Structure of LED base and pins and producing method

A manufacturing method and pin technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of narrowing pin spacing, increased drilling, uneven thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

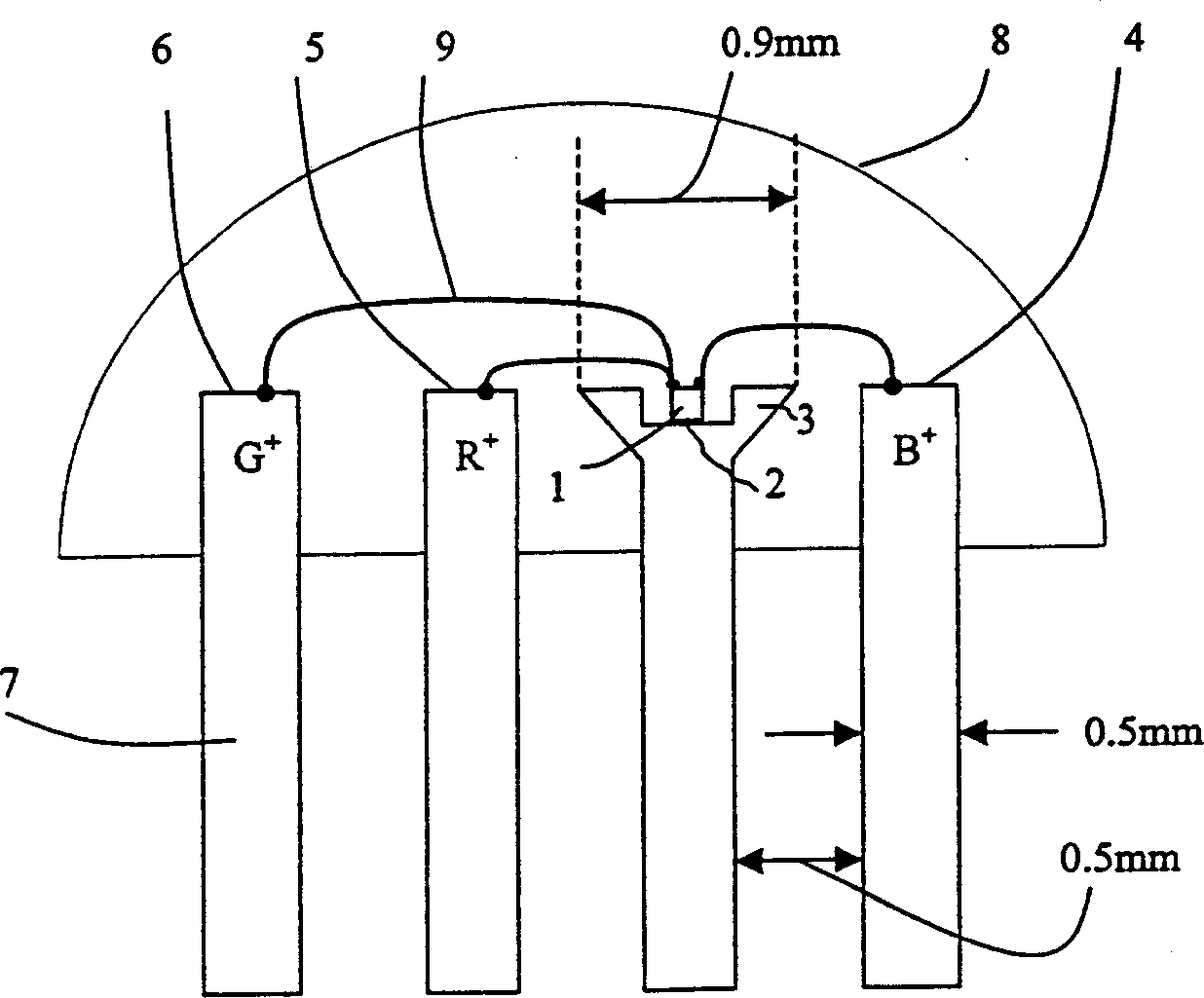

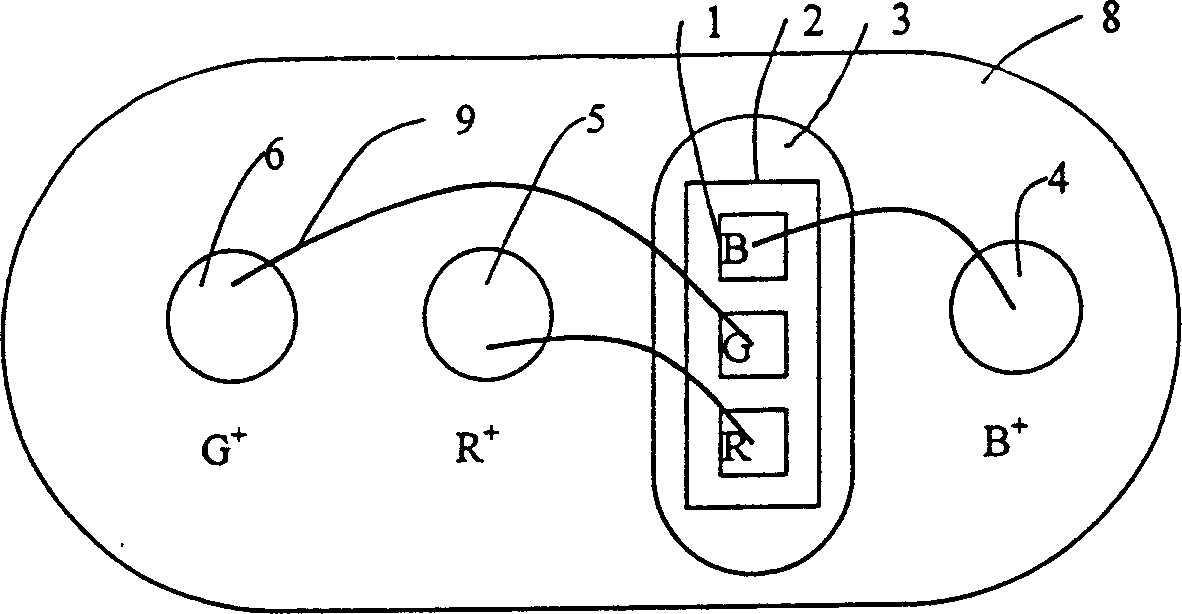

[0036] The content of the present invention can be illustrated through the following embodiments with the accompanying drawings. Although the structure and manufacturing method of the structure base and pins of the present invention take the package of four pins as an example. However, three or more pins can also be implemented utilizing the principles of the present invention.

[0037] According to the first embodiment of the present invention, refer to Figure 5 , which is a plan view of the structure of the four pins and the base of the three-primary-color LED. One end of the first pin 51 forms the base and the shared negative terminal block 3, and a groove forms a die seat 2 for stacking the three-primary-color LED dies for installation. The grain seat 2 is a groove with a circular parabolic side wall, which focuses the reflected light and then shines forward to increase the brightness. One end of the second, third, and fourth pins 52, 53, and 54 form blue, red, and gree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com