Gypsum type rapid precision casting method for nonferrous metal

A non-ferrous metal and precision casting technology, which is applied in the field of rapid precision casting of large and complex thin-walled parts, can solve the problems of under-casting (lack of meat, mold collapse, mechanical performance degradation, etc.), to reduce vacuuming time, Effect of improving casting quality and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

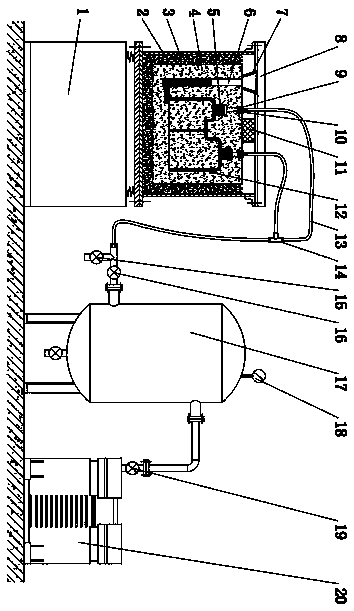

Image

Examples

Embodiment 1

[0036] Embodiment 1: The aluminum alloy motor shell is cast by this method, the material is ZL104, the outline size is 288mm×288mm×220mm, the minimum wall thickness is 3mm, and the rapid prototype material is PLA plastic.

[0037] It is a non-ferrous metal gypsum type rapid precision casting method, comprising the following steps:

[0038] Step 1 Rapid Prototyping

[0039] Use the 3D printer of the fused deposition modeling (FDM) process to make rapid prototypes of motor housings, runners, risers, and airways. The material of the rapid prototypes is PLA plastic;

[0040] Step 2 Make the plaster type

[0041]To prepare gypsum slurry, the powder ratio of gypsum-type materials used is: 50% α hemihydrate gypsum, 30% quartz sand (70 / 100 mesh), 20% quartz powder (320 mesh), gypsum-type gouache The ratio is 0.9; put the rapid prototype of the motor shell into the gypsum slurry, place the rapid prototype of the riser and the rapid prototype of the airway at the four positions with t...

Embodiment 2

[0058] Embodiment 2: The aluminum alloy motor shell is cast by this method, the material is ZL104, the outline size is 288mm×288mm×220mm, the minimum wall thickness is 3mm, and the material of the rapid prototype is photocurable resin.

[0059] It is a non-ferrous metal gypsum type rapid precision casting method, comprising the following steps:

[0060] Step 1 Rapid Prototyping

[0061] Use the 3D printer of the stereolithography (SLA) process to make the rapid prototype of the motor shell, the rapid prototype of the runner, the rapid prototype of the riser, and the rapid prototype of the airway. The material of the rapid prototype is light-cured resin;

[0062] Step 2 Make the plaster type

[0063] To prepare gypsum slurry, the powder ratio of gypsum-type materials used is: 50% α hemihydrate gypsum, 30% quartz sand (70 / 100 mesh), 20% quartz powder (320 mesh), gypsum-type gouache The ratio is 1; put the rapid prototype of the motor shell into the gypsum slurry, place the rap...

Embodiment 3

[0080] Embodiment 3: Cast zinc alloy motor shell by this method, its material is ZZnAl4-1, the outline size is 288mm×288mm×220mm, the minimum wall thickness is 3mm, and the rapid prototype material is ABS plastic.

[0081] It is a non-ferrous metal gypsum type rapid precision casting method, comprising the following steps:

[0082] Step 1 Rapid Prototyping

[0083] Use 3D printers to make rapid prototypes of motor housings, runners, risers, and air passages. The material of the rapid prototypes is ABS plastic;

[0084] Step 2 Make the plaster type

[0085]To prepare gypsum slurry, the powder ratio of gypsum-type materials used is: 50% α hemihydrate gypsum, 30% quartz sand (70 / 100 mesh), 20% quartz powder (320 mesh), gypsum-type gouache The ratio is 0.9-1.2; put the rapid prototype of the motor shell into the gypsum slurry, place the rapid prototype of the riser and the rapid prototype of the airway at the four positions with the largest wall thickness and local protrusions o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com