Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Play the role of recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

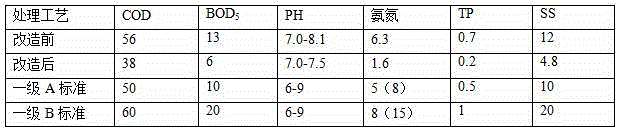

Urban comprehensive sewage treatment process

ActiveCN106630419AAchieve the effect of reducingReduce processing costsSpecific water treatment objectivesTreatment involving filtrationFiltrationWater quality

The invention relates to an urban comprehensive sewage treatment process which comprises the following steps: the urban comprehensive sewage passes through coarse and fine grates to remove large granular solid impurities, and enters a silt settling tank to further remove silt and small granular solids; supernatant of the silt settling tank enters an 'AAO' process stage, that is, an 'anaerobic-anoxic-aerobic' reaction tank; various pollutants are removed by microbial degradation; the effect of nitrogen and phosphorus removal is realized; an anaerobic tank is subjected to sludge discharge treatment periodically; a part of mixture flowing out of an aerobic reaction tank flows back to an anoxic reaction tank; an appropriate amount of LS nano-bio-circulating water treatment agent is pumped into a water outlet pipe of the aerobic reaction tank; the wastewater enters a sedimentation tank; the sedimentation tank is provided with sludge backflow for respectively flowing back to the aerobic reaction tank and the anaerobic reaction tank; the supernatant can be discharged on standard through filtration and disinfection. The urban comprehensive sewage treatment process achieves the reduction of sludge, further purifies the water quality, and greatly increases drainage.

Owner:江苏绿尚环保科技有限公司

Industrial wastewater treatment technology

ActiveCN106630418AEasy to handleNo secondary pollutionBacteriaSpecific water treatment objectivesSludge cakeHydrogen

The invention relates to an industrial wastewater treatment technology. The industrial wastewater treatment technology comprises the following steps of collecting the wastewater by a pipeline, filtering by a screen net, and sending into a dosage pretreatment reaction tank; adding alkaline liquid into the dosage pretreatment reaction tank to neutralize the wastewater until the pH (potential of hydrogen) value is 6 to 7, and adding an LS nanobiological circulating water treatment agent; sequentially sending supernantant in the dosage pretreatment reaction tank into an anaerobic reaction tank and an aerobic reaction tank to perform biochemical treatment; sending the settled sludge in the dosage pretreatment reaction tank into a sludge concentration tank to concentrate, and pressing the sludge into a sludge cake by a press filter; adding the LS nanobiological circulating water treatment agent into the effluent water of the aerobic reaction tank via a pipeline; sending the wastewater into a settling tank, refluxing the sludge in the settling tank into the anaerobic reaction tank and the aerobic reaction tank, and directly sending the effluent water of the settling tank into a pipeline network of a sewage treatment plant. The industrial wastewater treatment technology has the advantages that the sludge reduction effect is realized, the water quality is further purified, and the effluent effect is greatly improved.

Owner:江苏绿尚环保科技有限公司

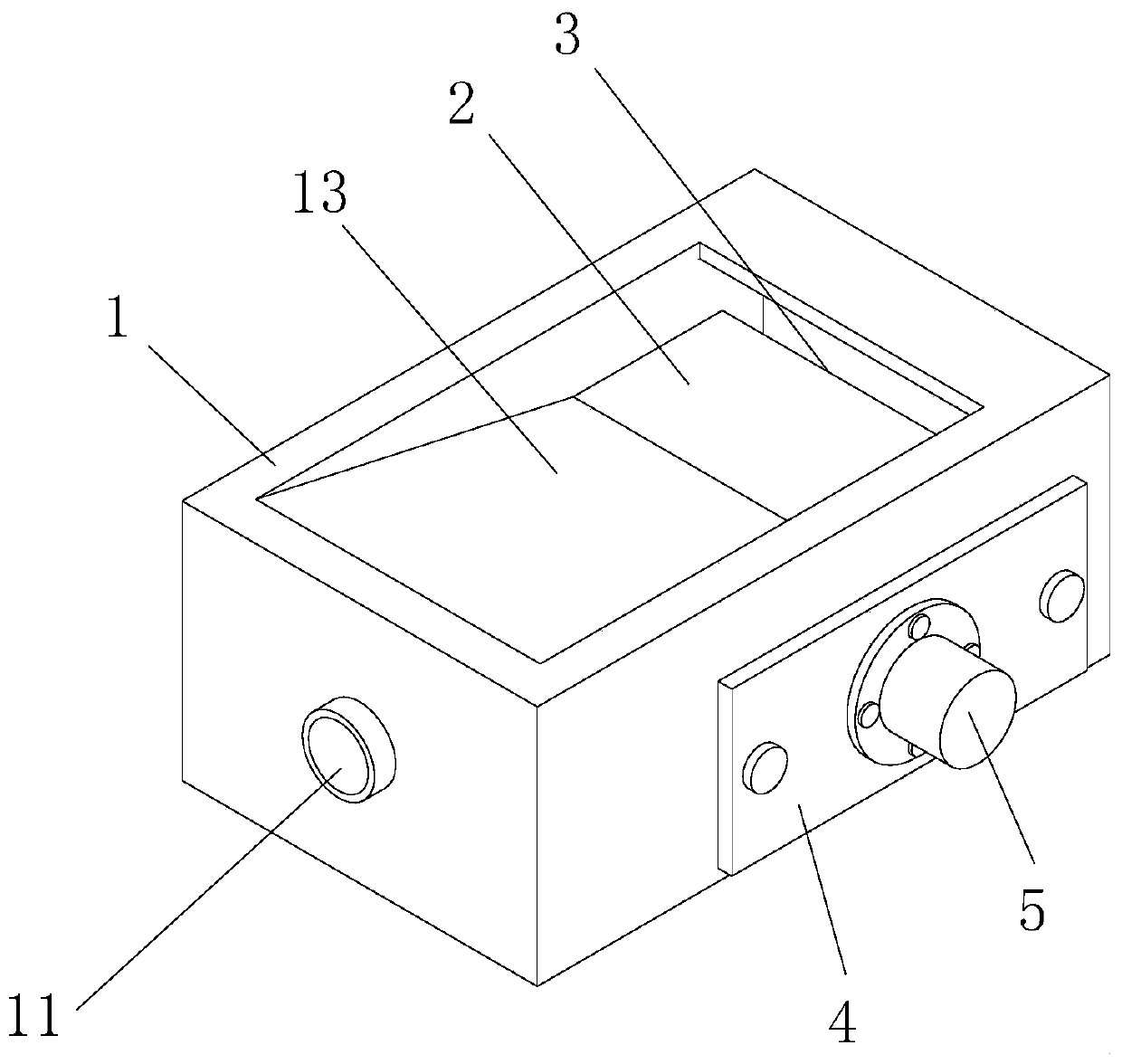

Plastic product sand removal device and method

InactiveCN108437280ASimple structureEasy to usePlastic recyclingCleaning using liquidsBristleShake up

The invention discloses a plastic product sand removal device and method in the technical field of plastic product sand removal. The device comprises a box body, a rotating rod is inserted in an innercavity of a bearing, cleaning rods are evenly arranged on the left side and the right side of the rotating rod, a first filter net, a second filter net, a hopper and a water box are sequentially arranged in an inner cavity of the box body from top to bottom, cleaning liquid is sprayed out through a water outlet hole through a water pump, plastic product surfaces are washed, the cleaning rods rotate to drive bristles to brush the plastic product, the first filter net separates the cleaning liquid mixed up with gravel and the plastic product, the second filter net separates the cleaning liquidand the gravel, the second filter net shakes up and down, filtering and cleaning of the gravel are facilitated, the cleaning liquid mixed up with fine gravel and dust is precipitated in a precipitation chamber, a mesh-free filter layer filters fine gravel and dust mixed up in the cleaning liquid, through layer-by-layer filtering of the cleaning liquid, circular utilization of the cleaning liquid is achieved, and resource waste is reduced.

Owner:CHENGDU PUJIANG KEXIAN TECH

Enzymatic packing for reactive distillation as well as coating method and application of enzymatic packing

InactiveCN107115889ANot easy to inactivateImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationCross-linkReactive distillation

An enzyme-catalyzed filler for reactive distillation and its coating method and application. The enzyme-catalyzed filler is prepared by the following method, including the following steps: immerse the filler in the sol containing biological enzyme for 20-30 seconds, take it out and dry it for 10-20 seconds; then immerse the filler in the sol again for 20-30 seconds, Take it out again and dry for 10 to 20 seconds; repeat the immersion-drying step 8 to 15 times; finally dry the filler until the weight remains unchanged, that is, obtain the enzyme-catalyzed filler with a biological enzyme coating attached; the composition of the sol is component A and component B; the A component includes an oxygen-containing silane mixture and a solvent; the B component includes a catalyst, a cross-linking agent, an enzyme solution and deionized water. The invention realizes the integration of biological enzyme immobilization technology and reactive distillation technology, and has novelty and economy.

Owner:HEBEI UNIV OF TECH

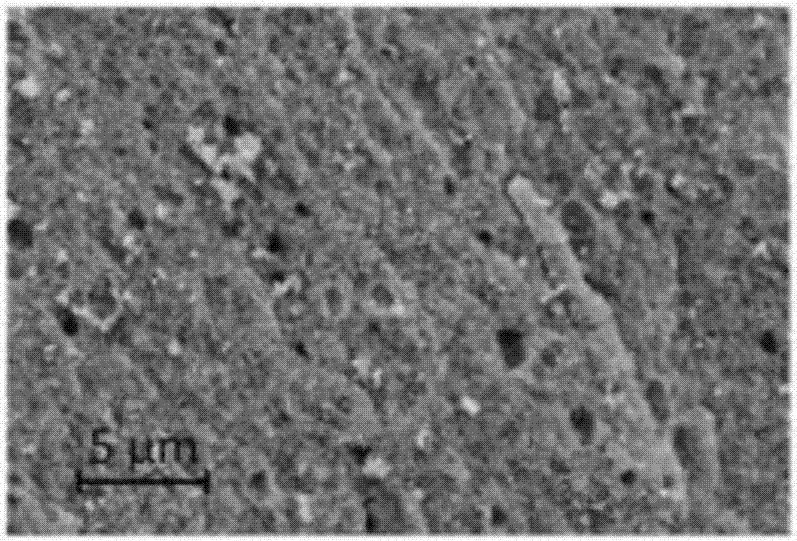

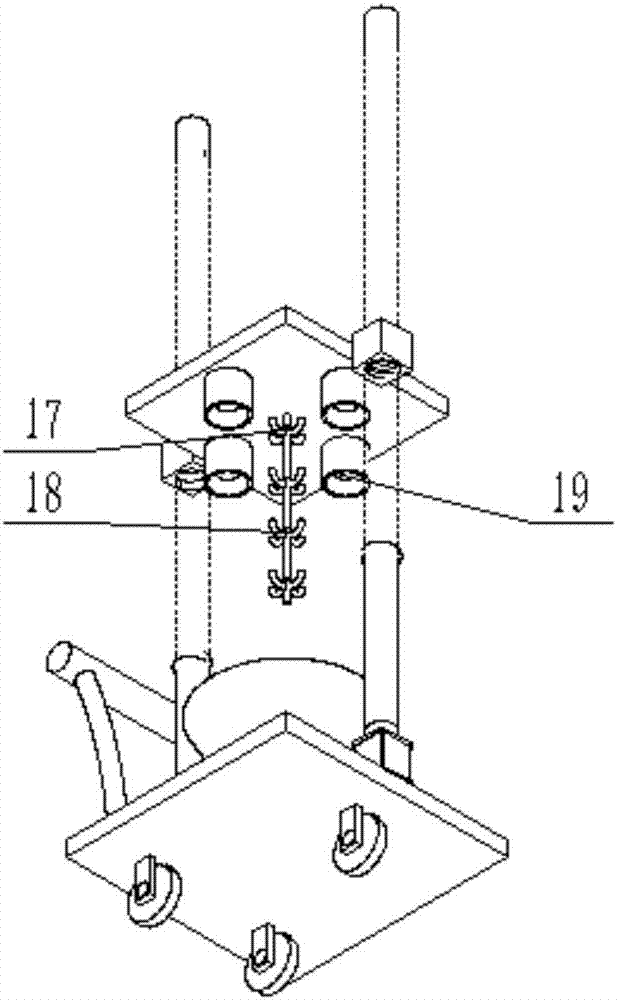

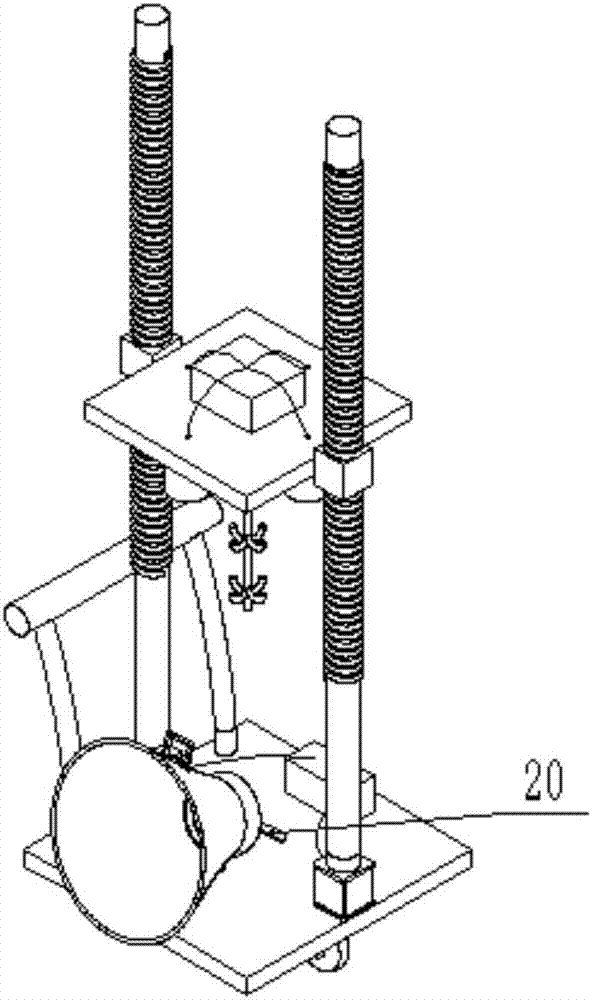

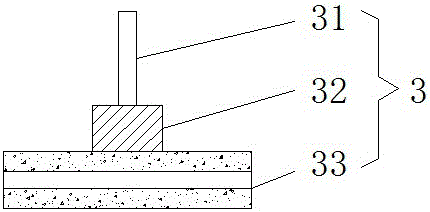

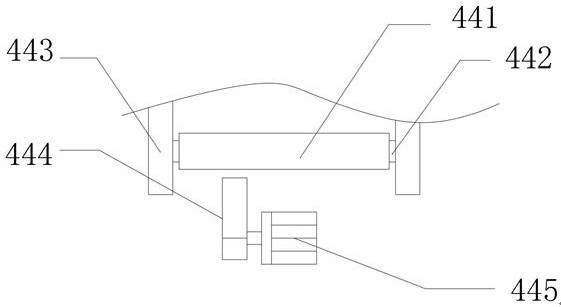

Firecracker firing and recovering device

ActiveCN106895748APrevent the phenomenon that cannot be ignitedAggregation is achievedFirecrackersFirecrackerFireworks

The invention discloses a firecracker firing and recovering device, and belongs to the field of firework and firecracker firing equipment. A firing barrel is arranged at the upper end of a bottom plate; a light concentration disc is arranged at the lower end in the firing barrel; two stepping motors are mounted on two sides of the firing barrel at the upper end of the bottom plate; an output shaft of each stepping motor is connected with an upright column; outside threads are formed in the circumference of each upright column; a connecting block sleeves the outside threads of each upright column and is fixedly connected with a lifting plate; the lower end of the lifting plate is fixedly connected with a hanging device; an incandescent lamp is mounted at the lower end of the lifting plate; and a lampshade is mounted at the periphery of the incandescent lamp; the upper end of the lifting plate is fixedly connected with a battery box which supplies power for the incandescent lamp; and a control cabinet is arranged on the bottom plate and is connected with the stepping motors. The firecracker firing and recovering device fires a firecracker by generating heat through light concentration and has the recovering function to firecracker skin generated after the firecracker is fired.

Owner:牟浩语

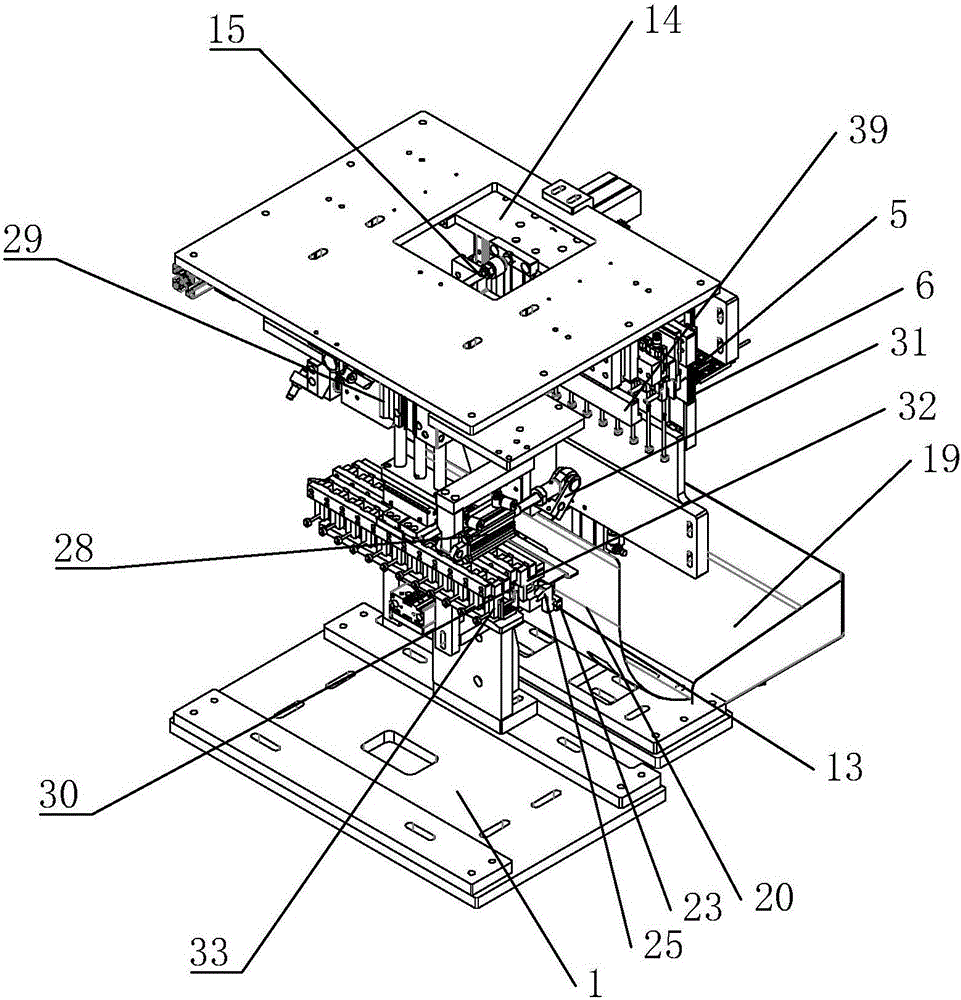

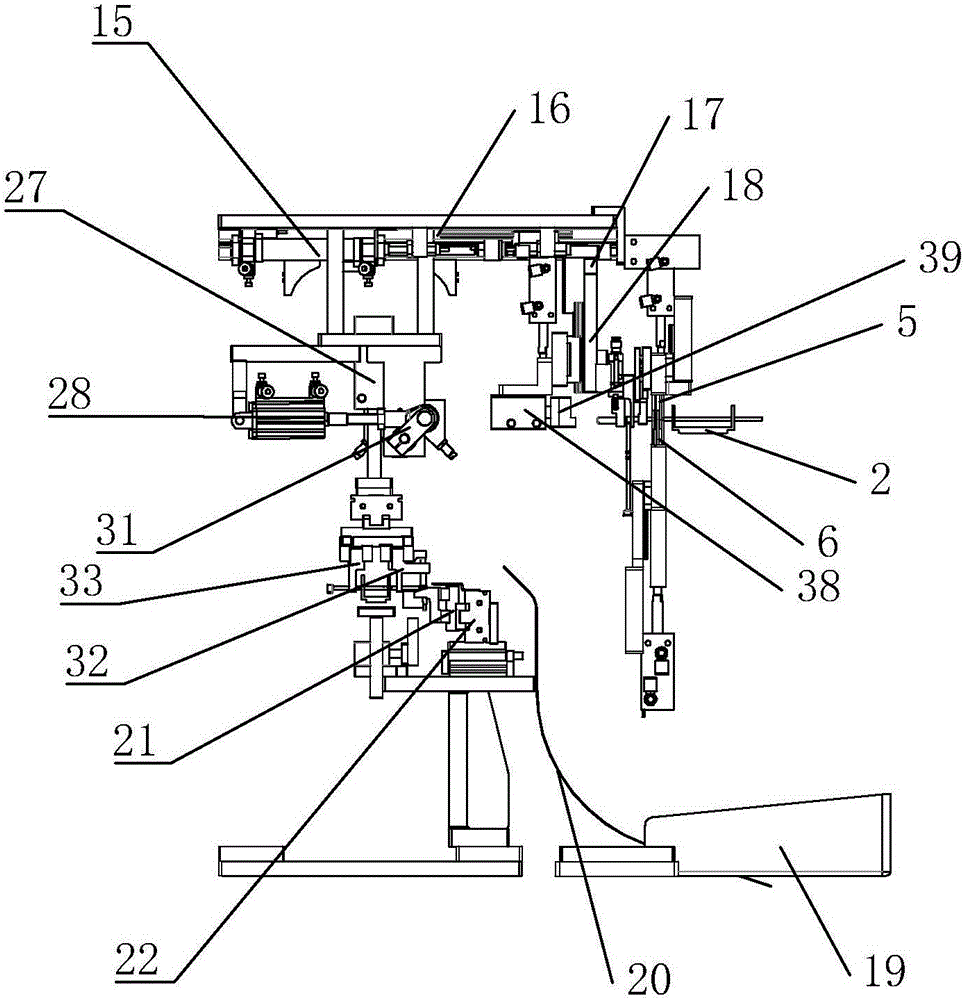

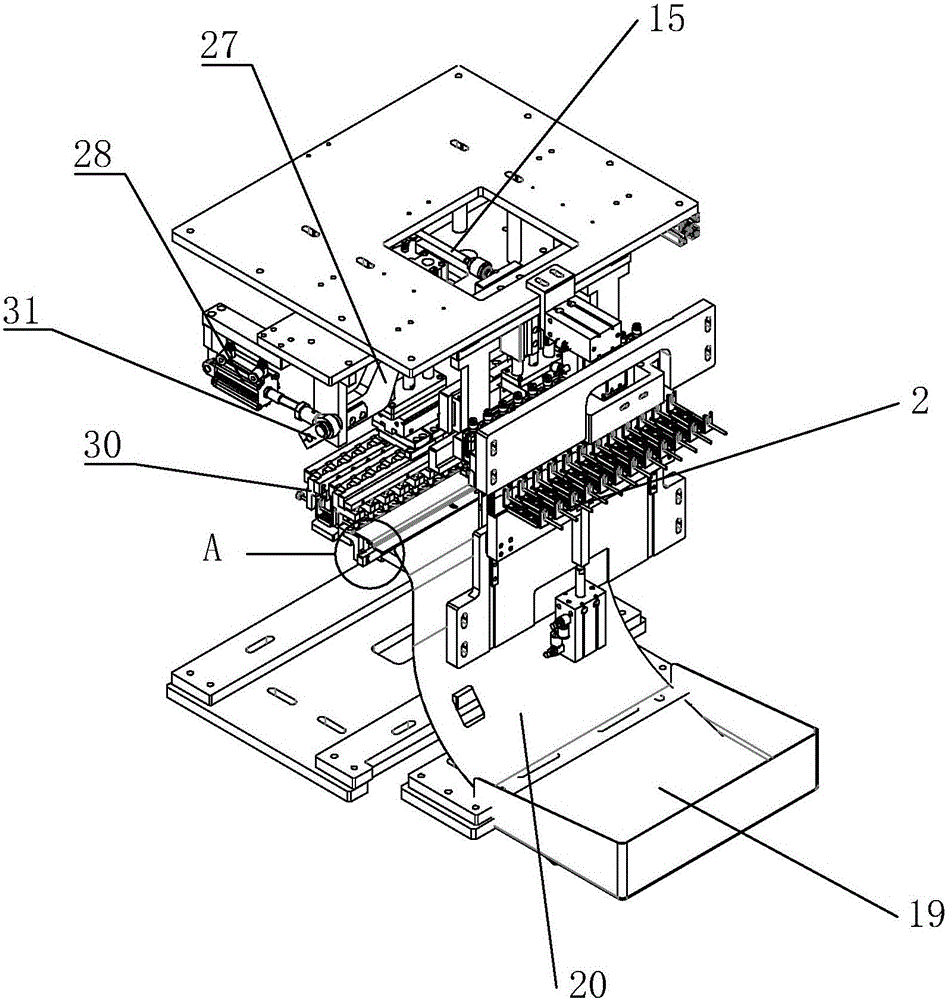

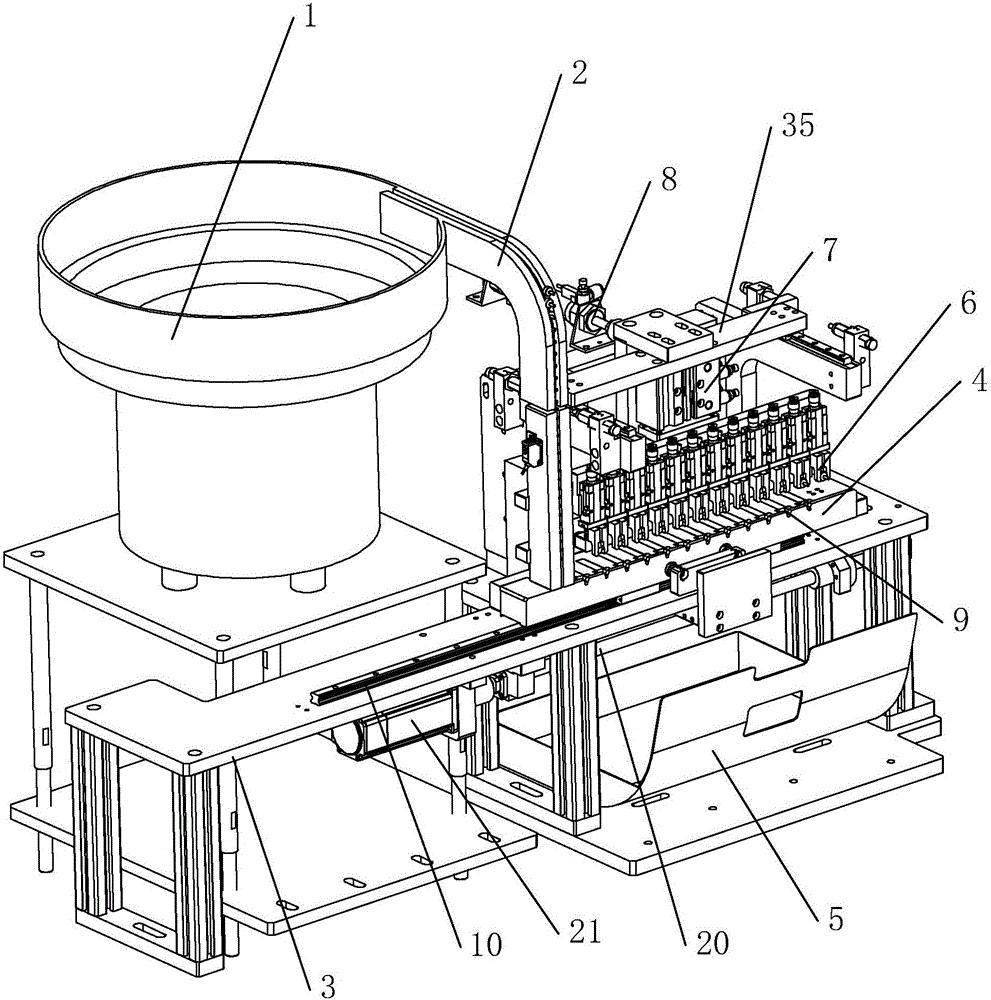

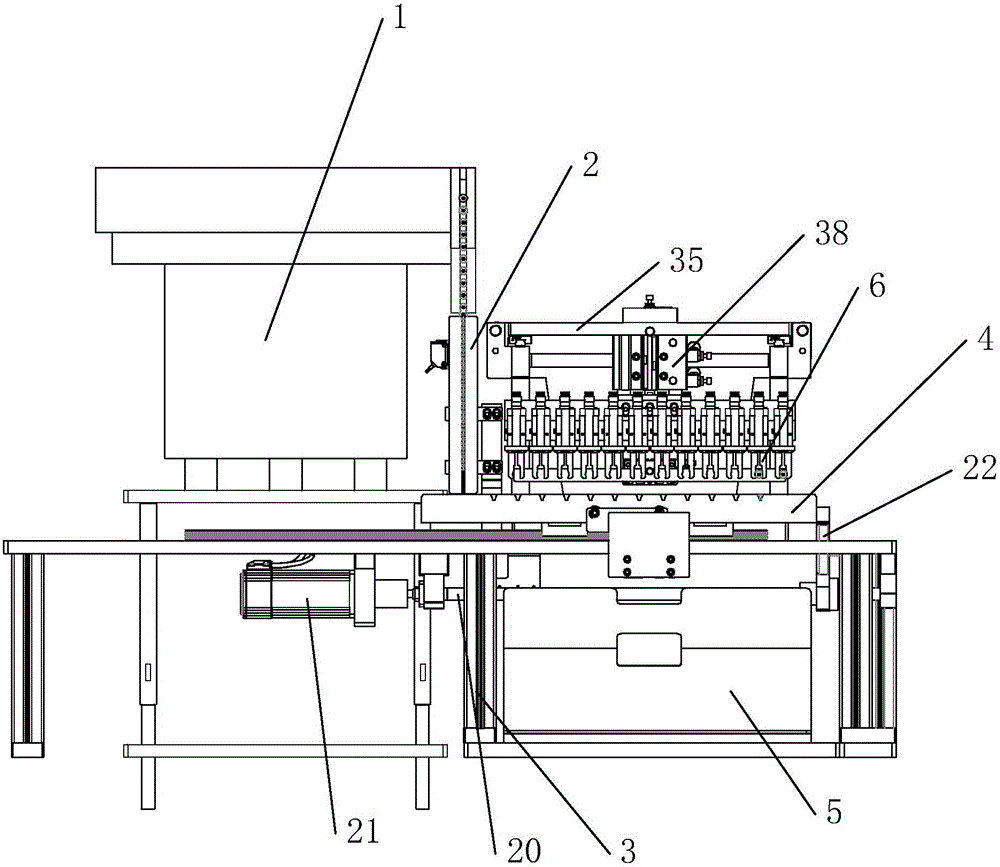

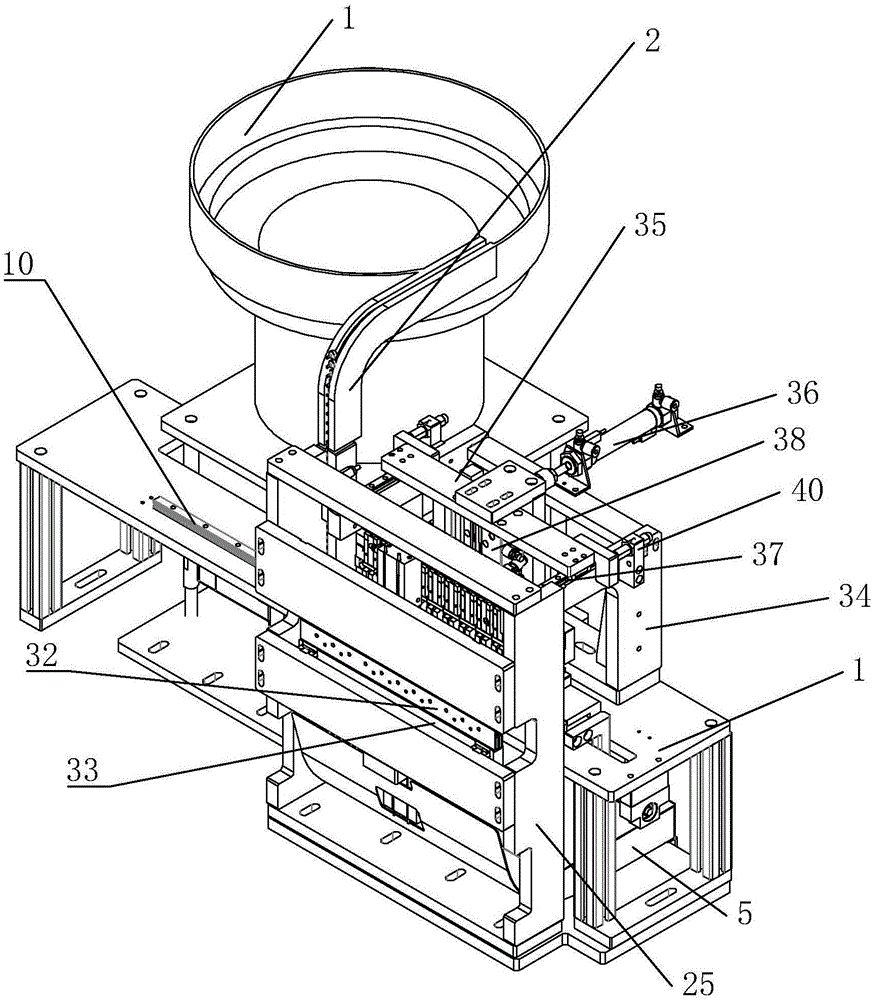

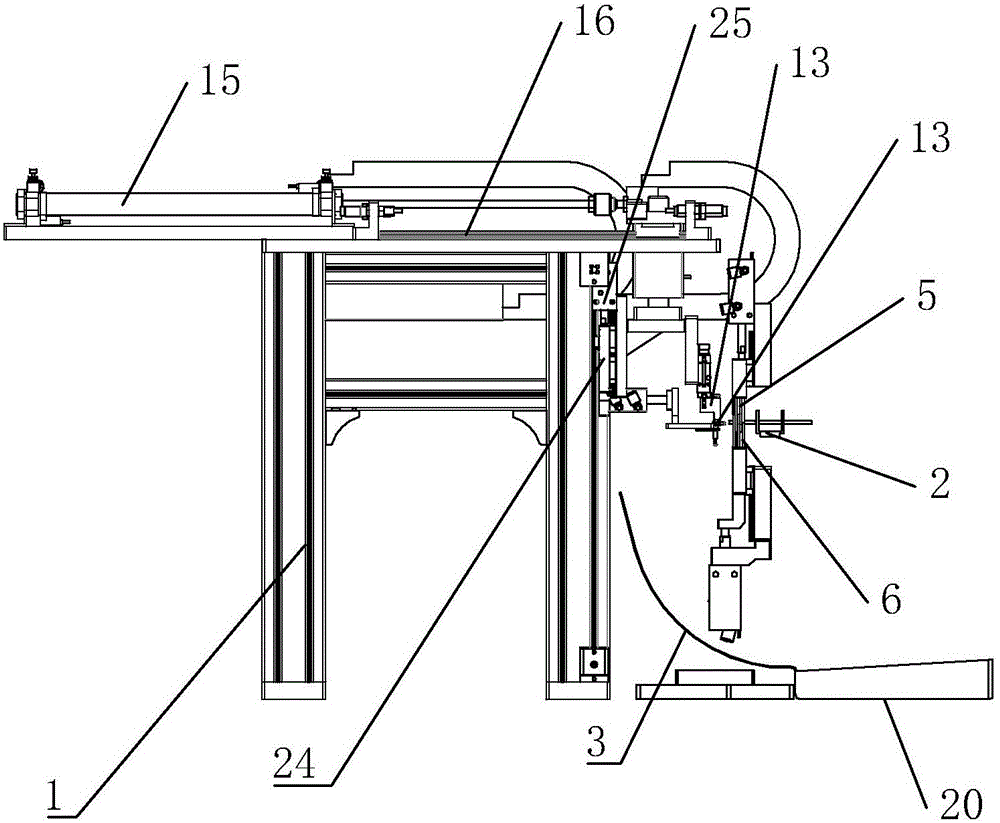

Mechanism for assembling bottle inserting needle assemblies of infusion tubes with guide tubes

The invention discloses a mechanism for assembling bottle inserting needle assemblies of infusion tubes with guide tubes. The mechanism is technically characterized by comprising a transmission chain, a guiding device, exhaust pipe fingers, a clamping mechanism, a locating mechanism and a mounting frame, wherein the guiding device, the exhaust pipe fingers, the transmission chain, the clamping mechanism and the locating mechanism are all mounted on the mounting frame, the bottle inserting needle assemblies can be guided by the guiding device, the guide tubes can be fixed by the locating mechanism, the bottle inserting needle assemblies on the guiding device are clamped by the exhaust pipe fingers, the bottle inserting needle assemblies on the exhaust pipe fingers are clamped by the clamping mechanism and are assembled with the guide tubes on the locating mechanism, a pushing mechanism used for pushing the bottle inserting needle assemblies on the clamping mechanism is further arranged on the mounting frame, and the pushing mechanism is arranged between the clamping mechanism and the locating mechanism. The device for assembling air filters and medical guide tubes can realize a technical effect of automatically assembling the bottle inserting needle assemblies with the guide tubes.

Owner:梁启明

Biomass composite heat storage material and preparation method thereof

InactiveCN110791256AHigh energy storage densityImprove thermal conductivityHeat-exchange elementsBiomass carbonParaffin wax

The invention provides a biomass composite heat storage material, which comprises a phase change material and a carrier matrix, wherein the phase change material is filled in the gaps of the carrier matrix, and is paraffin with a melting point of 55-65 DEG C, and the carrier matrix is a porous biomass carbon material obtained by pre-treating a biomass material. The preparation method of the heat storage material comprises: 1) heating, drying and crushing a biomass material to obtain biomass powder; 2) carrying out acid-alkali dissociation treatment on the biomass powder, drying, and carrying out heating activation to obtain a carrier matrix; and 3) mixing the carrier matrix and paraffin, filling the paraffin into the gaps of the carrier matrix through vacuum treatment, and cooling to obtain the composite heat storage material. According to the invention, the material can reduce environmental pollution caused by agricultural biological waste and achieve resource recycling, the preparation process is simple, and the cost is low.

Owner:SICHUAN TIANFA TECH +1

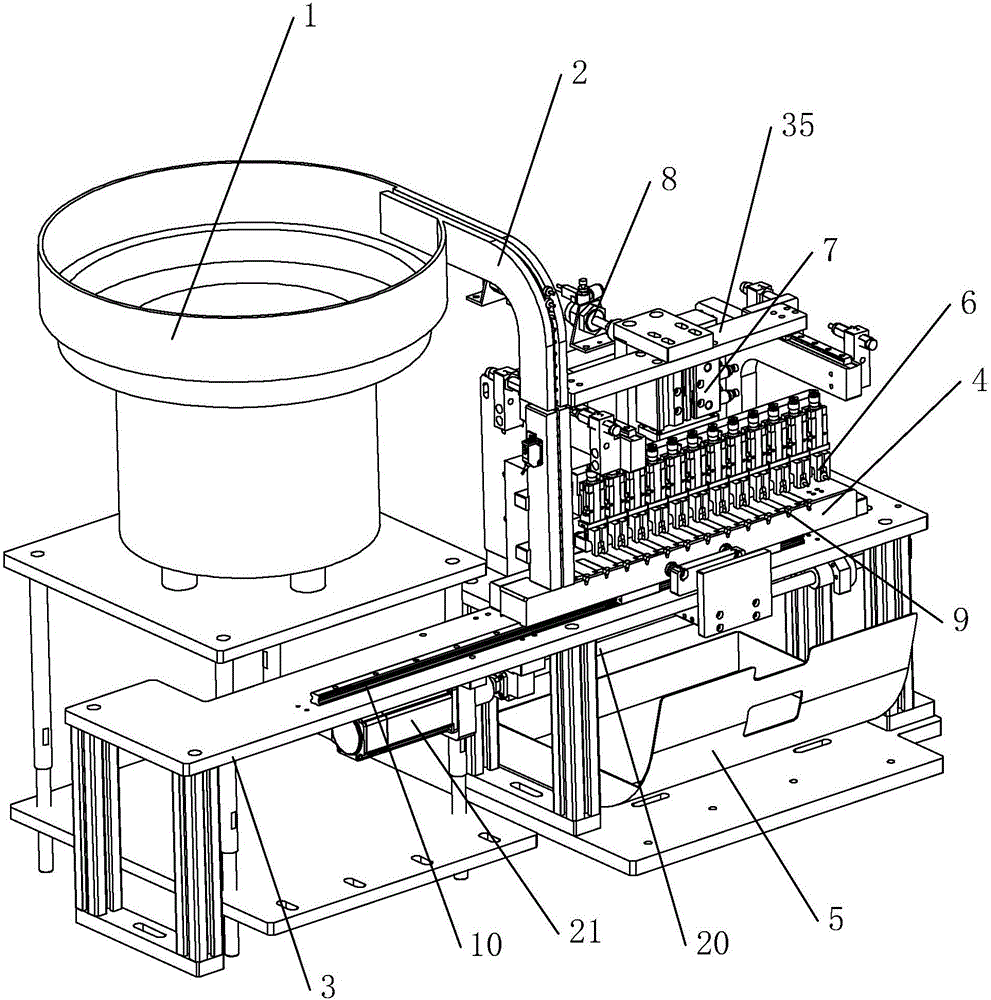

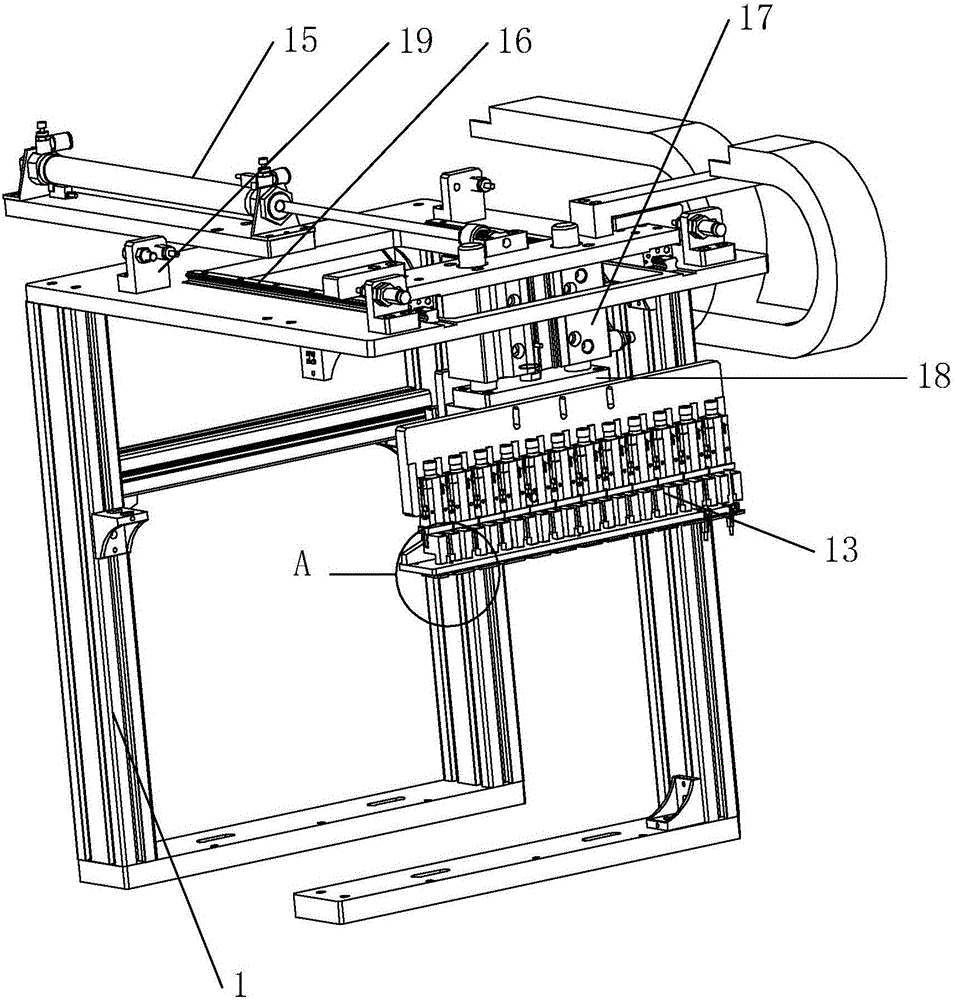

Air filter and medical catheter assembling mechanism

The invention discloses an air filter and medical catheter assembling mechanism. The air filter and medical catheter assembling mechanism is technically characterized in that a discharging track is provided with a feeding port and a discharging port; the feeding port of the discharging track is connected with a vibration disc, and a positioning mechanism can fix a medical catheter on a transmission chain; the discharging track is provided with a material guiding groove matched with the air filter, a material storage frame is arranged at the position, corresponding to the discharging port in the discharging track, of an installing frame, and a clamping mechanism used for grabbing the air filter on the material storage frame is arranged above the material storage frame. The clamping mechanism clamps the air filter on the material storage frame and is assembled with the medical catheter on the installing frame. The installing frame is further provided with a pushing mechanism. The clamping mechanism is arranged between the positioning mechanism and the pushing mechanism. When the air filter and the medical catheter are assembled, the pushing mechanism pushes the air filter, and the technical beneficial effect that the assembling efficiency of the air filter and the medical catheter is higher can be achieved.

Owner:梁启明

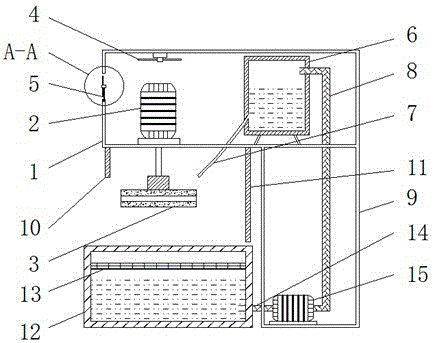

Environment-friendly cooling equipment for ceramic machining machine

InactiveCN106670918APlay the role of recyclingLow costEdge grinding machinesCeramic shaping apparatusPulp and paper industryEngineering

The invention discloses environment-friendly cooling equipment for a ceramic machining machine. The environment-friendly cooling equipment comprises a first machine body, an edge grinding motor is fixedly connected to the bottom end inside the first machine body, and an output shaft of the edge grinding motor is fixedly connected with an edge grinding device penetrating through the first machine body and extending out of the first machine body. A radiator fan is fixedly connected to the top end inside the first machine body. A ventilation fan device is formed on one side of the first machine body, one side of the edge grinding motor is fixedly connected with a water tank located at the bottom end inside the first machine body, the bottom end of one side of the water tank is fixedly connected with a flushing pipe penetrating through the first machine body and extending out of the bottom end of the first machine body, the bottom end of one side of the first machine body is fixedly connected with a second machine body, and the top end of the other side of the water tank is fixedly connected with one end of a conveying water pipe penetrating through the second machine body and extending into the second machine body. A water pump is arranged, the water pump pumps cooling water into the water tank from a recycle pool, the effect that cooling water is recycled is achieved, and the effects of cost reduction, environmental protection and cooling are achieved.

Owner:XIAOGAN CHUANGKE ELECTRONICS TECH

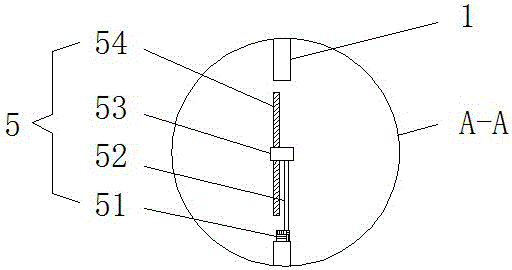

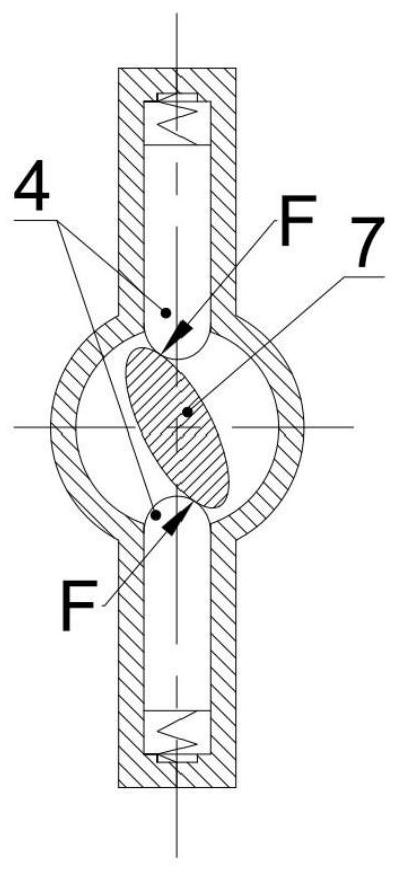

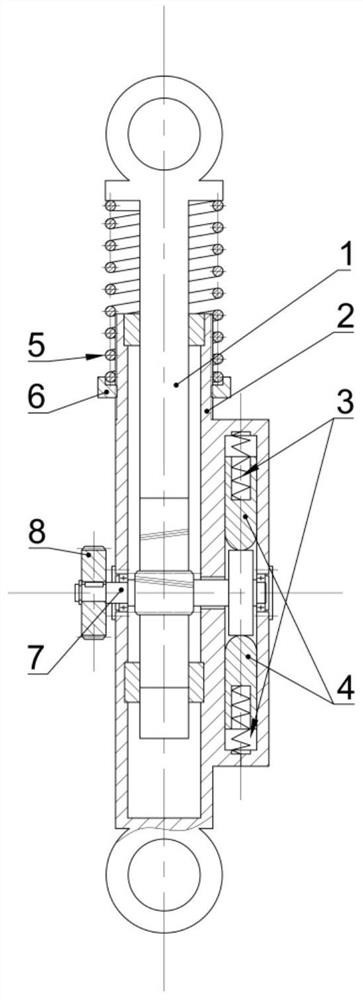

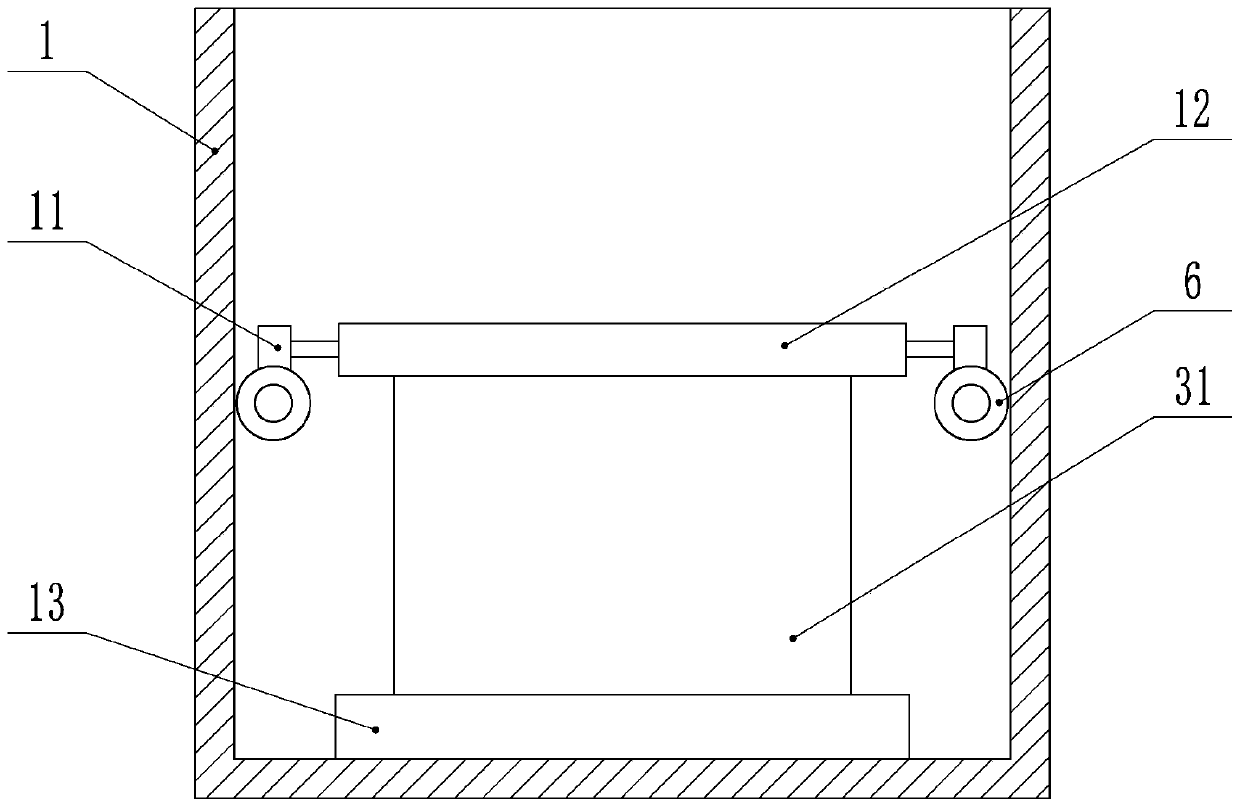

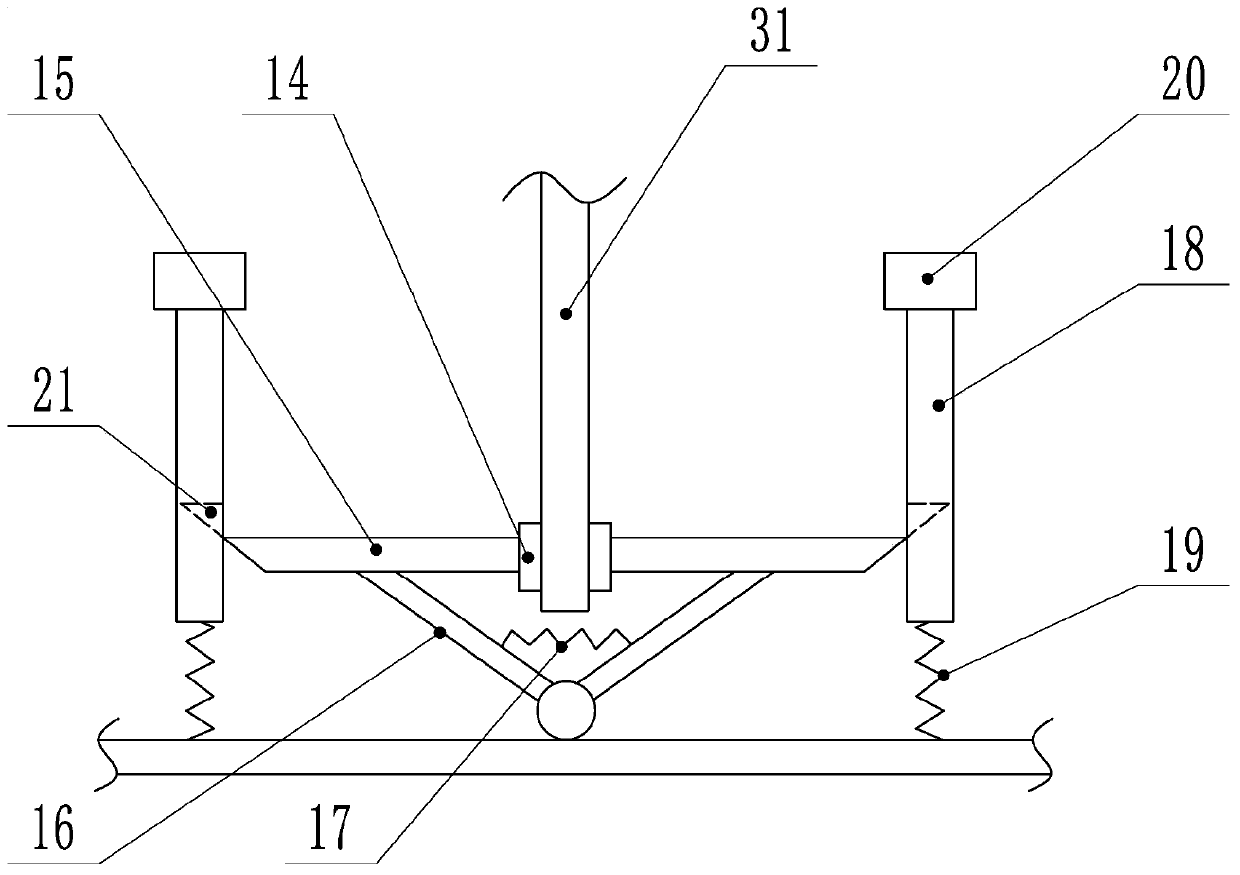

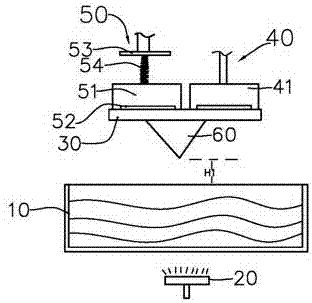

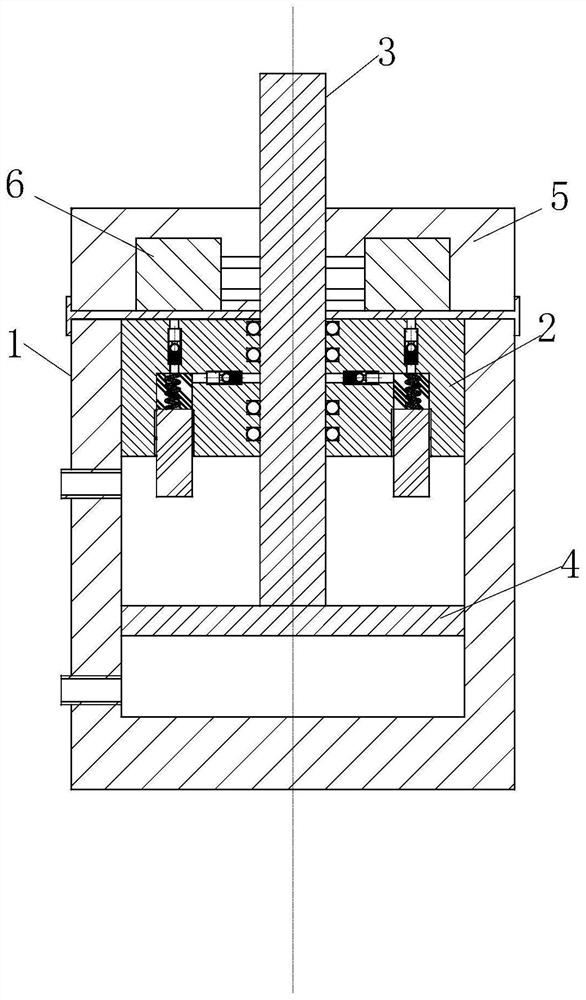

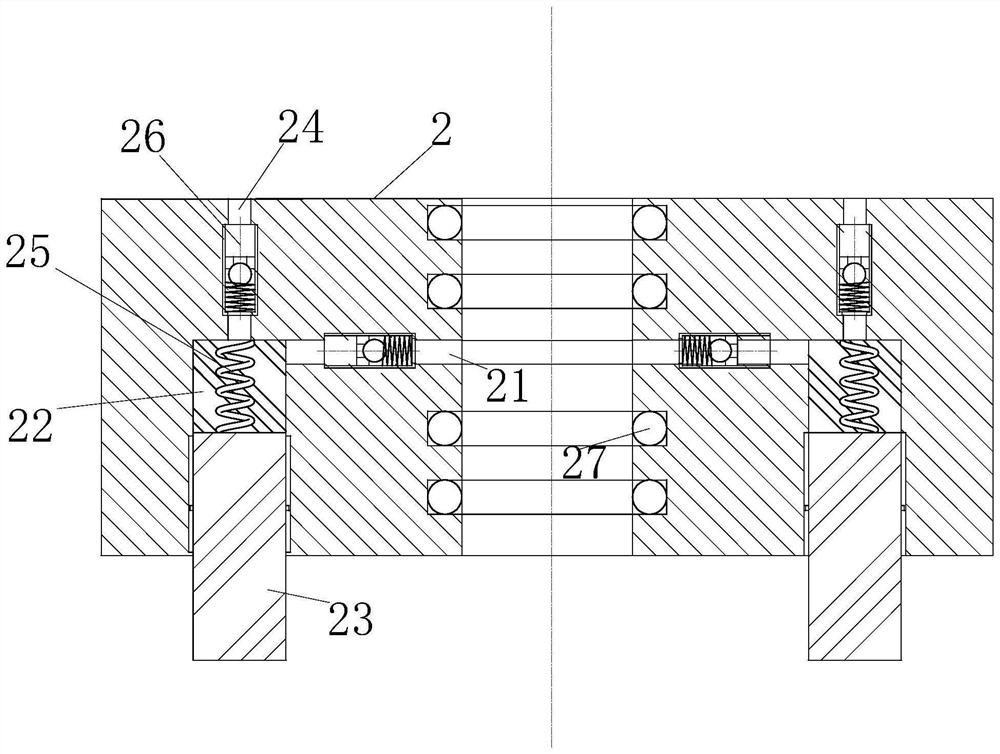

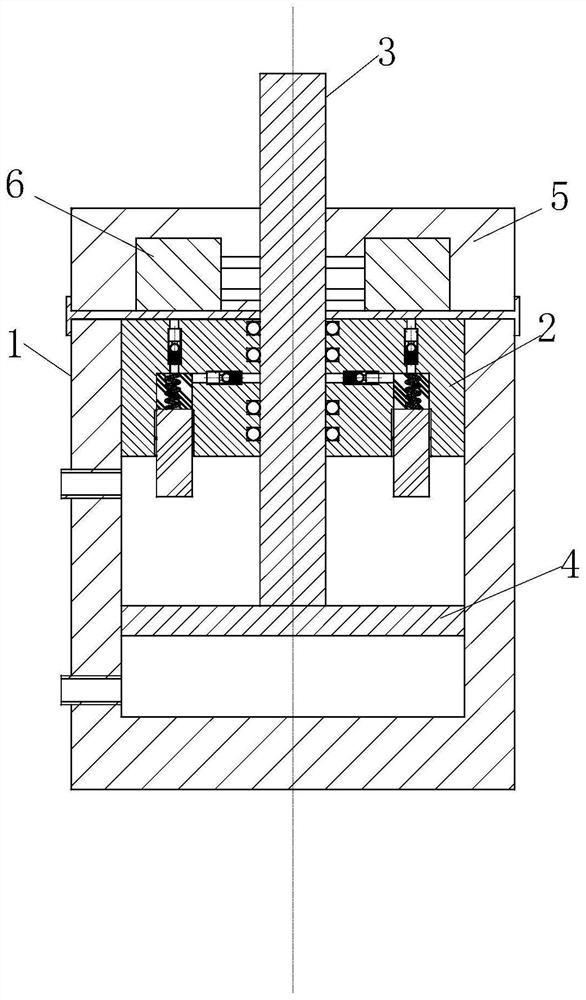

Quasi-zero stiffness vibration isolator with energy recovery function

ActiveCN112152387AReduce horizontal sizePlay the role of recyclingMechanical energy handlingShock absorbersGear driveGear wheel

The invention provides a quasi-zero stiffness vibration isolator with an energy recovery function, and belongs to the technical field of vibration isolation. The quasi-zero stiffness vibration isolator comprises a shell, a gear cam shaft and a rack shaft are connected into the shell, the axes of the gear cam shaft and the rack shaft are perpendicular, and the gear cam shaft is matched with the rack shaft. A slideway symmetrical about the axis of the gear cam shaft is arranged on the outer side of the shell, and a sliding column is embedded into the slideway, makes contact with an auxiliary spring and further makes contact with the cam end of the gear cam shaft; the adjusting mechanism is arranged at one end of the shell and makes contact with the rack shaft through a main spring. A gear pair is connected to the end, away from the cam, of the gear cam shaft and fixedly connected with an electric generator. The elastic direction of the auxiliary spring providing the negative stiffness isparallel to the elastic direction of a positive spring providing the positive stiffness, so that the transverse size of the vibration isolator is greatly reduced, and the vibration isolator can be applied to places with high space requirements; movement can be transmitted to the electric generator through gear transmission to achieve power generation, and energy recovery is achieved.

Owner:JIANGSU UNIV

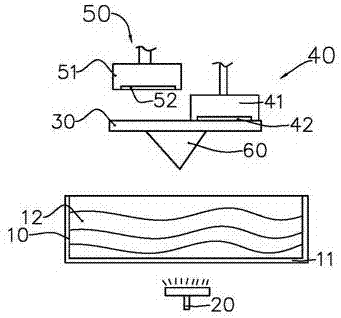

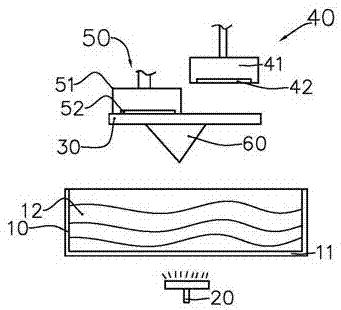

Textile Dyeing Unit

ActiveCN108221230BPrevent extrusionSlide to achieveLiquid/gas/vapor removalTextile treatment machine arrangementsStructural engineeringTextile dyeing

The invention relates to the technical field of textile processing and discloses a textile dyeing device. The textile dyeing device comprises a dyeing box, wherein a first sliding chute and a second sliding chute are formed in the dyeing box, the first sliding chute is slidably connected with a first sliding block, the second sliding chute is slidably connected with a second sliding block, two material guiding rollers are slidably connected in the dyeing box, a limit slot is formed in each material guiding roller, an object carrying frame is arranged in each limit slot, a material rolling roller is rotatably connected in each object carrying frame, a fixing mechanism is arranged in the dyeing box, the fixing mechanism comprises two clamping plates, each clamping plate is fixedly connectedwith a wedge rod, each wedge rod is fixedly connected with a connecting rod, two connecting rods are hinged on the inner wall of the dyeing box, two sliding rods are slidably connected in the dyeing box, a first electromagnet is arranged on each sliding rod, and a second electromagnet is arranged on the inner wall of the dyeing box; a discharging hole is formed in the dyeing box, a touch switch isarranged at the discharging hole, the discharging hole is connected with a material guiding plate, the material guiding plate is connected with a hollow elastic filter screen, and a recycling tank isconnected below the elastic filter screen. The textile dyeing device disclosed by the invention can rapidly and uniformly carry out dyeing.

Owner:NINGBO WENZE TEXTILE CO LTD

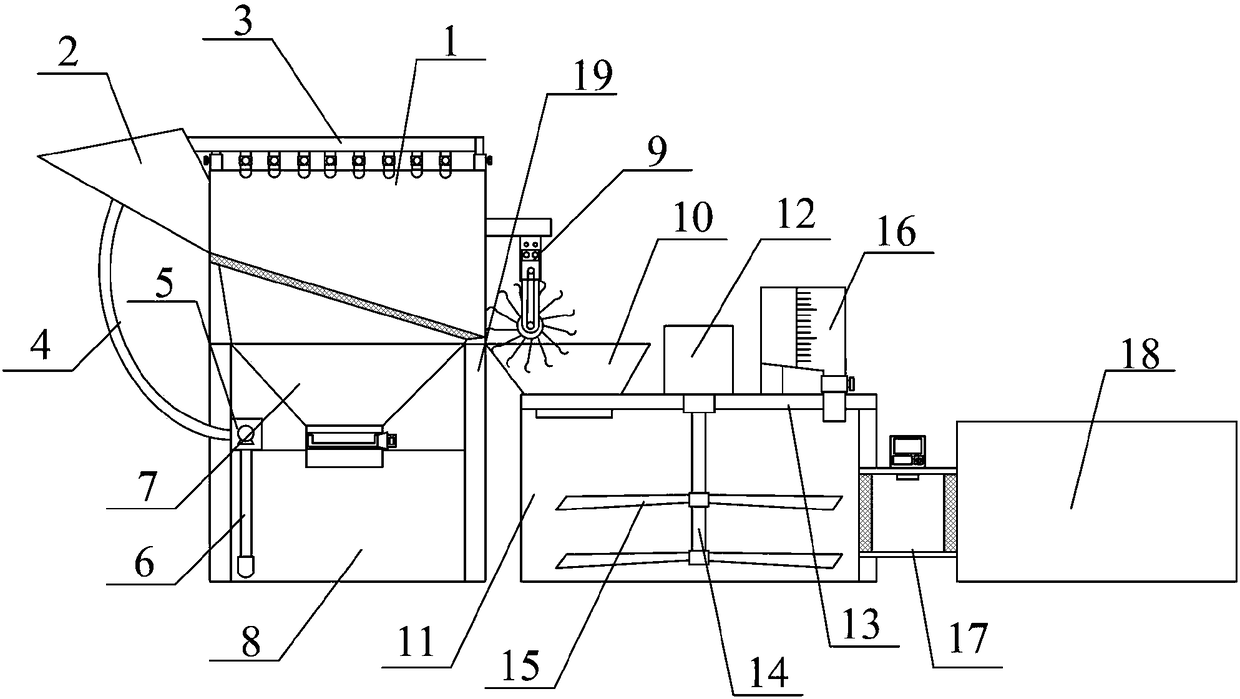

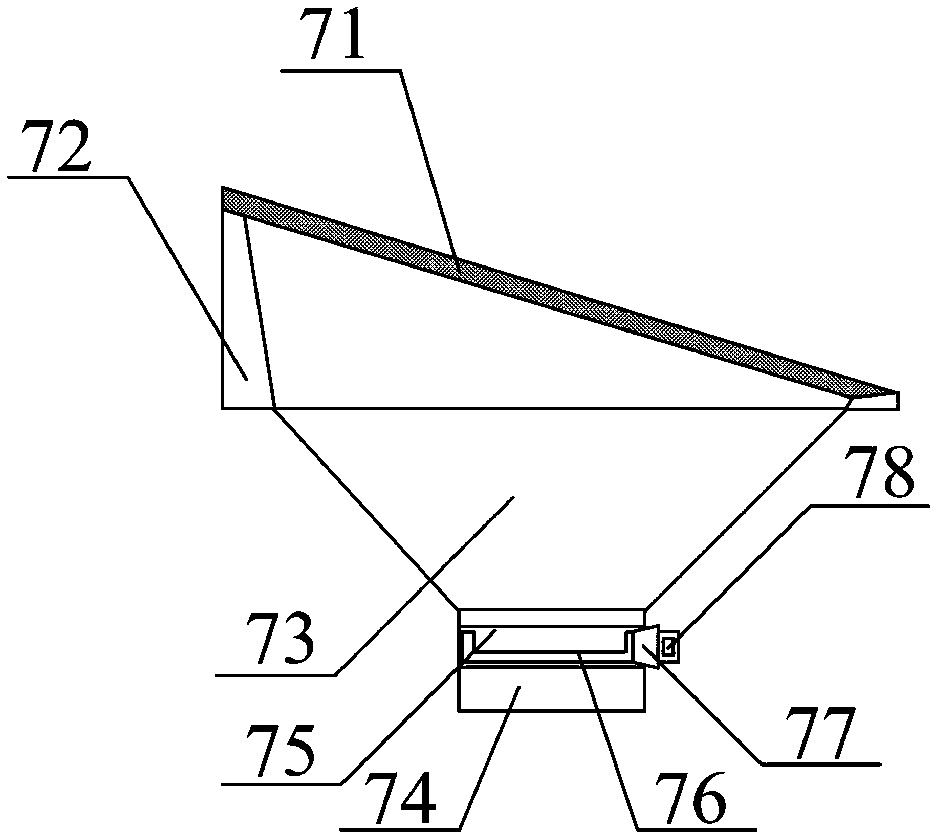

Multifunctional papermaking pulping system

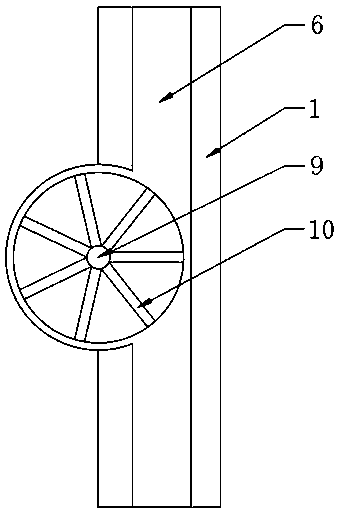

InactiveCN108570869APlay a role in humidificationPromote circulationPulp bleachingRaw material divisionDrive shaftWater storage tank

The invention provides a multifunctional papermaking pulping system. The system comprises a washing frame, a charging hopper, a spraying guide pipe structure, a water guide pipe, a water pump, a waterpumping pipe, a water circulating filter residue net rack structure, a water storage tank, a waste paper rotating scraping bracket structure, a guiding hopper, a waste paper crushing box, a top mounting plate, a drive shaft, crushing blades, a quantitative bleaching powder adding storage tank structure, a finished product box and a longitudinal support, wherein the charging hopper is mounted at the upper left part of the washing frame through bolts. By means of water spraying heads, water spraying pipes and first-grade adjusting valves, waste paper in the washing frame can be conveniently wetted; by means of the water guiding hopper, a water draining barrel and the water storage tank, the waste paper in the washing frame can be conveniently circulated in the water storage tank, and wastewater can be further recycled; by means of scale marks and second-grade adjusting valves, bleaching powder in the bleached powder storage tank can be conveniently and quantitatively detected, and bleaching powder is conveniently added to the waste paper crushing box.

Owner:HUBEI BAOTA PAPER

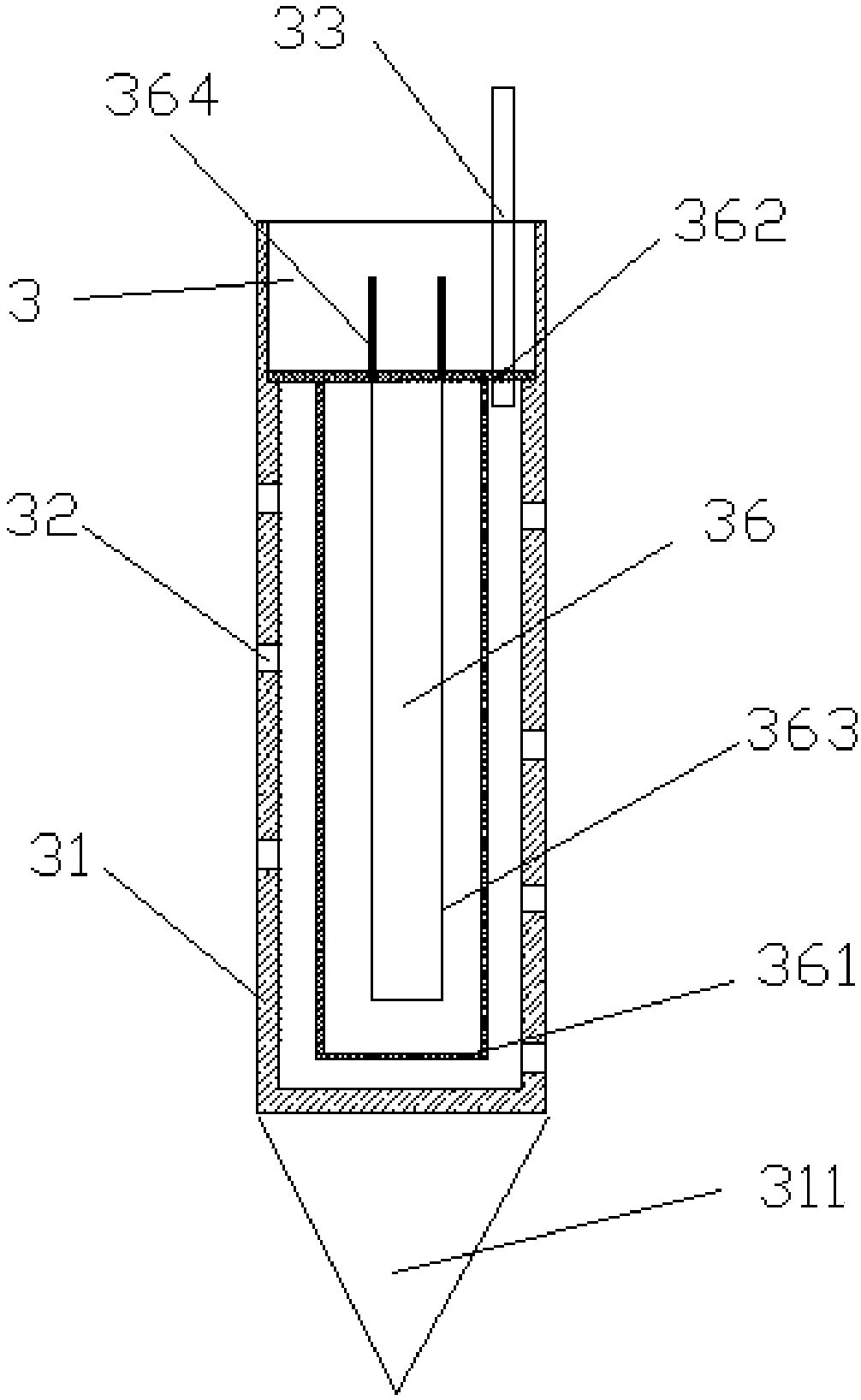

Thermal desorption device for amending and repairing polluted soil

InactiveCN108213063AIn situ processingSimplify remediation governance proceduresDispersed particle separationContaminated soil reclamationPollution soilEngineering

The invention provides a thermal desorption device for amending and repairing polluted soil. The thermal desorption device comprises a soil heating mechanism and an exhaust gas washing desorption mechanism, wherein the soil heating mechanism comprises a load-bearing tank, tubular heaters are arranged at the bottom of the load-bearing tank and comprise ground breaking tubes, each ground breaking tube is provided with a suction pipe and a plurality of exhausting holes, the suction pipes are separately converged to an exhaust pipe in an accommodating space, the exhaust pipe is connected with a gas stripping pump, the exhaust gas washing desorption mechanism is connected with the gas stripping pump, and heating pipes are arranged in the ground breaking tubes and are connected in parallel in the accommodating space through conducting wires. The device provided by the invention is applied to thermal desorption soil repairing treatment of organic matter polluted soil and can achieve the in-situ treatment of contaminated soil, repairing treatment procedures of the contaminated soil are simplified and are simple and efficient, and the device is applicable to the thermal desorption treatmentof large-area contaminated soil; meanwhile, an exhaust gas treatment system is arranged, the problem of environmental pollution is solved.

Owner:郑州恒之博新能源科技有限公司

Preparation method of feather peptide powder

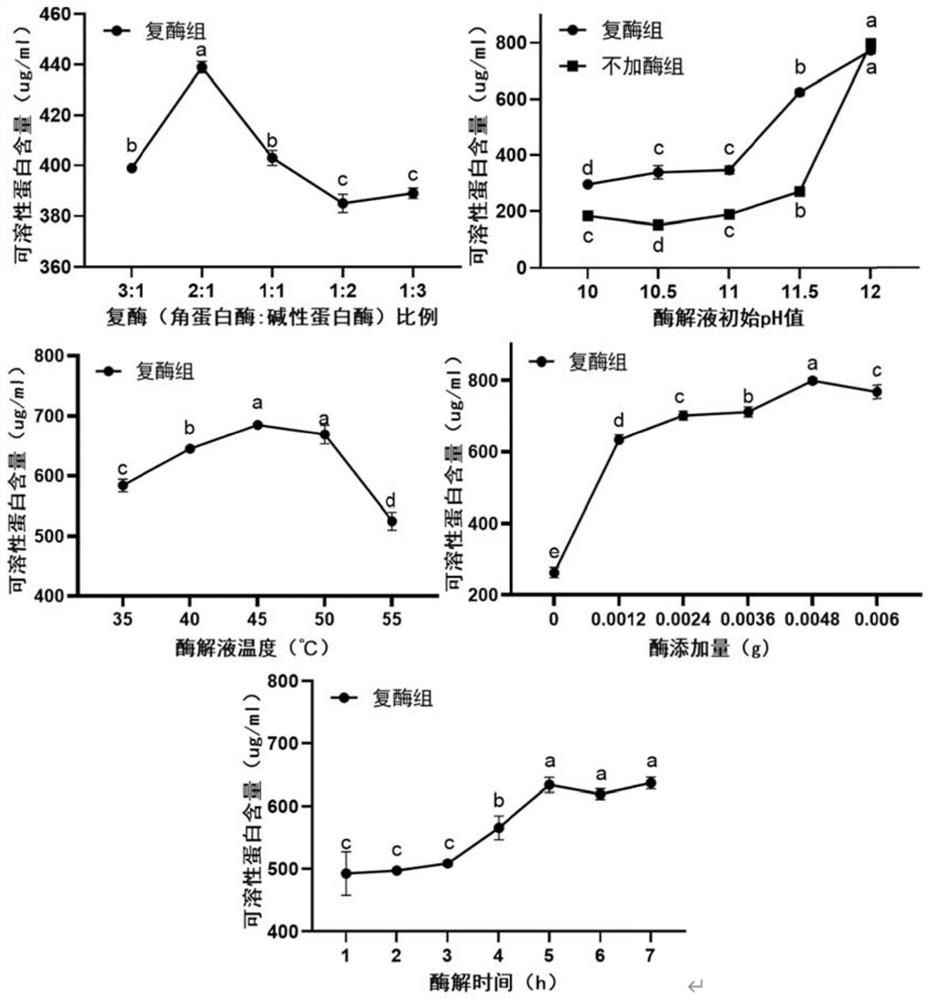

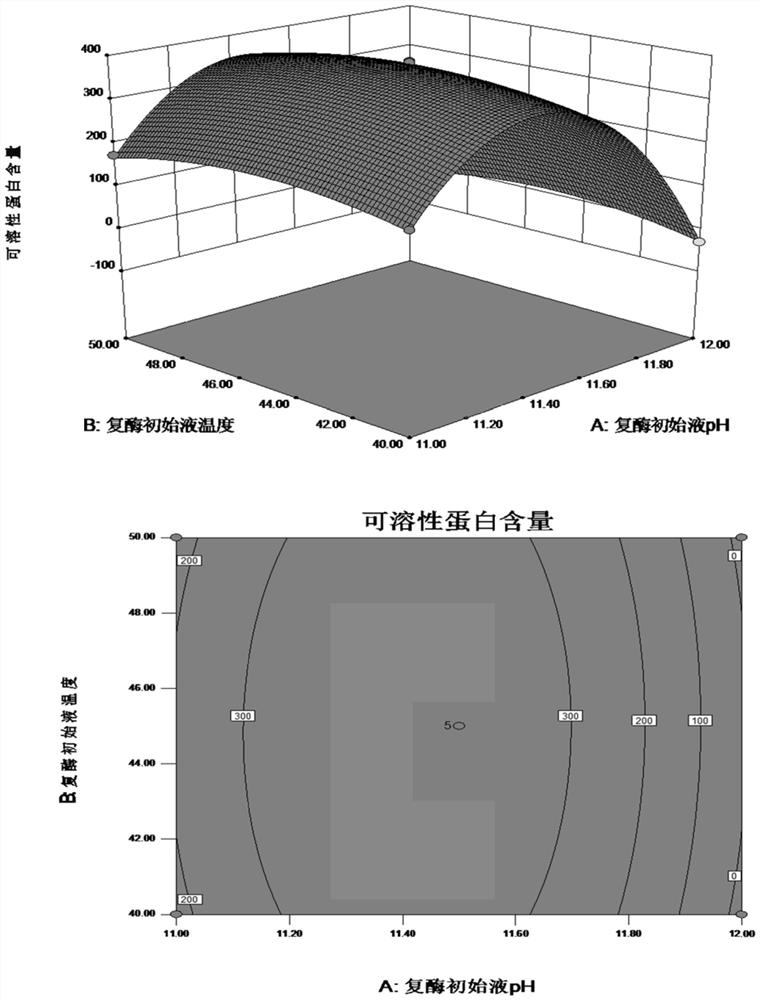

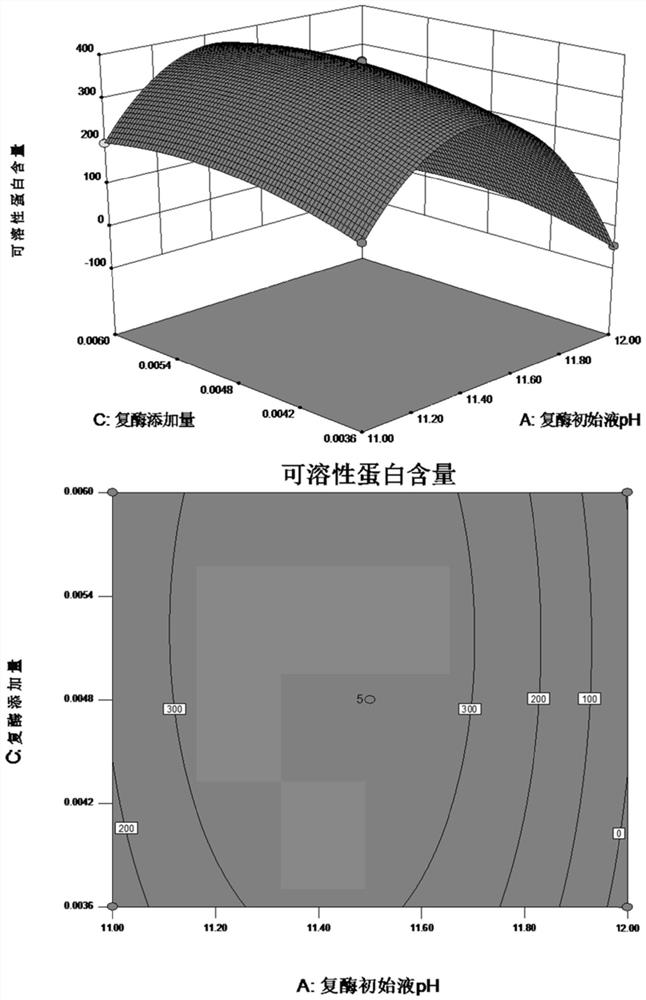

InactiveCN111802508AIncrease profitPromote safe productionAccessory food factorsAnimal proteins working-upBiotechnologyAlkaline proteinase

The invention relates to the technical field of resource utilization of poultry slaughtering waste, and particularly discloses a preparation method of feather peptide powder. The method takes poultryfeathers as a raw material, and is characterized by comprising the following steps of crushing the feathers, and then putting the crushed feathers into a container; injecting water, adding 50-400 U ofkeratinase and 1,000,000-3,600,000 U of alkaline protease into each 1g of feather, adjusting the pH to be 10-11.5, reacting at 40-50 DEG C for 4h-8h, and drying filtrate to obtain a peptide powder product. The process disclosed by the invention is simple to operate, safe and efficient, and has great significance for recycling slaughtering wastes such as feathers. The content of soluble protein inthe filtrate of the product is higher than 680 ug / ml, the peptide content in peptide powder is higher than 95%, the relative molecular mass of peptide is below 2000 Dalton, and the product has higherpurity, can be processed into an animal protein feed raw material, has wider application range and is suitable for wide popularization and application.

Owner:ZHEJIANG UNIV +1

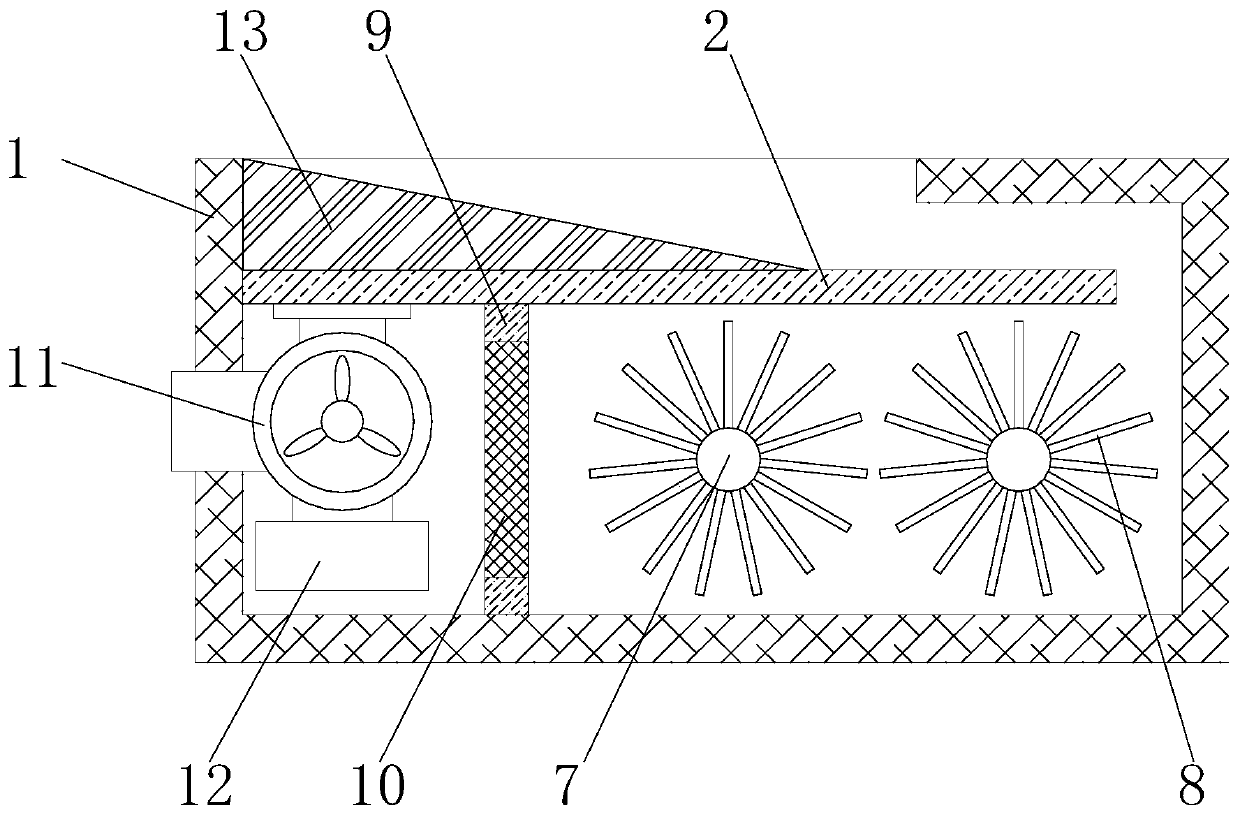

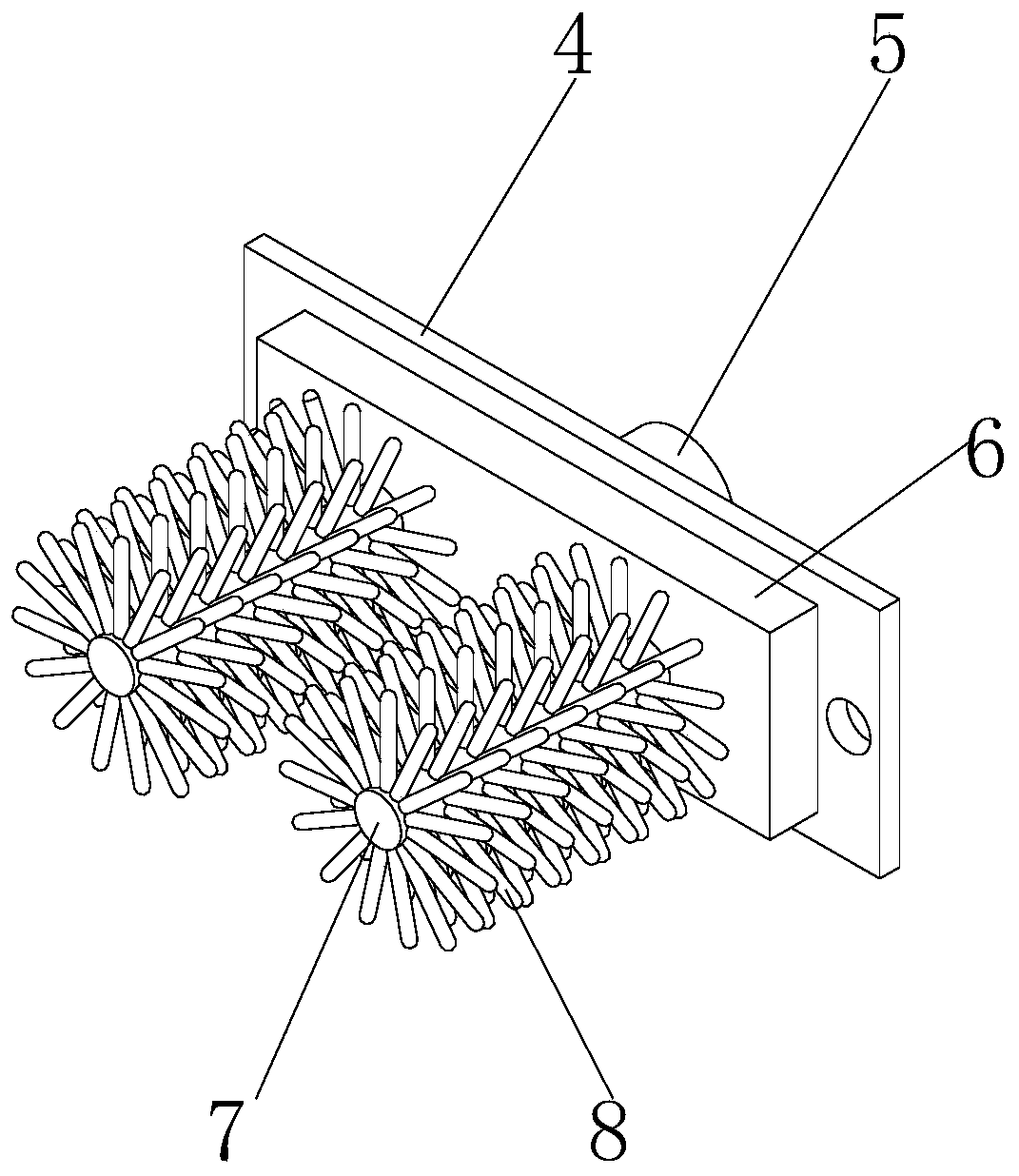

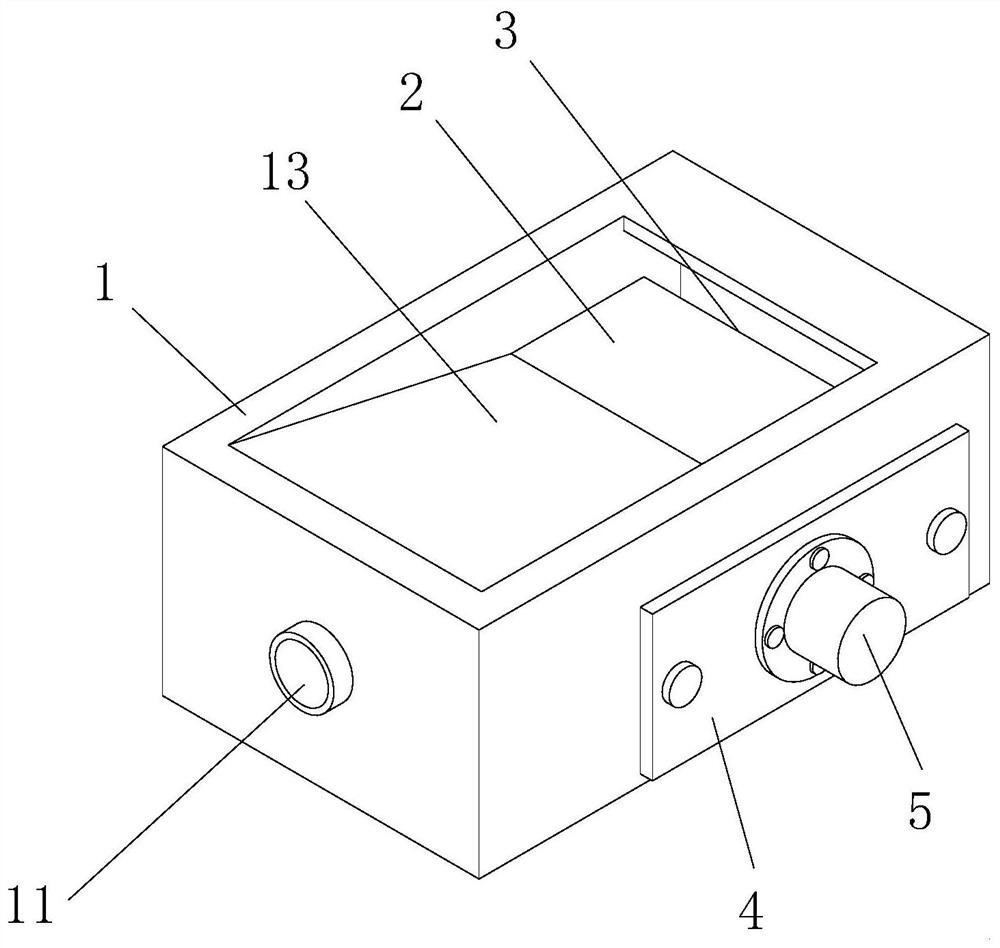

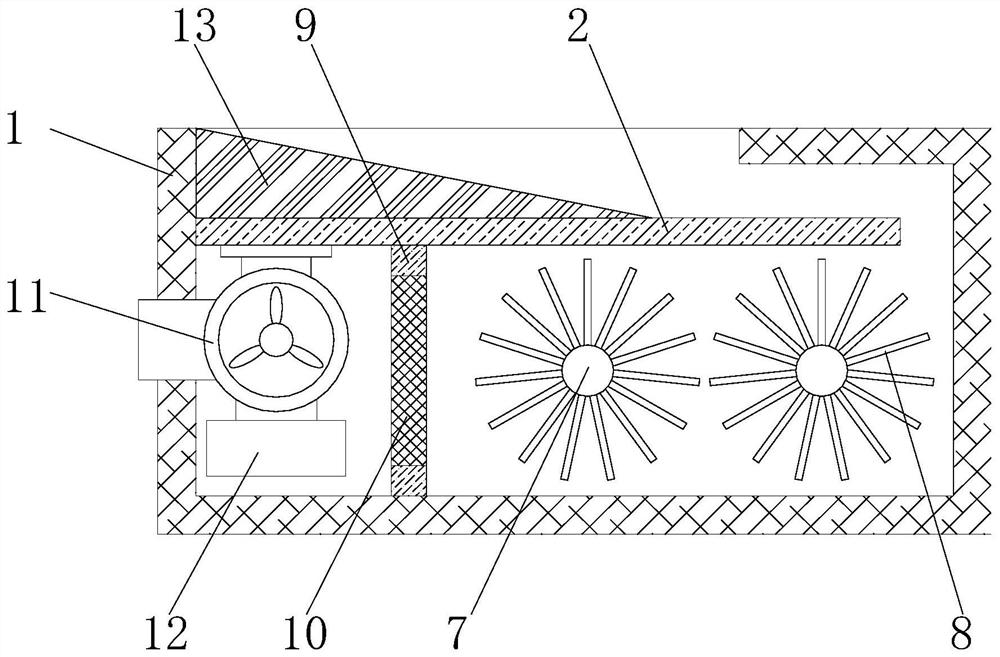

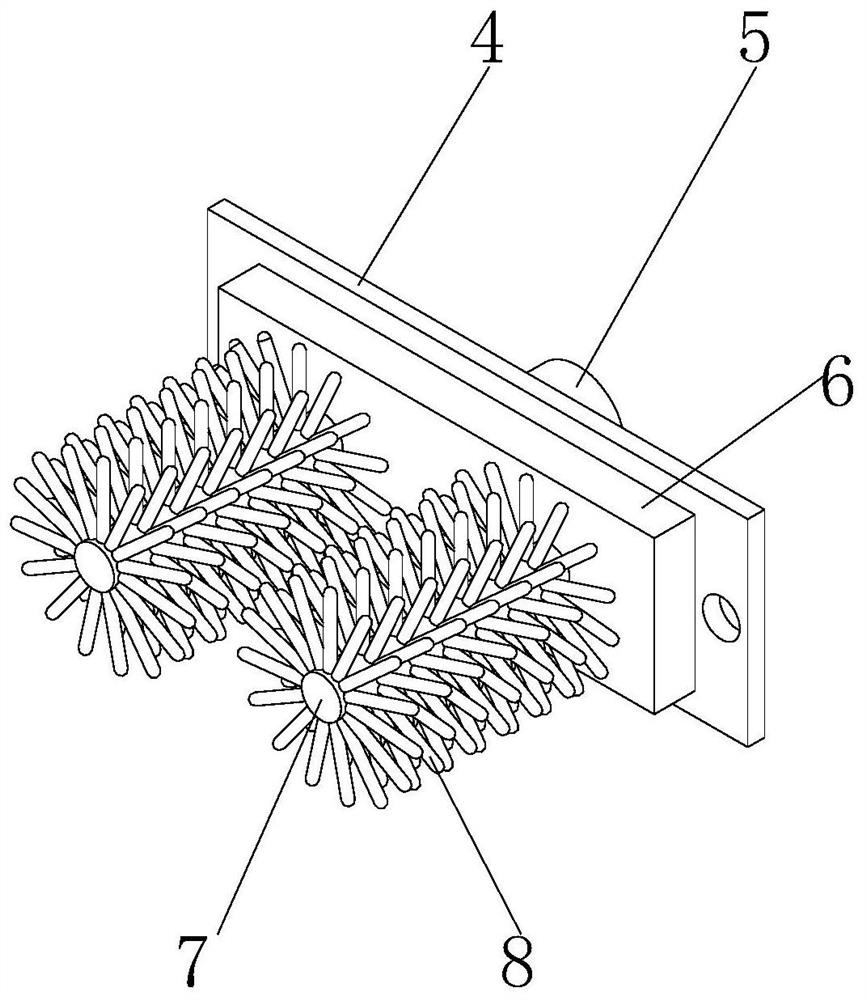

Automatic recovery device for broken fiber

ActiveCN111232753ASimple structureLow costFilament handlingElectrical and Electronics engineeringFiber

The invention discloses an automatic recovery device for a broken fiber. The automatic recovery device comprises a box body, and an inner cavity of the box body is fixedly connected with a fixing plate; an air hole is formed between the right side of the fixing plate and the box body, and the front surface of the box body is provided with a square mounting plate; the front surface of the square mounting plate is provided with a power structure, and the rear side of the square mounting plate is provided with a transmission structure; and the rear side of the transmission structure is provided with winding rollers. According to the automatic recovery device for the broken fiber, through cooperative application of the power structure, the transmission structure, the winding rollers, storage rollers and a negative pressure fan, the purpose of sucking the broken fiber into the inner cavity of the box body through wind power is achieved, and meanwhile the broken fiber is rolled and stored through the winding rollers and the storage rollers; the function of automatic recovery is achieved finally, so that the automatic recovery device for the broken fiber has the advantages of automatic recovery, the simple structure in the actual use process, low cost, easy maintenance and wide application range, and plays a role in recycling of fibers; the recycling of resources is achieved, and theautomatic recovery device facilitates users to use.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

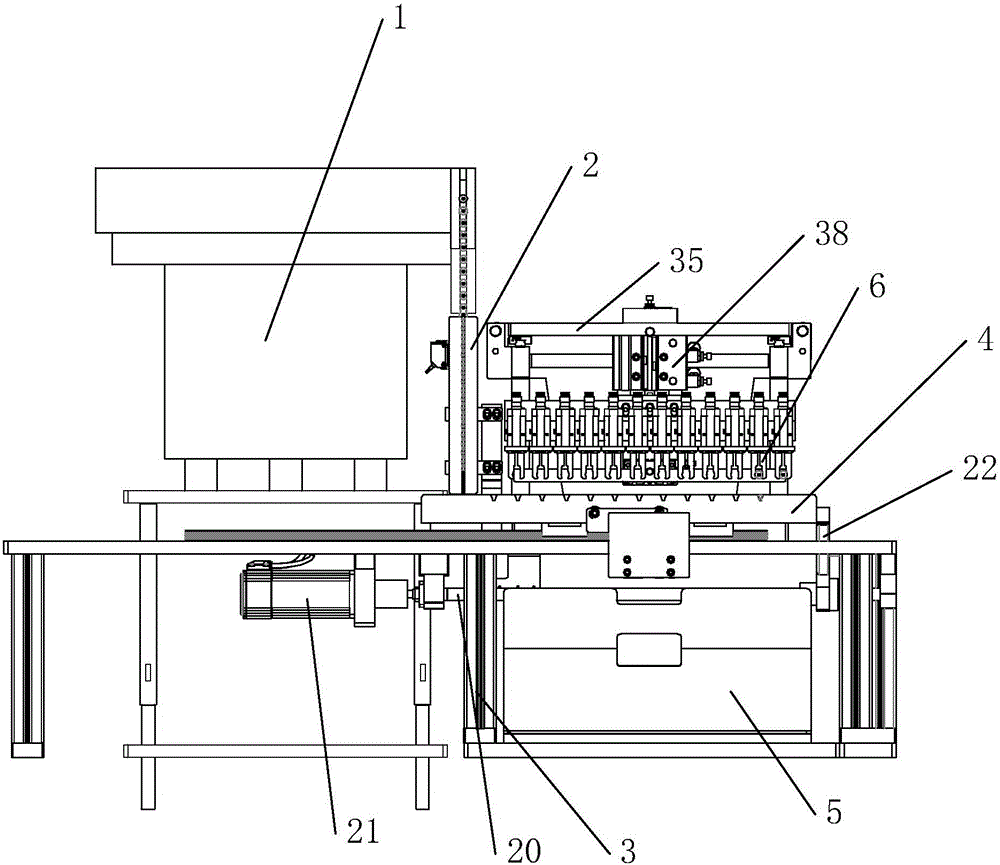

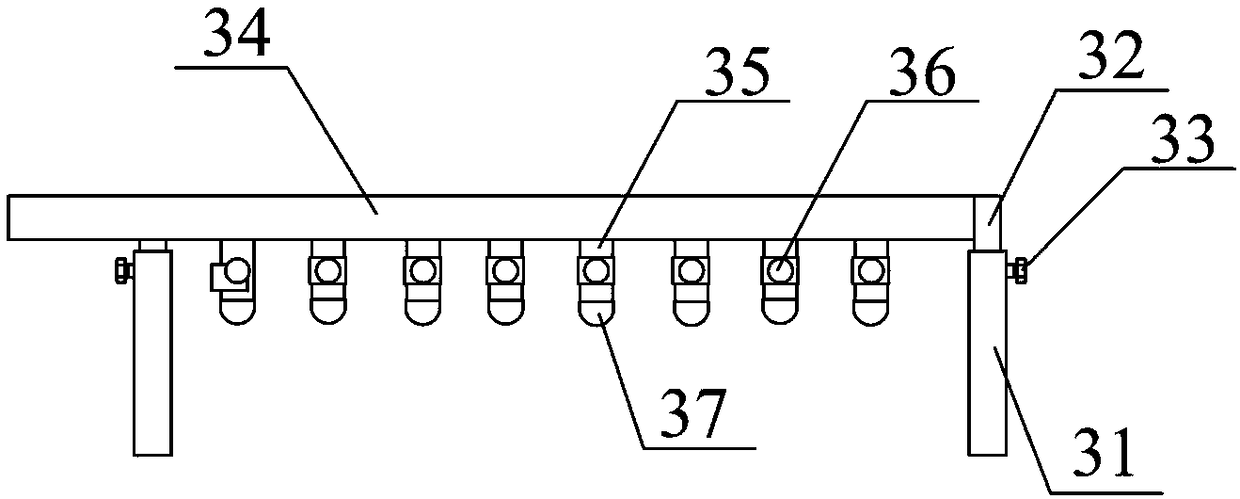

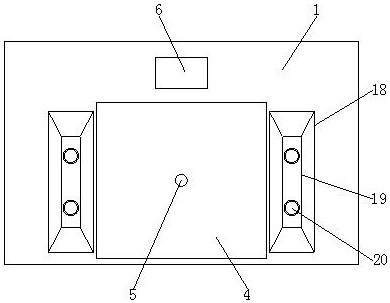

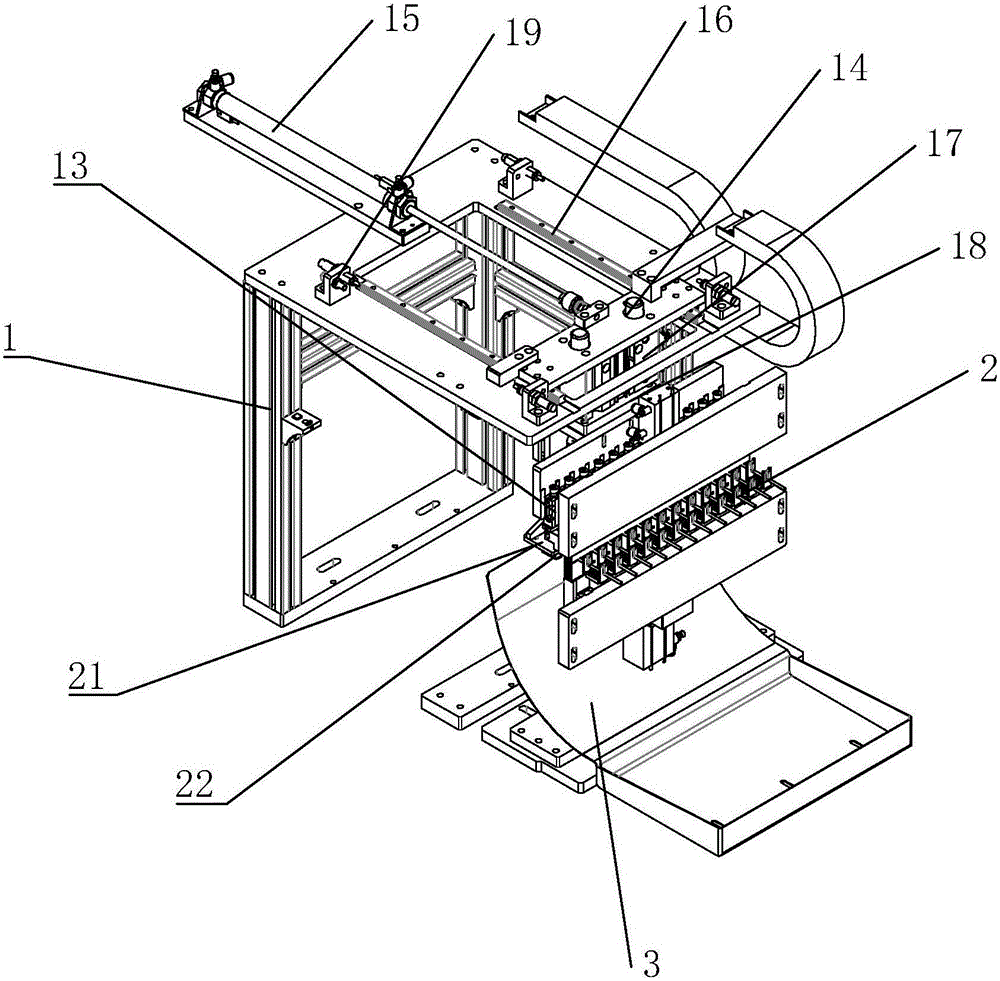

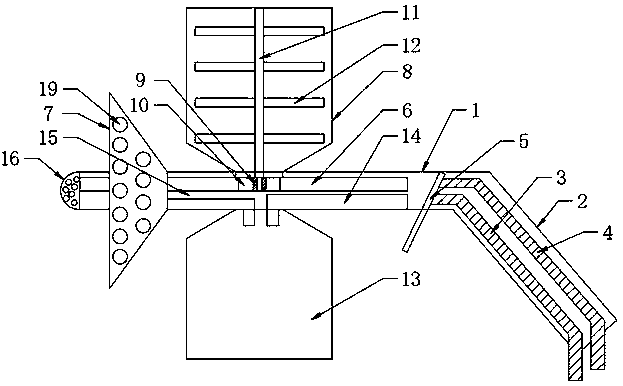

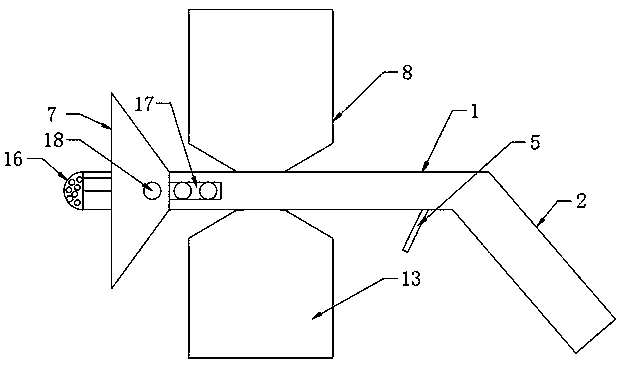

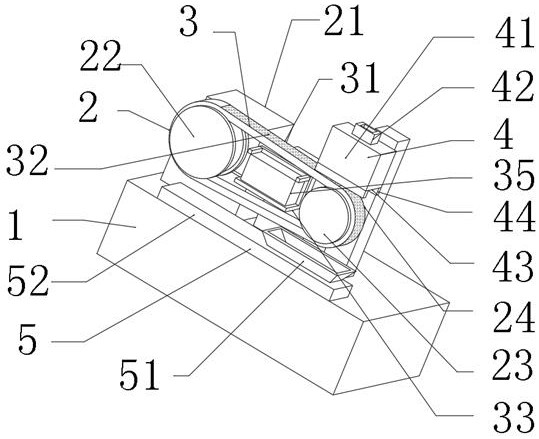

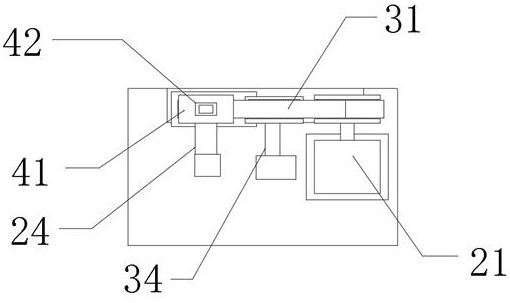

Drip chamber and catheter assembling mechanism

PendingCN106425399APlay the role of recyclingPlay the technical effect of recyclingMetal working apparatusEngineeringGuide tube

The invention discloses a drip chamber and catheter assembling mechanism. According to the technical key points, the drip chamber and catheter assembling mechanism comprises a vibration disc, an air cylinder front rail, a receiving jig, a clamping mechanism, a positioning mechanism and an installation frame. The vibration disc, the clamping mechanism, the receiving jig, the air cylinder front rail and the positioning mechanism are all installed on the installation frame. The vibration disc is provided with a discharging track. The discharging track is provided with a feed inlet and a discharge outlet. The feed inlet of the discharging track is connected with the vibration disc. The discharge outlet of the discharging track is connected with the air cylinder front rail. A limiting device is arranged between the discharging track and the air cylinder front rail. The clamping mechanism for grabbing a drip chamber on the air cylinder front rail is arranged above the air cylinder front rail. The positioning mechanism can fix a catheter. The clamping mechanism clamps the drip chamber on the receiving jig and the catheter on the positioning mechanism for assembling, a first optical fiber for controlling the limiting device and the clamping mechanism is arranged on the air cylinder front rail, the drip chamber and catheter assembling success rate is improved, and resource waste is reduced.

Owner:梁启明

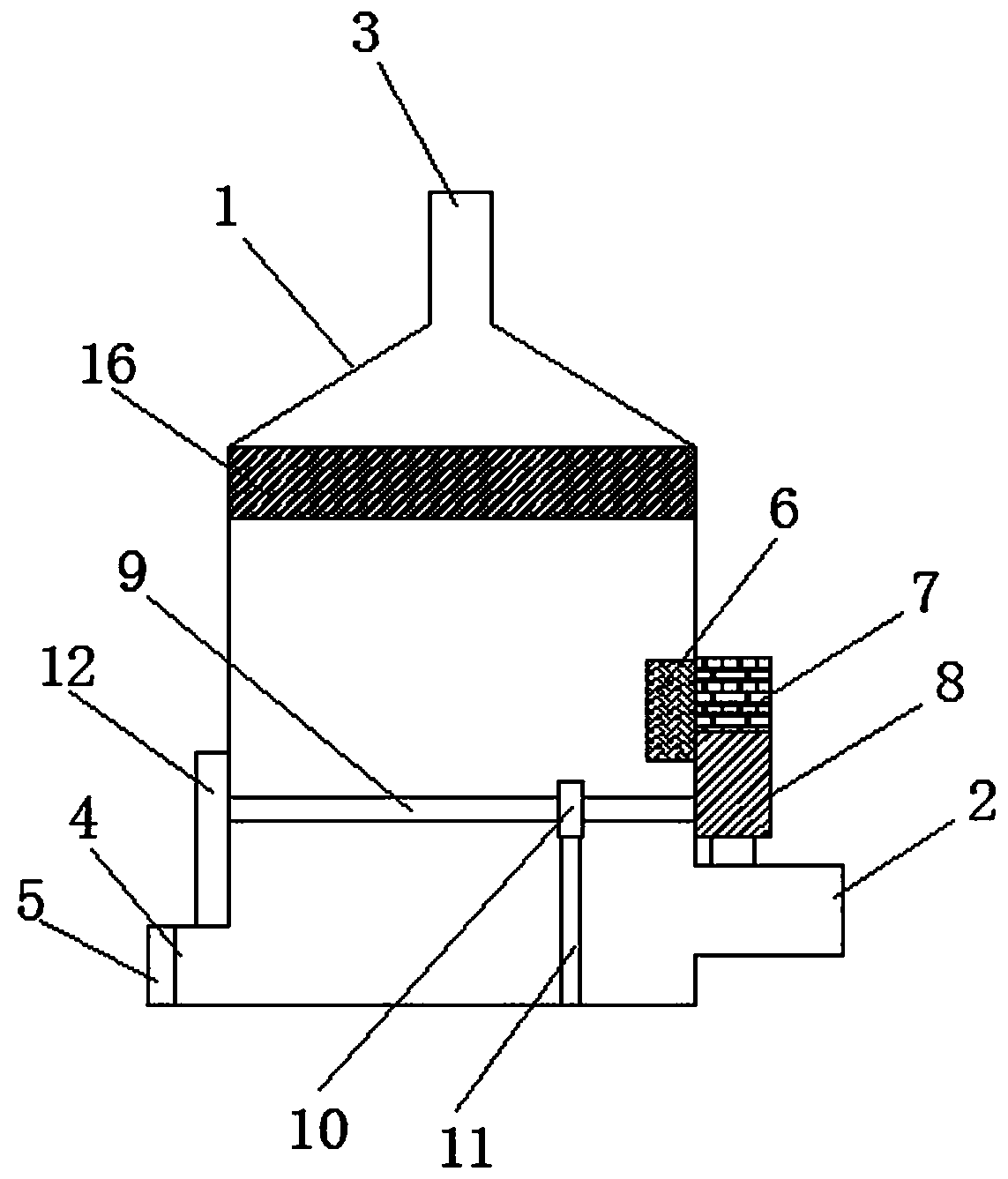

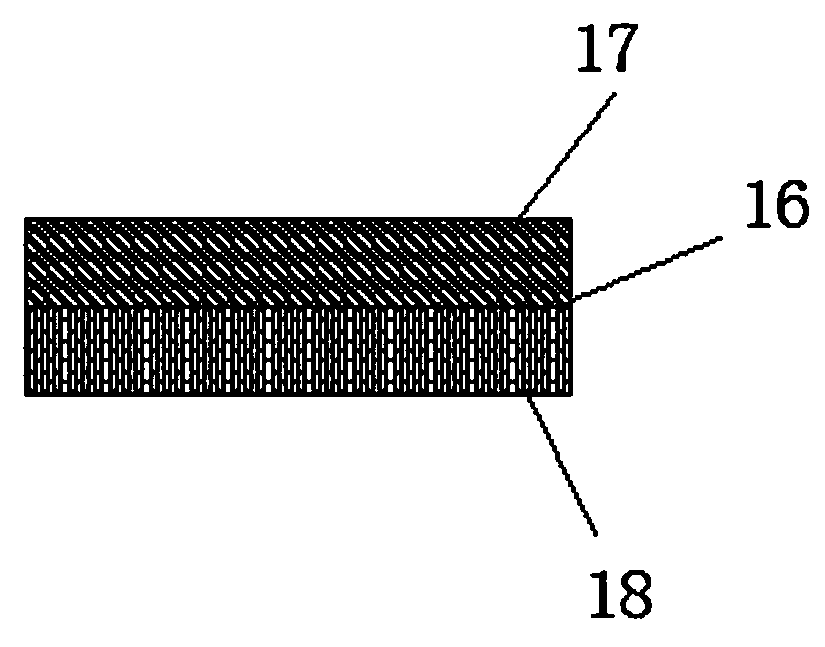

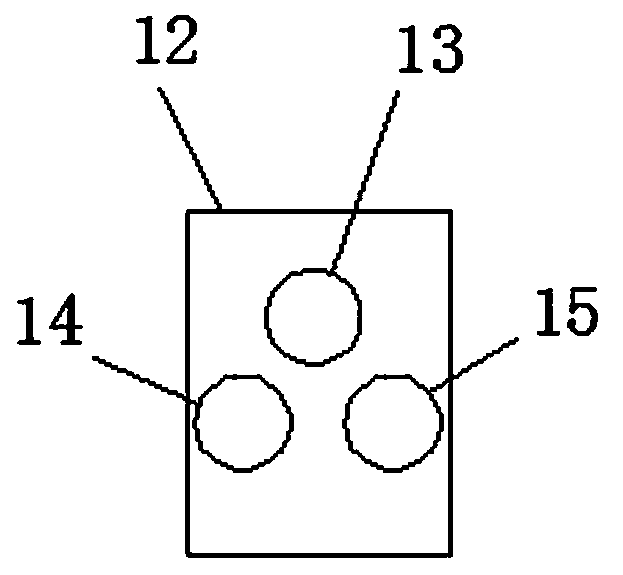

Incinerator gas path structure

ActiveCN109611869BIncrease the lengthPlay the role of recyclingIncinerator apparatusConductive materialsAir blower

Owner:浙江嘉策工程咨询有限公司

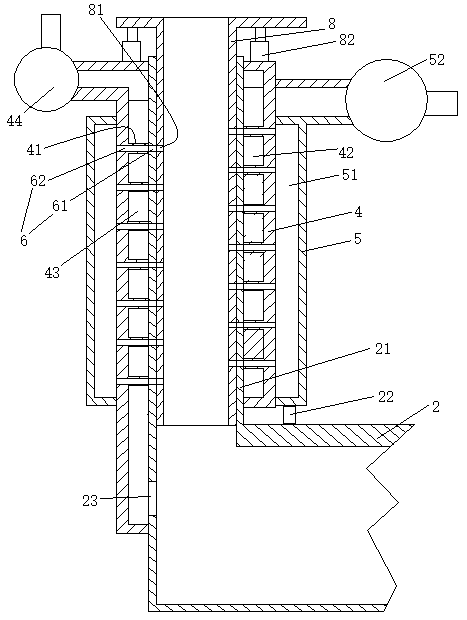

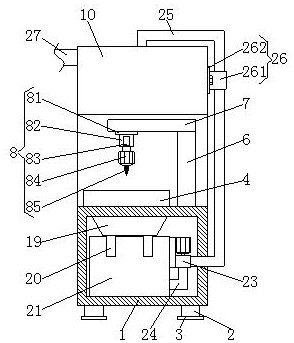

Photocuring three-dimensional printer and printing method thereof

InactiveCN107538737AAvoid pollutionPlay the role of recyclingAdditive manufacturing apparatusManufacturing recyclingManufacturing cost reductionEngineering

The invention discloses a photocuring three-dimensional printer and a printing method thereof. The photocuring three-dimensional printer comprises a containing groove, a curing light source, a printing platform, a moving assembly and a vibrating assembly. After the printing of a three-dimensional object is complete, the three-dimensional object on the printing platform is vibrated by the vibratingassembly, so that liquid photosensitive resin on the three-dimensional object is shaken off, consequently, environmental pollution caused by subsequent treatment is prevented, and the material can berecovered as well, so that manufacturing cost can be reduced. A first electromagnetic attraction unit and a second electromagnetic attraction unit cooperate with each other to respectively carry outattraction or separation on the printing platform at different time, the structural arrangement is reasonable, and the objective of recovering the liquid photosensitive resin remaining on the surfaceof a finished three-dimensional object is achieved.

Owner:陈静

Cooling device for machining and operation method thereof

InactiveCN111604516AGood cooling effectSpeed up coolingLoose filtering material filtersGravity filtersWater deliveryProcess engineering

The invention discloses a cooling device for machining and an operation method thereof. The cooling device comprises a box body. Four corners of the bottom of the box body are fixedly connected with supporting feet. The bottoms of the supporting feet are fixedly connected with anti-skid pads. A placement platform is fixedly connected to the center of the top of the box body. The cooling device hasthe advantage of good cooling effect through the cooperation of side panels, a first water tank, air holes, dust-proof nets, first water pumps, first pumping pipes, first water outlet pipes, anti-sway devices, spraying heads, leaking troughs, water collecting hoppers, water flowing pipes, a second water tank, a filter device, a second water pump, a second pumping pipe, a second water outlet pipe,a fixing mechanism and a water delivery pipe. When mechanical parts are cooled, the cooling rate of the mechanical parts can be effectively increased, the subsequent processing speed of the mechanical parts is increased, the processing efficiency of the mechanical parts is improved, and at the same time, water can be recycled to save water resources.

Owner:绍兴易者科技有限公司

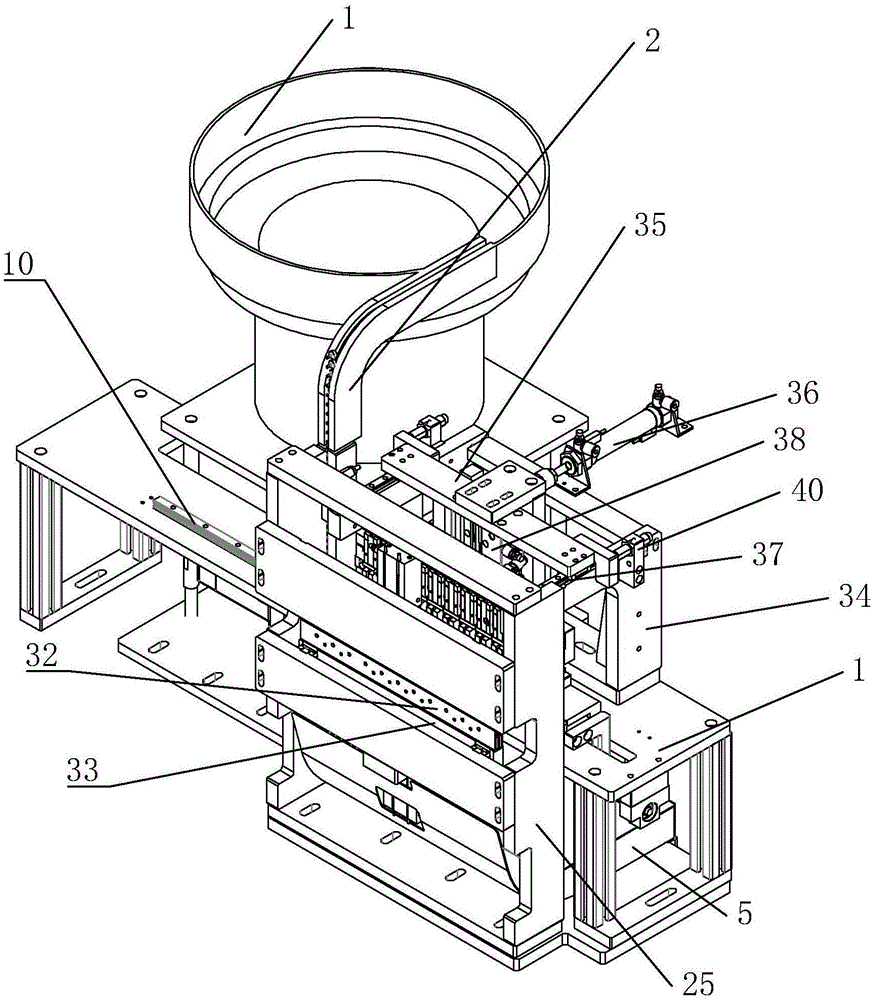

Assembling device for bottle inserting needle and conduit

The invention discloses an assembling device for a bottle inserting needle and a conduit. The assembling device is characterized by comprising a transmission chain, a clamping picking mechanism, a positioning mechanism and a mounting frame, wherein the transmission chain, the clamping picking mechanism and the positioning mechanism are mounted on the mounting frame; the positioning mechanism can be used for fixing the conduit; the clamping picking mechanism can be used for clamping and picking out the bottle inserting needle to assemble to the conduit on the positioning mechanism; a positioning clamp is arranged on the mounting frame and positioned below the clamping picking mechanism; when in the assembling of the bottle inserting needle and the conduit, the bottle inserting needle can be positioned through the positioning clamp. With the adoption of the assembling device for the bottle inserting needle and the conduit, the bottle inserting needle and the conduit can be automatically assembled.

Owner:梁启明

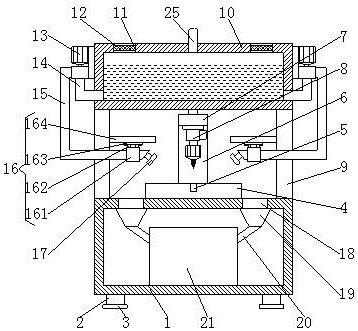

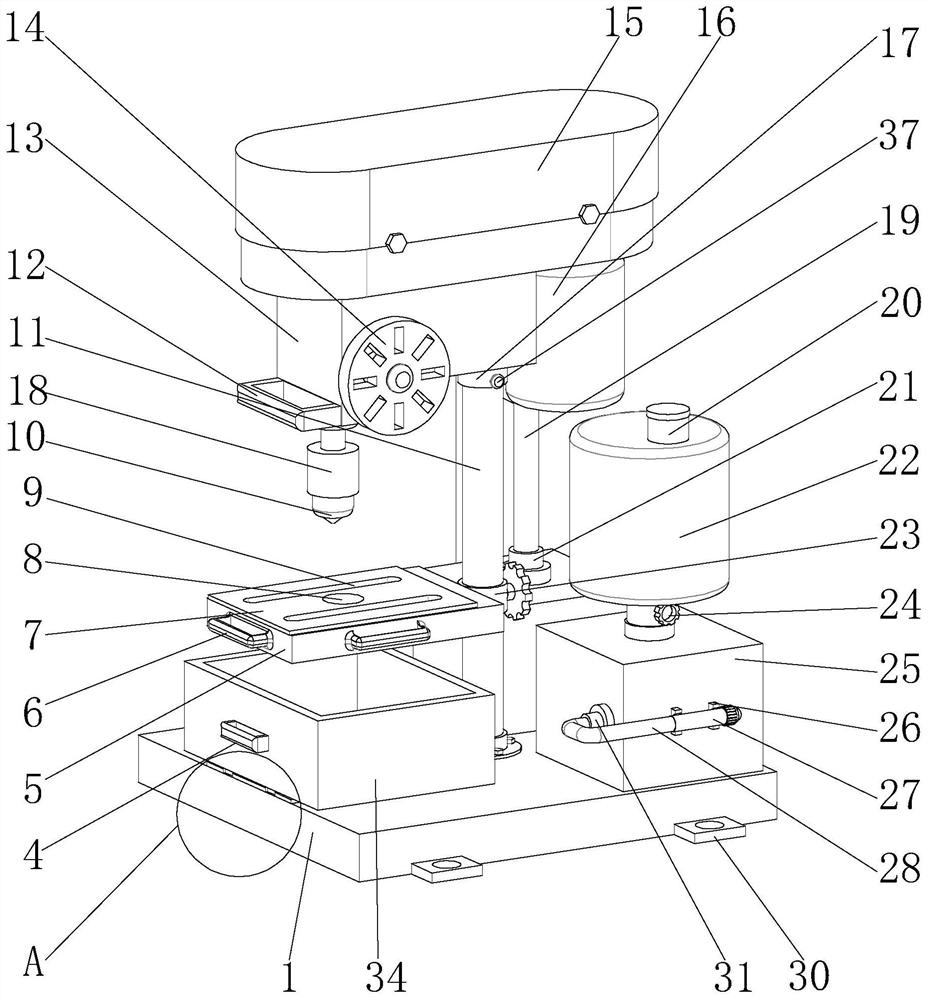

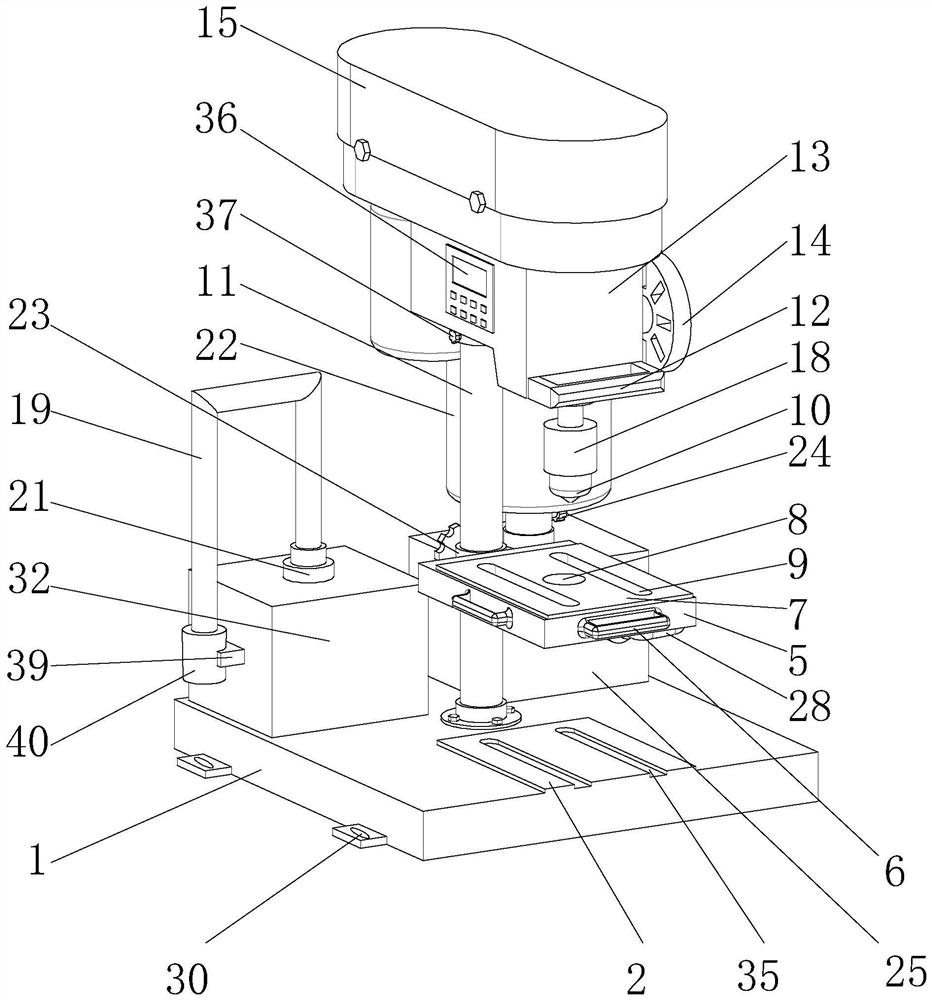

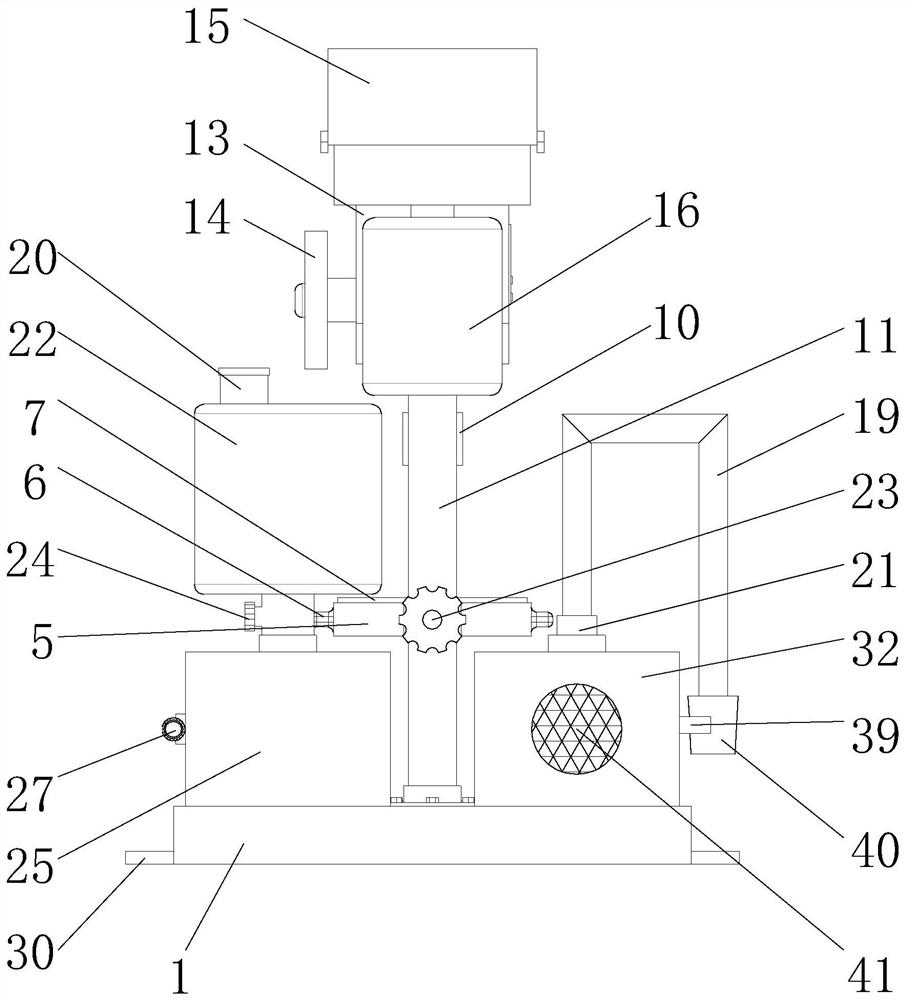

Shockproof mechanical drilling device with scrap cleaning and recycling function

InactiveCN112439915APlay the role of recyclingAvoid the effects of drillingFeeding apparatusBoring/drilling componentsProcess engineeringWorkbench

The invention discloses a shockproof mechanical drilling device with a scrap cleaning and recycling function. The shockproof mechanical drilling device with the scrap cleaning and recycling function comprises a base, wherein a first workbench is fixedly installed at the top of the base; a recycling box is fixedly installed at the top of the first workbench; a supporting rod frame is fixedly installed at the top of the base; a control shell is fixedly installed at the top of the supporting rod frame; a machine shell is fixedly installed at the top of the control shell; a water pump shell is fixedly installed at the top of the base; a drying device is fixedly installed at the top of the base; and the top of the drying device communicates with a first connecting pipe. A recovery box is arranged to slide into sliding grooves through bottom sliding blocks, so that drilling scraps falling from a second workbench can be received, the effect of recovering the scraps is achieved, the situationthat the scraps and garbage fall around and are difficult to clean is prevented, the influence of scraps covering the second workbench on the drilling of an object is avoided, the object drilling effect of a drill bit is improved to the maximum extent, and the problem that normal drilling cannot be conducted in the drilling work is effectively solved.

Owner:叶红飞

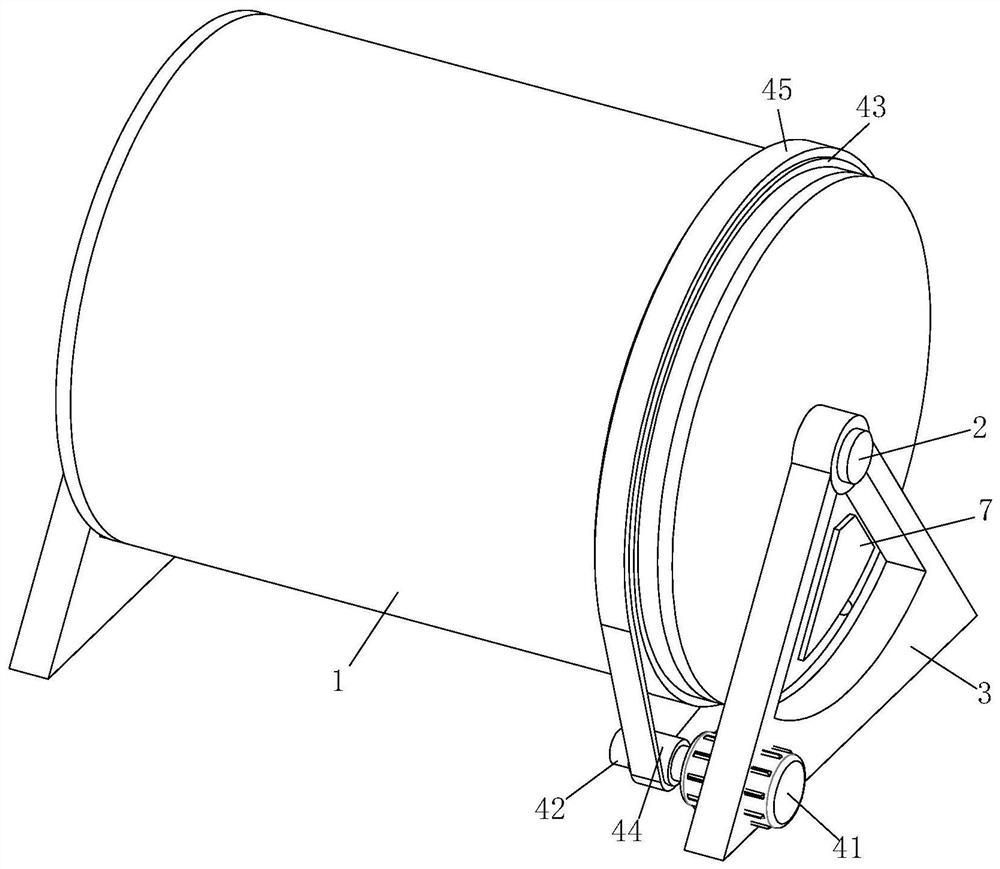

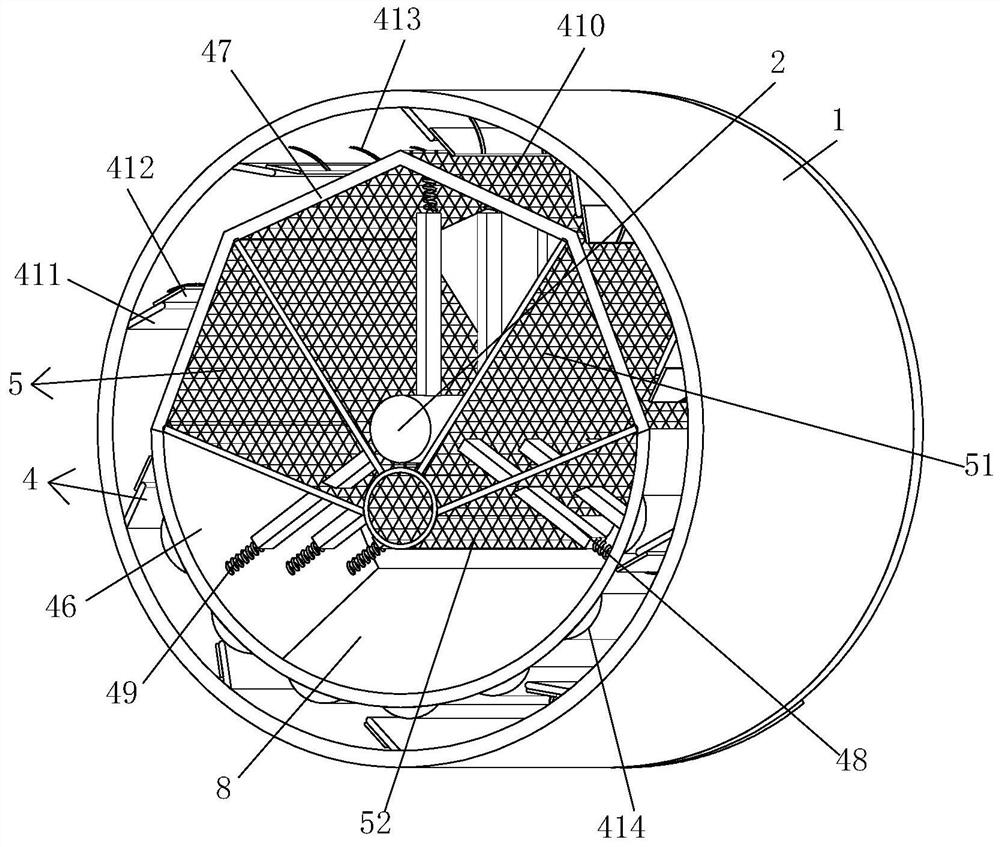

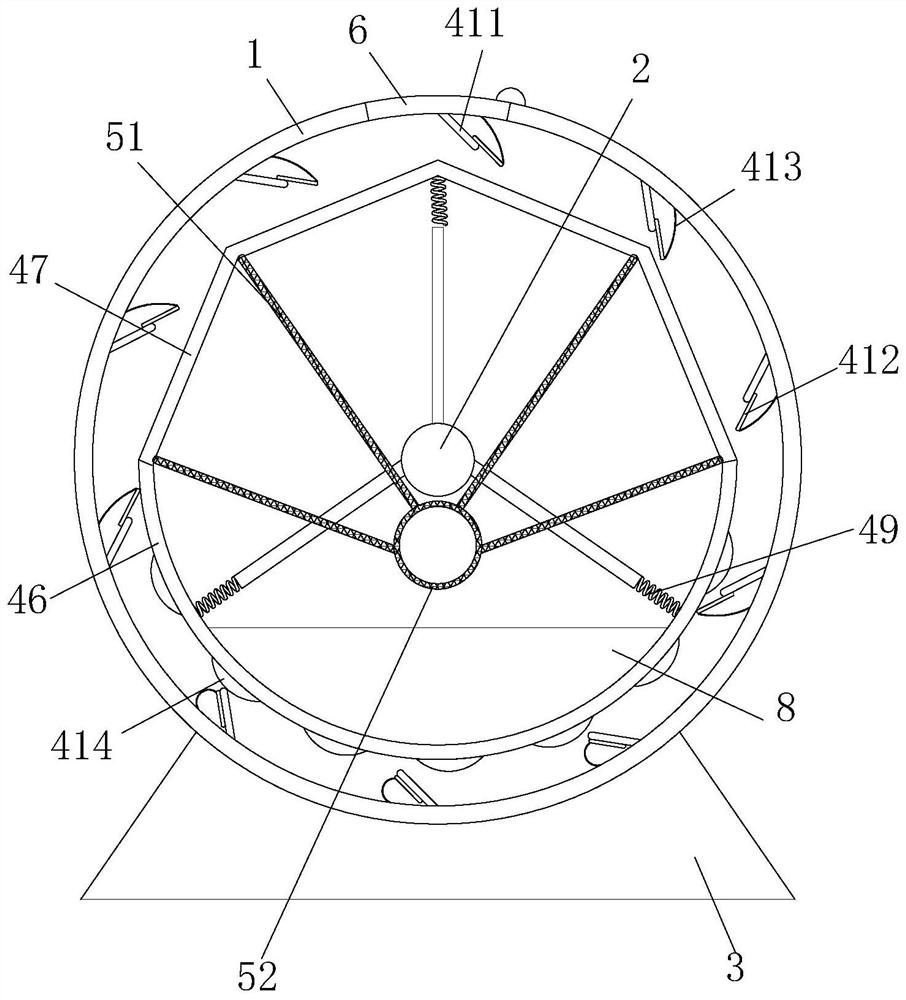

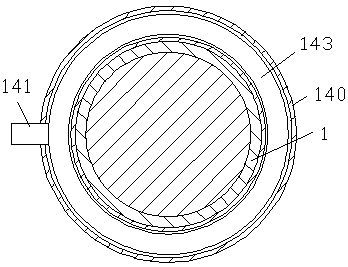

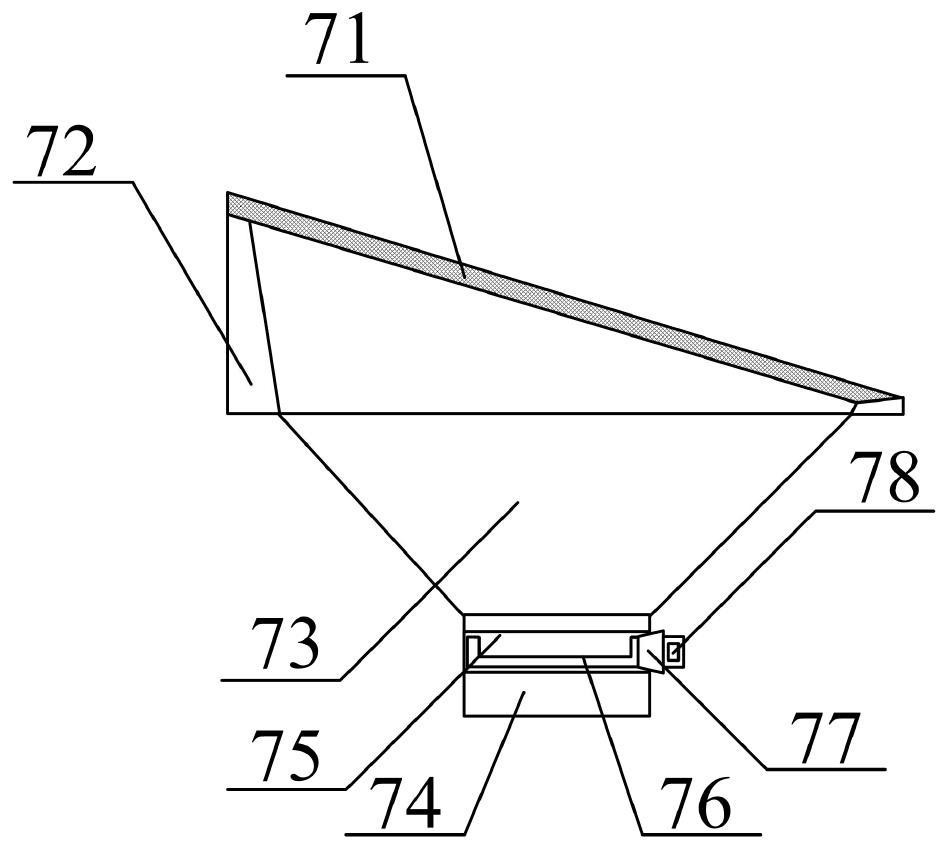

Drum-type sand screening device based on building construction

ActiveCN113070211AThere will be no situation of not touching the sand netImprove screening effectSievingScreeningArchitectural engineeringMechanical engineering

The invention provides a drum-type sand screening device based on building construction, and relates to the field of building. The device comprises a rotary drum for screening sand, a fixed shaft, two side supporting plates, a lifting screening mechanism for screening the sand and a dispersing screening mechanism for further screening the sand, a bearing matched with the fixed shaft is arranged on the surface of the rotary drum, and the surface of the fixed shaft is fixedly connected with an inner ring of the bearing. According to the drum-type sand screening device for building construction, a special structure capable of dispersing and screening sand and comprehensively screening the sand is designed according to the problems that an existing sand screening device is high in energy and low in efficiency, and therefore the problems that according to a common screening device, it is difficult to break and remove cakes of the sand, and due to the influence of the flowability of the sand, a lot of sand cannot be in contact with a sieve to be sieved in the flowing process, idle work is often performed, and high energy consumption and low efficiency are caused are solved.

Owner:山东龙翔节能科技有限公司

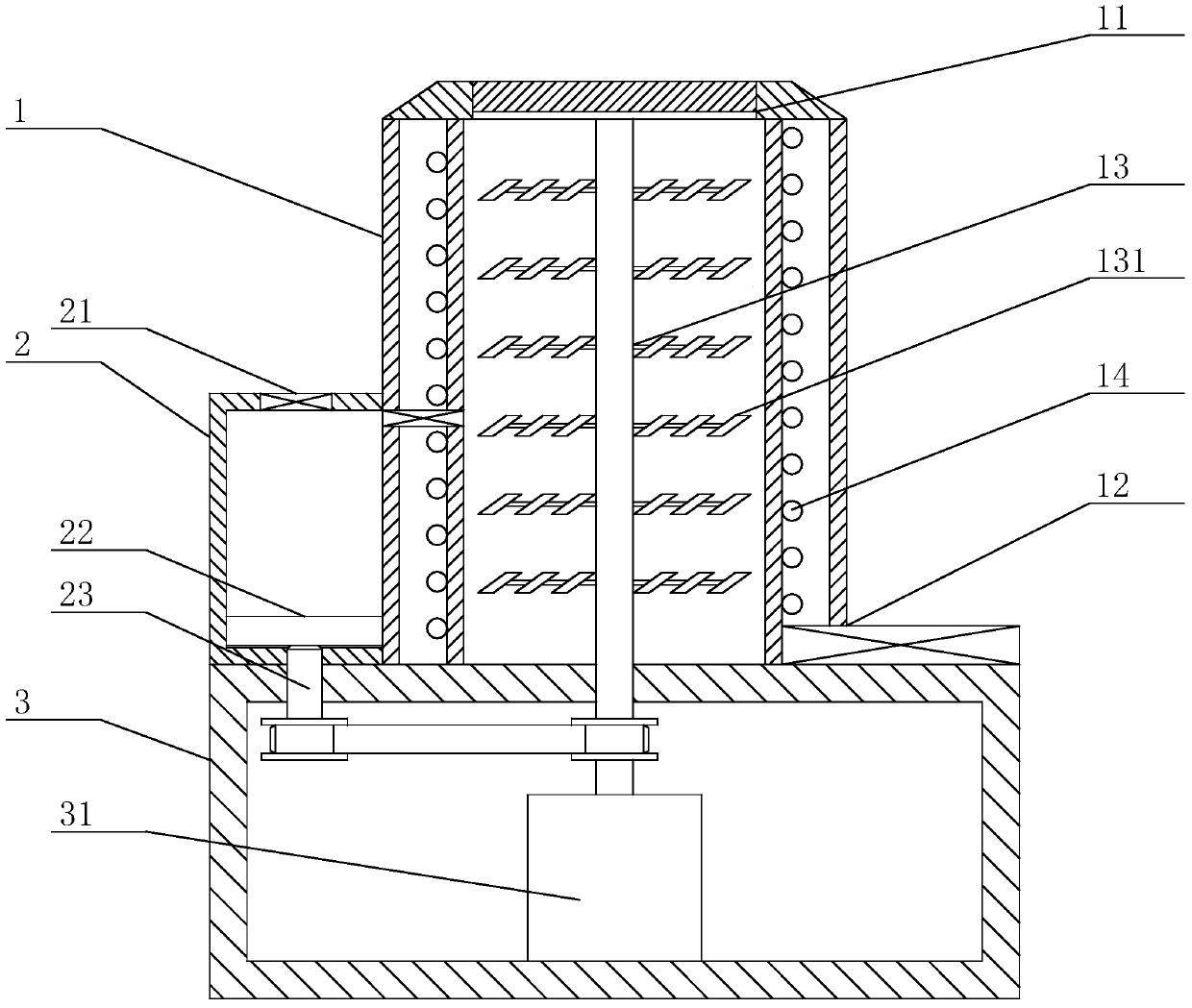

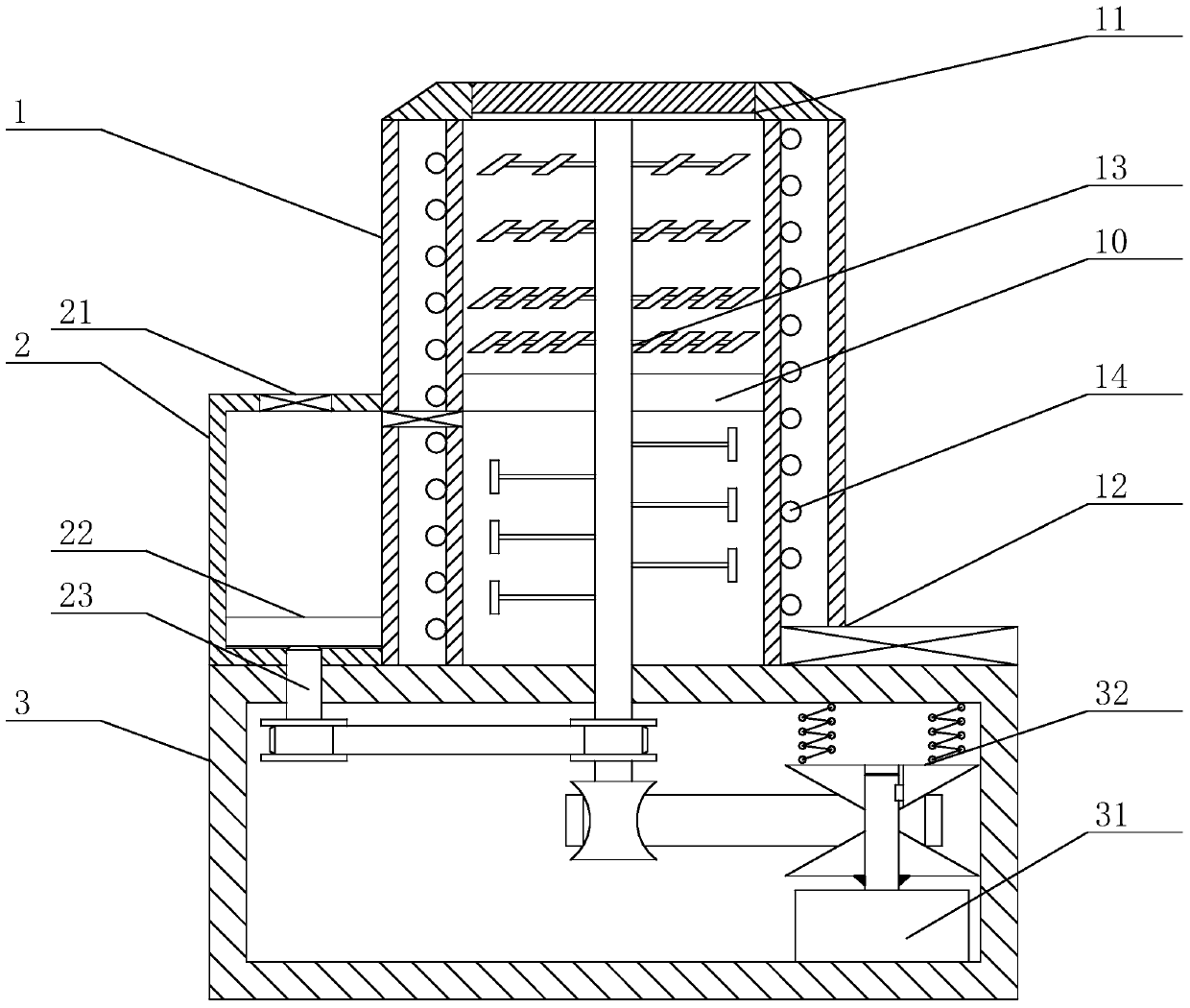

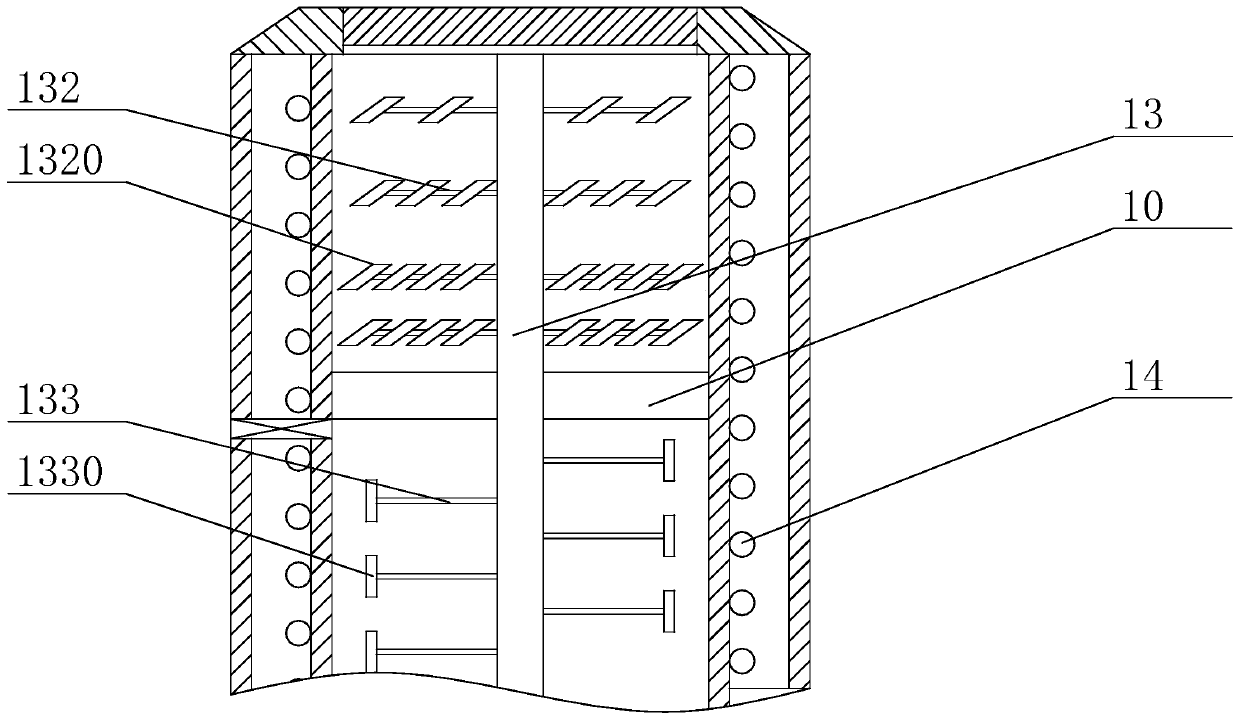

Solid waste integrated drying system based on environmental protection

PendingCN109307407AImprove work efficiencyPlay the role of recycling and reprocessingDrying gas arrangementsDrying solid materialsLiquid wastePulp and paper industry

The invention relates to the technical field of solid waste drying, and discloses a solid waste integrated drying system based on environmental protection. According to the system, solid waste and liquid waste can be effectively separated, and effective components in liquid can be recycled. The solid waste integrated drying system structurally comprises a drying machine, wherein a fan is connectedto one side of the drying machine, a discharge opening is formed in the bottom, an auxiliary heating device wraps the outer side of the drying machine, the auxiliary heating device comprises an annular box body which wraps the outer side of the drying machine, a conduction oil coil is wound in the annular box body, an oil inlet and an oil outlet of the conduction oil coil respectively protrude from one side of the annular box body and are connected with the heating device, the top of the drying machine is connected with the top of a vapor and liquid separation tank by virtue of a first connecting pipe, a first ball valve is arranged on the first connecting pipe, and a liquid recovery pipe is further arranged between the vapor and liquid separation tank and the drying machine. The solid waste integrated drying system has the advantages of simplicity in operation and convenience in use and can be used in various places.

Owner:ZHEJIANG EUCHEM CHEM

Environment-friendly quick paint spraying device

InactiveCN110882868AUniform concentration up and downDoes not affect the spraying effectLiquid spraying apparatusStructural engineeringIndustrial engineering

The invention discloses an environment-friendly quick paint spraying device. The environment-friendly quick paint spraying device comprises a main body, wherein one side of the main body is fixedly provided with a grip, an air suction pipe is mounted at the inner bottom end of the grip, the inner top end of the grip is provided with an air spray pipe, the top end of one side, close to the grip, ofthe main body is provided with a control rod, end points of the air suction pipe and the air spray pipe are connected with the control rod, and the end points, away from the control rod, of the air suction pipe and the air spray pipe are arranged outside the bottom end of the grip; the top end of one side, away from the grip, of the interior of the main body is provided with a spraying pipe, oneside, away from the grip, of the main body is provided with a suction cover, and one side, close to the suction cover, of the top end of the main body is provided with a paint spraying tank; and a rotating wheel is installed at the bottom end of the interior of the paint spraying tank, wherein the rotating wheel is installed inside the spraying pipe, and a baffle is arranged on the side surface ofthe rotating wheel. The environment-friendly quick paint spraying device has the advantages that the structure is simple, the use is convenient, paint in the paint spraying tank can be stirred when paint spraying is carried out, and residual paint in air can be effectively collected.

Owner:章玉红

A plant fertilizer preparation device

ActiveCN105777223BPromote conversionEfficient conversionClimate change adaptationOrganic fertilisersWater storageAgricultural engineering

The invention provides a preparation device for plant fertilizer and relates to the field of fertilizer preparation equipment.The preparation device for the plant fertilizer is delicate in structure, convenient to use, good in stability, capable of rapidly and effectively converting household garbage into the plant fertilizer, free of abnormal smells and easy to use.A preparation cavity is fixedly connected above a power cavity, a water storage cavity is fixedly connected to one side of the preparation cavity, a feed port is formed in the top of the preparation cavity, a discharge port is formed in the bottom of the preparation cavity, the middle of the preparation cavity is communicated with the top of the water storage cavity, and a water inlet is formed in the top of the water storage cavity.The bottom of a stirring shaft stretches into the power cavity and is fixedly connected with an output shaft of a motor.The bottom of a screw stretches into the power cavity, and the screw synchronously rotates along with the output shaft of the motor, the preparation device is convenient to use and free of abnormal smells, nutrients in the fertilizer are sufficient, and the irrigation effect on plants is extremely good.

Owner:YANGZHOU RUNZE HYDRAULIC

Novel chemical tail gas treatment device

InactiveCN109513304APlay the role of recyclingSave energyGas treatmentDispersed particle filtrationMotor driveEngineering

The invention discloses a novel chemical tail gas treatment device structurally comprising a device main body, a gas inlet pipe, a gas outlet and a filter layer; the right side of the device main bodyis provided with the gas inlet pipe; the gas outlet is fixedly formed in the top of the device main body; the upper side of the gas inlet pipe is provided with a motor of which the type is Y-160M; the top of the motor is fixedly connected with a power box; and the motor is connected with the power box by a connecting line by virtue of a circuit. According to the novel chemical tail gas treatmentdevice, the right side inside the device main body is fixedly connected with a condenser, and the condenser is connected with a power box by a connecting line by virtue of a circuit, so that a great number of organic matters in chemical tail gases can be condensed to form particle solids, then, the motor drives a push block, the push block drives a push plate to discharge the particle solids of the great number of organic matters falling on the bottom of the device main body from a recovery port, the valuable organic matters can be recovered, higher environment friendliness is achieved, meanwhile, the effect of recovering wastes is achieved, and the energy source is saved.

Owner:江苏华信环境检测服务有限公司

Sustainable use belt sander

InactiveCN112247768AGuaranteed sustainable useSustainable use withBelt grinding machinesAbrasive surface conditioning devicesSanderDrive wheel

The invention relates to the technical field of belt sanders, and discloses a sustainable use belt sander which comprises a mounting base. A driving mechanism is fixedly mounted at the top end of themounting base, a grinding abrasive belt is arranged on the outer surface of the driving mechanism, a repairing mechanism is arranged on one side of the driving mechanism, the driving mechanism comprises a driving motor, and one end of the driving motor is in transmission connection with a driving wheel. According to the sustainable use belt sander, through the arrangement of the structures such asthe grinding abrasive belt, an electromagnet, ferroferric oxide particles, a discharging mechanism and the repairing mechanism, during polishing, the ferroferric oxide particles can be attracted through the strong magnetism characteristic of the ferroferric oxide particles and under the cooperation with latitude lines such as a magnetic field emitted by the electromagnet, meanwhile, in cooperation with the repairing mechanism, ferroferric oxide particles at the position of the grinding abrasive belt can be added and repaired at any time, so that sustainable use of the belt sander is guaranteed, the beneficial effects of sustainable use and the like are achieved, and the above problem that the belt sander cannot be used sustainably is solved.

Owner:无锡兴华机械有限公司

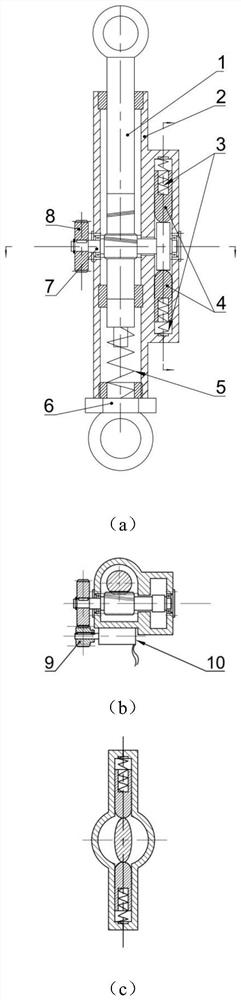

Guide sleeve of hydraulic oil cylinder

The invention belongs to the technical field of hydraulic oil cylinders and particularly relates to a guide sleeve of a hydraulic oil cylinder. The guide sleeve is characterized in that springs and sponges are arranged in a cavity; an annular ring is made of an elastic material, and can play a buffering role in the sponge and spring squeezing process, thereby reducing the impact of a piston on the guide sleeve, reducing the abrasion of a piston rod and the guide sleeve, and prolonging the service life; through the formation of a No.1 through hole, squeezed oil can enter the No.1 through hole and flow to the piston rod in the sponge squeezing process, so as to lubricate the piston rod; through the arrangement of oil suction pumps, the oil which is brought out by the piston rod from the interior of a cylinder body can be sucked and can flow through No.2 through holes into the cavity, thereby achieving the recycling effect; and grooves are formed in the inner wall of the guide sleeve in a spacing manner, and steel balls are arranged in the grooves and are in rolling connection with the piston rod, so that the friction between the piston rod and the guide sleeve can be reduced, the abrasion of the piston rod and the guide sleeve can be further reduced, and the service life of the hydraulic oil cylinder can be prolonged.

Owner:黄玉央

A broken fiber automatic recovery device

The invention discloses a broken fiber automatic recovery device, which comprises a box body, the inner cavity of the box body is fixedly connected with a fixing plate, an air hole is formed between the right side of the fixing plate and the box body, and the box body The front surface is provided with a square mounting plate, the front surface of the square mounting plate is provided with a power structure, the rear side of the square mounting plate is provided with a transmission structure, and the rear side of the transmission structure is provided with a take-up roller; the present invention adopts The combined use of power structure, transmission structure, take-up roller, storage roller and negative pressure fan realizes the use of wind force to suck the broken fiber into the inner cavity of the box, and at the same time the take-up roller and storage roller roll and store it, and finally realize The function of automatic recovery makes the broken fiber automatic recovery device have the advantages of automatic recovery. In the actual use process, the structure is simple, the cost is low, easy to maintain, and the scope of application is wide. It plays the role of optical fiber recovery and reuse, and realizes resource utilization. Recycling and reuse are convenient for users to use.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

A Multifunctional Papermaking Pulping System

InactiveCN108570869BPlay a role in humidificationPromote circulationPulp bleachingRaw material divisionWater storage tankPapermaking

The invention provides a multifunctional papermaking pulping system. The system comprises a washing frame, a charging hopper, a spraying guide pipe structure, a water guide pipe, a water pump, a waterpumping pipe, a water circulating filter residue net rack structure, a water storage tank, a waste paper rotating scraping bracket structure, a guiding hopper, a waste paper crushing box, a top mounting plate, a drive shaft, crushing blades, a quantitative bleaching powder adding storage tank structure, a finished product box and a longitudinal support, wherein the charging hopper is mounted at the upper left part of the washing frame through bolts. By means of water spraying heads, water spraying pipes and first-grade adjusting valves, waste paper in the washing frame can be conveniently wetted; by means of the water guiding hopper, a water draining barrel and the water storage tank, the waste paper in the washing frame can be conveniently circulated in the water storage tank, and wastewater can be further recycled; by means of scale marks and second-grade adjusting valves, bleaching powder in the bleached powder storage tank can be conveniently and quantitatively detected, and bleaching powder is conveniently added to the waste paper crushing box.

Owner:HUBEI BAOTA PAPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com