Harmless treatment process for sick and dead livestock and poultry

A technology for harmless treatment of sick and dead livestock and poultry, applied in the field of harmless treatment of sick and dead livestock and poultry, can solve the problems of high freshness of meat and bone meal, unstable raw water quality and high processing cost, shortening the vacuuming time, reducing The effect of removing water and energy consumption and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

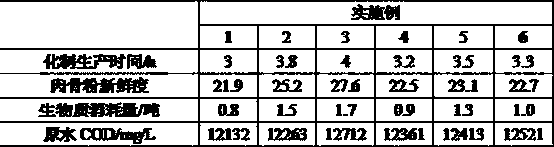

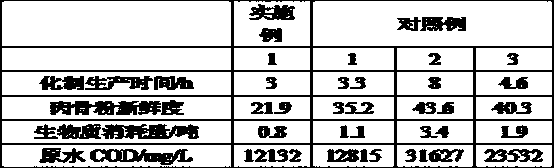

Examples

Embodiment 1

[0025] A harmless treatment process for sick and dead livestock and poultry, the treatment process includes the following steps:

[0026] (1) Disinfection treatment:

[0027] Carry out spray disinfection treatment to the corpses of 10 tons of sick and dead livestock and poultry with decyl ammonium bromide;

[0028] (2) Crushing treatment:

[0029] Transport the sterilized carcasses of dead livestock and poultry to the crusher for crushing, and crush them into meat pieces with a size of 5cm;

[0030] (3) High temperature system:

[0031] Spray decyl ammonium bromide on the surface of the meat, pump the meat to the chemical tank, control the temperature of the chemical tank at 145°C and 0.5MPa for heat treatment for 0.8h;

[0032] (4) Oil-water slag separation process:

[0033] Under the conditions of high temperature and positive pressure, the oil in the chemical tank is separated from the chemical tank to the oil-water separation tank through positive pressure, and the oil...

Embodiment 2

[0035] A harmless treatment process for sick and dead livestock and poultry, the treatment process includes the following steps:

[0036] (1) Disinfection treatment:

[0037] Spray and disinfect 10 tons of sick and dead livestock and poultry corpses with hypochlorite;

[0038] (2) Crushing treatment:

[0039] Transport the sterilized carcasses of dead livestock and poultry to the crusher for crushing, and crush them into meat pieces with a size of 5cm;

[0040] (3) High temperature system:

[0041] Spray hypochlorite on the surface of the meat, pump the meat to the chemical tank, control the temperature of the chemical tank at 135°C and 0.25MPa for heat treatment for 3 hours;

[0042] (4) Oil-water slag separation process:

[0043] Under the conditions of high temperature and positive pressure, the oil in the chemical tank is separated from the chemical tank to the oil-water separation tank through positive pressure, and the oil is pumped to the oil storage tank after sepa...

Embodiment 3

[0045] A harmless treatment process for sick and dead livestock and poultry, the treatment process includes the following steps:

[0046] (1) Disinfection treatment:

[0047] Use peracetic acid to spray and disinfect 10 tons of dead livestock and poultry corpses;

[0048] (2) Crushing treatment:

[0049] Transport the sterilized carcasses of dead livestock and poultry to the crusher for crushing, and crush them into meat pieces with a size of 5cm;

[0050] (3) High temperature system:

[0051] Spray peracetic acid on the surface of the meat, pump the meat to the chemical tank, and control the temperature of the chemical tank to 200 ° C and 5 MPa for heat treatment for 0.5 h;

[0052] (4) Oil-water slag separation process:

[0053] Under the conditions of high temperature and positive pressure, the oil in the chemical tank is separated from the chemical tank to the oil-water separation tank through positive pressure, and the oil is pumped to the oil storage tank after separ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com