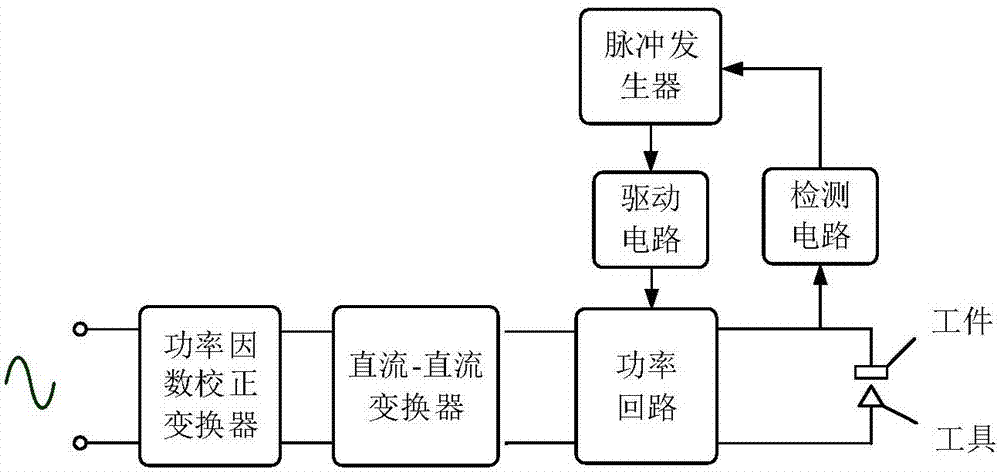

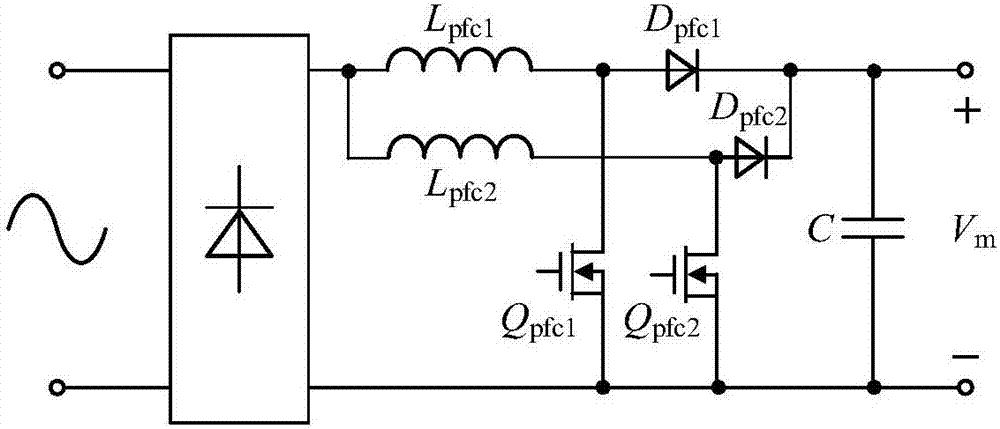

Micro electrical discharge pulse power source and segmental control method based on micro electrical discharge pulse power source

A pulsed power supply and electric spark technology, applied in control/regulation systems, circuits, manufacturing tools, etc., can solve the problems of low switching control accuracy and slowness, complex structure, etc., to ensure the multi-signal logic processing capability and driving speed, and simplify the circuit. Topology, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0045] Based on the novel electric spark pulse power supply provided by the present invention, the specific implementation of the segmental control method for gap voltage and gap current provided by the present invention is as follows:

[0046] The schematic diagram of each stage in a processing cycle in the new micro-EDM pulse power source processing is as follows: Figure 7 As shown, a processing cycle includes the processing stage and the deionization stage, and the processing stage includes the arc ignition stage and the discharge stage. A processing cycle 0~t 3 In the time period, the time t when the deionization phase starts 2 and the time t at the end of a processing cycle 3 They are all set, the transition time t between the arc ignition stage and the discharge stage 1 It is the moment when the gap is broken down, and it is constantly changing due to the influence of the state and properties of the gap. In the arc ignition stage, the gap has not been broken down, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com