Exploding type organic matter treatment equipment

A technology for processing equipment and organic matter, applied in mechanical equipment, grain processing, engine components, etc., can solve the problems of difficult to increase the pressure relief speed of the pressure relief device, unable to achieve the blasting effect, and difficult to increase the effective cross-sectional area, etc. Achieve compact structure, prevent material accumulation, and achieve the effect of small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

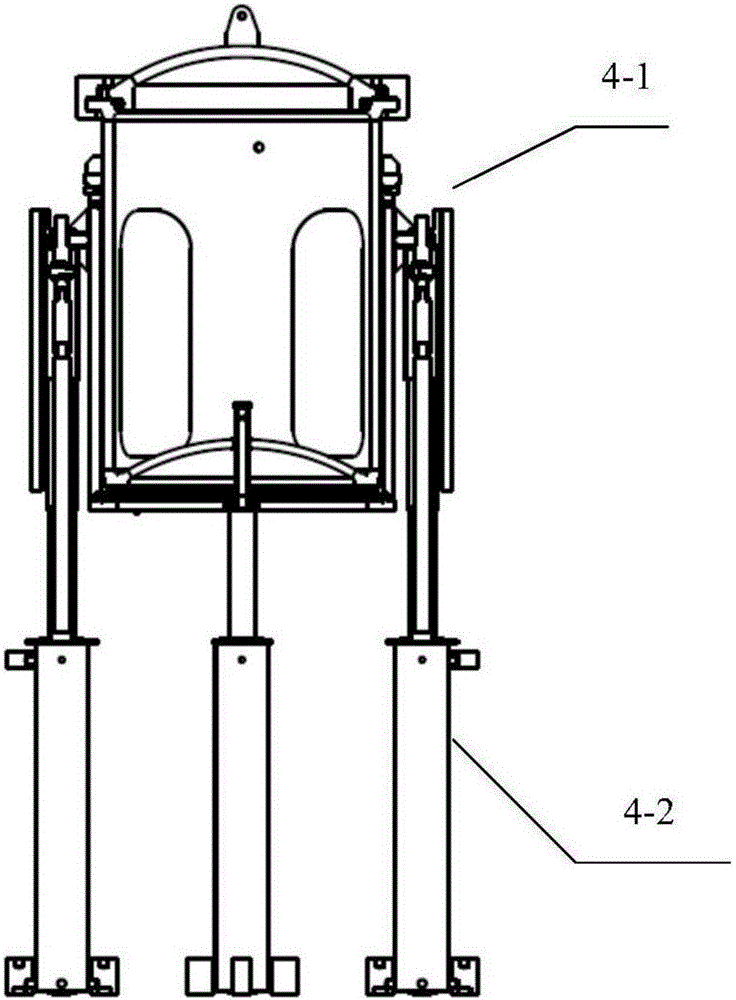

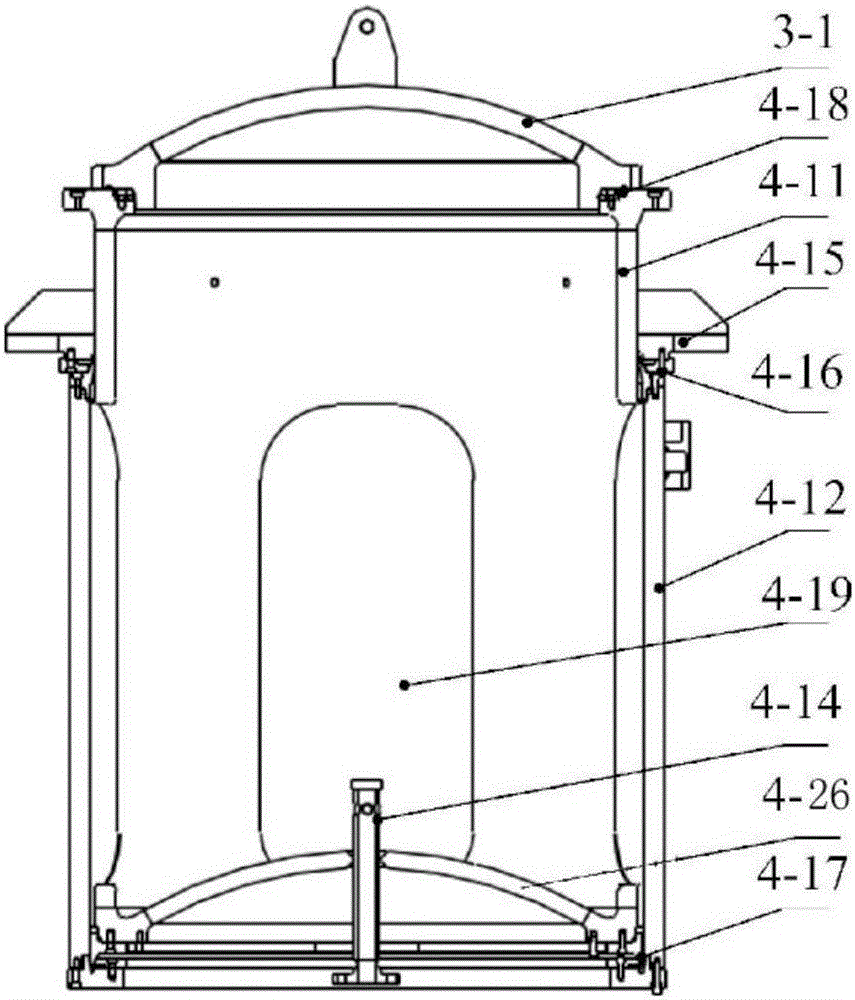

[0058] The sealed organic matter processing equipment of the present invention will be described in detail below with reference to the accompanying drawings.

[0059] like figure 1 Shown is a schematic structural diagram of a large-diameter organic matter processing equipment. It can be seen from the figure that the large-diameter organic matter processing equipment specifically includes a feeding device 1, a separator 2, a cap opening mechanism 3, a pressure relief device 4 and a discharge device 5, wherein the pressure The pressure relief device 4 is installed inside the separator 2 , the cap opening mechanism 3 and the feeding device 1 are installed on the upper part of the pressure relief device 4 , that is, the top of the separator 2 , and the discharge device 5 is located below the separator 2 . , in which the feeding device 1 fills the material into the pressure relief device 4 through the cap opening device 3, the pressure relief device 4 heats and pressurizes the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com