Drip chamber and catheter assembling mechanism

An assembly mechanism and catheter technology, applied in the field of medical devices, can solve problems such as reduced work efficiency, energy waste, and reduced assembly success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

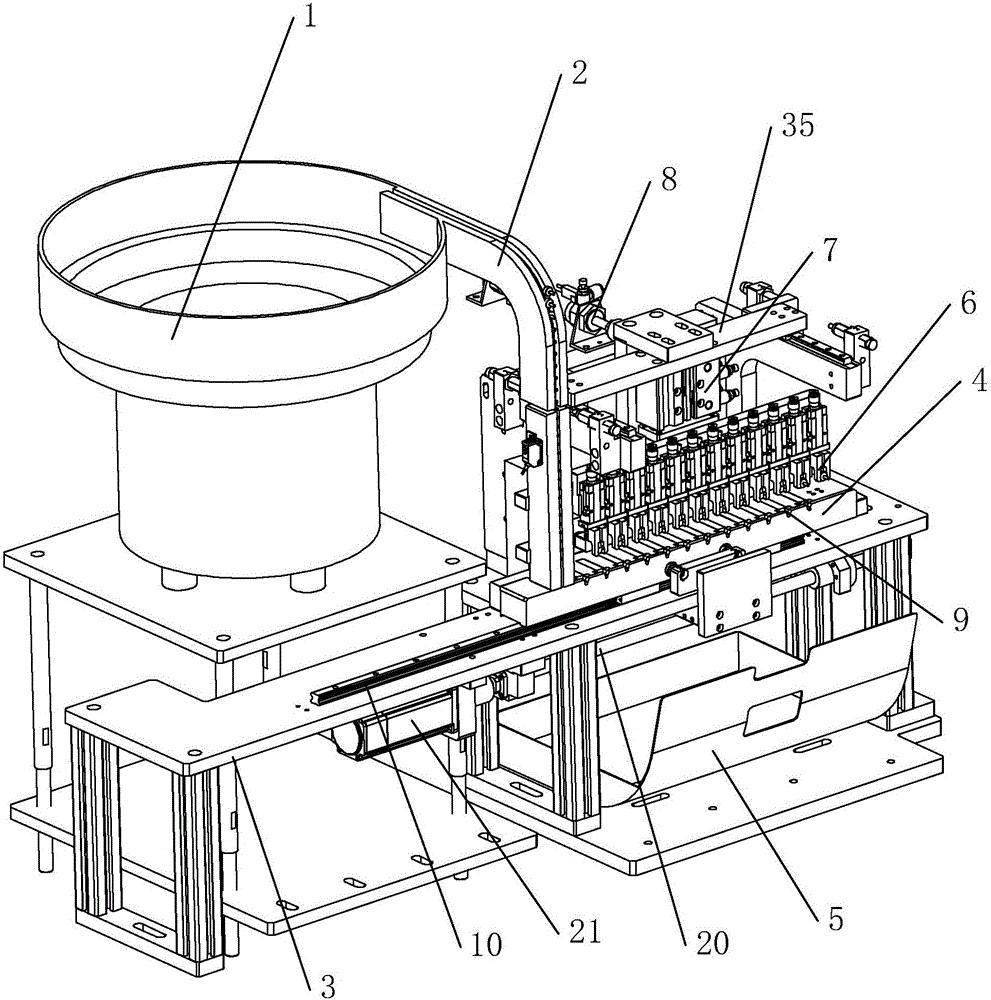

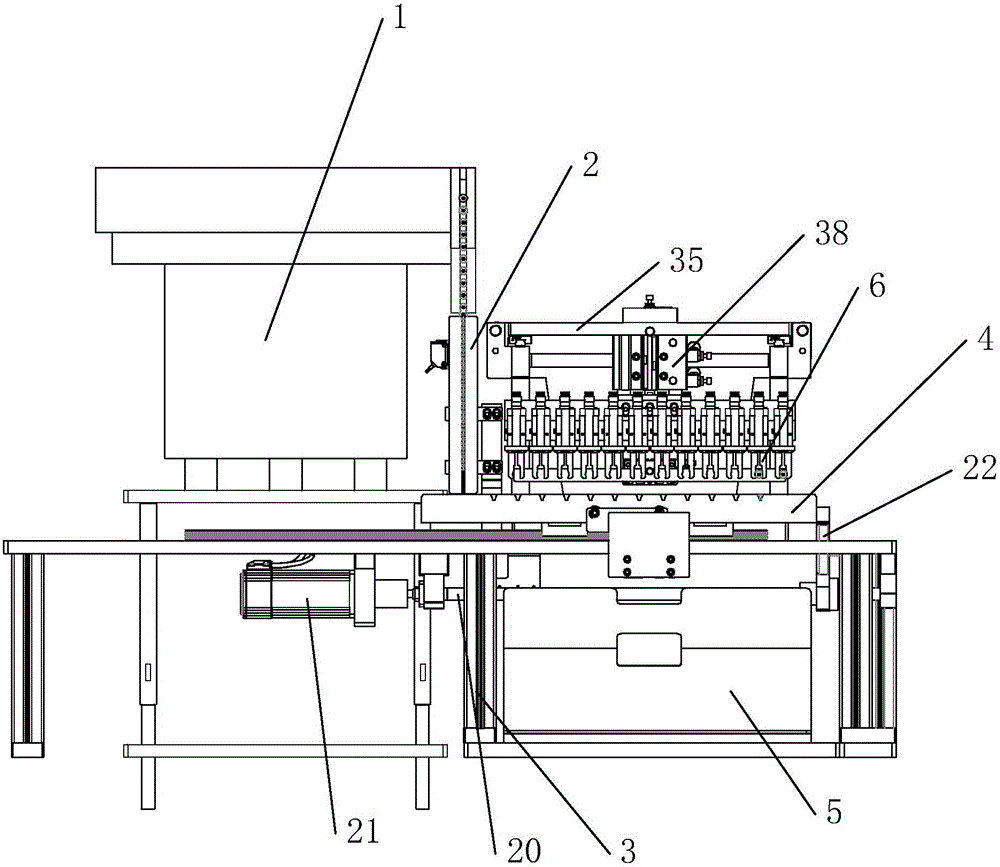

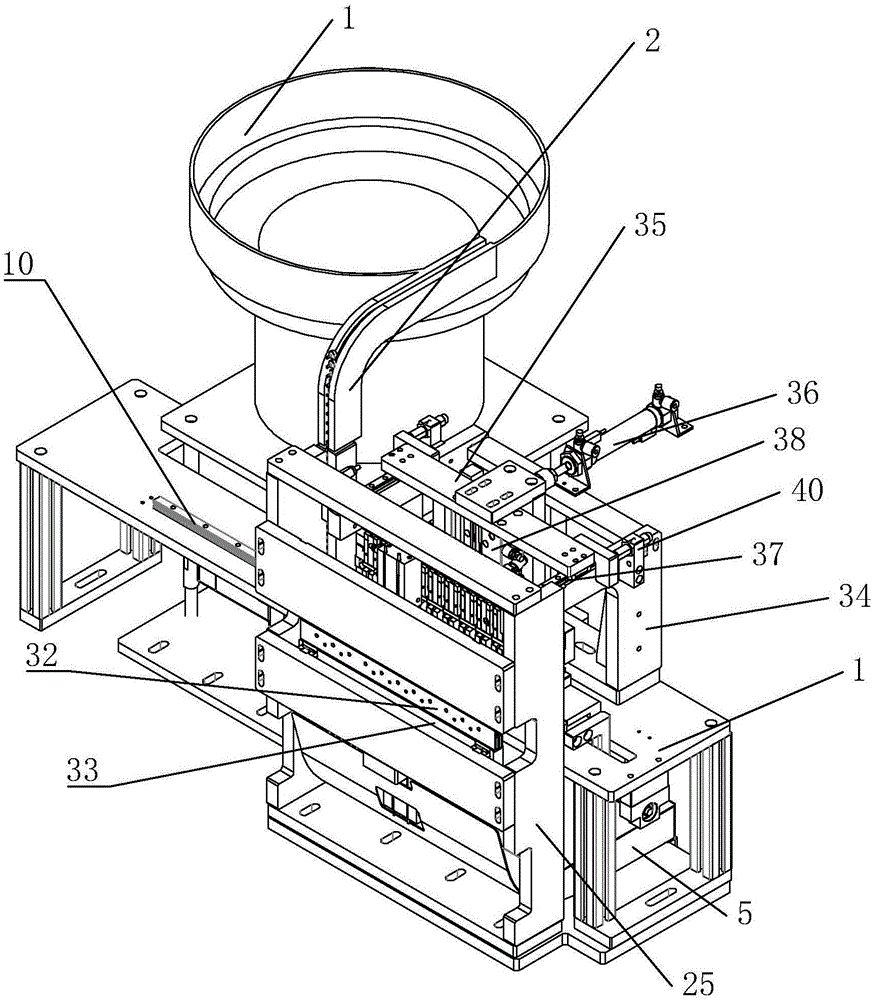

[0040] refer to Figure 1 to Figure 13 As shown, a dropping bucket and conduit assembly mechanism implemented in this case includes a vibrating plate 5, a cylinder front gear 6, a material receiving tool 21, a clamping mechanism, a positioning mechanism and a mounting frame 7, a vibrating plate 5, a clamping mechanism, The material receiving tool 21, the front gear 6 of the cylinder and the positioning mechanism are all installed on the mounting frame 7, the vibrating plate 5 is provided with a discharge track, the discharge track is provided with a feed port 9 and a discharge port 10, and the discharge track The material inlet 9 is connected with the vibrating plate 5, the material outlet 10 is connected with the cylinder front gear 6, a limit device is provided between the cylinder front gear 6 of the discharge track 8, and a stopper for grabbing the cylinder front gear is provided above the cylinder front gear. The clamping mechanism of the dripping funnel 1 on the gear 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com