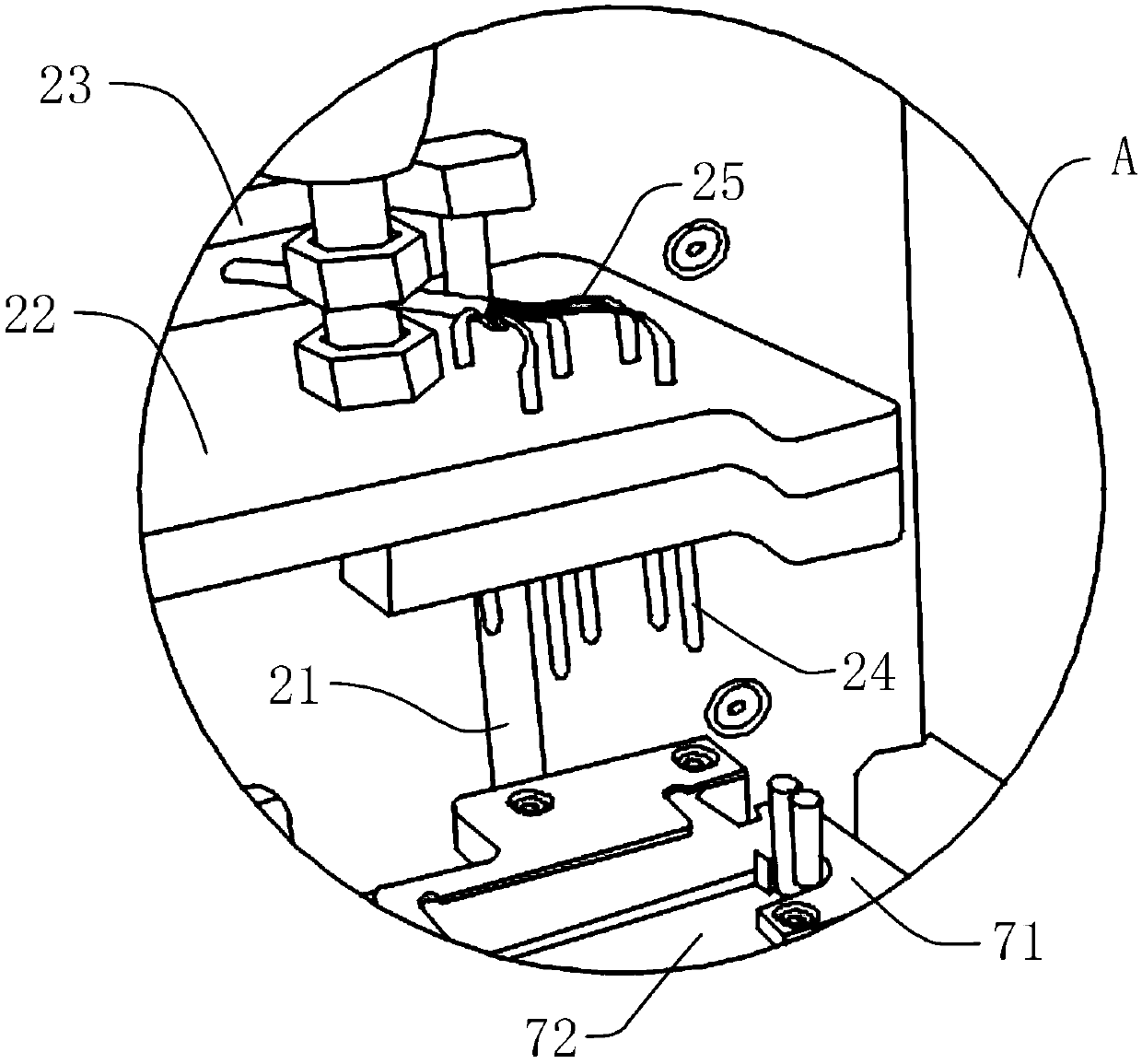

Double-sided circuit board testing device

InactiveCN107728044AReduce manufacturing costSave man hoursElectronic circuit testingStructural engineeringMechanical engineering

Owner:GUANGDONG FEIKETE ELECTRONICS TECH CO LTD

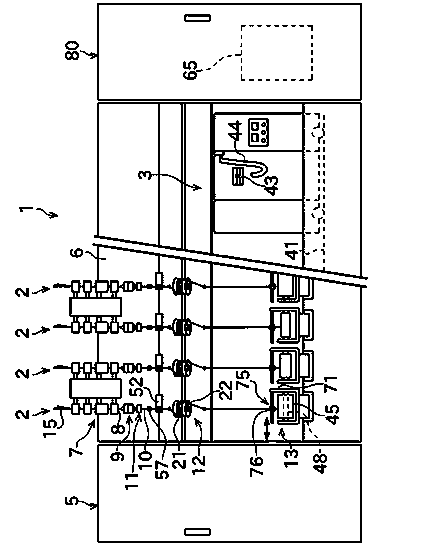

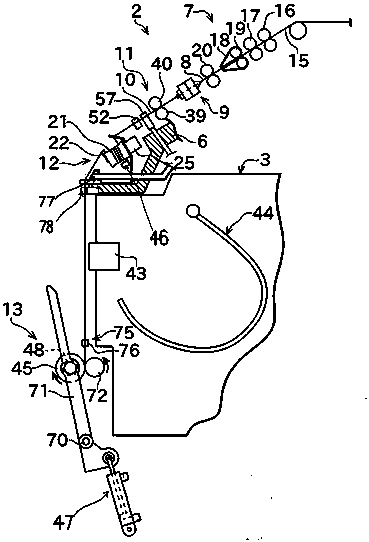

Spinning machine

PendingCN108286093AImprove production efficiencyIncrease productivityContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

The invention relates to a spinning machine. The machine includes spinning devices capable of generating spun yarns, a winding device for winding the spun yarns onto a package, a splicing work trolleywhich travels between the spinning devices, a yarn storage tension device between a spinning output roller and the winding device, and the spun yarns generated by the spinning devices are output by the output roller; a spinning yarn head sucking maintaining part with negative pressure is arranged on the downstream portion of the yarn storage tension device, and according to the spinning yarn headsucking maintaining portion, when the yarns are broken, a spinning yarn breaking head can smoothly enter a negative pressure passage of the maintaining portion and is at a predetermined position. According to the machine, the manufacturing efficiency of the spinning in each of spinning units can be improved, and the production efficiency of the package in the spinning machine can be improved.

Owner:ANHUI RIFA TEXTILE MACHINERY

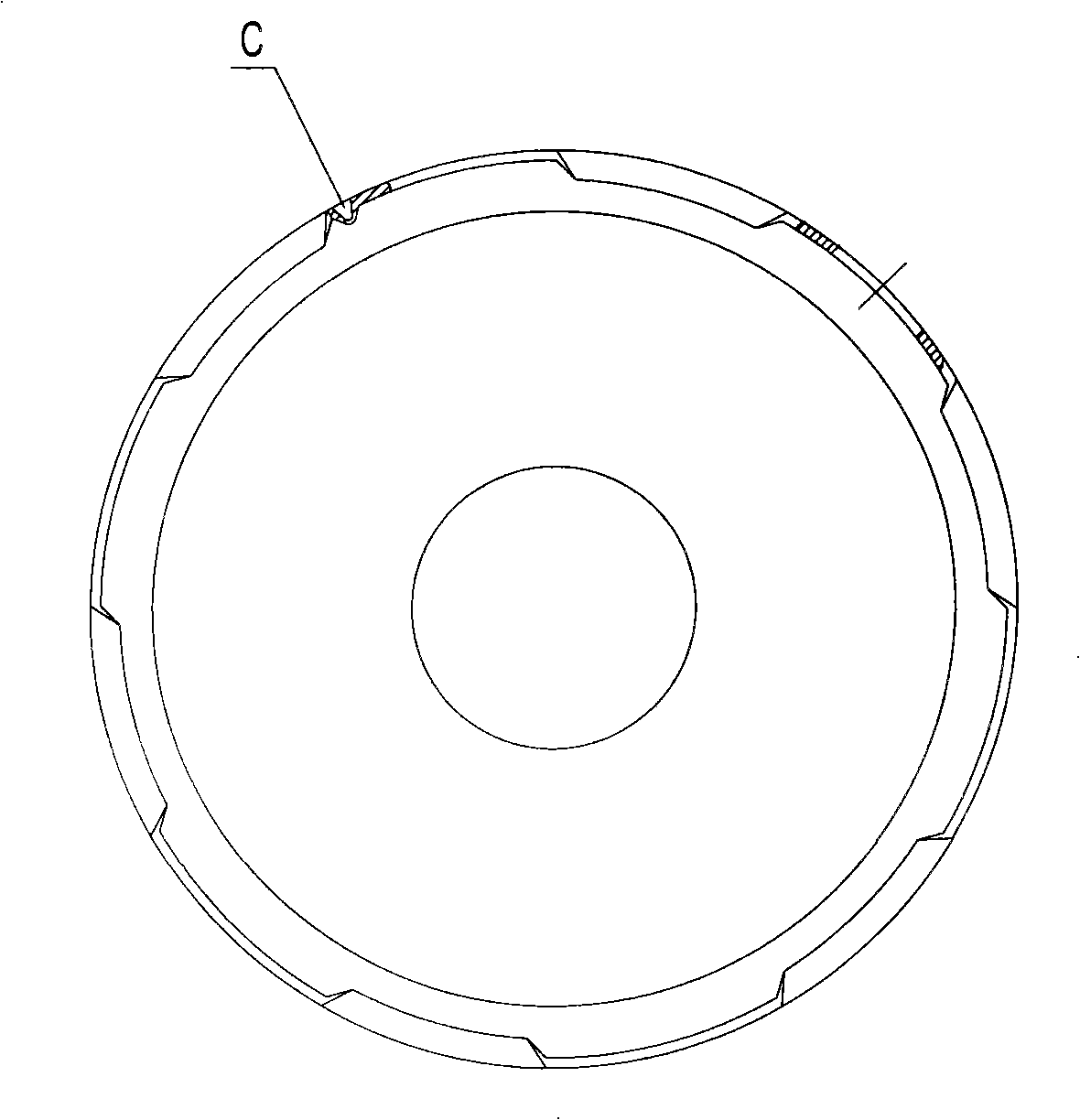

Use of thermoplastic polymer as waterborne polyurethane condom die material and method of producing condom die

InactiveCN111559033AGuaranteed uniformityGuaranteed introductionCoatingsPolymer sciencePolymer chemistry

The invention discloses use of a thermoplastic polymer as a die material for dip forming a waterborne polyurethane condom and a method of producing a condom die. Polyurethane can form a film uniformlydirectly on the thermoplastic polymer condom die to be demolded without an internal separant, so that the uniformity of the polyurethane film and introduction of other substances are guaranteed. After polyurethane forms the film uniformly directly on the thermoplastic polymer condom die, post-treatment sizing on performance of raw materials can be carried out directly without adding other steps such as demolding, so that the operation flow is reduced and the percent of pass of products is improved.

Owner:利洁时健康有限公司

Auxiliary device for fixing bridge cable and using method thereof

ActiveCN112761069AReduce tensionAvoid duplicationBridge structural detailsBridge erection/assemblyFixed BridgesScrew thread

The invention discloses an auxiliary device for fixing a bridge cable and a using method thereof. The auxiliary device comprises a rotating assembly, a guiding structure and a foundation anchor, a guiding rod is installed on one side of the interior of the foundation anchor, the guiding structure is slidably installed on one side of the guiding rod, and the rotating assembly is slidably installed on the side, away from the guiding rod, of the guiding structure; a tensioning nut is mounted in the center of the interior of the rotating assembly through a fixing screw, and a cable is connected to the interior of the tensioning nut through a threaded structure. The guiding rod is installed to guide the rotating assembly to move, a constructor can pull and tension the inhaul cable through a threaded structure, the constructor can conveniently adjust and control the tensioning force of stretching in the later period, pulling and tensioning are completed under the same structure, repeated operation of a user is avoided, and the operation process is shortened. And through cooperative use of the guiding structure and the rotating assembly, a constructor can conveniently and rapidly connect the foundation anchor and the cable, and the workload of the constructor is reduced.

Owner:郑州市公路工程公司

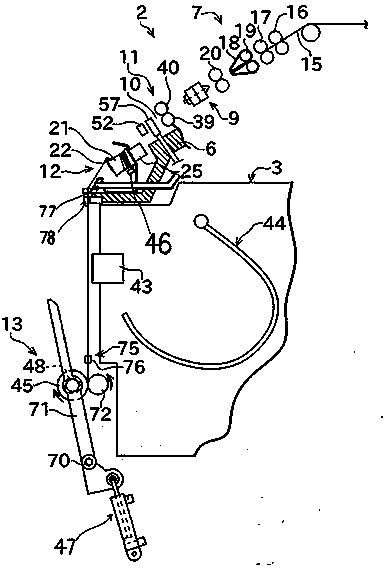

Composite mold of pressure cooker lid

ActiveCN101337252BReduce work flowProcess AssuranceShaping toolsMetal working apparatusPunchingWaste product

Owner:WUHAN SUPOR COOKWARE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com