Vacuum welding equipment with supersonic aging function and application method of vacuum welding equipment

A vacuum welding and ultrasonic technology, applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of weldment structural fatigue strength, reduction, and inability to weld continuously, achieve uniform and stable gas quenching cooling, and improve gas quenching The effect of the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

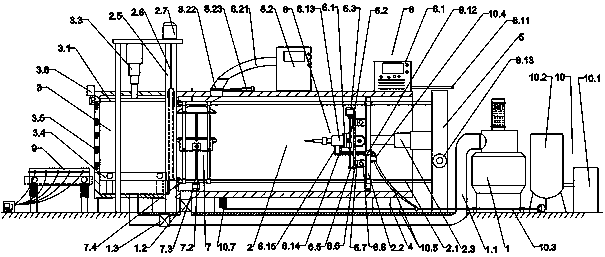

[0036]A vacuum welding device with an ultrasonic aging function, comprising a vacuum device 1, a welding vacuum chamber 2, a feeding vacuum chamber 3, an electron beam welding device 6, a welding table 7, an argon arc welding device 8, a nitrogen generating device 10, and equipment Supporting feet 4 and ultrasonic aging device 9, the vacuum device 1 is arranged on the right side of the vacuum welding equipment, the vacuum device 1 is provided with a vacuum pipeline 1.1, and the vacuum pipeline 1.1 is respectively connected to the welding vacuum chamber 2 and the feeding vacuum chamber 3. An electromagnetic valve I1.2 is provided before the vacuum pipeline 1.1 is connected to the welding vacuum chamber 2, and an electromagnetic valve II1.3 is provided before the vacuum pipeline 1.1 is connected to the feed vacuum chamber 3; the nitrogen making device 10 is set On the right side of the vacuum device 1, the nitrogen generator 10 includes a nitrogen generator 10.1 and a nitrogen st...

Embodiment 2

[0043] Embodiment 2 is basically the same in structure and principle as Embodiment 1, except that the vacuum insulated infusion tube 10.3 is connected to the vacuum insulated infusion hose 10.5, and the vacuum insulated infusion hose 10.5 is provided with a vaporizer 10.7, the vaporizer 10.7 is connected to the liquid nitrogen central distributor 7.17, when the weldment is heated as a whole, the cooling cover lifting hydraulic cylinder 7.16 tops the cooling cover 7.15 to the top of the weldment, and the vaporizer 10.7 starts to make the 99.99% purity After gasification, the liquid nitrogen enters the liquid nitrogen central distributor 7.17 and sprays it on the welding work through the electromagnetic nozzle 7.19 to carry out nitrogen protection heating, so that the overall heating of the weldment is more uniform.

Embodiment 3

[0045] The structure and principle of this embodiment 3 are basically the same as that of embodiment 1. The difference is that the workbench 7.11 is also provided with an overturning platform 7.8, and the bottom of the overturning platform 7.8 is provided with a semicircular gear 7.10. The bench 7.11 is hinged by the hinge II 7.9, the side of the working bench 7.11 is fixed with an overturning motor 7.13, the output of the overturning motor 7.13 is provided with an overturning gear 7.12, the overturning gear 7.12 meshes with the semicircular gear 7.10, and the overturning table 7.8 It can drive the weldment to turn over by 180° front and back when welding, so as to adapt to different welds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com