Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Play a role in collecting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

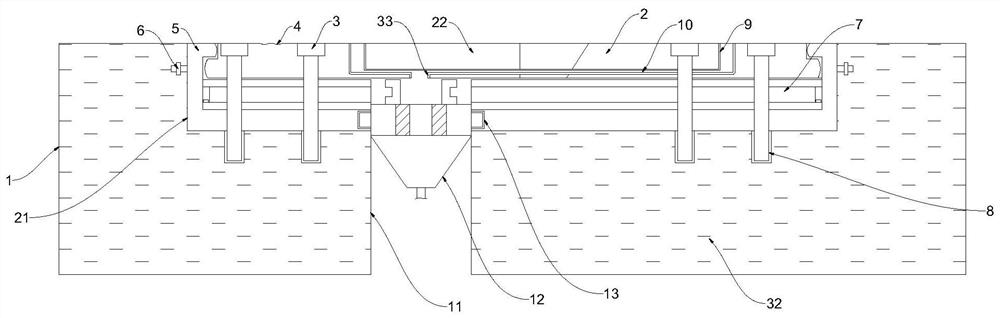

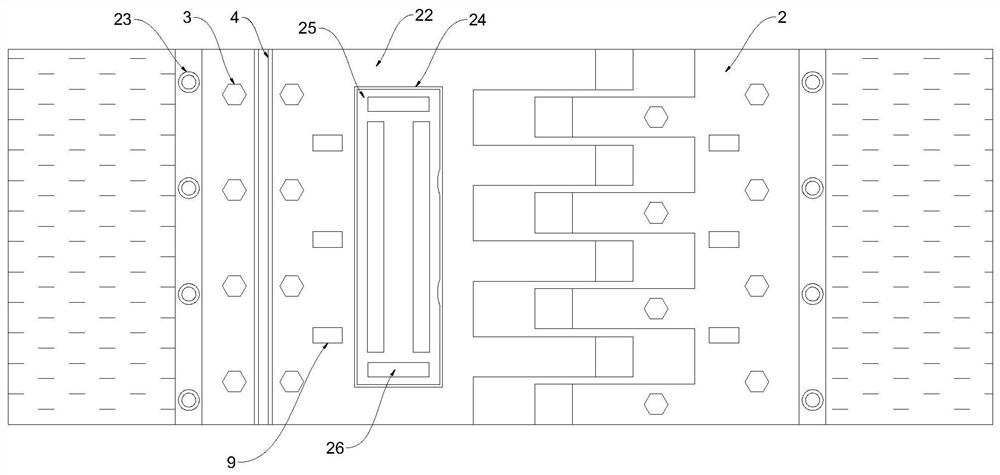

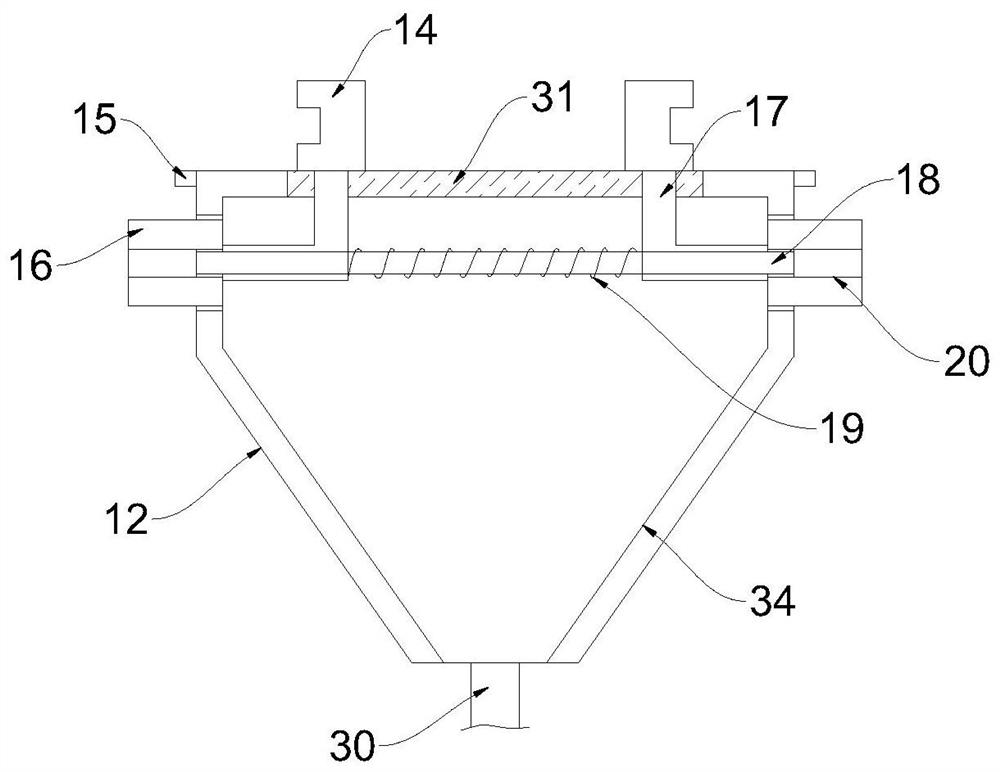

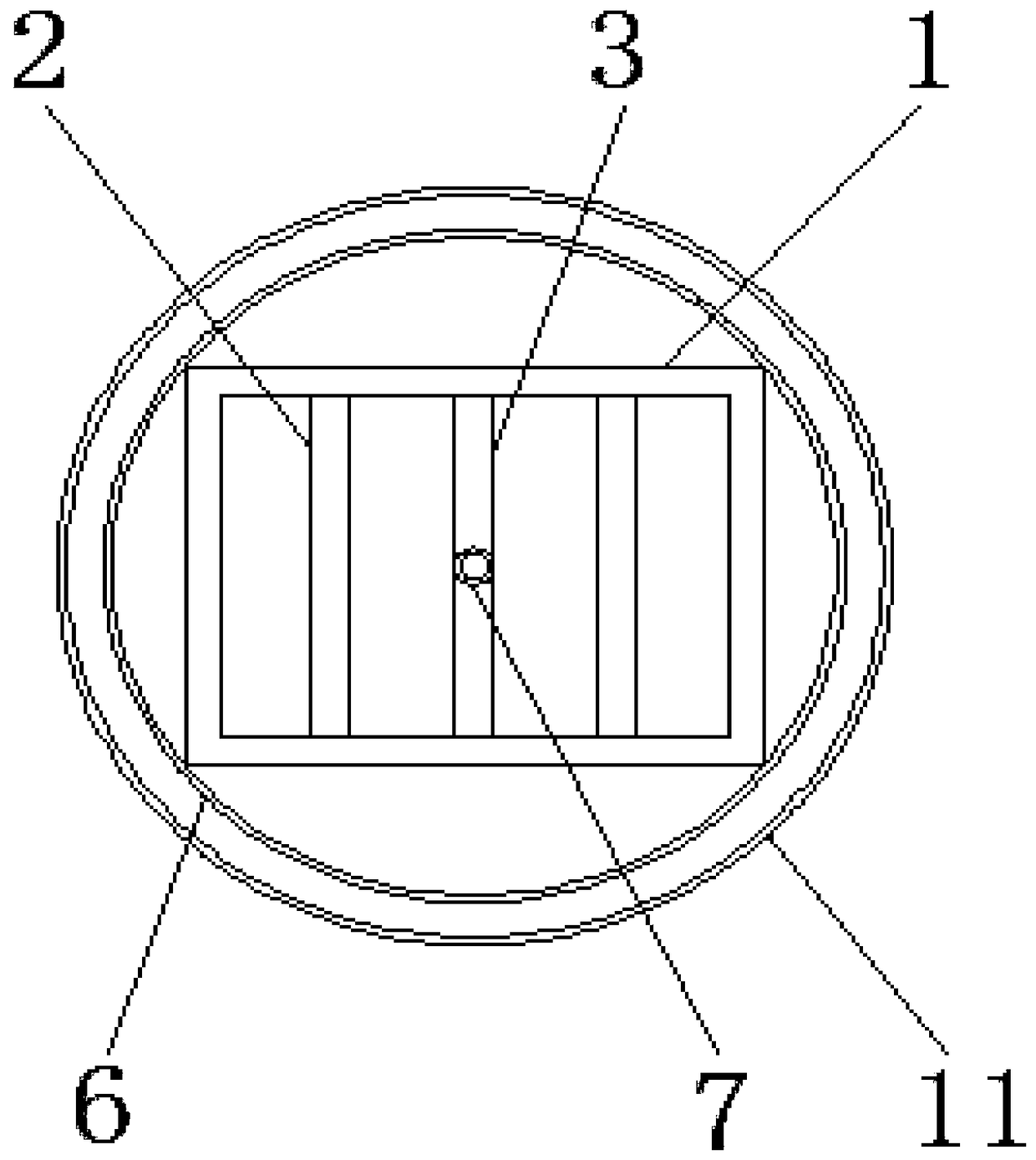

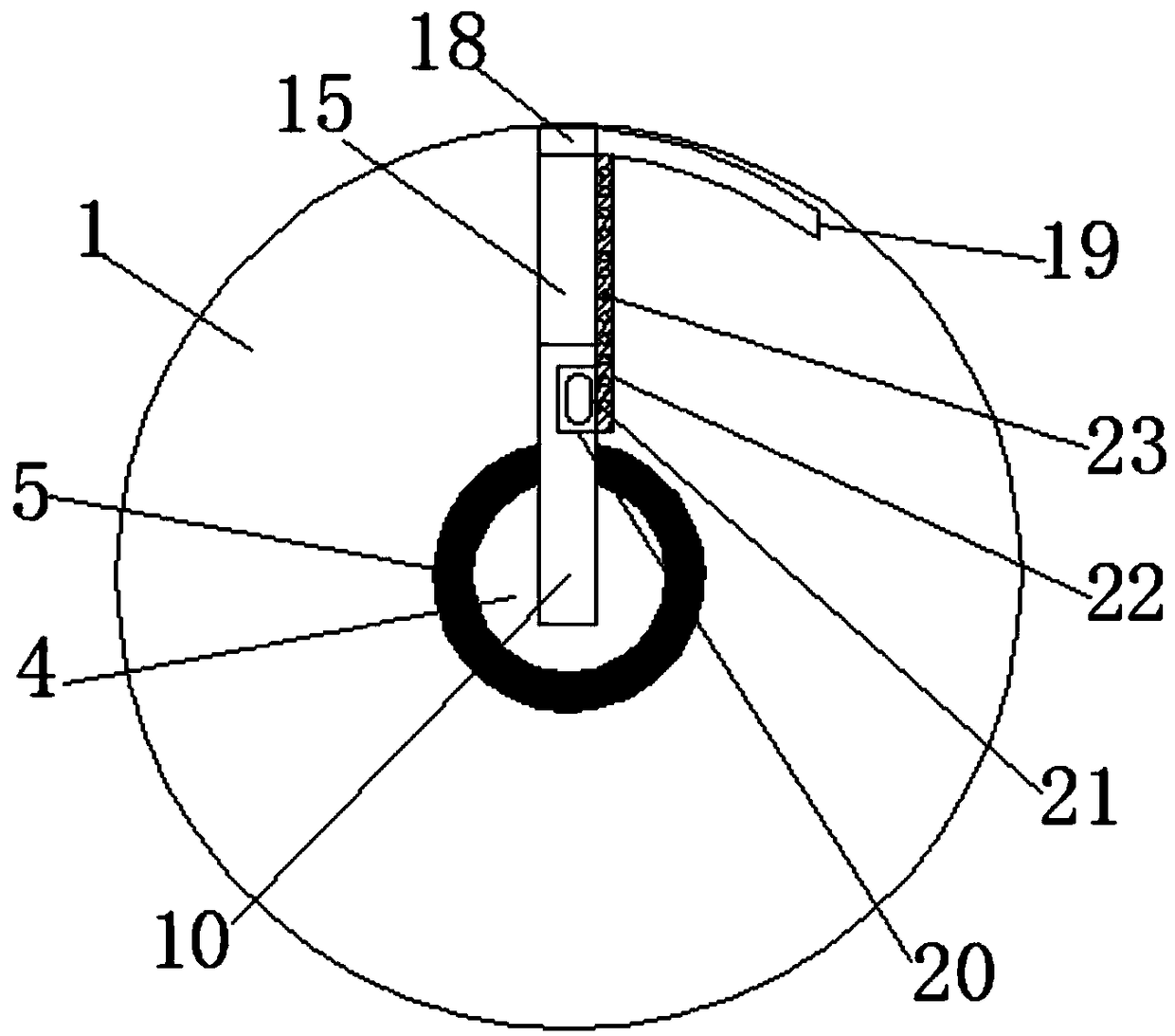

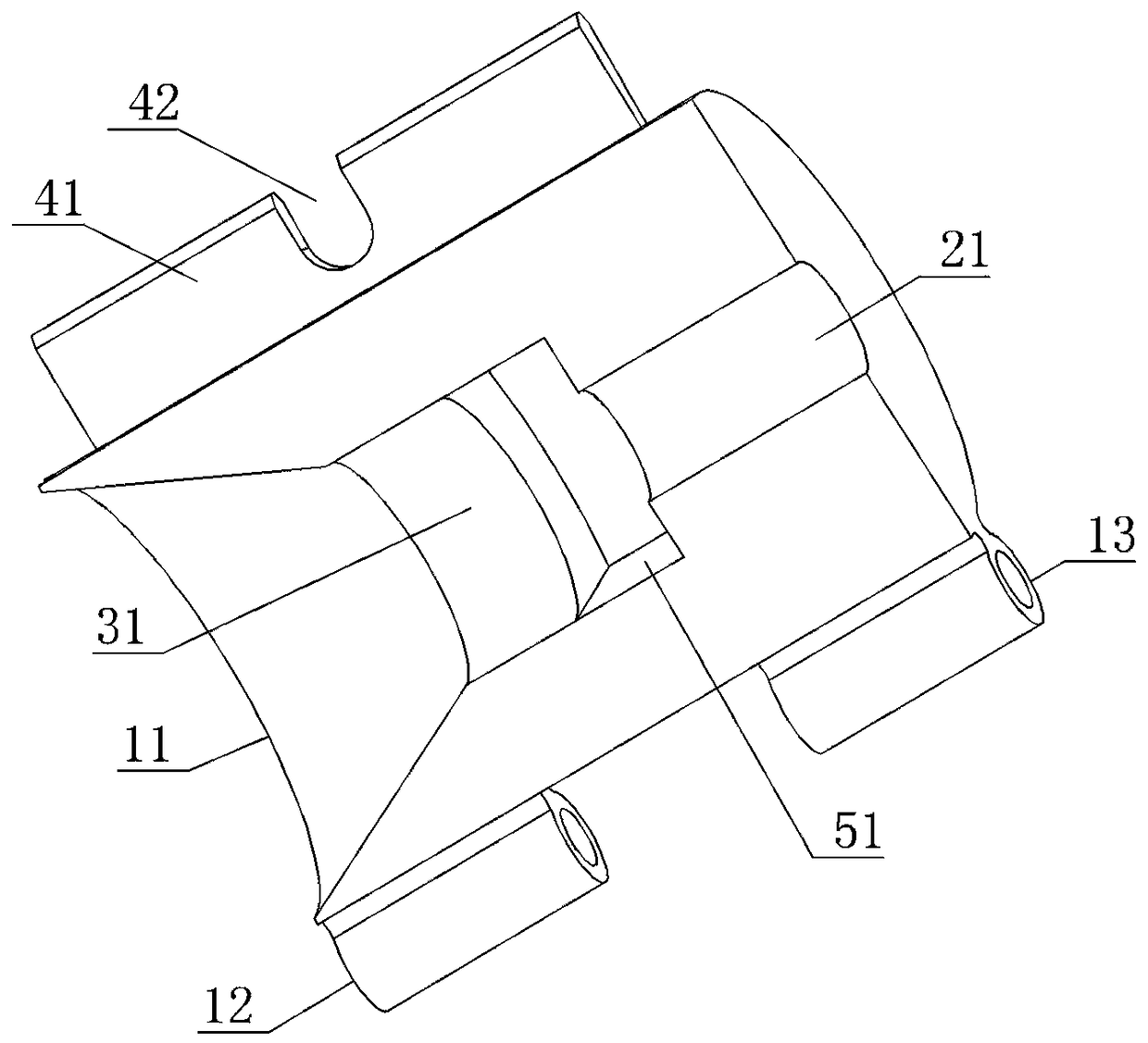

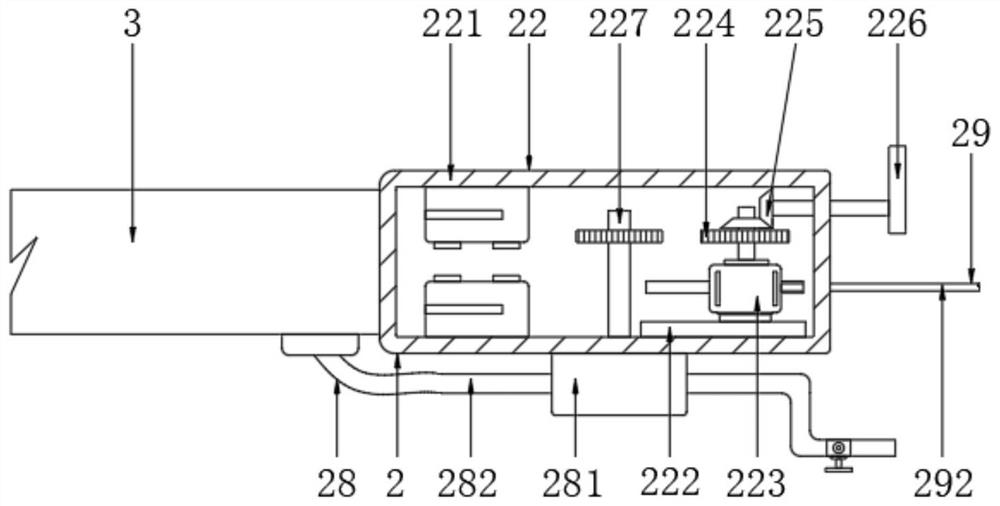

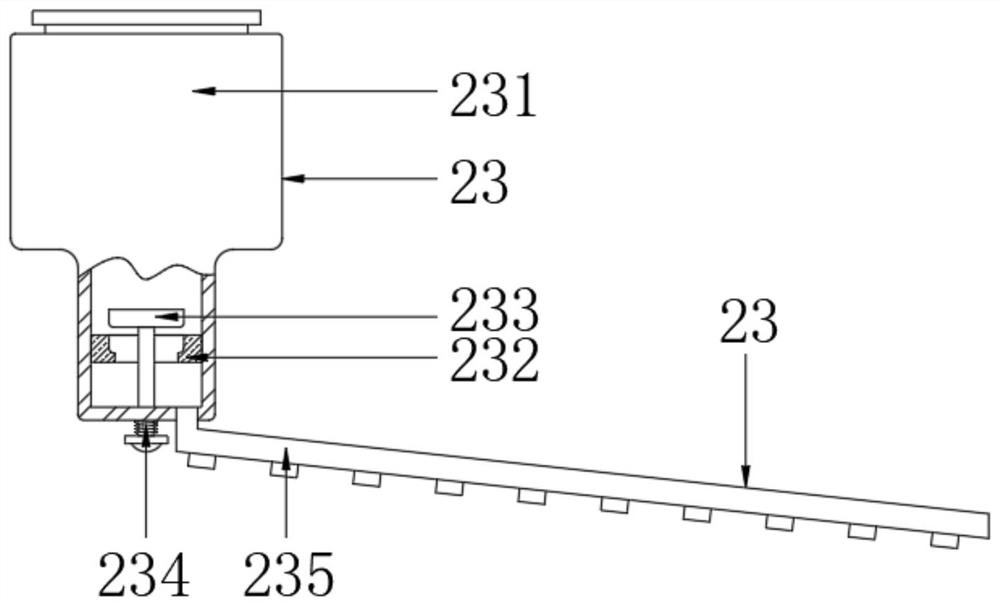

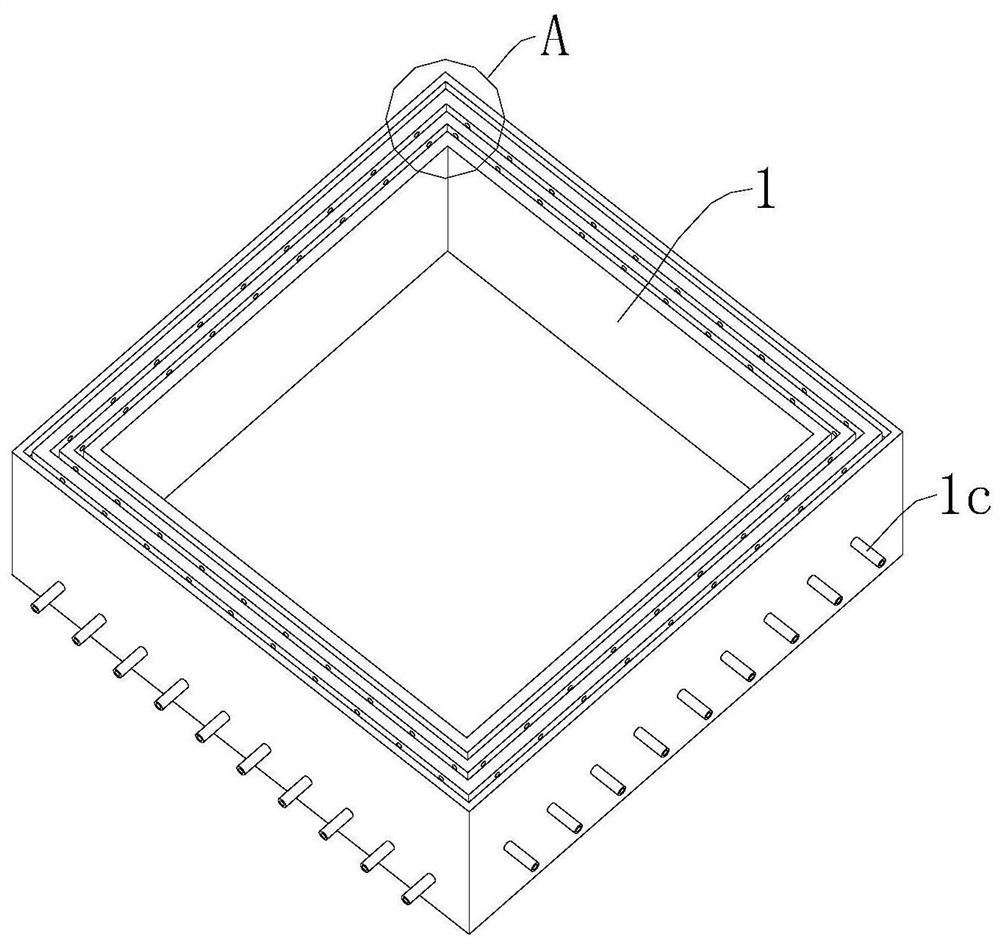

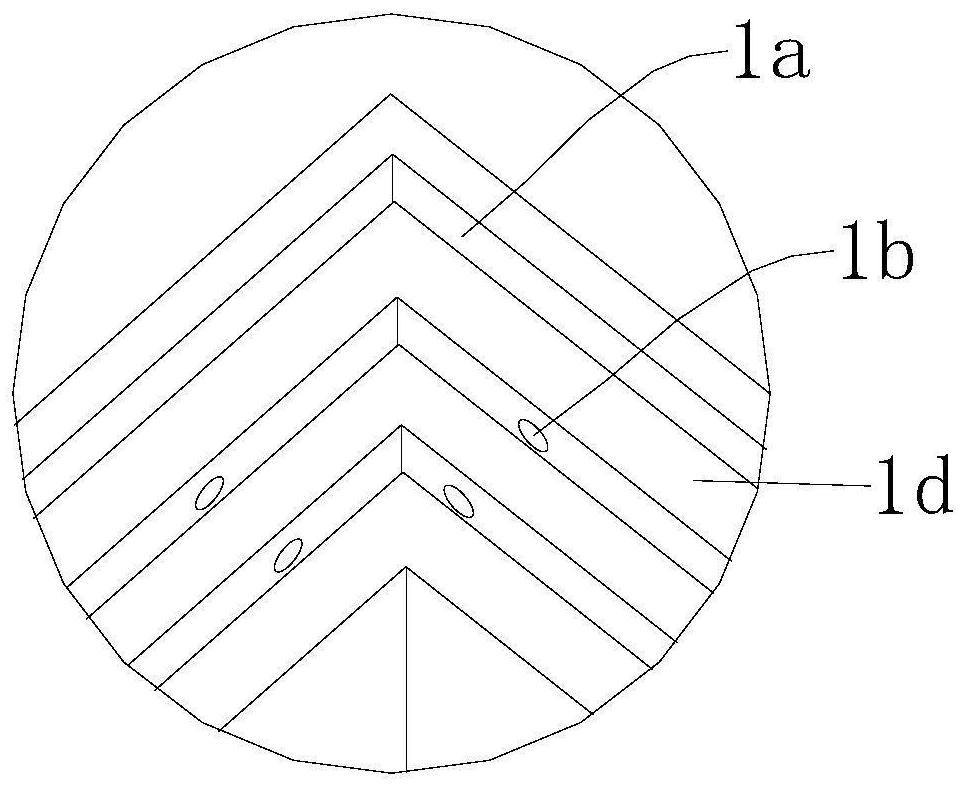

Comb-type bridge expansion joint plate structure and cleaning device thereof

InactiveCN112064498ALarge displacementPlay the role of anti-looseningBridge structural detailsRoad cleaningExpansion jointRivet

The invention discloses a comb-type bridge expansion joint plate structure and a cleaning device thereof. The comb-type bridge expansion joint plate structure comprises a first beam body, a second beam body arranged on one side of the first beam body, a comb plate supporting plate and a first comb-type expansion joint plate, wherein preformed grooves are formed in the first beam body and the second beam body respectively; an expansion joint is arranged between the first beam body and the second beam body; the comb plate supporting plate is arranged in the preformed grooves; the comb plate supporting plate is fixedly connected with the first beam body and the second beam body through fixing rivets; the first comb-type expansion joint plate is arranged in the comb plate supporting plate; anda second comb-type expansion joint plate is arranged on one side of the first comb-type expansion joint plate. The comb-type bridge expansion joint plate structure achieves the anti-seismic bufferingfunction; the strength of the structure at the expansion joint is improved; accumulated water and dust in the expansion joint are convenient to clean away; the internal structures of the expansion joint are prevented from being affected by the accumulated water; and the problem is solved that the first beam body and the second beam body squeeze each other to cause potential safety risks.

Owner:蒋明敏

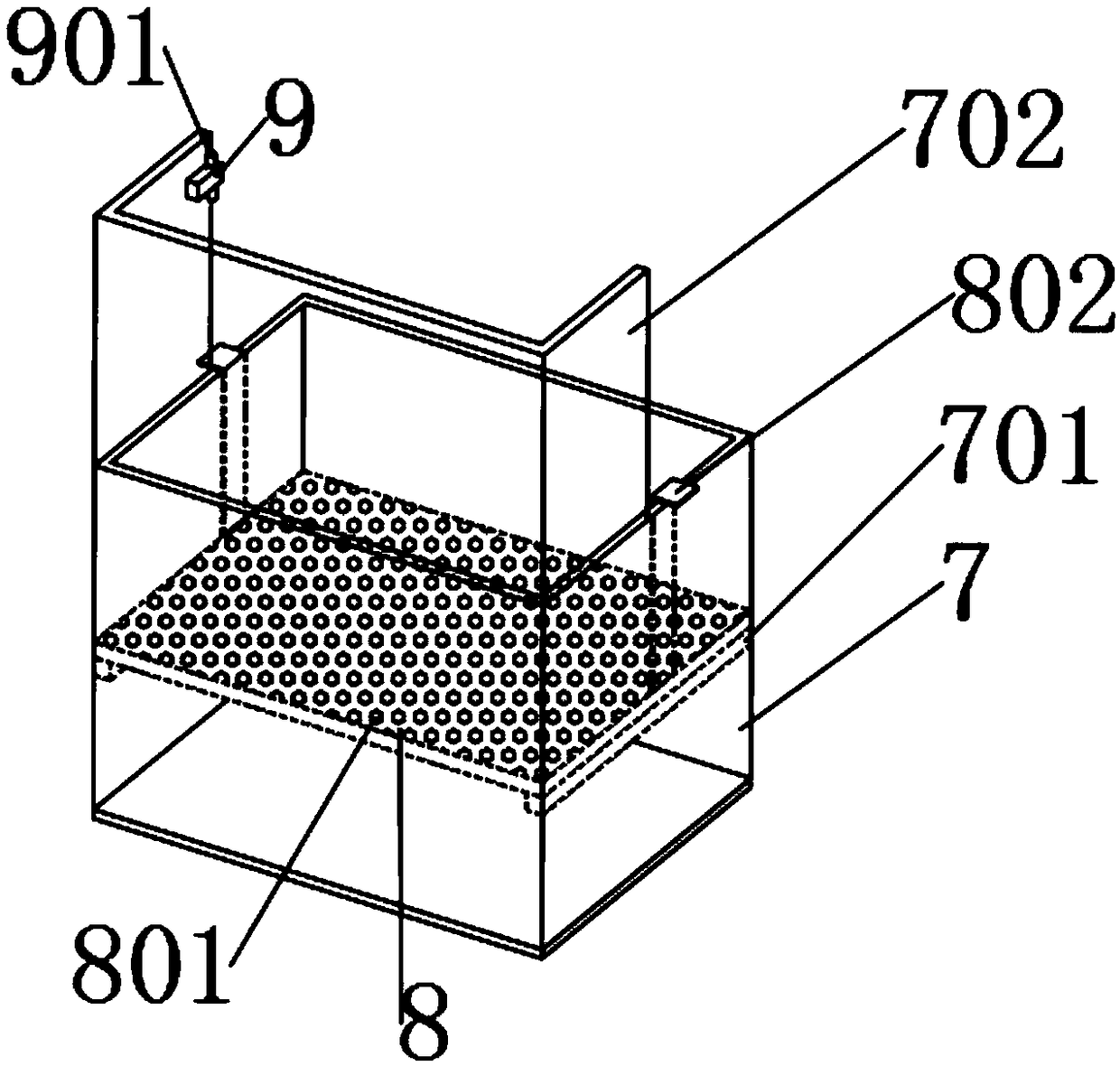

Plastic product sand removal device and method

InactiveCN108437280ASimple structureEasy to usePlastic recyclingCleaning using liquidsBristleShake up

The invention discloses a plastic product sand removal device and method in the technical field of plastic product sand removal. The device comprises a box body, a rotating rod is inserted in an innercavity of a bearing, cleaning rods are evenly arranged on the left side and the right side of the rotating rod, a first filter net, a second filter net, a hopper and a water box are sequentially arranged in an inner cavity of the box body from top to bottom, cleaning liquid is sprayed out through a water outlet hole through a water pump, plastic product surfaces are washed, the cleaning rods rotate to drive bristles to brush the plastic product, the first filter net separates the cleaning liquid mixed up with gravel and the plastic product, the second filter net separates the cleaning liquidand the gravel, the second filter net shakes up and down, filtering and cleaning of the gravel are facilitated, the cleaning liquid mixed up with fine gravel and dust is precipitated in a precipitation chamber, a mesh-free filter layer filters fine gravel and dust mixed up in the cleaning liquid, through layer-by-layer filtering of the cleaning liquid, circular utilization of the cleaning liquid is achieved, and resource waste is reduced.

Owner:CHENGDU PUJIANG KEXIAN TECH

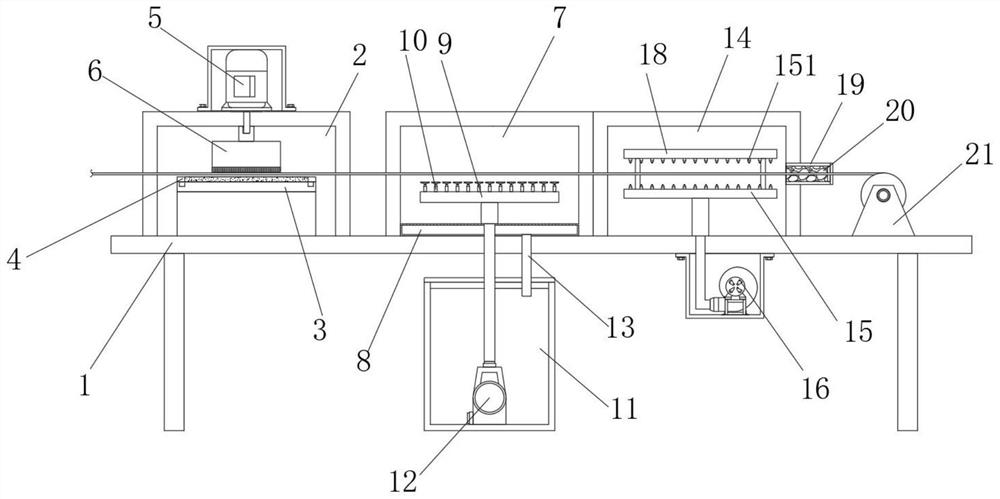

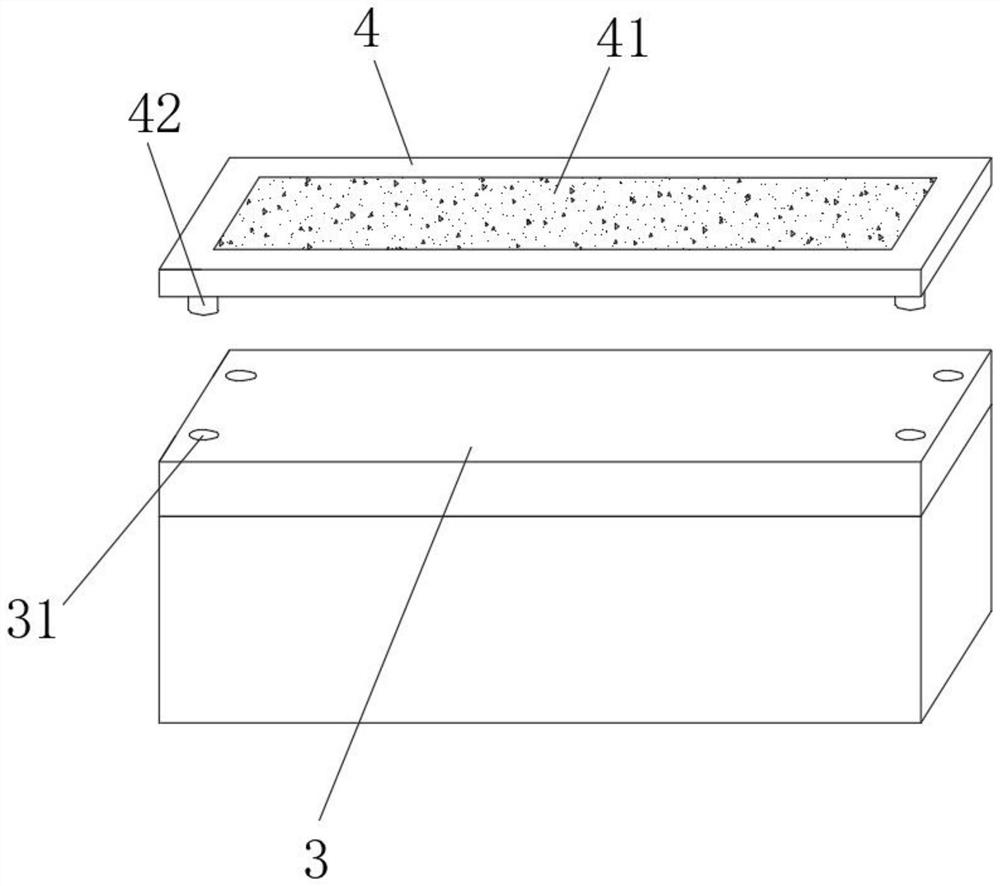

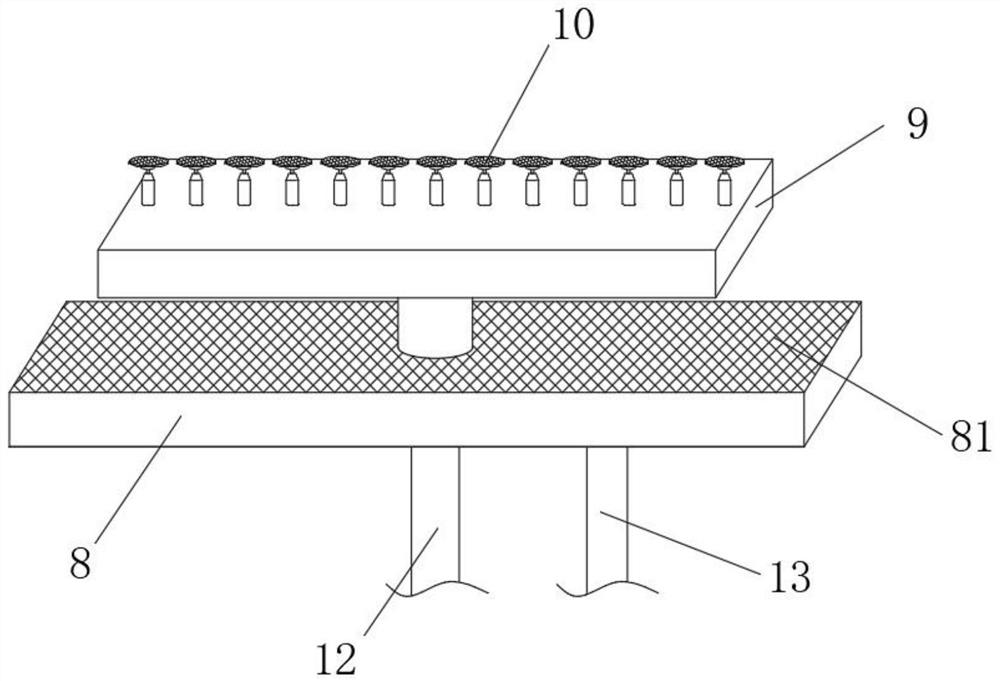

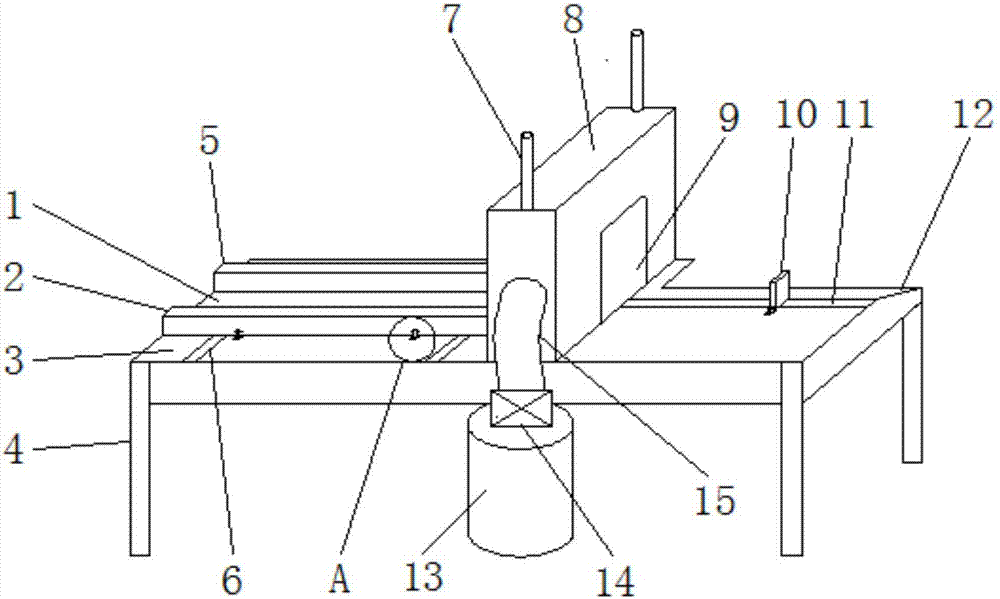

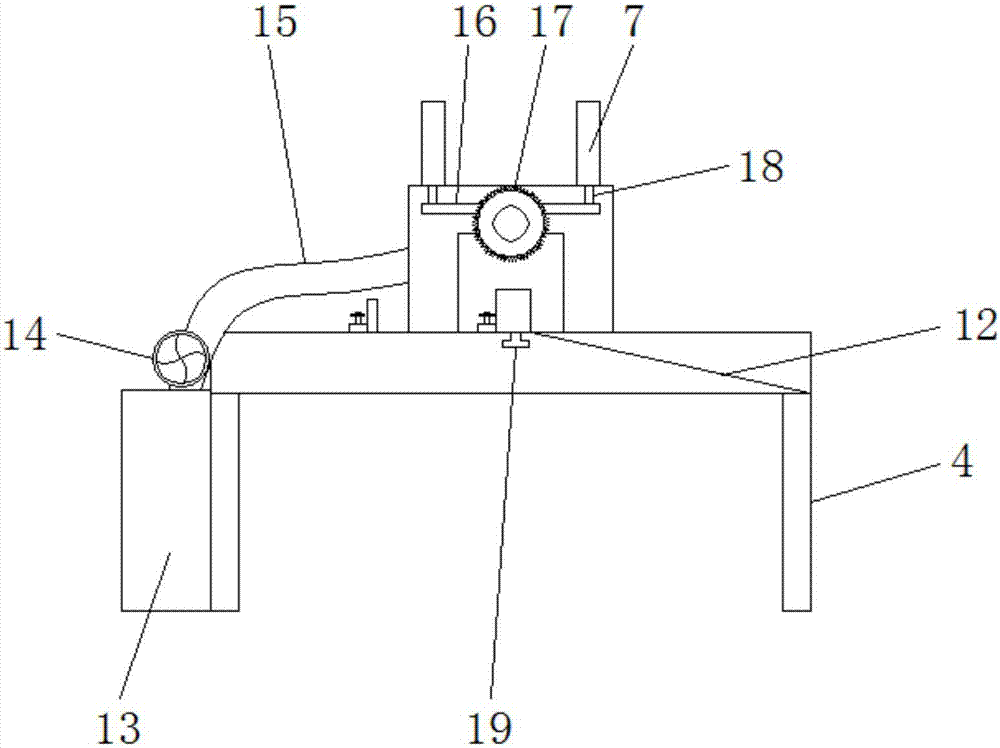

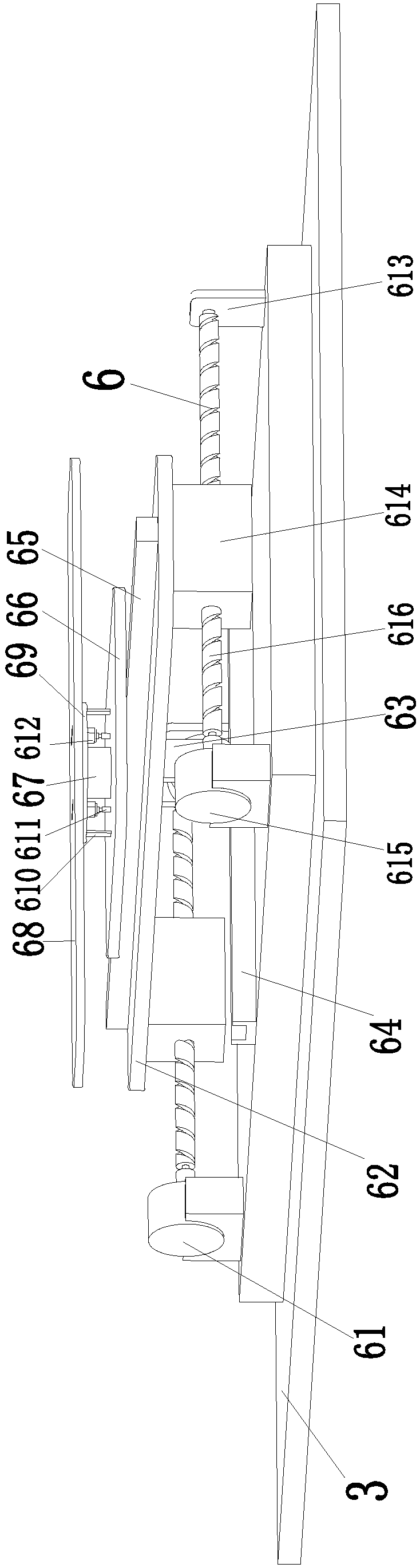

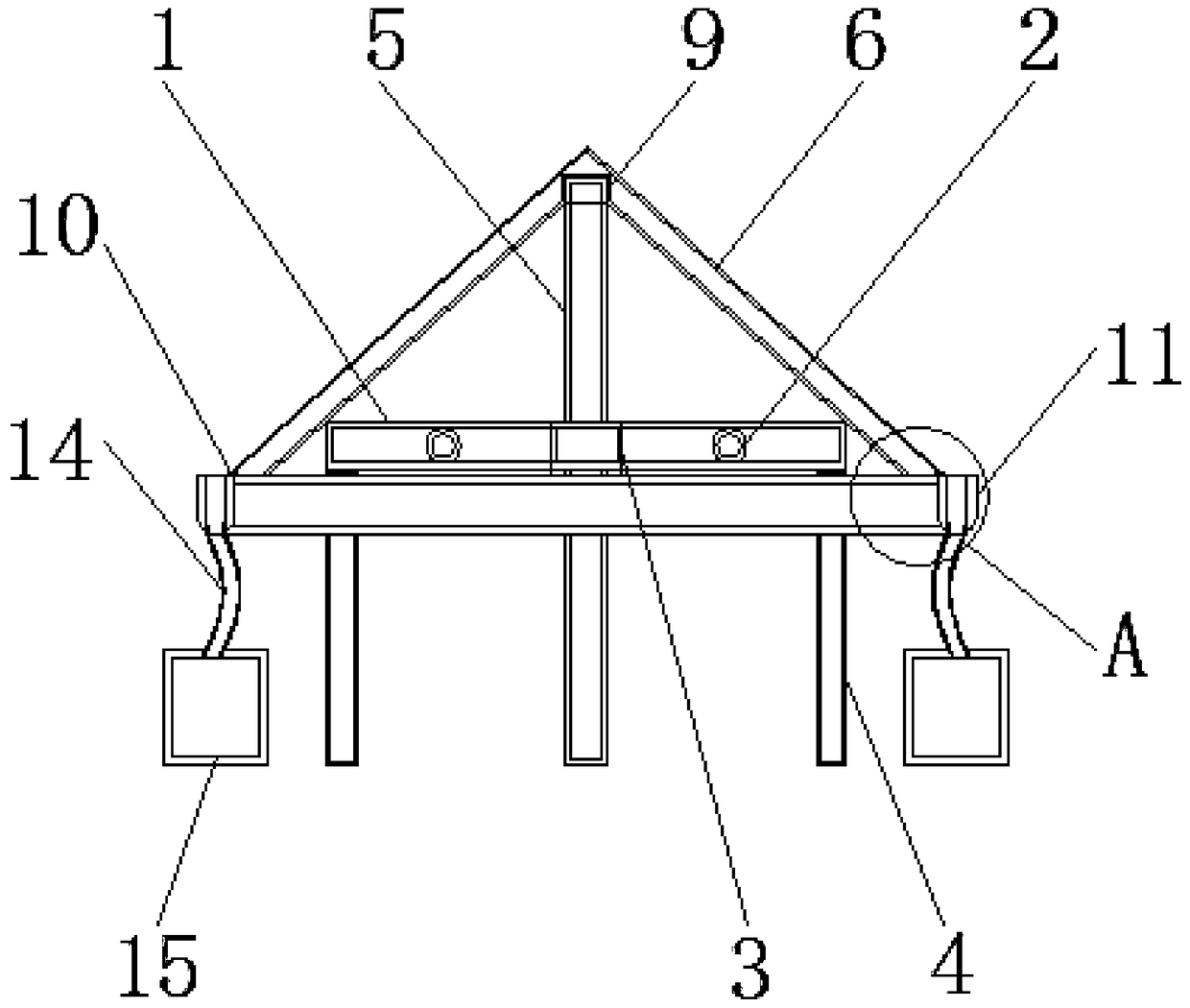

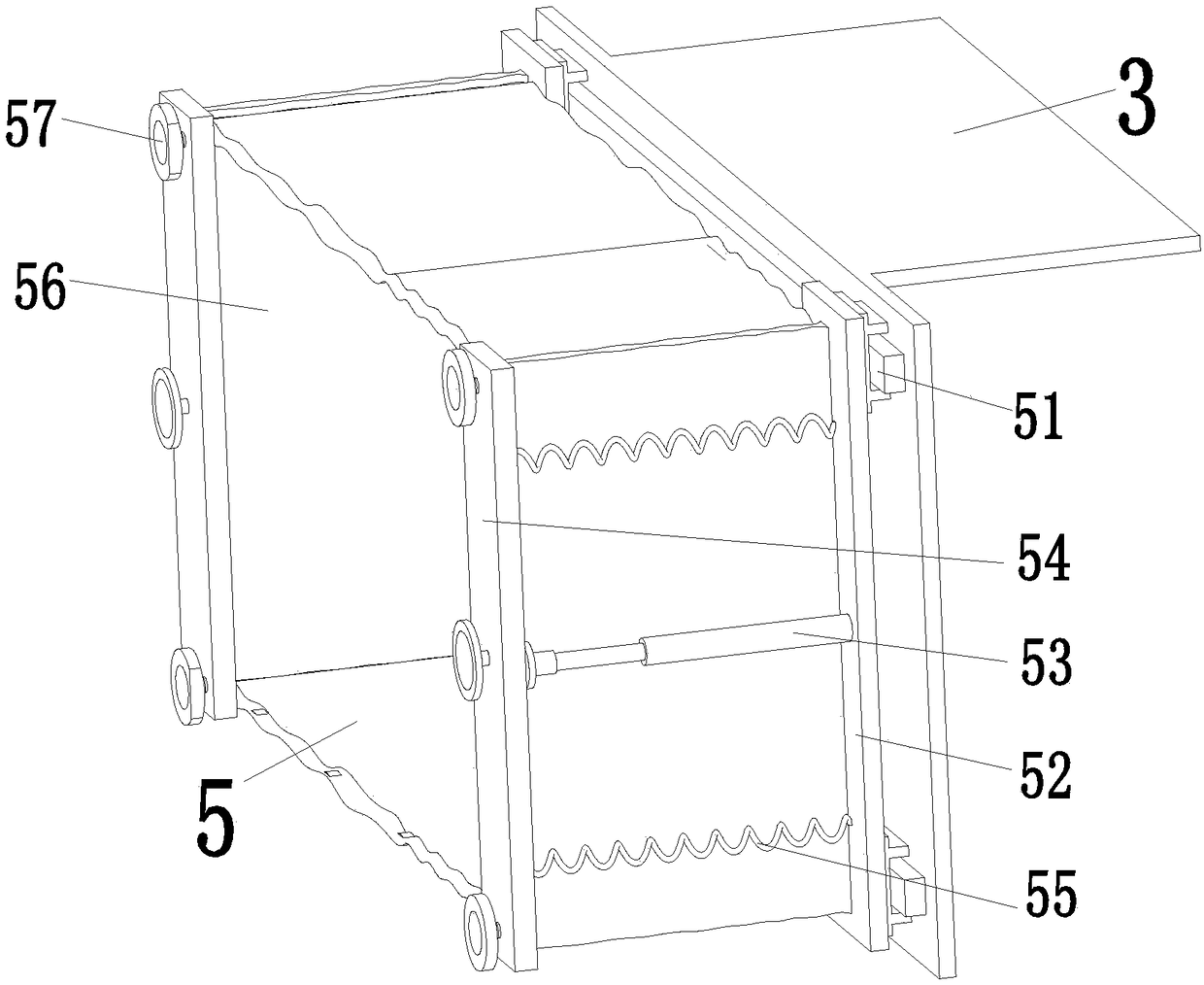

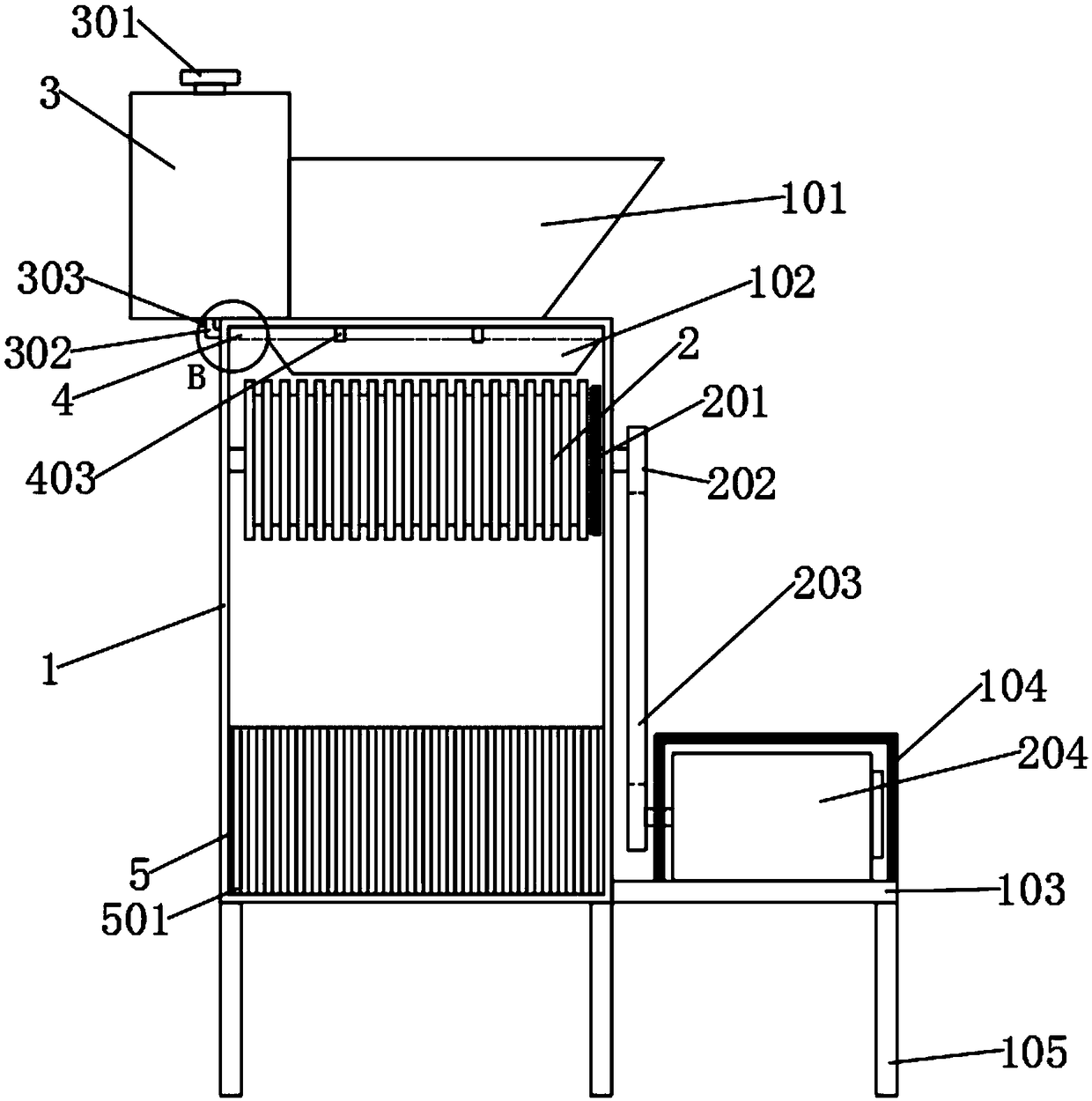

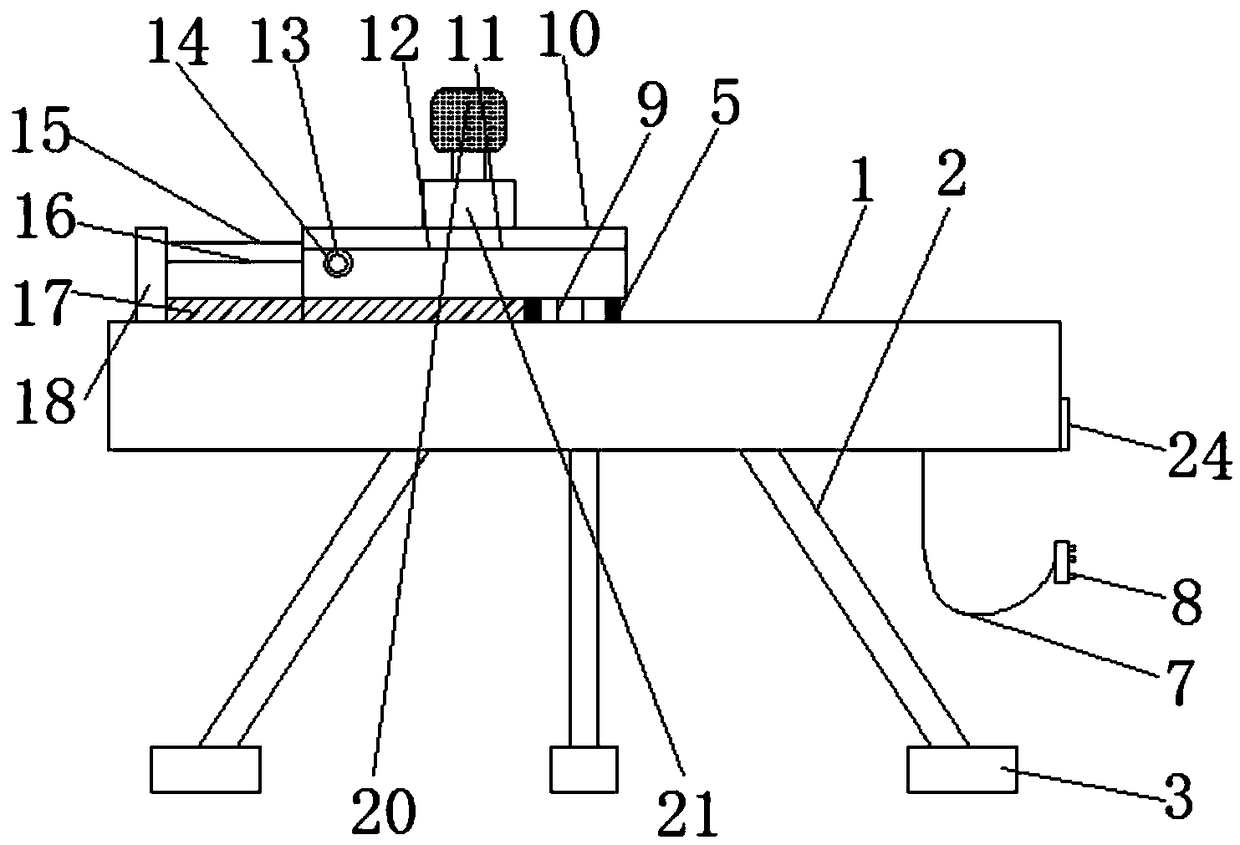

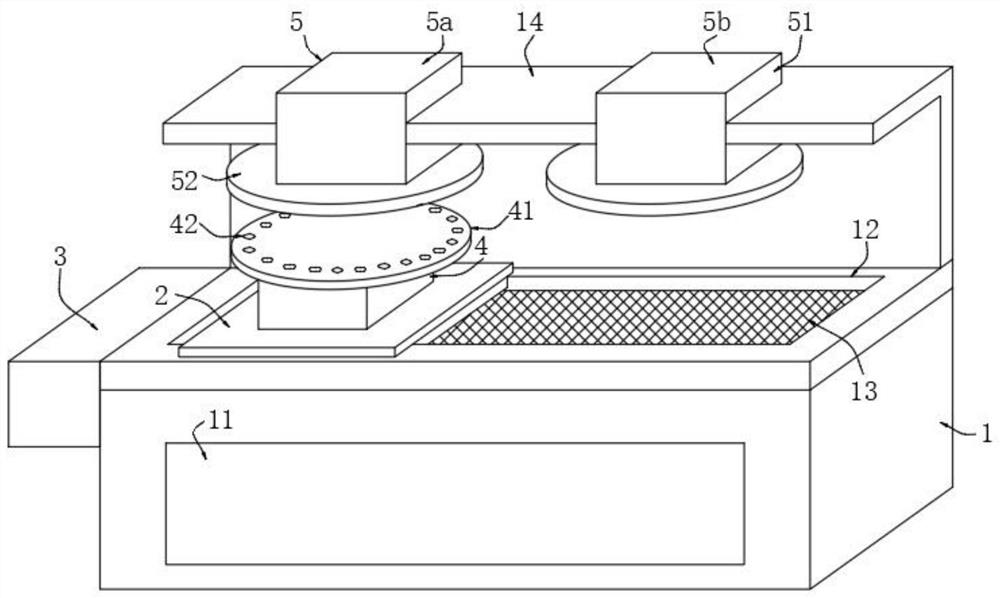

Chemical fiber silk pretreatment device for chemical fiber cloth manufacturing

InactiveCN111996643AImprove drying efficiencyPlay a role in collectingFibre cleaning/openingLiquid/gas/vapor removal by suctionElectric machineryChemical fiber cloth

The invention relates to the technical field of chemical fiber cloth production processing, and particularly discloses a chemical fiber silk pretreatment device for chemical fiber cloth manufacturing.The device includes a working table and a water storage tank, a dust removing tank, a washing tank, a drying tank and an automatic winding machine are fixedly connected with the top of the working table separately from left to right, a driving motor is fixedly connected with the middle of the top of the dust removing tank, the output end of the driving motor penetrates through the top of the dustremoving tank and is fixedly connected with a brushing disc, a water outlet board is fixedly connected with the middle of the bottom of the inner wall of the washing tank, an atomization nozzle is fixedly connected with the top of the water outlet board along the horizontal direction equidistantly, a water pump is fixedly connected with the bottom of the inner wall of the water storage tank, cleaning liquid fills the water storage tank, a first air outlet board is fixedly connected with the bottom of the inner wall of the drying tank, and a hot air blower is fixedly connected with the position corresponding to the drying tank of the bottom of the working table. According to the device, the effect of fur removing and leveling of the chemical fiber silk can be achieved, and the silk can bewoven subsequently and conveniently by a worker.

Owner:唐敏

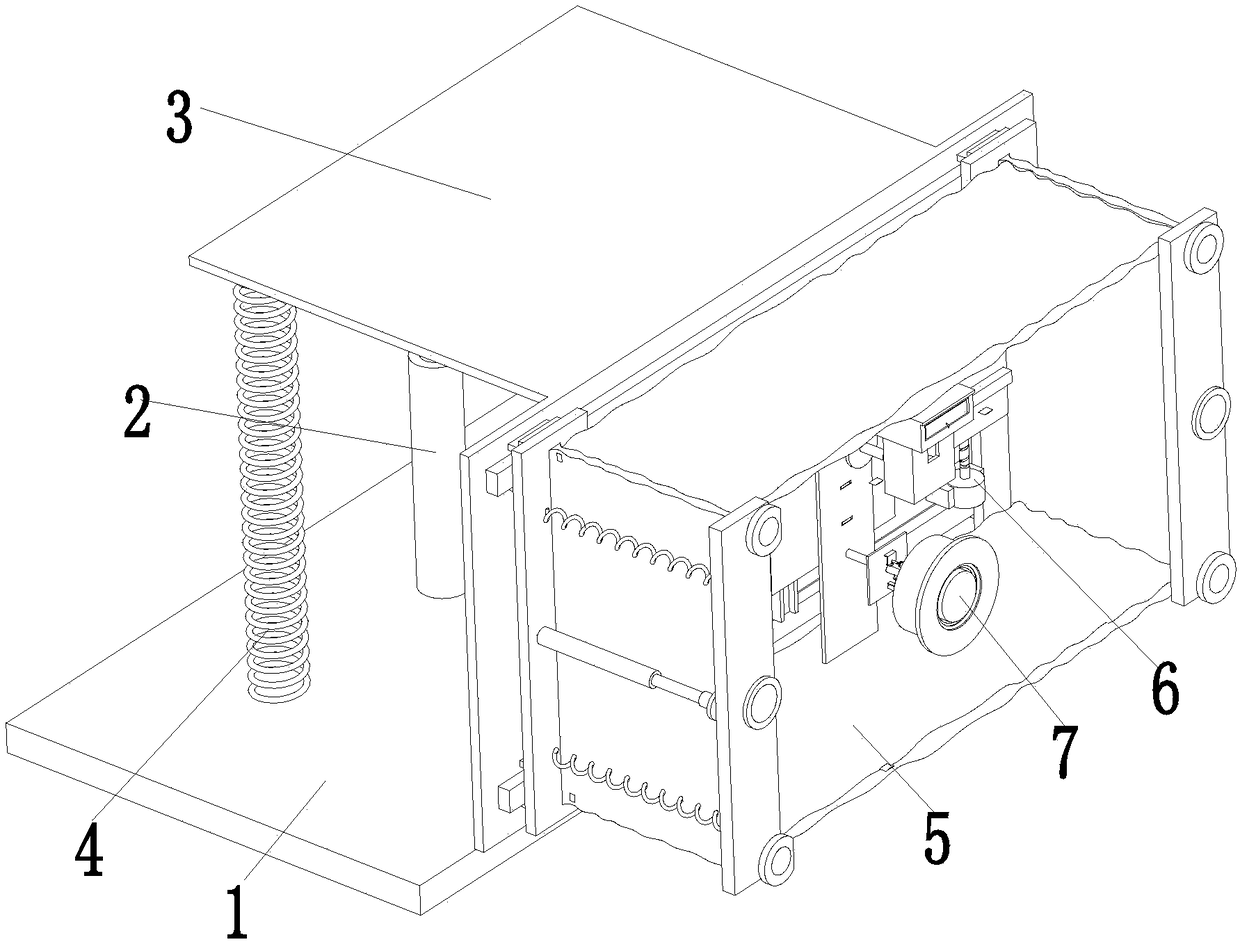

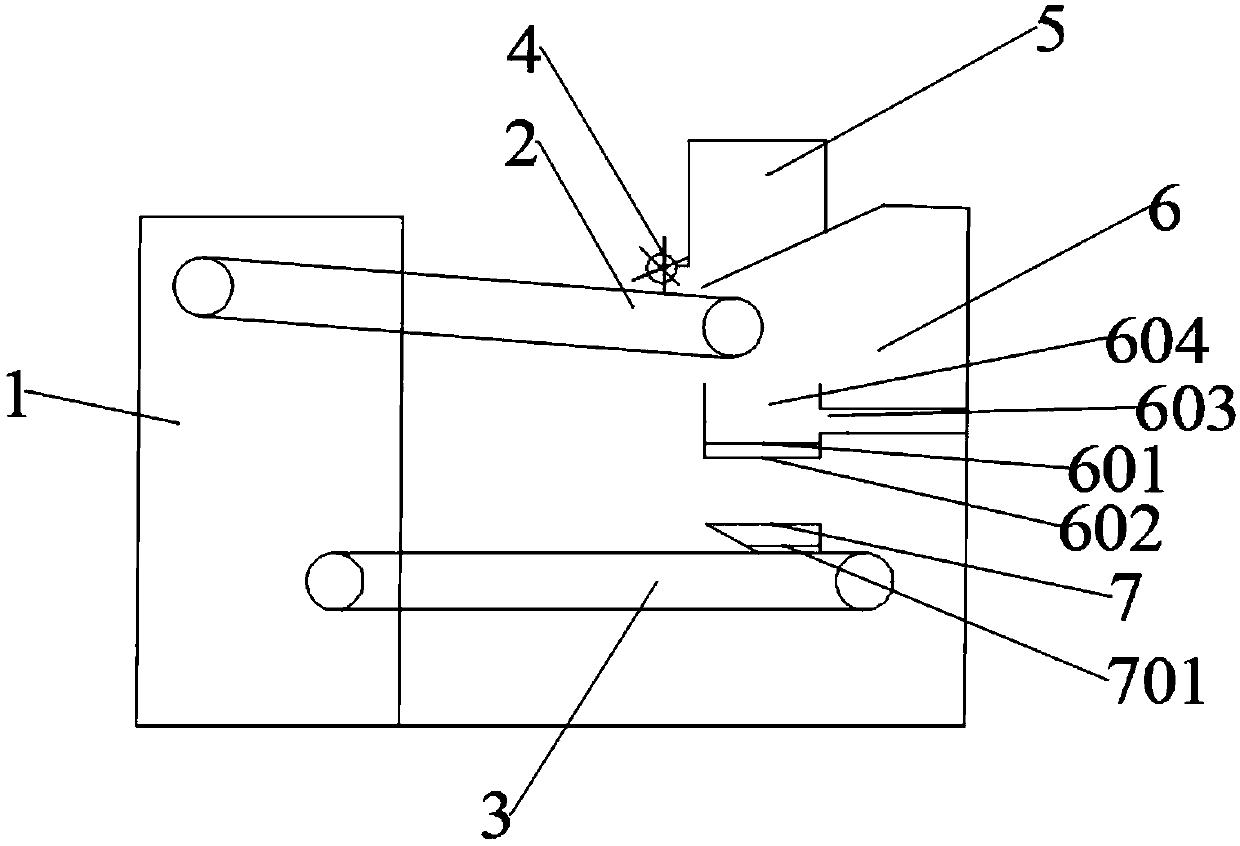

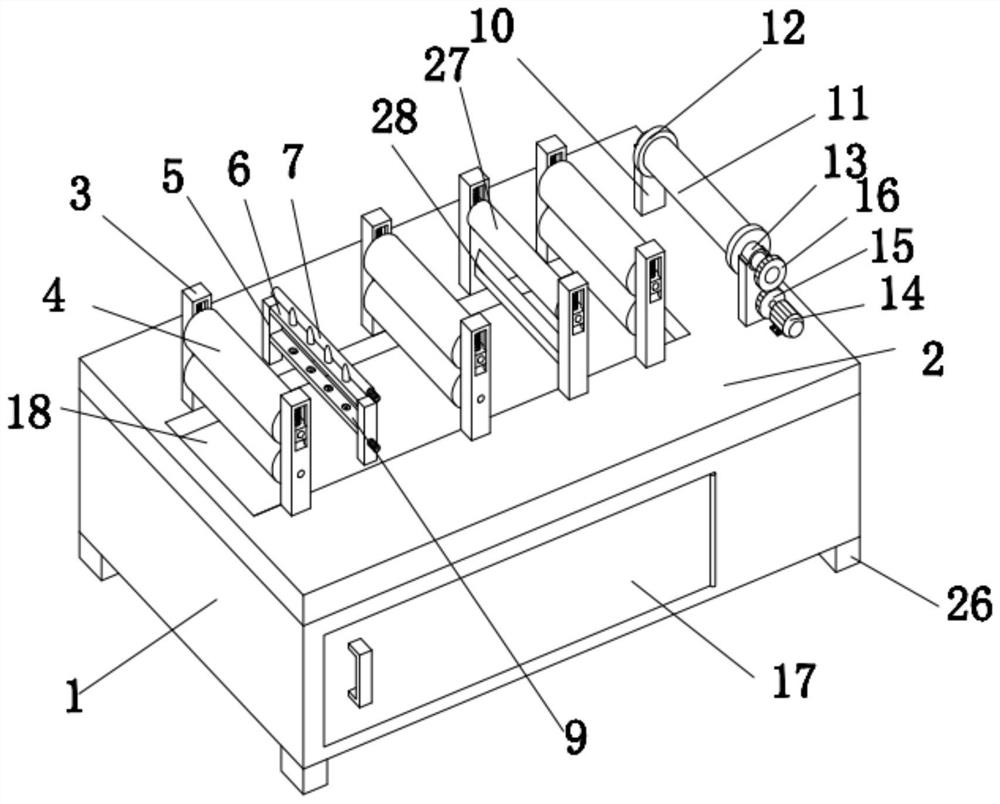

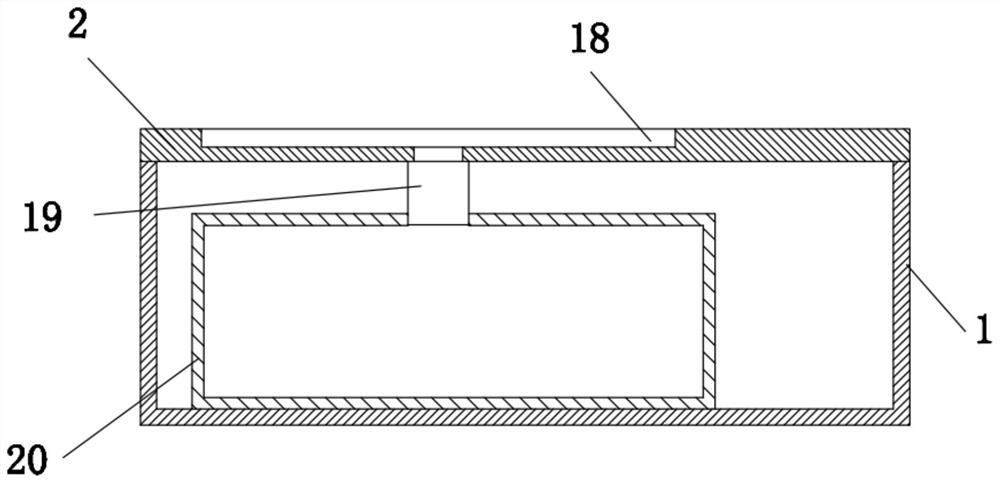

Slicing machine facilitating fixing for bamboo wood processing

InactiveCN107225643AImprove cut qualityAvoid displacementCane mechanical workingVeneer manufactureWood processingHydraulic cylinder

The invention discloses a slicer for bamboo and wood processing which is easy to fix, comprising a slicer main body, a first positioning block, a second positioning block, a hydraulic cylinder, a cutting port, a third positioning block, a sliding slope, a fan, a cutting piece and Turn the handle, the main body of the slicer is provided with a processing table, the lower ends of the first positioning block and the third positioning block are provided with sliding blocks, and the second positioning block is arranged on the rear side of the first positioning block. The hydraulic cylinder is arranged above the cutting frame, the cutting port is arranged on both sides of the cutting frame, the third positioning block is arranged on the right side of the cutting frame through the second sliding groove and the sliding block, and the cutting piece is supported by The frame is arranged inside the cutting frame, and the rotating handle is arranged under the first positioning block and the third positioning block. In the easy-to-fix slicer for bamboo and wood processing, a sliding slope is set on the rear side of the third positioning block to make the cut bamboo and wood slide to a designated position, which is beneficial to the transportation of the cut bamboo and wood.

Owner:安吉县怡成竹木工艺品厂

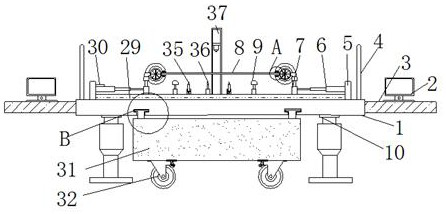

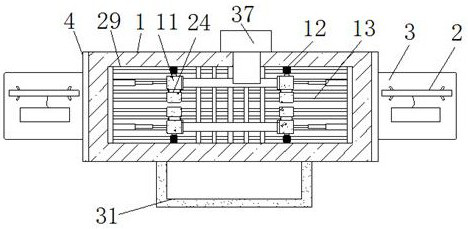

Float glass process TFT-LCD glass production process

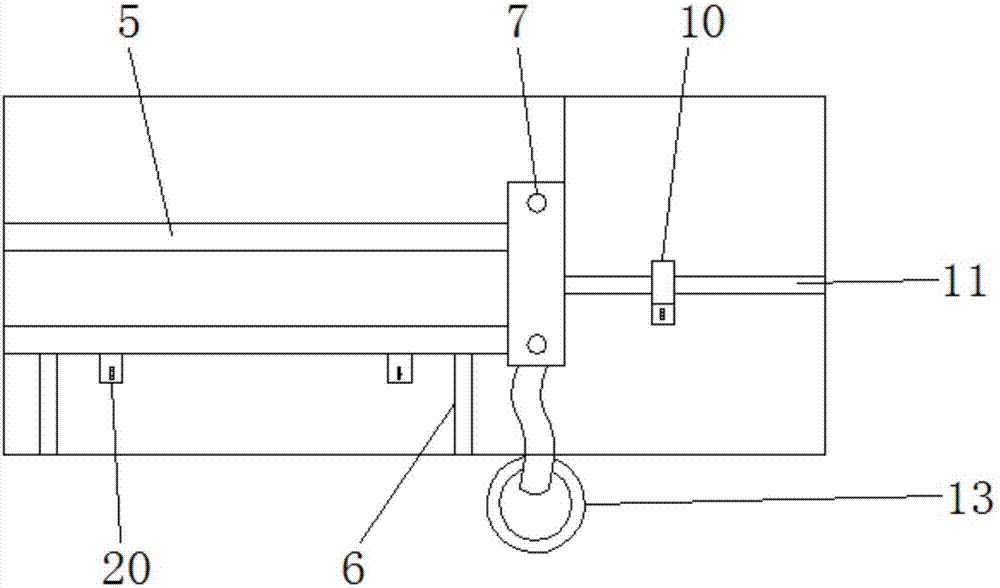

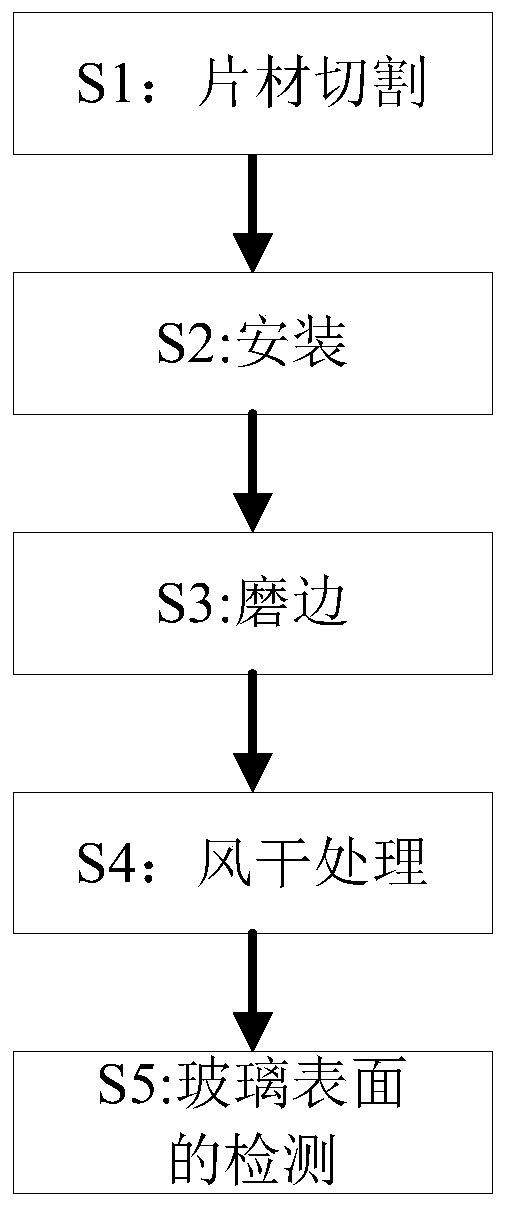

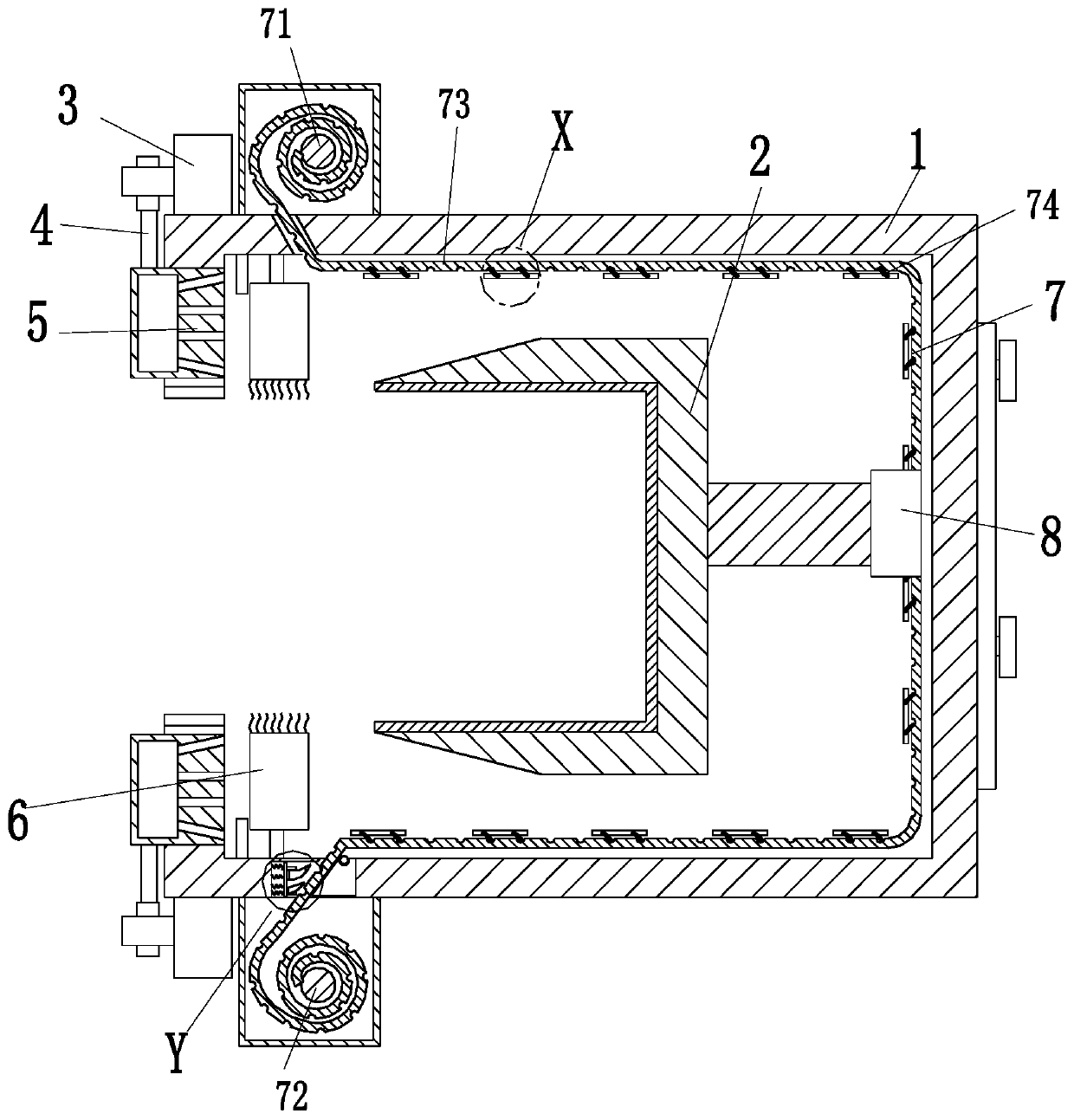

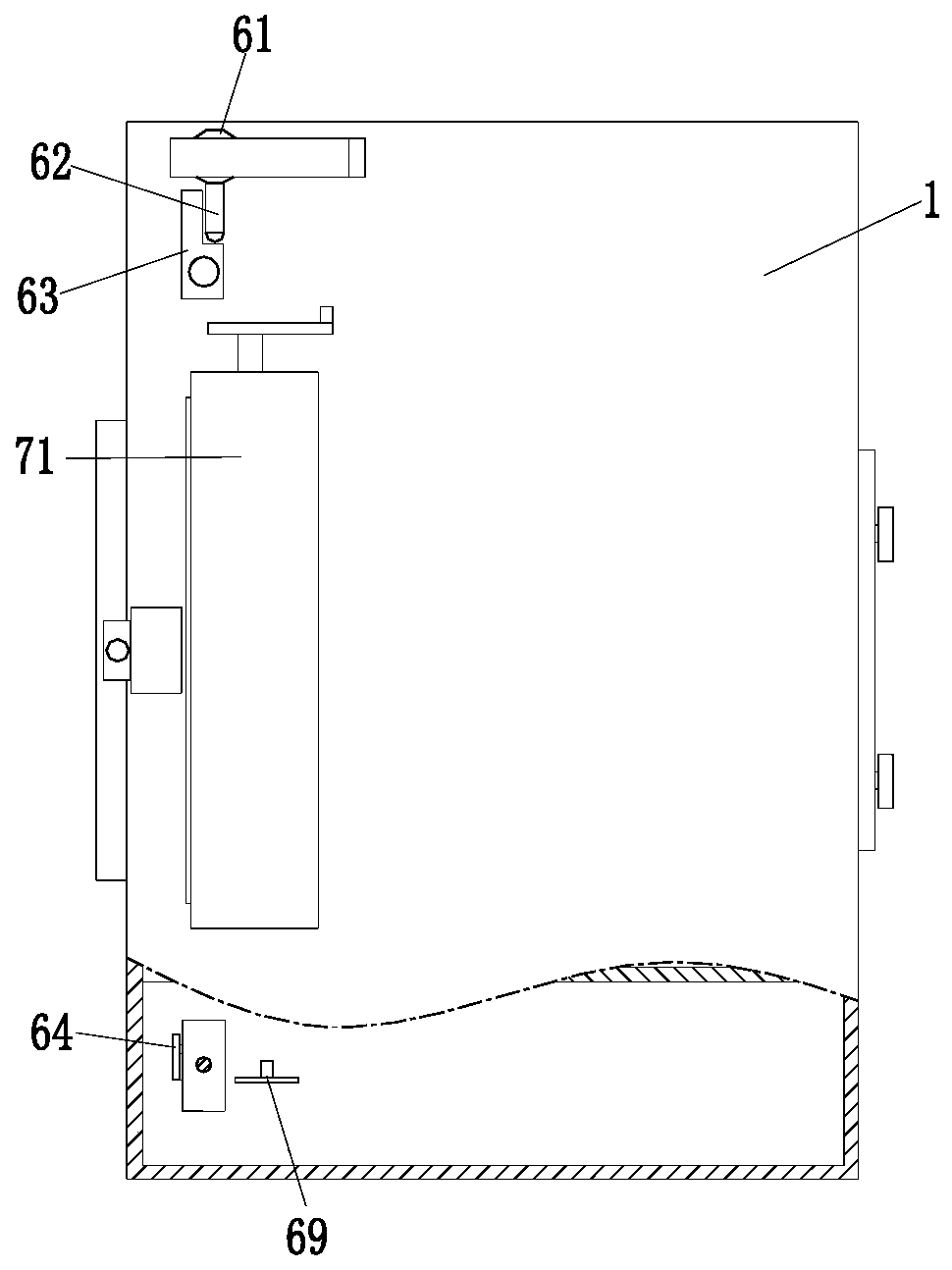

ActiveCN110315405AHigh recovery rateAvoid aspirationEdge grinding machinesCleaning using toolsScrapEngineering

The invention provides a float glass process TFT-LCD glass production process. The TFT-LCD glass production process is composed of a sealing frame, a grinding head, two air pumps, two air pipes, two air nozzles, two cleaning devices, an adhesion device and the electric sliding block are matched to complete operation. The TFT-LCD glass production process disclosed by the invention can be used for solving the problem that in the edge grinding process, an existing edge grinding head is usually directly exposed in air when an edge grinding head works, due to the fact that the generated grinding scraps are light in weight and not collected in time, so that the grinding scraps are easy to float up, and a certain harm is caused to the health of a human body due to the fact that the floating grinding materials are mistakenly sucked by people.

Owner:阜阳市远大浮法玻璃制品有限公司

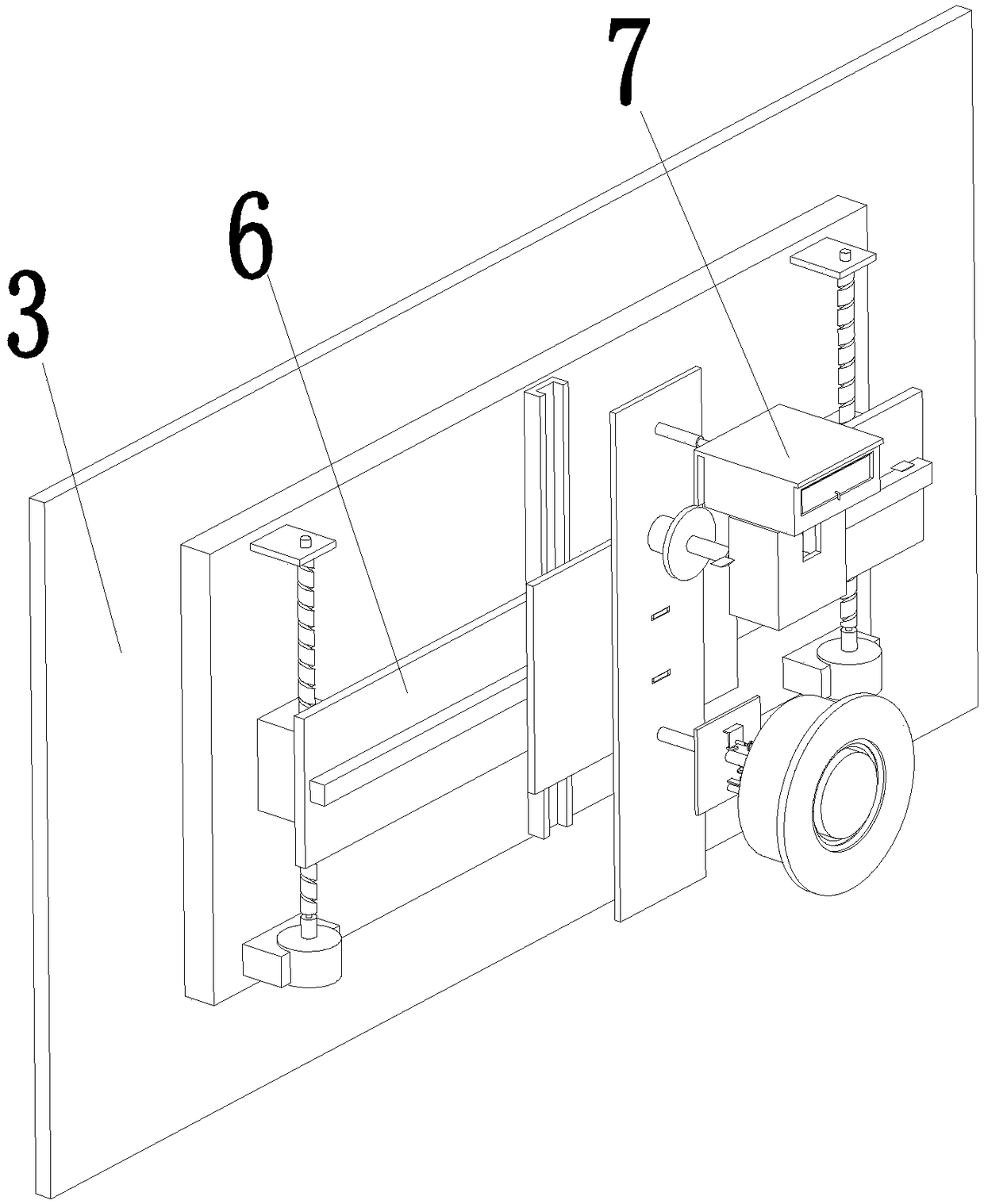

Building environment-friendly wall body equipment

InactiveCN108381319AWon't slipReduce labor intensityGrinding carriagesGrinding headsRebarBuilt environment

The invention relates to building environment-friendly wall body equipment comprising an adjusting supporting frame. A sheltering protection device is mounted on the side wall of the adjusting supporting frame, a converting adjusting device is mounted on the adjusting supporting frame, and an executing operation device is mounted on the converting adjusting device. The sheltering protection devicecomprises sheltering electric sliding blocks mounted on the adjusting supporting frame, and a sheltering moving plate is mounted between the sheltering electric sliding blocks. According to the building environment-friendly wall body equipment, the problems that in the existing wall surface polishing cutting process, steel bars remained on the wall surface need to be cut manually, the wall surface needs to be polished manually by means of a polishing tool, a cutting tool is prone to being damaged due to vibration of the steel bars in the process that the steel bars are cut manually by means of the cutting tool, in the cutting operation process, generated cut particles easily cause harm to workers, dust generated when the workers conduct polishing work by means of the tool causes environment pollution, and the body health of the workers is affected by noise generated in the cutting and polishing processes.

Owner:仇芳

Fabric fast-carding device for textile production

ActiveCN110318244AEasy to installEasy to disassemble and replaceMechanical cleaningPressure cleaningCorrosionMoisture

The invention discloses a fabric fast-carding device for textile production. The device includes a fixing support, a heating plate and a dust sucking head; the upper ends of the fixing support are provided with a support frame, an unreeling shaft is fixed to the interior of the support frame, the two ends of the unreeling shaft are provided with thread blocks, rotating blocks are fixed to the outer surfaces of the thread blocks, the unreeling shaft is provided with a roll shaft, and the outer surfaces of the two ends of the roll shaft are provided with balls. Compared with an existing common fabric fast-carding device for textile production, the fabric fast-carding device for textile production can remove dust, cotton fibers and other impurities adhering to fabrics, the carding effect of the carding device is improved, water is prevented from overflowing during the use of the device so as to avoid parts from moisture and corrosion, centralized treatment of waste liquid is convenient, waste of water resources is avoided, meanwhile, the fabrics with different thicknesses can be flattened, and the applicability of the device is improved.

Owner:YUHUAN ZITI COSMETICS CO LTD

Automatic treatment equipment for building walls

InactiveCN108340229APhysical health will not affectIncrease labor intensityGrinding machine componentsPlane surface grinding machinesPhysical healthAutomatic test equipment

The invention relates to automatic treatment equipment for building walls. The automatic treatment equipment for the building walls comprises an adjusting supporting frame; a shielding protection device is installed on the side wall of the adjusting supporting frame; a conversion adjusting device is installed on the adjusting supporting frame, is provided with an execution operating device and comprises two conversion moving mechanisms installed on the adjusting supporting frame; the two conversion moving mechanisms are symmetrically located on the left side and the right side of the adjustingsupporting frame; and a conversion moving plate is installed between the two conversion moving mechanisms. By means of the automatic treatment equipment for the building walls, the problems that in existing wall grinding and cutting processes, steel bars left on a wall need to be manually cut and the wall needs to be manually ground by aid of a grinding tool, in the process of cutting the steel bars manually by aid of a cutting tool, the cutting tool is prone to being damaged due to vibration of the steel bars and the cut-off portions of the steel bars need to be manually collected, and whenworkers work by aid of a grinding tool, dust generated by grinding causes pollution to the environment and the physical health of the workers is affected can be solved.

Owner:丁佐琳

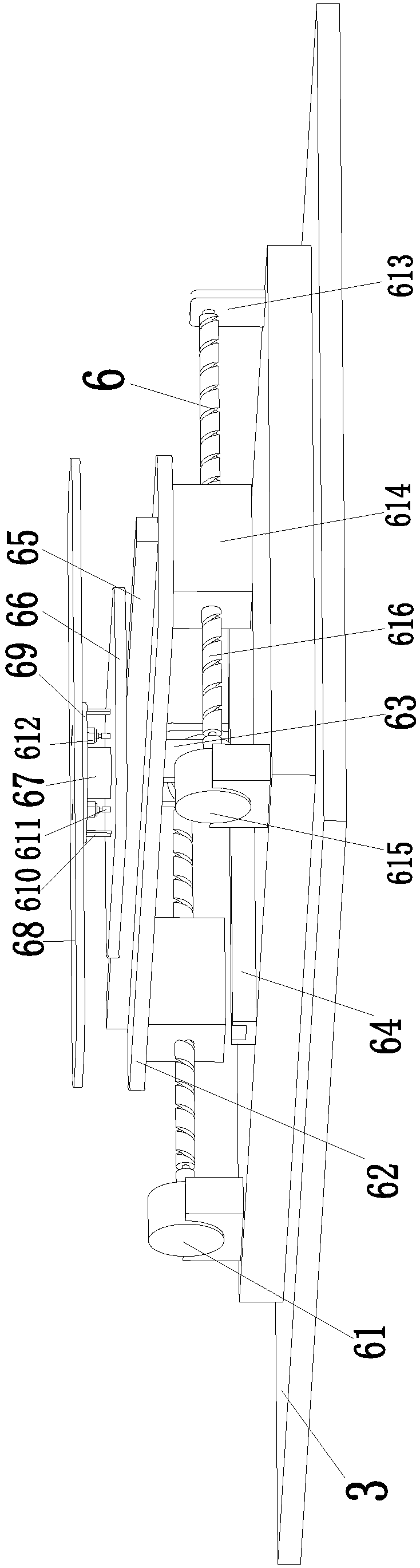

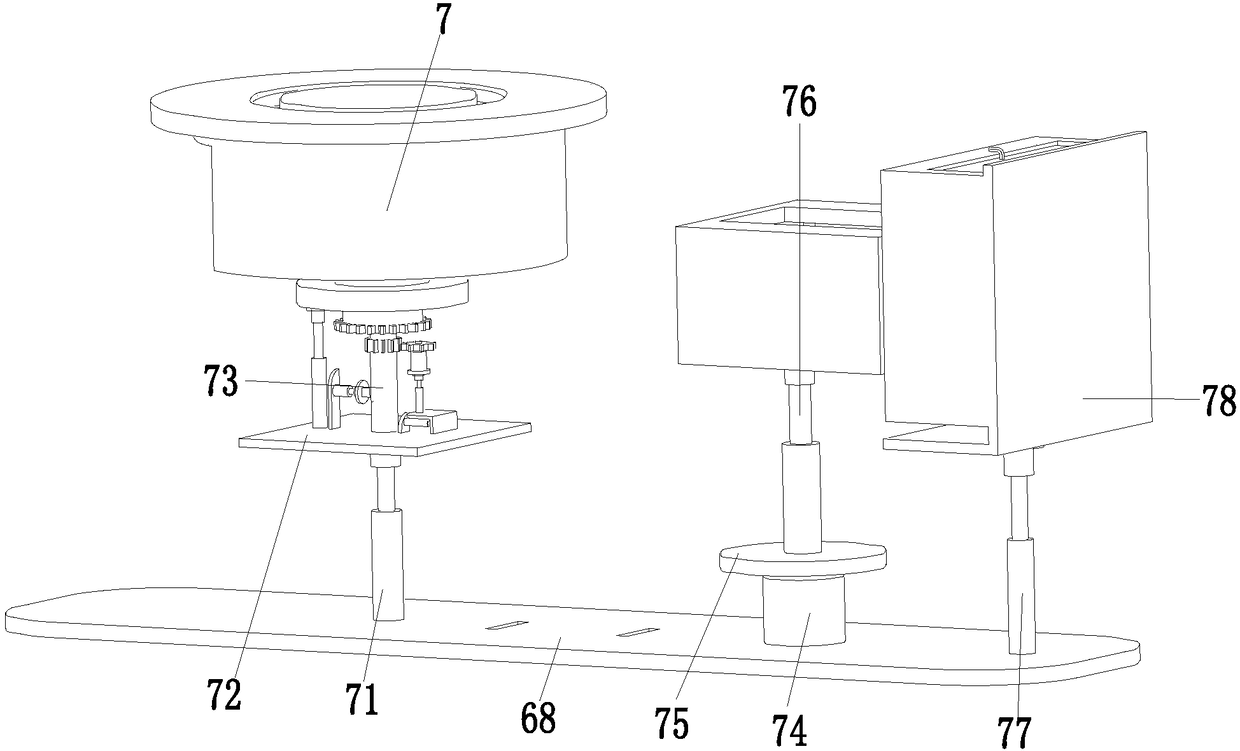

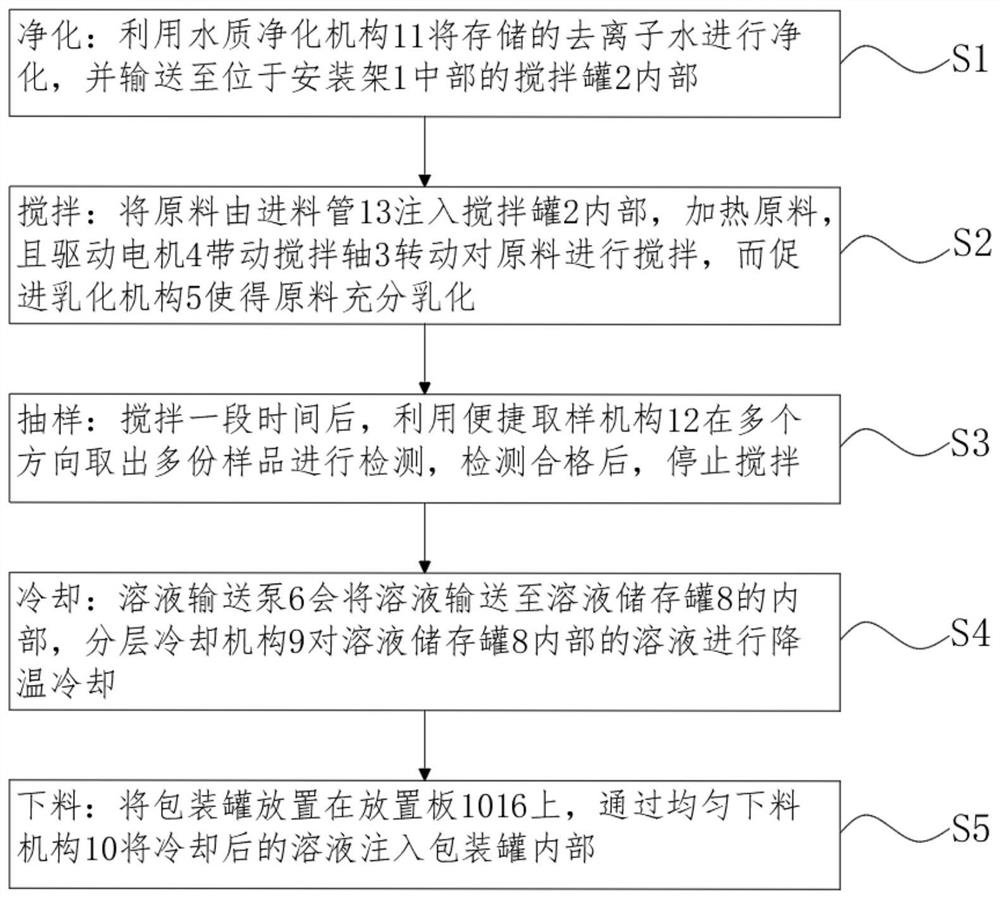

Preparation method of decontamination type laundry detergent

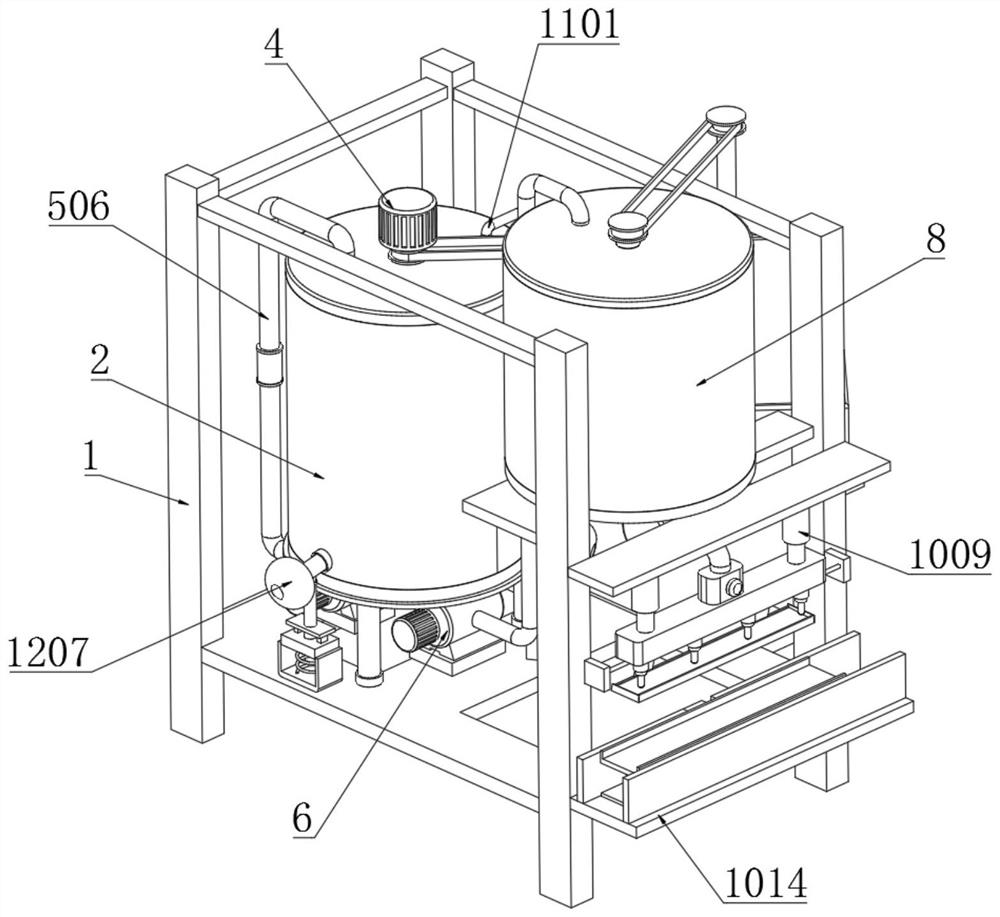

InactiveCN112169610AStir wellWell mixedWater/sewage treatment by irradiationFlow mixersProcess engineeringDrive motor

The invention discloses a preparation method of a decontamination type laundry detergent. The method comprises the following steps of: purification: purifying stored deionized water by using a water quality purification mechanism, conveying the purified deionized water into a stirring tank in the middle of a mounting frame; stirring: injecting raw materials into the stirring tank through a feedingpipe, heating the raw materials, and driving a stirring shaft to rotate by a driving motor so as to stir the raw materials, and fully stirring the raw materials through an emulsification promoting mechanism. The raw materials in the stirring tank can be fully mixed through the emulsification promoting mechanism, the raw materials can be fully mixed, and the situation that the quality of the prepared laundry detergent is unqualified due to uneven mixing of the raw materials is avoided, and meanwhile, through cooperative use of a circulating pump and a circulating conveying pipe, the mixed solution at the bottom of the stirring tank is pumped out and then re-injected into the stirring tank, the problem that the solution is deposited at the bottom of the stirring tank and cannot be fully mixed is avoided, raw materials are fully emulsified, raw material mixing is promoted, and the activity of the raw materials can be improved.

Owner:周燕芳

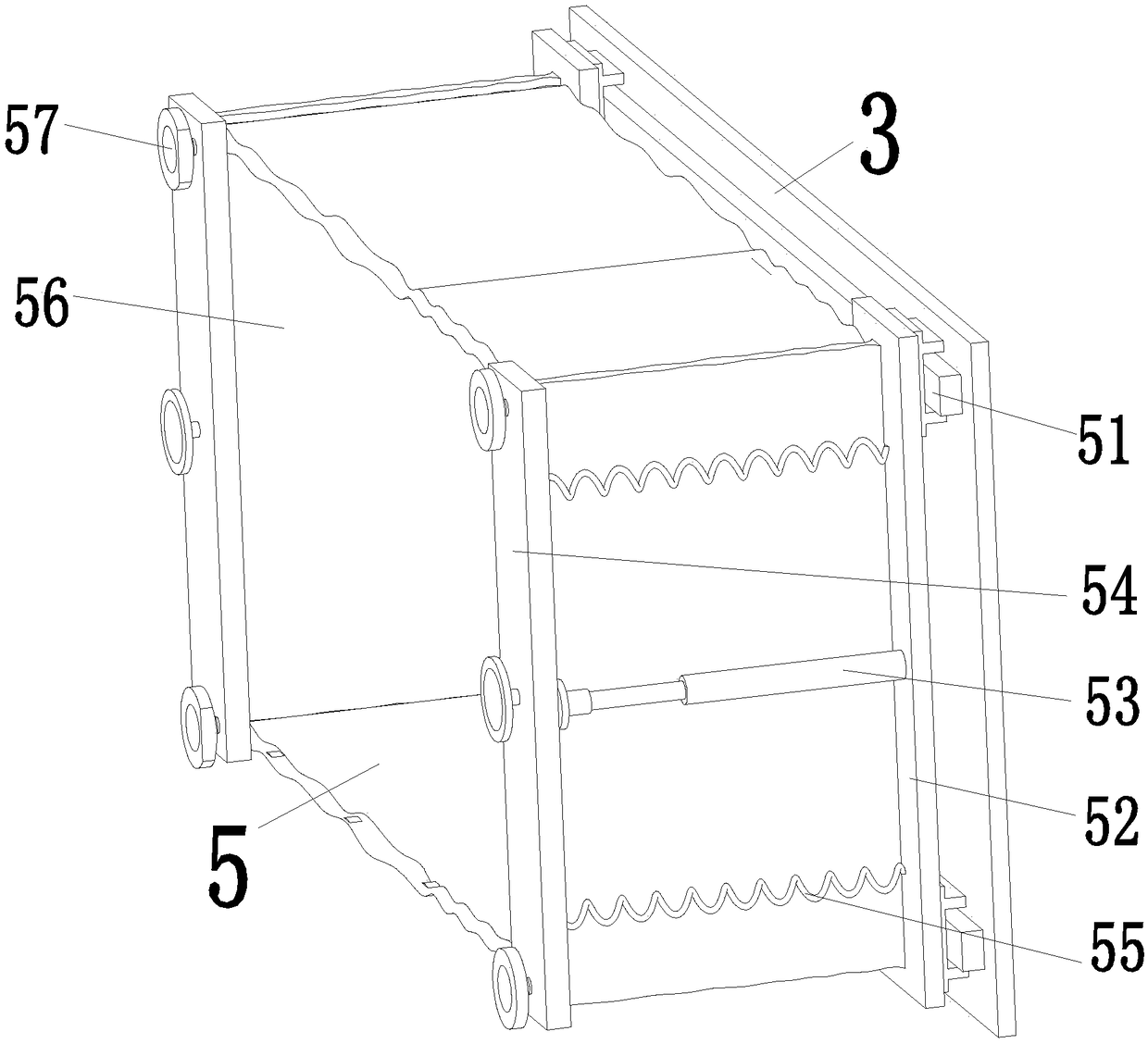

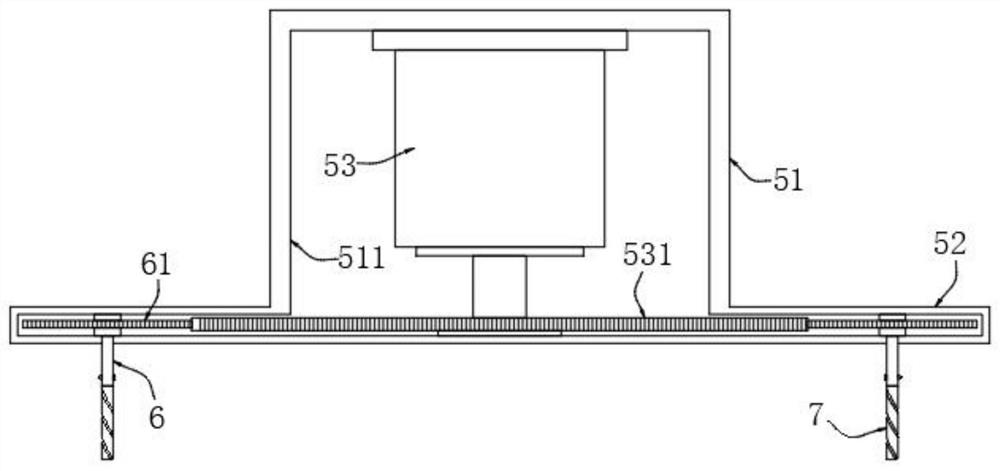

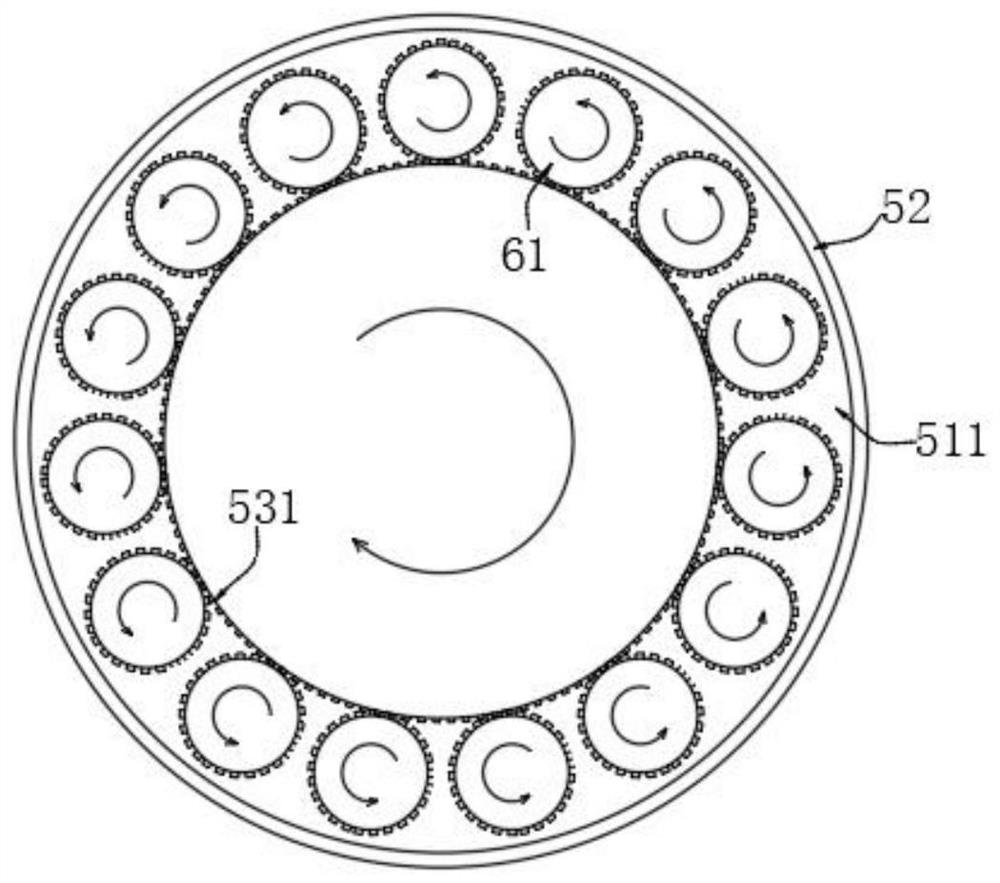

Textile drying device capable of automatically replacing winding roller

PendingCN112197556AImprove stabilityImprove practicalityDomestic cooling apparatusDrying machines with progressive movementsElectric machineryStructural engineering

The invention discloses a textile drying device capable of automatically replacing a winding roller. The textile drying device comprises a body, a storage roller, a motor, a first cavity and a secondcavity, a placement roller is mounted on the right side of the body, the second cavity is mounted on the left side in the body, and a guide roller is mounted below the first cavity and the second cavity; and a collector is mounted below the guide roller, a connecting block is mounted above a pressing block, an air cylinder is mounted in the middle of the rear portion of the storage roller, a mounting block is mounted on the outer side of a connector, a guide block is mounted on the inner side of the connector, connecting frames are mounted on the two sides of the motor, a telescopic rod is mounted in the middles of the connecting frames, and the telescopic rod is mounted behind the motor. The textile drying device capable of automatically replacing the winding roller is provided with a mounting groove and the mounting block, through arrangement of the mounting groove and the mounting block, connection between the storage roller and the connector can be more stable, the phenomenon thatthe storage roller suddenly falls off in the winding process is effectively prevented, and the stability of the device is improved.

Owner:吴晓琴

Spinning dust-removing cotton fluffer

InactiveCN107699994AEfficient popping work efficiencyPlay the role of fixing and anti-looseningCarding machinesElectric machineryEngineering

The invention discloses a spinning dust-removing cotton fluffer which comprises a cotton fluffer body. A first roller is arranged on one side of the top of the cotton fluffer body, an induced draft fan is arranged inside the first roller, a vent pipe is arranged at the top of the induced draft fan, a hollow plate is arranged on the outer surface of the first roller, a conveying belt is arranged onone side of the first roller, a drying pad is arranged at the bottom of the conveying belt, a second roller and a pressing roller are horizontally and sequentially arranged at the top of an operatingboard, the first roller is in transmission connection with a motor in the operating board through a rotating shaft, a discharging belt is welded on the outer side of the operating board, a dust outlet pipe is welded at the bottom of the first roller, a dust separating pipe is welded on one side of the dust outlet pipe, a dust collecting bin is welded at the bottom of the dust outlet pipe, and a partition plate is welded on the inner surface wall of the dust collecting bin. The cotton fluffer is simple and reasonable in integral structural design, safe and stable in running, flexible and convenient to operate and high in practicability, and has strong self-protection capacity.

Owner:CHENGDU RONGCHUANG ZHIGU SCI & TECH

Rain-proof clothes air-drying device

InactiveCN108774855AAvoid soakingPlay a role in collectingGeneral water supply conservationOther drying apparatusEngineeringSunlight

A rain-proof clothes air-drying device mainly comprises a main body, a support rod and water pipes, wherein air-drying rods are fixed on the inner side of the main body; an inserting hole is formed ina fixed rod; the support rod is fixed in the inserting hole; clamp slots are formed in a transparent block and located on the outer side of the transparent block; a threaded hole is formed in the inner side of the transparent block; a water receiving pipe is connected with the other end of a backing ring; water outlet holes are formed in the bottom end of the water receiving pipe; the two ends ofa guiding block are connected with the water outlet holes; one end of each water pipe is connected with the corresponding water outlet hole; a water tank is arranged at the bottom end of the main body. According to the rain-proof clothes air-drying device, the transparent block of an umbrella-shaped structure is fixed at the top end through the support rod, the main body is arranged in the transparent block, and therefore, the transparent block cannot block sunlight in an air-drying process of the clothes and can prevent the air-drying clothes from getting wet by rainwater during raining.

Owner:陈伊诺

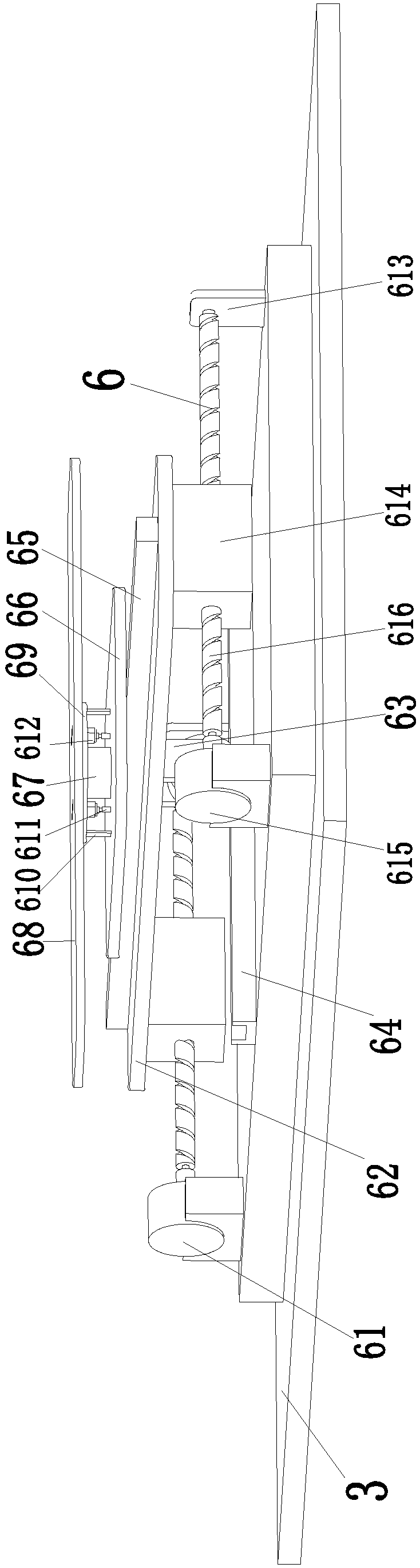

Special environment-friendly construction equipment for wall treatment

InactiveCN108296904AWon't slipReduce labor intensityPlane surface grinding machinesGrinding/polishing safety devicesEnvironmental resistancePhysical health

The invention relates to special environment-friendly construction equipment for wall treatment. The special environment-friendly construction equipment comprises a bottom plate; an adjustment liftingair cylinder is arranged on the bottom plate; the top end of the adjustment lifting air cylinder is arranged at an adjustment supporting frame through a flange; a shielding protective device is arranged on the side wall of the adjustment supporting frame; a conversion adjustment device is arranged on the adjustment supporting frame; and an actuating operation device is arranged on the conversionadjustment device. The special environment-friendly construction equipment can solve the problems that steel bars remained on the wall surface are cut manually in grinding and cutting process of an existing wall surface, the wall surface is subjected to grinding treatment manually by virtue of a grinding tool, a cutting tool is prone to damage due to vibration of the steel bars when a worker cutsthe steel bars by virtue of the cutting tool, cut particles produced in the cutting operation process are likely to hurt staff, the cut steel bars require manual collection, grinding dust may cause environmental pollution when the worker works by virtue of the grinding tool, and physical health of the staff is affected.

Owner:龚大娇

Garbage treatment device

InactiveCN108816491AAvoid breedingPlay the role of supporting the output partsHollow article cleaningGrain treatmentsEngineeringControl valves

The invention provides a garbage treatment device. The garbage treatment device comprises a hanging piece, an installing groove, a material receiving piece, a lower stop piece, an upper stop piece, afixing piece and a spring. The side edge of a base and the side edge of a body are connected in a welding manner, a protection cover is arranged above the base in a welding manner, and standing legs are arranged at the bottom of the base in a welding manner. The rear portion of a discharging piece is arranged in front of the body in a welding manner. A liquid adding port above a disinfection box is twisted through manpower, then, disinfection liquid is added into the disinfection box through the liquid adding port, after usage of the device, a control valve is opened through manpower, the disinfection liquid flows through a connecting pipe, enters a liquid outlet pipe and then is discharged through liquid outlet holes, the liquid outlet pipe at the position is fixed to the upper edge position in the body, accordingly, the disinfection liquid can disinfect the inner wall of the body, and garbage residues are discharged along with the disinfection liquid.

Owner:程度

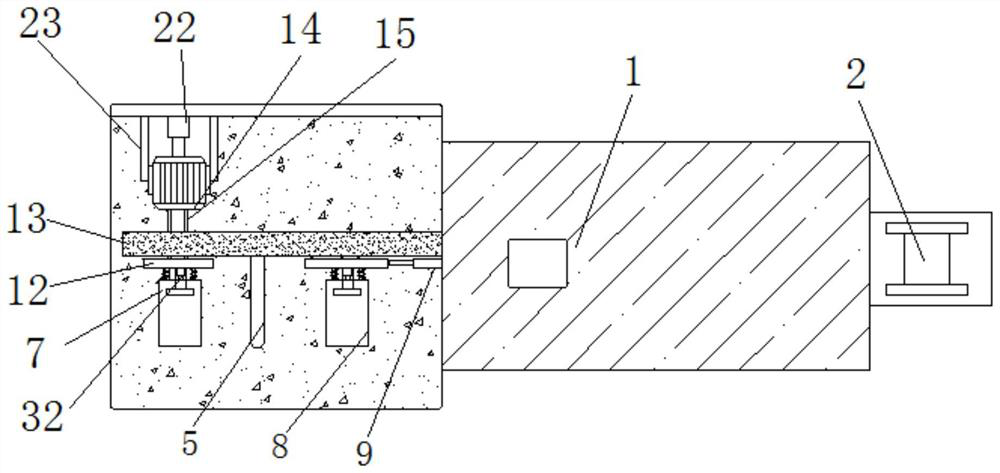

Textile fabric elasticity detection device convenient for synchronous comparison

PendingCN112525680AIncrease the credibility of detection dataEasy to observe the differenceMaterial strength using tensile/compressive forcesElectric machineryStructural engineering

The invention discloses a textile fabric elasticity detection device convenient for synchronous comparison. The textile fabric elasticity detection device comprises a body, a detection product, a toppenetrating device, a placing device and a motor, a connecting block is installed at the upper end of a sliding block, an installing frame is installed at the upper end of the connecting block, the connecting frame is installed at the outer end of a connector, the motor is installed in the installing frame, a connecting shaft is installed on the outer side of the motor, a shaft sleeve is arrangedin a placer, an adjusting rod is installed in the placer, a limiting block is installed at the end of an adjuster, the top penetrating device is installed in a sliding groove, the detection product isinstalled in the placer, and a sensor is installed on the outer surface of the telescopic rod. The textile fabric elasticity detection device convenient for synchronous comparison is provided with the top penetrating device, and due to the arrangement of the top penetrating device, the problem that only the overall elasticity of the fabric can be detected and the local elasticity of the fabric cannot be detected when the elasticity of the fabric is detected in the past is solved, and the credibility of detection data of the device is improved.

Owner:孙江

Purification type respiratory nursing device for hospital infection department

ActiveCN111686380ASimple device structureImprove securityElectrostatic separationDispersed particle separationEngineeringFamily medicine

The invention discloses a purification type respiratory nursing device for a hospital infection department. The purification type respiratory nursing device comprises an air breathe-in hood, wherein an air inlet pipe and an air outlet pipe are arranged on the air breathe-in hood; one ends, away from the air breathe-in hood, of the air inlet pipe and the air outlet pipe respectively communicate with an air inlet box and an air outlet box through pipe connectors; first one-way valves are arranged on the pipe connectors; a first disinfection device is arranged inside the air inlet box; the firstdisinfection device comprises an air inlet; the air inlet is formed in one end, away from the air inlet pipe, of the air inlet box; and electrostatic dust removal plates are arranged at the positions,at two sides of the interior of the air inlet box, of one side of the air inlet. The purification type respiratory nursing device for the hospital infection department has the beneficial effects thatthe device is simple in structure, can disinfect and sterilize inhaled and exhaled air, and can increase the humidity of air people breathe in, so that the comfort degree is increased when a patientbreathes.

Owner:车文华 +2

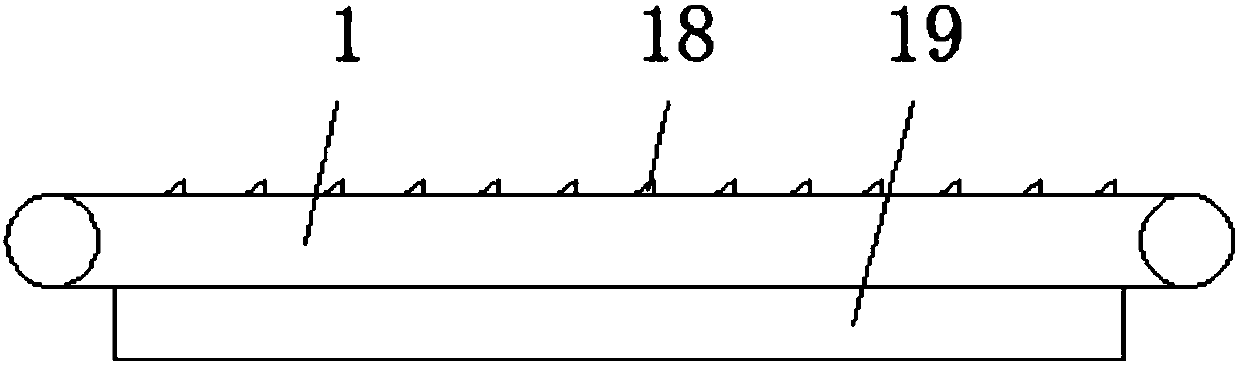

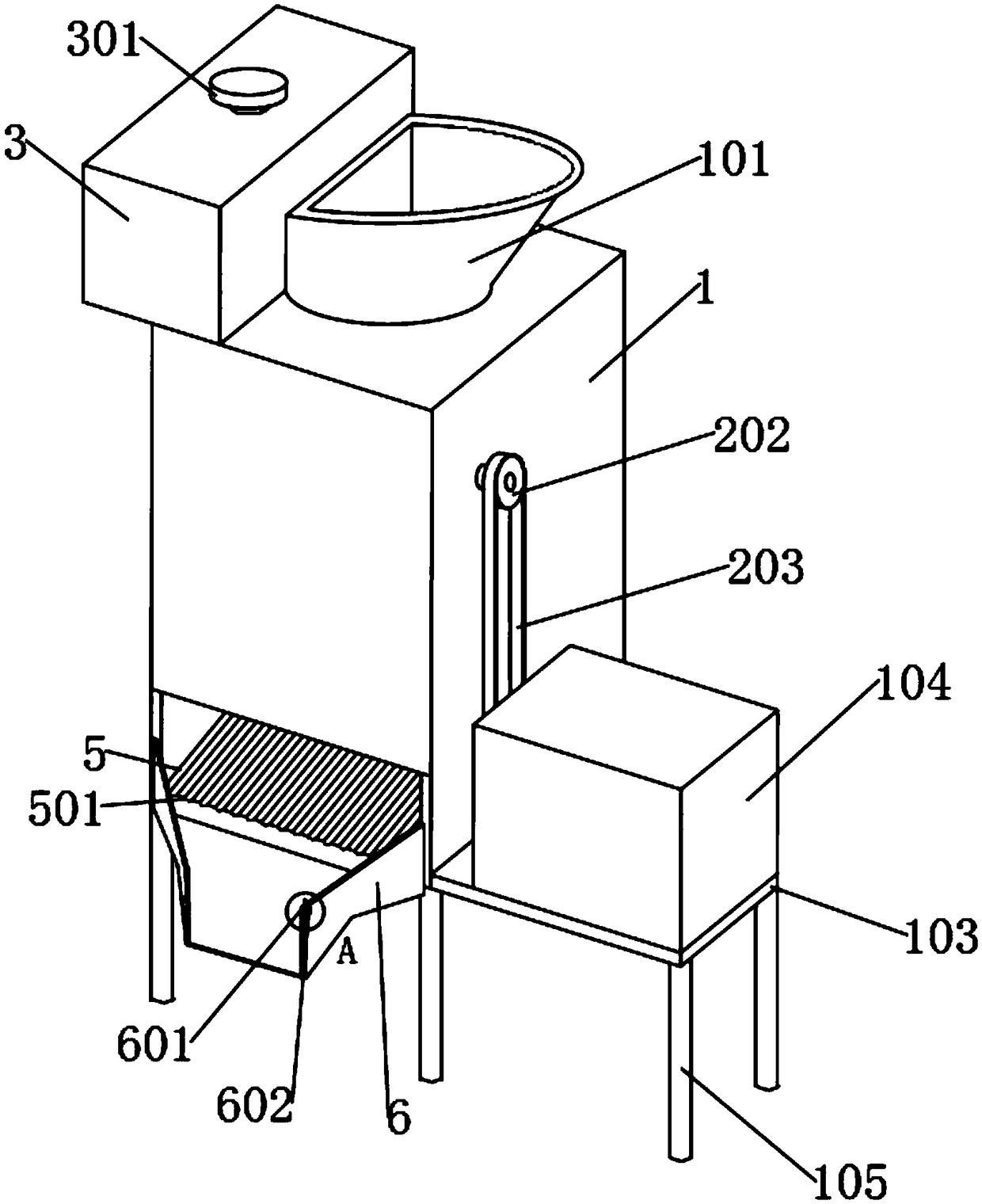

Leaked material recycling device for tea leaf conveying

InactiveCN107792689APlay a role in collectingReduce operating burdenControl devices for conveyorsLoading/unloadingEngineeringTea leaf

The invention discloses a leaking material recovery device for tea delivery, which comprises a leaking material conveyor belt and a vibrating leaf connecting device. The leaking material conveyor belt is arranged under the tea conveyor belt, and a leaking material receiving box is fixedly arranged on the surface of the leaking material conveyor belt, and the leaking material receiving box is located on the tea Below the tail of the conveyor belt, there is a pressure sensor 2 on the inner bottom of the leakage material receiving box; a vibration leaf connecting device is installed between the leakage material receiving box and the tea conveyor belt, and the bottom of the vibration leaf connecting device is equipped with an openable bottom plate. A pressure sensor 1 is arranged on the surface. The beneficial effect of the invention is that it can automatically collect the material leakage during the tea drying and conveying process, which improves the production efficiency and saves the operation cost of machinery and equipment.

Owner:CHIBI ZHAOLI QIAODONGZHUANG TEA

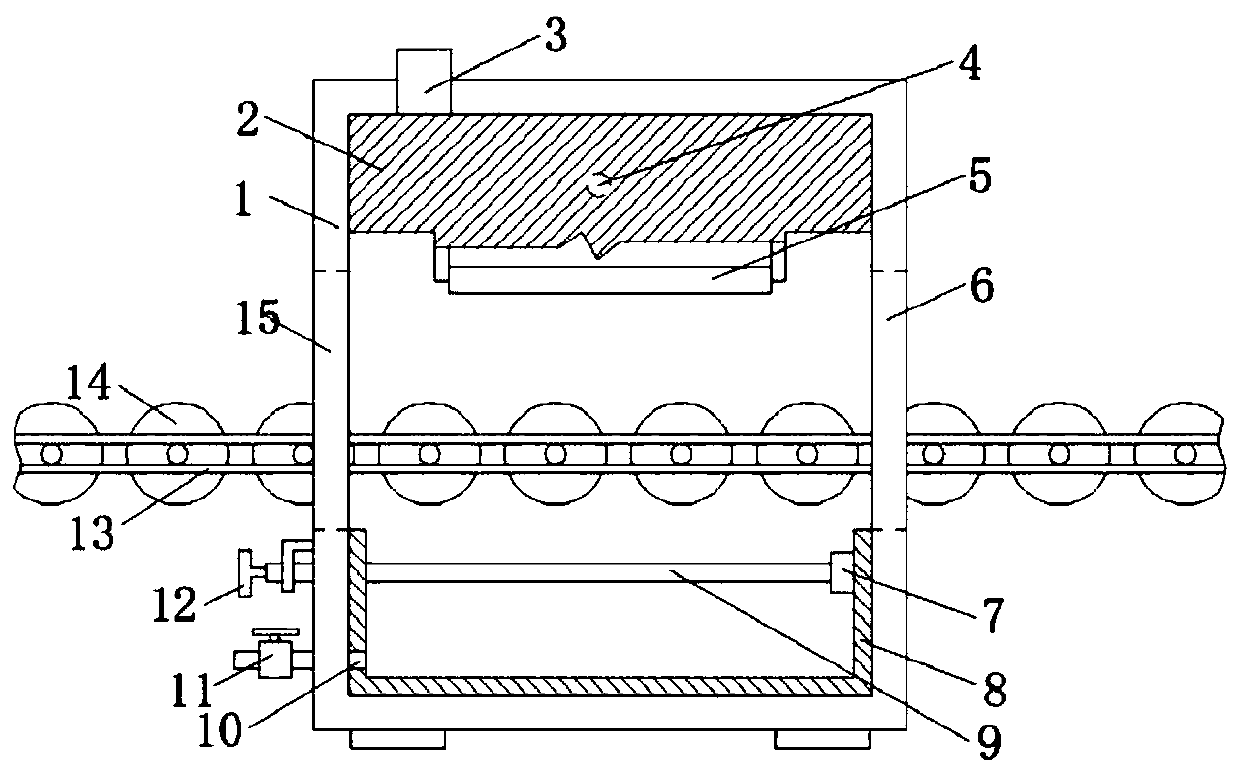

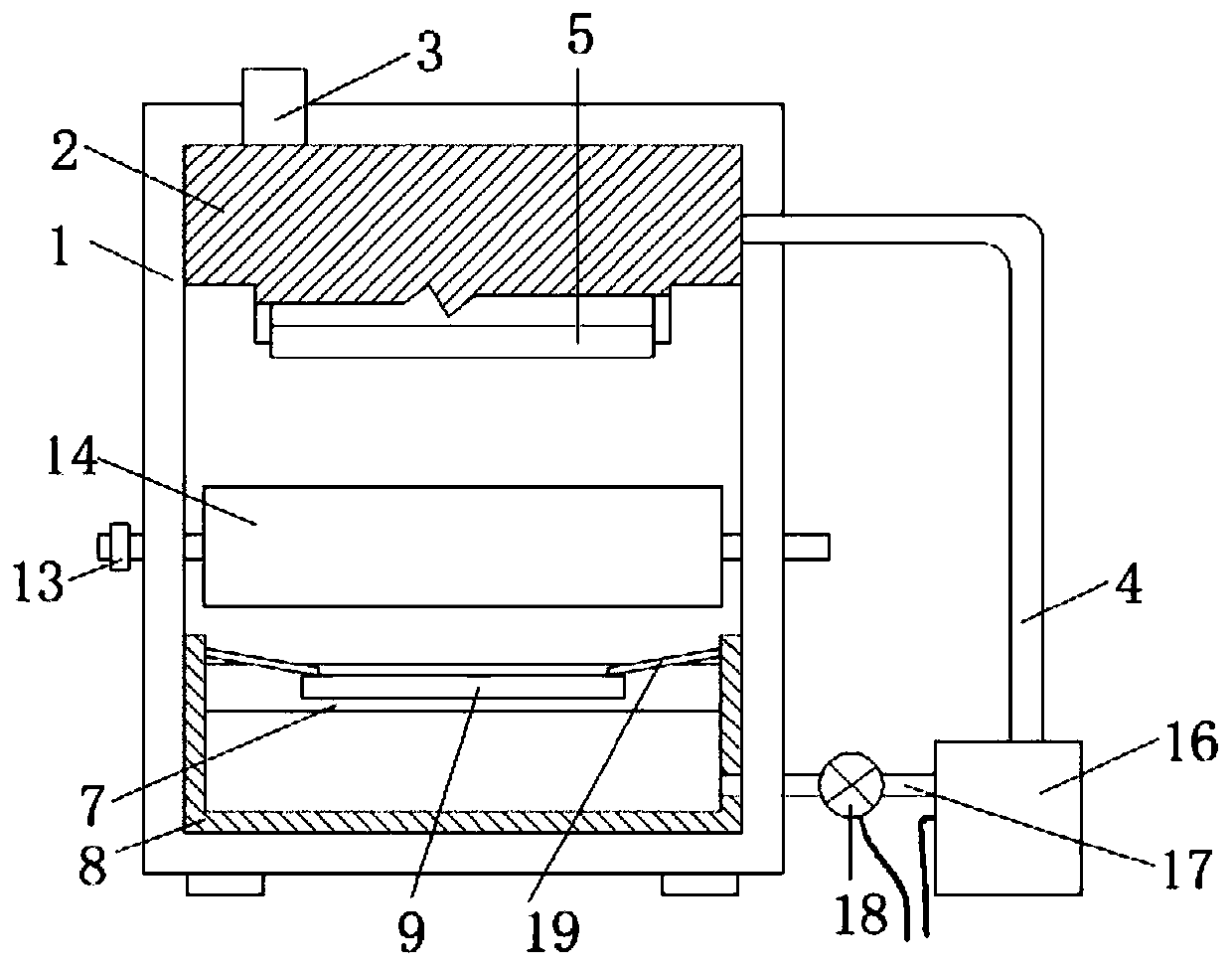

Cooling device for container Q235C steel smelting

PendingCN111451302APlay a role in collectingEasy to recycleFurnace typesWork cooling devicesWater storage tankCooling chamber

The invention discloses a cooling device for container steel smelting. The cooling device comprises a cooling chamber, a water storage tank, a water outlet net, a recycling shell and a water refrigeration circulator, wherein a feeding port is formed in one end of the cooling chamber, and a discharging port is formed in the other end of the cooling chamber; a material guiding roller connected through a belt is arranged in the cooling chamber; the water storage tank is fixed to the inner top of the cooling chamber through bolts; a water injection hole is formed in the upper portion of the waterstorage tank, and a water injection pipe is fixed to the upper portion of the water storage tank through bolts; the water outlet net is arranged at the bottom of the water storage tank; the water storage tank is further connected with a circulating pipe, one end of the circulating pipe is connected to the water refrigeration circulator, and the water refrigeration circulator is further connected with a water outlet pipe; and the recycling shell is arranged at the inner bottom of the cooling chamber, and a screen is transversely arranged in the recycling shell. Cooling water sprayed out throughthe water outlet net falls onto the screen and is collected into the recycling shell, the recycling shell can collect the used cooling water, and the cooling water can be recycled conveniently.

Owner:河北敬业中厚板有限公司

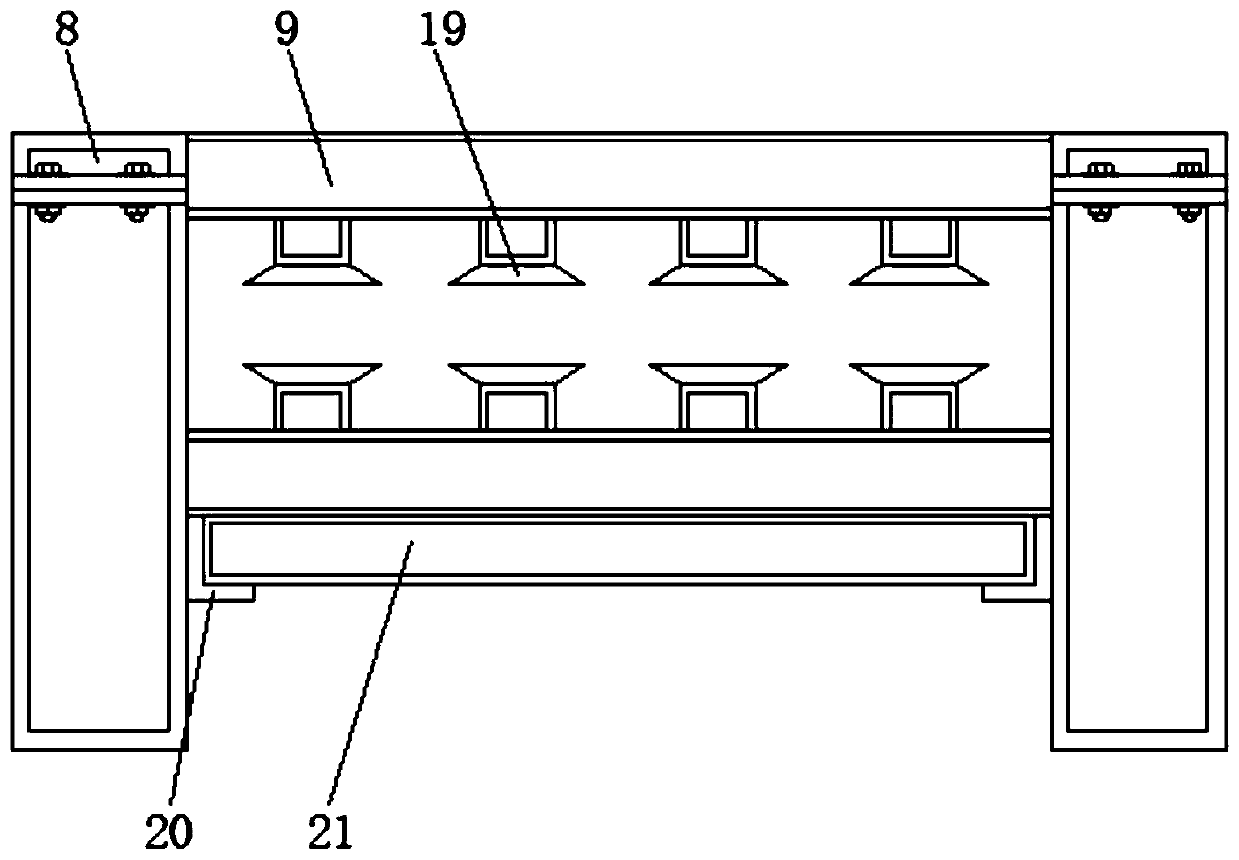

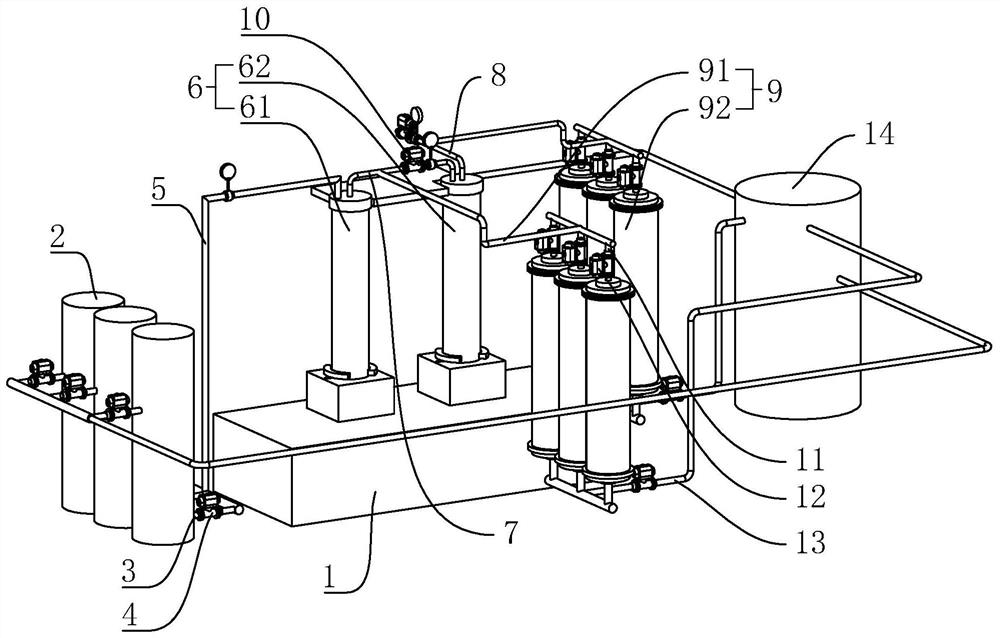

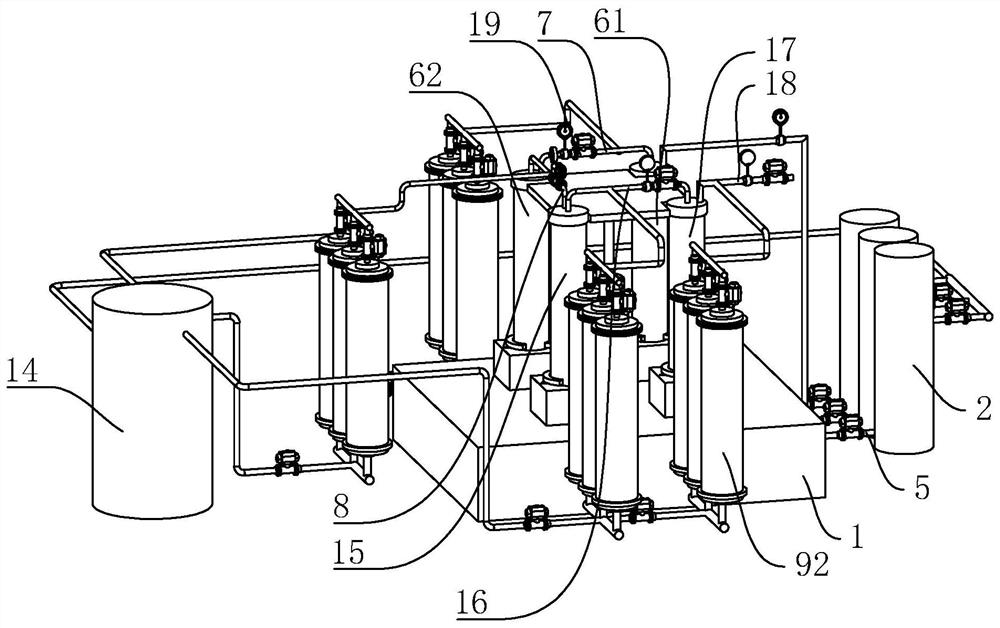

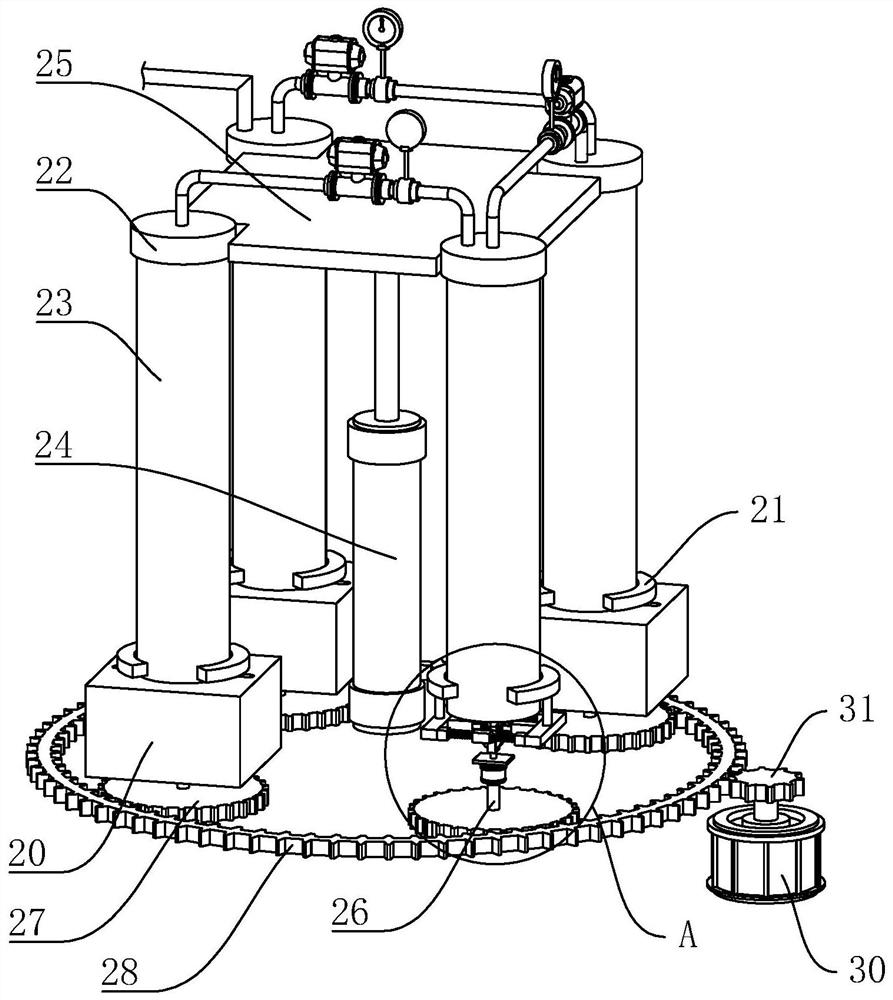

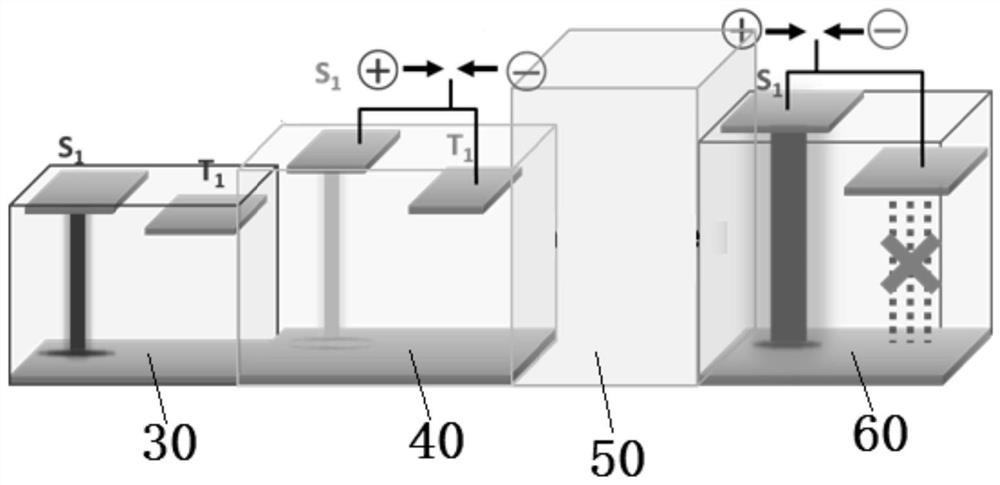

An energy-saving water purification tool testing machine

ActiveCN111257194BDetection of decontaminationCheck water filter functionSemi-permeable membranesPermeability/surface area analysisWater filterFiltration

The invention relates to an energy-saving water purification tool testing machine, which includes a support platform, a water supply tank is arranged on one side of the support platform, and a test tank group is arranged on the support platform, and the test tank group includes a first test filter tank and a second filter tank. The test filter tank, the first test filter tank and the second test filter tank are connected through the first purified water outlet pipe, the second test filter tank is connected with the second purified water outlet pipe, and the second purified water outlet pipe is connected with the purified water outlet pipe. The water testing component, the purified water testing component includes a first drainage pipe and a sampling pipe. When the present invention simulates the water filtration environment of the reverse osmosis water purification device, the first test filter tank and the second test filter tank can filter the test water, and the filtered and purified water enters the sampling tube, which can filter the water in the sampling tube. Purified water is detected and observed, so that the purification performance of the first test filter tank and the second test filter tank can be accurately detected, and the water filtration function of the filter membrane in working condition can be detected more accurately.

Owner:苏州市创联净化设备有限公司

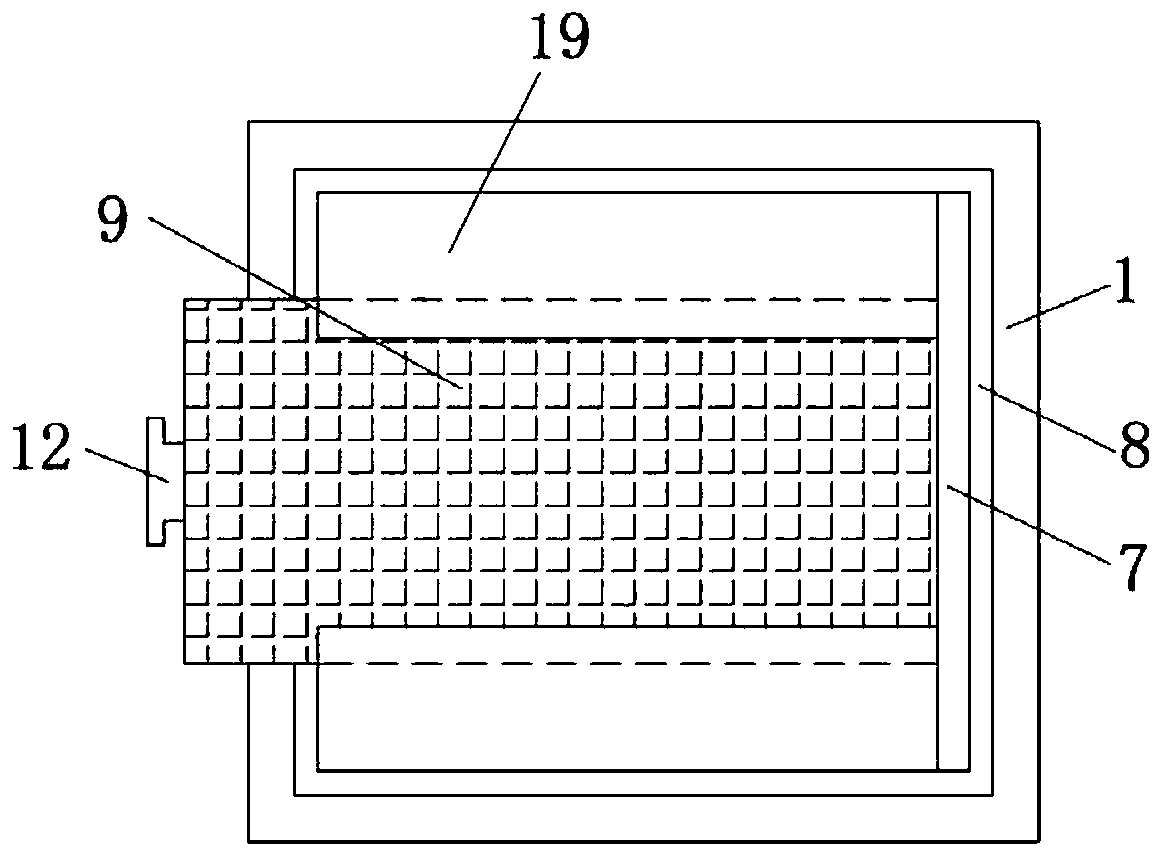

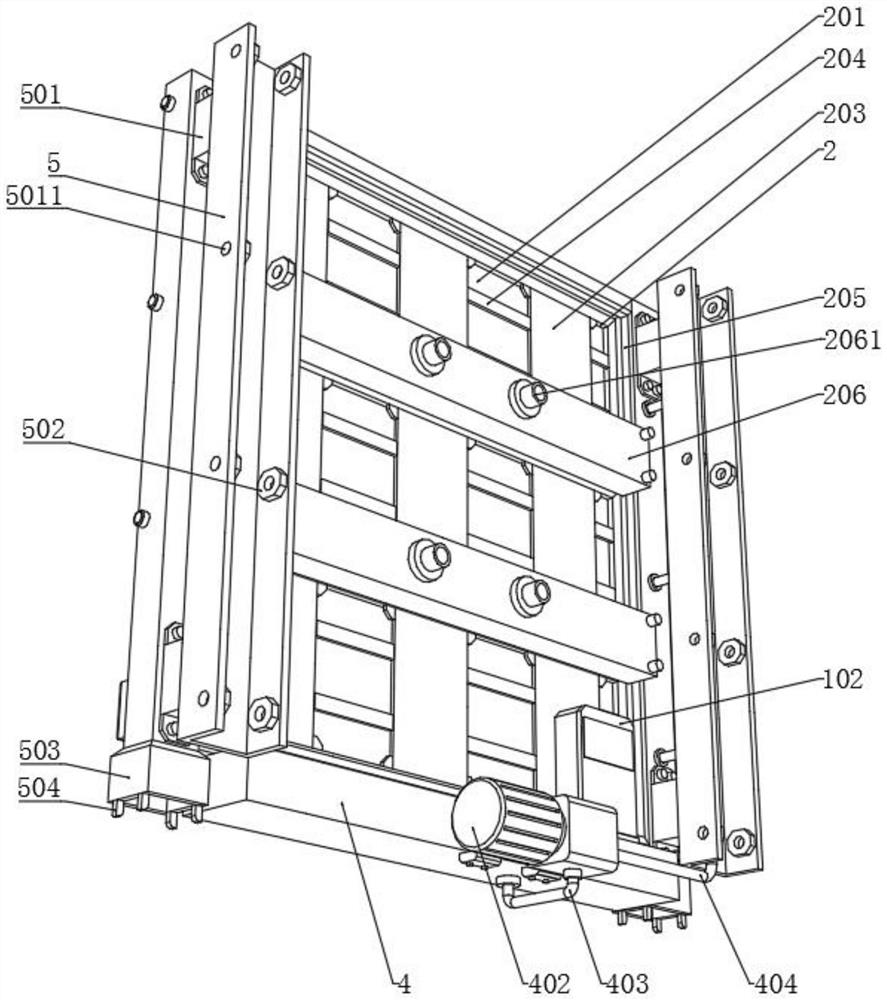

Green energy-saving building and construction method thereof

PendingCN114263372APlay a role in collectingEfficient receptionPhotovoltaic supportsGeneral water supply conservationLight energyArchitectural engineering

The invention discloses a green energy-saving building and a construction method thereof, the green energy-saving building comprises a building structure frame and inner stays, more than two inner stays are mounted in the building structure frame, more than two photovoltaic mounting frames are arranged on the inner side of the building structure frame, photovoltaic mounting plates are arranged in the photovoltaic mounting frames, and photovoltaic receiving plates are fixed on the front end surfaces of the photovoltaic mounting plates. The photovoltaic installation frames are arranged, the photovoltaic installation frames are evenly distributed and installed on the inner side of the building structure frame, the photovoltaic receiving plates are installed on the inner sides of the photovoltaic installation frames through the photovoltaic installation plates, the photovoltaic collection effect can be achieved, and the reinforcing supporting plates and the reinforcing ribs are installed on the other sides of the photovoltaic installation plates to improve the supporting force; the inner supporting strips are further installed on the inner side of the building structure frame, and the electricity storage box is installed through the inner supporting strips, so that the collected light energy can be converted and stored, the green and energy-saving effects are provided, and the external light energy is effectively received through the evenly-distributed photovoltaic receiving plates in the using process.

Owner:瑞宇建设有限公司

Fast self-cleaning dining table

The invention relates to the technical field of dining tables, in particular to a fast self-cleaning dining table comprising a table top. The bottom of the table top is in threaded connection with three supporting legs, the ends of the three supporting legs away from the table top are in threaded connection with three supports, the middle portion of the basic face of the table top is provided witha groove, a cylindrical baffle having a certain diameter is disposed at the position of a groove notch and located on the basic face of the table top, a motor is fixedly disposed in the groove and fixedly connected with a wire, the end of the wire away from the motor is wirelessly connected with a plug, a driving rod is fixedly disposed on the motor and clamps a first brush sleeve, the inner wallof the first brush sleeve is provided with a first spring steel piece, the first spring steel piece is matched with the first brush sleeve to clamp a first cleaning rubber strip, the end of the firstbrush sleeve away from a driving motor is provided with a through hole, a clamping pin is fixedly disposed in the through hole to clamp a second brush sleeve, and the inner wall of the second brush sleeve is provided with a second spring steel piece. The fast self-cleaning dining table achieves automatic cleaning of the table top, and the table top can be cleaned quickly and more efficiently.

Owner:安徽新店软件开发有限公司

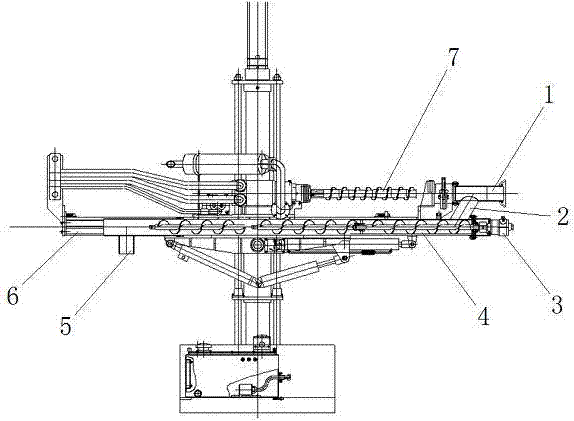

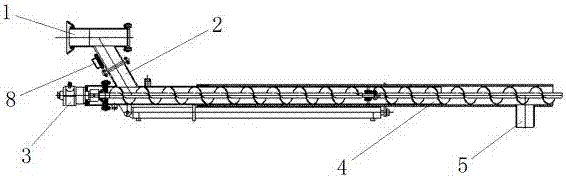

Integrated slag discharge device for drill carriage

InactiveCN107339075ASolve problems that require manual cleanupReduce labor intensityConstructionsDrilling with mechanical conveyingSlagUltimate tensile strength

The invention provides an integrated slag discharge device for drilling rigs, the pulverized coal collecting cylinder of the device can collect the pulverized coal produced during construction; the connecting cylinder transfers the pulverized coal to the screw conveyor; the air motor Provide power for the screw conveyor to push the pulverized coal to the tail end of the screw conveyor; it is discharged from the pulverized coal outlet at the tail end of the screw conveyor. When in use, the device can be fixedly connected to the drilling rig, and one end of the pulverized coal collection tube is attached to the coal wall to be drilled. Drilling action is performed, and the powder produced can be discharged in a centralized manner through the above working principle. The present invention has simple overall structure, convenient transformation, good stability and high reliability. The application of the present invention can effectively solve the problem that the coal dust produced in the large-diameter pressure relief drilling needs to be manually cleaned, thereby reducing the labor intensity of workers and improving work efficiency.

Owner:淄博中安工程技术有限责任公司

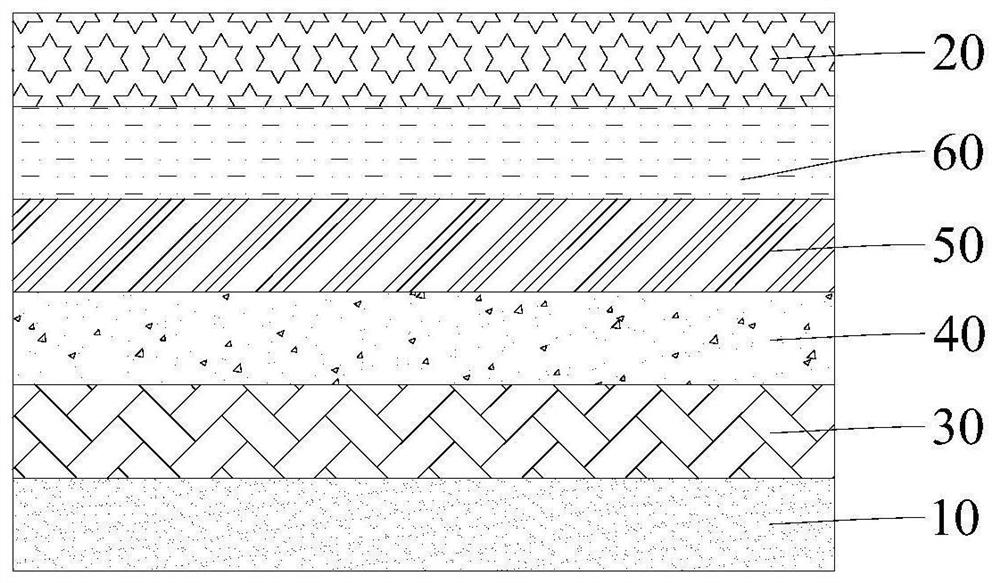

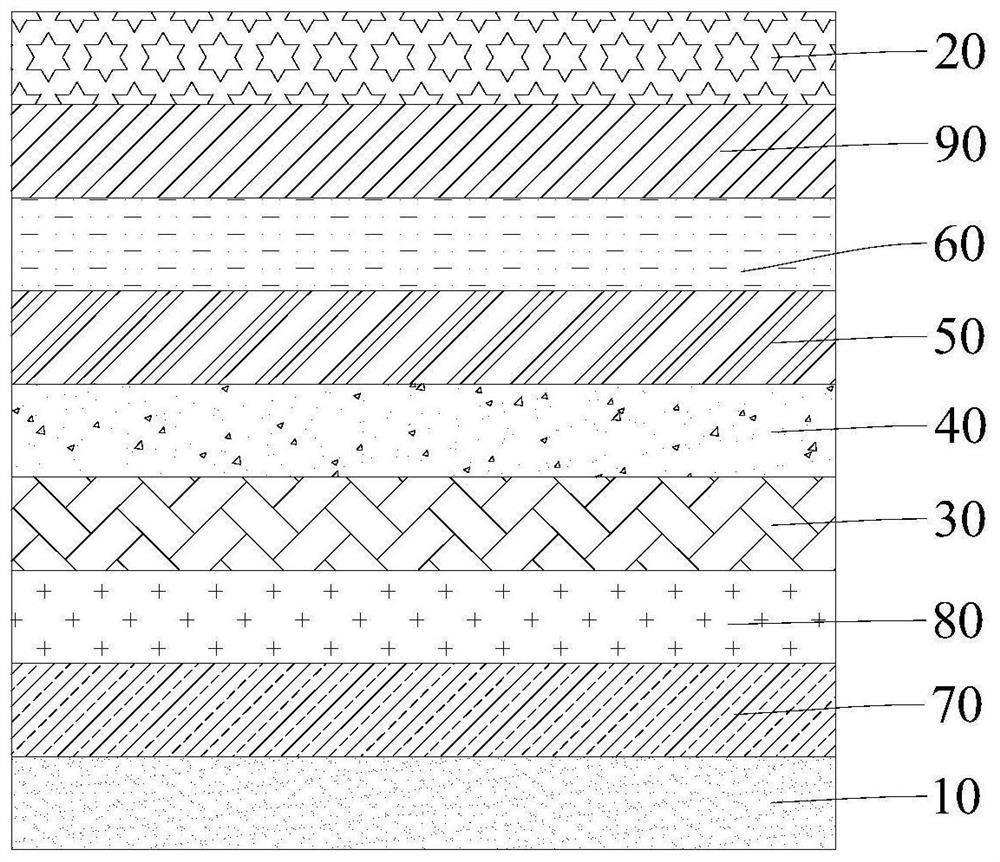

WOLED device, manufacturing method thereof and WOLED display device

PendingCN111785851AReduce manufacturing costExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceRed fluorescence

The invention provides a WOLED device, a manufacturing method thereof and a WOLED display device. The WOLED device comprises a cathode and an anode which are arranged oppositely; a red fluorescent light-emitting layer arranged at the side, close to the cathode, of the anode; a green fluorescent light-emitting layer arranged on the surface, close to the cathode, of the red fluorescent light-emitting layer; a spacer layer arranged on the surface, close to the cathode, of the green fluorescent light-emitting layer and comprising a first main body material and a first thermal delay fluorescent material; and blue fluorescent light-emitting layer arranged on the surface, close to the cathode, of the spacer layer. The first main body material and the first thermal delay fluorescent material in the spacer layer of the WOLED device have relatively high triplet state and singlet state, in the TADF material, the energy difference between S1 and T1 energy states is very small, excitons in the T1 state can jump to S1 in an intersystem manner, and then transition from the S1 state to a ground state is carried out to carry out composite luminescence. The TADF plays a role in exciton collection, so that T1 excitons which originally cannot emit light in a transition manner are converted into S1 excitons, and 100% of S1 excitons are formed; the WOLED device is in a full-fluorescence light emitting mode and has a longer service life.

Owner:BOE TECH GRP CO LTD

Printing packaging film waste treatment equipment and method

PendingCN113183360AReduce wasteReduce processing costsPlastic recyclingDirt cleaningWaste processingStructural engineering

The invention provides printing packaging film waste treatment equipment with novel structural design and a treatment method of the printing packaging film waste treatment equipment. The printing packaging film waste treatment equipment comprises a bottom box, wherein a workbench is arranged on the outer wall of the top of the bottom box through bolts, four supporting frames are arranged on the outer wall of the top of the workbench through screws, two clamping rollers are rotationally connected between the outer walls of the opposite sides of the three supporting frames through rotating shafts, a fixing frame is arranged on the outer wall of the top of the workbench through bolts, and an upper mounting plate and a lower mounting plate are arranged between the inner walls of the opposite sides of the fixing frame through bolts. According to the printing packaging film waste treatment equipment, a spray head, a friction roller and a scraper are arranged, the two surfaces of a packaging film are sprayed through the spray head, then the outer wall of the top and the outer wall of the bottom of the packaging film are cleaned through the friction roller and the scraper respectively, so that residual printing marks and residues on the packaging film can be removed, then the packaging film can be reused, waste of resources is relieved, and the processing cost can be reduced.

Owner:滁州远达彩印包装有限公司

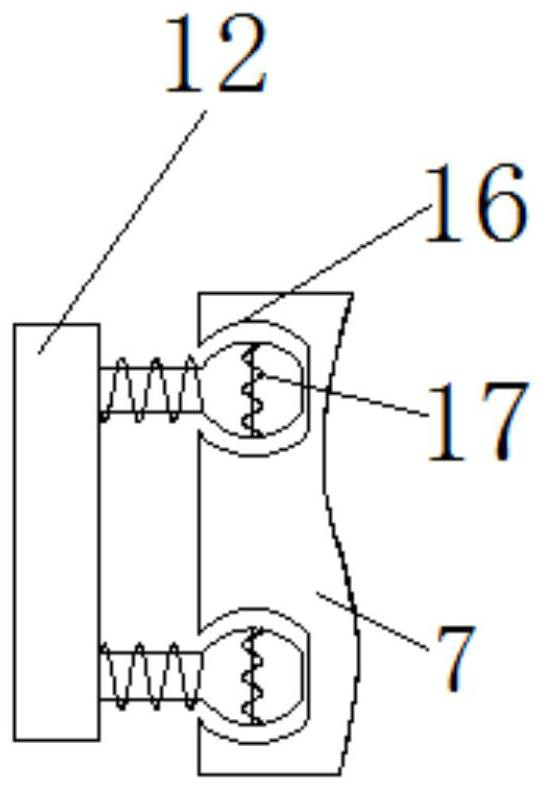

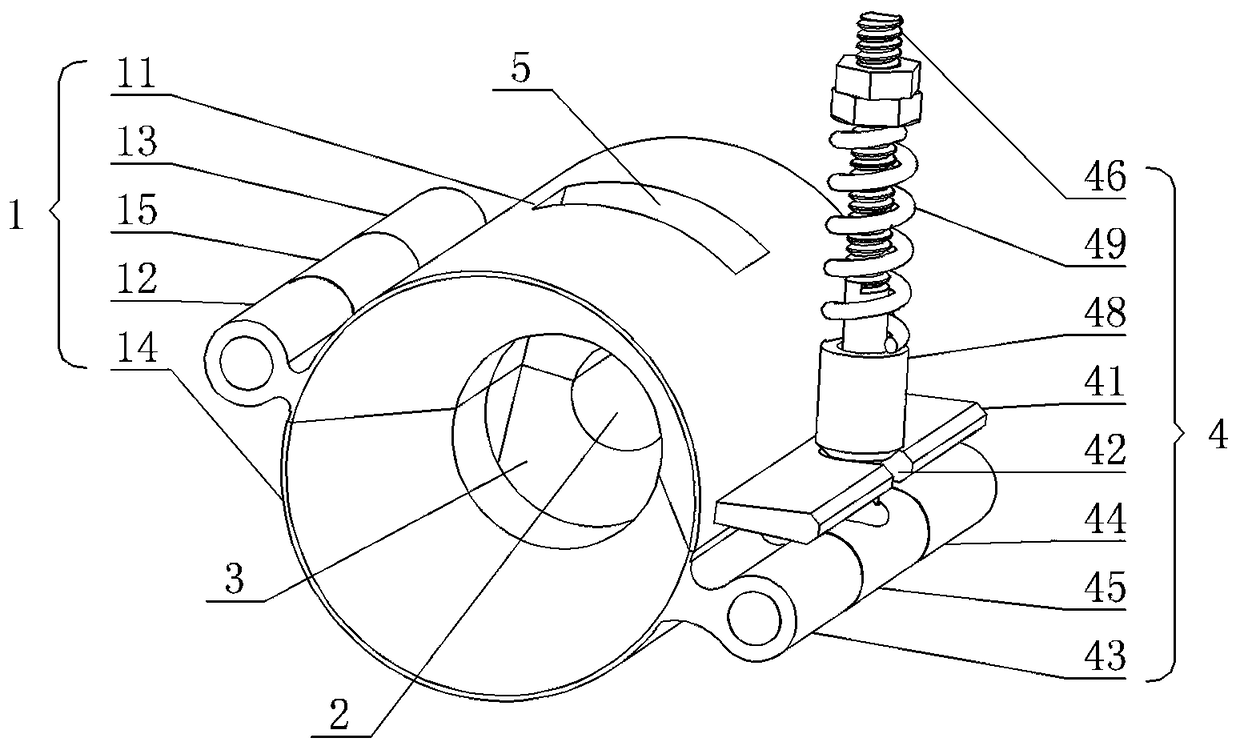

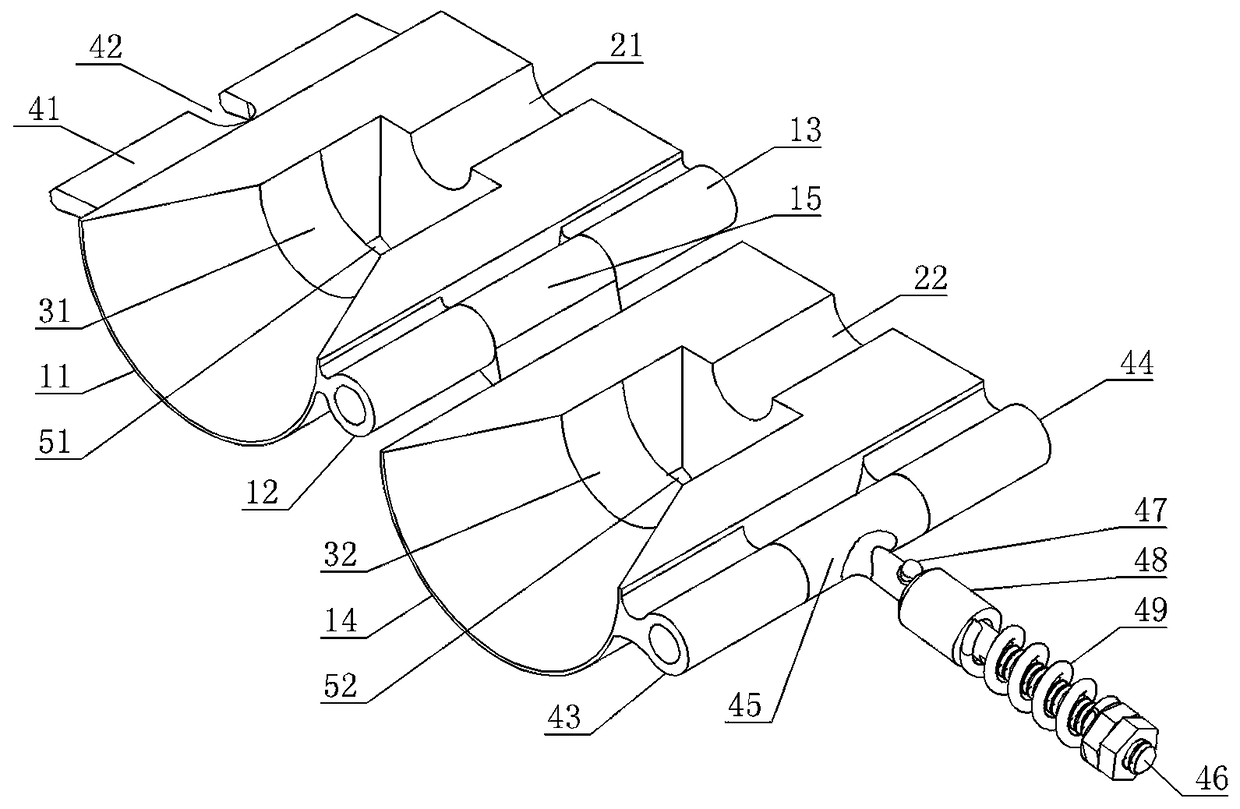

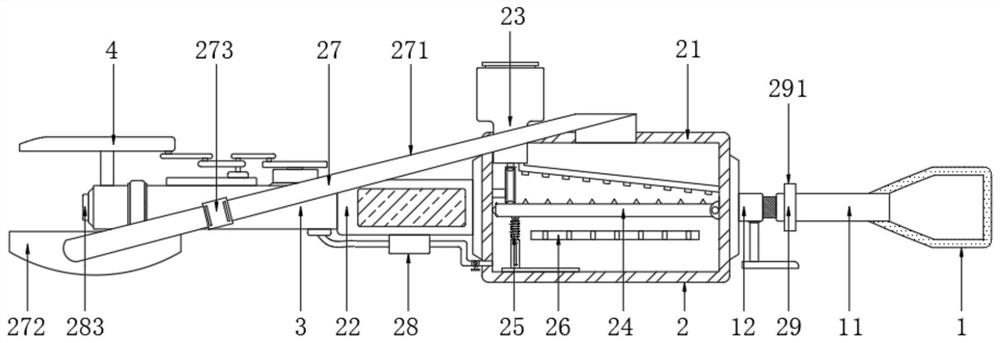

Fixture for repairing transmission conductors

PendingCN108173166AImprove operational efficiencyImprove job qualityApparatus for overhead lines/cablesElectric powerEngineering

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD

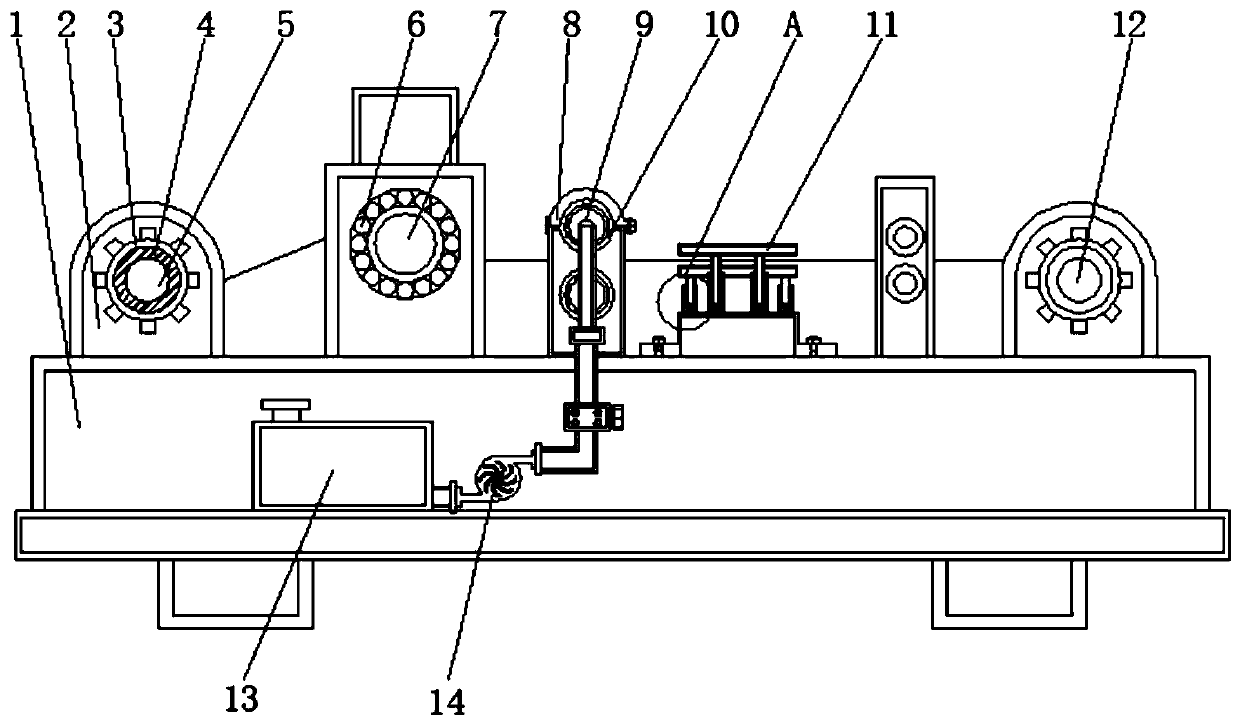

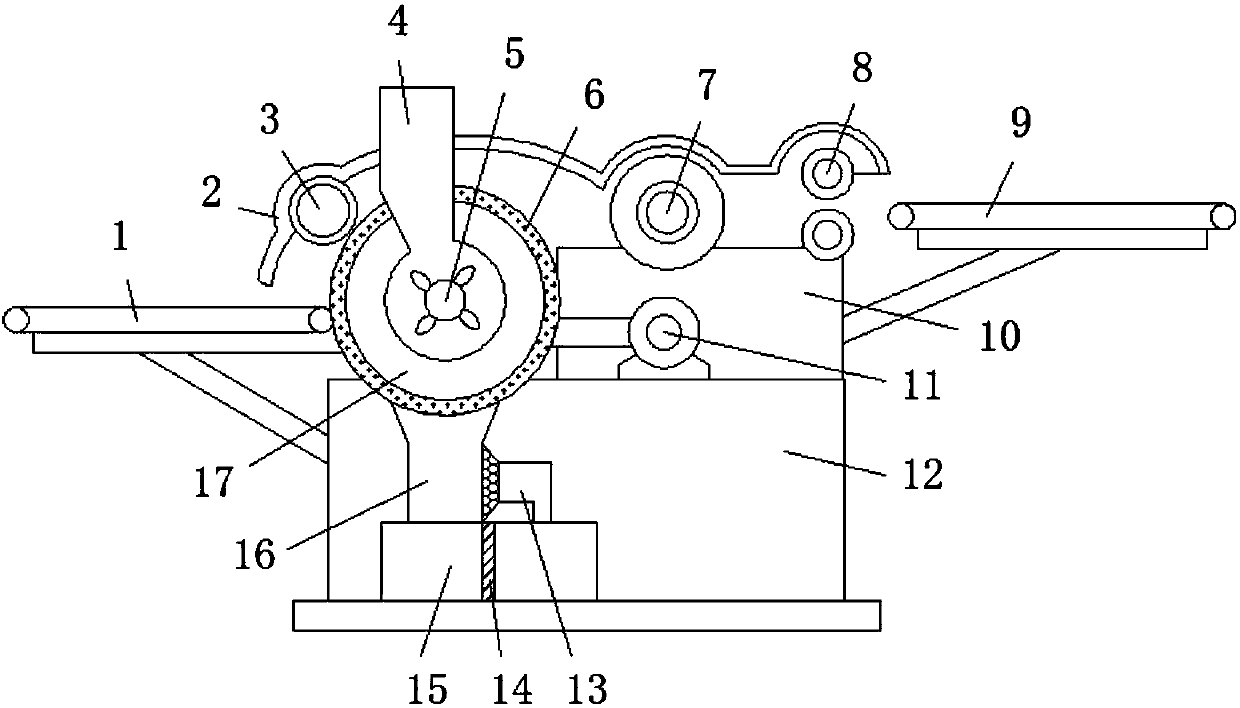

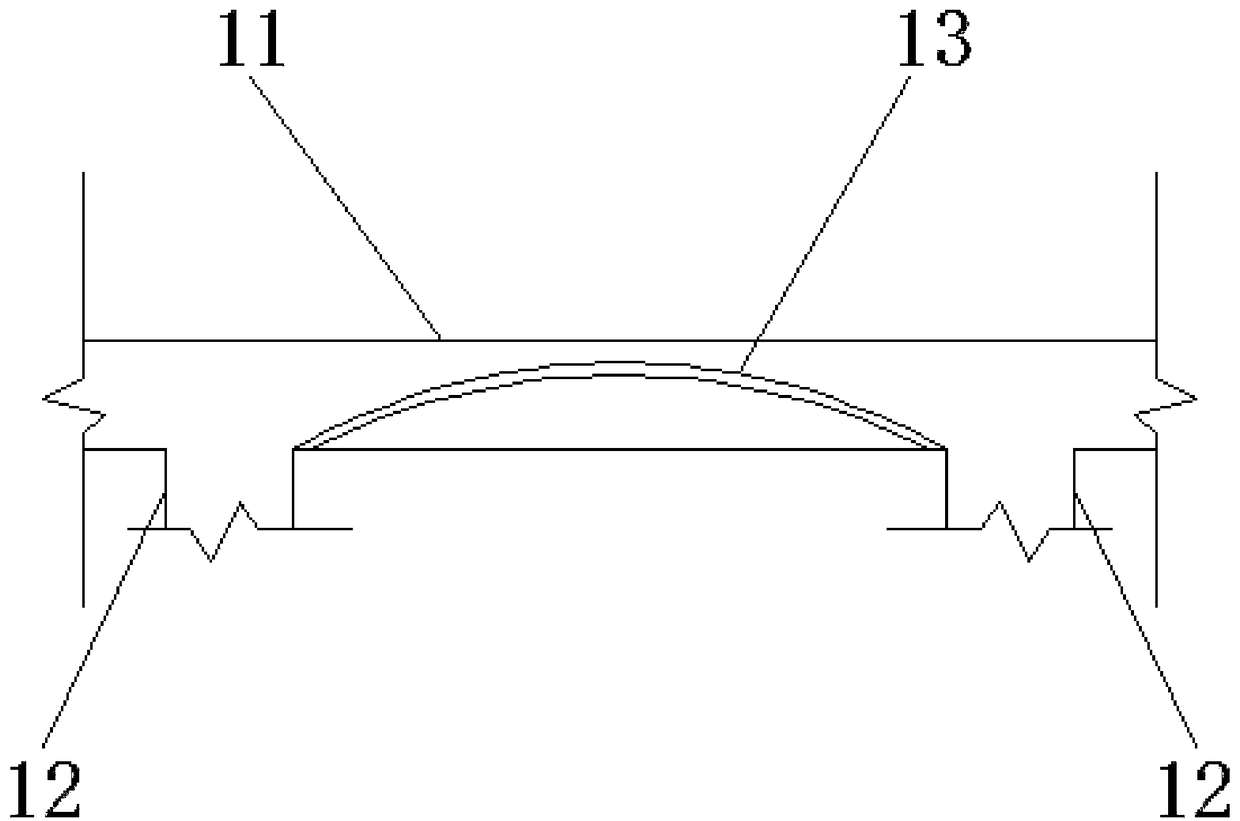

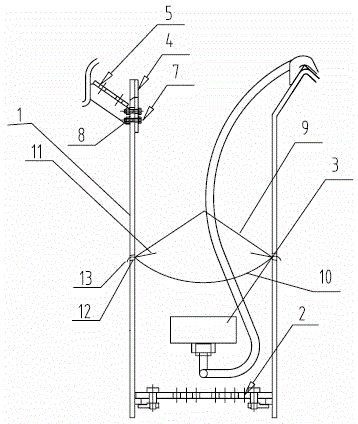

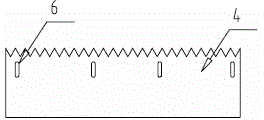

Spinning machine bath

ActiveCN104451913AAdequate responseMeet production requirementsArtificial thread manufacturing machinesWet spinning methodsPulp and paper industrySpin speed

The invention relates to the technical field of spinning, in particular to a spinning machine bath. The spinning machine bath comprises a bath body, a perforated plate is arranged at the bottom of the bath body, a spinning jet is arranged inside the bath body, a sawtooth plate is arranged on the inner wall of the bath body, stripped holes are arranged in the sawtooth plate, an obliquely-arranged filter-hole plate is arranged on the outer wall of the bath body, a purification filter unit is arranged in the middle of the bath body and comprises an upper filter screen and a lower filter screen, the upper filter screen is upwardly conical, the lower filter screen is downwardly arced, a filter partition is arranged between the upper filter screen and the lower filter screen, and a notch is formed in the side face, corresponding to the end face of the filter partition, of the bath body. Corresponding bath depth is acquired by reasonably adjusting sawtooth plate according to production yield and spinning speed, impurities in acid bath are reduced, and production and process requirements are met.

Owner:CHENGDU GRACE FIBER

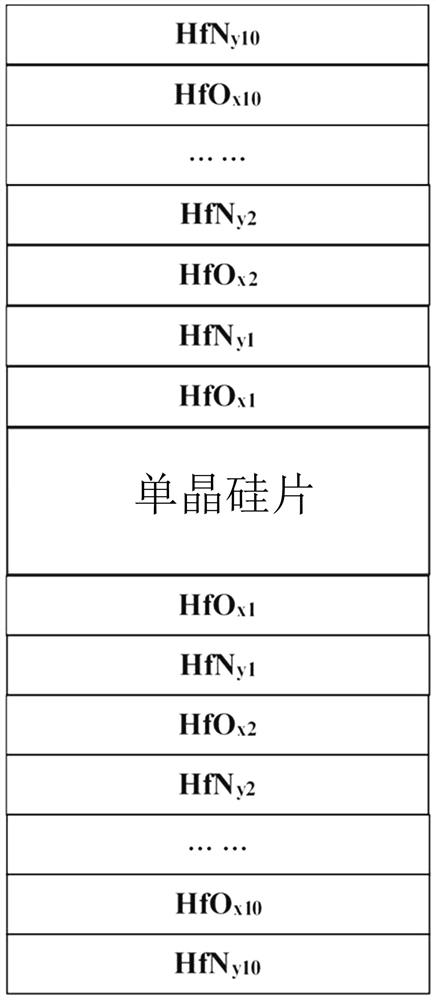

Monocrystalline silicon passivation contact structure and preparation method thereof

ActiveCN112349792AOvercoming the shortcomings of passivated contact technologyHave a passivating effectFinal product manufactureSemiconductor/solid-state device manufacturingThin membraneMaterials science

The invention discloses a monocrystalline silicon passivation contact structure and a preparation method thereof. The monocrystalline silicon passivation contact structure comprises a monocrystallinesilicon wafer, n layers of HfOx and HfNy are alternately deposited on the front and back surfaces of the monocrystalline silicon wafer, and n is equal to 5-20. The thickness of each layer of HfOx or HfNy is 3nm, wherein the layer closest to the monocrystalline silicon wafer is the first layer, namely HfOx1 and HfNy1, and the layer farthest from the monocrystalline silicon wafer is the n-th layer,namely HfOxn and HfNyn; 2.0 > x1 > x2 >... > x9 > xn > 1.0, and 1.33 > y1 > y2 >... > y9 > yn > 0.67. An HfOx / HfNy multilayer film with gradually changed components is deposited by adopting a reactivemagnetron sputtering method, full-surface passivation and selective contact of monocrystalline silicon are realized, the defects of a tunneling oxide layer passivation contact technology can be overcome, and the monocrystalline silicon passivation contact structure has the advantages of no use of dangerous gas (silane, phosphorane or borane), high deposition speed, low cost and the like.

Owner:ZHEJIANG NORMAL UNIVERSITY

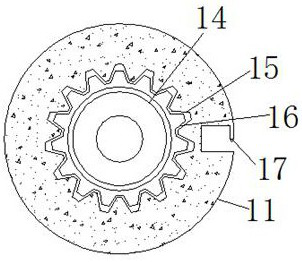

Novel multifunctional lock nut machining equipment and machining method thereof

InactiveCN111843491ARealize the integration of punching and tappingImprove drilling efficiencyOther manufacturing equipments/toolsPunchingStructural engineering

The invention belongs to the technical field of part machining, and particularly relates to novel multifunctional lock nut machining equipment and a machining method thereof. The novel multifunctionallock nut machining equipment comprises a machining table, wherein a sliding platform is slidably connected into a material collecting cavity, and a lifting table is arranged on the upper end face ofthe sliding platform; a mounting frame is fixedly connected to the upper end face of the machining table, and machining components comprise punching mechanisms and tapping mechanisms; and an extendingplate is fixedly connected to the bottom faces of rotating boxes, a plurality of rotating columns corresponding to workpiece grooves are rotationally connected to the bottom face of the extending plate, and working pieces are detachably connected to the bottom faces of the rotating columns. The rotating columns drive the working pieces arranged at the bottoms to rotate workpieces, at the moment,the lifting table ascends upwards, then the machined nuts can be subjected to the machining effect of drill bits, and secondary machining is carried out through the tapping mechanisms, so that punching and tapping integration of the plurality of nuts is achieved, and meanwhile, machining of the plurality of nuts in two procedures can be completed through two driving pieces.

Owner:HAIYAN HATEHUI MACHINERY HARDWARE

Handheld tree pruning device capable of killing stabbing moths for garden plants

InactiveCN112715190AReduced susceptibility to gnat moths that linger on foliagePlay a role in collectingCuttersCutting implementsGarden plantsHand held

The invention discloses a handheld tree pruning device capable of killing stabbing moths in the technical field of tree pruning. The handheld tree pruning device capable of killing the stabbing moths comprises a handheld assembly, a treatment assembly and an electric scissor body, wherein the handheld assembly comprises a grip, and the left end of the grip is sleeved with a connecting sleeve rod in a threaded mode; the treatment assembly comprises a treatment shell fixed to the left end of the connecting sleeve rod, and a power shell assembly is fixedly arranged on the left side of the treatment shell; the electric scissor body is fixed to the left side of the top of a connecting column. According to the handheld tree pruning device capable of killing the stabbing moths, the treatment assembly is arranged, sheared branches and leaves enter a collecting hopper and enter the treatment shell through an exhaust fan, the branches and leaves entering the treatment shell are located on a filter plate assembly through the arrangement of the power shell assembly, the filter plate assembly and a liquid outlet piece, and liquid is sprayed to the branches and leaves through the liquid outlet piece to kill the stabbing moths remaining on the branches and leaves, so that the effect of collecting and killing the stabbing moths is achieved; on one hand, the collecting burden after manual cutting is reduced, on the other hand, the situation that a user is easily affected by the stabbing moths remaining on the branches and leaves in the collecting process is also reduced.

Owner:林彩平

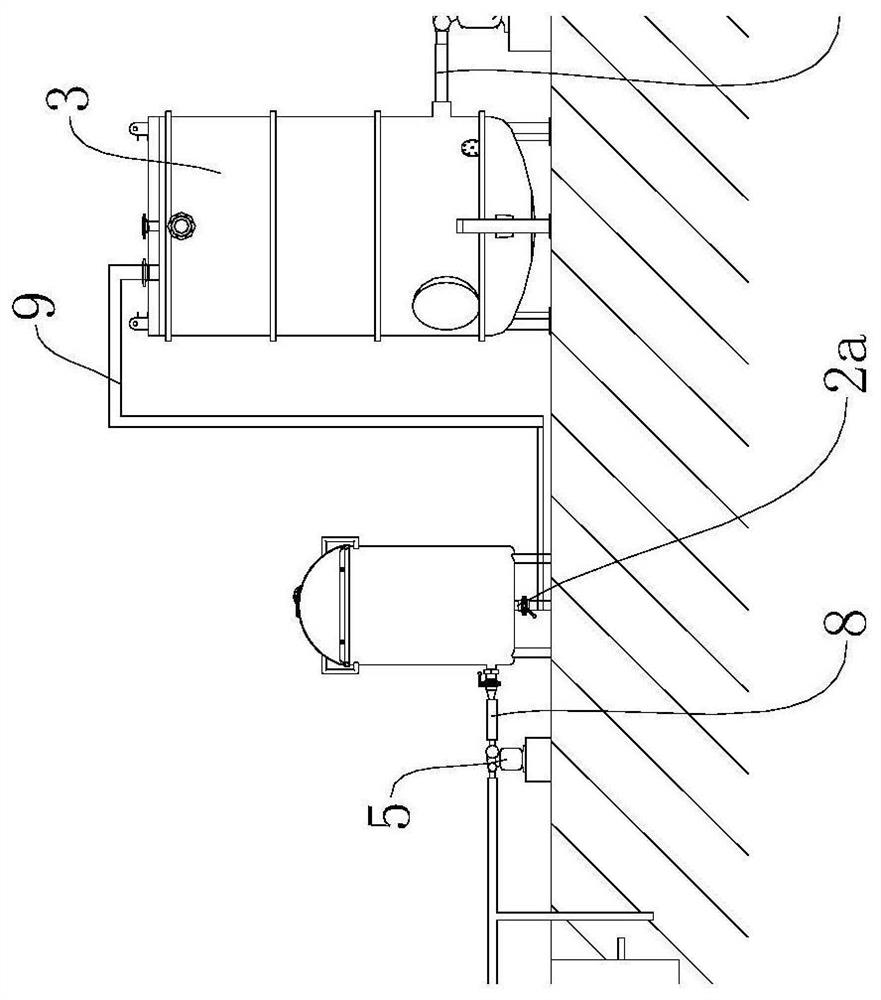

Device and method for collecting, treating and saving building water resources

InactiveCN111779008AImprove waterlogging abilityPlay a role in collectingFoundation engineeringWater useWater storage

The invention relates to the field of building construction, in particular to a device and method for collecting, treating and saving building water resources. The device comprises a foundation pit body, a filter tank, a main water storage tank and an auxiliary water storage tank, wherein at least one circle of water collecting ditches is arranged at the edge of the foundation pit body, the watercollecting ditches are arranged in a hollow-square shape, and the plurality of circles of water collecting ditches are coaxially arranged at the outer edge of the foundation pit body; the filter tankis arranged on the side of the foundation pit body, and a first water pump is arranged between the filter tank and the foundation pit body; the first water pump pumps out water accumulated in the foundation pit body, and sand and gravel are filtered at the filter tank; the main water storage tank communicates with the filter tank for water storage and backfilling and water injection of the foundation pit body; and the auxiliary water storage tank communicates with the main water storage tank to provide water for construction facilities and municipal fire fighting systems. Rainwater is collected by the water collecting ditches, and the collected rainwater is filtered and then is recharged to surrounding strata to maintain balance of water system supply, so that the purpose of water recycling is achieved.

Owner:杨华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com