A preparation method of biological composite coating and intelligent colorimetric film material

A composite coating and colorimetric technology, applied in coatings, analytical materials, cellulose coatings, etc., can solve problems such as failure to meet the requirements of film use, failure to meet the needs of film formation, loss of flexibility, etc., to achieve reversibility and Good stability, extended shelf life, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

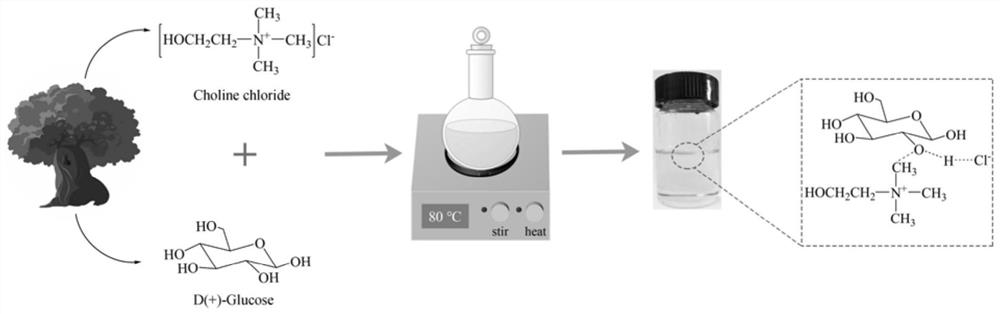

[0066] A preparation method for the preparation of deep co-solvents such as figure 1 Including the following steps:

[0067] Mix choline chloride and glucose at a mass ratio of 2:1, heat and stir in an oil bath at 80°C for 10 hours to obtain a colorless and transparent solution, which is a deep co-solvent.

[0068] By observing the table, it is found that the color of the deep co-solvent prepared in this embodiment is close to the transparent color.

Embodiment 2

[0069] Example 2 Preparation method optimization for preparing deep co-solvent

[0070] Adjustment 1: Adjust the glucose in Example 1 to sucrose, and keep the others unchanged to obtain a deep co-solvent.

[0071] It was found that the color of the prepared deep co-solvent was close to the transparent color.

[0072] Adjustment 2: Adjust the mass ratio of choline chloride and glucose in Example 1 to 10:1, 5:1, 1:1 and 1:5, and keep the others unchanged to obtain a deep co-solvent.

[0073] Result finds, along with the increase of choline chloride consumption, the color of co-solvent is deepened, affects the color of film itself, and is easy to solidify under normal temperature, and then is difficult to obtain application in fresh-keeping; If the amount of choline chloride is too little ( Choline chloride and glucose=1:5), the time required to form a solution is longer, and its plasticization and color enhancement are very poor; after combining with hydroxypropyl guar gum and ...

Embodiment 3

[0077] A preparation method of biological composite coating, comprising the steps of:

[0078] Dissolve 0.6g of hydroxypropyl guar gum in 60g of water for later use, add 20g of nanocellulose crystals, and then add different amounts of deep co-solvents (0, 0.1, 0.2, 0.3, 0.4g) and 0.1g of Anthocyanin, stirring at room temperature, stirring speed is 500rpm, stirring time is 3h; obtain film-forming liquid; then soak fresh blueberries, cherries, red bayberry and other fruits in the film-forming liquid for 1min, take out and dry naturally, that is, the surface layer of the fruit is formed A biocomposite coating.

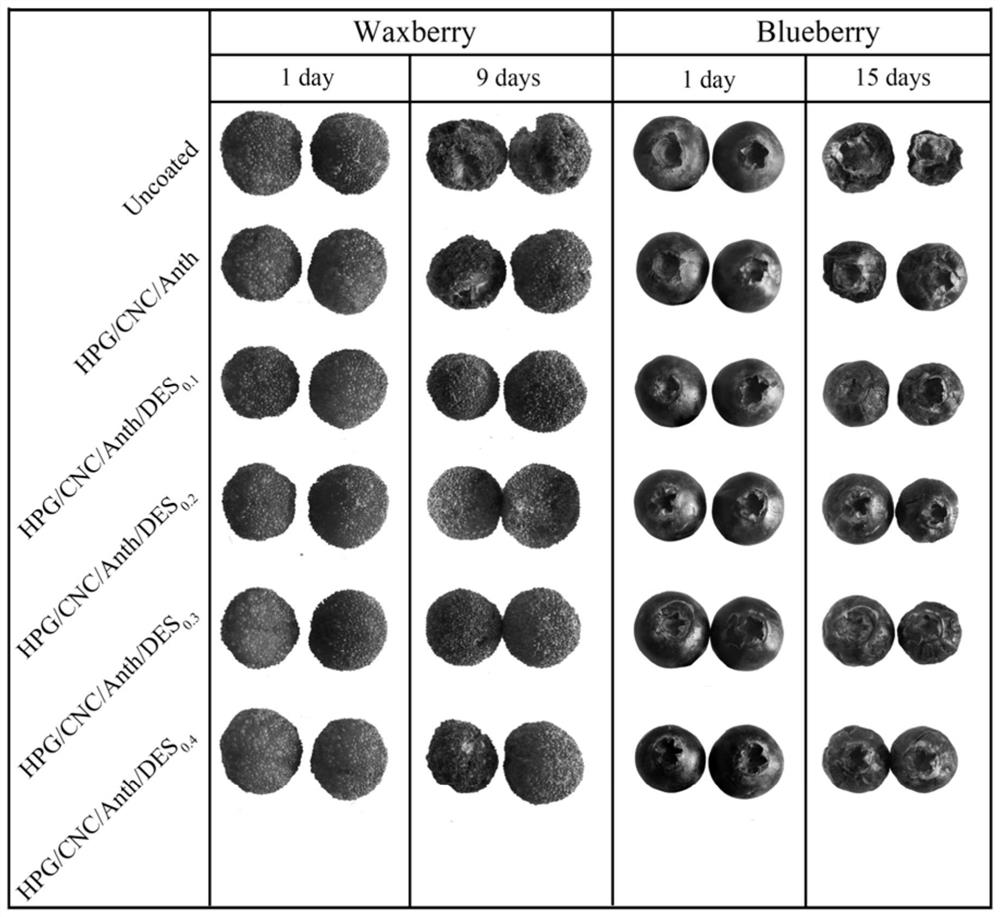

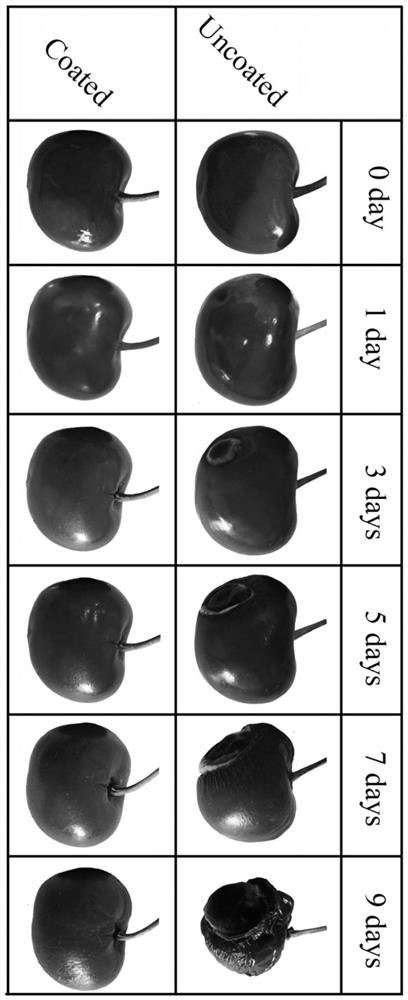

[0079] The uncoated fruit is regarded as the control group, and the coated fruit is regarded as the experimental group. They are placed under the same experimental conditions (room temperature), weigh the fruit every other day, calculate the weight loss, and take pictures to record the degree of decay of the fruit (Table 1, Table 2, Table 3), such as figure 2 , image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com