A Multifunctional Papermaking Pulping System

A multi-functional, pulping technology, applied in papermaking, pulp bleaching, textiles and papermaking, etc., can solve the problems of lack of pulp concentration, inconvenient quantitative addition of bleaching powder, and easy adsorption of waste paper on the guide hopper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] as attached figure 1 To attach Figure 6 shown

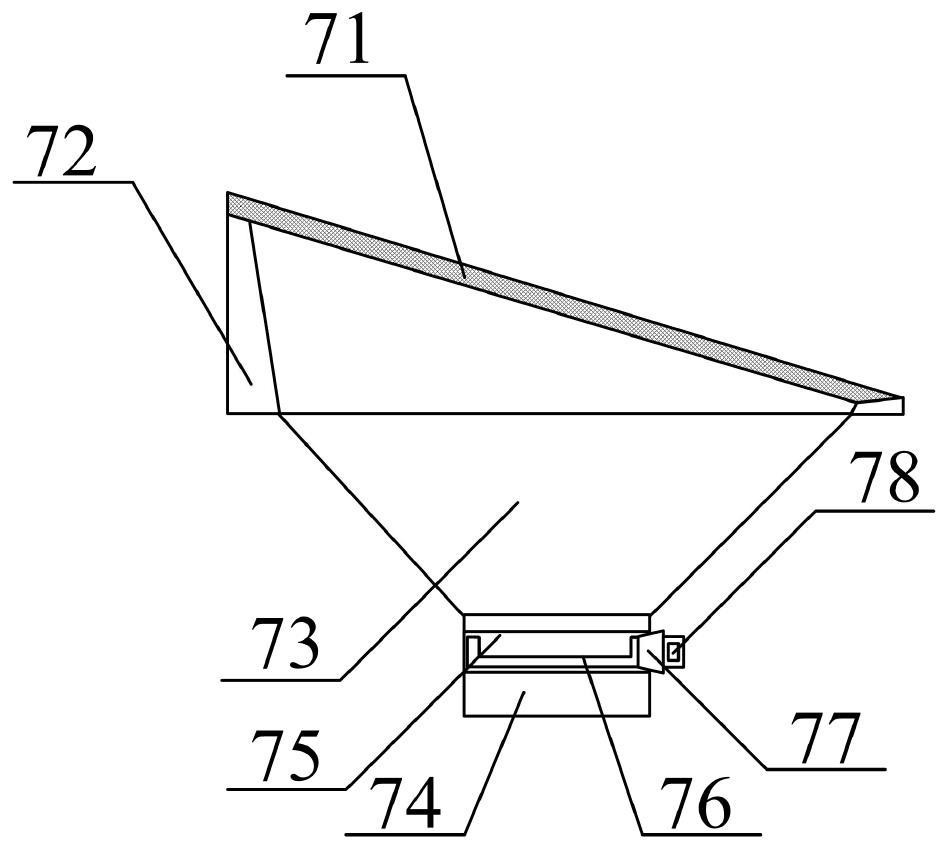

[0038] The present invention provides a multi-functional pulping system for papermaking, which includes a flushing frame 1, a hopper 2, a spraying conduit structure 3, an aqueduct 4, a water pump 5, a water pipe 6, a water circulation filter slag grid structure 7, a water storage tank 8, Waste paper rotating scraper structure 9, guide hopper 10, waste paper crushing box 11, crushing motor 12, top mounting plate 13, transmission shaft 14, crushing blade 15, bleaching powder quantitative addition storage tank structure 16, paper block pulp concentration detection barrier tube Structure 17, finished product hopper 18 and longitudinal support 19, the bolts of the hopper 2 are installed on the upper left side of the flushing frame 1; the bolts of the spraying conduit structure 3 are installed on the upper part of the flushing frame 1; 4. One end is connected to the water outlet of the water pump 5, and the other end is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com