Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105results about How to "Reduce vacuum time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

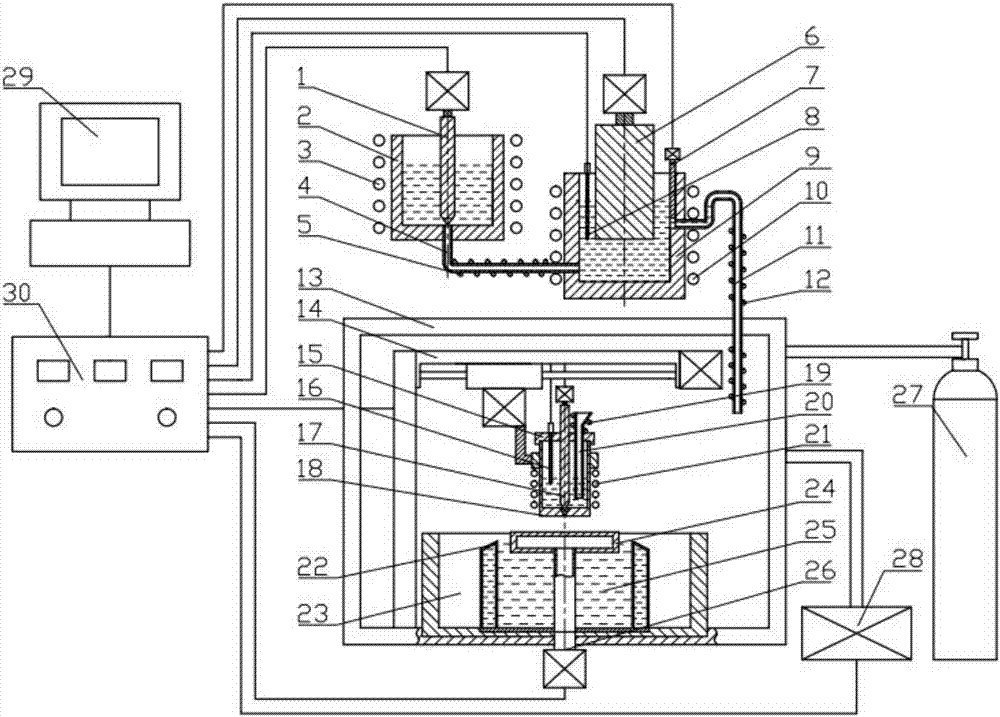

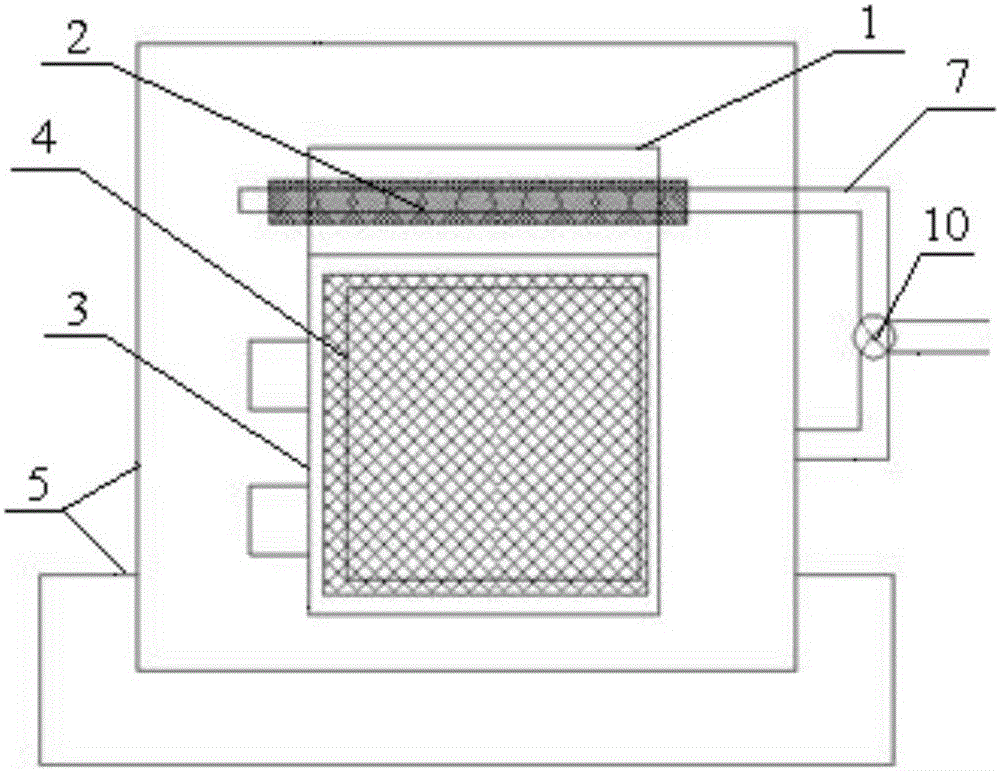

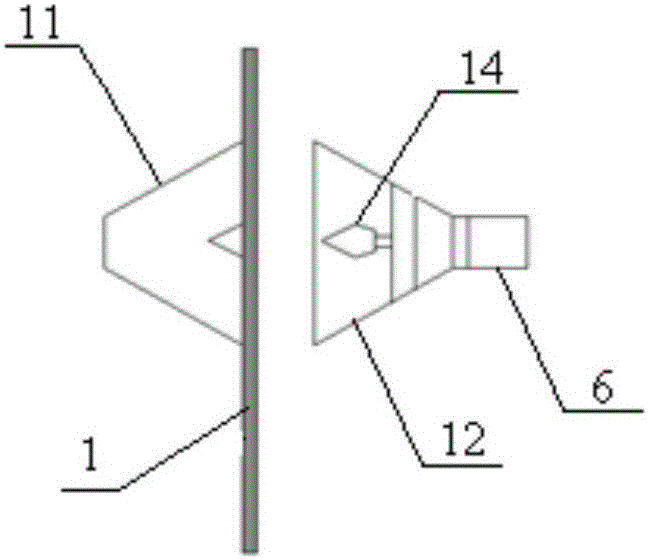

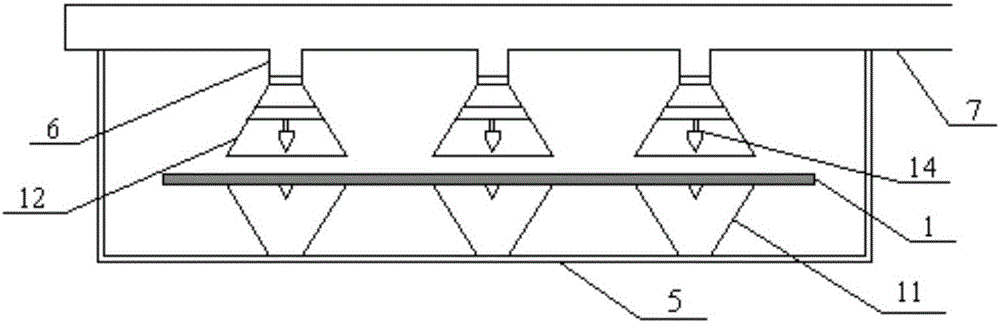

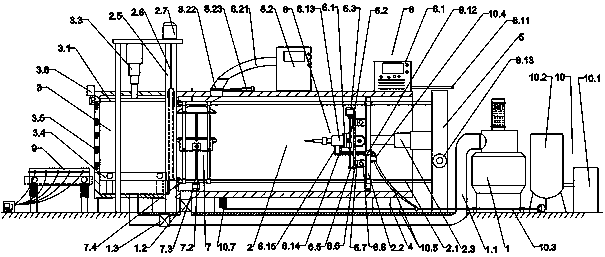

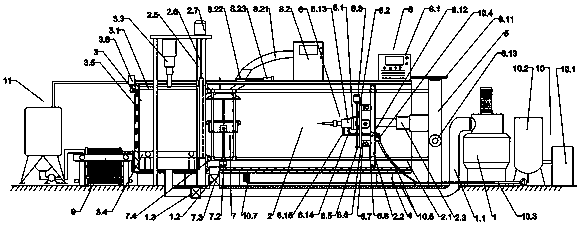

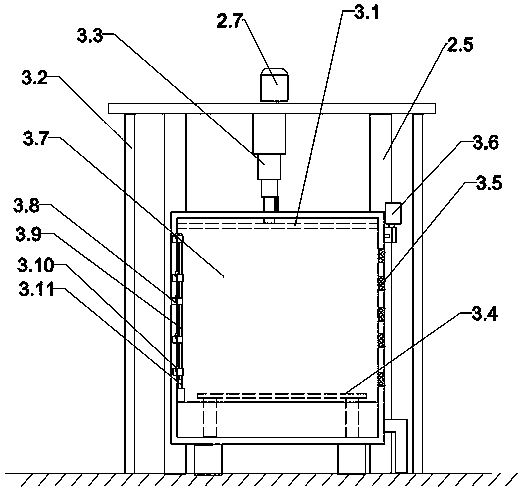

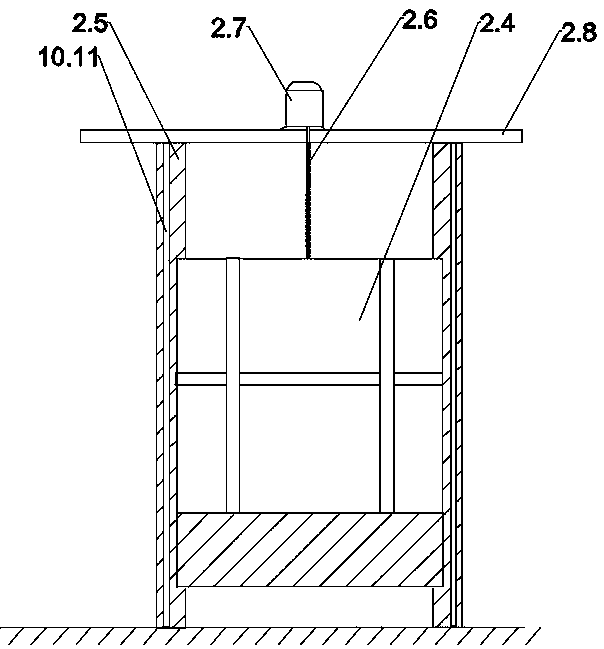

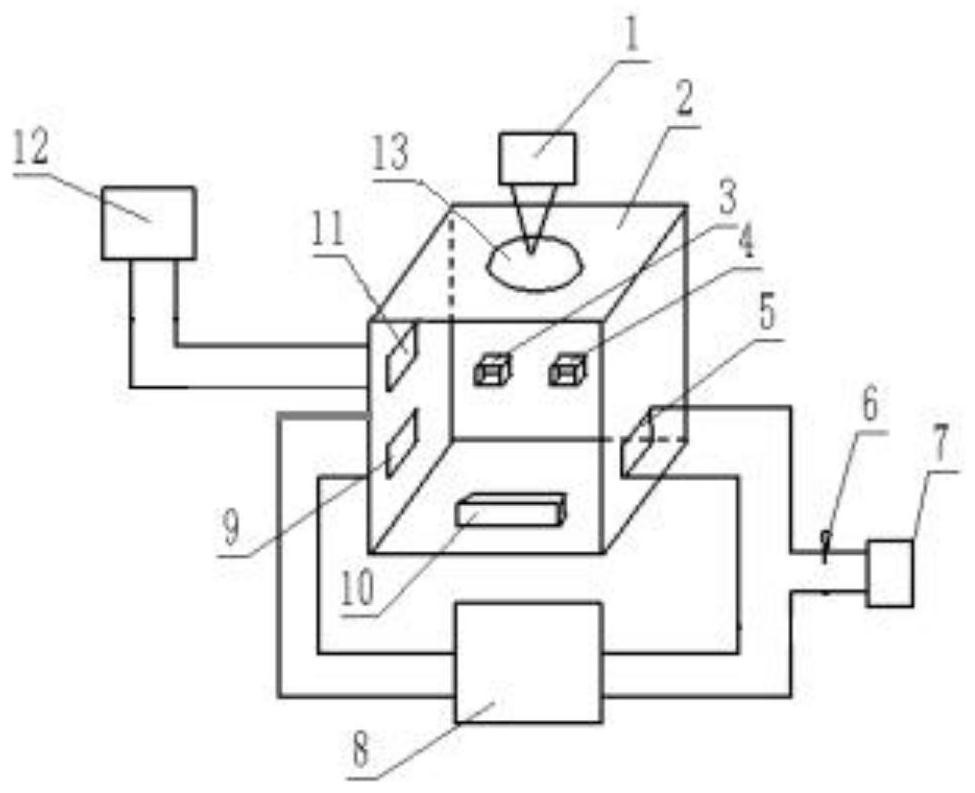

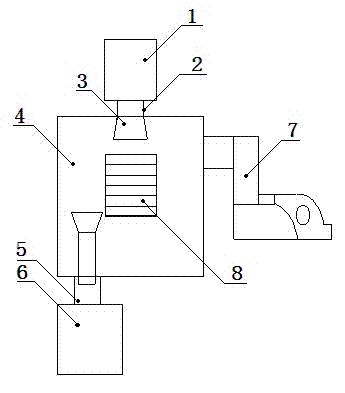

High-efficiency metal 3D printing equipment and method

ActiveCN106925783AHigh precisionLow costAdditive manufacturing apparatusIncreasing energy efficiencySpray nozzleEngineering

The invention discloses high-efficiency metal 3D printing equipment and a method, and belongs to the technical field of 3D printing. Through such measures as separation of a supply system of metal 3D printing equipment from a discharge system, separation of a printing forming area from a cooling medium, positioning of the supply system out of a forming room and capability of controlling the size of a discharge port of a nozzle according to sizes of products, based on direct melt supply and cooling medium cooling, the high-efficiency metal 3D printing equipment and method adopt 3D printing to form high-quality metal products with high efficiency and low cost, and in particular, are suitable for high-efficiency formation of large metal products. The 3D printing equipment is flexible in mechanism actions, fast in operating speed, high in flexibility, high in sensitivity and low in manufacturing cost; the 3D printing forming process is high in efficiency; process parameters are liable to control; and the metal products formed by printing are excellent in quality and repeatability and low in production cost.

Owner:UNIV OF SCI & TECH BEIJING

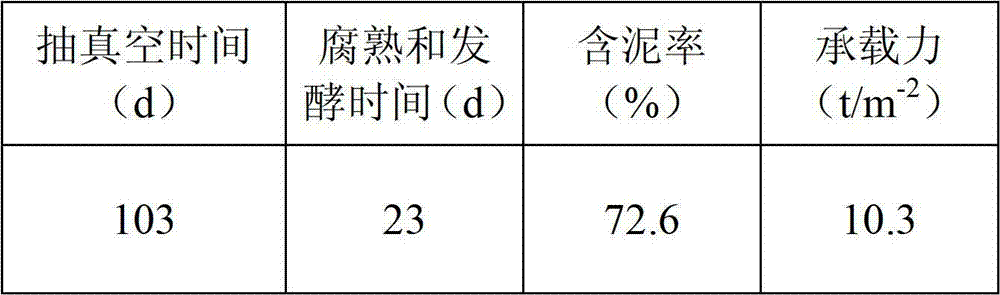

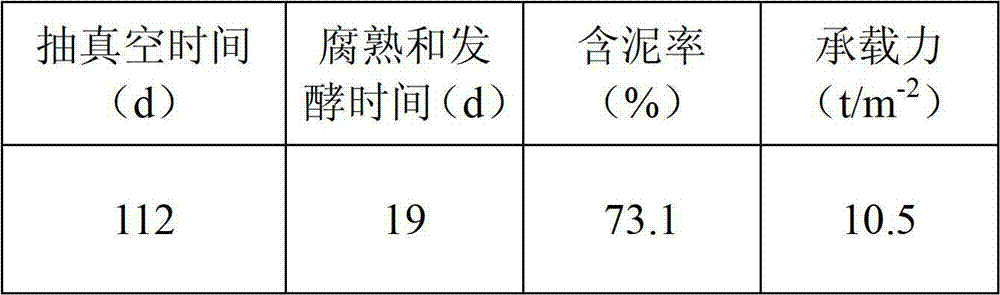

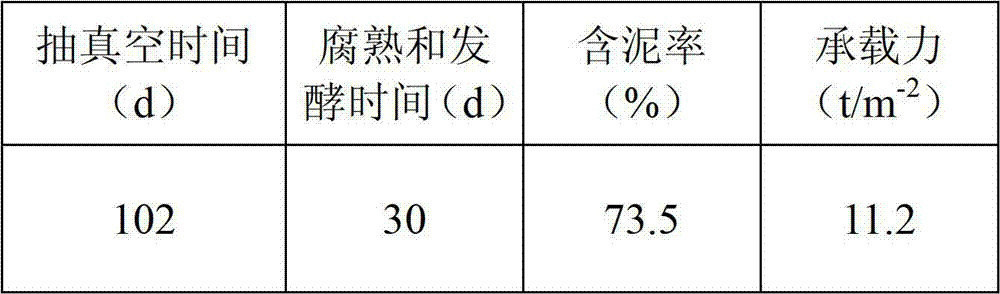

Method for promoting rapid drying of dredged silt by microorganism

ActiveCN102815854ARapid flocculation sedimentation concentrationLow costSludge treatment by de-watering/drying/thickeningBiological sludge treatmentLife activityDecomposition

The invention relates to a method for promoting rapid drying of dredged silt by a microorganism. The method includes: taking straw and other organic matters as a substrate, conducting anaerobic fermentation and decomposition, burying the substrate in a silt storage yard, pre-burying a vacuum pumping pipe network system, inputting dredged silt, and then adding a flocculant and a coagulant aid to perform initial concentration, vacuum pumping, compression and other processes. The method for promoting rapid drying of dredged silt by a microorganism makes use of life activities of the microorganism and the produced gas to change the compact silt state formed during vacuum pumping, makes the silt become loose and porous, promotes flow of moisture, thereby improving the water pumping and drainage effect of vacuum preloading, and transforming the dredged silt from a fluid state to a plastic state or semi-solid state rapidly. Thus, the method realizes rapid dewatering and drying of dredged sludge, and has the characteristics of low cost and short construction period.

Owner:JIANGSU JIANGDA ECOLOGICAL SCI & TECHCO

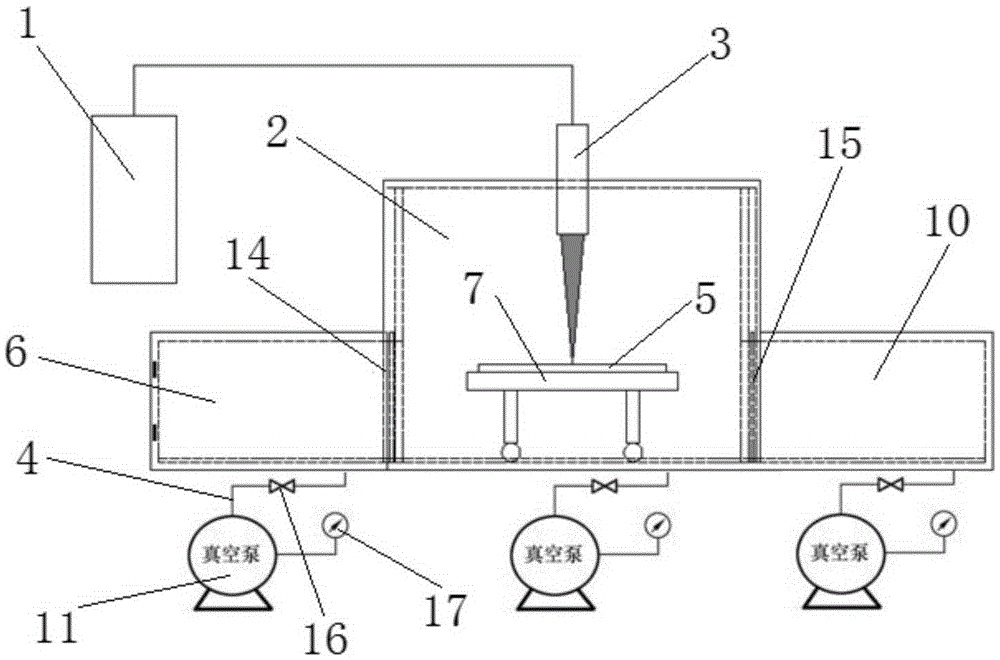

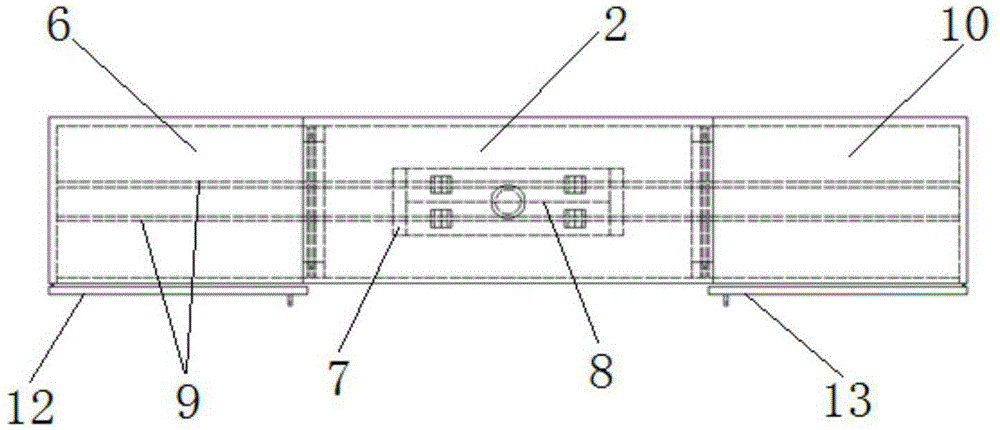

Vacuum welding device and method for preventing laser seam from generating pores

InactiveCN105290613AAvoid formingWon't get involvedLaser beam welding apparatusVacuum pumpingVacuum pump

The invention relates to a vacuum welding method for preventing a laser seam from generating pores. A vacuum welding device for preventing the laser seam from generating the pores is designed for the method. The vacuum welding device comprises a laser, a welding chamber, a focusing head and a vacuum pump; the laser and the vacuum pump are located outside the welding chamber; one end of the focusing head is connected with the laser through a laser conducting cable; the other end of the focusing head is inserted into the welding chamber; a pre-vacuum-pumping chamber is arranged on one side of the welding chamber; a postwelding sampling chamber is arranged on the other side of the welding chamber; the welding chamber is communicated with the pre-vacuum-pumping chamber and the postwelding sampling chamber; the pre-vacuum-pumping chamber, the welding chamber and the postwelding sampling chamber are communicated with the vacuum pump. The vacuum welding device and method for preventing the laser seam from generating the pores can prevent from generating the pores when the laser seam is solidified, the process is simple, and operation is convenient.

Owner:武汉钢铁有限公司

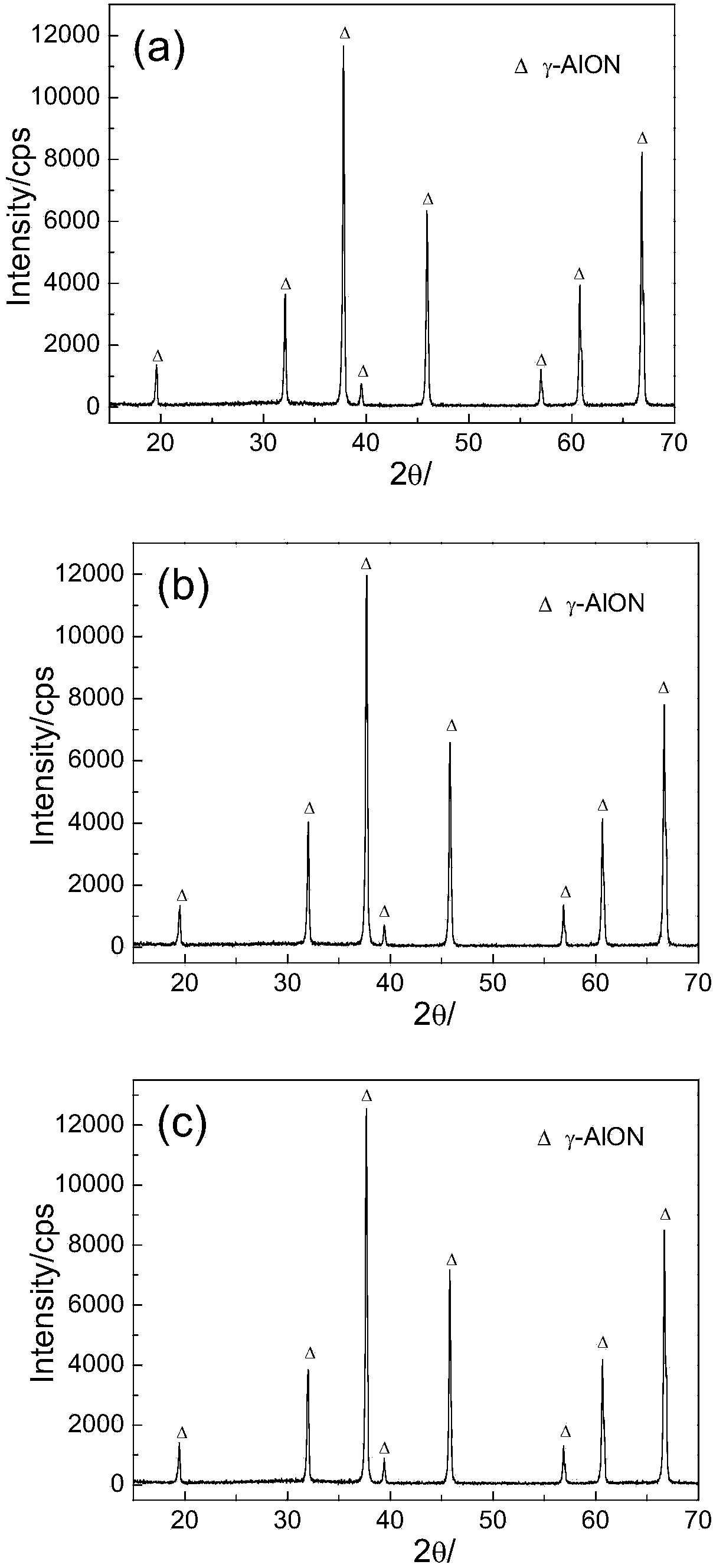

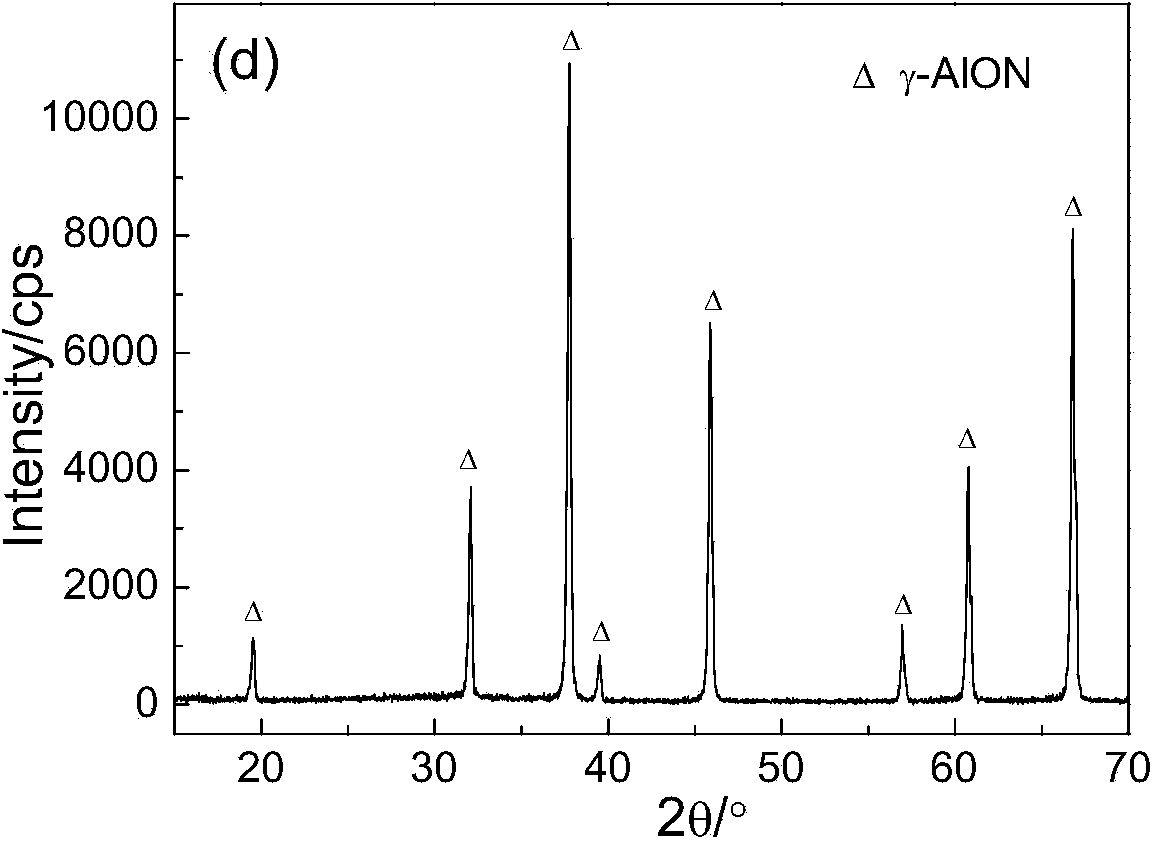

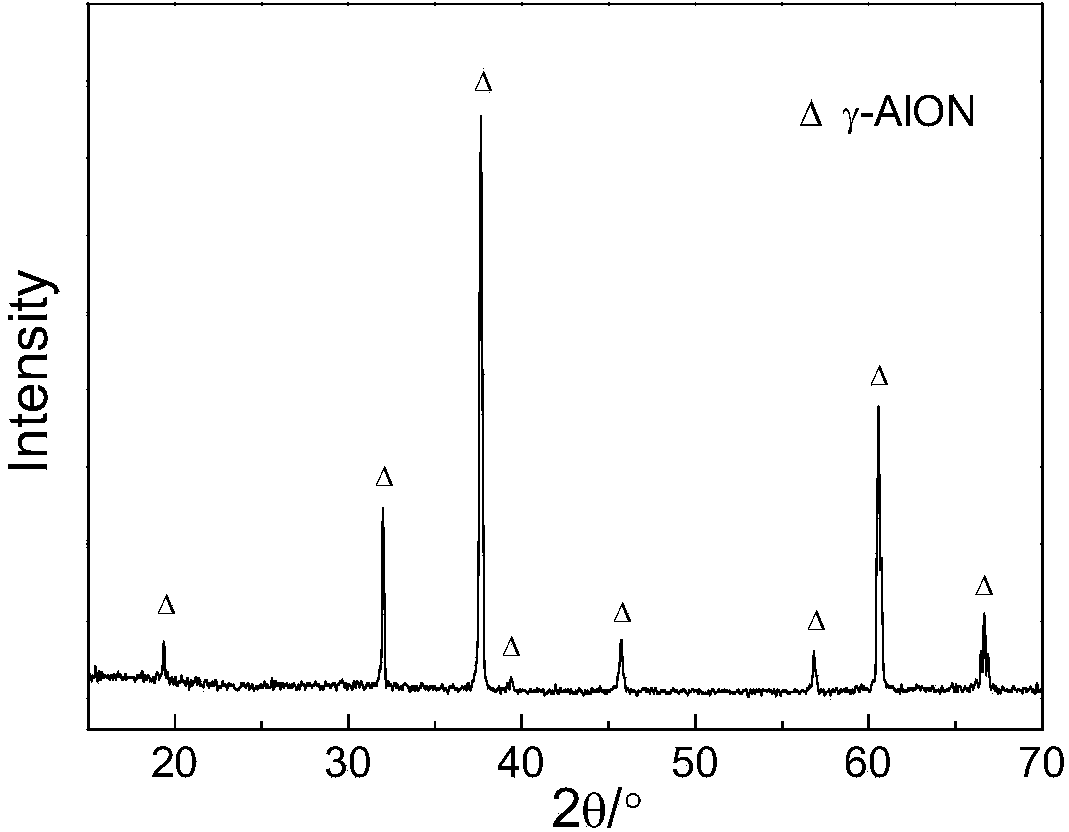

Preparation method for gamma-AlON transparent ceramic powder

The invention relates to a method for preparing pure-phase gamma-AlON transparent ceramic powder by carbothermal reduction of gamma-Al2O3, and belongs to the field of preparation of transparent ceramic materials. According to the preparation method, nano-alpha-Al2O3 and activated carbon are taken as raw materials; powder is filled in a graphite crucible loosely, wherein an aluminum oxide plate is paved at the bottom of the graphite crucible; an air hole which penetrates through the powder is preformed at the aluminum oxide plate; a graphite cover provided with fine and dense air holes is used for covering the hole; the pure-phase gamma-AlON transparent ceramic powder is prepared by adopting a two-step heating process in a flowing nitrogen environment with a micro positive pressure. By the adoption of the preparation method, the vacuumizing difficulty can be effectively reduced, powder is prevented from scattering in a vacuumizing stage, the time required for discharging adsorbed gas can be greatly shortened, the vacuumizing speed is high, and the preparation efficiency of the gamma-AlON powder is greatly improved; the obtained gamma-AlON powder phase has stable and reliable compositions and can be used for pressure-less sintering preparation of AlON transparent ceramics with high transmittance; the process is simple and is easy to operate, and is suitable for industrial production.

Owner:DALIAN MARITIME UNIVERSITY

Flexibly packaged lithium battery evacuation apparatus and use method thereof

ActiveCN105552441ADischarge fullyReduce overflowFinal product manufactureElectrolyte accumulators manufactureVacuum pumpingPulp and paper industry

The invention discloses a flexibly packaged lithium battery evacuation apparatus and a use method thereof. The purpose of the invention is to solve the problems of long vacuum pumping time and electrolyte overflow in the vacuum pumping and dwelling process of present flexibly packaged lithium batteries. The flexibly packaged lithium battery evacuation apparatus comprises a vacuum chamber and a vacuum pipeline, a vacuum adsorption port is arranged in the vacuum chamber, the vacuum pipeline is connected with the vacuum adsorption port, a combined sucker is arranged in the vacuum chamber, the combined sucker comprises a fixed sucker and a telescopic driving sucker, the fixed sucker is fixedly arranged on the inner wall of the vacuum chamber, the driving sucker is arranged facing to the fixed sucker and is connected with the vacuum adsorption port in the vacuum chamber, and a telescopic bayonet is arranged in the driving sucker. Two-stage vacuum pumping of a flexibly packaged lithium battery is carried out through the combined sucker, so the vacuum pumping time is shortened, electrolyte overflow is reduced, and pollution of the electrolyte gasified at a negative pressure to the surface of the battery is avoided.

Owner:WANXIANG 123 CO LTD

Evaporating device

ActiveCN104726827AReduce transfer timeReduce vacuum timeVacuum evaporation coatingSputtering coatingEvaporationEngineering

Owner:BOE TECH GRP CO LTD +1

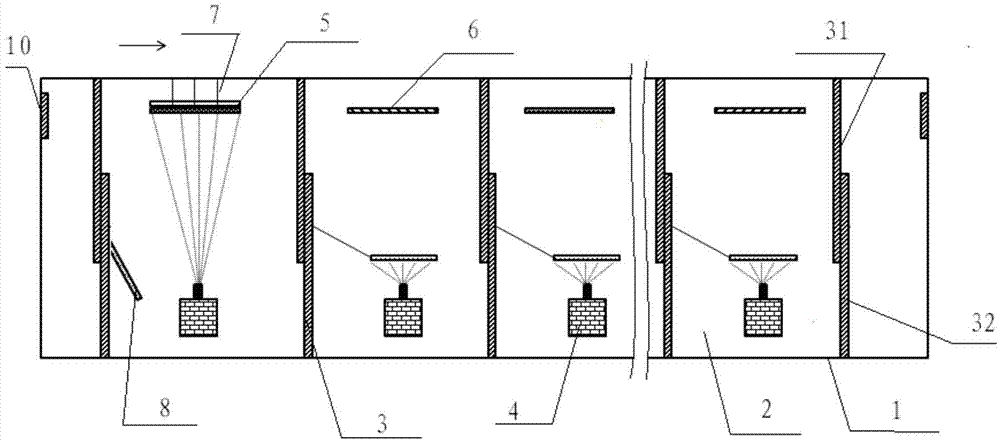

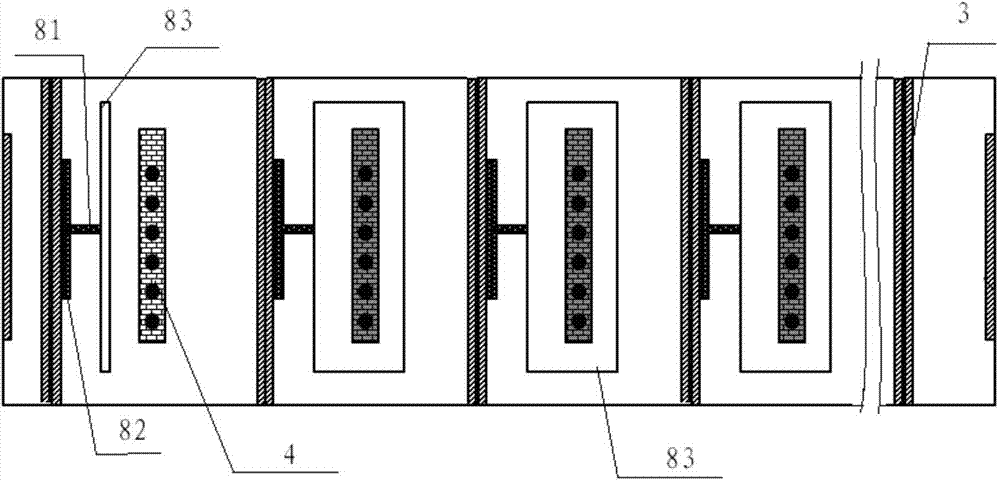

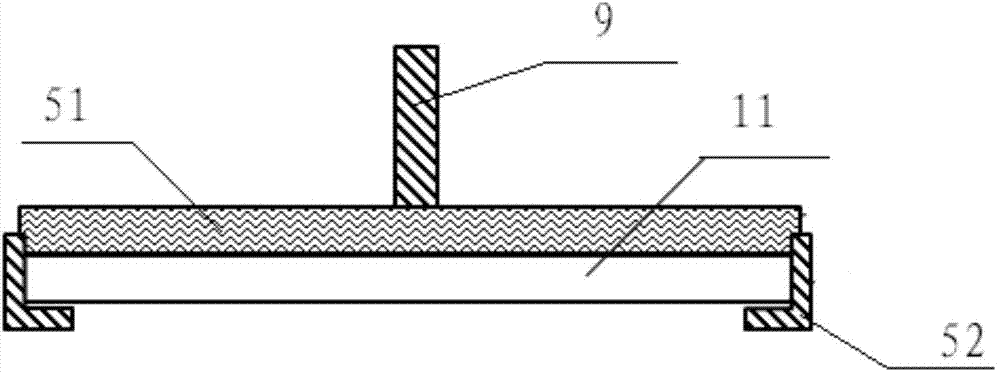

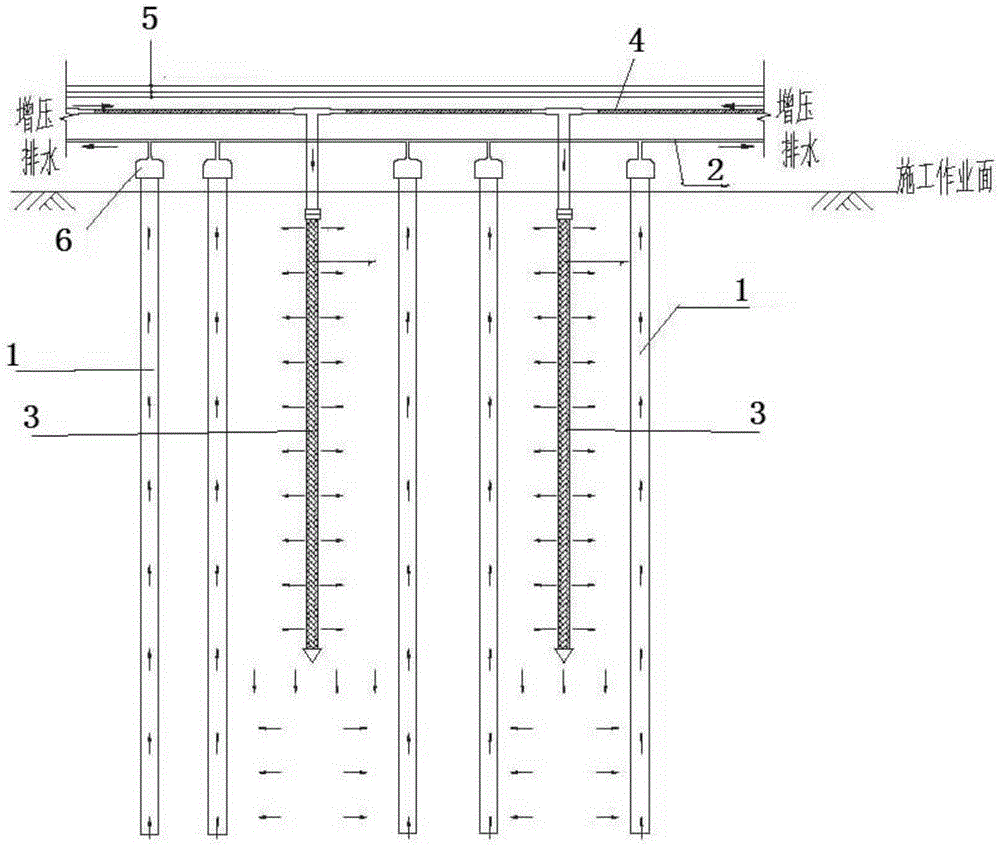

Rapid treatment system and rapid treatment method for soft soil foundation

A rapid treatment system for a soft soil foundation comprises a plurality of drainage plates vertically inserted into a soft soil stratum; the drainage plates are connected with a drainage pipe through hand-shaped joints; the drainage pipe is connected into a gas-liquid dispersion tank; a self-controlled drainage pump is arranged in the tank; above the tank, a vacuum-pumping pipeline system is connected with a high-vacuum pump; pressurization pipes are arranged in the soft soil stratum between the drainage plates; and the pressurization pipes are connected with a booster pump. According to the technology and a method adopted by the invention, adverse effects of well resistance and a smearing effect on drainage consolidation can be obviously reduced, blocking of a drainage channel is reduced, a dead zone of a traditional vacuum preloading drainage channel can be eliminated, dependence on sand resources in the traditional technology can be eliminated, vacuum-pumping time is shortened and vacuum-pumping units are reduced, and 100 percent of operation rate is realized; moreover, the drain pipe is recovered, so that power consumption is reduced, engineering cost is reduced, and the construction period is shortened.

Owner:SHANGHAI STRONG FOUND ENG

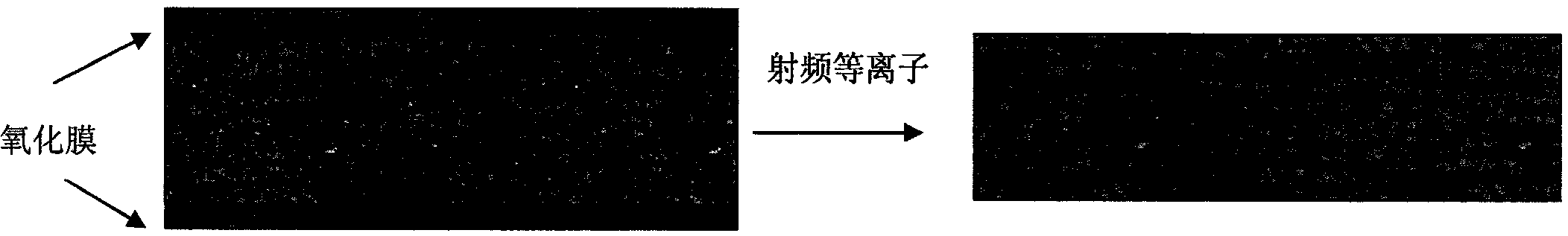

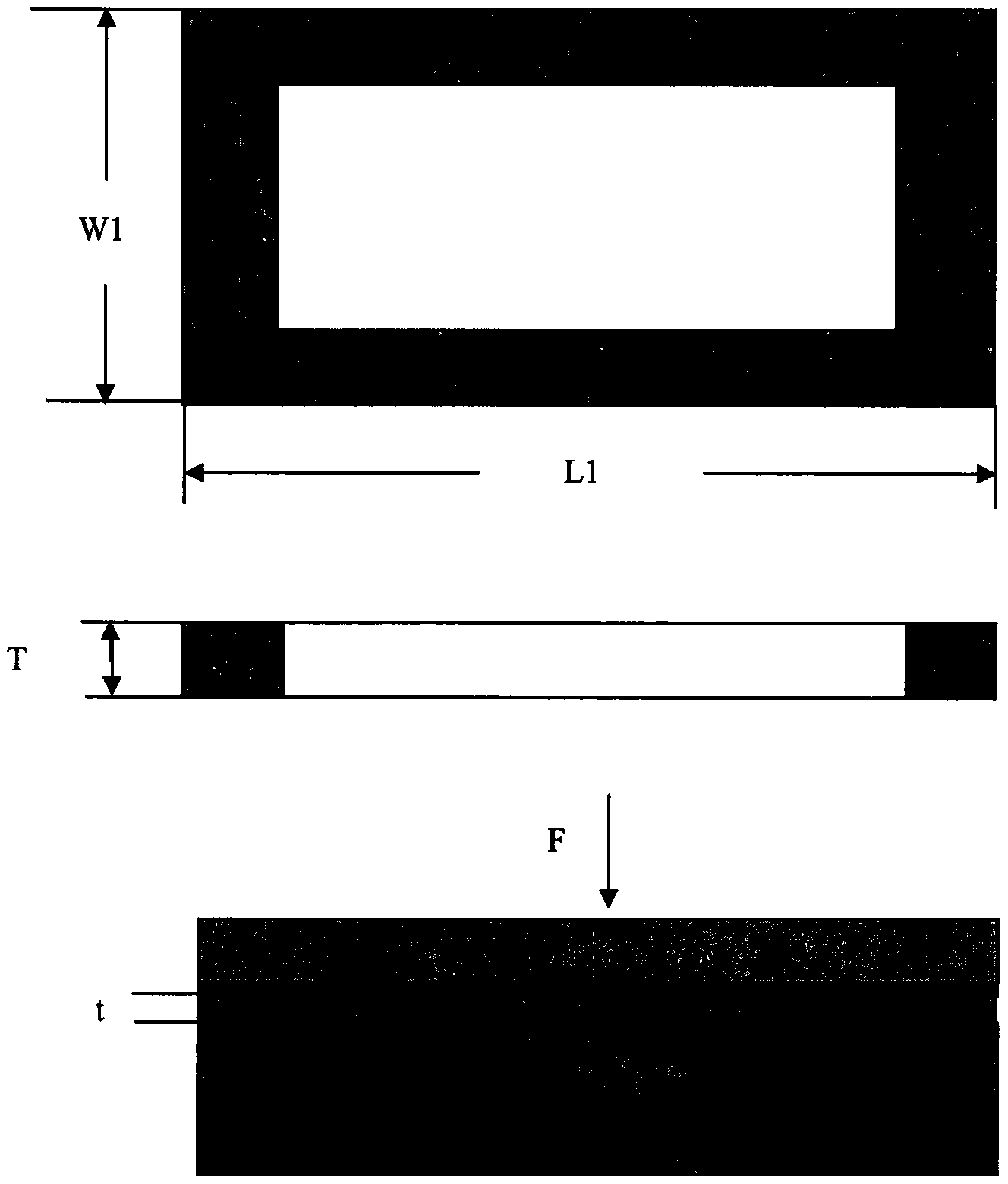

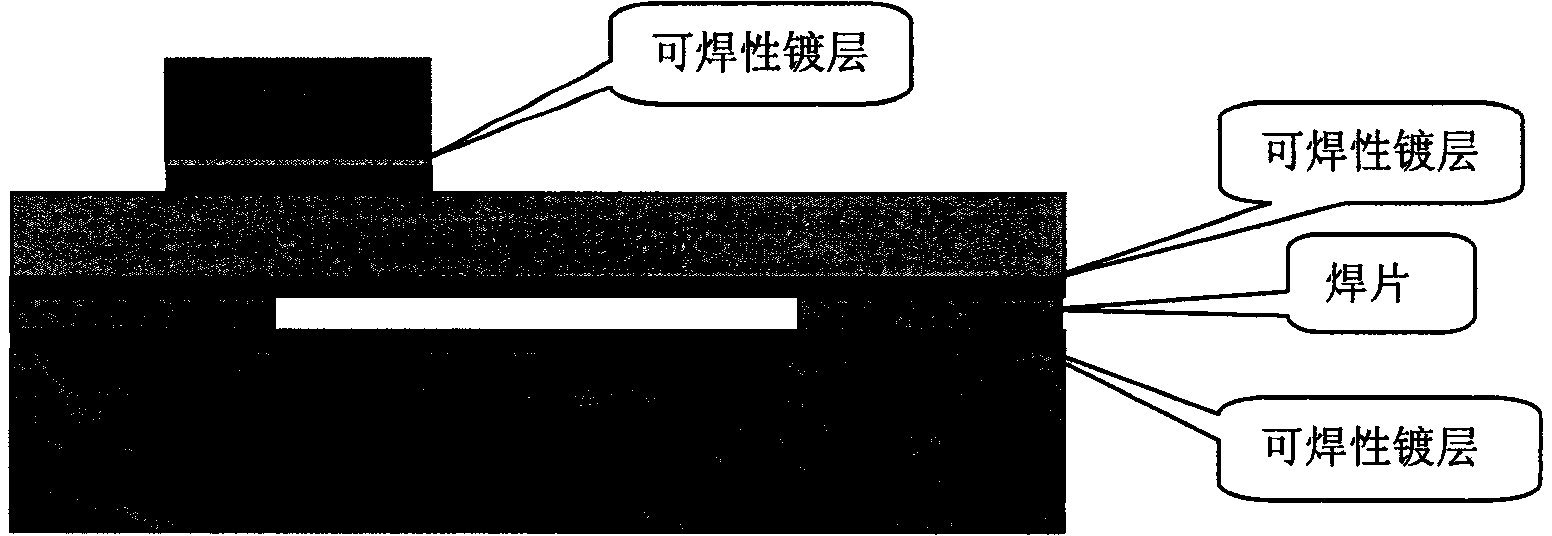

A high brazing rate vacuum welding method based on plasma cleaning

ActiveCN106134330BFast heat conductionEfficient removalWelding/cutting media/materialsSoldering mediaRoom temperatureSoldering

A high brazing rate vacuum welding method based on plasma cleaning, the steps are as follows: (1) plasma cleaning the solder sheet; The shape of the parts is the same, and the middle is hollowed out to form a gasket shape; (3) The welded workpiece, the solder piece, and the carrier are superimposed together in sequence, and a certain weight of tooling is added to exert pressure on the welded workpiece; (4) The superimposed good The workpiece is placed on the heating platform at room temperature, and the heating platform is placed in the vacuum furnace cavity, and the vacuum is started until the vacuum degree is less than 100Pa. At this time, the temperature of the solder piece is at room temperature; (5) The heating platform preheats the workpiece, and keep warm; (6) continue heating until the melting point of the solder sheet is 30-40°C above, and keep warm; (7) backfill the vacuum furnace cavity with the atmosphere, so that the air pressure in the cavity where the workpiece is located returns to atmospheric pressure; (8) cool down until the solder Below the melting point of the sheet, the welding is completed.

Owner:BEIJING SATELLITE MFG FACTORY

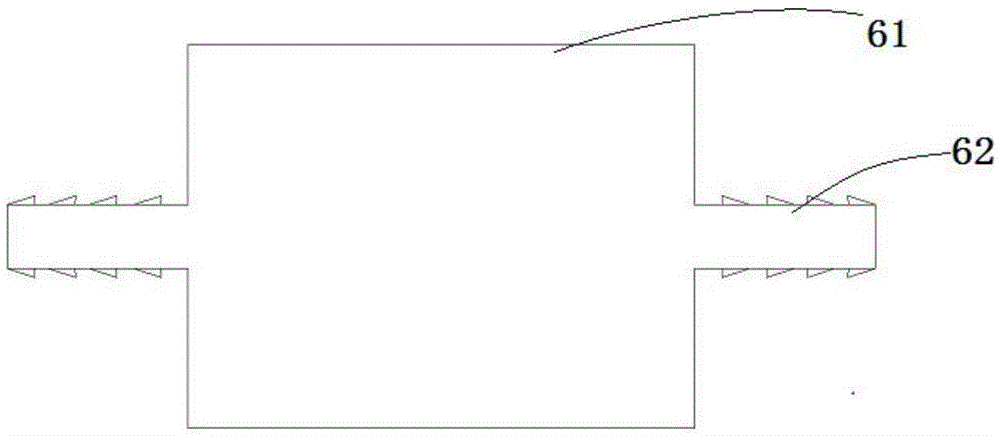

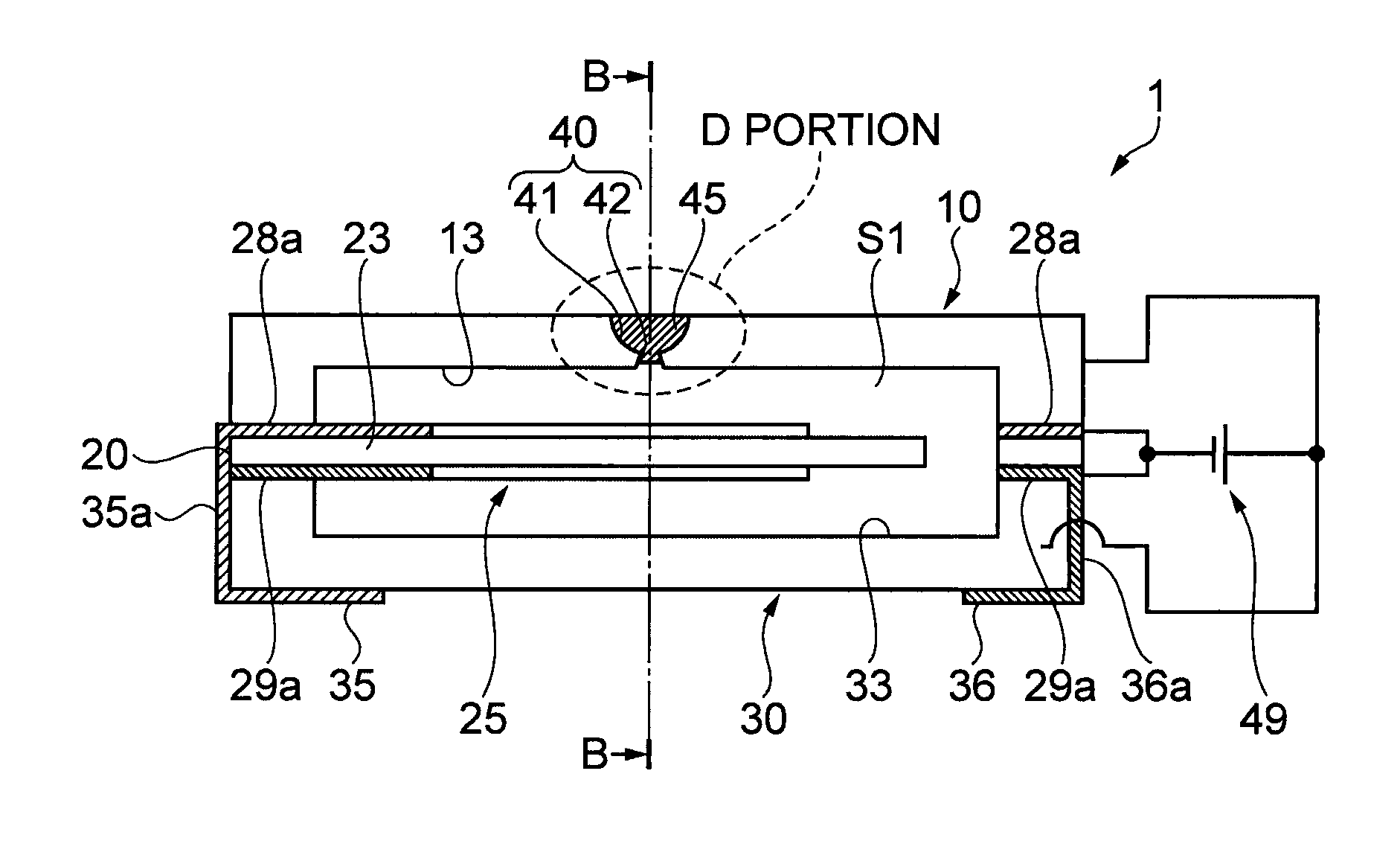

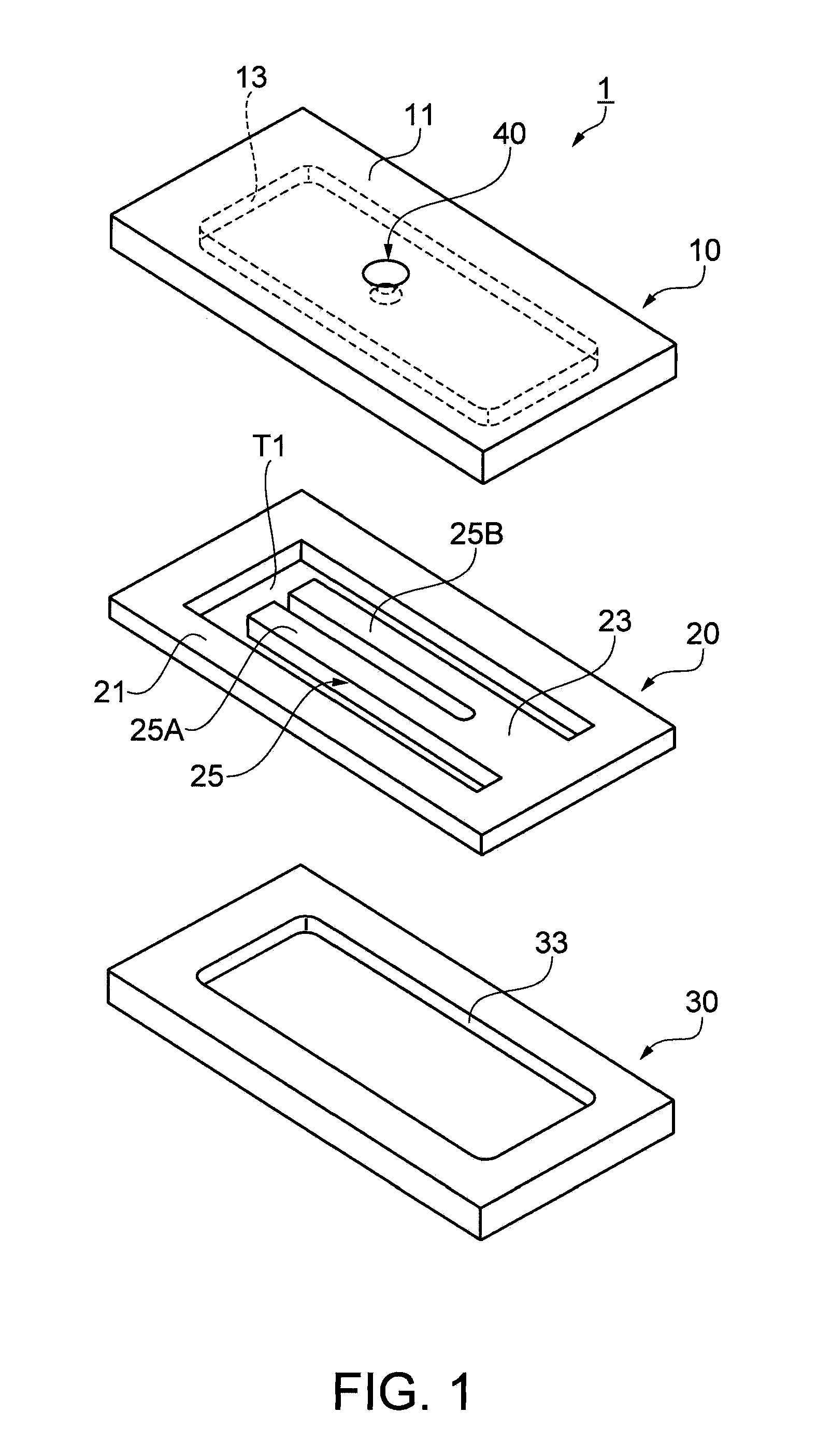

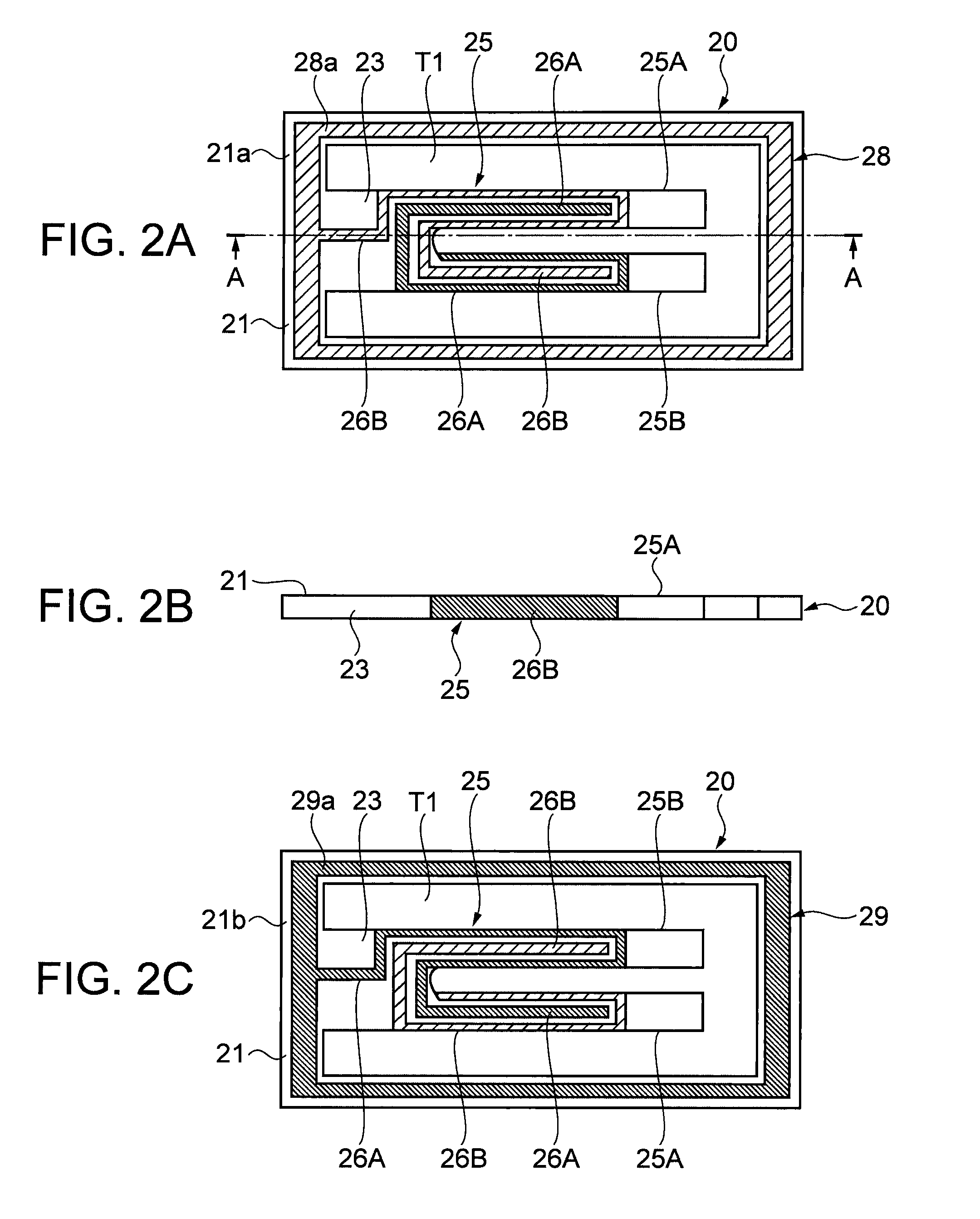

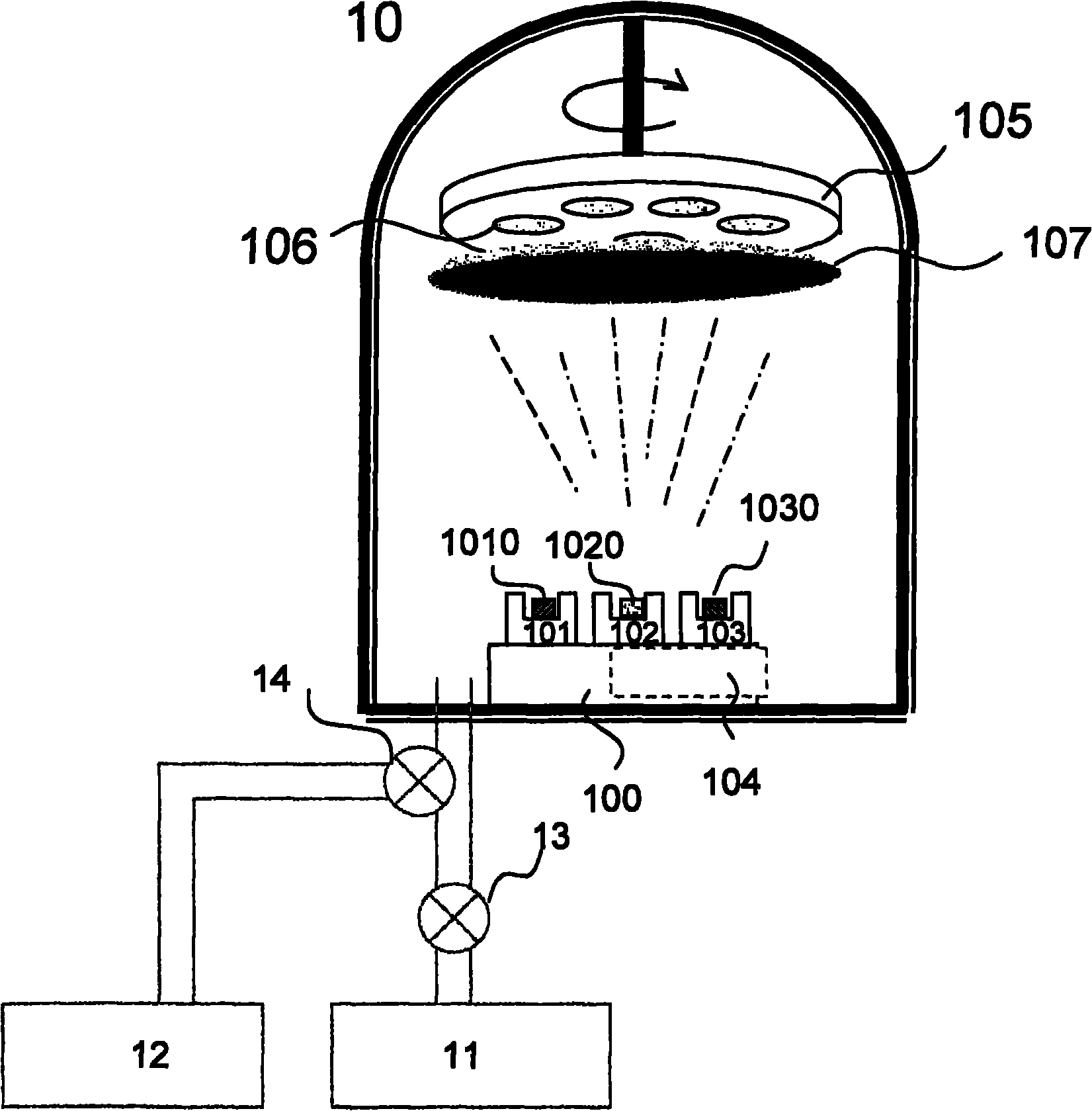

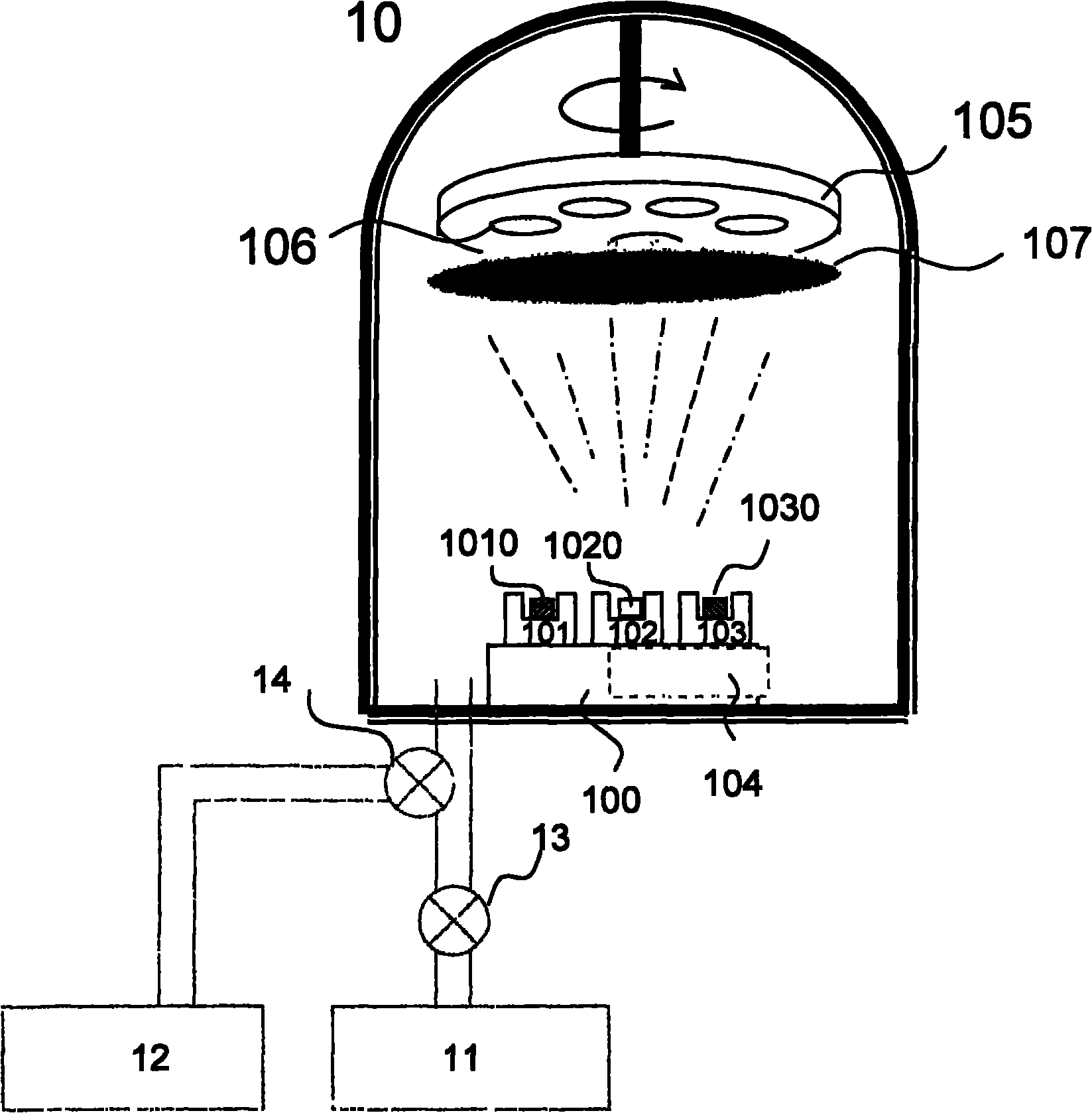

Package for electronic component, piezoelectric device and manufacturing method thereof

ActiveUS8334639B2Stable oscillation characteristicImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesImpedence networksInterior spaceEngineering

Owner:138 EAST LCD ADVANCEMENTS LTD

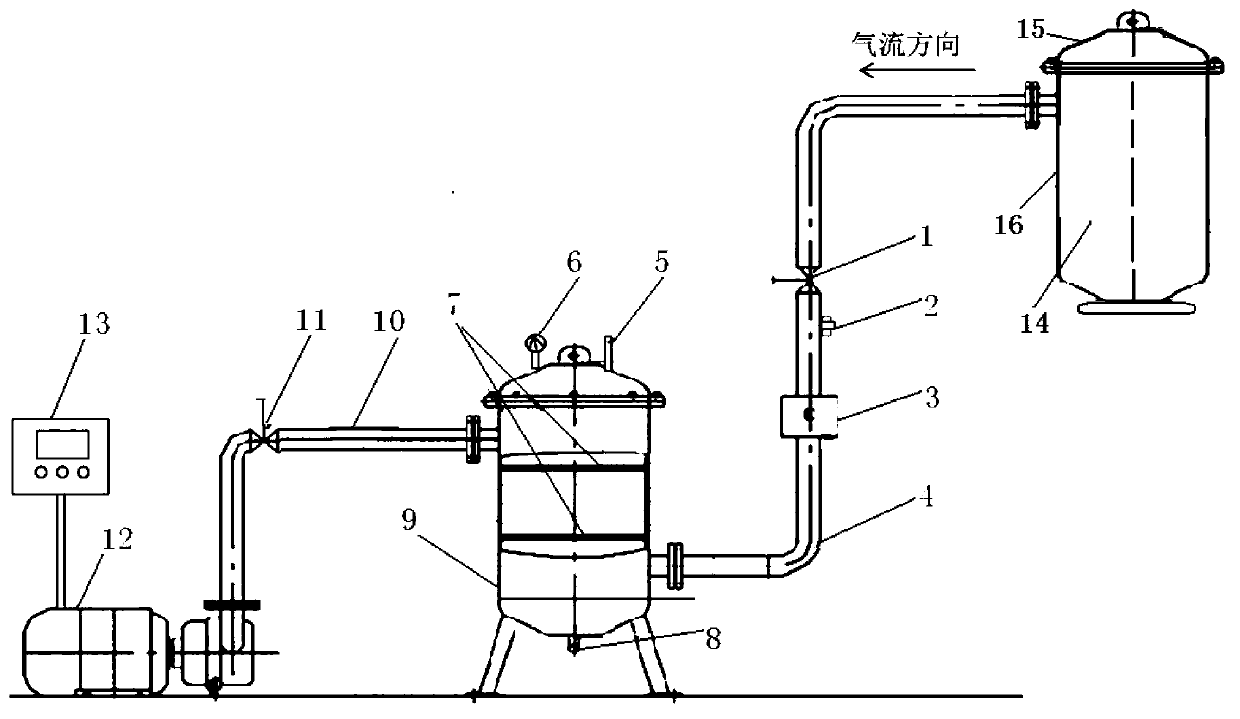

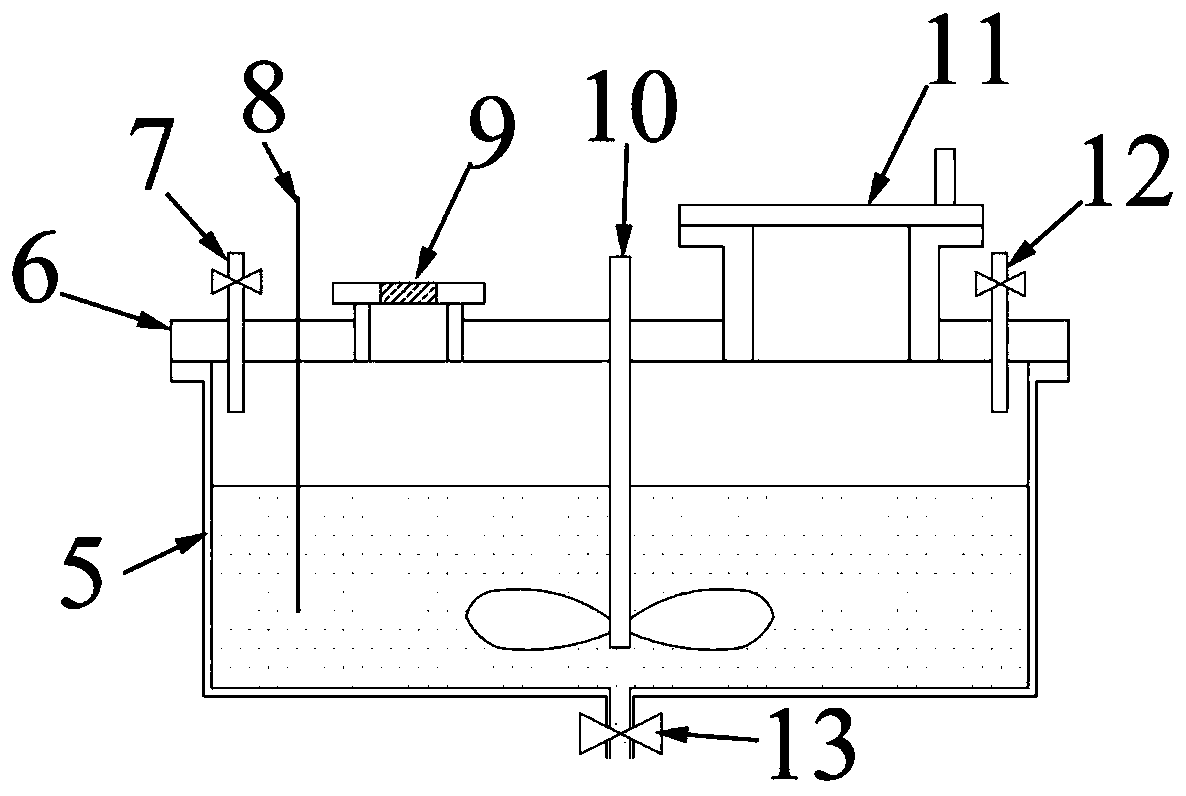

Vacuum variable-pressure buffering device for food processing

ActiveCN103340474AReduce vacuum timeAvoid enteringPressurized chemical processFood shapingBuffer tankProcess engineering

The invention discloses a vacuum variable-pressure buffering device for food processing. The device is characterized by comprising a food processing tank, a vacuum pump and a vacuum buffering tank, wherein the food processing tank comprises a tank body and a close cover, to-be-processed food is arranged in the food processing tank, and a cavity is reserved between the to-be-processed food and the close cover; the vacuum buffering tank is a closed tank body and is communicated with the cavity of the food processing tank through a first gas pipeline and communicated with the vacuum pump through a second gas pipeline, the gas transmission paths of the first gas pipeline and the second gas pipeline in the vacuum buffering tank are provided with at least one layer of filter screen, and the bottom of the vacuum buffer tank is provided with a drain valve. The vacuum variable-pressure buffering device disclosed by the invention has the beneficial effect that the filter screen in the vacuum buffering tank is capable of removing the moisture, grease and other impurities entering along the air in vacuumizing so as to protect the vacuum pump and the second gas pipeline. In conclusion, the vacuum variable-pressure buffering device is simple in structure, easy to operate, low in cost and capable of realizing large-scale production.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

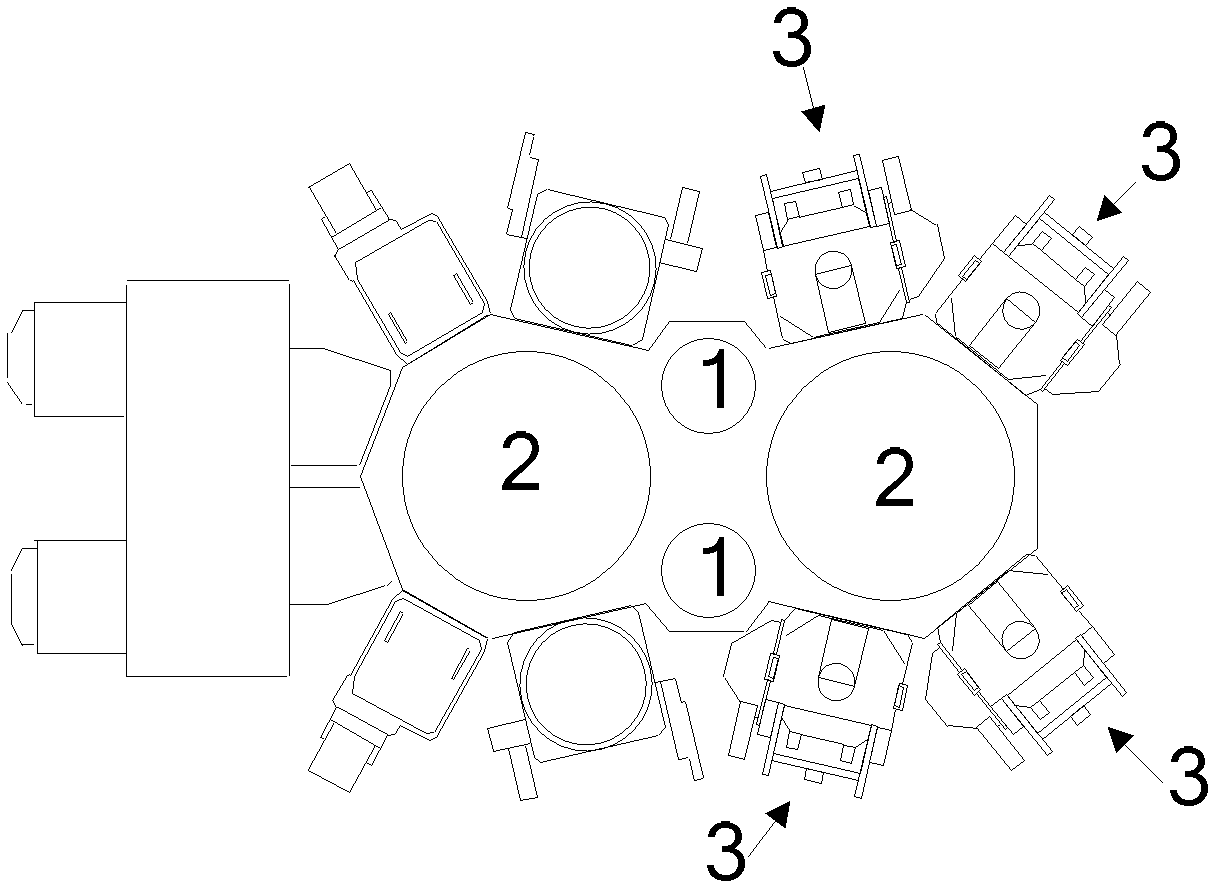

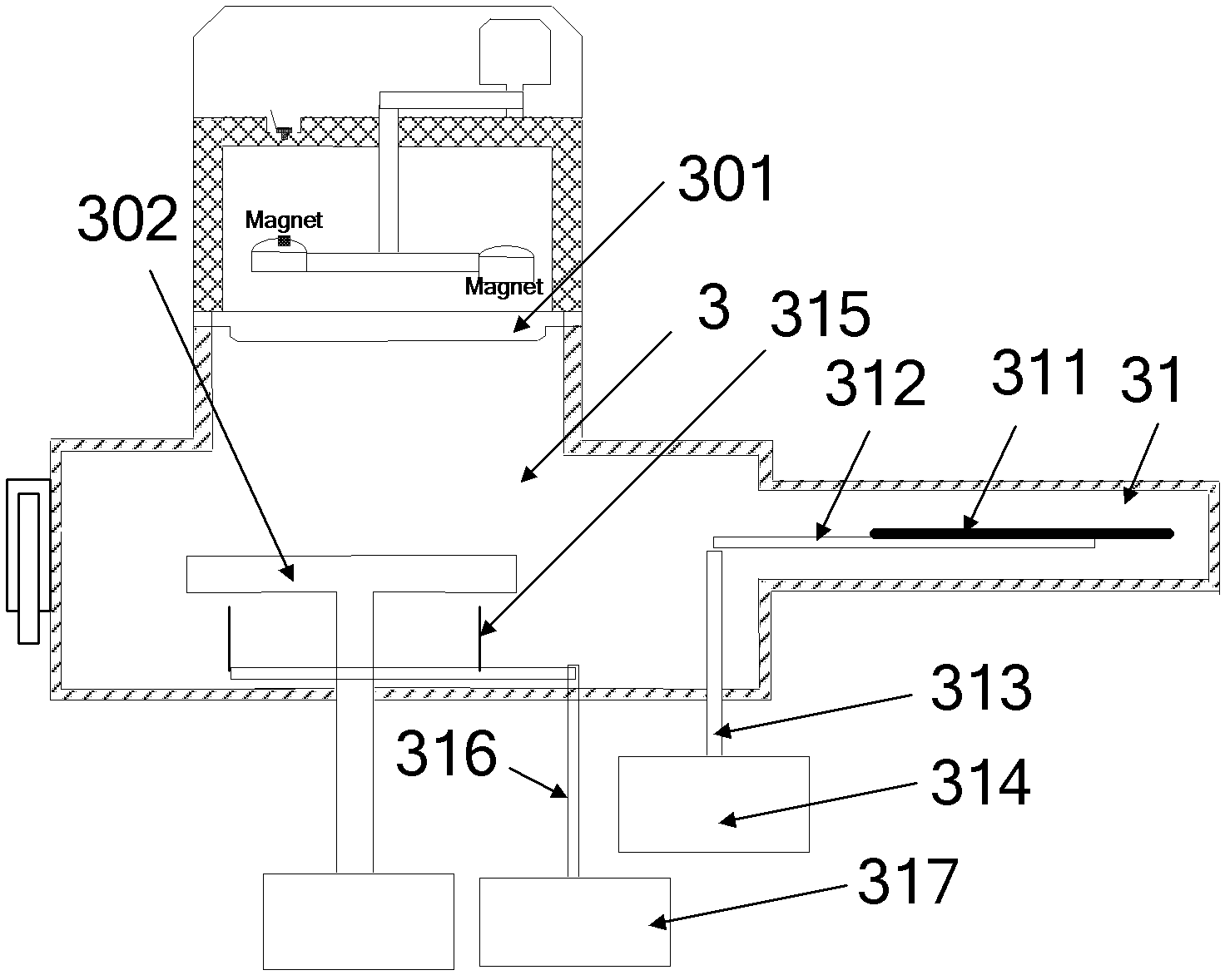

Magnetron sputtering apparatus and process

ActiveCN103173730ASimple structureReduce manufacturing costVacuum evaporation coatingSputtering coatingSputteringEngineering

The invention provides a magnetron sputtering apparatus and process. The magnetron sputtering apparatus comprises a loading / unloading chamber, a reaction chamber and a transmission chamber, wherein the loading / unloading chamber is used for loading and unloading a processed workpiece; an electrostatic chuck for supporting the processed workpiece is arranged in the reaction chamber; a mechanical arm for transmitting the processed workpiece between the loading / unloading chamber and the reaction chamber is arranged in the transmission chamber; an obstruction tray for obstructing the surface of the electrostatic chuck is arranged outside the reaction chamber; when the surface of the electrostatic chuck needs to be obstructed, the obstruction tray is transmitted to a position above the electrostatic chuck through the mechanical arm; and when the surface of the electrostatic chuck does not need to be obstructed, the obstruction tray is transmitted from the position above the electrostatic chuck to the outside of the reaction chamber through the mechanical arm. Thus, the invention reduces the volume of the reaction chamber, simplifies the structure of the magnetron sputtering apparatus and lowers the manufacturing cost of the magnetron sputtering apparatus.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Gypsum type rapid precision casting method for nonferrous metal

The invention relates to a gypsum type rapid precision casting method for nonferrous metal. The gypsum type rapid precision casting method is characterized by including the steps that a rapid prototype part of a to-be-cast part, a runner rapid prototype part, a riser rapid prototype part and an air channel rapid prototype part are manufactured through a 3D printer and placed in prepared gypsum slurry, and air pipe joint inserts are sleeved with the air channel rapid prototype part; a dried gypsum mold is heated, the rapid prototype part of the part, the runner rapid prototype part, the riser rapid prototype part and the air channel rapid prototype part are burnt out, and then a part cavity, a runner, an air channel and a riser are formed in a gypsum casting mold; the gypsum casting mold is placed in a casting box, the periphery of the gypsum casting mold is filled with dry sand, and a sprue cup is placed in an opening in the upper end of the runner; the gypsum casting mold is fixed through a pressing beam and a rubber pressing block for vibration and compaction, and then the part cavity, the runner, the air channel and the riser are vacuumized; and nonferrous metal casting liquid is poured which vibration is carried out, vibration is stopped after pouring is finished, the gypsum casting mold is taken out, and a needed casting is obtained. The casting quality of the nonferrous metal part can be improved, and the beneficial effects of being easy and convenient to operate and the like are achieved.

Owner:苏州森斯杰网络科技有限公司

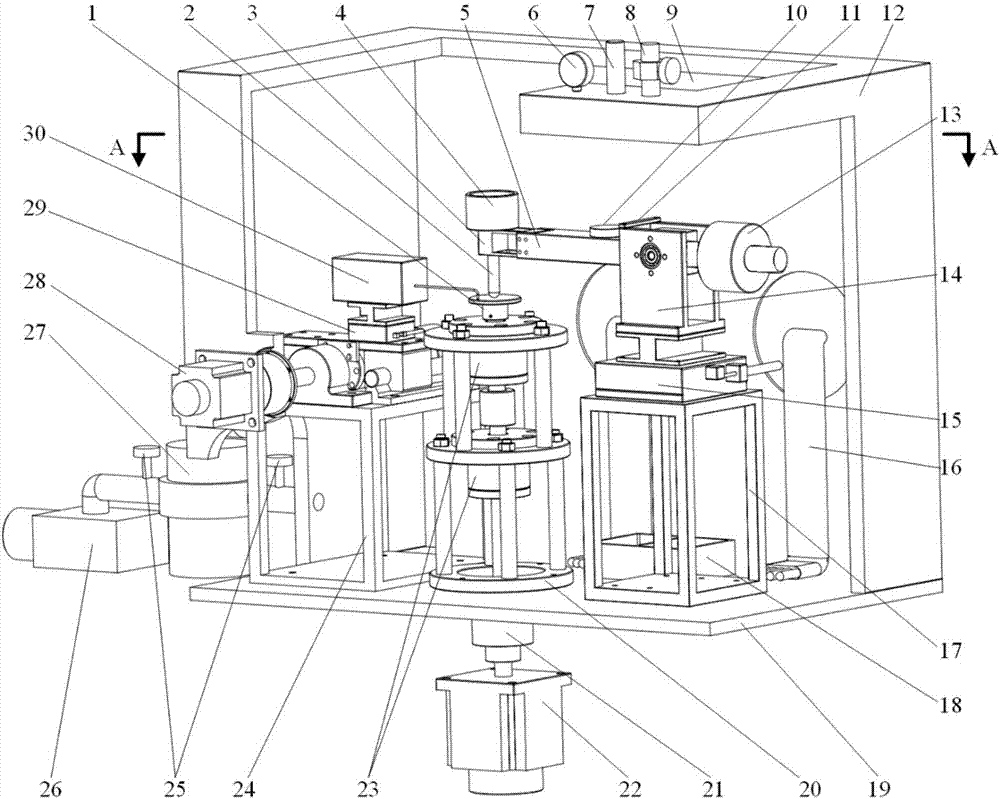

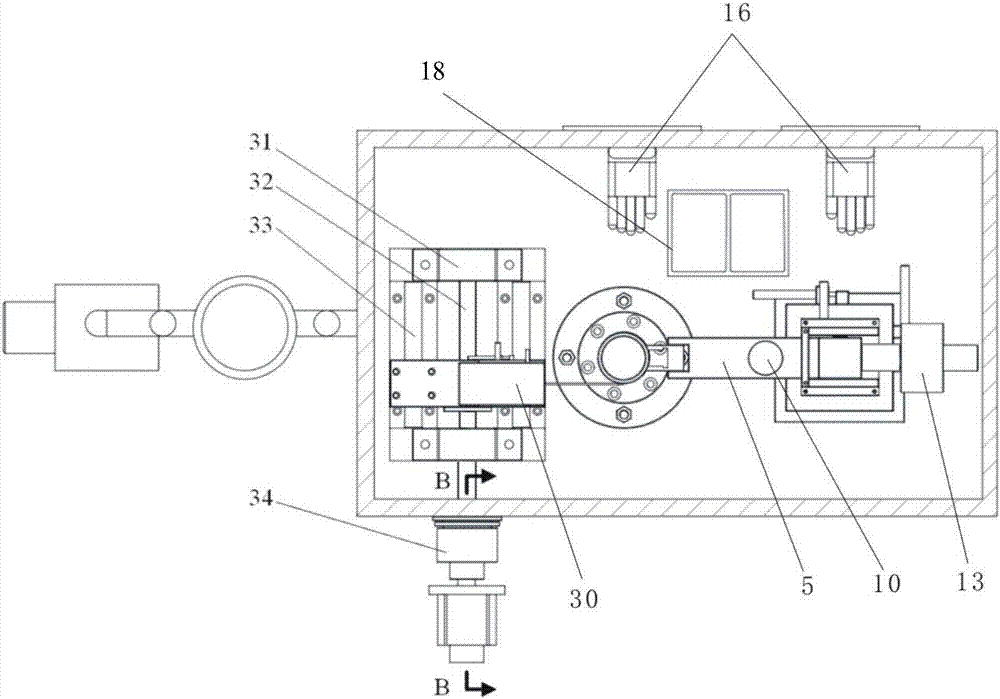

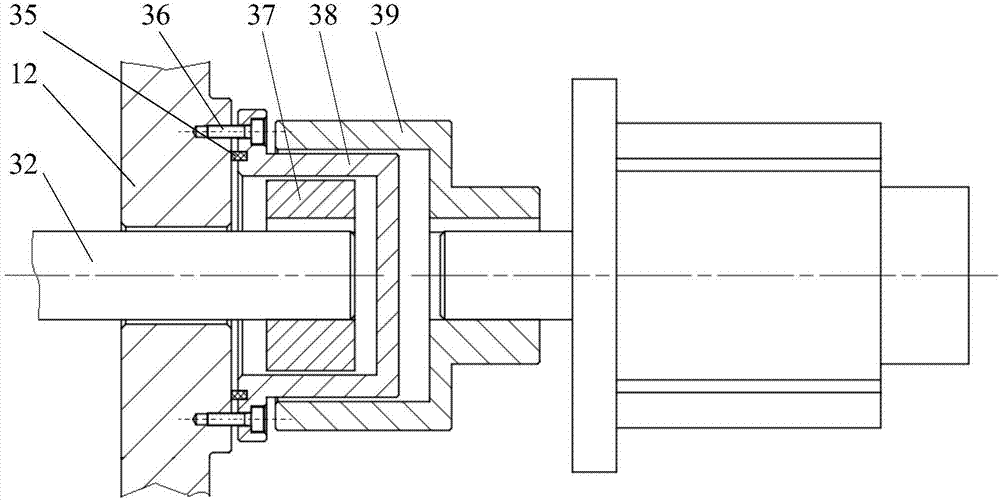

Friction wear testing device for online measuring abrasion loss in vacuum environment

InactiveCN107356524ARealize online measurementReduce leakageUsing mechanical meansMaterial analysisTest efficiencyWear testing

The invention discloses a friction wear testing device for online measuring abrasion loss in a vacuum environment. The testing device comprises a friction coefficient measuring mechanism arranged on a substrate and a wear surface contour measuring mechanism. The testing device also comprises a vacuum cap. The vacuum cap is covered on the substrate so as to form a vacuum environment between the vacuum cap and the substrate. The testing device can quickly evaluate the friction wear property of a material in a vacuum environment. The vacuumizing is only performed once during the experiment process, moreover, the vacuumizing time is shortened, frequent vacuumizing is avoided, the test efficiency is largely improved, and furthermore, the friction radius can be adjusted flexibly. At the same time, linear speeds in a wide range can be obtained through changing the rotation speed of a motor, the cost is low, the sealing performance is good, and the maintenance during the using process can be performed more conveniently.

Owner:XIAN UNIV OF TECH

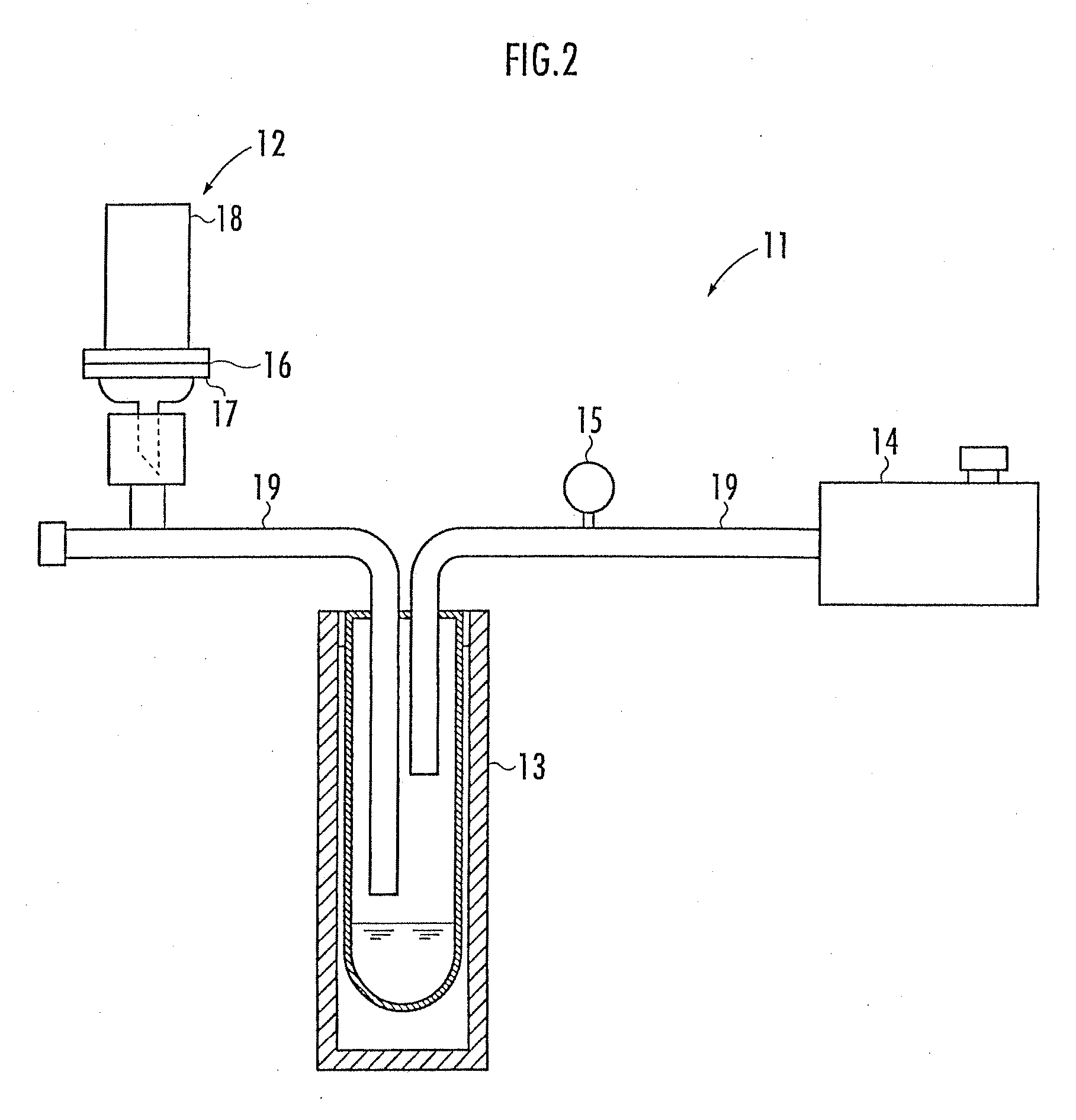

High-purity high-homogenization casting method of magnesium alloy and magnesium-lithium alloy

The invention discloses a high-purity high-homogenization casting method of magnesium alloy and magnesium-lithium alloy. The method comprises the following steps: (1) putting fully preheated magnesiumingots into a smelting crucible, and protecting the melt by adopting vacuum and inert gas; (2) performing electrifying to melt the magnesium ingots, adding alloying raw materials, keeping argon gas introduction in the feeding process, and adjusting the argon gas pressure to 1*10<5>Pa; (3) pushing the melt to carry out underflow type transfer injection by utilizing potential energy difference andgas pressure difference; and (4) carrying out homogenization solidification and waste heat homogenization on the melt. The invention realizes high-efficiency and continuous casting production of magnesium-lithium alloy ingot blanks and the casting. The reinjection process becomes simple and efficient by undercurrent reinjection. Through capturing of the valley bottom of a U-shaped solid-liquid interface in real time, the solid phase region at the lower part of the valley bottom of the solid-liquid interface starts to be homogenized at a constant temperature when the temperature of a core partis close to the solidus temperature, so that solidification shrinkage is reduced, and the cracking risk of a large ingot is greatly reduced.

Owner:GRIMAT ENG INST CO LTD

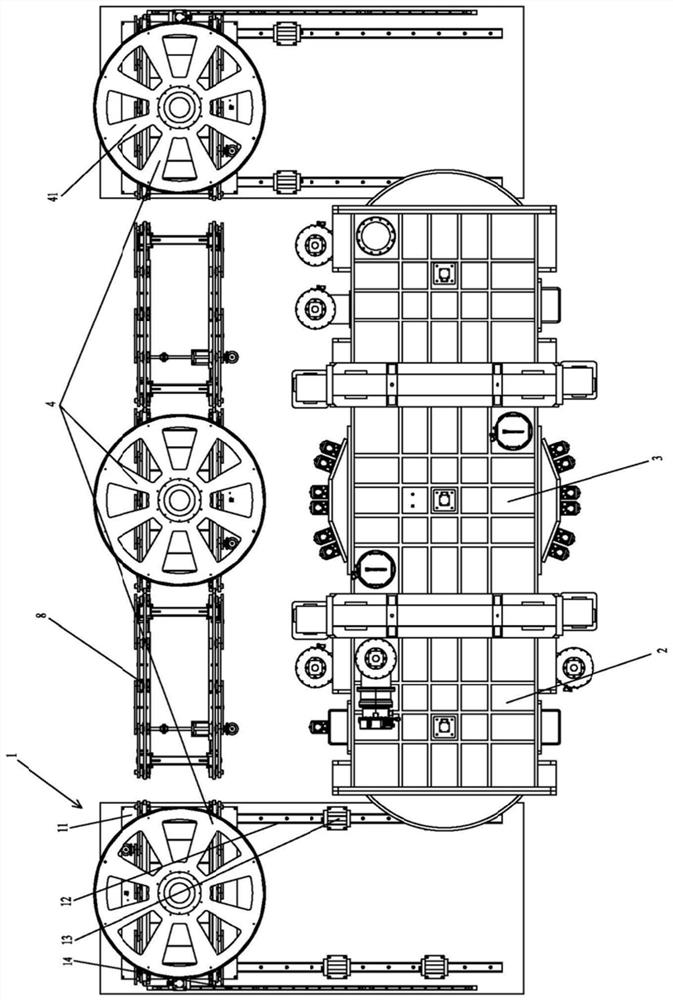

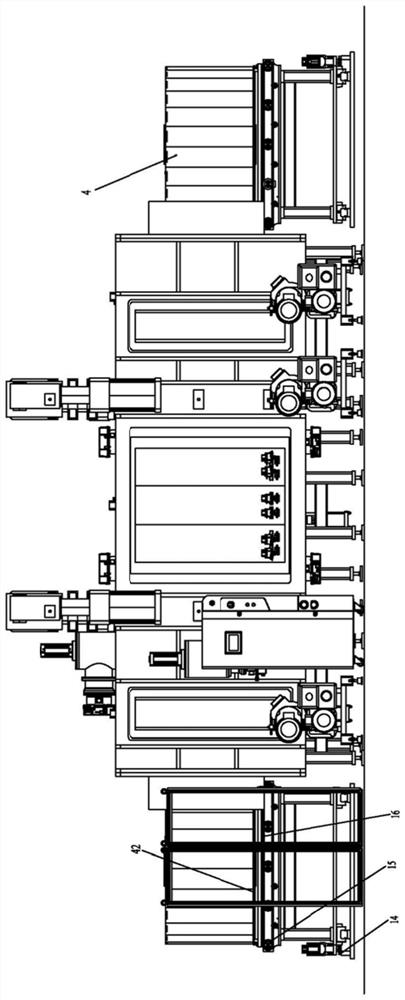

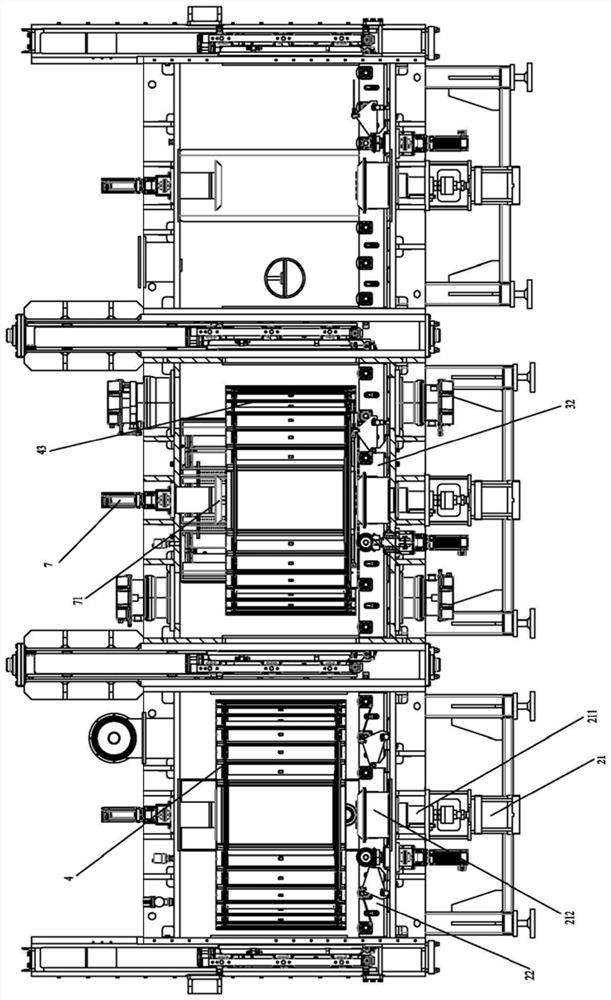

Vacuum welding equipment capable of automatically detecting weld joint and using method of vacuum welding equipment

InactiveCN109570725AReduce vacuum timeIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLiquid nitrogen

The invention provides vacuum welding equipment capable of automatically detecting a weld joint and a using method of the vacuum welding equipment. The vacuum welding equipment comprises a vacuum device, a welding vacuum chamber, a feeding vacuum chamber, an electron beam welding device, a welding worktable, an argon arc welding device, a nitrogen generation device and a weld joint detecting device; the welding vacuum chamber and the feeding vacuum chamber are provided with a piston sealing plate and a lifting sealing plate correspondingly; the electron beam welding device is arranged on the piston sealing plate, and the welding worktable can be overturned by 180 degrees and rotated by 360 degrees; the argon arc welding device is mounted on the piston sealing plate in a replaceable mode, and the nitrogen generation device can provide liquid nitrogen for a welding gun and a weldment for cooling; and the weld joint detecting device is arranged at the bottom of a feeding conveying belt. Adetecting frame is arranged to be of a semi-arc structure and can rotate, detection through a probe on the detecting frame is more thorough, when the weldment is transferred out from the equipment, the quality of the weld joint of the weldment can be quickly, conveniently and accurately detected, and the production efficiency is effectively improved.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

Vacuum welding equipment with supersonic aging function and application method of vacuum welding equipment

InactiveCN109570724AHeating evenlyUniform and stable air quenchingWelding/cutting auxillary devicesAuxillary welding devicesNitrogenLiquid nitrogen

The invention provides vacuum welding equipment with an supersonic aging function and an application method of the vacuum welding equipment. The vacuum welding equipment comprises a vacuum device, a welding vacuum chamber, a feeding vacuum chamber, an electron beam welding device, a welding working table, an argon arc welding device, a nitrogen making device, and an supersonic aging device. The welding vacuum chamber and the feeding vacuum chamber are separately provided with a piston sealing plate and a lifting sealing plate. The electron beam welding device is arranged on the piston sealingplate. The welding working table can rotate at 180 degrees and 360 degrees. The argon arc welding device is mounted on the piston sealing plate in a replacing mode. The nitrogen making device can provide liquid nitrogen for a welding gun and a weldment for cooling. The supersonic aging device is arranged on a conveying belt. Continuous production is achieved. The size of the vacuum chamber can beadjusted based on the size of the weldment. Impurities of the weldment can be shaken off before the weldment entering the vacuum chamber. The supersonic aging is adopted to remove welding stress afterwelding. The fatigue life of a welding structure is prolonged. The welding quality is guaranteed.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

Vacuum welding equipment with interlayer for cooling and heating and application method of vacuum welding equipment

InactiveCN109570723AReduce vacuum timeIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesHeat conductingEngineering

The invention provides vacuum welding equipment with an interlayer for cooling and heating and an application method of the vacuum welding equipment. The vacuum welding equipment comprises a vacuum device, a welding vacuum chamber, a feeding vacuum chamber, an electron beam welding device, a welding working table, an argon arc welding device, a nitrogen making device, and a heat exchanging device.The welding vacuum chamber and the feeding vacuum chamber are separately provided with a piston sealing plate and a lifting sealing plate. The electron beam welding device is arranged on the piston sealing plate. The welding working table can rotate at 180 degrees and 360 degrees. The argon arc welding device is mounted on the piston sealing plate in a replaceable mode. The nitrogen making devicecan provide liquid nitrogen for a welding gun and a weldment for cooling. The heat exchanging device is connected to a vacuum chamber interlayer. Continuous production is achieved. The size of the vacuum chamber can be adjusted based on the size of the weldment. Welding technologies can be shifted. A welding smoke processing device is arranged, so that environment protection is achieved. The interlayer is arranged in the vacuum chamber. The interlayer is filled with heat conducting oil for cooling or heating. The requirements for temperatures of different welding technologies can be met.

Owner:GUANGXI NANNING SHENGQIAN TECH DEV CO LTD

Weak-atmosphere environment laser welding device and method

PendingCN111633328AReduce vacuum timeImprove welding efficiencyLaser beam welding apparatusShielding gasDust control

The invention discloses a weak-atmosphere environment laser welding device and method. The method comprises the following steps that S1, a to-be-welded workpiece is placed into a working cabin, a gasstorage device and an exhaust device are protected, and the atmosphere environment inside the working cabin forms the protective gas atmosphere under low vacuum; S2, a gas circulation device is turnedon, a welding head emits laser and penetrates through a light transmitting lens arranged on the surface of the working cabin, the to-be-welded workpiece is welded, and after welding, the workpiece istaken out. Within a short period of time, the weak-atmosphere environment applicable to laser welding is achieved, the traditional mode of achieving laser welding environment through vacuumizing is changed, the vacuumizing time is shortened, and the welding efficiency is improved. Gas circular purification under the weak atmosphere environment is achieved, dust removal and purification are performed on smoke and dust inside the working cabin in time, and long-time operation and high-quality welding in the laser welding process are ensured.

Owner:武汉光谷航天三江激光产业技术研究院有限公司

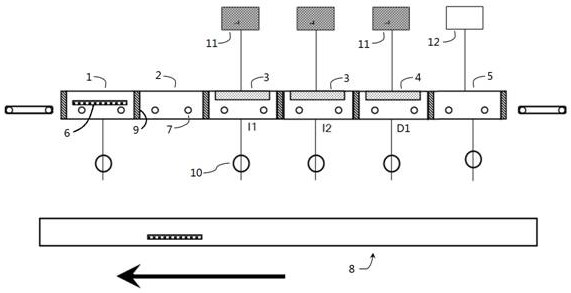

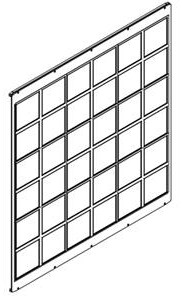

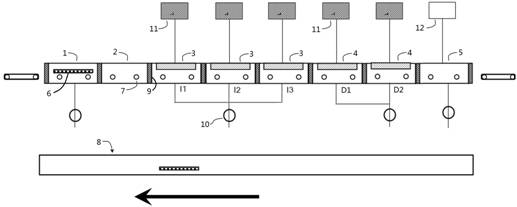

Film coating equipment, method and system, solar cell, assembly and power generation system

ActiveCN111739971AReduce processing waiting timeImprove processing efficiencyFinal product manufactureChemical vapor deposition coatingHeterojunctionEngineering

The invention discloses heterojunction solar cell coating equipment, method and system, a solar cell, an assembly and a power generation system, and belongs to the field of solar cell processing. Theheterojunction solar cell coating equipment is used for depositing a heterojunction solar cell amorphous silicon-based thin film, and comprises a process cavity, wherein the process cavity comprises at least two intrinsic process cavities used for deposition of an intrinsic layer silicon thin film process, and at least one doping process cavity used for deposition of an N-type silicon film or P-type silicon film process, and the cavities in the intrinsic process cavities and the doping process cavity are isolated by isolation valves. By combining the control of gas proportion and pressure, theequipment can process a plurality of solar cells at the same time, so that the overall processing efficiency is greatly improved, and the equipment is suitable for commercial use.

Owner:SUZHOU MAIZHENG TECH CO LTD

Method for sealing vacuum glass exhaust tube

InactiveCN101602569AAccurate radiationImprove seal qualityGlass reforming apparatusBreakage rateEngineering

The invention relates to a method for sealing a vacuum glass exhaust tube. The exhaust tube outside a base glass is provided with an induction medium, a gap of 0 to 5 millimeters is reserved between the induction medium and the end face of the base glass, an induction coil is arranged outside the induction medium, the induction coil is connected with a variable frequency induction device and heats the induction medium, and the induction medium finishes sealing the exhaust tube by heating and melting the exhaust tube through radiant heat. By using a variable frequency induction heating mode to heat and seal the exhaust tube, a tail tube of the exhaust tube is parallel to or lower than the base glass, the plain-end tailless sealing of the exhaust tube is realized, the vacuum glass is convenient to transport and mount and has attractive appearance, and the breakage rate is reduced; and the method is suitable for automatic production and operation, solves the unsolved problems up to now at home and abroad, and contributes to the vacuum glass industry.

Owner:左树森

Preparing method for enhanced breathable insulating materials

The invention discloses a preparing method for enhanced breathable insulating materials. alkali-free glass fiber and water drawing glass fiber are as raw materials, the alkali-free glass fiber and water drawing glass fiber are enabled to be mixed, meanwhile, white water is added in, achieved mixed liquor is stirred to be in a suspension dispersed state, then mixed liquor of alkali-free glass fiber and the white water is added in, and pulping is continuously to be done; formed seriflux is enabled to be transported to a multitube seriflux arranging machine through a stainless steel screw pump, the seriflux through the multitube seriflux arranging machine enters a breast box and flows naturally to a forming part to form a wet paper sheet, the wet paper sheet is enabled to be secondary formed through a press roll, then the wet paper sheet achieved through the steps is sent into a natural gas tunnel-type drying oven, and a rough blank is achieved; the dried rough blank is enabled to be parted off and rolled up according to demanded specification, and then the needed enhanced breathable insulating materials are achieved.

Owner:JIANGSU DALI ENERGY SAVING TECH CO LTD

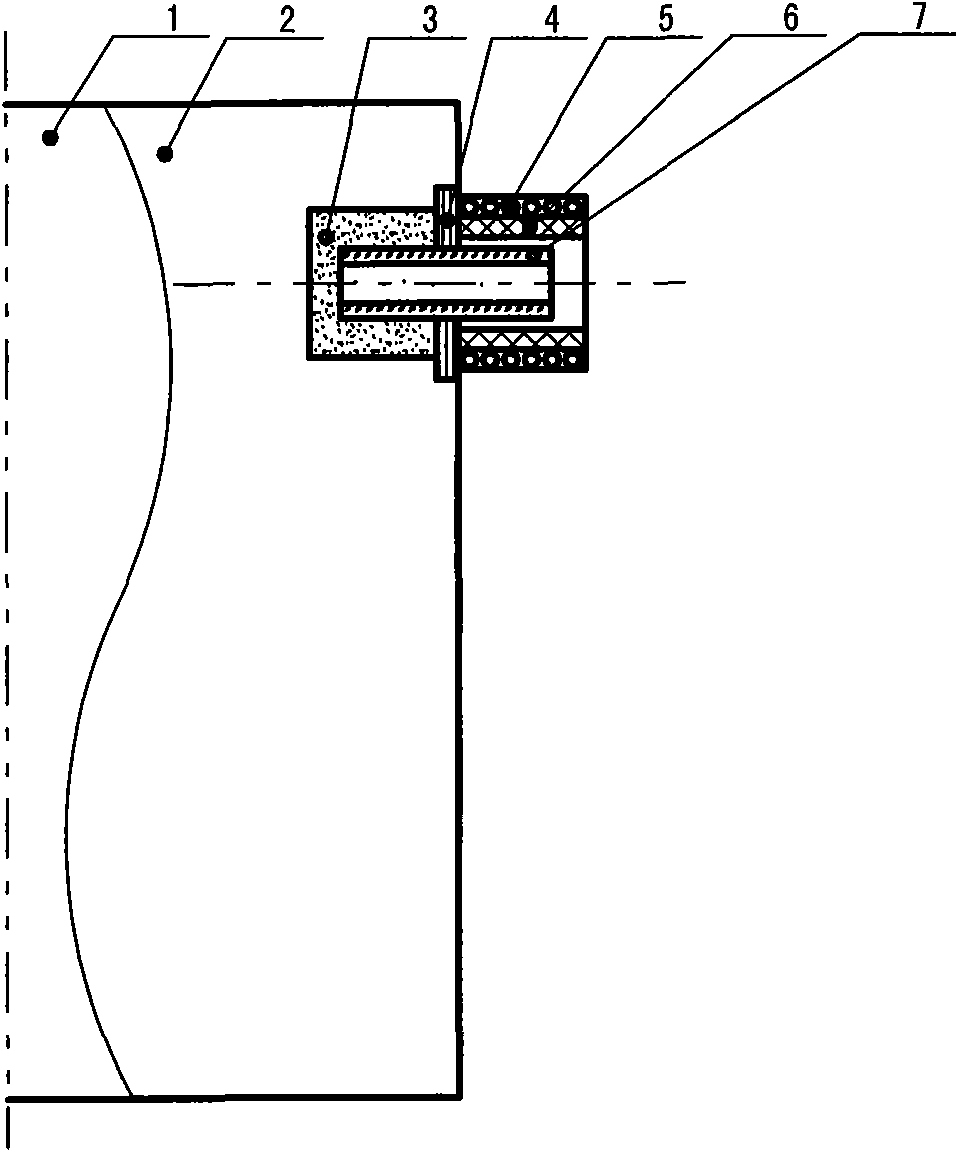

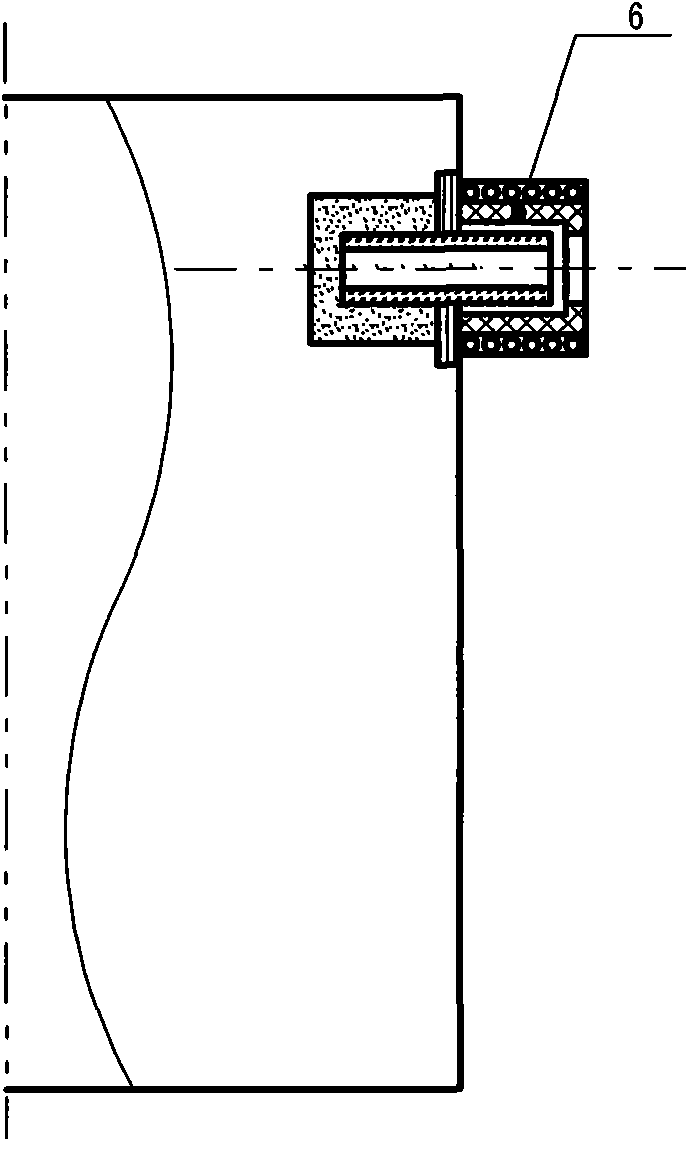

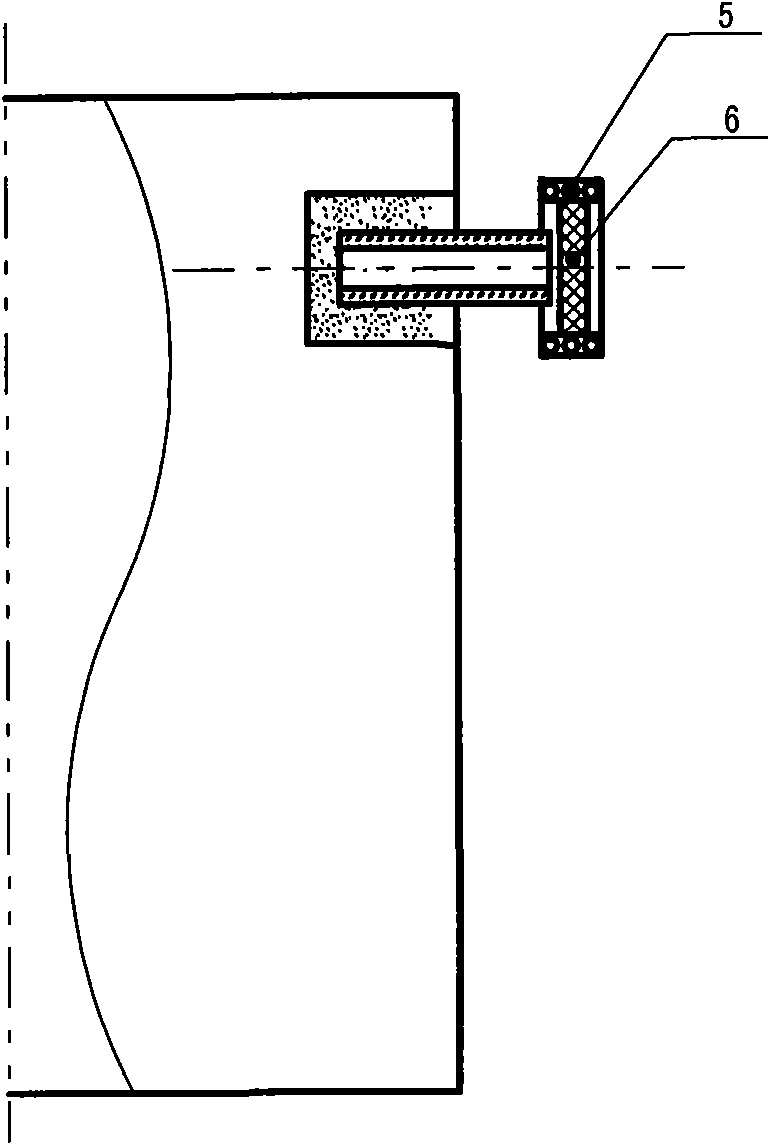

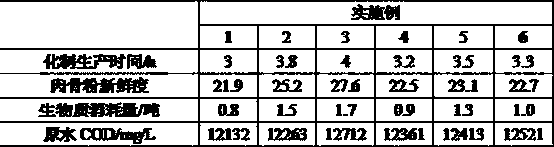

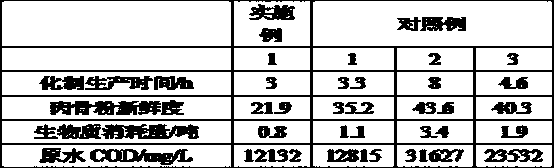

Harmless treatment process for sick and dead livestock and poultry

InactiveCN110180867AReduce decayIncrease contact areaTransportation and packagingSolid waste disposalDisinfectantWater quality

The invention relates to a harmless treatment process for sick and dead livestock and poultry. The harmless treatment process comprises the following steps of (1), disinfecting sick and dead livestockand poultry corpses with disinfectants; (2), transporting the disinfected corpses of the sick and dead livestock and poultry to a crusher for crushing, and crushing the corpses into 5 cm meat pieces;(3), spraying the disinfectants on the surfaces of the meat pieces, and pumping the meat pieces into a rendering pot for rendering; and (4), after separating oil and fat, transferring materials intoa reactor, adding medicines into the reactor, stirring uniformly, standing, discharging the upper layer of clean water into a sewage treatment tank, transferring the lower layer of the materials to afilter press for filter pressing, and drying filter cakes to obtain meat and bone meal. The harmless treatment process for the sick and dead livestock and poultry has the advantages of simple operation, low energy consumption, low production cost, low water content of the meat and bone meal and the like, and the quality of raw sewage water is stable.

Owner:东营市利民无害化处理有限公司 +1

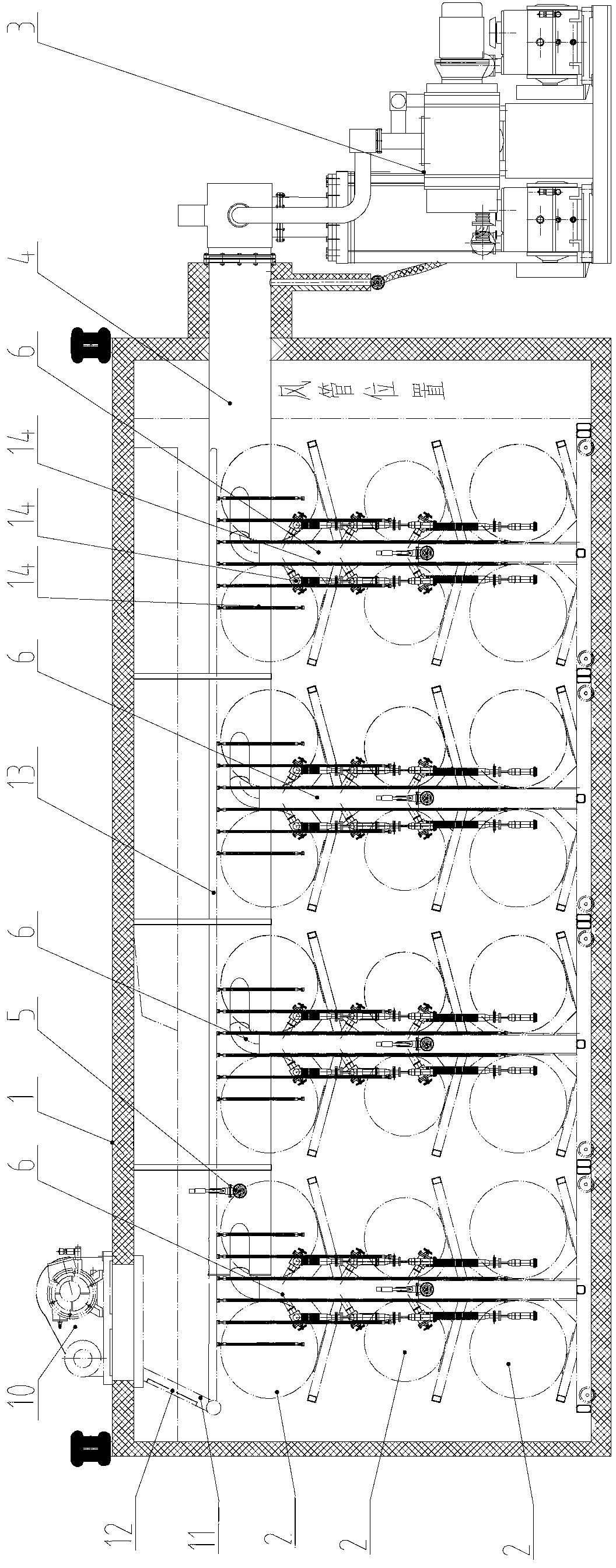

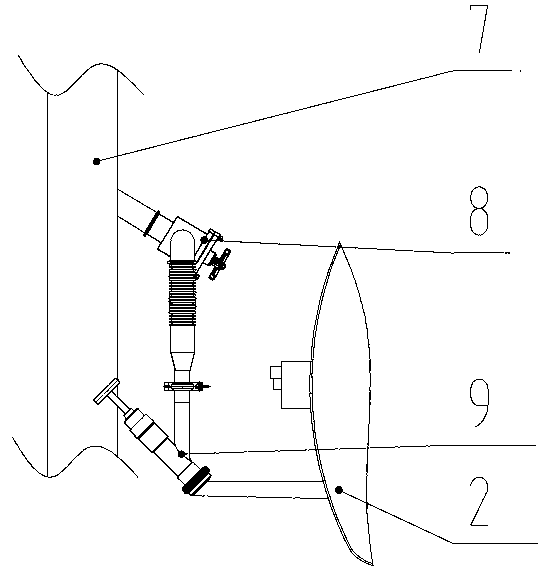

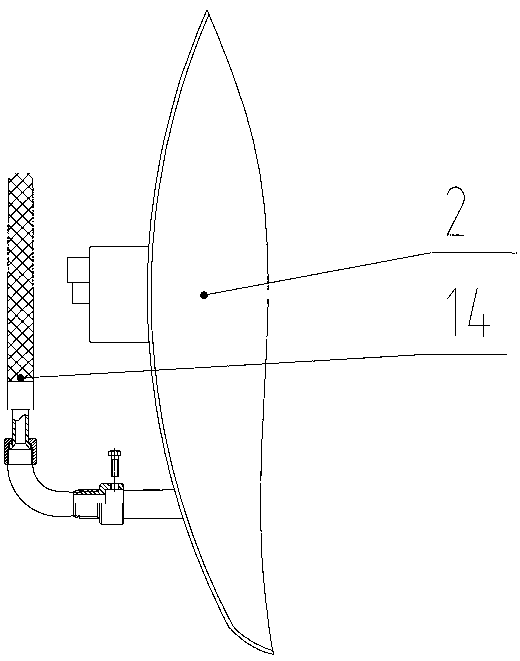

Low-temperature gas cylinder vacuuming system

The invention discloses a low-temperature gas cylinder vacuuming system comprising a furnace body, a plurality of gas cylinder to be pumped arranged in the inner cavity of the furnace, and a vacuuming set communicating with the gas cylinders to be pumped. The vacuuming set is connected with a main pipe. A plurality of primary branch pipes are arranged on the main pipe. A plurality of secondary branch pipes are arranged on the primary branch pipes. The secondary branch pipes are corrugated pipes and are connected with the vacuuming ports of the gas cylinder to be pumped. The low-temperature gas cylinder vacuuming system provided by the invention has the advantages of high efficiency and good vacuuming effect.

Owner:ZHANGJIAGANG FURUI SPECIAL EQUIP CO LTD

Method for obtaining ultrahigh vacuum in vacuum electron beam welding of niobium materials

InactiveCN103143830AIncrease vacuumThe purity of niobium is goodElectron beam welding apparatusWelding/soldering/cutting articlesSacrificial metalNitrogen

The invention provides a method for obtaining ultrahigh vacuum in the vacuum electron beam welding of niobium materials, which includes the following steps: niobium workpieces and sacrificial metal are put into a welding vacuum room; the welding vacuum room is vacuumized by a vacuum system of a vacuum electron beam welding machine until ultimate vacuum is reached; the electron beam of the vacuum electron beam welding machine is used for bombarding the sacrificial metal, so that a weld crater is formed in the electron beam spot area of the surface of the heated sacrificial metal; and within ten minutes, the electron beam is started to weld the niobium workpieces within the shortest time. The method can be adopted to provide a higher vacuum environment for the welding of niobium materials, so that the welding of niobium materials can sufficiently avoid the pollution of oxygen, nitrogen and other gaseous impurities, and thereby better niobium material-welding purity can be obtained.

Owner:NINGXIA ORIENT SUPERCONDUCTOR TECH

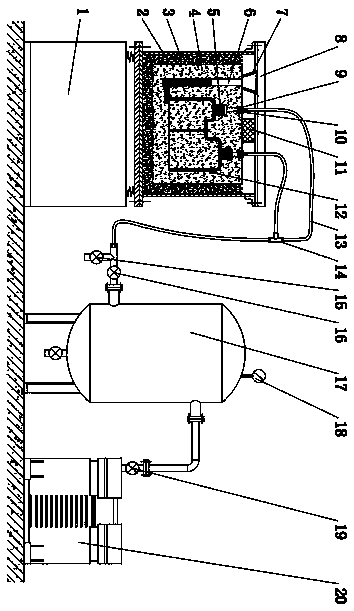

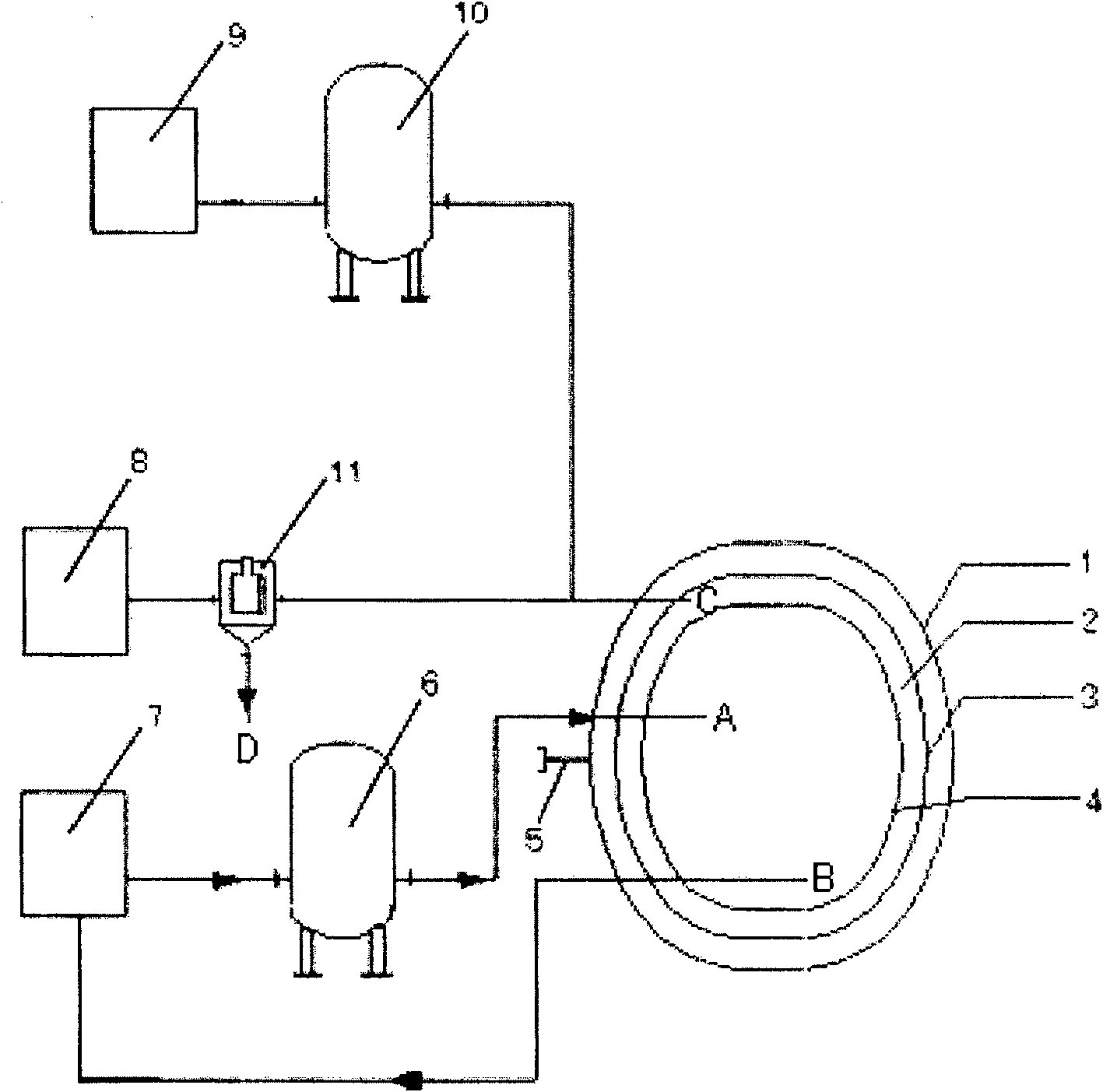

Vacuum-pumping method and apparatus thereof

ActiveCN100554682CReplace completelyReduce vacuum timePumpsPositive-displacement liquid enginesVacuum pumpingGas heater

The invention discloses a vacuuming method and a device thereof, which are used for vacuuming the interlayer between the outer cylinder and the inner cylinder of a multilayer heat-insulating container. Wherein the vacuum pumping device comprises: a first gas conveying device, which has a gas outlet; a first gas heater, whose inlet is connected with the gas outlet of the first gas conveying device, and whose outlet is connected with the air inlet of the inner cylinder pass; vacuum unit, which communicates with the interlayer; the second gas delivery device, which has a gas outlet; the second gas heater, whose inlet is connected with the gas outlet of the second gas delivery device, and whose outlet is connected with the interlayer connected. By adopting the vacuum pumping method and its device of the present invention, the vacuum pumping time of multi-layer thermal insulation storage tanks, tank containers, and tank trucks is shortened from 7-15 days to 3-6 days, which greatly shortens the time for high-vacuum multi-layer thermal insulation storage tanks. , tank container, tank car manufacturing cycle, reducing manufacturing costs.

Owner:CIMC VEHICLES (GROUP) CO LTD

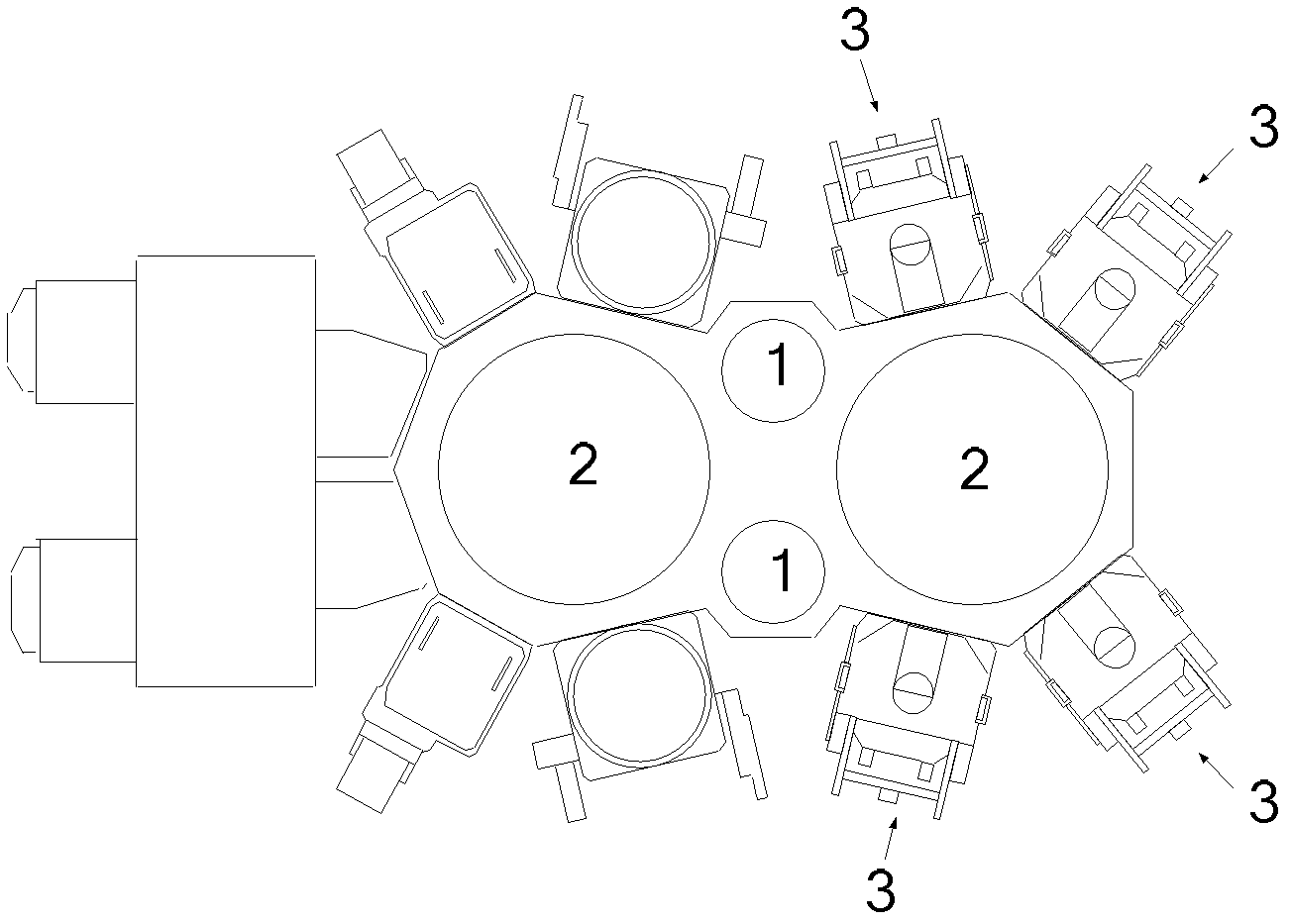

Multi-chamber continuous optical coating machine

ActiveCN112080731AReduce vacuum timeSave energyVacuum evaporation coatingSputtering coatingContinuous lightOptical coating

The invention discloses a multi-chamber continuous optical coating machine. The multi-chamber continuous optical coating machine comprises an operating mechanism, at least one transfer part, at leastone front chamber and at least one coating chamber. A plating part is arranged on a workpiece rotating rack, the transfer part is joined to the front chamber, the front chamber is joined to the coating chamber, the transfer part, the front chamber and the coating chamber form a coating channel of the plating part, the front chamber and the coating chamber are provided with vacuum equipment independently, the front chamber and the coating chamber are independent sealing cavities, and the workpiece rotating rack rotates in the coating chamber through the operating mechanism. The invention provides the multi-chamber continuous optical coating machine which improves the coating efficiency and saves the energy sources, and the coated plating part is uniform in film thickness.

Owner:XIANGTAN HONGDA VACUUM TECH CO LTD

Method for vacuumizing cavity

ActiveCN101877302AReduce vacuum timeShorten the timeVacuum evaporation coatingSputtering coatingSecondary stageEngineering

The invention relates to a method for vacuumizing a semiconductor process thin film deposition cavity, which comprises the following steps of: providing a semiconductor process thin film deposition cavity, carrying out air exhaust on the semiconductor process thin film deposition cavity by using a low vacuum pump, carrying out second stage air exhaust by using a high vacuum pump to adjust a baffle plate to block a wafer, heating an air absorbing material in a crucible by using a heater to generate steam used for capturing residual gas in the cavity to form a compound, deposing the compound on the baffle plate until reaching the target vacuum degree, stopping heating the air absorbing material, and opening the adjustable baffle plate for carrying out the next procedure.

Owner:MOSEL VITELIC INC

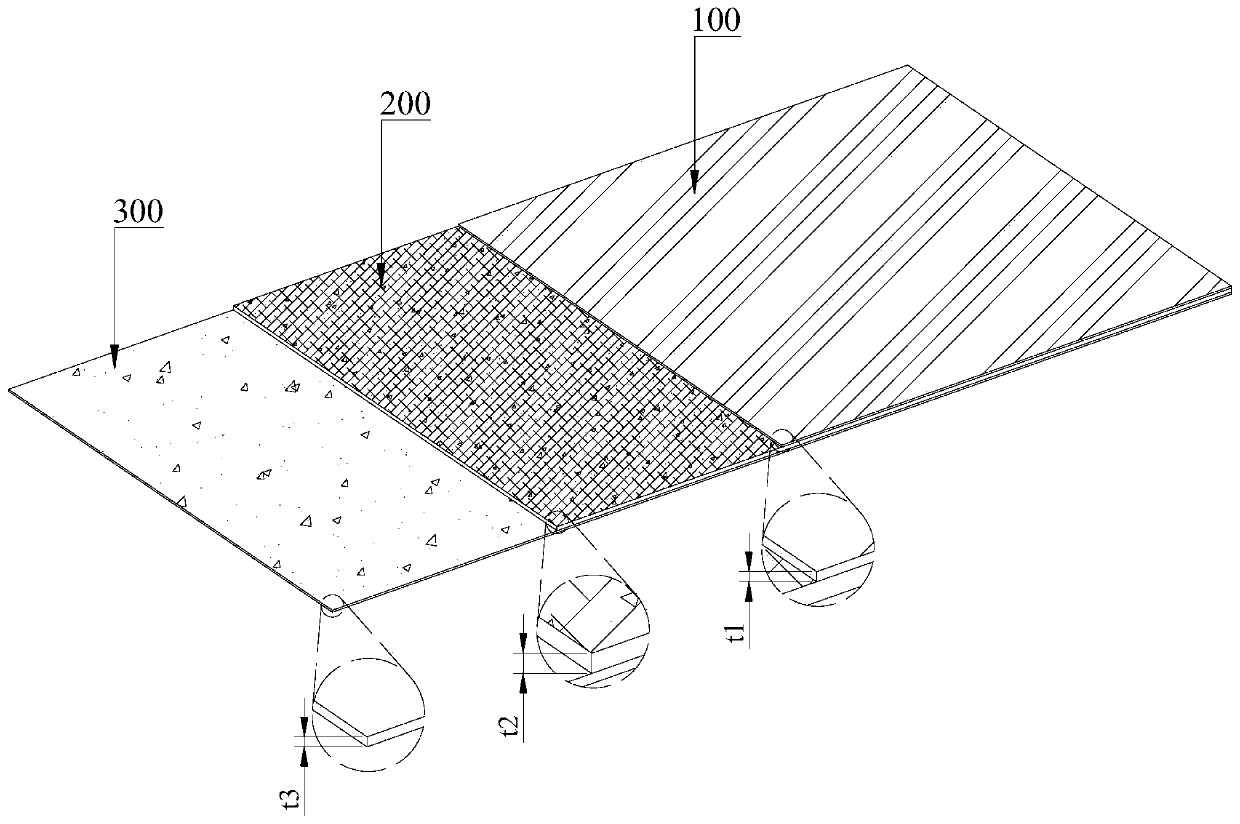

Organic fiber toughened inorganic composite artificial stone panel and preparation method thereof

InactiveCN110746152AImprove compactnessImprove production efficiencyCovering/liningsFeeding arrangmentsFiberArtificial stone

Owner:黄贺明 +1

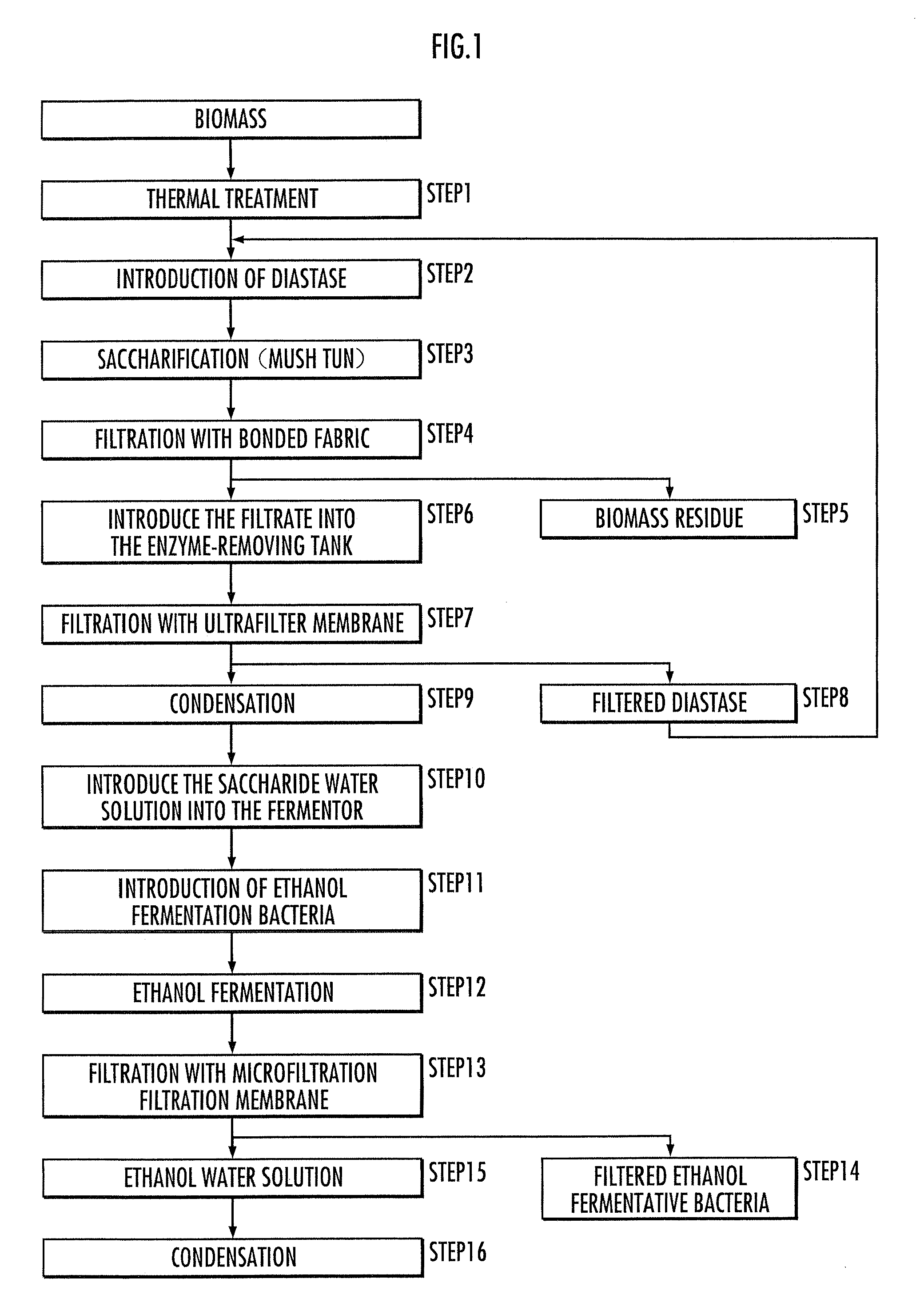

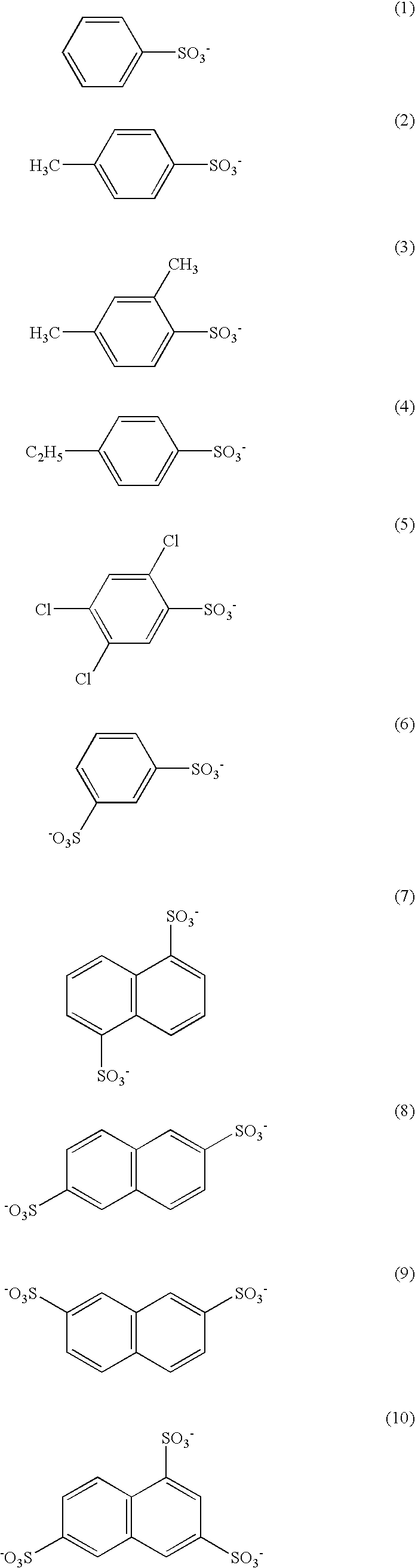

Ethanol preparation method

Provided is a method for preparing ethanol in high efficiency. The ethanol preparation method includes a step of yielding a saccharide water solution through saccharification of cellulose with an enzyme in water, a step of condensing the saccharide water solution, and a step of yielding an ethanol water solution by fermenting the saccharide in the condensed saccharide water solution into ethanol, wherein the step of condensing the saccharide water solution is performed through a pervaporation treatment on the saccharide water solution by using a water separation membrane composed of polypyrrole doped with a sulfonate ion.

Owner:HONDA MOTOR CO LTD

Split magnesium-lithium alloy vacuum smelting furnace

InactiveCN102767948AReduce vacuum timeIncrease productivityFurnace typesMagnesiumElectromagnetic valve

A split magnesium-lithium alloy vacuum smelting furnace comprises a primary material feeding furnace. The primary material feeding furnace is communicated with a material feeding mechanism through a vacuum electromagnetic valve, the material feeding mechanism is further communicated with a secondary smelting furnace, the secondary smelting furnace is communicated with a tertiary casting furnace through a second electromagnetic valve, and one side of the secondary smelting furnace is further connected with a vacuumizing device. After the vacuumizing device vacuumizes the primary material feeding furnace, the secondary smelting furnace and the tertiary casting furnace, the primary material feeding furnace and a secondary smelting furnace cavity are disconnected through the vacuum electromagnetic valve, the secondary smelting furnace cavity and a tertiary casting furnace cavity are disconnected through the second electromagnetic valve, vacuum degree in a primary material feeding furnace cavity, the secondary smelting furnace cavity and the tertiary casting furnace cavity is respectively kept, and material loading, smelting and casting processes are respectively finished in the primary material feeding furnace, the secondary smelting furnace and the tertiary casting furnace. The split magnesium-lithium alloy vacuum smelting furnace has the advantages of being high in vacuumizing efficiency and production efficiency and achieving large-scale production.

Owner:西安四方超轻材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com