Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Reduce the impact of processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

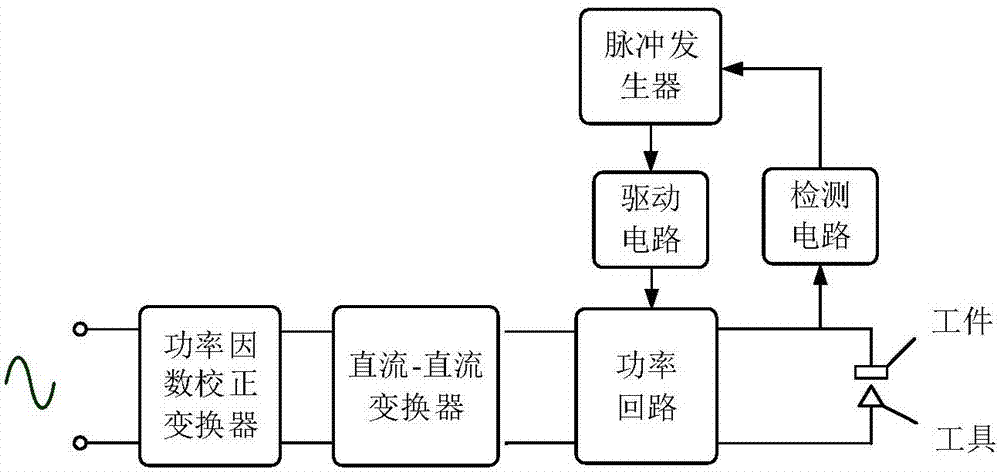

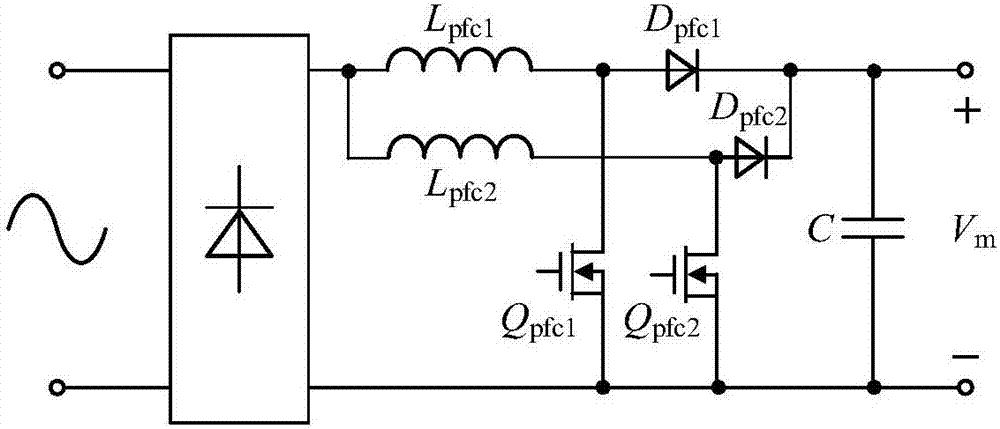

Micro electrical discharge pulse power source and segmental control method based on micro electrical discharge pulse power source

ActiveCN107276405ASimple topologyReduce volumeDc-dc conversionElectric circuitsDriver circuitDc dc converter

The invention discloses a micro electrical discharge pulse power source. The micro electrical discharge pulse power source comprises a power factor correction converter, a DC-DC converter, a power loop, a driving circuit, a pulse generator and a detection circuit, wherein the power loop comprises 6 switch tubes Qp, Q1, Q2, Q3, Q4 and Qoff and one inductor Llimit, the four switch tubes Q1-Q4 are connected in a bridge structure, the switch tube Qp is connected with an output side of the DC-DC converter and an input side of a full-bridge converter, after the switch tube Qoff is in parallel connection with a gap, one end of the switch tube Qoff is connected with a center point of a bridge arm through the inductor Llimit, and the other end is directly connected with a center point of another bridge arm. The invention further comprises a segmental control method based on the micro electrical discharge pulse power source. The micro electrical discharge pulse power source is advantaged in that only one power loop is comprised, the structure is simple, the volume is small, switching of voltage control and current control is carried out in a set of power loop through the corresponding segmental control method, voltage control and current control are mutually independent, and fast switching and precise and stable control can be realized.

Owner:NANJING UNIV OF SCI & TECH

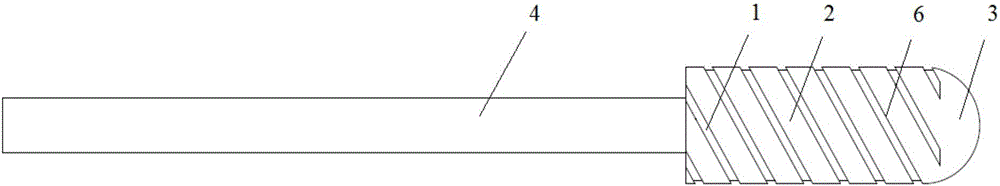

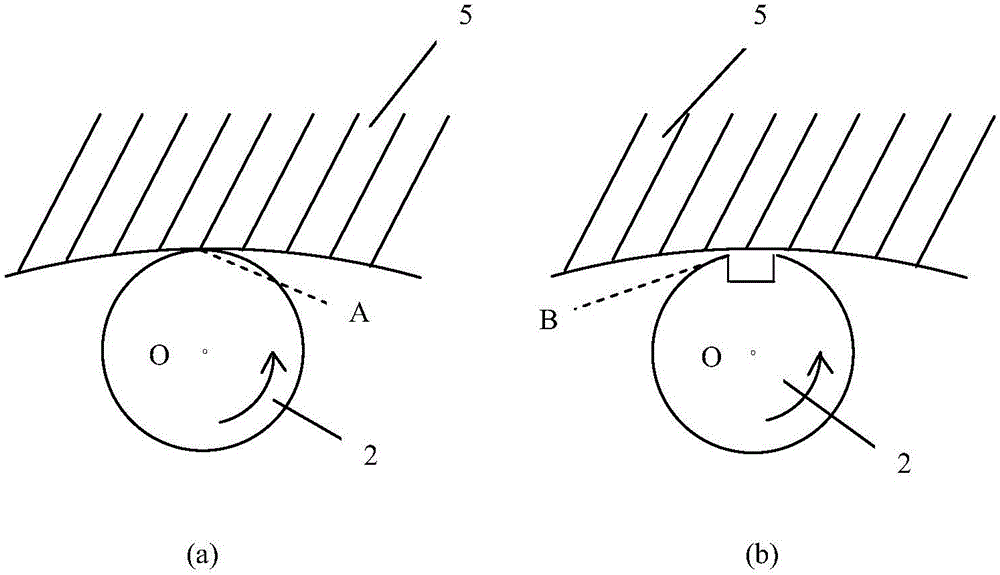

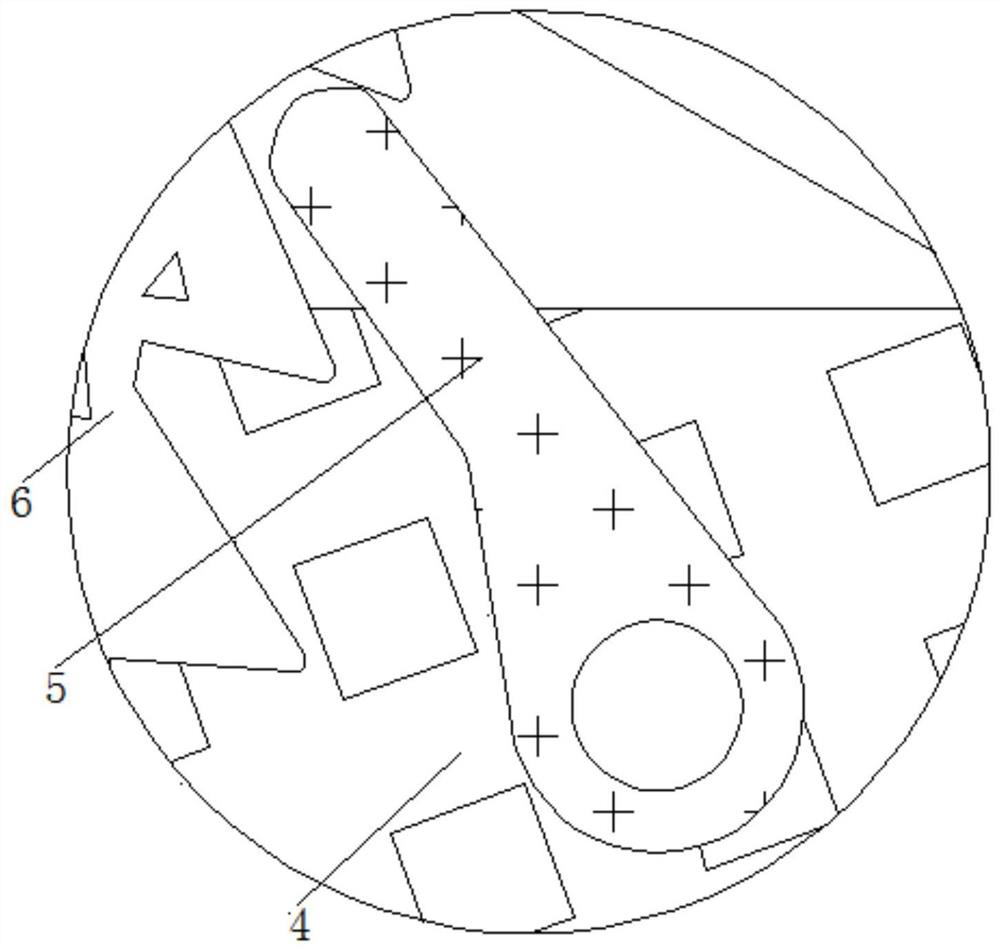

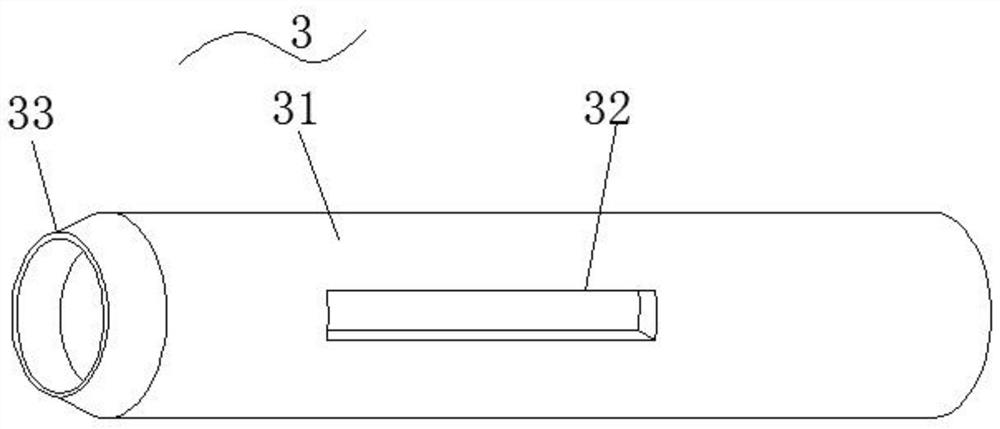

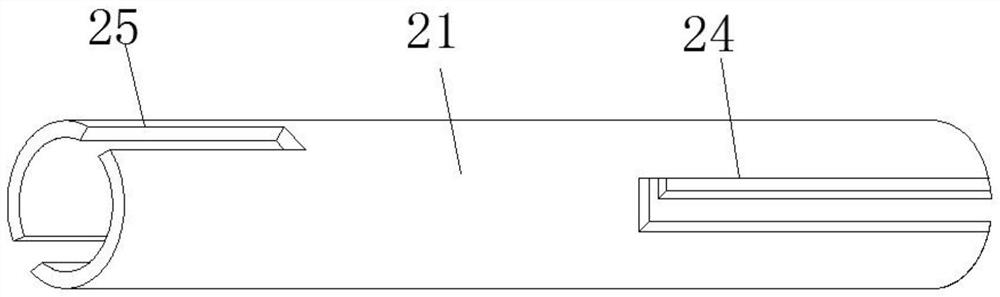

Method for machining narrow groove system impeller, grinding head and preparation method of grinding head

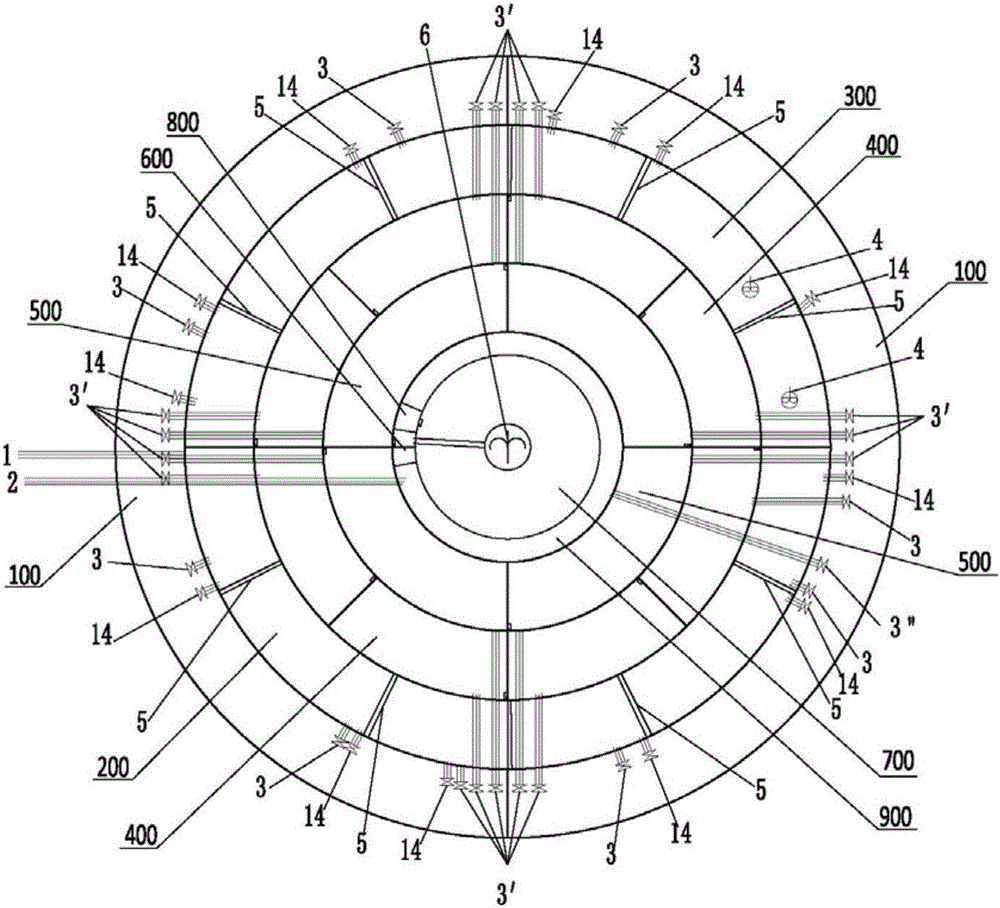

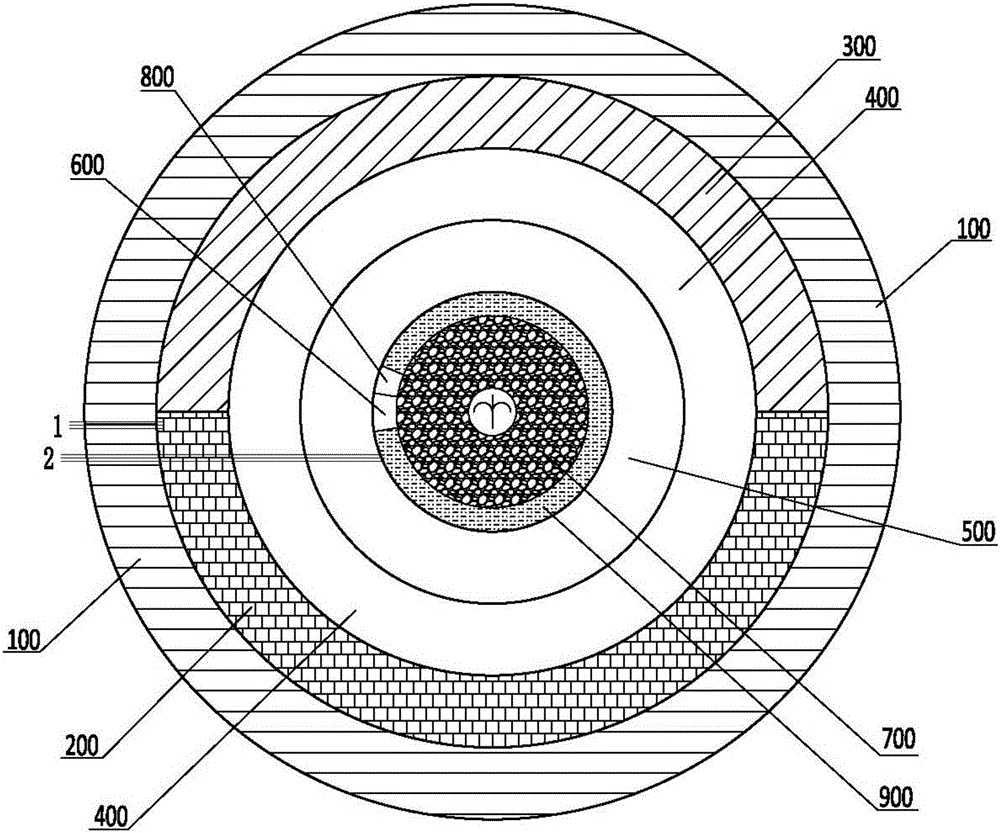

The invention provides a method for machining a narrow groove system impeller, a grinding head and a preparation method of the grinding head. The grinding head is a cylinder. The top end of the grinding head is in the shape of a spherical surface, and a spiral groove is formed in the side wall of the grinding head. The preparation method includes the steps that materials for use are calculated; ingredients are weighed; wetting and material mixing are performed; pressing of grinding head sand blocks is performed; drying is performed; the firing link is performed; and the grinding head sand blocks which are qualified through checking are selected and enter an adhesion processing procedure of a cutter handle, the cutter handle is bonded, after adhesives are cured and stabilized, laser dressing is performed, grooving is performed, and acceptance check of the grinding head is performed, and therefore preparation of the grinding head is completed. The method for machining the narrow groove system impeller through the grinding head includes the steps that fluttering stability analysis is performed, and a stable lobe graph of a grinding system is established; the technological parameter selecting range of stable grinding is determined; and technological parameters of stable grinding are selected, and the grinding head is installed for grinding machining. By means of the grinding head, the grinding temperature is effectively lowered, the adhesion and abrasion effects of cuttings on the grinding head are reduced, the machining surface burning problem is reduced, and better machining surface quality is acquired.

Owner:NORTHEASTERN UNIV

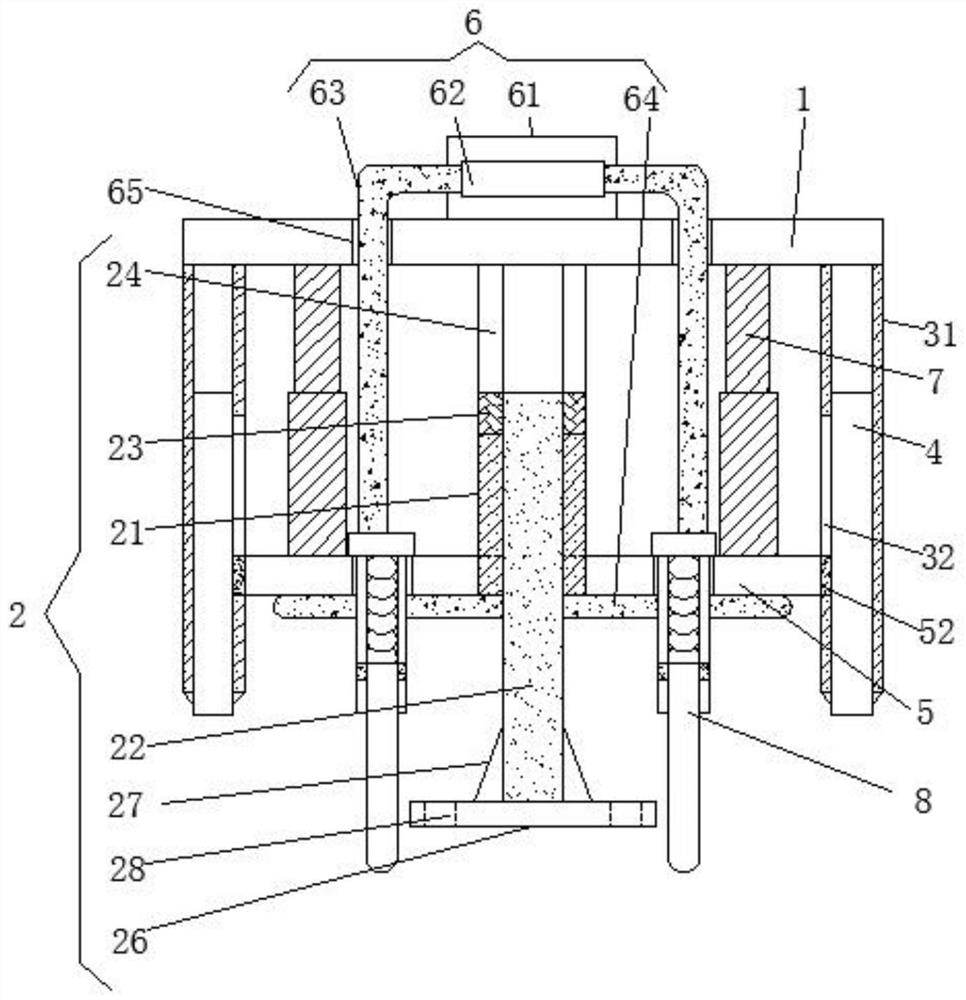

Atmosphere plasma processing device suitable for aspheric optical element with large calibre

InactiveCN103227093ASimple structure controlWide range of applicationsElectric discharge tubesRadio frequencyPlasma processing

The invention relates to an atmosphere plasma processing device suitable for an aspheric optical element with large caliber, and belongs to the field of optical processing. The atmosphere plasma processing device aims to solve the problem that the conventional mechanical polishing technology is low in processing efficiency and cannot meet the large-batch requirements on optical elements with large caliber in the optical field. A rotary electrode of the atmosphere plasma processing device is arranged in a sealing hood and is connected with the output end of a radio frequency power supply to be used as an anode for atmosphere plasma discharge. The upper end of the sealing hood is connected to a work shaft in an insulating manner, and an optical element to be processed is clamped on a work platform. The work platform is grounded as the cathode for atmosphere plasma discharge. A discharge gap is formed between the rotary electrode and the surface to be processed of the optical element to be processed. The atmosphere plasma processing device can be used for carrying out non-contacted atmosphere plasma processing on the aspheric optical surface with large and high in processing speed, and the edge effect is avoided.

Owner:HARBIN INST OF TECH

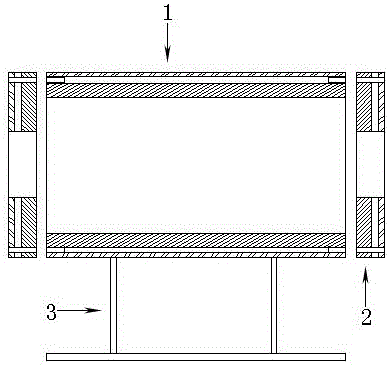

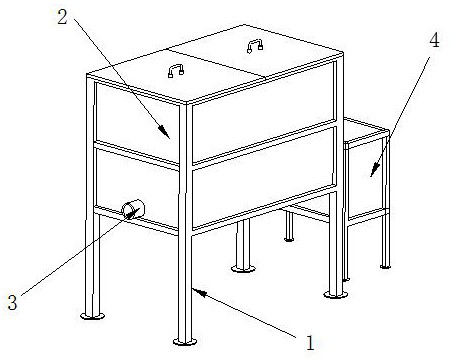

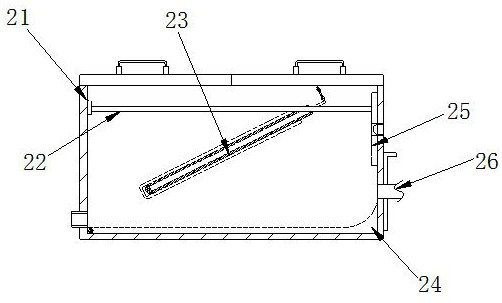

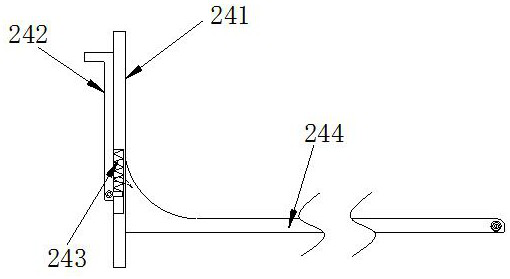

Continuous heat treatment device of wheel hub blank

ActiveCN103911504AProcessing speedIncrease productivityFurnace typesHeat treatment furnacesTherapeutic effectEngineering

The invention provides a continuous heat treatment device of a wheel hub blank, which comprises a solid solution furnace for solid solution treatment of a wheel hub blank; a quenching pool for cooling the wheel hub blank after solid solution treatment; an aging oven for aging treatment of the wheel hub blank; a hanging rack on which the wheel hub blank is hung by a hook; and a material conveying line for transporting the wheel hub blank to a specified position. The solid solution furnace is communicated with the aging oven through a connecting pipe, and a regulating valve is disposed on the connecting pipe. According to the continuous heat treatment device of a wheel hub blank provided in the invention, the solid solution furnace and the aging oven are disposed side by side, which reduces the land occupation of the continuous heat treatment device, decreases the transport distance of the wheel hub blank between the solid solution furnace and the aging oven, increases the treatment speed of the wheel hub blank, and thus improves the production efficiency of wheel hubs; the wheel hub blank is subjected to heat treatment in a hanging manner, which enables the wheel hub blank to be heated uniformly, improves the heat treatment effect of the wheel hub blank, reduces influence on subsequent machining of the wheel hub blank, and improves the qualified rate of wheel hubs.

Owner:ZHEJIANG JINFEI KAIDA WHEEL

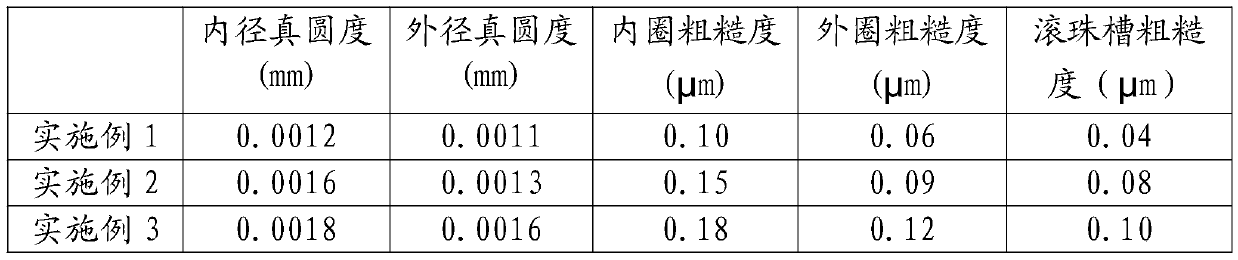

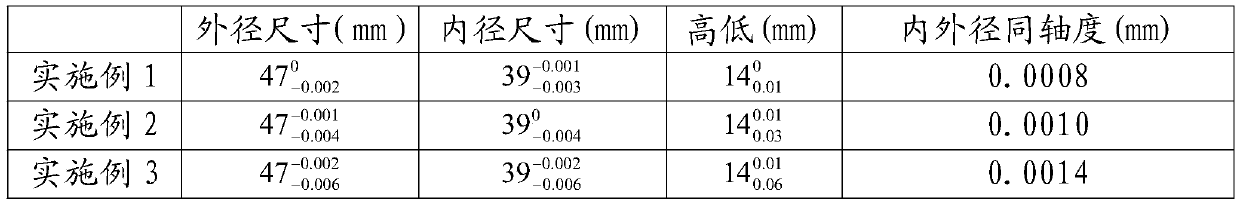

High-precision bearing forge piece machining method

The invention discloses a high-precision bearing forge piece machining method. The machining method comprises the following steps of workblank detection, part reference machining, other end face machining, inner diameter cutting of a bearing outer ring, three times of detection, polishing and four times of detection. According to the machining method, the appearance and the interior of the workblank are detected before production, defective products are screened timely before machining, resource waste is reduced, and the qualified rate of finished products is improved. According to the machining method, a way of combining rough machining and finish machining is adopted for machining, so that the condition that the one-time cutting amount is large is avoided, poor tool vibration is reduced,and the service life of a tool is ensured; in the machining method, in the machining process of a whole lathe, cooling liquid at the temperature of 18-22 DEG C is adopted for cooling the machined part, the temperature difference change of the environment is ensured, the influence of the temperature on part machining is reduced, and machining precision is improved. Paint spraying marks are adoptedfor the defective products, so that distinguishing of the defective products is facilitated, and outflow of the defective products is effectively avoided.

Owner:河北鑫泰轴承锻造有限公司

Special tool for processing end surface of bearing cover

ActiveCN105290838AImprove work efficiencyReduce labor intensityPositioning apparatusMetal-working holdersPosition errorMechanical engineering

The invention provides a special tool for processing the end surface of a bearing cover. The special tool comprises a die holder, wherein the upper end surface of the die holder is connected with a rotating module, and the periphery of the bottom end of a pin shaft positioned in the rotating module is orderly sleeved with a plane bearing and a belleville spring; the bottom end of the pin shaft penetrates through the die holder to be connected with a locknut; the rotating module rotates round the pin shaft on the die holder and is positioned with the die holder through a positioning bolt; the upper end of the rotating module is connected with a central stud, the central stud is movably sleeved with a backing plate and a pressing plate, and a flanged nut is arranged at the top end of the central stud; a positioning column used for positioning the outer wall of the rotating module is clamped on the die holder positioned outside the rotating module. The special tool adopts the 180 degrees of rotation of the rotating module to meet the processing of the two parallel surfaces of the bearing cover, therefore realizing the purpose that one-time clamping meets the processing of two working procedures, greatly improving the processing efficiency and precision, and avoiding a repetitive position error.

Owner:ANHUI HELI CO LTD

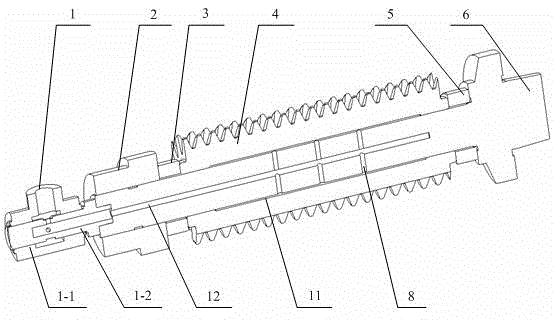

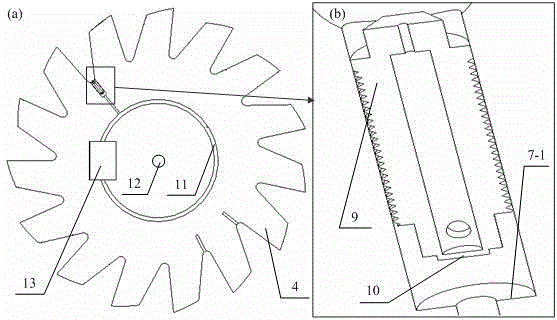

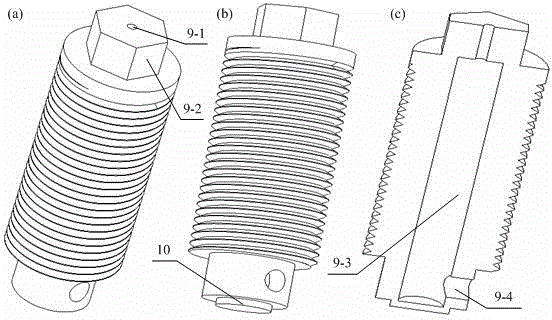

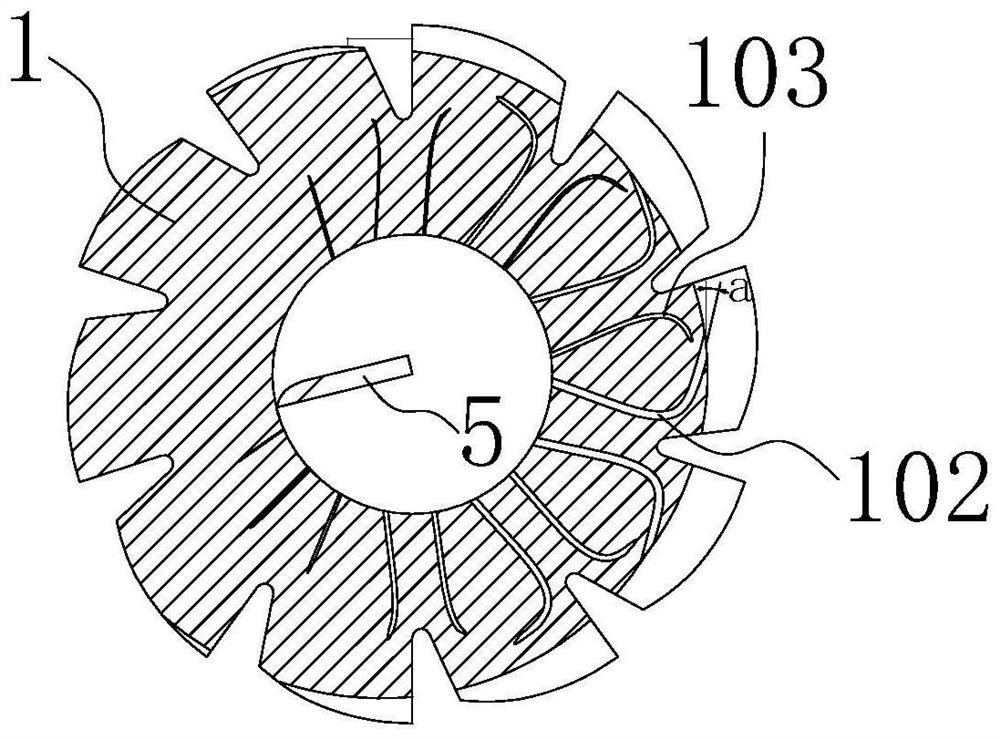

Inner-cooling type hobbing cutter

ActiveCN104588785AReduce dosageAvoid wastingMilling cuttersGear teeth manufacturing toolsHobbingEngineering

The invention provides an inner-cooling type hobbing cutter which comprises a cutter rod and a hobbing cutter body. An oil hole channel is arranged in a chip containing groove, corresponding to front cutter faces of cutter teeth, of the hobbing cutter body. A hole plug is correspondingly arranged on the upper portion of the oil hole channel, and the lower portion of the oil hole channel is communicated with a cutter retreating groove of the hobbing cutter body. The whole plug with an jet hole in the head portion is connected with the oil hole channel through threads. A cutter rod axial oil hole and cutter rod radial oil holes communicated with the cutter rod axial oil hole are formed in the cutter rod. The cutter rod axial oil hole is communicated with a center hole of a connector stator through a center hole of a connector rotor. The oil hole channel in the hobbing cutter body and the hole plug for opening and closing the hole channel are adopted, cutting oil / liquid and compressed air are directly jetted on the front cutter faces of the cutter teeth of the hobbing cutter body through the oil hole channel, the cooling and lubricating function is fully achieved, the temperature of the hobbing cutter is reduced, the service life of the hobbing cutter is prolonged, the hobbing cutter can direct jet cooling media nearby a cutting area, cutting heat is taken away to the greatest extent, and the influence of the cutting heat on hobbing machining is reduced.

Owner:CHONGQING UNIV +1

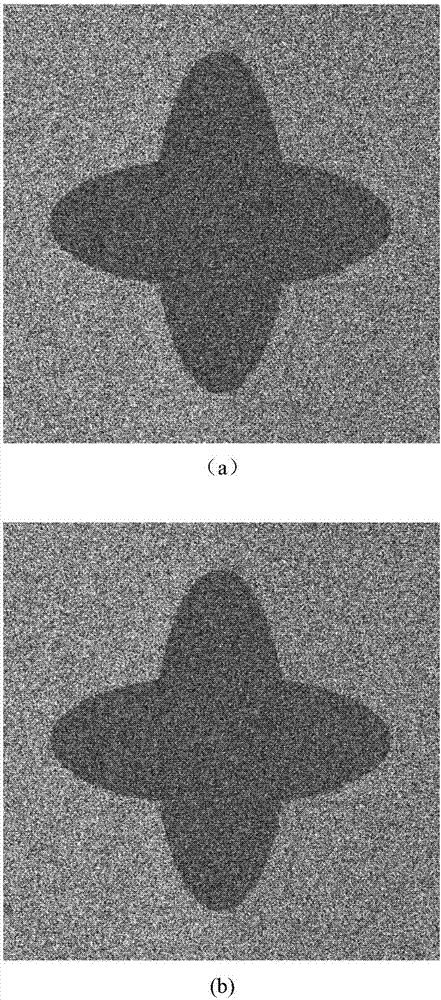

SAR (Synthetic aperture radar) image super pixel segmentation method based on Gamma filtering

InactiveCN106934805AReduce the impact of processingImprove accuracyImage enhancementImage analysisPattern recognitionSynthetic aperture radar

The invention provides a SAR (Synthetic aperture radar) image super pixel segmentation method based on Gamma filtering, so as to solve the technical problem of low super pixel segmentation result accuracy existing in the present filtering-based super pixel segmentation method. The method comprises realization steps: mean filtering is adopted to filter an inputted original SAR image, and the mean value and the standard deviation of pixel grays are obtained; the variance coefficient of the pixel gray mean value, the variance coefficient of speckle noise and the variation coefficient of the SAR image are calculated respectively; the relationship among the coefficients is judged, and whether to carry out Gamma filtering is determined; the Gamma filtering method is adopted to carry out speckle noise reduct5ion on the inputted original SAR image; and super pixel segmentation is carried out on the SAR image after noise reduction, and multiple super pixel blocks are obtained and outputted. Influences of speckle noise in the SAR image can be reduced, the SAR image super pixel segmentation accuracy is improved, and the method can be used for target detection, recognition and classification on the SAR image.

Owner:XIDIAN UNIV

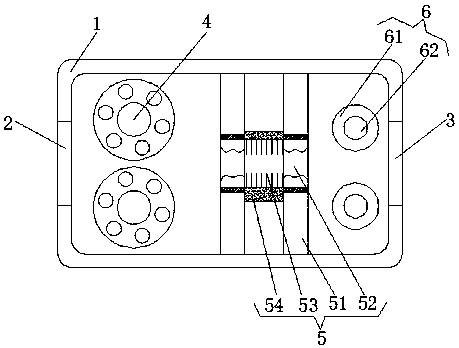

Under-actuated multi-rod type intelligent tea leaf continuous-vibration shaping machine

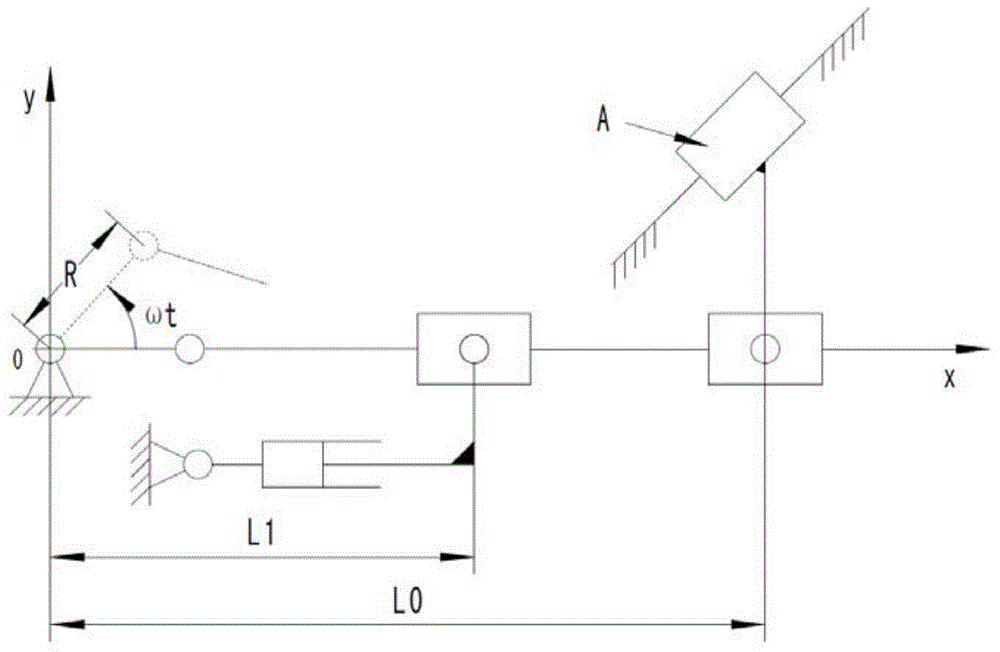

ActiveCN104472737ALarge forward rotation energyHigh forward rotation energyPre-extraction tea treatmentVibration amplitudeEngineering

The invention relates to an under-actuated multi-rod type intelligent tea leaf continuous-vibration shaping machine. The under-actuated multi-rod type intelligent tea leaf continuous-vibration shaping machine comprises a rack, a lathe bed, an under-actuated multi-rod horizontal vibration system for realizing continuous vibration and shaping of the tea leaves, an amplitude real-time adjusting system, a real-time boiler bath vertical angle adjusting system, a boiler bath vibration direction adjusting structure, a furnace-boiler integrated bath, a dynamic flow weighing system and an intelligent control system, wherein the amplitude real-time adjusting system is used for adapting to the amplitude modulation in a vibration shaping process of different varieties of tea leaves in different picking times; the real-time boiler bath vertical angle adjusting system is used for controlling the vertical angle of the boiler bath during tea leaf vibration shaping; the boiler bath vibration direction adjusting structure is used for changing the motion trail of the tea leaves in the boiler bath and improving the tea leaf shaping quality; the furnace-boiler integrated bath is used for improving the energy utilization rate; the dynamic flow weighing system is used for controlling the flow rate of the tea leaves; and the intelligent control system is used for comprehensively and intelligently adjusting the heating temperature, the vibration frequency and the vibration amplitude of the shaping machine.

Owner:ZHEJIANG UNIV OF TECH

Ecological peristalsis bed reactor and method using same to treat waste water

ActiveCN105668937AInhibit swellingAvoid it happening againFatty/oily/floating substances removal devicesSpecific water treatment objectivesSludgeLandscaping

The invention relates to an ecological peristalsis bed reactor. The ecological peristalsis bed reactor comprises an equipment room unit, a greenhouse unit, a primary pretreating unit, a secondary biological treating unit and a tertiary deep treating unit, wherein an oil-insulation sedimentation area and a coagulation sedimentation area, a water pipe, an oil discharge pipe and a first sludge discharge pipe are arranged in the primary pretreating unit; a biological carrier, an aeration system, a first sludge sedimentation area and a second sludge discharge pipe are arranged in the secondary biological treating unit; a plant absorption area, a sterilizing area, a second sludge sedimentation area and a third sludge discharge pipe are arranged in the tertiary deep treating unit. To-be-treated waste water can reach the first-grade A standard after being treated by the primary pretreating unit, the secondary biological treating unit and the tertiary deep treating unit. The ecological peristalsis bed reactor has the advantages that a greenhouse is mounted at the top of a treating area, special aquatic plants are planted in the plant absorption area, aisle flower beds are designed, the temperature in the greenhouse is kept, linkage treatment by microorganisms and the plants is achieved, and integration, automation, deodorization and landscaping of waste water treatment are achieved.

Owner:北京中淏环保科技有限公司

Machining magnetic field shielding method and device for permanent magnet contained workpiece

InactiveCN106737202AHigh precisionQuality improvementScreening apparatusMaintainance and safety accessoriesClosed loopMagnet

The invention discloses a machining magnetic field shielding method and device for a permanent magnet contained workpiece. When the permanent magnet workpiece is machined, the part containing a permanent magnet is covered with a shielding cover, magnetic induction lines emitted by the permanent magnet in the permanent magnet workpiece form closed loop circuits between the shielding cover and the permanent magnet workpiece, and therefore the magnetic field produced by the permanent magnet workpiece is shielded. The permanent magnet workpiece is sleeved with the magnetic field shielding device, and therefore the negative effects of the magnetic field can be shielded when the permanent magnet workpiece is machined in a turning or milling or grinding manner, and the machining precision and the machining quality of the permanent magnet workpiece and the precision of three-dimensional loss metering are improved.

Owner:ZHUZHOU GOFRONT EQUIP

Anti-splashing device of milling machine cuttings

InactiveCN107662130AGood sealingEasy to collectMaintainance and safety accessoriesEngineeringCantilever

The invention discloses a chip anti-splash device for a milling machine, which is installed on the milling machine. The milling machine is equipped with a main shaft and a workbench. The anti-splash device includes a beam installed above the main shaft, an air channel arranged in the beam, and A plurality of nozzles installed vertically under the air channel; the beam is a cantilever structure, and the nozzles are installed along the side of the beam away from the main shaft; transparent cutting baffles are arranged on both sides of the workbench, and the transparent cutting baffle The top of the plate is in contact with the beam. In the present invention, nozzles are installed at one end of the beam of the machine tool and transparent cutting baffles are installed on both sides of the workbench, relying on the pressurized air flow ejected from the nozzles and the transparent cutting baffles to form a "U"-shaped anti-cutting and splashing area to seal the working area of the machine tool , to avoid the chips splashing to the outside of the machine tool, causing hidden dangers of safety accidents, and the air wall and transparent cutting baffle will not affect the operator's sight, reducing the impact on processing after adding this device.

Owner:成都立威斯科技有限公司

ICP (inductively coupled plasma) processing machine tool cavity air pressure control method based on PLC (programmable logic controller)

InactiveCN104773961ADamage healthPrevent the effect of processingAtmospheric airProgrammable logic controller

The invention discloses an ICP (inductively coupled plasma) processing machine tool cavity air pressure control method based on a PLC (programmable logic controller), and belongs to the technical field of plasma processing machine tools. In order to overcome various defects that reaction gas is directly discharged into the atmosphere by virtue of previous plasma machine tools, the ICP processing machine tool cavity air pressure control method is disclosed aiming at maintaining the stability of machine tool cavity pressure and preventing the pressure change from influencing processing results in a machine tool processing procedure; and after processing, residual reaction gas in a machine tool cavity and gas obtained after reaction can be pumped and discharged; and then further tail gas treatment can be performed to prevent environmental pollution and damages to the health of operators.

Owner:HARBIN INST OF TECH

Process for demetalizating of hydrocarbon oil

InactiveCN1295303CProduce secondary pollutionReduce the impact of processingHydrocarbon oils refiningOil processingDemulsifier

A demetallating process for the hydrocarbon oil includes such steps as mixing the acetylacetone as demetalating agent with raw hydrocarbon oil, water and demulsifier, and oil-water separation. Its advantage is high effect to remove Ca, Mg, Fe, etc.

Owner:EAST CHINA UNIV OF SCI & TECH

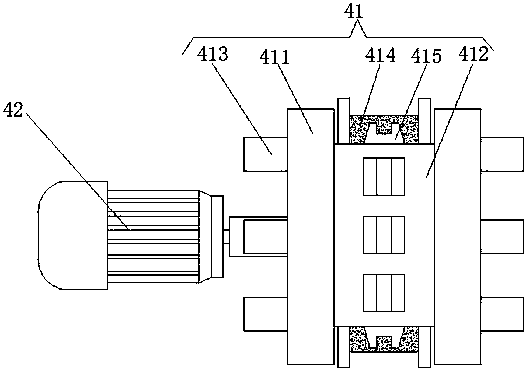

Self-cooled hob capable of preventing chips from remaining

ActiveCN112548231AAvoid damageReduce the temperatureGear teeth manufacturing toolsGear teethHobbingSpiral blade

The invention belongs to the technical field of metal cutting tools, and relates to a self-cooled hob capable of preventing chip residues. The self-cooled hob is characterized by comprising a hob bodyand a rotary mounting head, wherein a first installation end and a second installation end are arranged at the two ends of the hob body, a center hole is formed in the hob body, a spiral blade is fixedly arranged in the center hole, a channel is formed in the first mounting end and communicates with the center hole, through holes are uniformly formed in the circumferential side of the first mounting end and communicate with the channel, a rotary connector is rotationally mounted at the first mounting end and wraps the through holes, a connecting port is formed in the rotary connector and communicates with the channel through the through holes, a pressure relief opening is further formed in the rotary connector, a convex ring and a pressure relief valve are arranged in the pressure reliefopening, and the pressure relief opening communicates with the channel through the through holes. According to the hob, cuttings at the bottom of the cutting edge can be washed away, the influence ofcutting heat on hobbing can be reduced, the temperature of the hob is reduced, and the service life of the hob is prolonged.

Owner:南京迈森智能装备有限公司

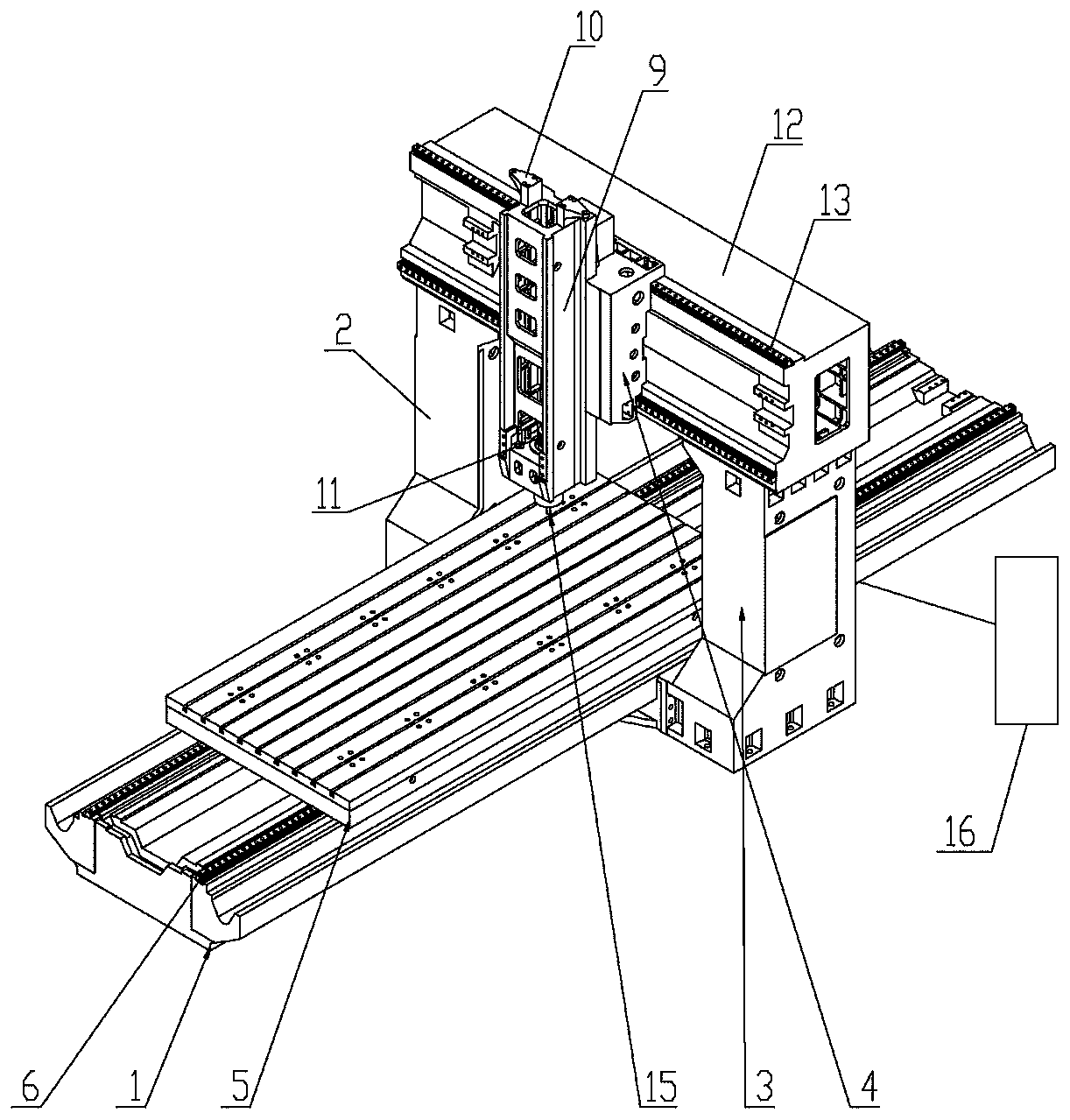

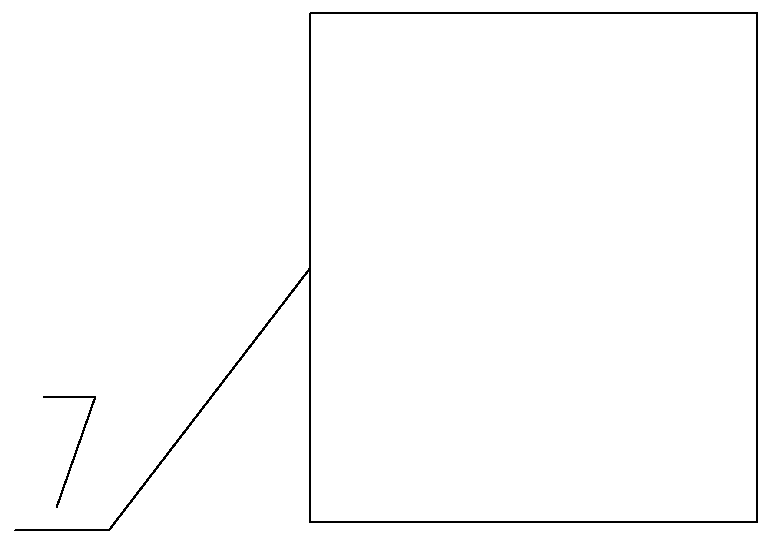

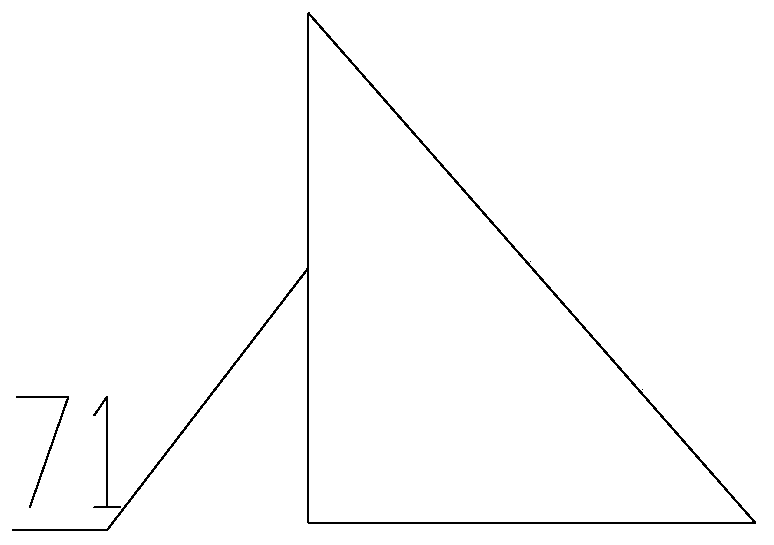

Method for correcting perpendicularity between Y axis sliding saddle and X axis workbench of large numerical control gantry machining center

InactiveCN111230589AHigh precisionReduce the impact of processingMeasurement/indication equipmentsNumerical controlMeasuring instrument

The invention provides a method for correcting perpendicularity between a Y axis sliding saddle and an X axis workbench of a large numerical control gantry machining center. The method for correctingperpendicularity between the Y axis sliding saddle and the X axis workbench of the large numerical control gantry machining center comprises a gantry base, a left stand column, a right stand column, amachined workpiece, a right-angle workpiece, a cross beam fine adjustment device, an articulated arm measuring instrument, a motor and related power distribution; the fine correcting process comprises the steps that a numerical control gantry machine tool is used for fine correcting of the full-stroke right-angle workpiece, the articulated arm measuring instrument is used for measuring an included angle of the machined workpiece in the XY plane; and according to the measurement result, the machining size of the square workpiece is modified, the measurement result is added between XY of the square workpiece and correcting is carried out, trial machining is carried out again according to a regenerated model, a cross beam is adjusted to enable the Y axis to be parallel to the Y direction ofthe workpiece, it is guaranteed that the precision is within the range of 0.015 mm (within any 1000 mm stroke), after the adjustment is completed, machining is carried out by using a normal program, after machining is completed, a joint arm is used for measuring the included angle of the XY plane, and the process continues to be repeated if requirements are not met. According to the method for correcting perpendicularity between the Y axis sliding saddle and the X axis workbench of the large numerical control gantry machining center, the precision is high, and the XY perpendicularity precisionof a gantry can be corrected to 0.02 to 0.03 mm.

Owner:广州义同机械实业有限公司

Grease wastewater treatment equipment

InactiveCN112239246AEasy to clean upReduce the impactFatty/oily/floating substances removal devicesCleaning using toolsProcess engineeringWater storage tank

The invention discloses grease wastewater treatment equipment, and the equipment structurally comprises a support, a machine body, an oil discharge port and a water storage tank; the top surface of the support is connected with the bottom surface of the machine body in a welded mode, an outer ring of the oil discharge port is communicated with the left side of the machine body, and the left side of the water storage tank is communicated with the right side of the machine body. According to the invention, heavy oil is emulsified and deposited on the accumulation table through the machine body;after water liquid is pumped out, the oil accumulation table is lifted by lifting the clamping rod, and heavy oil flows to the oil outlet through gravity; meanwhile, heavy oil sediment on the oil accumulation table is pushed and cleaned through mutual cooperation of the scraping block and the threaded ejector rod, and box opening is not needed, generated odor is prevented from affecting workers; cleaning operation is convenient, and the influence on the next grease wastewater treatment is reduced.

Owner:GUANGZHOU LIANJIANG SOFTWARE DEV LLC

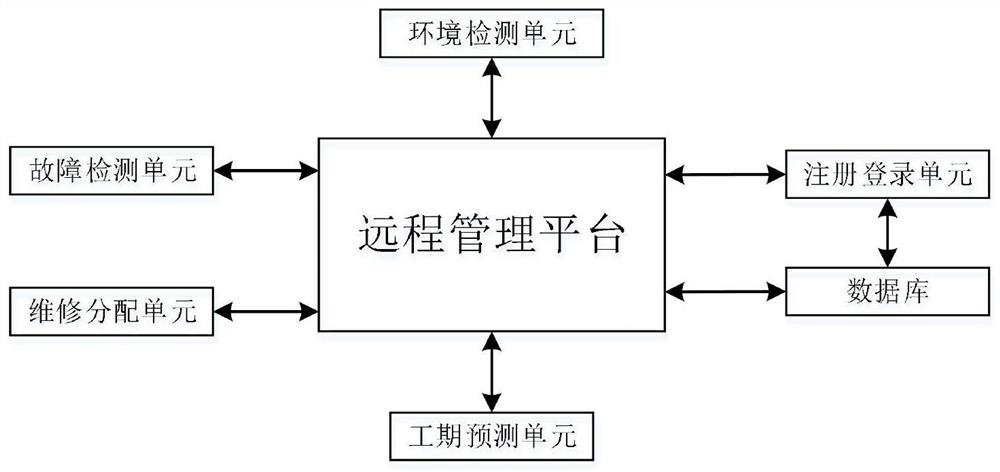

Remote management system for alloy material processing

InactiveCN113487173AImprove work efficiencyImprove management efficiencyResourcesManufacturing computing systemsProcess engineeringAlloy

The invention discloses a remote management system for alloy material processing, relates to the technical field of remote management for processing, and solves the technical problem of low processing efficiency caused by incapability of performing fault detection on alloy processing equipment in the prior art. The invention comprises analyzing operation information of the alloy material machining equipment through a fault detection unit, so that fault detection is conducted on the alloy material machining equipment; obtaining the analysis detection coefficient FXi of the alloy material processing equipment through a formula, and if the analysis detection coefficient FXi of the alloy material processing equipment is larger than or equal to the analysis detection coefficient threshold value of the processing equipment, judging that the corresponding processing equipment breaks down; generating an equipment fault signal and sending the equipment fault signal to a remote management platform; and performing fault diagnosis on the alloy material processing equipment, so that the working efficiency of total material processing is improved, and meanwhile, the management efficiency of the management system is improved.

Owner:安徽众成合金科技有限公司

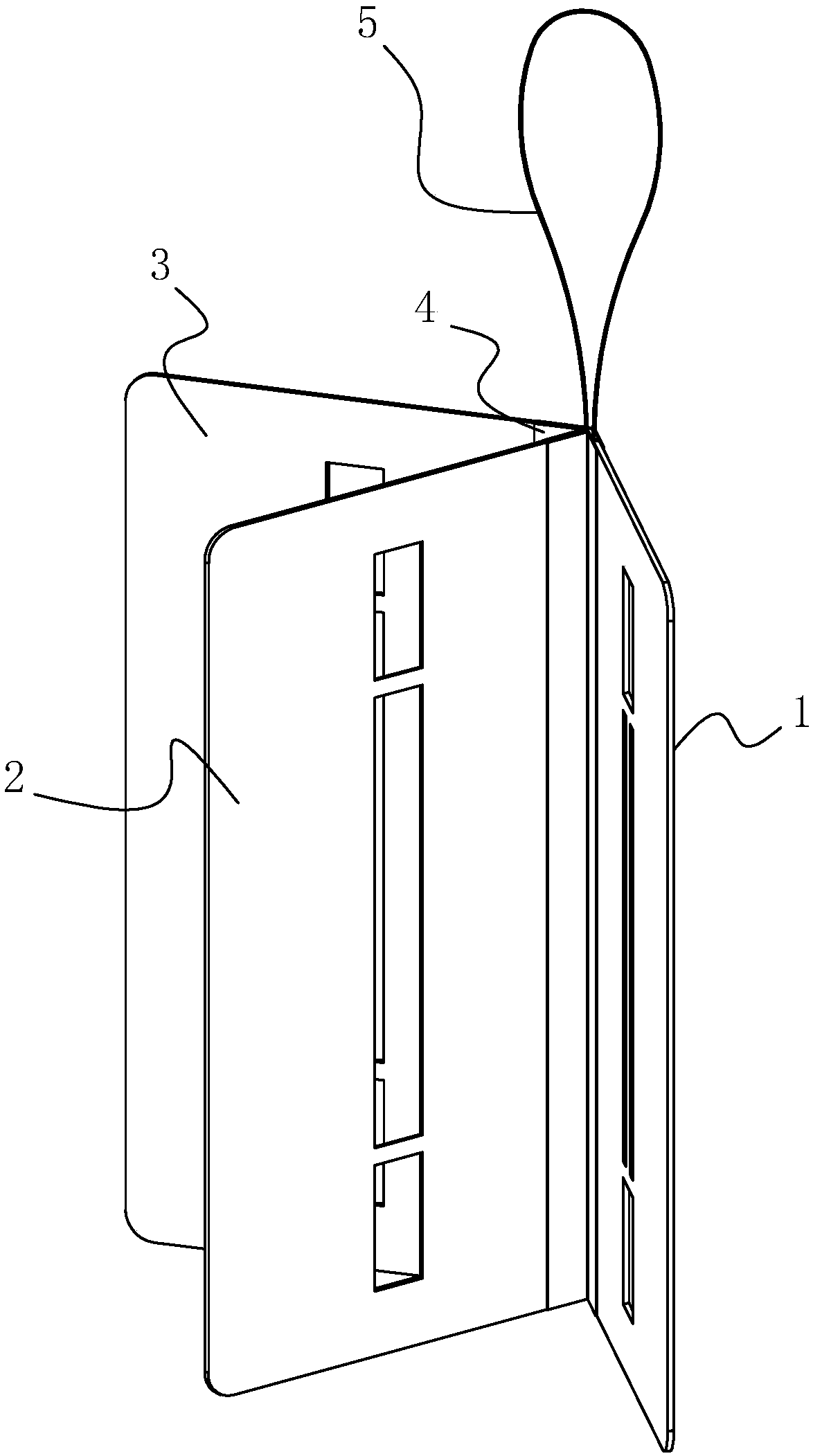

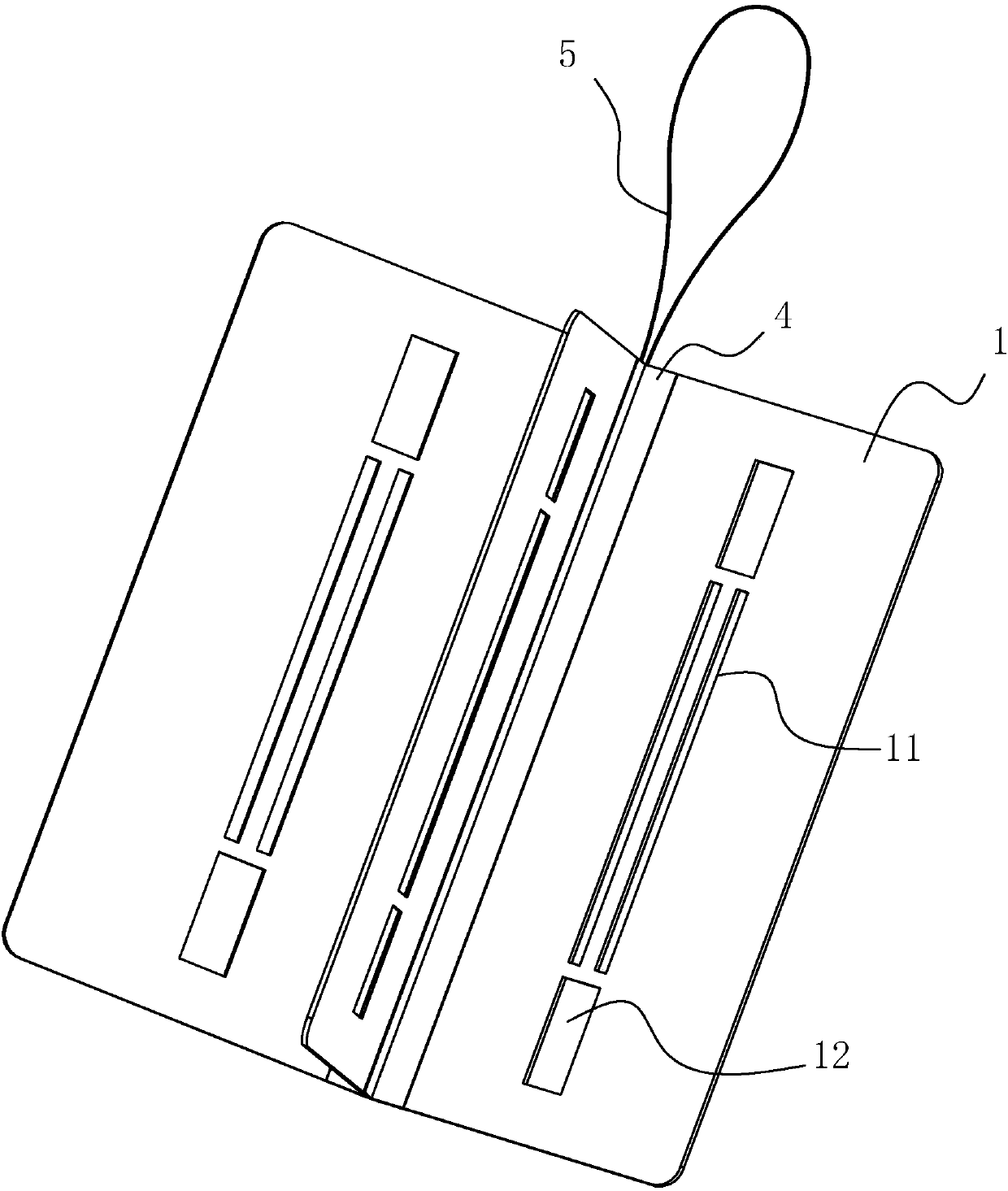

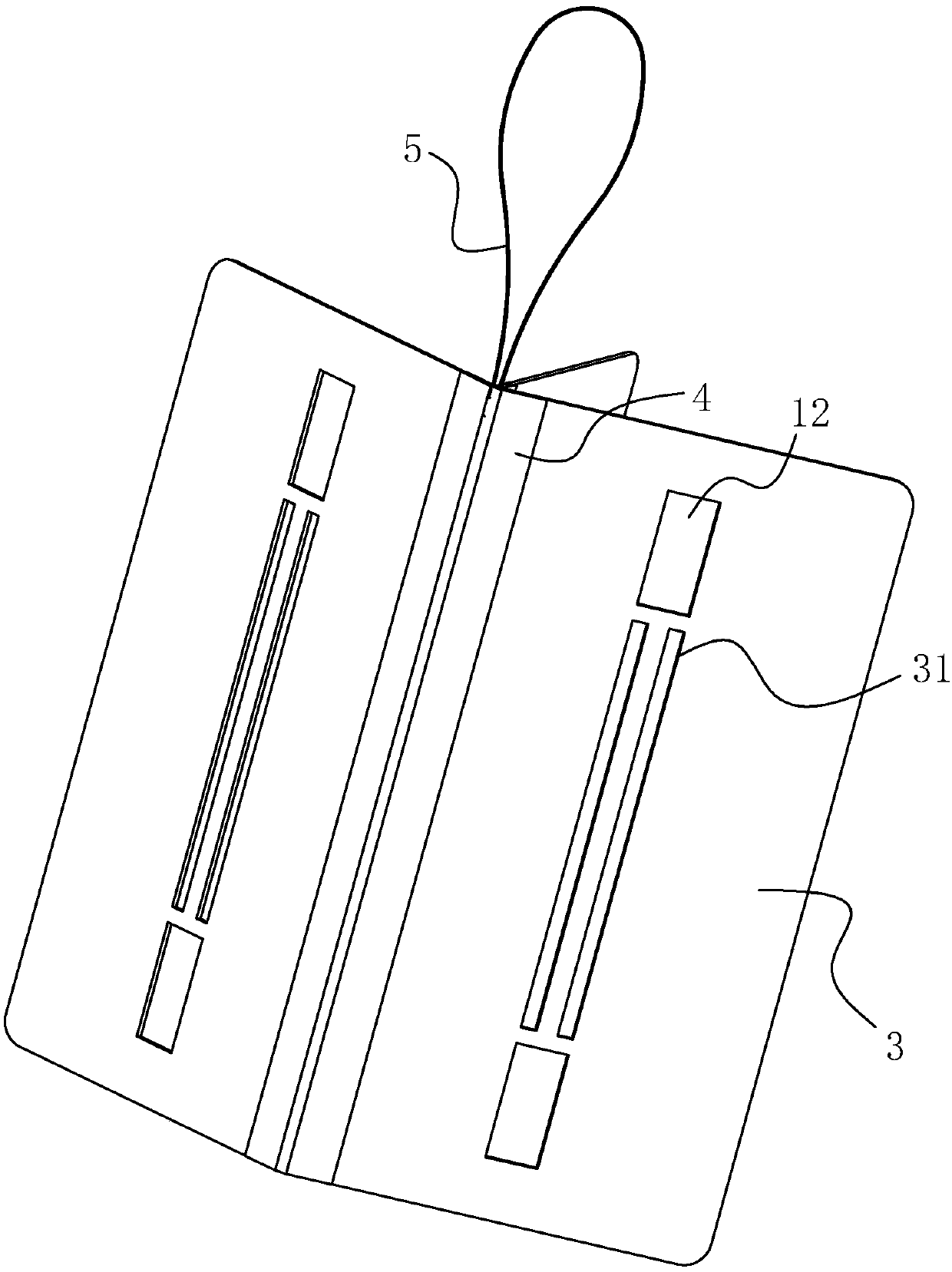

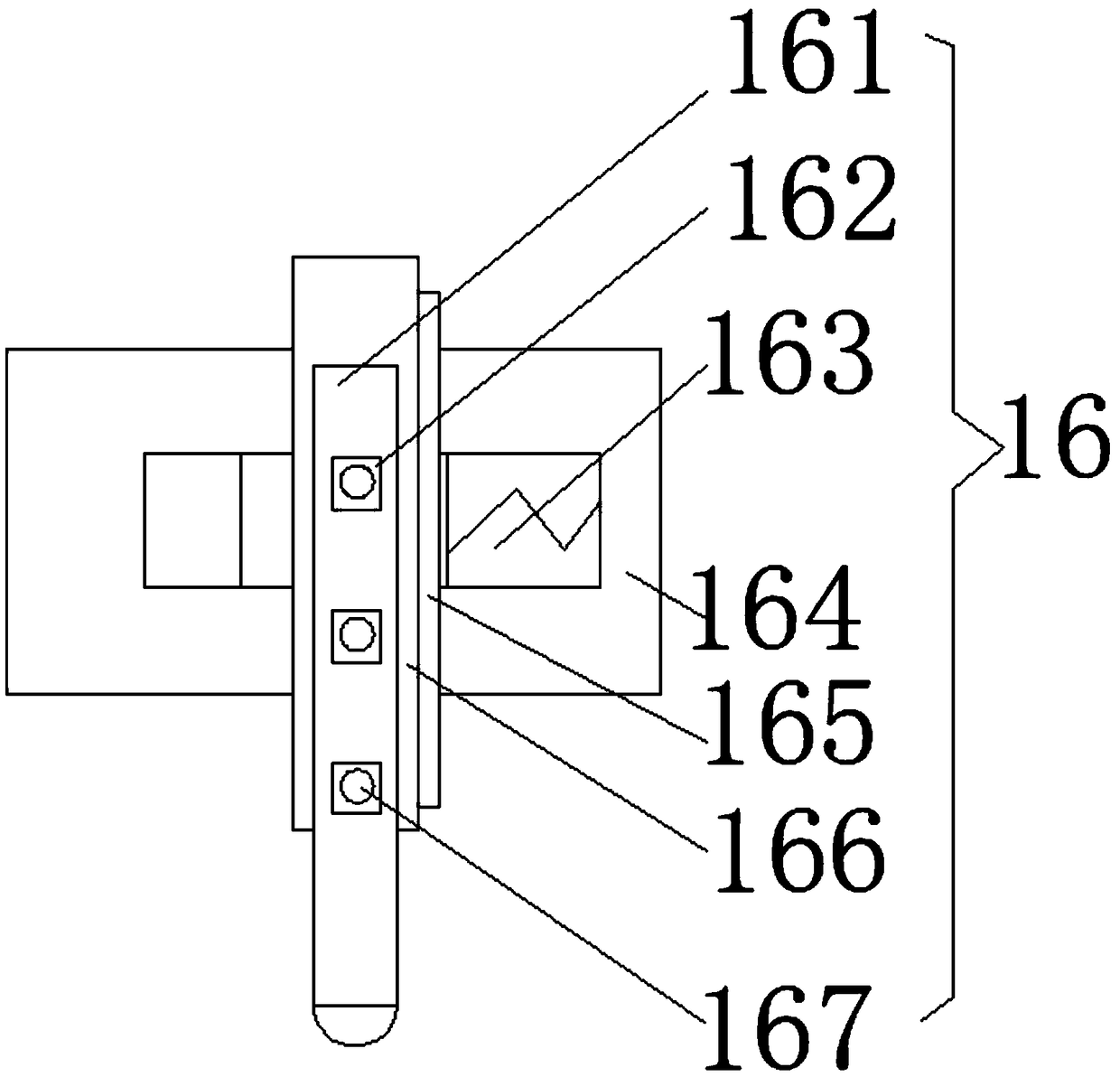

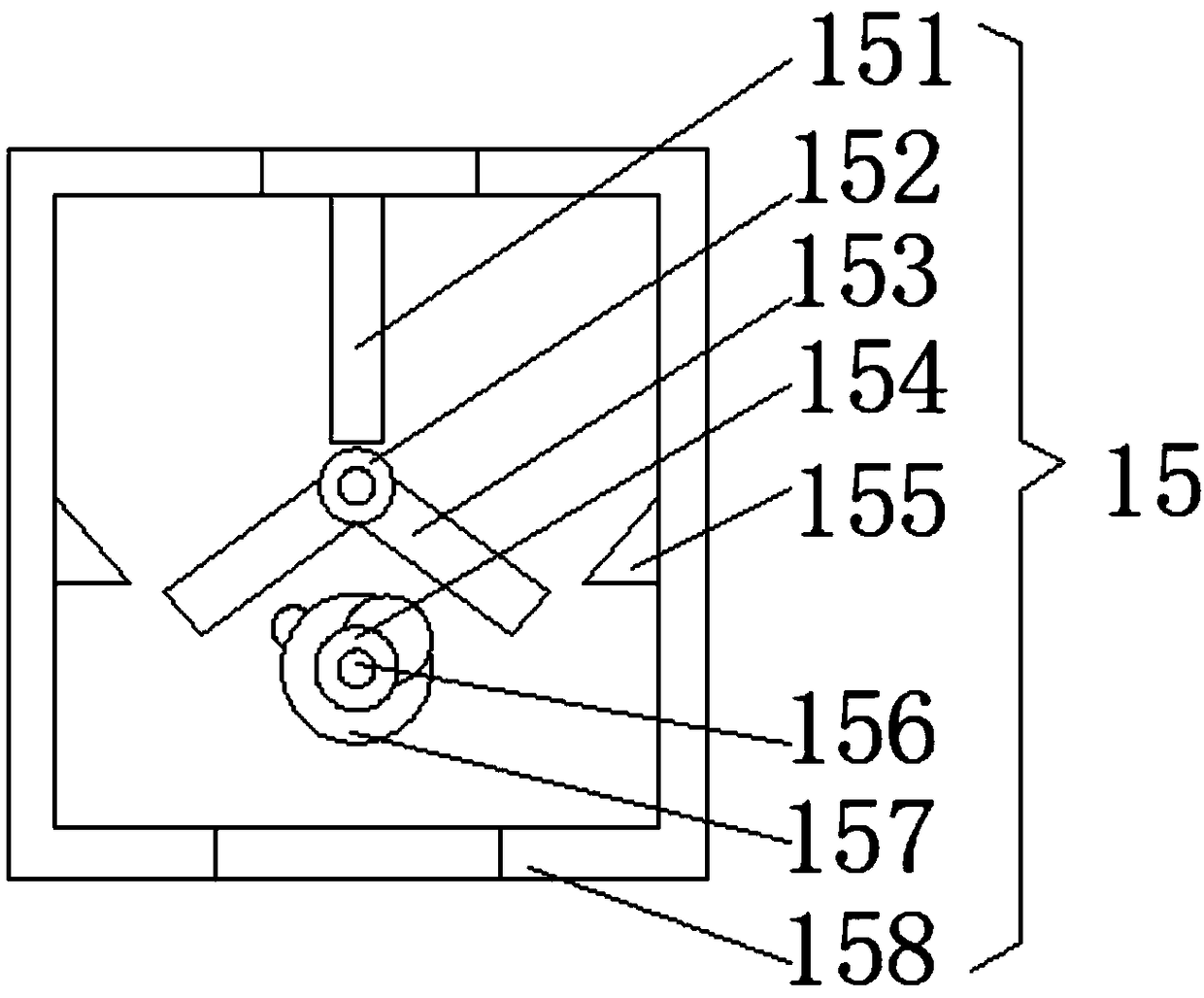

Pocket zipper sewing formwork

InactiveCN110158243AImprove product qualityReduce the impact of processingWork-feeding meansEngineeringProduction quality

The invention discloses a pocket zipper sewing formwork and relates to the technical field of garment manufacturing. The pocket zipper sewing formwork comprises a first faceplate, a second faceplate and a third faceplate sequentially arranged in a stacked manner, two first sewing notches are formed in the first faceplate, a positioning groove is formed in the second faceplate, a sewing groove is formed in the middle in the positioning groove, and two second sewing notches identical with the first sewing notches in shape and size are formed in the third faceplate. Through cooperation of the first faceplate and the second faceplate, cut cloth which is soft in texture can be fixed, and a zipper which is soft in texture can be fixed on the cut cloth by utilizing the second faceplate and the third faceplate, so that impact of the texture of the zipper and the cloth on processing is lowered, and effect of improving pocket production quality is improved.

Owner:兴雪莱(厦门)体育用品有限公司

Anti-dripping device for soft ceramic processing production line

ActiveCN108748647AEasy to removePrevent overflowAuxillary shaping apparatusProduction lineEngineering

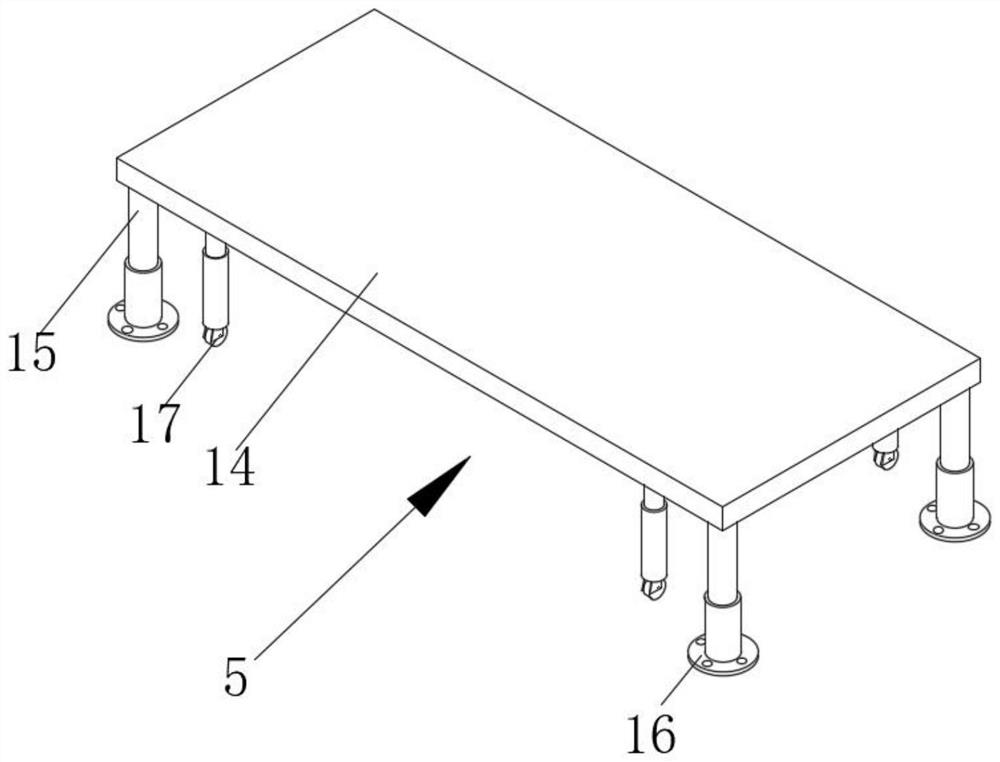

The invention provides an anti-dripping device for a soft ceramic processing production line, and relates to the field of soft ceramic processing. The anti-dripping device for the soft ceramic processing production line comprises a worktable; support legs are fixedly connected to the bottom of the worktable; damping sizing blocks are fixedly connected to the bottom ends of the support legs; the bottoms of the damping sizing blocks are fixedly connected with the ground; collecting pieces are fixedly connected to the inner sides of the support legs; the connecting pieces comprise collecting tankbodies; the bottoms in the collecting tank bodies are inverted hoppers; and the bottoms of the collecting tank bodies are fixedly connected with collecting boxes communicating with the inverted hoppers. The anti-dripping device for the soft ceramic processing production line is provided with a division plate, a first cam and an adjusting box; a servo motor is used for driving an adjusting shaft to rotate to drive the first cam and a second cam, staggered from each other, to extrude or slide through a first adjusting plate in sequence, so that the passing speeds of materials on the two sides are adjusted; and when the materials are close to the edge sides of baffle plates, the unloading is reduced to prevent material overflowing and dripping.

Owner:范瑶飞

Characteristic rule enabling method and device

ActiveCN107547533AReduce the impact of processingAvoid Undetectable ProblemsTransmissionSimulationMirror image

The embodiment of the invention provides a characteristic rule enabling method and device. The method comprises the following steps: safety equipment receives a traffic, and sends a traffic mirror image to traffic learning equipment if the traffic is not matched with any enabled characteristic rule of the safety equipment; the traffic learning equipment detects a first characteristic rule matchedwith the traffic from enabled characteristic rules of the traffic learning equipment, and sends an enabling command for the first characteristic rule to the safety equipment, wherein the enabling command is used for instructing the safety equipment to enable the first characteristic rule; and the safety equipment receives the enabling command and enables the first characteristic rule according tothe enabling command. The method and device provided by the embodiment of the invention has the advantages that effects on the processing of normal services can be reduced, and the network safety canbe improved.

Owner:NEW H3C SECURITY TECH CO LTD

Protection device for offset press

The invention discloses a protection device for an offset press, comprising an offset press body, a protective shell, an air blowing mechanism and a drying mechanism. The periphery of the offset pressbody is connected with the protective shell of a box body structure through a plurality of screws; the top end of the protective shell is connected with the air blowing mechanism and the drying mechanism; the bottom end of the offset press body is connected with a movable support mechanism; an air treatment mechanism is arranged at the top end of the movable support mechanism; the air blowing mechanism comprises a liquid storage box, an exhaust fan, an ion fan and an air blowing pipe; the liquid storage box is arranged above the protective shell; two ventilation channels are formed in the topend of the liquid storage box; the inner walls of the two ventilation channels are connected with the exhaust fan and an ion fan for removing static electricity through a plurality of screws; funnel-shaped ventilation hoppers are welded to the two sides of the exhaust fan and the top end of the ion fan; and an air suction pipe is welded to the top end of each ventilation hopper above the exhaustfan. The protection device for the offset press not only can remove dust and static electricity, but also can treat air.

Owner:SHANGHAI XUANREN MACHINERY EQUIP

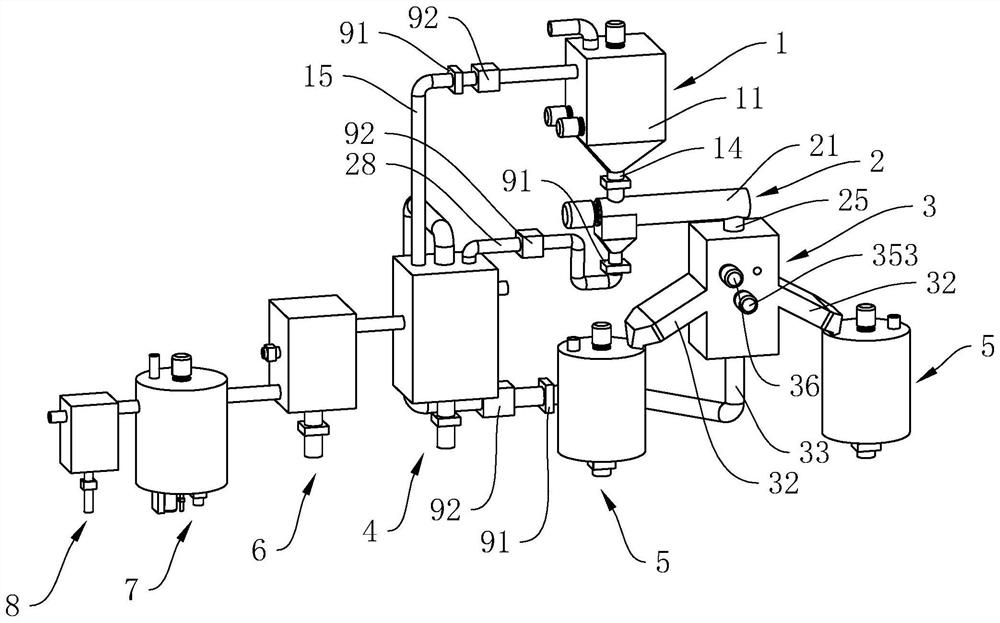

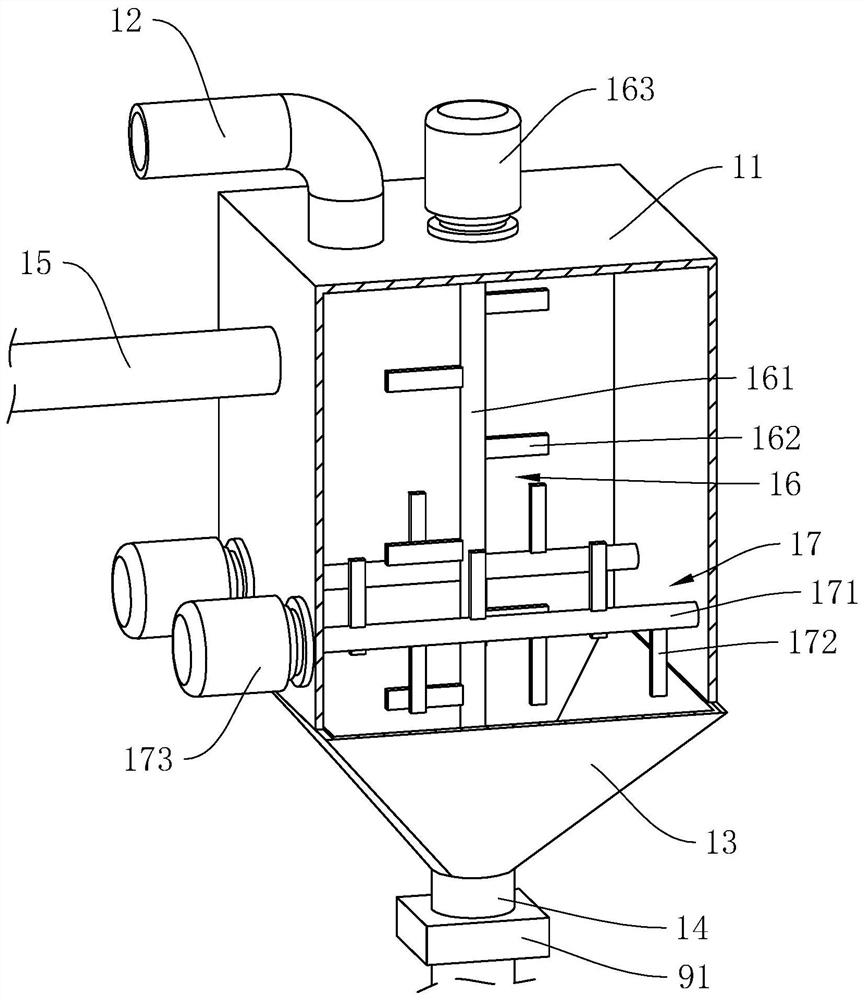

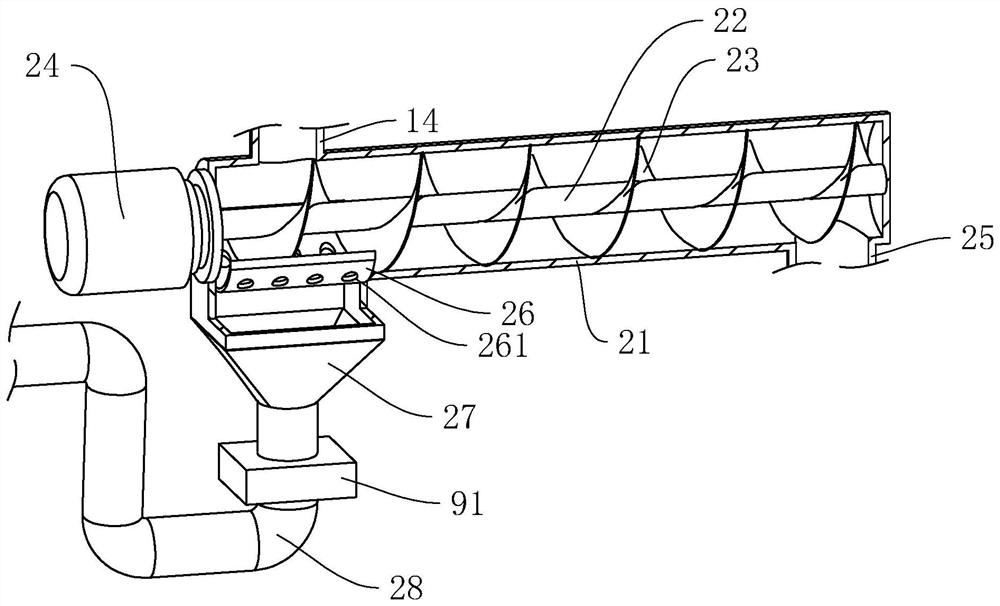

Pretreatment device and pretreatment method for rural sewage

ActiveCN112851019AReduce the impact of processingEasy to handleFatty/oily/floating substances removal devicesTreatment using aerobic processesPretreatment methodElectric machinery

The invention relates to the technical field of sewage pretreatment, and particularly discloses a pretreatment device and a pretreatment method for rural sewage. The pretreatment device comprises a collection mechanism, a first separation mechanism, a first precipitation mechanism, a crushing mechanism, a fermentation mechanism, a second separation mechanism, an aerobic mechanism and a second precipitation mechanism, wherein the collection mechanism comprises a collection box body, a first discharging pipe, a feeding pipe and a first discharging pipe; the first separation mechanism comprises a first collection box body, a driving shaft, a first spiral conveying blade, a third motor and a second discharging pipe, a discharging opening is formed in the bottom of the feeding end of the first collection box body, a first filtering plate is fixedly arranged at the position, located at the discharging opening, of the first collection box body, and a second discharging pipe is arranged at the position, located at the discharging opening, of the first collection box body; and the crushing mechanism comprises a crushing box body, two crushing rollers, a fourth motor, a filtering assembly, a third discharging pipe and a third discharging pipe. According to the pretreatment device, solid waste in sewage can be conveniently removed, and the influence of the solid waste on sewage treatment is reduced.

Owner:正中路桥建设发展有限公司

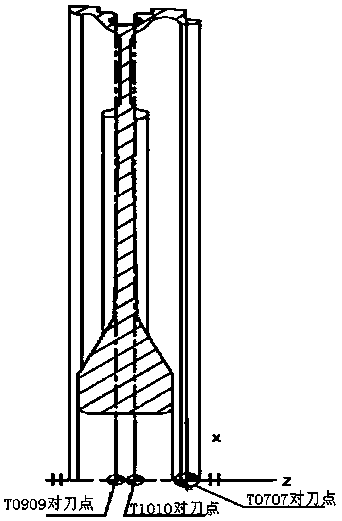

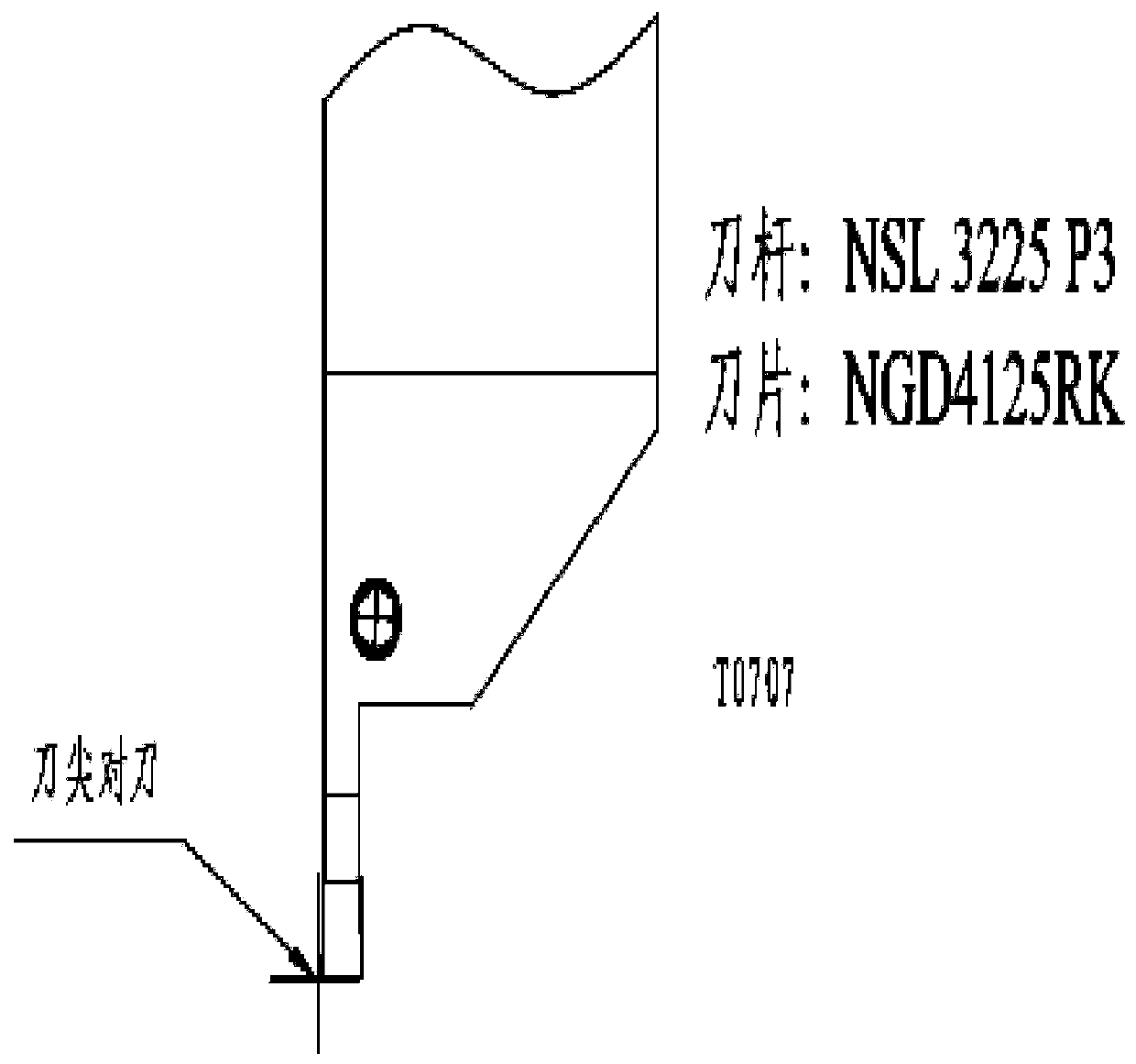

Tool setting method for annular mortise machining

ActiveCN109719308AGuaranteed accuracyGuaranteed machining accuracyTurning machinesSet pointEngineering

The invention discloses a tool setting method for annular mortise machining. An excircle open groove is formed in the side surface of a part to be machined, and an annular mortise is formed in the longitudinal direction of the middle part; an exposed straight opening of the excircle open groove in the side surface is chosen as a first longitudinal tool setting point at first, and the end surface of the excircle open groove is chosen as a first transversal tool setting point; after the excircle open groove is machined, the right side or the left side of the bottom end surface of the annular mortise is taken as a second longitudinal tool setting point, and the right side surface or the left side surface of the narrowest part of the annular mortise is taken as a second transversal tool setting point; and finally the left side or the right side of the bottom end surface of the annular mortise is taken as a third longitudinal tool setting point, and the left side surface or the right side surface of the narrowest part of the annular mortise is taken as a third transversal tool setting point. The tool setting method is applicable to turning machining for annular mortises in various typesof disc parts of aero-engines, and capable of ensuring the technical requirements of machining accuracy, symmetry degree, position degree and the like for the mortise.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

A method for processing narrow-groove impellers, a grinding head and a preparation method thereof

Owner:NORTHEASTERN UNIV LIAONING

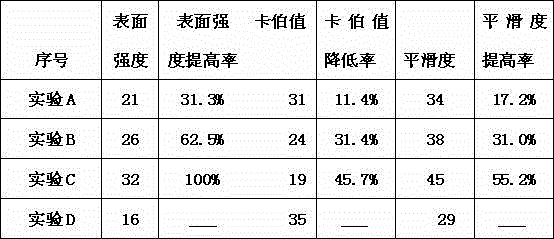

Spraying reinforcing agent used for brightening and reinforcing paper, and preparation method and application thereof

InactiveCN104610520AImprove surface strengthImprove water resistanceReinforcing agents additionHazardous substancePolymer solution

The invention discloses a preparation method for apaper brightening and reinforcing emulsion. The method comprises the following steps: S1, mixing water, an emulsifying dispersant and starch to prepare a starch emulsion; S2, adding a viscosity reducer into the starch emulsion under stirring, carrying out heating to 60 to 75 DEG C, and adding an initiator to adjust the pH value of the solution to 5 to 6; S3, adding an aqueous polymer solution, carrying out reacting for 3 to 5 hours, carrying out cooling, and adding a pH adjusting agent to adjust the pH value of the solution to 6 to 8; and S4, adding an anticorrosion stabilizer, wherein the degree of substitution is measured to be 0.03 to 0.06, and a grafted starch emulsion is prepared; i.e., the paper brightening and reinforcing emulsion is prepared. The preparation method for the paper brightening and reinforcing emulsion provided by the invention has the advantages of simple process, extremely short usage flow, exemption of production of harmful by-products and containment of harmful substances like formaldehyde and benzene and reduction of environmental hazards. The paper brightening and reinforcing emulsion of the invention can effectively improve paper tension, enables the paper to be smooth and glossy, can be directly used by mixing with a surface sizing or spraying glue solution when in use, and has the characteristics of simple and convenient use, low wastage rate, etc.

Owner:SHANGHAI XINGLIN ENVIRONMENT PROTECTION TECH

Metal cutting device based on capacitor plate discharge principle

InactiveCN112453604AProcessing environment safetyReduce wearElectrical-based auxillary apparatusPhysicsCapacitance

The invention relates to the technical field of electronic components, and discloses a metal cutting device based on a capacitor plate discharge principle. The metal cutting device based on the capacitor plate discharge principle comprises a shell, wherein a connecting rod I is movably connected into the shell, a connecting rod II is movably connected into the connecting rod I, and a connecting rod III is movably connected into the connecting rod II; under the interaction of the connecting rod I, the connecting rod II, the connecting rod III, a swing rod, a gear, a belt wheel, a belt, a fixingframe, an electrifying ring, a capacitor plate I, a capacitor plate II, an insulating block, a cutting blade, a time delay assembly, a gas tank and a cooling plate, the heat generated during metal processing can be quickly released through the cooling plate, so that processing personnel are prevented from making contact with metal to be scalded in an operation process; and meanwhile, the capacitor discharging principle is adopted in the device, abrasion of a cutter can be greatly reduced, and the metal machining efficiency is increased, so that accelerated advancing for the working progress is benefited.

Owner:广州旭卓科技有限公司

A self-cooling hob to prevent chips from remaining

ActiveCN112548231BAvoid damageReduce the temperatureGear teeth manufacturing toolsGear teethHobbingSpiral blade

Owner:南京迈森智能装备有限公司

A conveying device for processing electric vehicle handlebars

ActiveCN106076906BImprove the delivery effectProtect the aestheticsCleaning using toolsRollersElectric machineryEngineering

The invention discloses a conveying device for electric vehicle handlebar processing, which includes a casing. A material inlet is provided on the left side of the casing, and a material inlet is provided on the right side of the casing at a position corresponding to the material inlet. The discharge port, the inner cavity of the housing is fixedly installed with a brake guide wheel set, a wiping device and a guide device from left to right. The brake guide wheel set includes two brake wheels distributed up and down, and The axes of the two brake wheels are fixedly connected to the rotating shafts of the two motors respectively, and the two motors are installed on the bearing seats on the outer wall of the housing. Through the improvement of the brake guide wheel set, the present invention makes the handlebar raw material conveying effect better, avoids slipping during the transportation process, reduces the scratches on the surface of the raw materials when the brake guide wheel set is conveying, and protects the appearance of the raw materials. , and a wiping device is installed to reduce the impact of impurities on the surface of the raw material on processing, and it cooperates with the guide device to facilitate the discharge of raw materials from the discharge port.

Owner:平湖岳氏车业股份有限公司

Anti-blocking cutter for paperboard drilling

InactiveCN112873399AKeep hollow designAchieve relative motionMetal working apparatusPaper dustPaperboard

An anti-blocking cutter for paperboard drilling comprises a top plate, a connecting piece is fixedly connected to the circle center of the top plate, cutter cylinders are evenly arranged at the bottom of the top plate and located on the periphery of the connecting piece, fixing rods are arranged in the cutter cylinders, the interiors of the cutter cylinders are dredged, a stabilizing plate is arranged between the fixing rods and the connecting piece to limit and stabilize the cutter cylinders, an exhaust mechanism is arranged between the top plate and the stabilizing plate, a retractable air cylinder is arranged between the stabilizing plate and the top plate, and a limiting assembly is arranged on the surface of the stabilizing plate to limit and stabilize the overall stability of a cutter. Through cooperation of the cutter cylinders and the fixing rods, the fixing rods can clean the interior of the cutter cylinders after drilling of the cutter cylinders, paper scraps entering the interior of the cutter cylinders are discharged, in addition, the end openings of the fixing rods are located on the outer side of the cutter cylinders through relative movement between the fixing rods and the cutter cylinders, and therefore the cutter cylinders are not affected by the paperboard scraps.

Owner:马鞍山章鱼心网络科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com