Photocuring three-dimensional printer and printing method thereof

A technology of 3D printing and light curing, applied in the direction of manufacturing auxiliary devices, additive manufacturing, processing and recycling, etc., can solve the problems of environmental pollution, increase the manufacturing cost of 3D objects, waste resources, etc., so as to avoid environmental pollution, rational structure setting, reduce The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

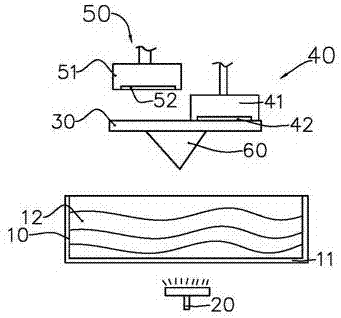

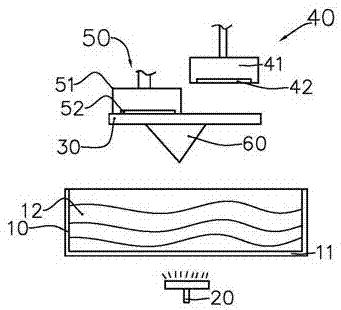

[0038] Such as figure 1 and figure 2 As shown, the photo-curing three-dimensional printing device of this embodiment includes a housing tank 10 , a curing light source 20 , a printing platform 30 , a moving component 40 and a vibrating component 50 .

[0039] The accommodating tank body 10 is used for loading photosensitive resin raw materials 12 , and the accommodating tank body 10 includes a transparent tank bottom plate 11 . The curing light source 20 is arranged at the lower part of the containing tank body 10 , and the light emitted by the curing light source 20 can pass through the transparent tank bottom plate 11 to irradiate and cure the liquid photosensitive resin in the containing tank body 10 . The printing platform 30 is arranged on the top of the transparent tank bottom plate 11 , and the printing platform 30 is used to carry the solidified three-dimensional object 60 .

[0040] The moving assembly 40 has a first connecting portion 41, the first connecting port...

no. 2 example

[0050] The structure and function of the photo-curing three-dimensional printing device of this embodiment are basically the same as those of the above-mentioned first embodiment, and only the differences will be described in detail below.

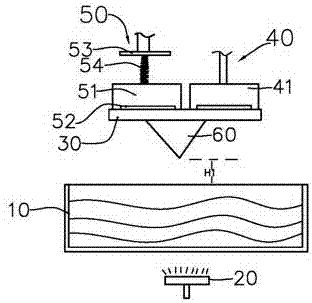

[0051] Such as image 3 and Figure 4 As shown, the vibrating assembly of this embodiment includes a fixing member 53 and an elastic member 54 , the fixing member 53 , the elastic member 54 and the second connecting portion 51 are sequentially connected, and the elastic member 54 is a spring.

[0052] In S6, the following steps are also included:

[0053] T1: The printing platform 30 and the finished three-dimensional object 60 are located above the receiving tank 10, the printing platform 30 is at the first height H1, and the spring is in a free state, that is, in image 3 the state shown;

[0054] T2: The moving component 40 drives the printing platform 30 and the finished three-dimensional object 60 to continue to move upward, the pr...

no. 3 example

[0058] The structure and function of the photo-curing three-dimensional printing device of this embodiment are basically the same as those of the above-mentioned first embodiment, and only the differences will be described in detail below.

[0059] The vibrating assembly in this embodiment is connected to the moving assembly, and the moving assembly can drive the vibrating assembly and the printing platform to move together; the vibrating assembly includes a fixing member and a spring, and the fixing member, the spring and the second connecting part are sequentially connected;

[0060] In S6, the following steps are also included:

[0061] Y1: The printing platform and the finished three-dimensional object are located above the housing tank as a whole, and the spring is in a compressed state;

[0062] Y2: Keep the second electromagnetic adsorption unit to generate adsorption force, that is, the vibration component generates adsorption force on the printing platform; at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com