Shockproof mechanical drilling device with scrap cleaning and recycling function

A mechanical drilling and functional technology, applied in the direction of feeding device, boring/drilling, drilling/drilling equipment, etc., can solve the problems of affecting the drilling of objects, reducing the service life of machinery, and excessive heat generation, etc., to reduce The effect of not being able to drill normally, improving work efficiency, and increasing versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

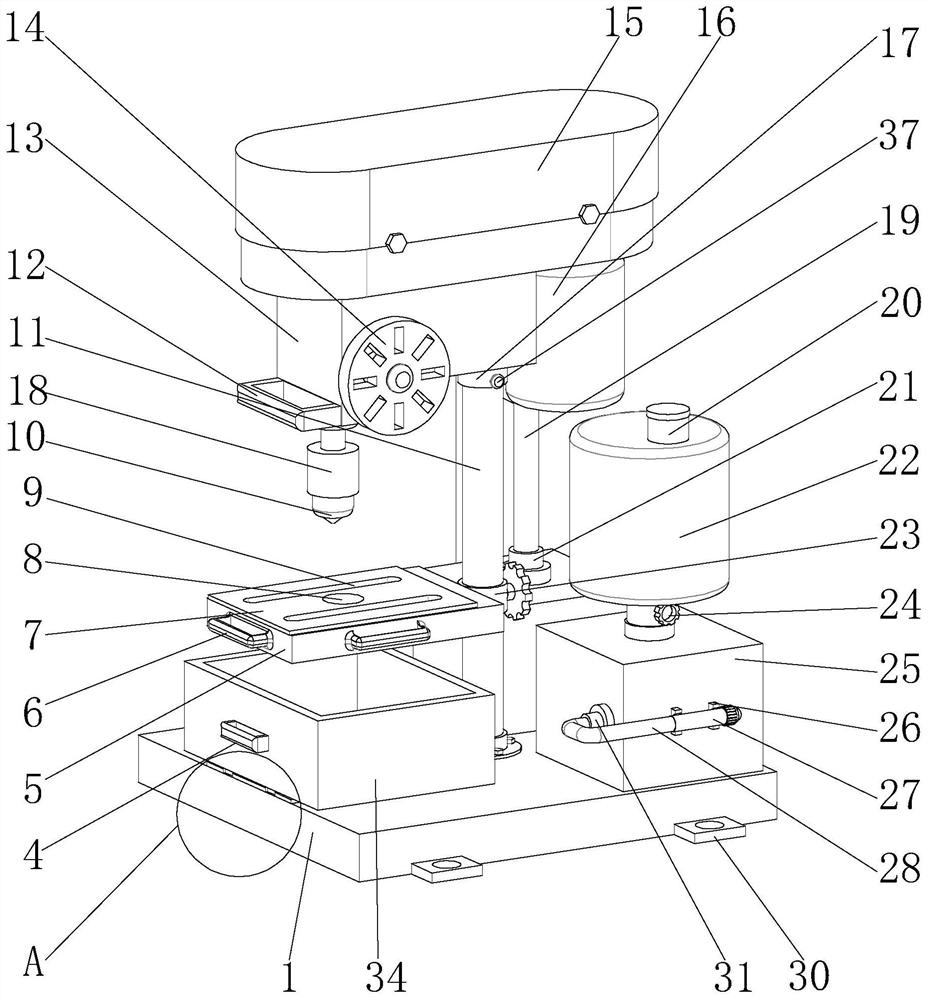

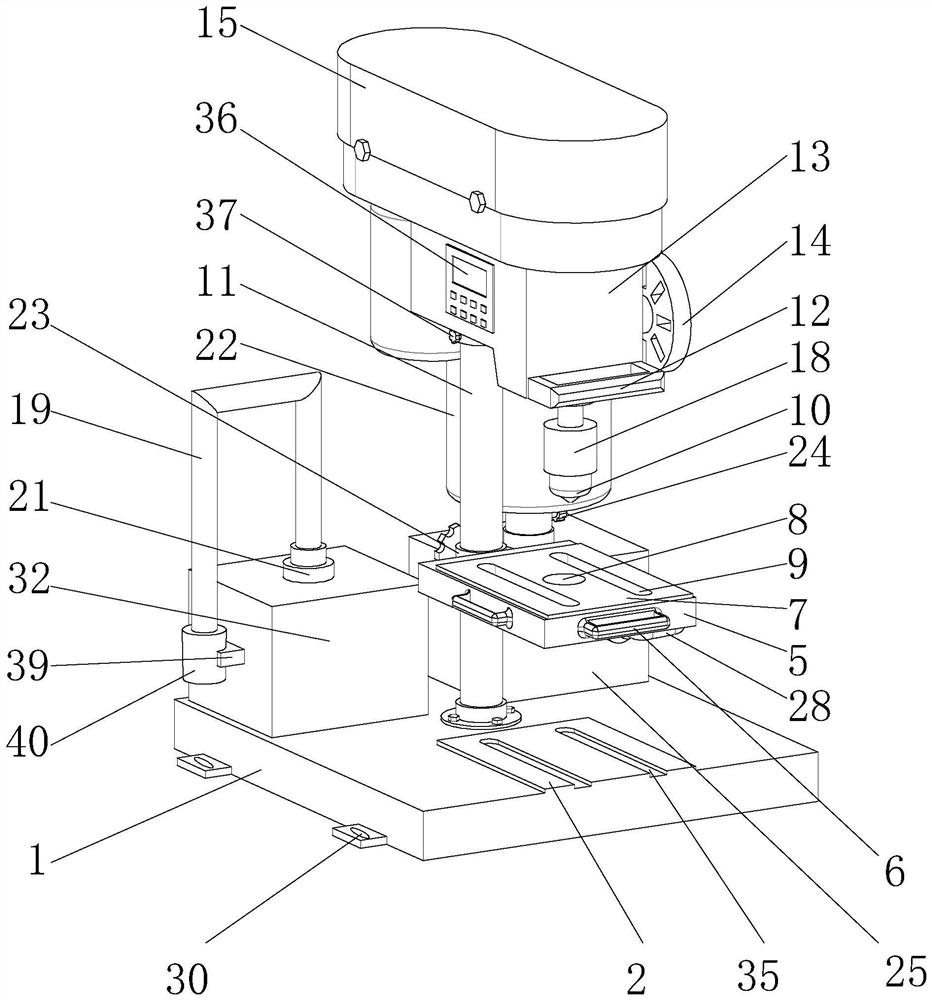

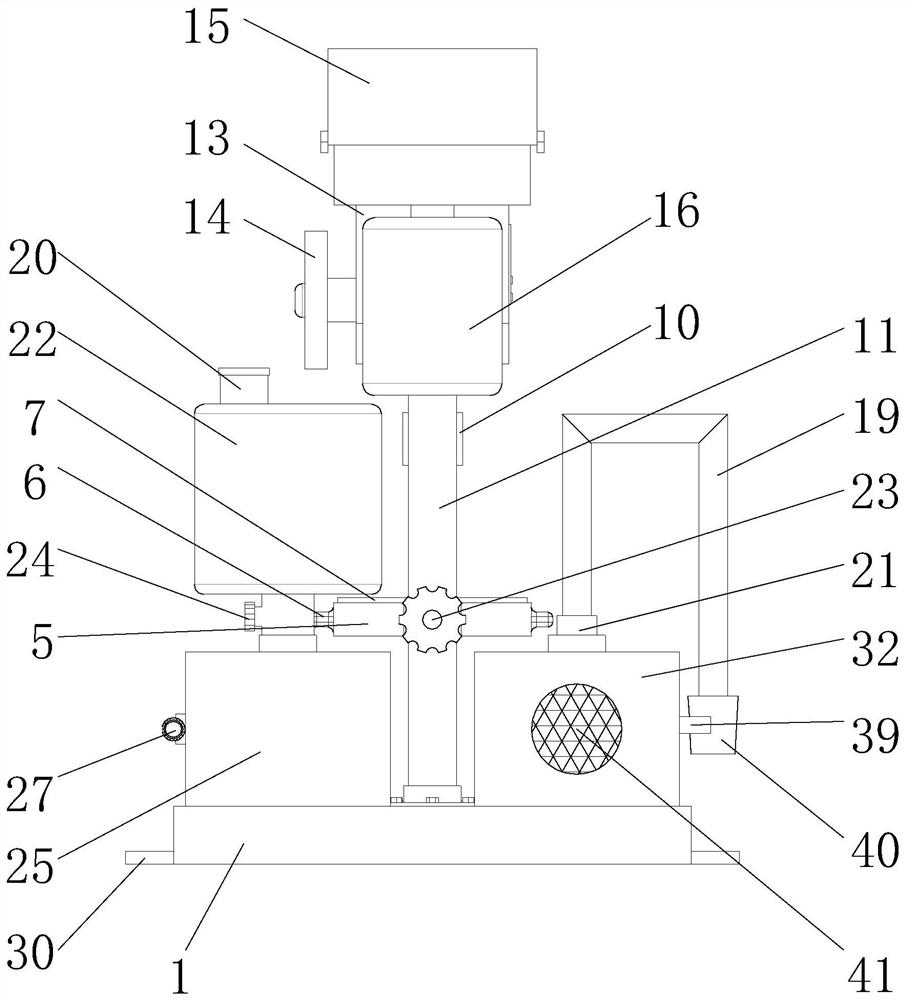

[0030] see Figure 1-8 , the present invention provides a technical solution: including a base 1, a first workbench 2 is fixedly installed on the top of the base 1, a recovery box 34 is movably installed on the top of the first workbench 2, and a pole frame is fixedly installed on the top of the base 1 11. The top of the rod frame 11 is movably installed with a control case 13, the top of the control case 13 is fixed with an organic case 15, the top of the base 1 is fixed with a water pump casing 25, and the front of the water pump casing 25 is connected with a second connecting pipe 31 The end of the second connecting pipe 31 far away from the water pump housing 25 is connected with a soft water pipe 28, and the end of the soft water pipe 28 away from the second connecting pipe 31 is fixedly installed with a nozzle 27, and the top of the water pump housing 25 is connected with a water bucket 22, and the top of the base 1 A drying device 32 is fixedly installed, and the top of...

Embodiment 2

[0033] Such as Figure 1-8 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the front of the recovery box 34 is fixedly equipped with a push-pull handle 4, the inside of the first workbench 2 is provided with a chute 35, and the bottom of the recovery box 34 is fixed A slide block 3 is installed, and the slide block 3 is slidably installed in the inside of the chute 35. An adjustment ring 23 is installed on the outside of the pole frame 11, and a base 5 is fixedly installed on the end of the adjustment ring 23 away from the pole frame 11. The front and both sides of 5 are all fixedly installed with first handle 6, and the top of base 5 is fixedly installed with second workbench 7, and the inside of base 5 and second workbench 7 is provided with drill hole 8, and base 5 is connected with the second workbench 7. The inside of the second workbench 7 is provided with a card slot 9 .

[0034] In this embodiment, sliding the slider 3 at t...

Embodiment 3

[0036] Such as Figure 1-8 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the bottom of the control shell 13 is fixedly installed with a rotating device 17, and the rotating device 17 is sleeved on the outside of the top of the pole frame 11, and the rotating device 17 is installed with fastening bolts 37, the front of the control shell 13 is fixedly equipped with a second handle 12, one side of the control shell 13 is fixedly equipped with a control panel 14, and the side of the control shell 13 away from the control panel 14 is fixedly installed with a Control panel 36, hydraulic cylinder 18 is installed on the inside of control shell 13 bottom, the bottom of hydraulic cylinder 18 is fixedly equipped with deep hole drill bit 10, the bottom of casing 15 is fixedly installed with rotating motor 16, and the top of hydraulic cylinder 18 is fixedly connected with Shaft 43, a second gear 42 is fixedly installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com