Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Reduce stacking area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation and use method of fly ash based mineral polymer

InactiveCN101353232AAvoid pollutionReduce manufacturing costSolid waste managementCement productionGeopolymerSolid content

The invention relates to a preparation for a fly ash-based geopolymer and an application method thereof. The method mainly comprises the following steps: excitant solution and fly ash are mixed and stirred to paste; the paste is injected into a mold frame for molding; the molded product is maintained; the excitant solution is 2mol / L-5mol / L of silicate solution or water glass solution with the solid content to be 25-40% and the modulus to be 1.0-1.5. The preparation and the application method of the fly ash-based geopolymer fully use the industrial waste fly ash, which has the advantages of reducing cost, being favorable for environmental protection, reducing energy consumption and convenient application; the product obtained has the excellent characteristic of geopolymer.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Sludge curing agent and application thereof

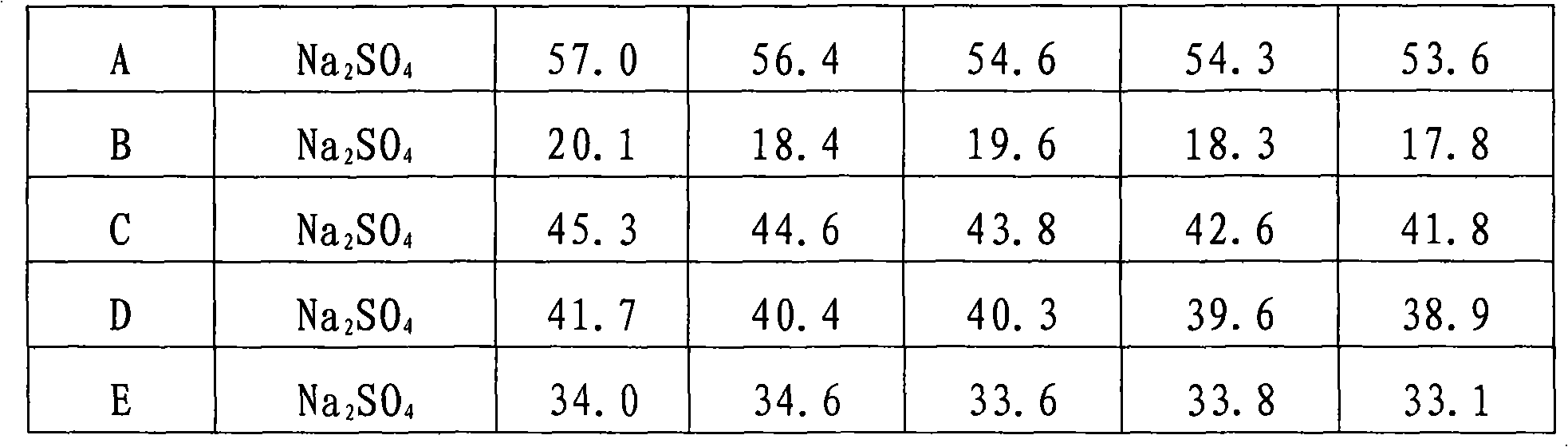

ActiveCN107673572AAchieve reuseAchieve solidificationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeFlexural strength

The invention discloses a sludge curing agent and application thereof. The sludge curing agent is suitable for curing treatment on high-water-content sludge in town sewage treatment plants, rivers andlakes. The sludge curing agent comprises the following raw materials in percentage by weight: 26 to 44 percent of silicon aluminum iron calcium oxide, 19 to 37 percent of calcium oxide, 13 to 30 percent of special cement, 5 to 25 percent of polyacrylamide and 0.2 to 3 percent of chitosan. The sludge curing agent realizes sludge curing and stabilization through the chemical property of the industrial waste and the mutual activity excitation; the water content of the sludge is effectively reduced, the early-stage compressive strength and the flexural strength of the sludge are improved, and mechanical operation during backfilling is facilitated; heavy metal in the sludge is adsorbed by the chitosan, organic matters are degraded, the pathogene is deactivated, pollution is reduced and stink can be eliminated; and the sludge curing agent is low in price and simple in curing process, and the cured sludge does not cause secondary pollution.

Owner:武汉鹏森环境科技有限公司

Process for producing pellet by mixing and processing hematite, siderite and vanadium titano-magnetite concentrate

The invention discloses a process for producing pellet by mixing and processing hematite, siderite and vanadium titano-magnetite concentrate, comprising the following steps of: proportioning, mixing, granulating, sieving, drying, preheating and roasting. The specific process conditions are adopted for proportioning, mixing, granulating, sieving, drying, preheating and roasting so that the mixed hematite and siderite and the surface submarginal vanadium titano-magnetite which are difficult to utilize can be well processed and produced into the pellet, wherein the mixed hematite and siderite has the iron concentrate (TFe) grade of 56%, the phosphor content of 0.21-0.35% and the silicon dioxide content of 9.34-10.12%, and the surface submarginal vanadium titano-magnetite has the iron concentrate (TFe) grade of more than 56%, the phosphor content of 0.015% and the silicon dioxide content of 9.13%. Therefore, the advantages of the mixed hematite and siderite and the surface submarginal vanadium titano-magnetite are complemented, and the mixed hematite and siderite and the surface submarginal vanadium titano-magnetite meet the smelting requirement. The invention effectively enhances the utilization rate of the ores and can bring high economic benefit for enterprises and decrease the land occupation of stacked waste ores and the adverse effect on environment.

Owner:TAIHE IRON MINE CHONGQING IRON & STEEL GROUP MINING +2

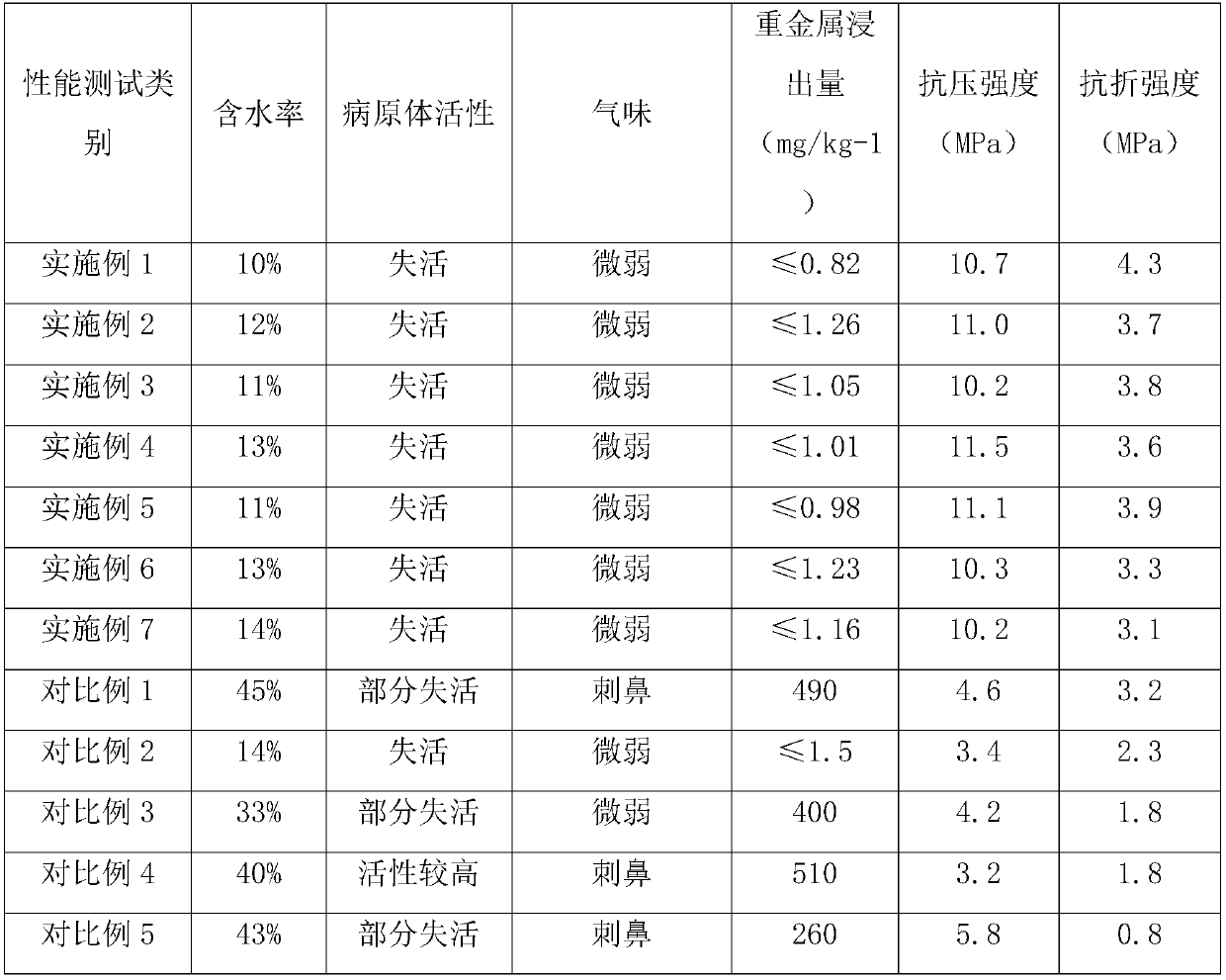

Mining method with mining-dressing and filling treatment

InactiveCN109488301AWide range of sorting particle sizeReduce water consumptionUnderground miningSurface miningControl measureCoal gangue

The invention discloses a mining method with mining-dressing and filling treatment, which includes design of main gangue sources for a little gangue working face, and gangue-reducing measures; ganguesorting system arrangement and equipment, and sorting process; filling-cooperated caving-type coal efficient stoping system arrangement and equipment, and production process; environmental influence pretreatment and pre-control measures before and after gangue filling; design principle and steps of the mining method with 'mining-dressing and filling treatment'. The method herein helps solve the long-range conveying problem of gangue, reduce underground gangue lifting cost, reduce mine auxiliary lifting and surface coal washery burden, effectively treat coal gangue to reduce surface piling areaof coal gangue, reduce mine ecological environment damage, protect the ecological environment; gangue filling and coal efficient stoping face has high unit production under high unit efficiency, therequirements of modern mines for production capacity can be met, and the method herein has a good application prospect.

Owner:CHINA UNIV OF MINING & TECH

Green recycled building material

InactiveCN102476931ASolve environmental pollutionReduce stacking areaSolid waste managementCarbonizationUrban waste

The present invention relates to a green recycled building material. The material is characterized in that: the method for producing the green recycled building material comprises the following steps: 1, carrying out mechanical crushing on building wastes from building demolition to obtain recycled sand with a fine sand state; 2, adopting the recycled sand to prepare concrete and mortar, and adding an additive, such that the performances of the concrete mixture meet the following requirements, wherein a ratio of the recycled sand to the additive is 97:3, and the requirements comprise that: the strength grade is C20, the water cement ratio is 0.60-0.62, and the collapsing degree (cm) is 5.0. With the green recycled building material of the present invention, the environmental pollution due to the discharged wastes during the building demolition process is effectively solved, the shortage problem of the natural sand source is solved, and the problems of area occupying due to urban waste stacking, and environmental pollution are reduced. The experiment results show that: performances of compressive strengths, mechanical properties, freezing resistance, carbonization properties and the like of the masonry mortar and the concrete reach or exceed the design standards, wherein masonry mortar and the concrete are prepared by using the recycled sand. In addition, significant economic benefits and significant social benefits are provided.

Owner:周立志

Anti-radiation mineral admixture containing barium slag

The invention relates to anti-radiation mineral admixture containing barium slag. The anti-radiation mineral admixture comprises, by mass, 50%-60% of the levigated barium slag, 20%-30% of coal ash, 10%-15% of levigated mineral powder, 0.5%-1% powder polycarboxylic acid water reducer, 0.1%-0.3% of polypropylene fiber, 5%-10% of silica fume and 0.5%-1% of thickener. The anti-radiation mineral admixture has the following advantages that a barium slag reuse way is provided; good radiation resistance is achieved; the anti-radiation mineral admixture can replace part of cement to be used in concrete, and the production cost of the concrete is lowered; the anti-radiation mineral admixture containing the barium slag is simple in preparing method, easy and convenient to prepare, low in cost and suitable for being produced on a large scale.

Owner:WUHAN UNIV OF TECH

Sand-washing technique of slate flour

InactiveCN101367630ASolving resource constraintsReduce stacking areaSolid waste managementSolid waste disposalWaste treatmentCrusher

The invention relates to a process for sand washing with stone dust. The invention is characterized in that the process for sand washing with stone dust comprises the following steps: (1) performing filtering and water scrubbing to separate out fine sand, soil particles and water; (2) sending the separated rough sand into a crusher for crush with water; (3) separating the sand, soil particles and water which are recrushed, refiltered and rescrubbed and the mixture of the sand, soil particles and water which are crushed, refiltered and scrubbed at the first time; (4) separating the mixture of sand, soil particles and water and then obtaining the finished sand and the finished soil particles which can be used to improve soil, wherein the water can be recycled for use. The invention performs three-waste treatment and processing to the waste stone dust generated during the production in a quarry, uses the stone dust which contains dust, fine sand and rough sand in the quarry as the raw materials to produce the building sand, thereby not only saving the problem concerning the shortage of the natural fine aggregate resource, but also being favorable for the environment protection in a aggregate production place and reducing the stacking place of the quarry waste and the environmental pollution.

Owner:刘庆凯

Composite modified cement stabilized regenerative aggregate base mixture and preparation method thereof

The invention discloses a composite modified cement stabilized regenerative aggregate base mixture and a preparation method thereof. The base mixture is prepared from the following raw materials in parts by weight: 100 parts of aggregate, 3 to 7 parts of cement, 0.09 to 0.49 part of composite modified material, 0.2 to 1.2 parts of rubber granules, 0.05 to 0.2 parts of basalt fibers and 5.6 to 6.6parts of water. The composite modified cement stabilized regenerative aggregate base mixture added with fibers and rubber has excellent mechanical strength, such as drying shrinkage, temperature shrinkage, frost resistance and compression resistance. The invention further discloses the preparation method for the composite modified cement stabilized regenerative aggregate base mixture added with fibers and rubber, the sources of the raw materials used by the preparation method are wide, prices are low, the preparation process is simple, and the preparation method has economic and social benefits.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

UHPC with high-volume mixed ceramic tile aggregate C160 and preparation method thereof

The invention discloses UHPC with high-volume mixed ceramic tile aggregate C160 and a preparation method thereof. The UHPC is prepared from the following components in percentage by weight: 757.5 kg / m<3> of cement, 151.4 kg / m<3> of silica fume, 37.9 kg / m<3> of fly ash, 151.0 kg / m<3> of ceramic tile powder, 46.4 kg / m<3> of a high efficiency water reducing agent, 212.2 kg / m<3> of aggregate, 848.6 kg / m<3> of quartz sand, 189.3 kg / m<3> of water and 156 kg / m<3> of steel fiber. The invention further discloses a preparation method of the UHPC. A curing method comprises the following steps: tightly wrapping a concrete test block with wet cotton cloth, and performing high-frequency intermittent watering curing or curing in water. The curing system is simplified, and evaporation of water in concretecan also be effectively prevented. The UHPC has the following technical advantages: waste ceramic tiles are recycled, consumption of natural materials is reduced, and effects of energy conservation and environmental protection are achieved; the ceramic tile powder has pozzolanic activity, and improves strength, durability, cracking resistance and flexural strength of the concrete. The ceramic tile powder with different particle sizes is added to fill gaps accumulated between quartz sand, so that the structure is more compact; the water-binder ratio and the high-efficiency water reducing agentare preferably selected, and the UHPC has the advantage of self-compacting.

Owner:XIANGTAN UNIV

Seawater mixed culture coral reef sand C120UHPC and preparation method thereof

The invention discloses seawater mixed culture coral reef sand C120UHPC and a preparation method thereof. The UHPC comprises the following components in proportion: 690.2 kg / m<3> of aluminoferrite cement; 138.6 kg / m<3> of fine coral reef powder; 194.1 kg / m<3> of coarse coral reef powder; 776.3 kg / m<3> of quartz sand; 138.6 kg / m<3> of silica fume; 34.7 kg / m<3> of fly ash; 182.3 kg / m<3> of seawater;41.6 kg / m<3> of a superplasticizer; and 140.4 kg / m<3> of steel fibers. The invention also discloses a preparation method of the UHPC, and a curing method comprises the following steps: placing a concrete test block in a standard curing chamber, covering the test block with wet linen, or placing the test block in water, maintaining multiple watering curing in the curing process, and preventing evaporation of water in the concrete, so that the curing method avoids steam curing of the UHPC. The seawater mixed culture coral reef sand C120UHPC and the method have the technical advantages that themethod is beneficial to application and popularization of UHPC, has important significance in meeting large-scale engineering construction of island reefs in the South China Sea, achieving local material utilization, reducing cost, shortening the construction period and the like, the construction cost of offshore engineering is reduced, and the requirements for greenization, energy conservation and environmental protection of civil engineering are met.

Owner:XIANGTAN UNIV

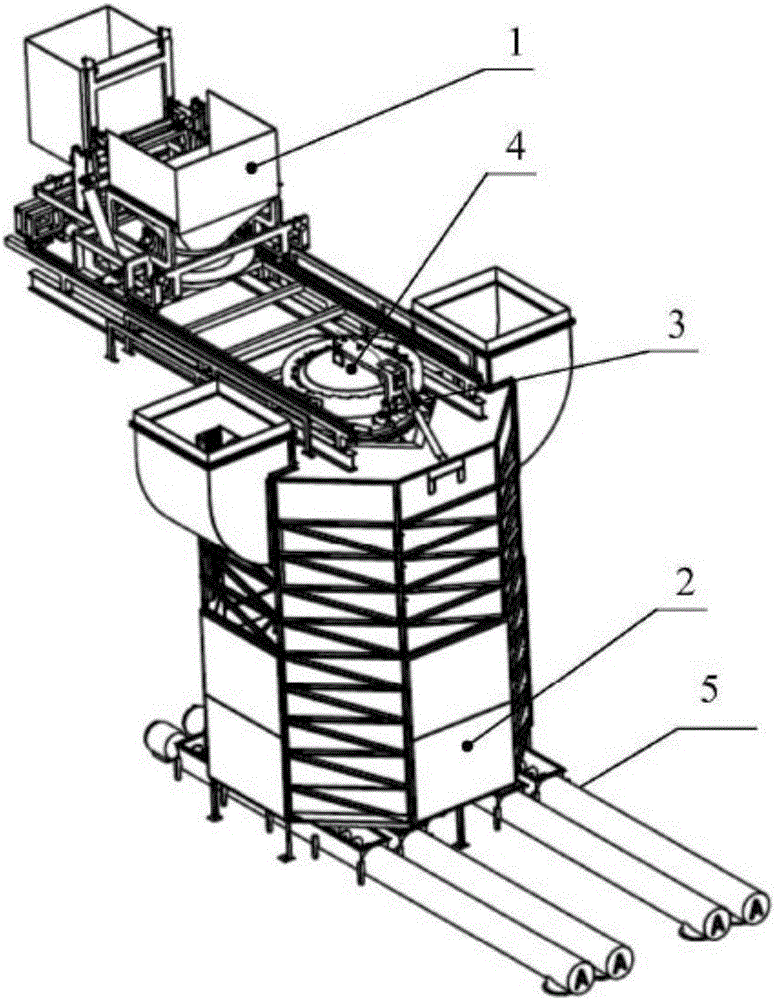

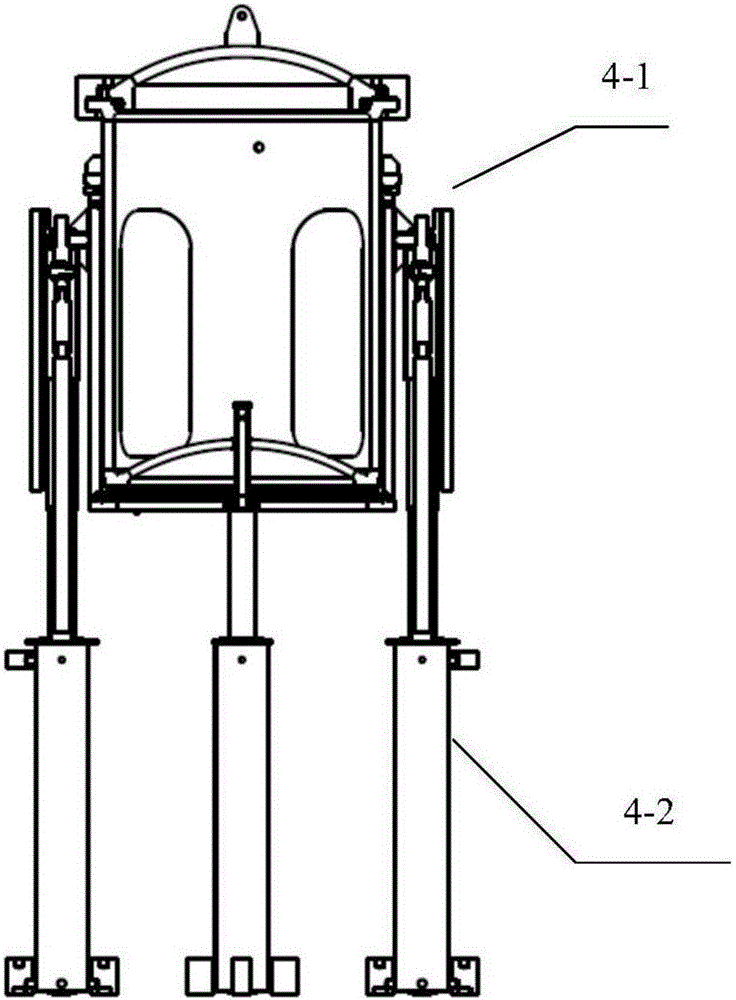

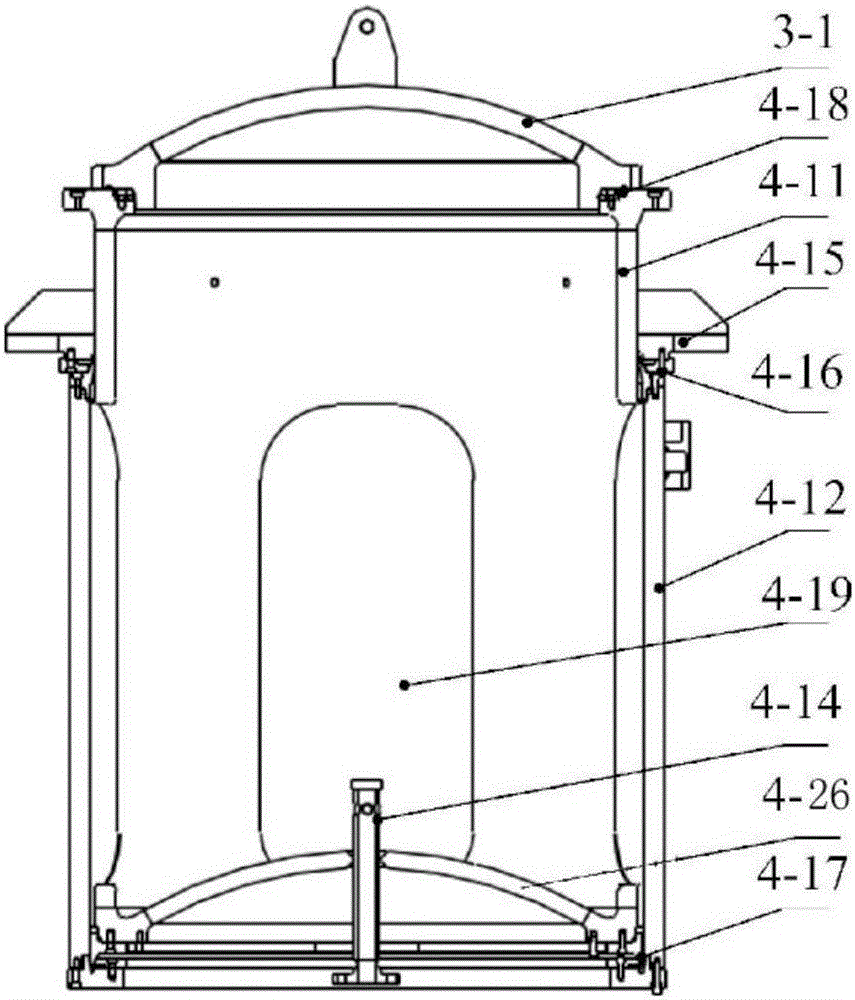

Organic matter processing equipment with high sealing performance

InactiveCN106040711AAvoid accumulationIncrease the exhaust discharge areaEngine sealsSolid waste disposalEngineeringOrganic matter

The invention discloses organic matter processing equipment with high sealing performance. The organic matter processing equipment comprises a feeding device, a separator, a cover opening device and a pressure increasing and releasing device which is installed inside the separator. The separator conducts gas-solid separation on processed materials. The feeding device and the cover opening device are both arranged at the upper portion of the pressure increasing and releasing device, namely the top of the separator. The feeding device injects the materials into the pressure increasing and releasing device through the cover opening device. In the pressure increasing and releasing device, the material weight and steam outward pressure are borne by an upper cylinder barrel, an air cylinder is only used for supporting and pushing a lower cylinder barrel, and the requirement for thrust of the supporting air cylinder is lowered; and meanwhile a half-hidden type sealing structure is adopted, materials are directly prevented from making contact with the sealing position in the discharging process, the service life of a sealing piece is prolonged, and the reliability of the sealing piece is improved.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

Building hollow brick prepared by dredged sludge and preparation method thereof

InactiveCN106278122AIncrease moisture contentReduce intensitySolid waste managementCeramicwareWater contentGypsum

The invention discloses a building hollow brick prepared by dredged sludge. The building hollow brick is prepared from the following raw materials in parts by weight: 10 to 28 parts of dredged sludge (weight after dehydration), 30 to 55 parts of coal gangue, 8 to 16 parts of quick lime, 4 to 8 parts of gypsum, 10 to 18 parts of water glass, 10 to 15 parts of cement, and an accelerator which is 0.2 to 0.4 percent of the total weight of the raw materials. The invention also discloses a method for preparing the building hollow brick by using the dredged sludge. The method comprises the following steps: processing raw materials, stirring and mixing, pressing for molding, and maintaining, thereby obtaining a finished product. By adopting the technical scheme, a great amount of coal gangue is consumed, and thus the floor occupation is gradually reduced; when the water content of the dredged sludge reaches a certain value, the dredged sludge can be used, so that the water consumption is reduced, the stacking time is reduced, and the occupied floor is further reduced; and meanwhile, a great number of harmful substances generated by decomposing organic matters in the naturally drying process of the dredged sludge are reduced, so that the environmental pollution caused by the harmful substances is avoided.

Owner:明光市凯旋新型建材厂

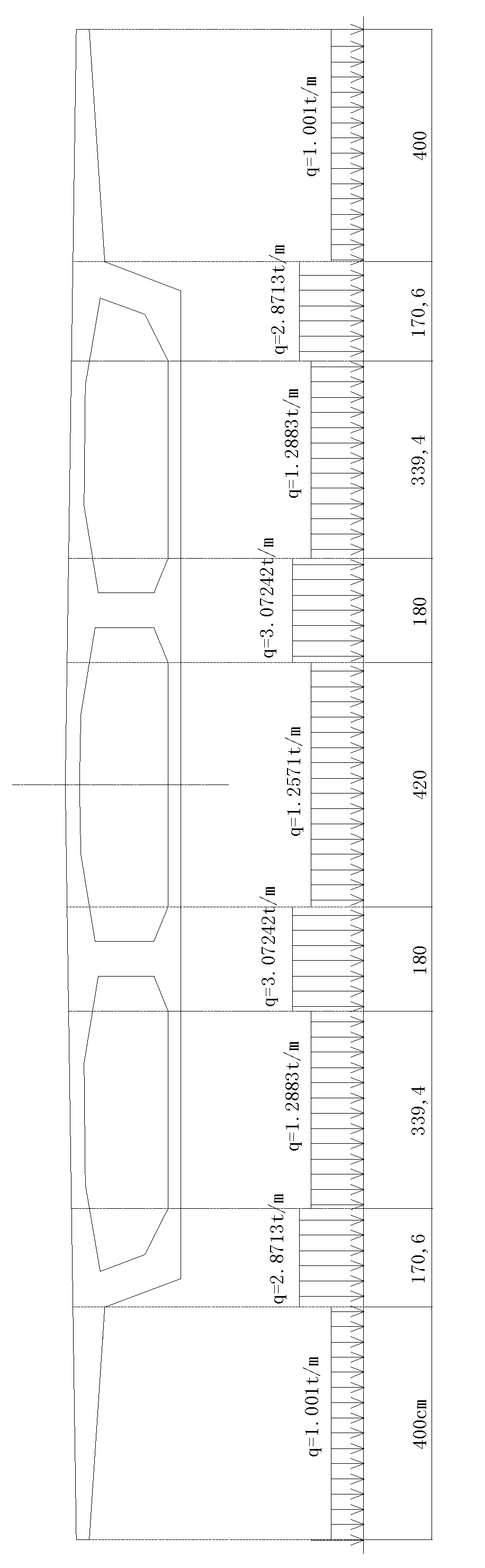

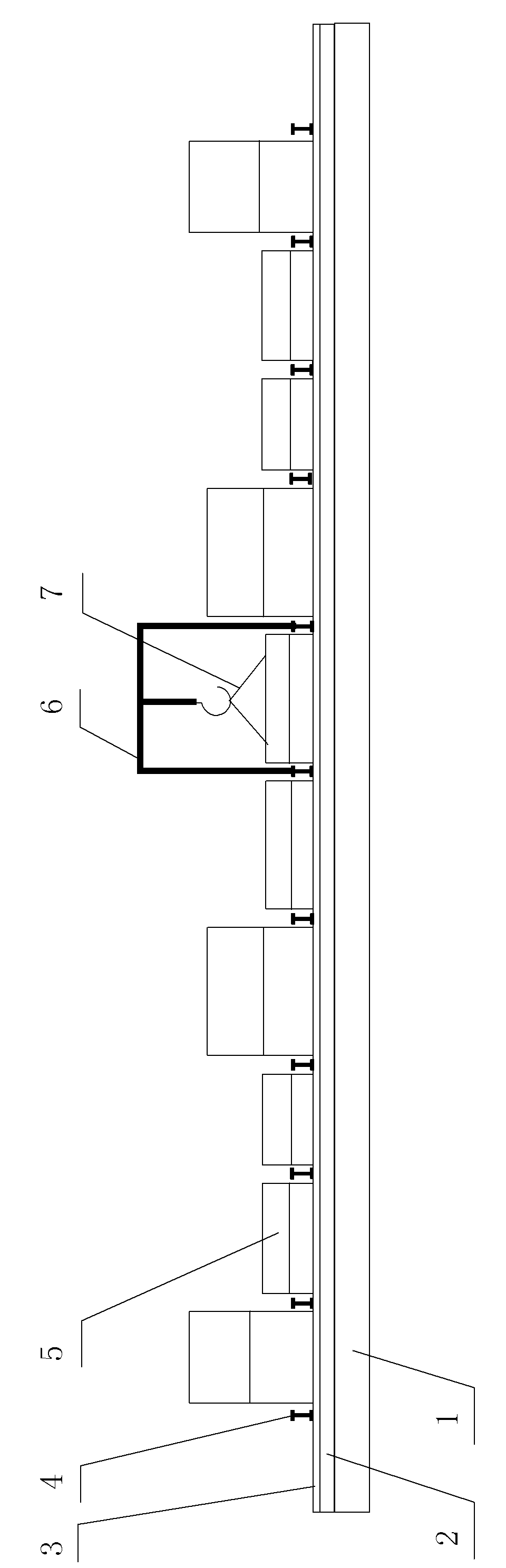

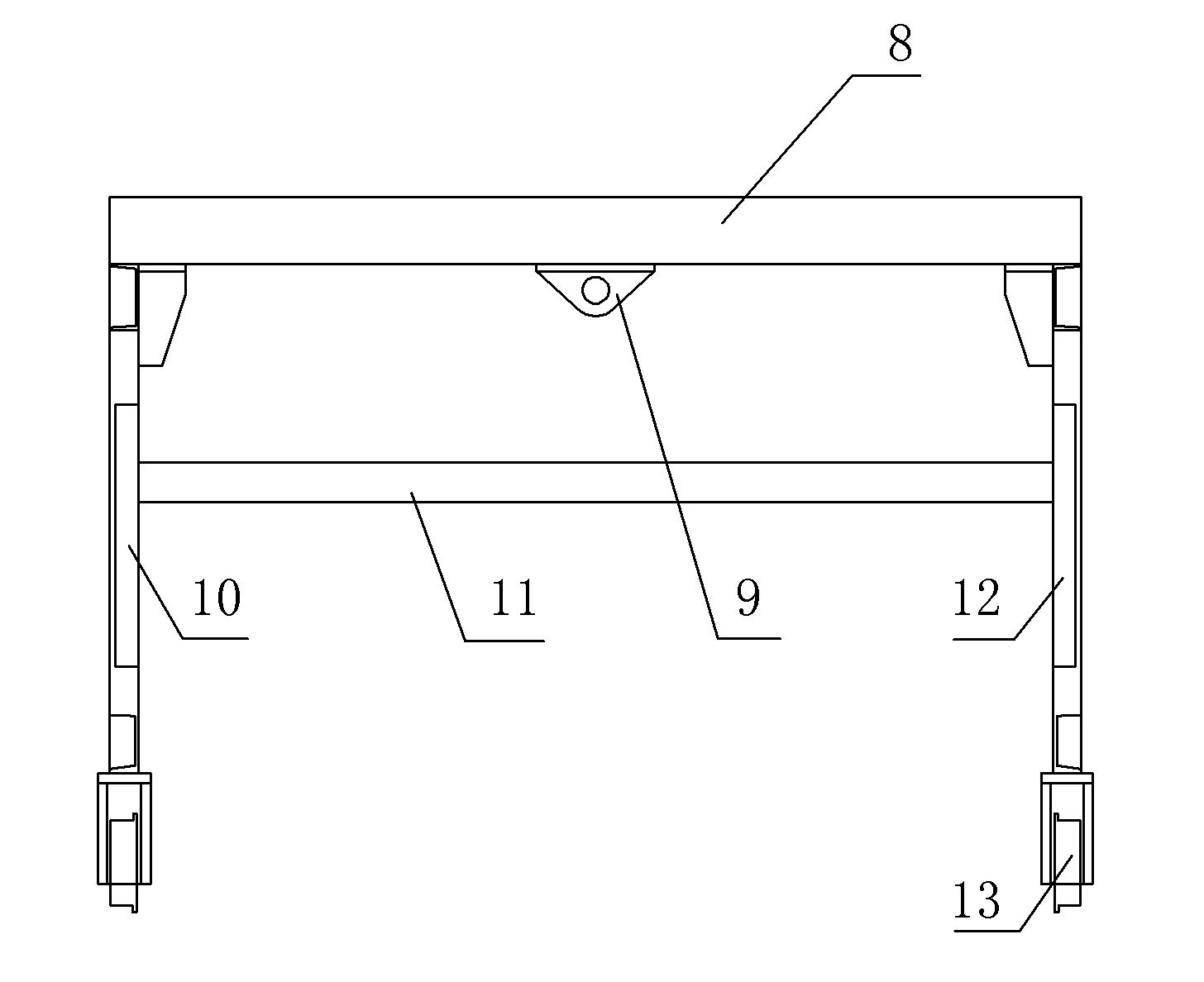

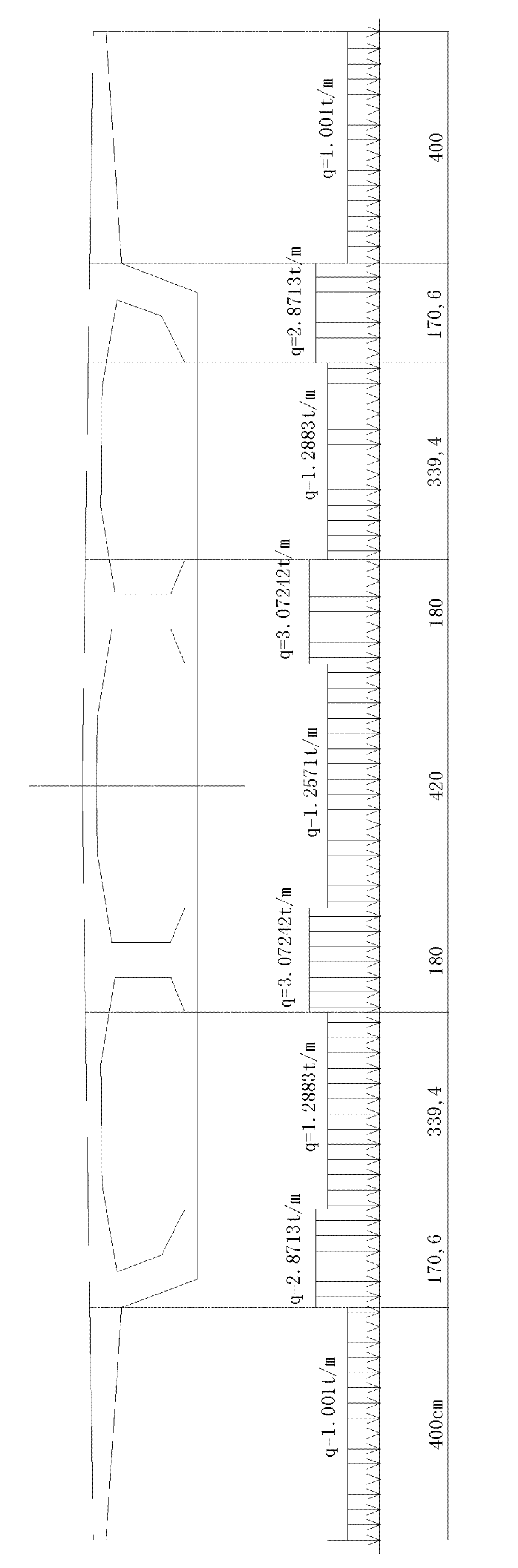

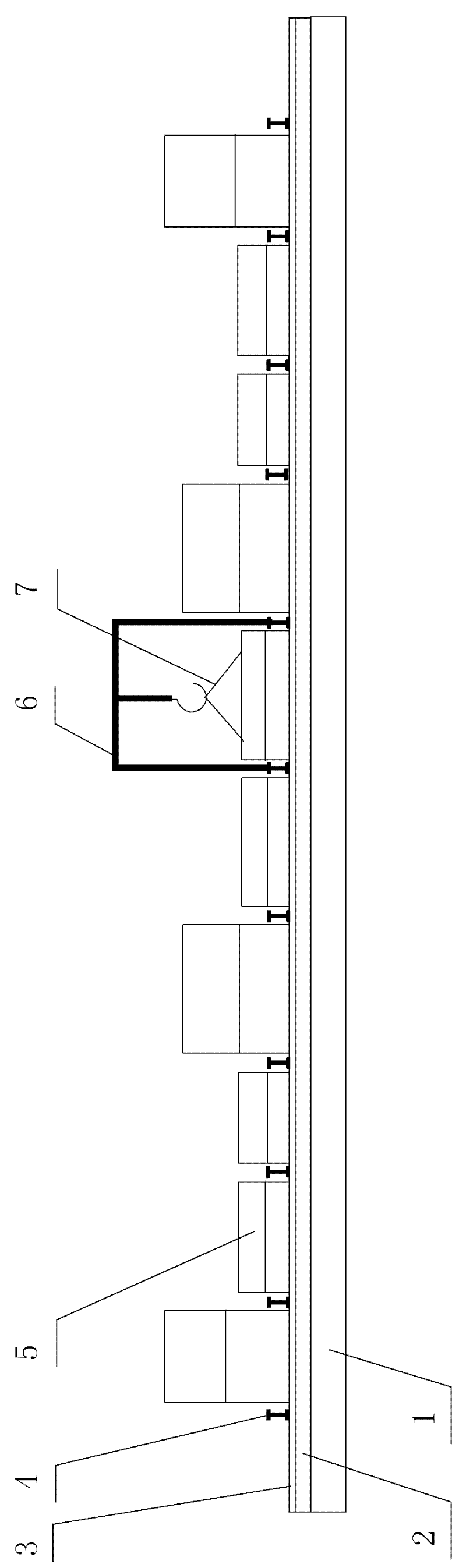

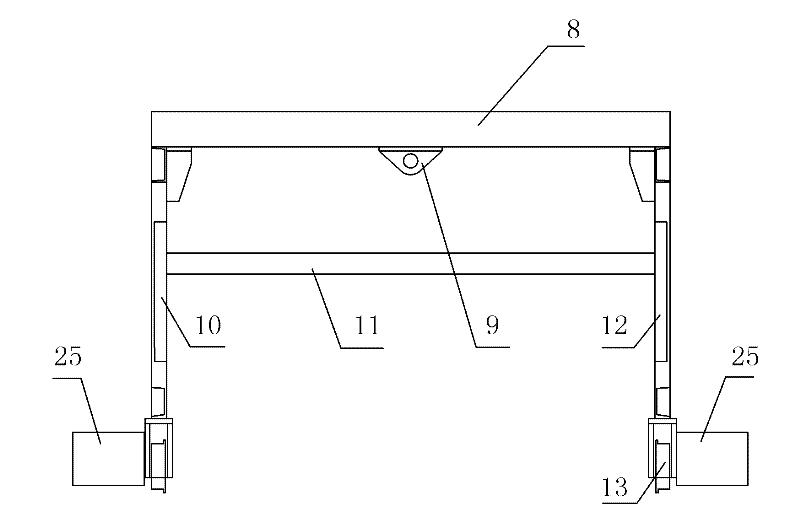

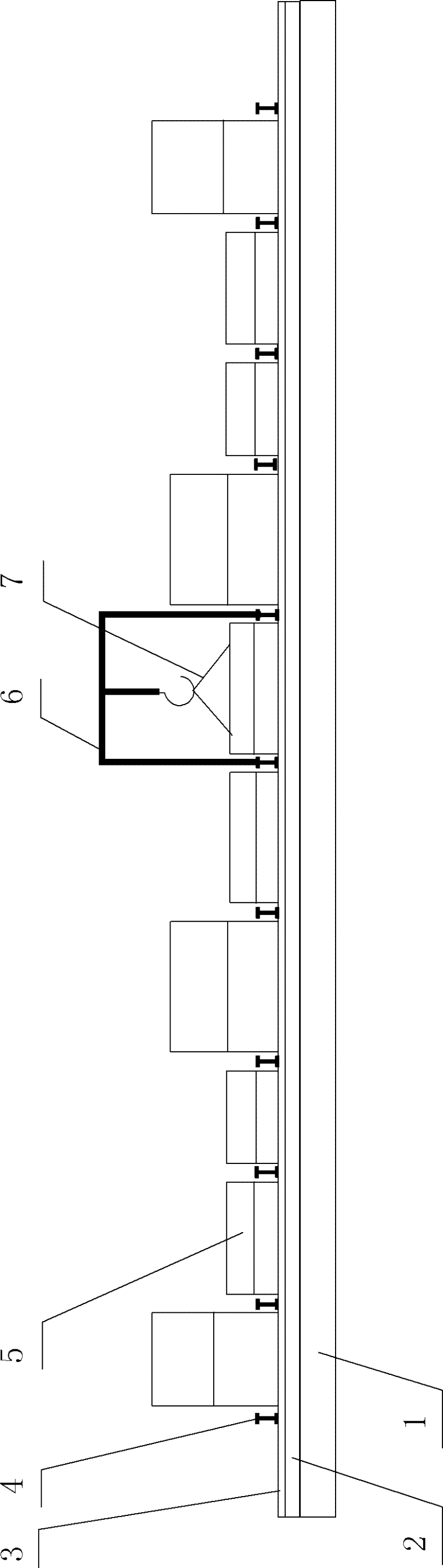

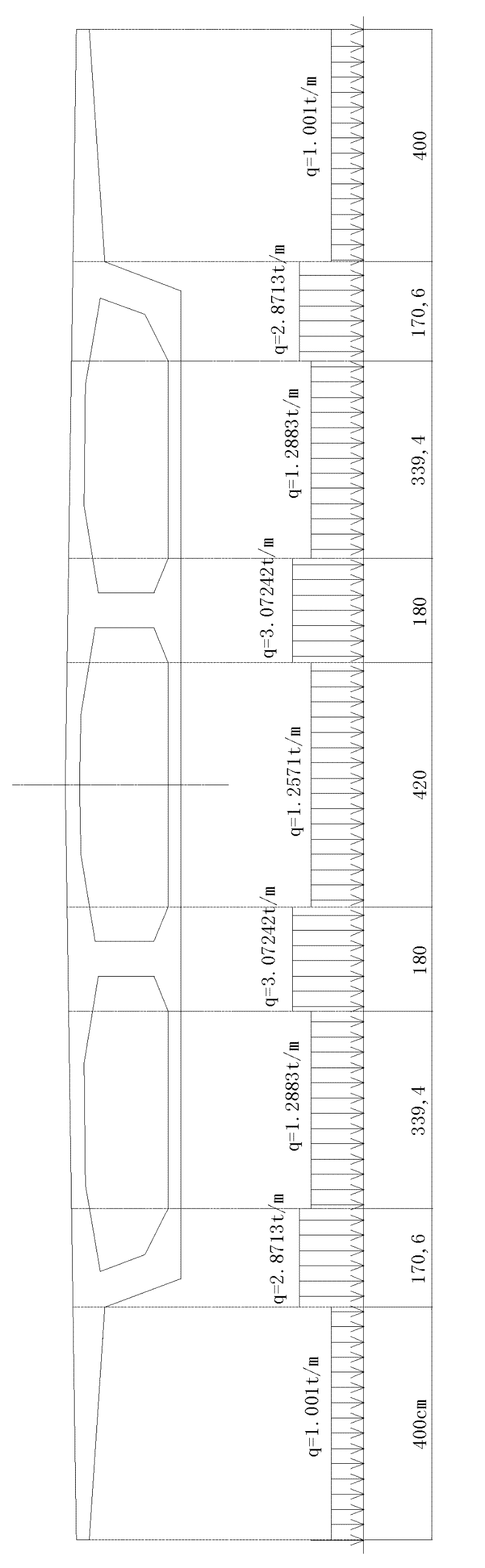

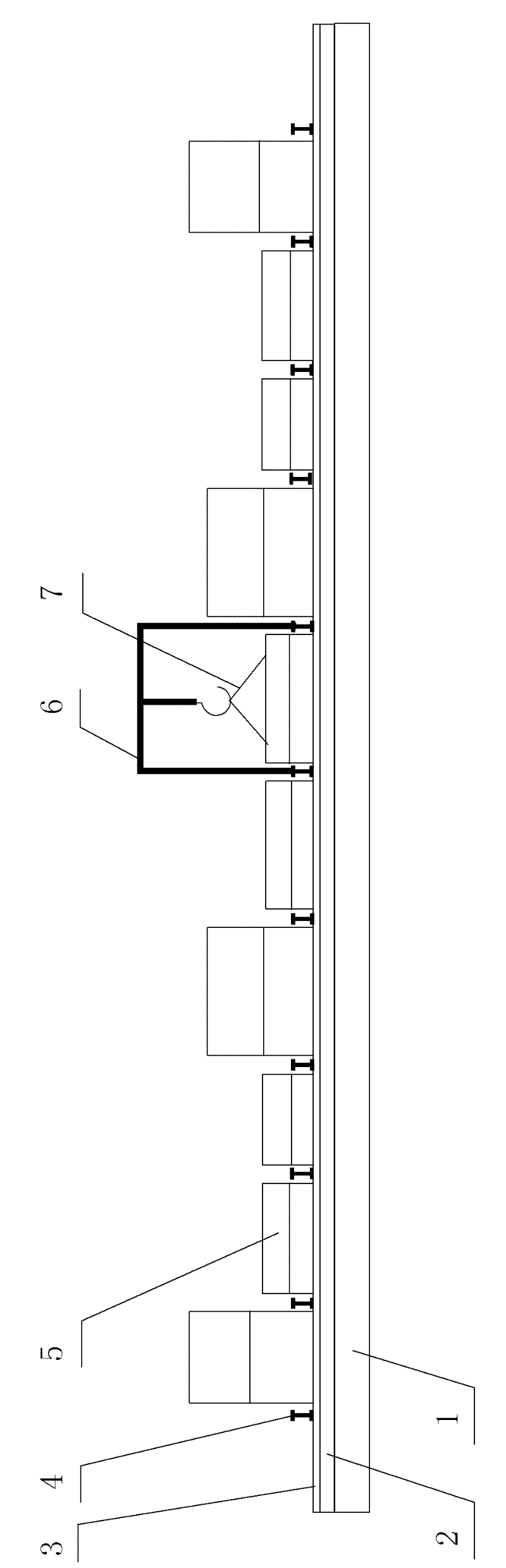

Method for carrying out load test on bridge support frame by prefabricated parts moved through tractive walking

InactiveCN102012313AReduce collapse accidentsReduce casualtiesMachine part testingTest efficiencyGallows

The invention relates to a method for carrying out load test on a bridge support frame. The method for carrying out load test on the bridge support frame by prefabricated parts moved through tractive walking is characterized by comprising the following steps: firstly placing a template special for loading on a box-beam template on the bridge support frame; installing a plurality of rails on the template special for loading along the longitudinal direction of the bridge support frame; placing gallows frames on the rails, using a tractor to tow the gallows frames to walk to transport the prefabricated parts horizontally to lift and lower the prefabricated parts on the first layer, carrying out load test detection on the bridge support frame and then lifting and lowering the prefabricated parts on the second layer after meeting the requirement; carrying out detection again after completing loading; after test detection meets the requirement, firstly unloading the prefabricated parts on the second layer and then unloading the prefabricated parts on the first layer after all the prefabricated parts on the second layer are unloaded. The method has good reliability and safety, high test efficiency, standard test measurement and high precision of load simulation.

Owner:CHINA FIRST METALLURGICAL GROUP

High-volume mixed glass powder C190UHPC (Ultra-High Performance Concrete) and preparation method thereof

The invention discloses high-volume mixed glass powder C190UHPC (Ultra-High Performance Concrete) and a preparation method thereof. The high-volume mixed glass powder C190UHPC is prepared from the following components in proportions: 773.4kg / m<3> of cement, 154.7kg / m<3> of silica fume, 38.7kg / m<3> of pulverized fuel ash, 154.7kg / m<3> of fine glass powder, 46.4kg / m<3> of a superplasticizer, 216.6kg / m<3> of coarse glass powder, 866.2kg / m<3> of quartz sand, 193.4kg / m<3> of water and 156kg / m<3> of steel fiber. The invention also discloses the preparation method of the high-volume mixed glass powder C190UHPC. A maintenance mode is characterized by tightly coating a concrete test block by using wet cotton cloth, and intermittently spraying water at a high frequency for maintaining, or maintaining in water. Not only a maintenance system is simplified, but also evaporation of water in concrete is effectively prevented. The high-volume mixed glass powder C190UHPC disclosed by the invention hasthe following technical advantages that waste glass can be recycled, consumption of natural materials is reduced, and the effect of environmental protection is achieved; the glass powder has pozzolanic activity, so that the strength and the durability of the concrete are increased; due to the doping of the glass powder in different grain diameters, accumulation gaps between the quartz sand is remedied, and the structure is tighter; a water-glue ratio and the superplasticizer are preferably selected, so that the high-volume mixed glass powder C190UHPC has the advantage of self-compaction.

Owner:XIANGTAN UNIV

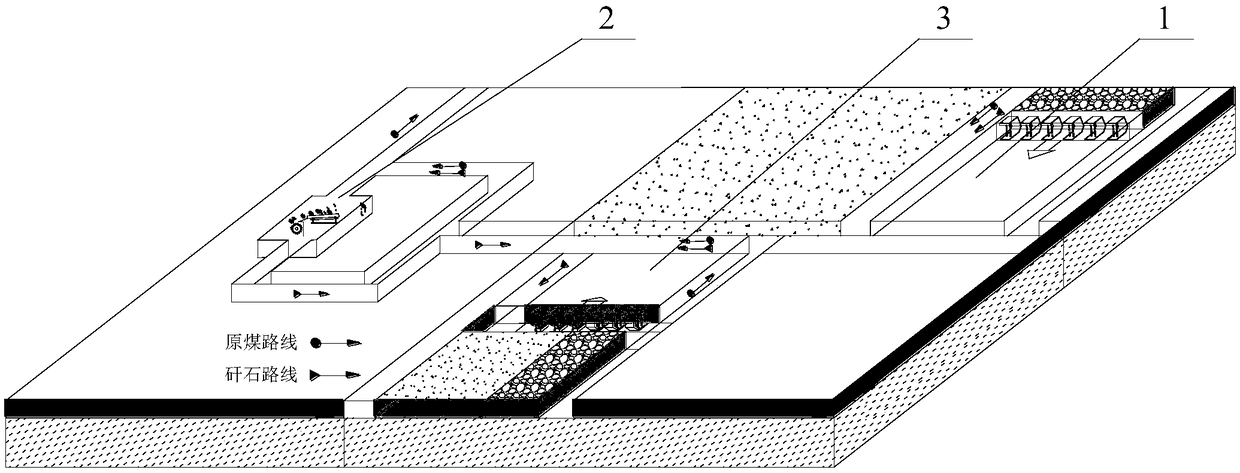

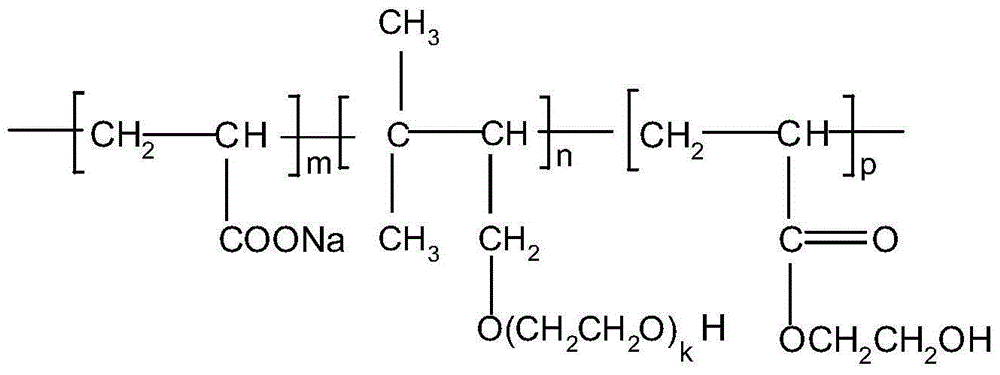

Automatic production equipment and process of environment-friendly polycarboxylate superplasticizer

ActiveCN114433462AAvoid sticking to each otherReduce stacking areaSievingConveyorsAcid waterSuperplasticizer

The invention relates to the field of water reducing agents, in particular to automatic production equipment of an environment-friendly polycarboxylic acid water reducing agent and a process thereof. The technical problems that existing polycarboxylate superplasticizer residues are attached to a conveying belt and can corrode the conveying belt, existing equipment is poor in cleaning effect on the conveying belt through brushes, and filtering matching is difficult to achieve in the feeding process are solved. According to the technical scheme, the automatic production equipment for the environment-friendly polycarboxylate superplasticizer comprises a first mounting plate, a dispersing system and the like; and a dispersing system is connected between the opposite sides of the two first mounting plates. The powder water reducing agent is driven to be sieved in a centrifugal mode, large-particle and blocky water reducing agents are subjected to collision type separation in the sieving process, the powder water reducing agent in the conveying process is turned over, and meanwhile the accumulated water reducing agent is subjected to vertical separation so as to reduce the accumulation area; and the polycarboxylate superplasticizer on the surface of the conveyor belt is removed in a mutual dislocation mode.

Owner:山西科腾环保新材料股份有限公司 +1

Exploding type organic matter treatment equipment

InactiveCN106040710AAvoid accumulationIncrease the exhaust discharge areaEngine sealsSolid waste disposalOrganic matterMechanical engineering

The invention discloses exploding type organic matter treatment equipment which comprises a feeding device, a separator, a cover opening device, a discharging device and a pressurization and pressure relief device. The pressurization and pressure relief device is installed in the separator. The separator carries out gas-solid separation on treated materials. The discharging device is located below the separator and conveys separated solids out. The feeding device and the cover opening device are installed on the pressurization and pressure relief device, namely on the top of the separator. The feeding device fills the materials into the pressurization and pressure relief device through the cover opening device. In the pressurization and pressure relief device, pressure exerted on the outside from the material weight and steam is borne by the upper cylinder barrel. An air cylinder is just used for supporting and pushing the lower cylinder barrel, and the requirement for thrust for supporting the air cylinder is lowered. Meanwhile, a semi-hidden type sealing structure is adopted, the situation that the materials make contact with the sealing position in the discharging process is directly avoided, the life of a sealing part is prolonged, and the reliability of the sealing part is improved.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

Preparation method of novel building reclaimed sand

The invention discloses a preparation method of novel building reclaimed sand. The building reclaimed sand is prepared by the following steps: mechanically pulverizing construction waste, generated after building demolition, into the construction waste in a gravel state; mechanically pulverizing the construction waste in the gravel state again to form reclaimed sand in a fine sand state, wherein technical indicators of the reclaimed sand are as follows: bulk density is 1150kg / m<3>, mud content is 6.0%, clod content is 1.2%, the water absorption rate is 5%, total brick content is 0.2%, and organic matter content is qualified; preparing concrete and mortar with the reclaimed sand to improve the performance of concrete and mortar, reduce bleeding, increase the fluidity and workability of a mixture, and adding a reinforcing agent, so that the performance of a concrete mixture reaches the standards. The invention solves the environment pollution problem caused by waste discharged during building demolition, solves the problem of natural fine aggregate resource shortage, is conducive to the environment protection of an aggregate production area, and reduces the problems of land occupation and environment pollution of urban waste.

Owner:绍兴悦植科技有限公司

High-volume mixed ceramic tile aggregate C150UHPC (Ultra-High Performance Concrete) and preparation method thereof

The invention discloses high-volume mixed ceramic tile aggregate C150UHPC (Ultra-High Performance Concrete) and a preparation method thereof. The high-volume mixed ceramic tile aggregate C150UHPC is prepared from the following components in proportions: 776.5kg / m<3> of cement, 155.3kg / m<3> of silica fume, 38.8kg / m<3> of pulverized fuel ash, 155.3kg / m<3> of ceramic tile powder, 46.6kg / m<3> of a superplasticizer, 217.4kg / m<3> of ceramic tile aggregate, 869.7kg / m<3> of quartz sand, 184.4kg / m<3> of water and 156kg / m<3> of steel fiber. The invention also discloses the preparation method of the high-volume mixed ceramic tile aggregate C150UHPC. A maintenance mode is characterized by tightly coating a concrete test block by using wet cotton cloth, and intermittently spraying water at a high frequency for maintaining, or maintaining in water. Not only a maintenance system is simplified, but also evaporation of water in concrete is effectively prevented. The high-volume mixed ceramic tile aggregate C150UHPC disclosed by the invention has the following technical advantages that waste ceramic tiles can be recycled, consumption of natural materials is reduced, and the effect of environmental protection is achieved; the ceramic tile powder has pozzolanic activity, so that the strength , the durability, the cracking resistance and the bending strength of the concrete are increased; due to the doping of the ceramic tile powder in different grain diameters, accumulation gaps between the quartz sand is remedied, and the structure is tighter; a water-glue ratio and the superplasticizer are preferably selected, so that the high-volume mixed ceramic tile aggregate C150UHPC has the advantage of self-compaction.

Owner:XIANGTAN UNIV

Multifunctional clamping system for forklift

InactiveCN114408811AImprove concentrationImprove the efficiency of scattered small objectsLifting devicesControl engineeringElectric machinery

The invention belongs to the technical field of forklift equipment, and particularly relates to a multifunctional clamping system for a forklift, which comprises a base plate module, two groups of moving adjusting modules are slidably connected in the base plate module, and clamping modules for clamping and gathering goods are rotatably connected in the moving adjusting modules. By arranging the clamping modules capable of being gathered, scattered light objects can be conveniently gathered, and therefore the efficiency of the forklift for transporting the scattered small objects is improved. Two first gear motors are fixed to the upper portion of the back face of a bottom plate, motor shafts, located in the bottom plate, of the first gear motors are in transmission connection with first rope winding wheels, two second guide wheels are fixed to the inner top face of a second square pipe, and one end of a first traction rope is wound around the outer wall of each first rope winding wheel; the other end of the first traction rope sequentially passes through the second guide wheel, the third guide wheel and the first guide wheel on the same side to be fixedly connected with the traction shaft, in this way, the second rotating frame connected with the clamping module drives the clamping module to swing by controlling the first gear motor, and therefore the object stacking area is reduced.

Owner:郭海龙

Method for carrying out load test on bridge support frame by prefabricated parts moved by electrically operated gallows frames

InactiveCN102012314BReduce collapse accidentsReduce casualtiesMachine part testingGallowsStandard test

Owner:CHINA FIRST METALLURGICAL GROUP

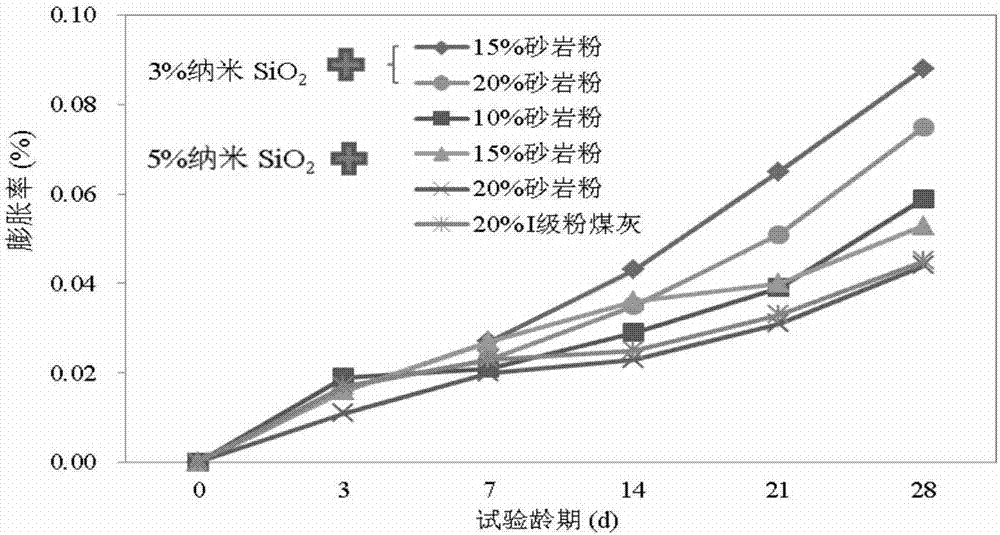

Alkaline activity inhibition material based on active sandstone aggregate and preparation method thereof

The invention provides an alkaline activity inhibition material based on active sandstone aggregate and a preparation method of the alkaline activity inhibition material. By adopting the sandstone aggregate with potential alkaline activity, sandstone powder with the specific surface area of (645 to 950) m<2> / kg is prepared through twice grinding of a vertical mill and a ball mill, and the sandstone powder is uniformly mixed with medium heat cement and nano SiO2 in a certain proportion. The inhibition material is prepared from the following raw materials in percentages by weight: 75% to 87% of the medium heat cement, 10% to 20% of the sandstone powder and 3% to 5% of the nano SiO2. The alkaline activity inhibition material prepared in the invention has the technical advantages that the raw materials are easy to get, the machinability is good, the preparation technology is simple, the alkaline activity inhibition effect is obvious, and the preparation process is free of pollution to the environment, and is beneficial to large-scale production and application of engineering.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

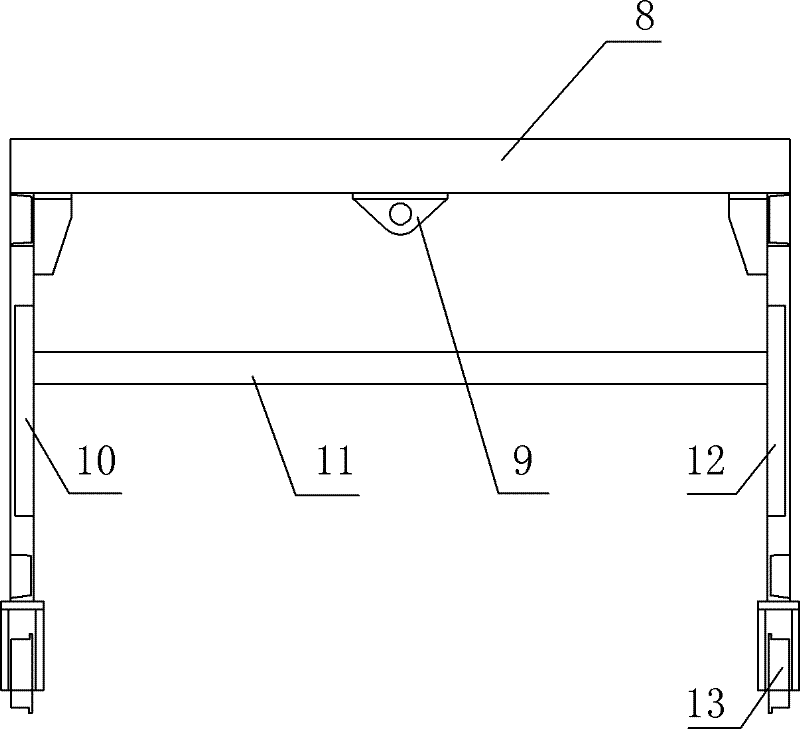

Method for performing load test for bridge support frame with hand-propelled movable prefabricated part

InactiveCN102023092BReduce collapse accidentsReduce casualtiesMachine part testingEngineeringStandardization

The invention relates to a method for performing a load test for a bridge support frame. The method for performing the load test for the bridge support frame with a hand-propelled movable prefabricated part is characterized in that the method comprises the following steps of: firstly installing a load special mould on a box girder mould arranged on the bridge support frame; installing a pluralityof tracks on the load special mould along the vertical direction of the bridge support frame; installing door-shaped hangs on the tracks; pushing the door-shaped hangs with hands to realize the horizontal transportation of the prefabricated part for carrying out the hanging and release of a first layer of prefabricated part, performing load test detection for the bridge support frame, and then carrying out the hanging and release of a second layer of prefabricated part after the requirement of load test detection is reached; and carrying out the detection again after finishing loading; unloading after requirements of testing and detecting are reached, wherein the second layer of prefabricated part is unloaded firstly, and the first layer of prefabricated part is unloaded after the second layer of prefabricated part is completely unloaded. The method has good reliability and safety, and also has high accuracy for test measure standardization and load simulation.

Owner:CHINA FIRST METALLURGICAL GROUP

Sand-fixing structure of gravel construction waste and gravel and method of making the same

InactiveCN104328779BSolve the puzzles of the siegeImprove ecologySoil preservationRainfall runoffEngineering

Owner:GANSU DESERT CONTROL RES INST

Method for carrying out load test on bridge support frame by prefabricated parts moved through tractive walking

InactiveCN102012313BReduce collapse accidentsReduce casualtiesMachine part testingTest efficiencyGallows

Owner:CHINA FIRST METALLURGICAL GROUP

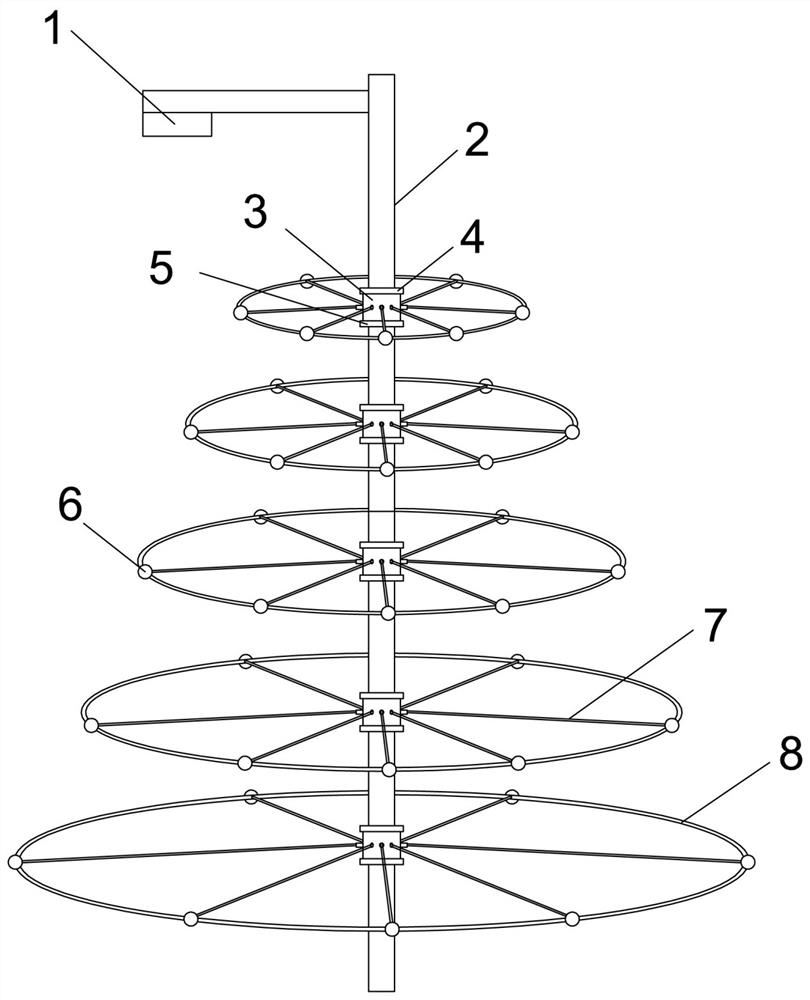

Novel waste slag pile slope stabilizing device

ActiveCN112681344AReduce the likelihood of landslidesPlay a role in shapingExcavationsBulkheads/pilesSlagMechanical engineering

The invention relates to the technical field of engineering waste slag treatment, in particular to a novel waste slag pile slope stabilizing device. The stabilizing device comprises a stabilizing rod, an image acquisition device is arranged on the stabilizing rod, fixing hoops are further arranged on the stabilizing rod, a plurality of supporting rope discs are arranged on the peripheral side of the stabilizing rod from bottom to top and from large to small, and first ropes in the supporting rope discs are fixedly connected to the fixing hoops. According to the novel waste slag pile slope stabilizing device, the stability of the whole waste slag pile can be improved, the whole waste slag pile is restrained, the waste slag pile can be shaped through mutual cooperation of the stabilizing rod and the supporting rope discs, the stacking area of the waste slag pile is reduced, the stacking stability rate is improved within the framing range of the supporting rope discs, the landslide phenomenon of the slope is avoided, and casualties and property losses are reduced.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

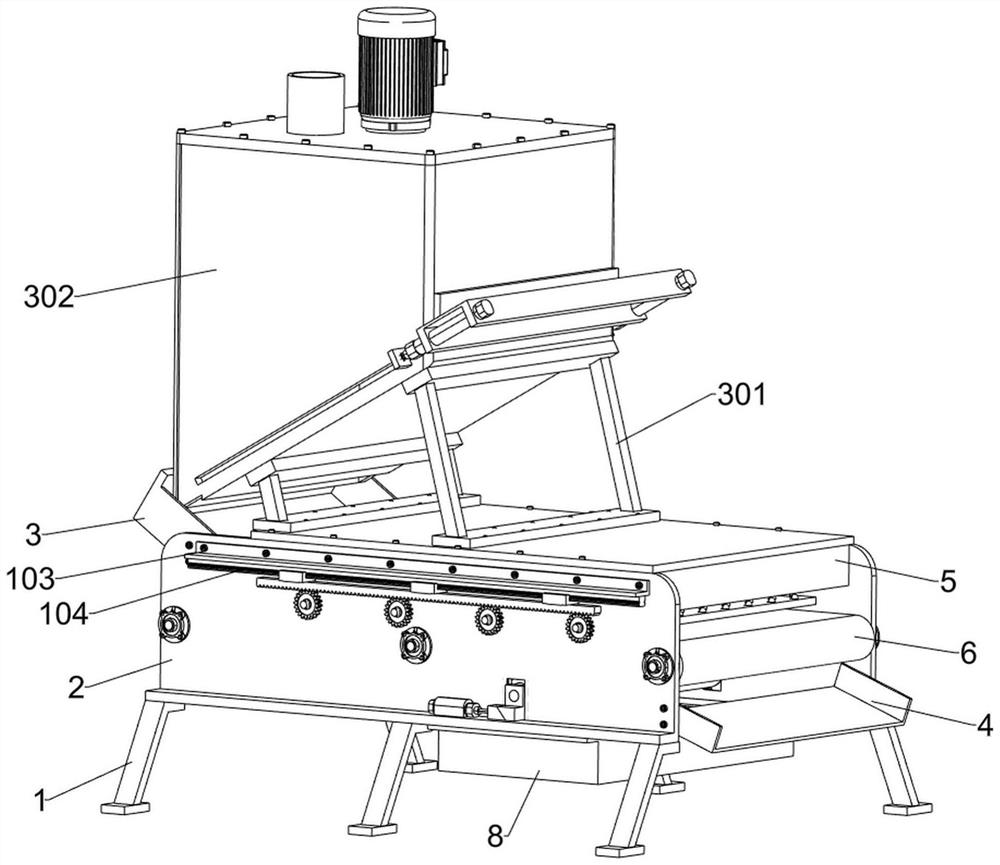

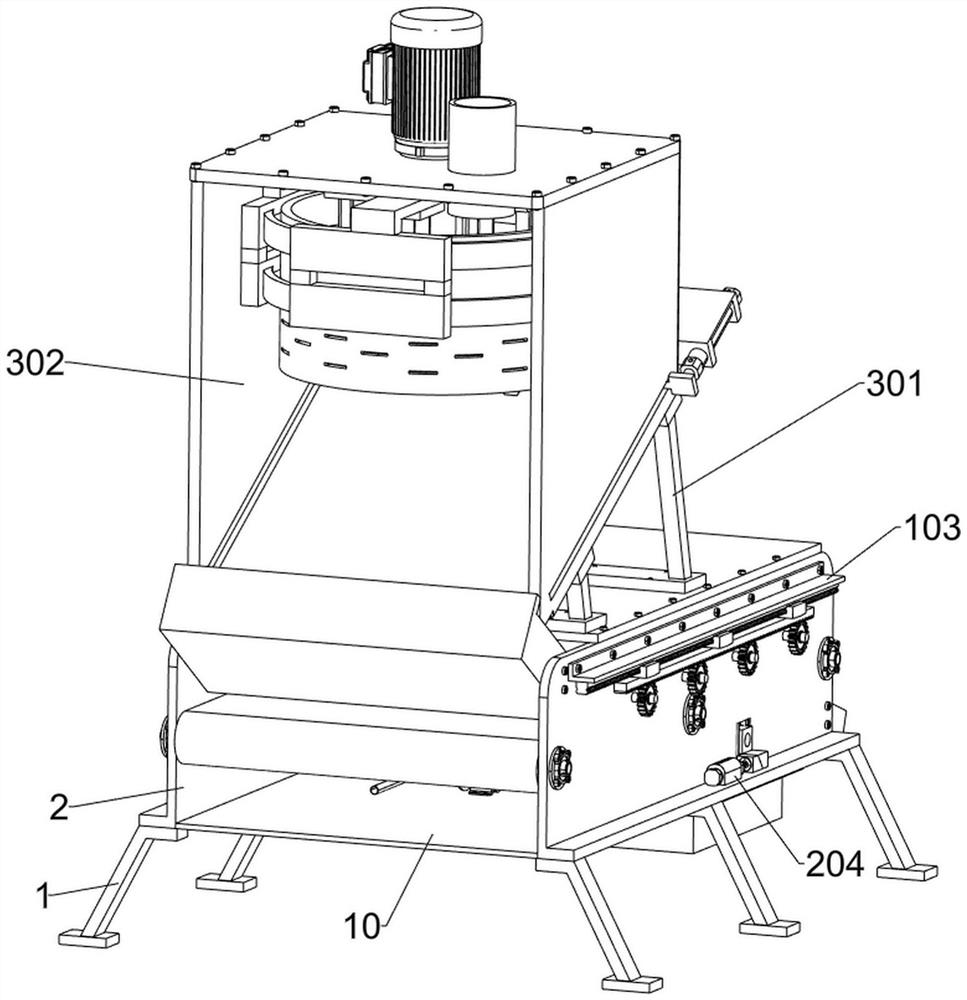

A device for accurately proportioning and feeding straw board surface materials

ActiveCN110978201BControl the feeding speedControl vacuum speedWood working apparatusDomestic articlesWood shavingsFrequency changer

The invention relates to the technical field of straw board production, in particular to a feeding device for accurately proportioning the surface material of straw boards, comprising a wooden surface bunker, a straw shaving bin, and a scraper conveyor. The wooden surface bunker and the straw shaving bin are symmetrical. It is set that the bottom ends of the wooden surface silo and the straw shaving silo are connected with a tapered discharge pipe, and an auger conveyor is fixed below the wooden surface silo and the straw shavings silo, and the conical discharge pipe The feed pipe is connected with the feed port of the auger conveyor, the discharge port of the auger conveyor is arranged directly above the feed end of the scraper conveyor, and a first motor is arranged outside the feed port of the auger conveyor, A frequency converter is fixed on the outside of the first motor; the present invention can not only realize the controllability of the material ratio of the surface layer of the straw board through the frequency converter, but also ensure that the transportation speed of the auger conveyor is relatively fast. The accuracy of raw materials ensures the quality of the straw board produced.

Owner:铜陵万华禾香板业有限公司

Plastic refractory for repairing furnace lining of medium-frequency induction furnace and preparation method of plastic refractory

The invention relates to a plastic refractory for repairing a furnace lining of a medium-frequency induction furnace and a preparation method of the plastic refractory. According to the technical scheme, 63.0 wt%-78.0 wt% of vanadium iron slag, 12.0 wt%-17.0 wt% of basalt, 8.0 wt%-13.0 wt% of bauxite and 2.0 wt%-7.0 wt% of bentonite serve as raw materials, a binding agent accounting for 4.0 wt%-5.5 wt% of the raw materials is added, the raw materials are mixed to be uniform, and the plastic refractory for repairing the furnace lining of the medium-frequency induction furnace is obtained. The vanadium iron slag comprises the following main chemical components: more than or equal to 83.5 wt% of Al2O3, more than or equal to 9.0 wt% of MgO, less than or equal to 5.0 wt% of CaO, less than or equal to 0.3 wt% of SiO2, less than or equal to 0.2 wt% of Fe2O3 and less than or equal to 0.2 wt% of IL. Therefore, the method has the characteristics of environmental friendliness, simple process and low production cost; and the prepared plastic refractory for repairing the furnace lining of the medium-frequency induction furnace is convenient in construction mode, high in bonding strength, excellent in slag resistance and long in service life.

Owner:山东泰力克新材料科技有限公司

Preparation method of novel building material

InactiveCN105776924AAvoid pollutionResolve tensionSolid waste managementAbsorption rateResource constraints

The invention relates to a preparation method of a novel building material. The novel building material preparation method is characterized in comprising the following steps: (1) construction waste obtained after building demolition is mechanically crushed into reclaimed sand with a state of fine sand, wherein the technical specifications for the reclaimed sand are as the follows: a bulk density is 1180kg / m<3>, a clay content is 5.0%, a clay lump content is 1.5%, and a water absorption rate is 7%; (2) the reclaimed sand is used for preparing concrete and mortar. An additive composed of 15% of triethanolamine, 25% of ferric oxide and 60% of fly ash is added, and the ratio of the reclaimed sand to the additive is 97:3, such that the performance of an obtained concrete mixture can reach the following specifications: the strength level is C20, the water-cement ratio is 0.60-0.62, and the slump by cm is 5.0. With the novel building material preparation method, environment pollution caused by waste discharged during building demolition is effectively solved, and a problem of natural sand resource constraints is solved.

Owner:韩军

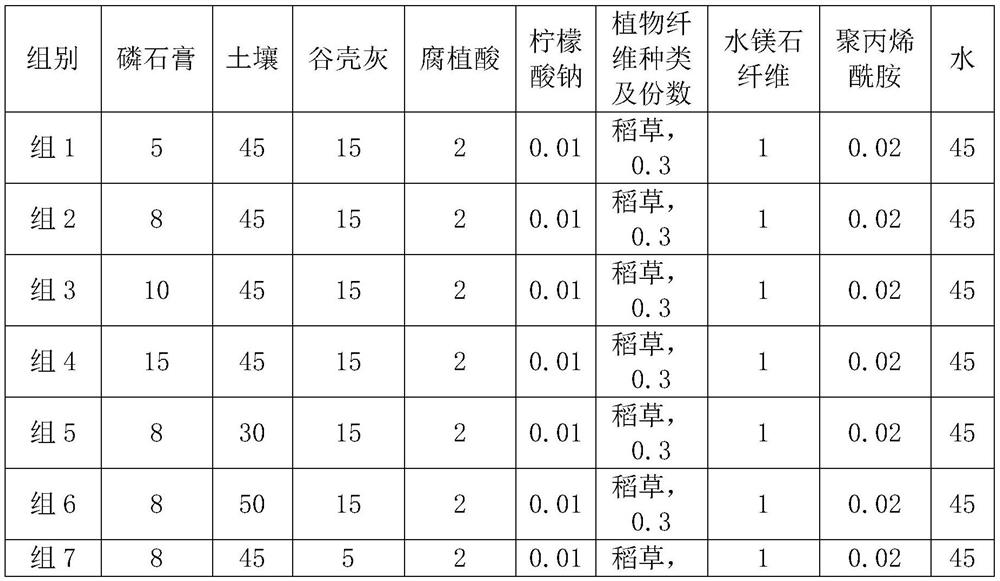

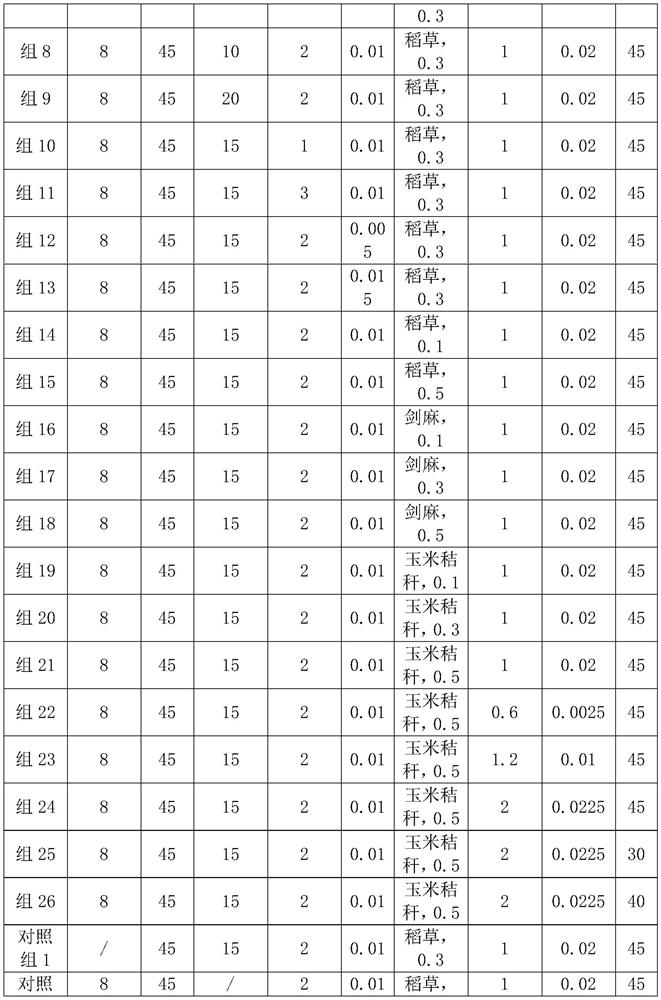

A kind of phosphogypsum-based vegetation concrete and its construction method

ActiveCN108911672BHigh bonding strengthImprove stress resistanceCoastlines protectionGrowth substratesCrack resistanceAgricultural engineering

The present invention belongs to the technical field of water and soil protection, and particularly relates to phosphogypsum-based vegetation concrete and a construction method thereof. The specific technical solution is as follows: the phosphogypsum-based concrete comprises phosphogypsum, soil, rice husk ash, humic acid, a retarder, plant fibers, brucite fibers, a water retaining agent and water.A large amount of the phosphogypsum and rice husk ash are used; high bonding strength between the concrete and slopes is high; anti-pressure and anti-tensile abilities are strong; an anti-erosion ability is strong; the phosphogypsum-based vegetation concrete also provides nutrient elements required for growth of various surface layer grass seeds; the humic acid further helps quick ecological recovery; and long fibers and short fibers are also combined to improve the own performance of the concrete, help vegetation to grow rapidly and exist for more than ten years or even decades, continuouslystrengthen and toughen the concrete, and improve the crack resistance and durability of the concrete.

Owner:重庆市建筑科学研究院有限公司 +1

Production method of novel building material

The invention belongs to a production method of a novel building material. The production method comprises the following steps of 1, mechanically crushing building waste obtained after a building is detached and dug into reclaimed sand in the fine sand state; 2, utilizing the reclaimed sand for preparing concrete and mortar. By means of the production method of the novel building material, the problems that environment pollution is caused by waste discharged when the building is detached and dug, and natural sand sources are lacked are effectively solved, and the problems of stacking occupation, and environment pollution of the urban waste are reduced. It is proved through experiments that compression strength, mechanical performance, freezing resistance, carbonizing performance and the like of masonry mortar and concrete prepared by the reclaimed sand all reach or exceed the design standards, and the production method has significant economic benefits and social benefits.

Owner:绍兴悦植科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com