Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Overcome the disadvantage of low strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Martensitic stainless steel seamless steel tube for oil and gas exploitation and manufacturing method thereof

ActiveCN104988403AHigh strengthOvercome the disadvantage of low strengthTemperingMartensitic stainless steel

The invention discloses a martensitic stainless steel seamless steel tube for oil and gas exploitation and a manufacturing method thereof. The seamless steel tube comprises, by weight, 0.20% to 0.60% of C, 0% to 1.00% of Si, 0% to 1.00% of Mn, 12.0% to 14.0% of Cr, 0% to 0.01% of S, 0% to 0.02% of P, 0% to 0.60% of Ni and the balance iron and unavoidable impurities. The manufacturing method includes the main steps that molten steel is smelted firstly according to chemical components, a billet is formed by the molten steel in a pouring mode and forged to be a solid circular tube blank, then the circular tube blank is extruded to be a seamless steel tube in the required specification, and the high-strength, high-tenacity and corrosion-resistant martensitic stainless steel seamless steel tube meeting the use requirement can be obtained after the tempering process and the follow-up finishing process.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

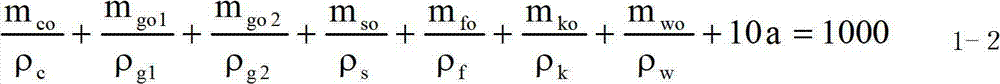

Method for preparing high-strength semi-regenerative coarse aggregate concretes

The invention discloses a method for preparing high-strength semi-regenerative coarse aggregate concretes, and belongs to the technical field of regenerative coarse aggregate concretes. The preparation method comprises the step of preparing the high-performance semi-regenerative coarse aggregate concretes with good working performance, high early strength and good development in long-term strength by regulating the mixing amount of additives, mineral powder and coal ash in reference to the using amount of rubber materials of the common concretes.

Owner:BEIJING UNIV OF TECH

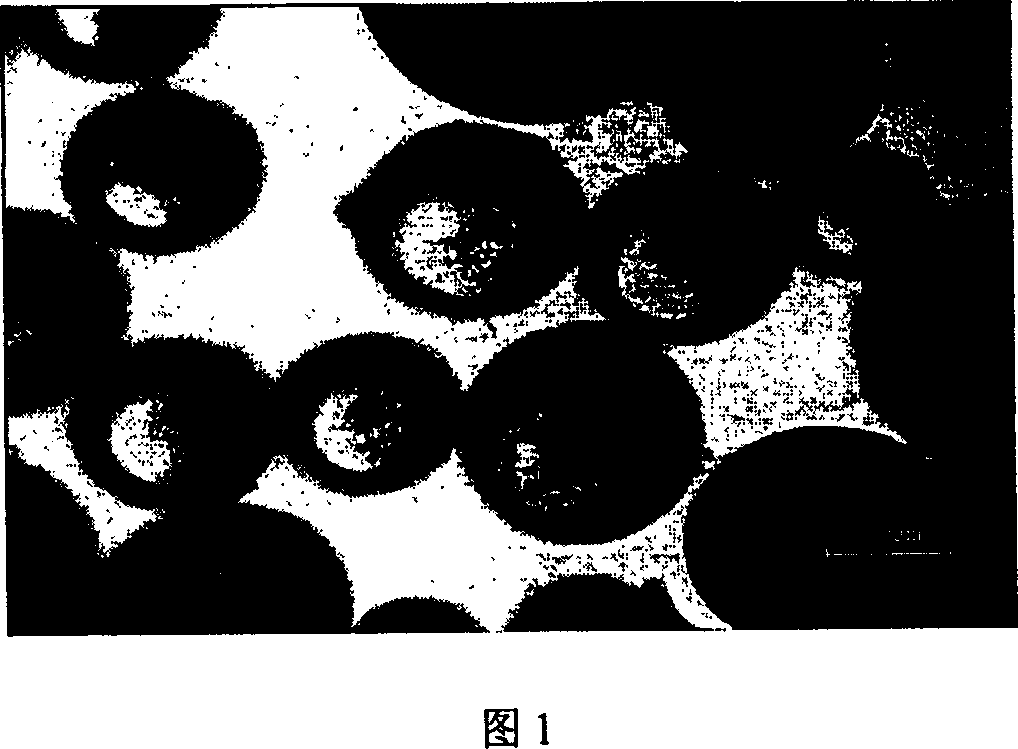

Prepn process of microcapsule containing Hansa yellow 100 electrophoresis liquid

InactiveCN1772364AOvercome the disadvantage of low strengthSimple processMicroballoon preparationNon-linear opticsEpoxyElectrophoresis

The present invention discloses the preparation process of microcapsule containing Hansa yellow 10G electrophoresis liquid, and belongs to the field of the preparation technology of electronic ink microcapsule. The preparation process includes: adding Hansa yellow 10G into solvent including toluene to compound dispersant solution and adding surfactant including Span-80 and grinding to prepare suspended electrophoresis liquid; compounding water solution of gelatin and Arabic gum separately; mixing the suspended electrophoresis liquid and epoxy resin to form homogeneous dispersant liquid, dispersing the dispersant liquid into water solution of Arabic gum, adding water solution of gelatin, dropping acid to regulating pH and to take re-condensation reaction, cooling, adding formaldehyde or glutaraldehyde for cross-linking solidification, adding CMCNa, dropping NaOH to regulate pH, and heating to react to obtain the microcapsule containing Hansa yellow 10G electrophoresis liquid.

Owner:TIANJIN UNIV

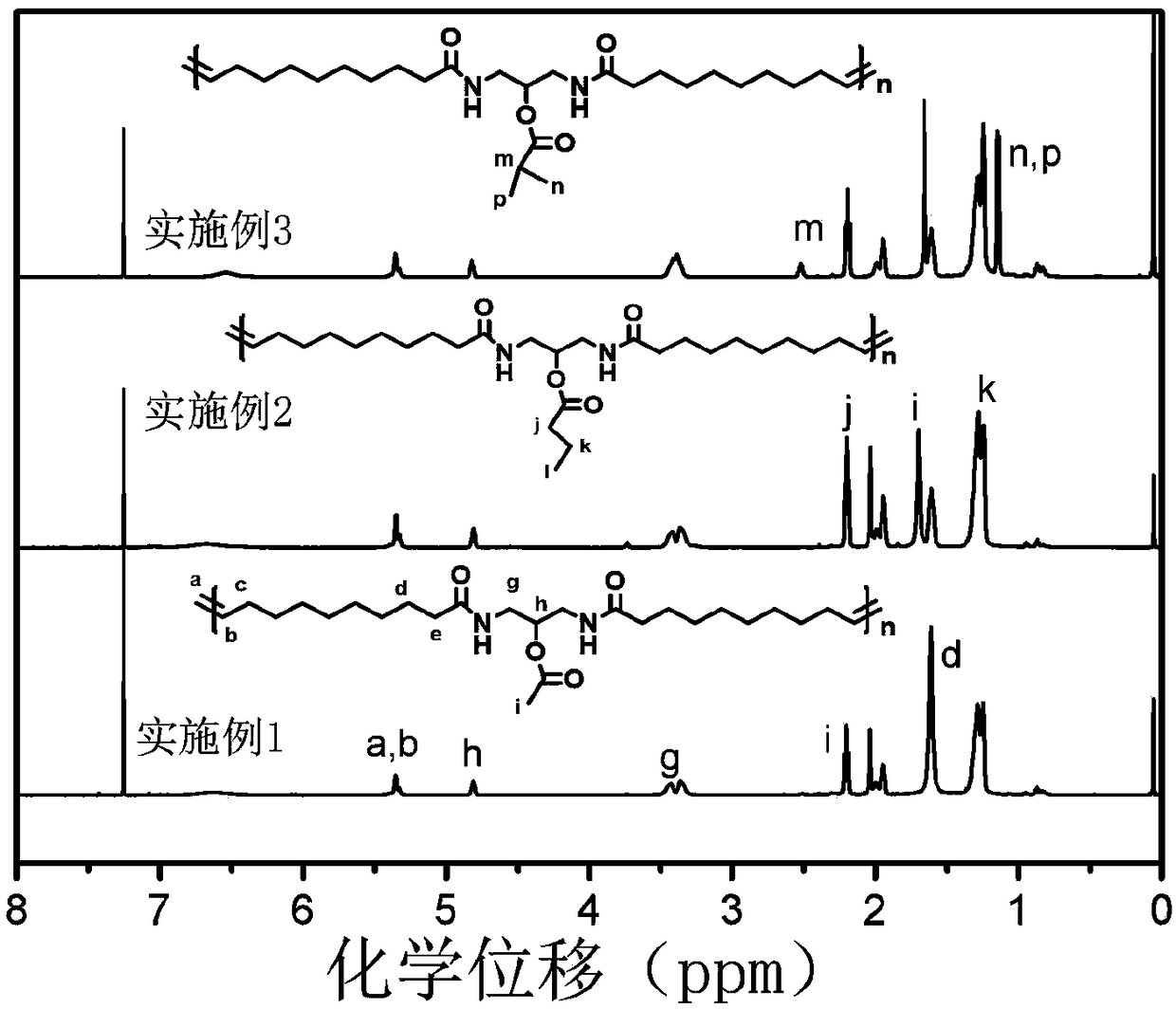

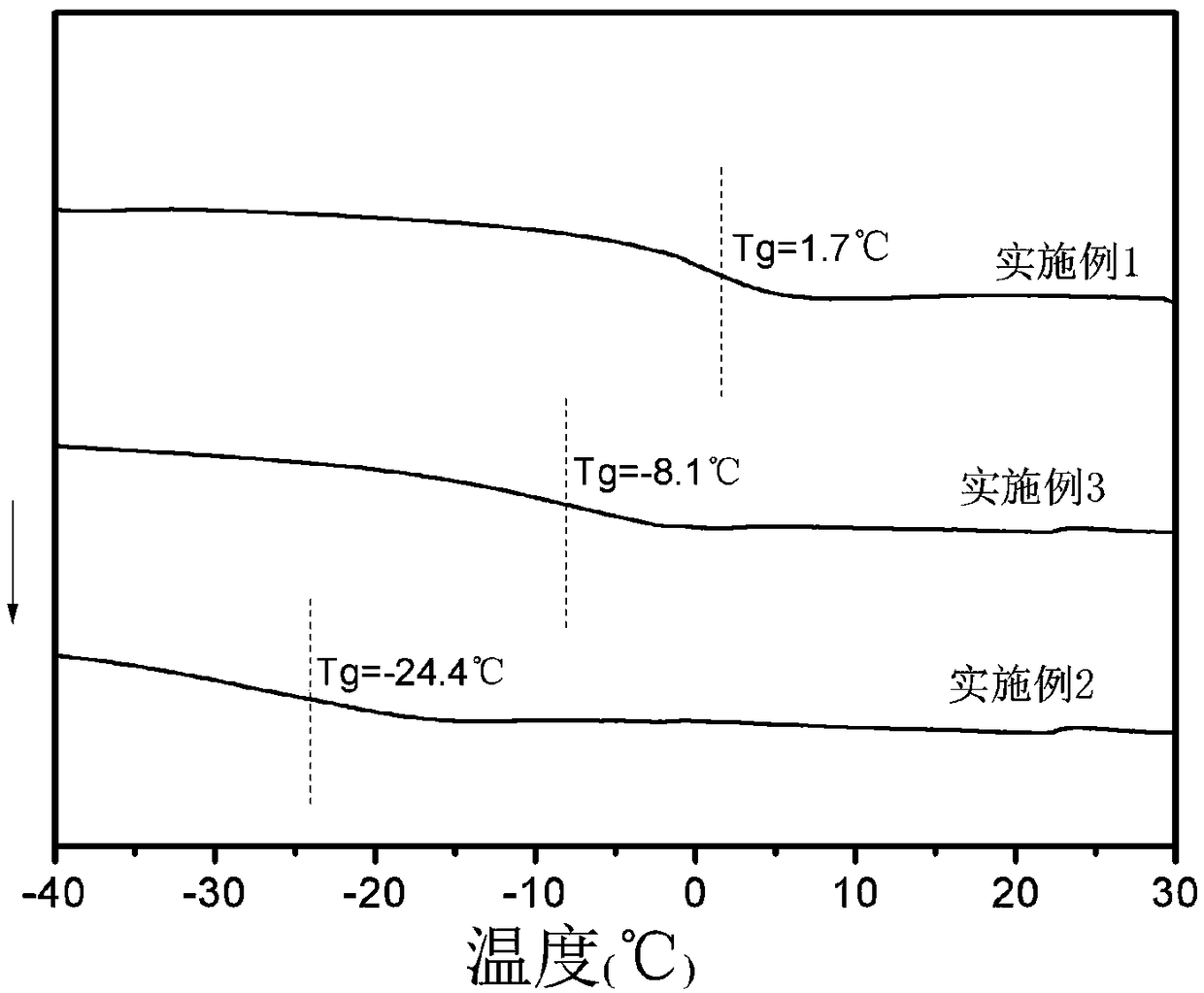

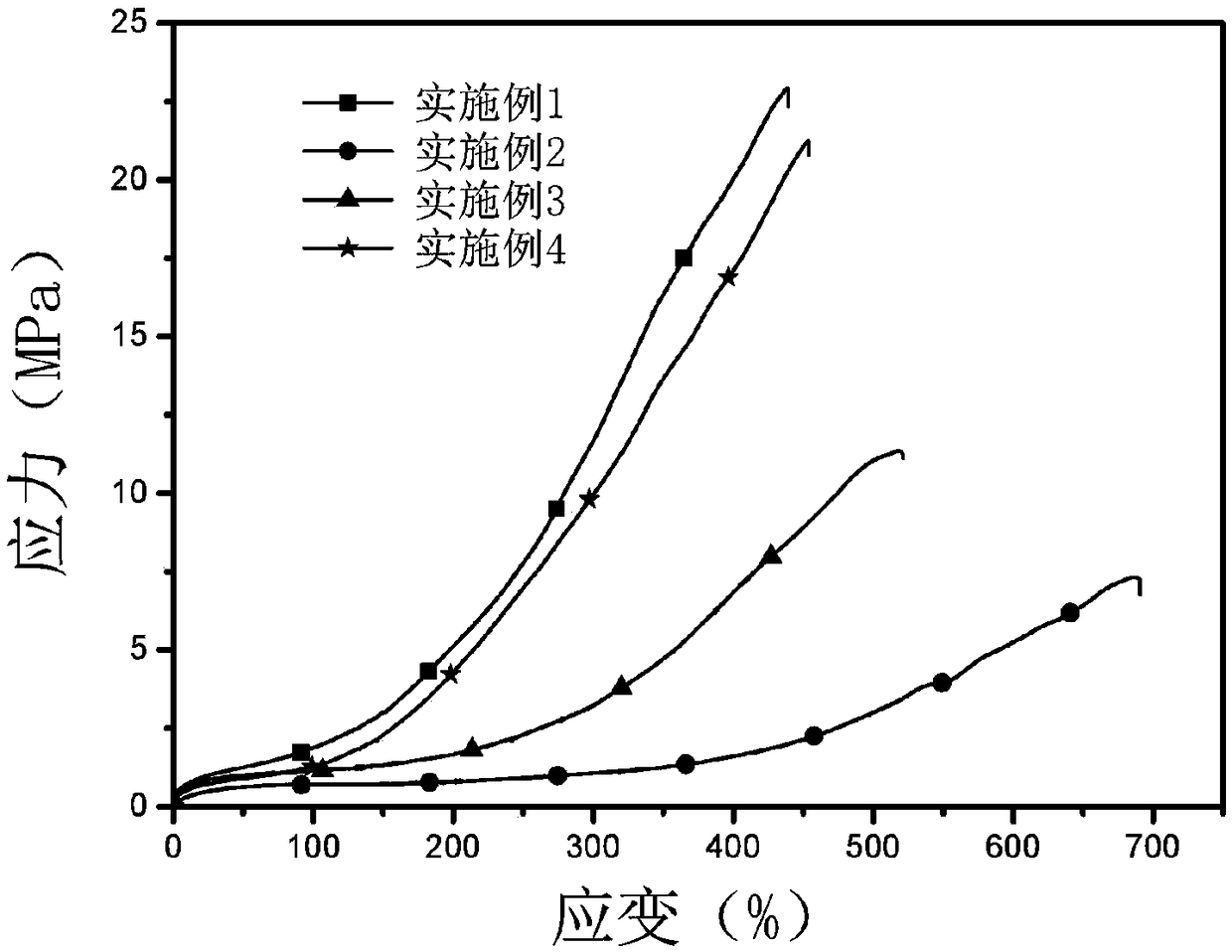

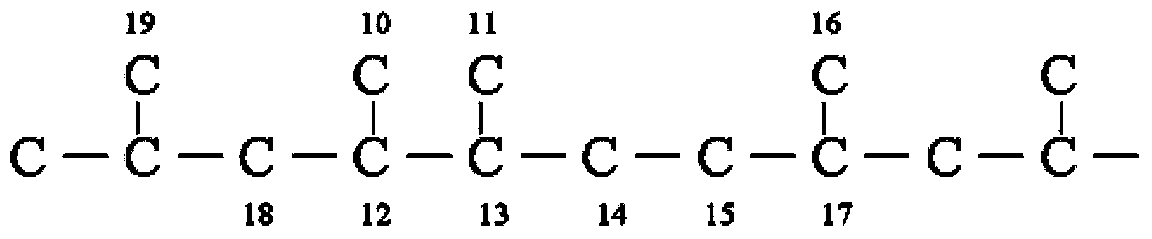

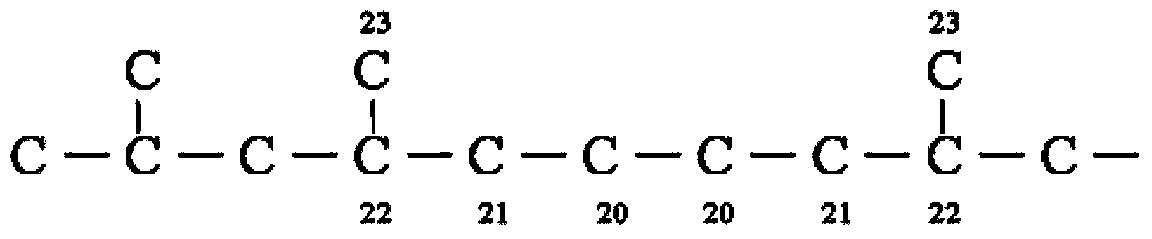

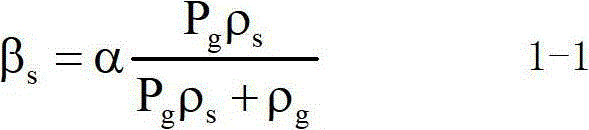

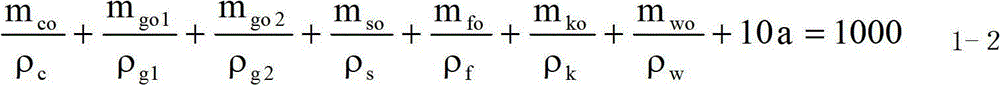

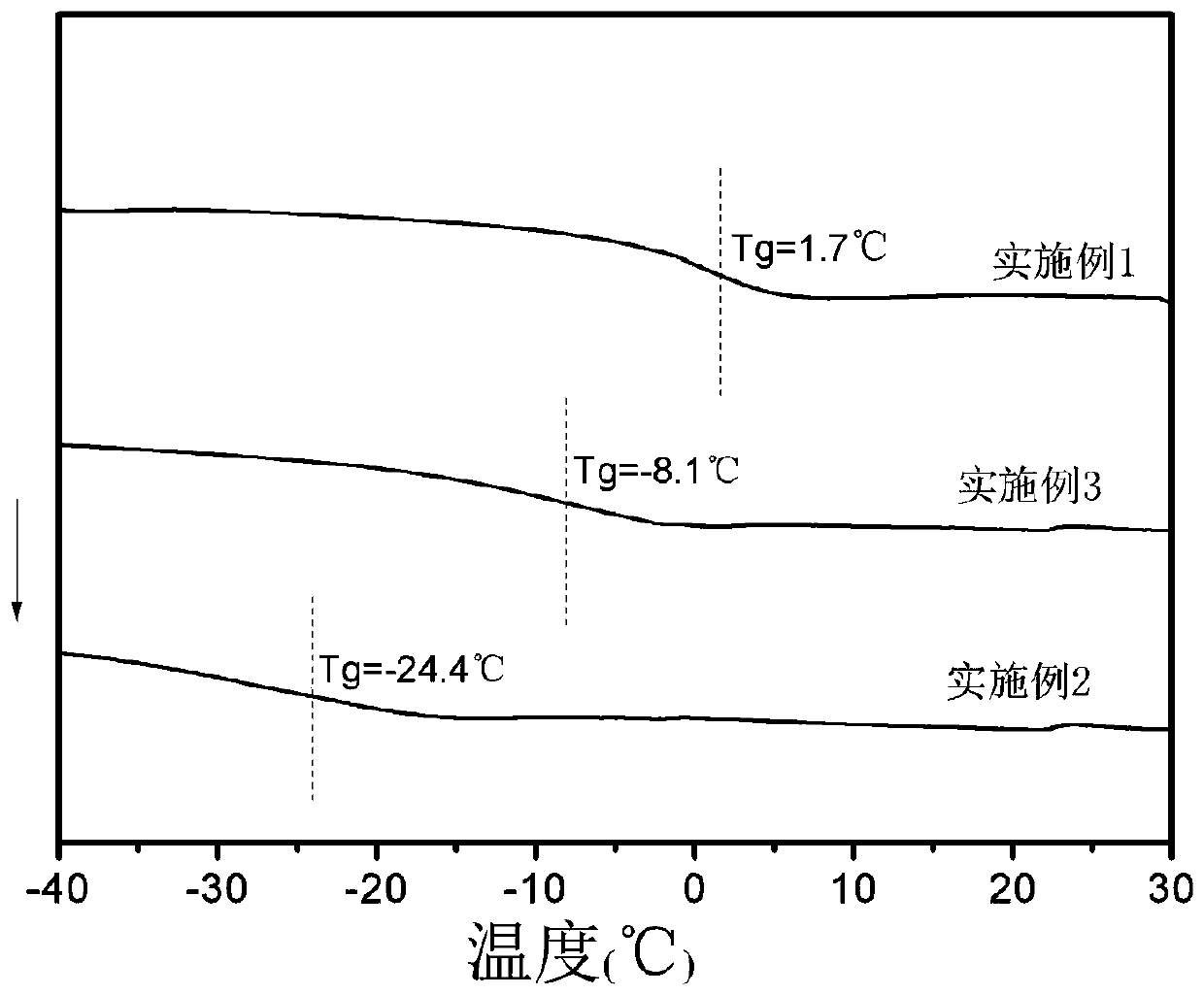

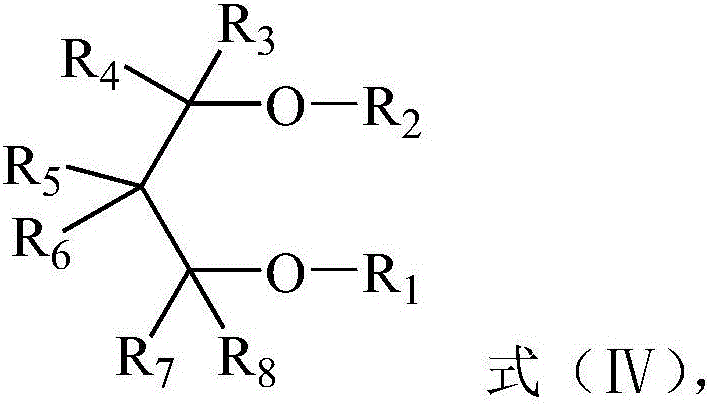

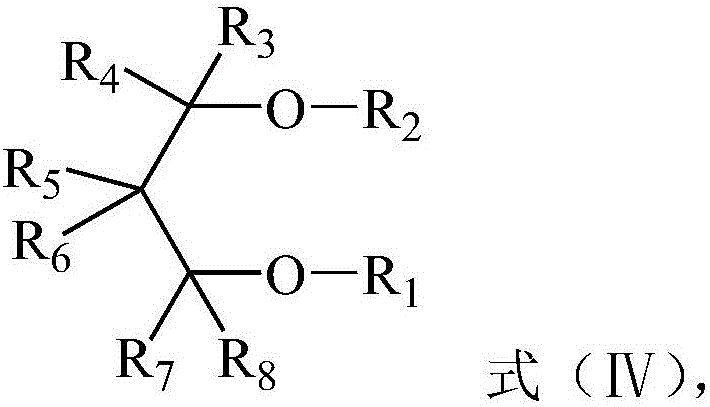

High-strength self-healing material and preparation method thereof

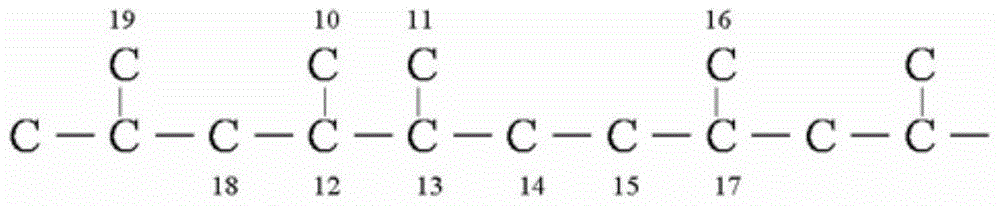

ActiveCN108659167ALower glass transition temperatureImprove self-healing abilityChemical structurePolyamide

The invention relates to a high-strength self-healing material and a preparation method thereof. The high-strength self-healing material adopts a structural formula as follows: FORMULA, wherein a lateral group R1 adopts a structural formula of -OCOR1' or -OH, and n is greater than or equal to 5 and smaller than or equal to 500. The high-strength self-healing material is prepared by polymerizing the same polyamide monomer under vacuum or copolymerizing different polyamide monomers under vacuum. The high-strength self-healing material synthesized by the preparation method provided by the invention has a large number of non-covalent bonds and relatively low glass transition temperature, so that the high-strength self-healing material has excellent autonomous healing ability; moreover, the high-strength self-healing material adopts a unique chemical structure, and has a large number of reversible non-covalent bonds and a large number of uniformly distributed nanocrystalline regions, so that the defect of low strength of an autonomous healing material is overcome.

Owner:ANHUI AGRICULTURAL UNIVERSITY

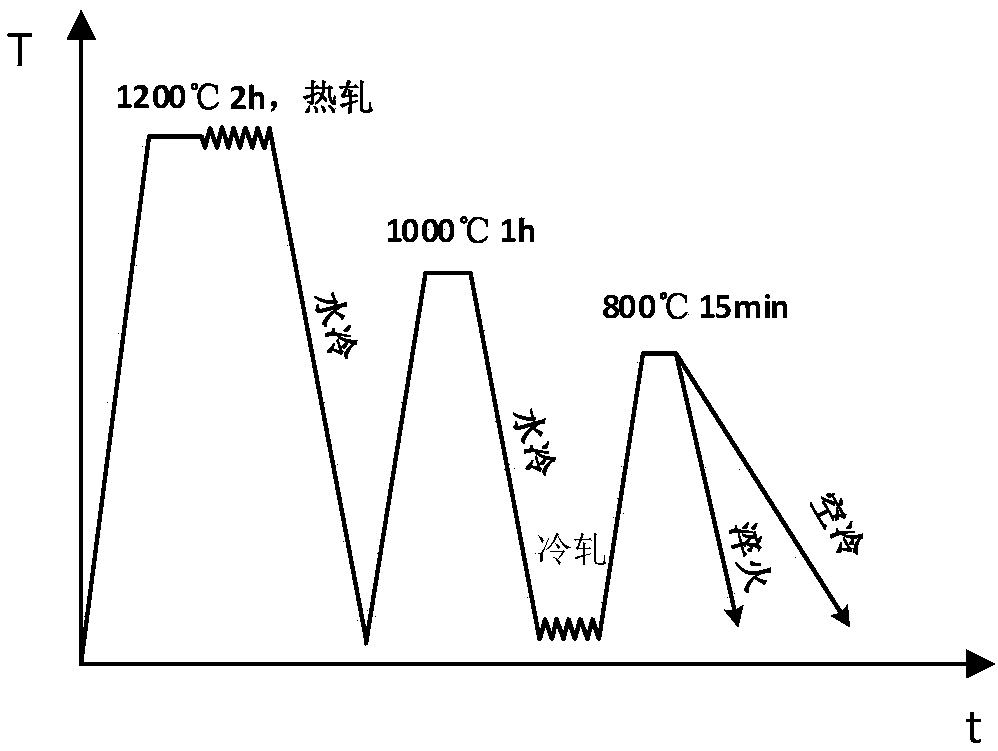

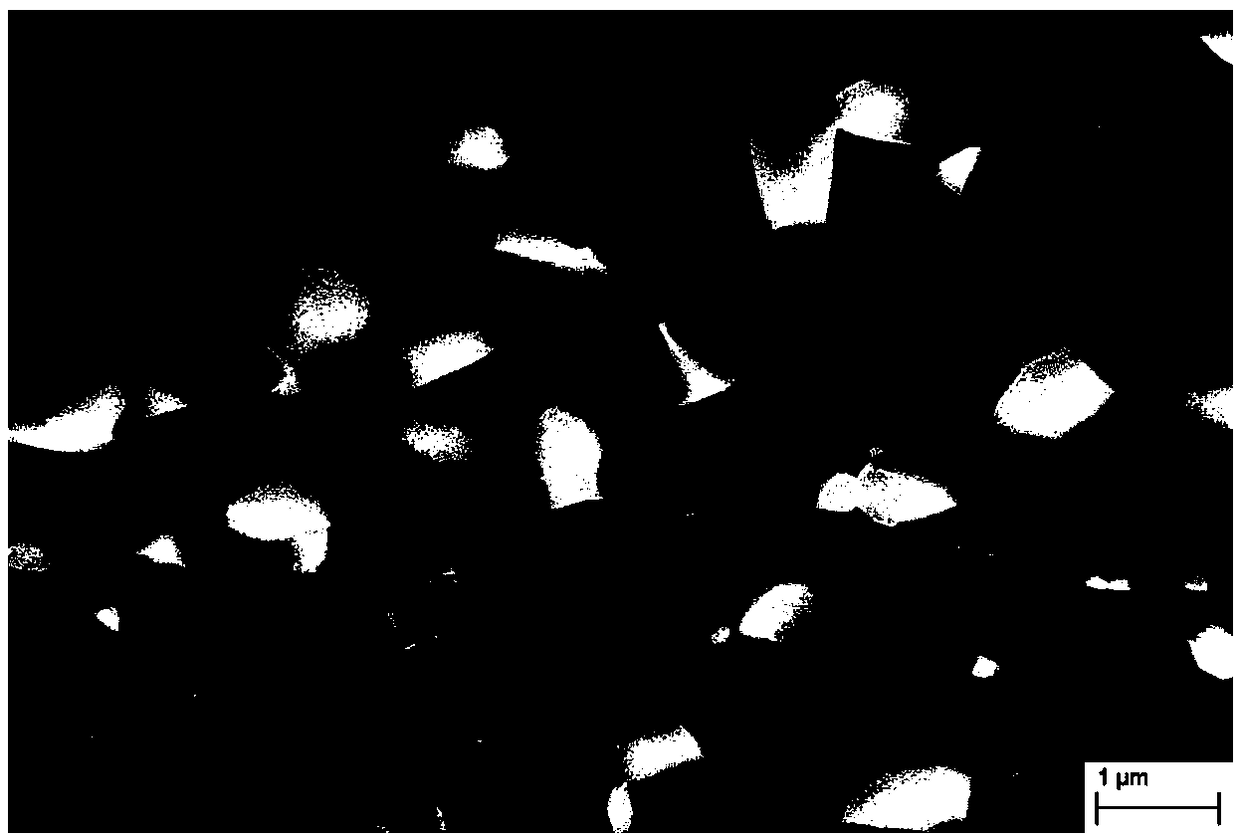

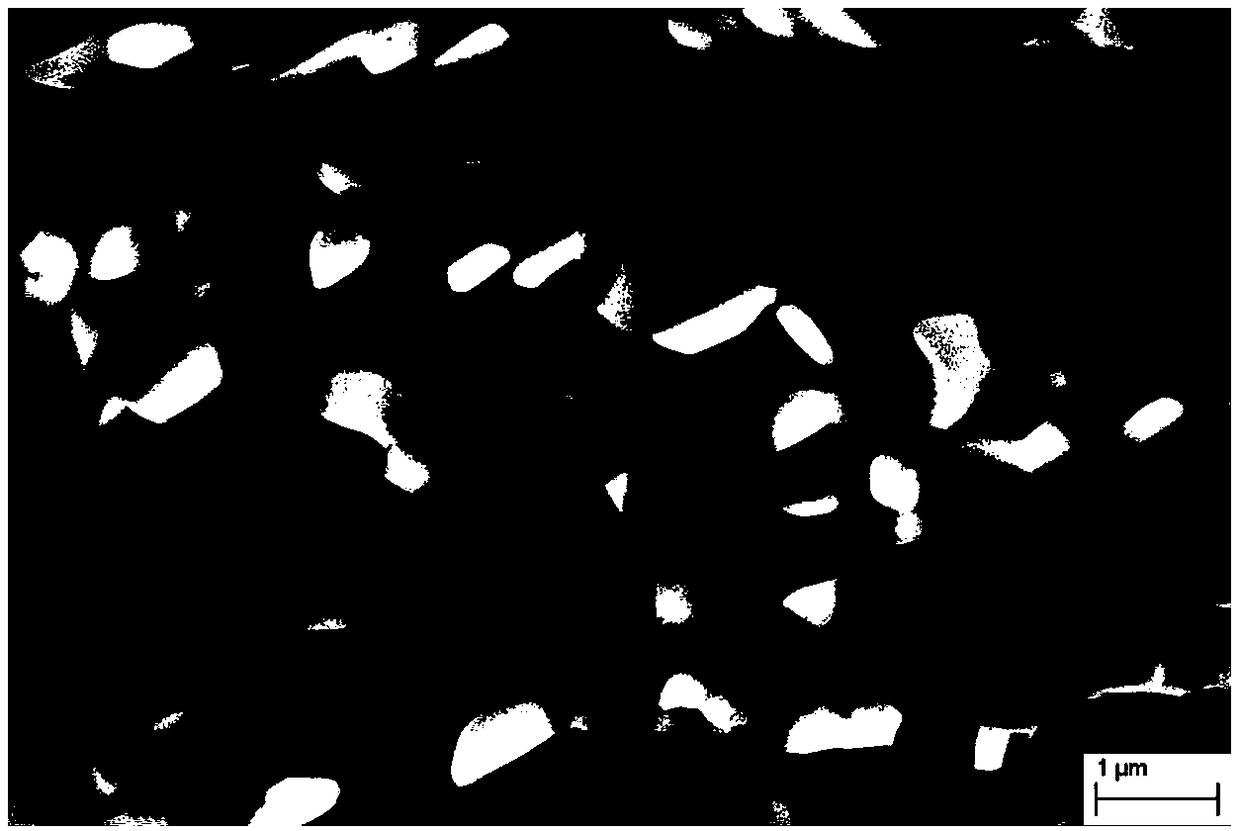

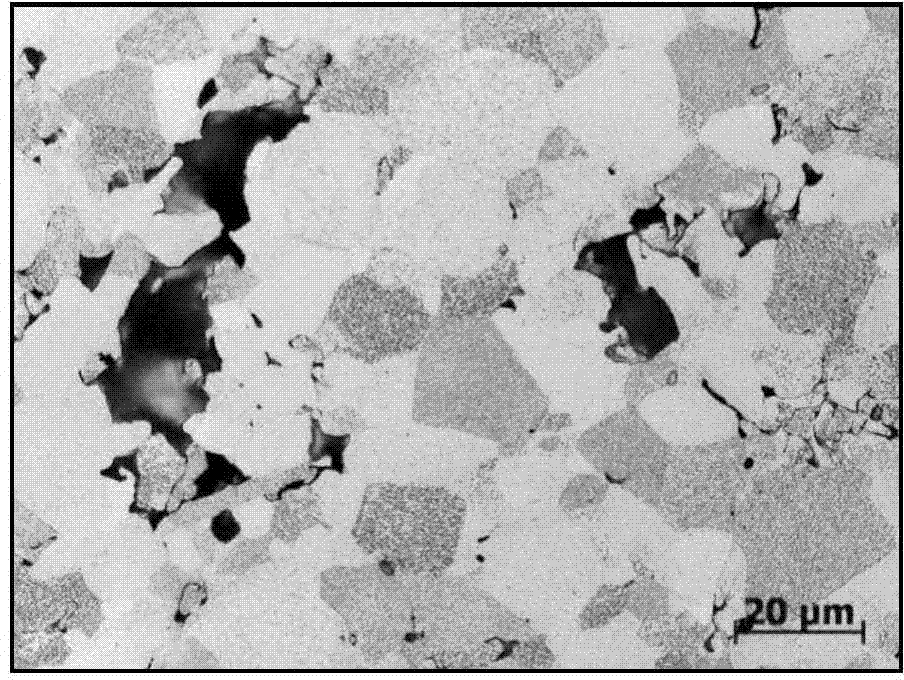

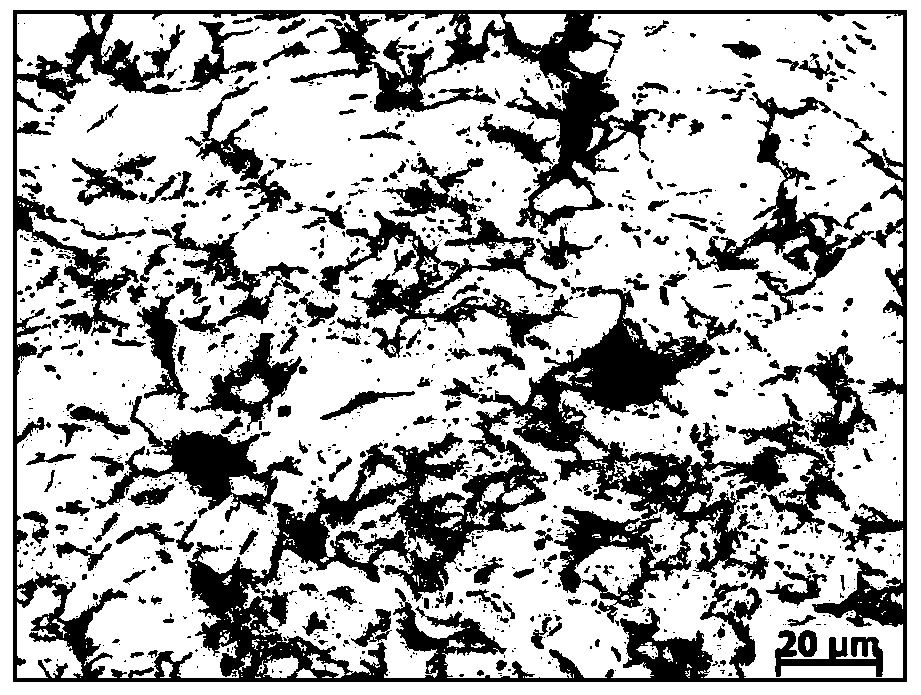

Fe-Mn-Al-C series cold-rolled automobile steel and preparation method

The invention discloses a Fe-Mn-Al-C series cold-rolled automobile steel and a preparation method, and belongs to the field of material processing. The steel comprises the following chemical components of, by mass, 0.7-0.9% of C, 10.0-14.0% of Mn, 7-9% of Al, less than 0.005% of P, less than 0.002% of S, and the balance Fe and inevitable impurities. The preparation method comprises the following steps that 1), according to the composition proportion of the Fe-Mn-Al-C series cold-rolled automobile steel, smelting and casting are carried out to obtain a ingot blank; 2), the ingot blank undergoesheating and heat preservation and then undergoes forging; 3), the ingot blank undergoes heating and heat preservation and then undergoes hot rolling, then the ingot blank undergoes water cooling to reach the room temperature, and a hot rolled plate is obtained; 4), the hot rolled plate undergoes heating and heat preservation, and then undergoes cold rolling, then the plate undergoes water coolingto reach the room temperature, and a cold rolled plate is obtained; and 5), the cold rolled plate undergoes heating and heat preservation, and then is cooled to reach the room temperature, and the Fe-Mn-Al-C series cold-rolled automobile steel is prepared. According to the steel prepared by the method, the tensile strength is 1014.9-1039.8 MPa, the yield strength is 789.6-839.2 MPa, the elongation rate is 42-43%, the strong plastic volume is 42.6-44.7 GPa.%.

Owner:NORTHEASTERN UNIV

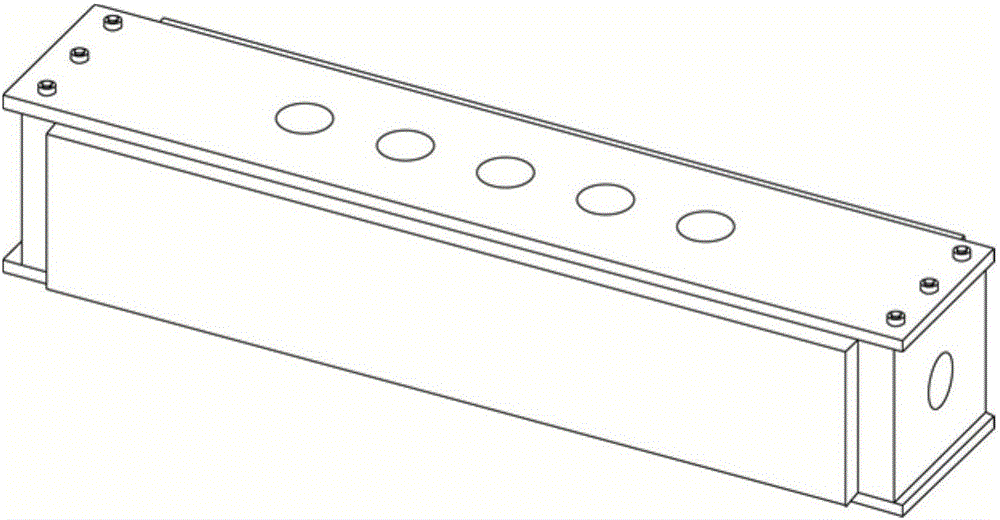

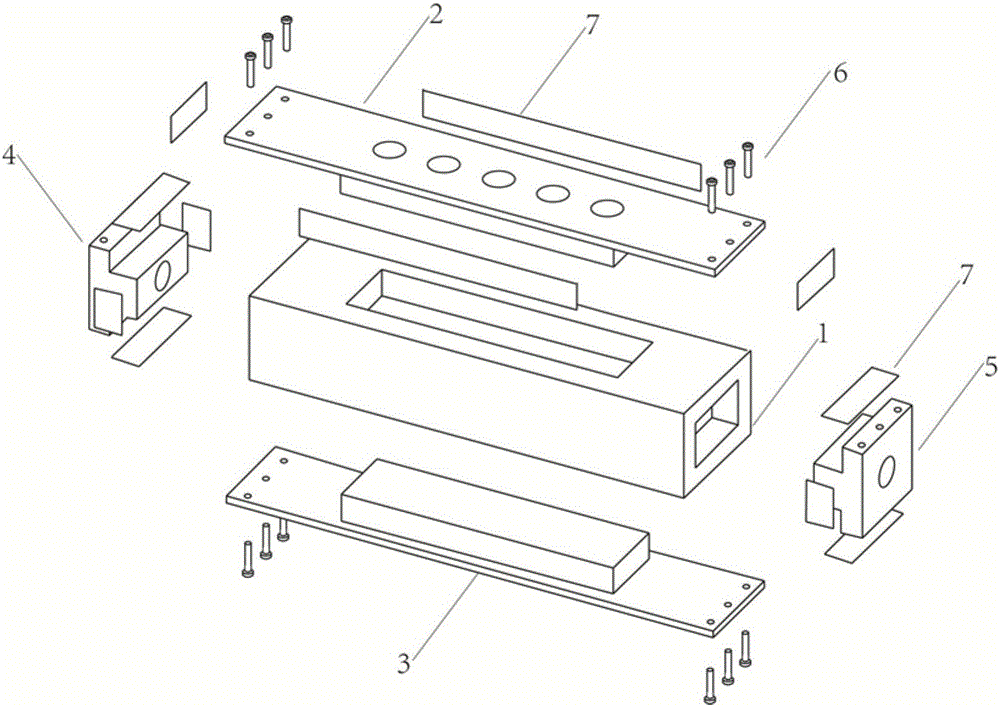

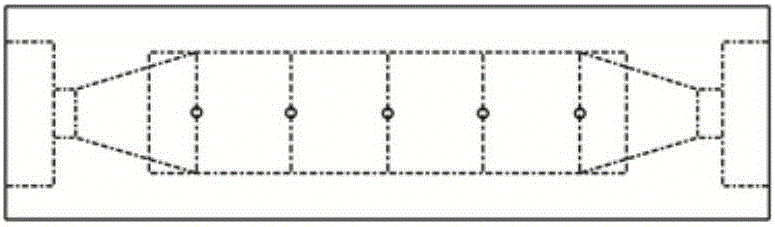

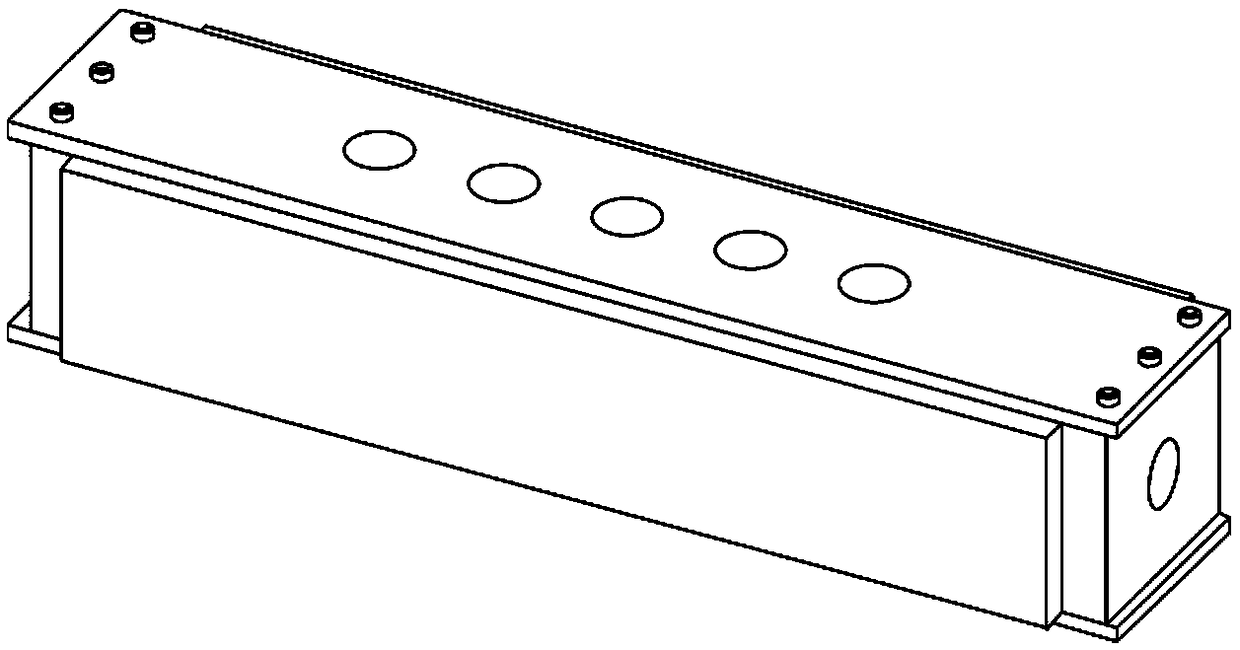

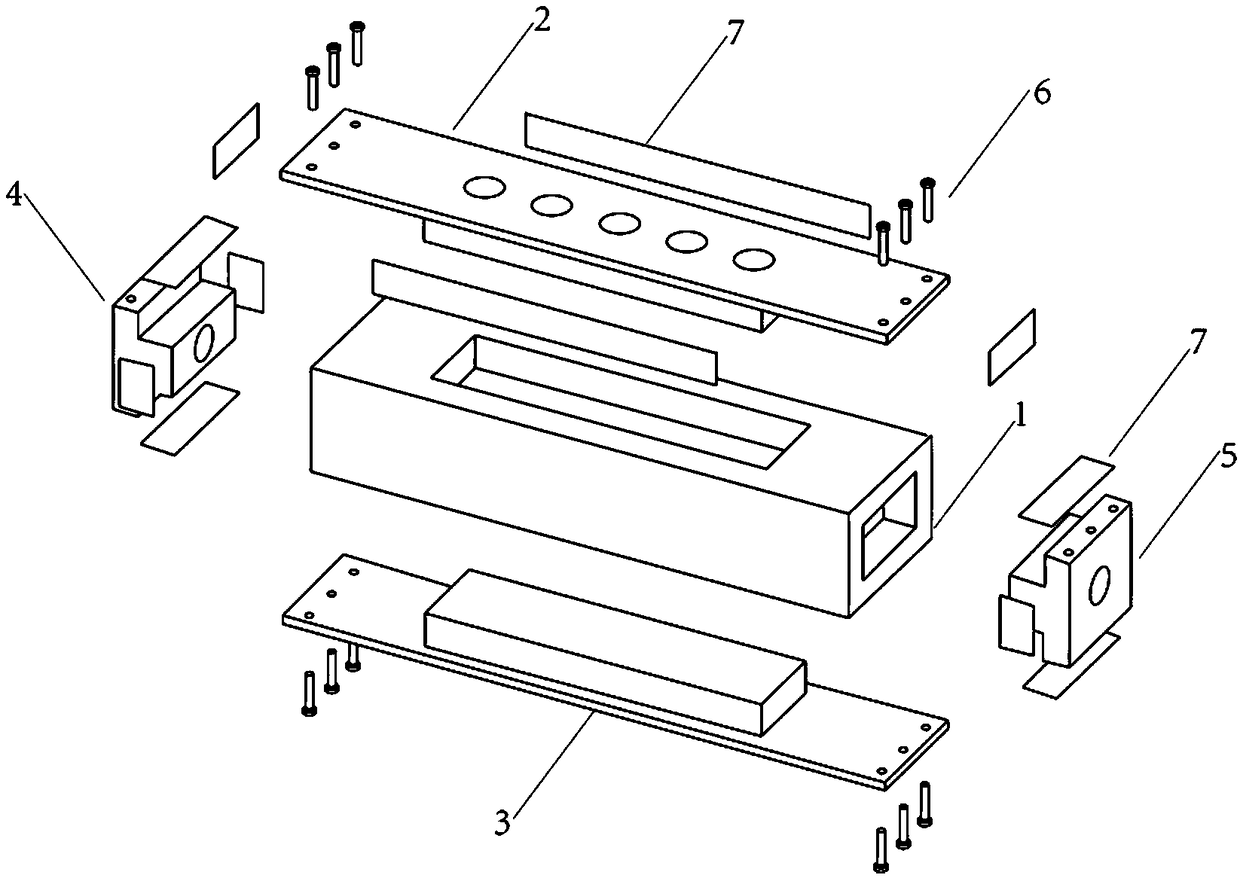

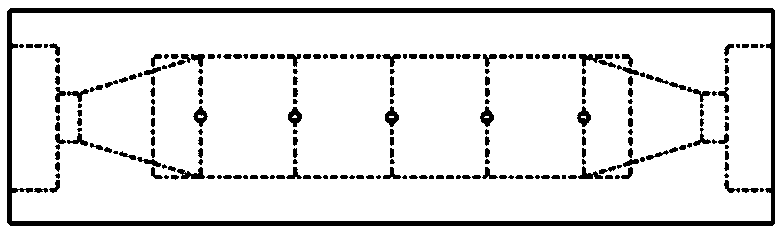

Rock coarse fracture seepage simulation model and making method

ActiveCN106353233AReduce intensityOvercome the disadvantage of low strengthPermeability/surface area analysisEngineeringWater pressure

The invention discloses a rock coarse fracture seepage simulation model and a making method. The rock coarse fracture seepage simulation model comprises a fracture main board, a left mounting board, a right mounting board, an upper mounting board and a lower mounting board, the fracture main board is of a cuboid structure, a hydrophobic area is arranged on one side of the cuboid structure, a water gathering area is arranged on the other opposite side, the hydrophobic area is communicated with the water gathering area, the outer side of the hydrophobic area is matched with the left mounting board, and the outer side of the water gathering area is matched with the right mounting board; the upper surface and the lower surface of the cuboid structure are respectively matched with the upper mounting board and the lower mounting board, and a pressure measuring hole communicated with a communicating area between the hydrophobic area and the water gathering area is formed in the upper mounting board. 3D printing technology is adopted to manufacture the fracture main board which is fixed through the upper, lower, left and right mounting boards, and a bolt or a water pressure sensor is mounted on each mounting board, so that the making method of the rock coarse fracture seepage simulation model is simple to make, convenient to experiment and capable of reflecting rock fracture seepage characteristics more really and more accurately.

Owner:SHANDONG UNIV

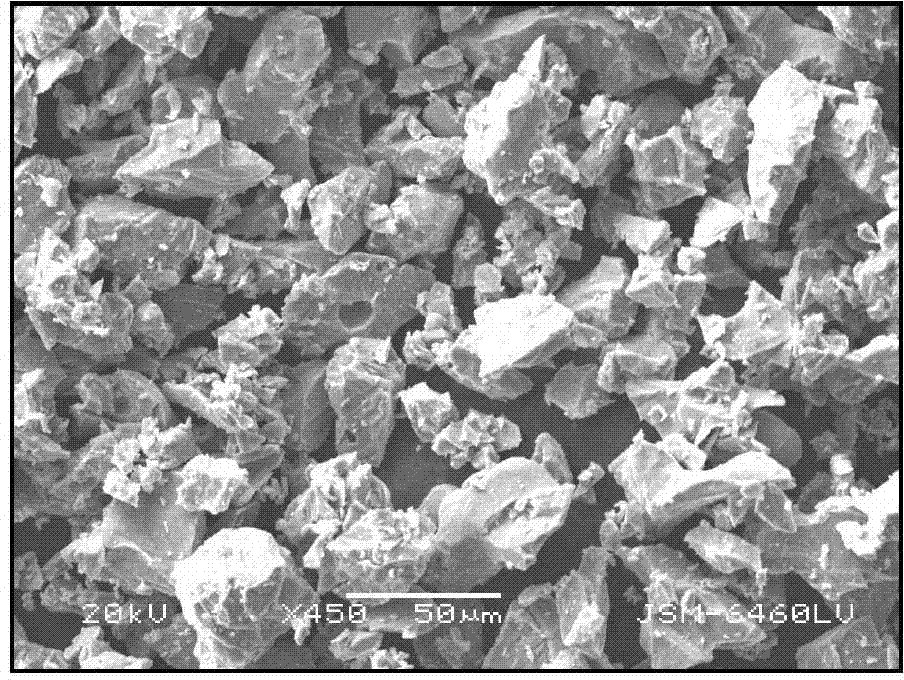

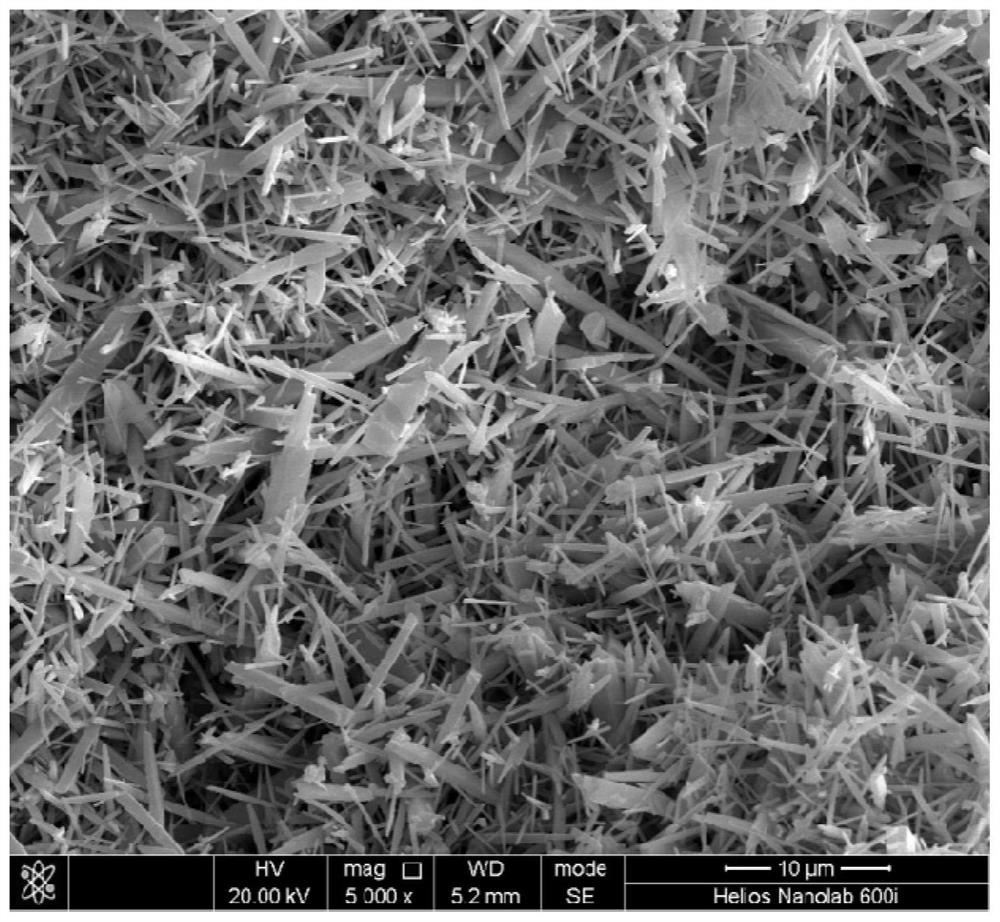

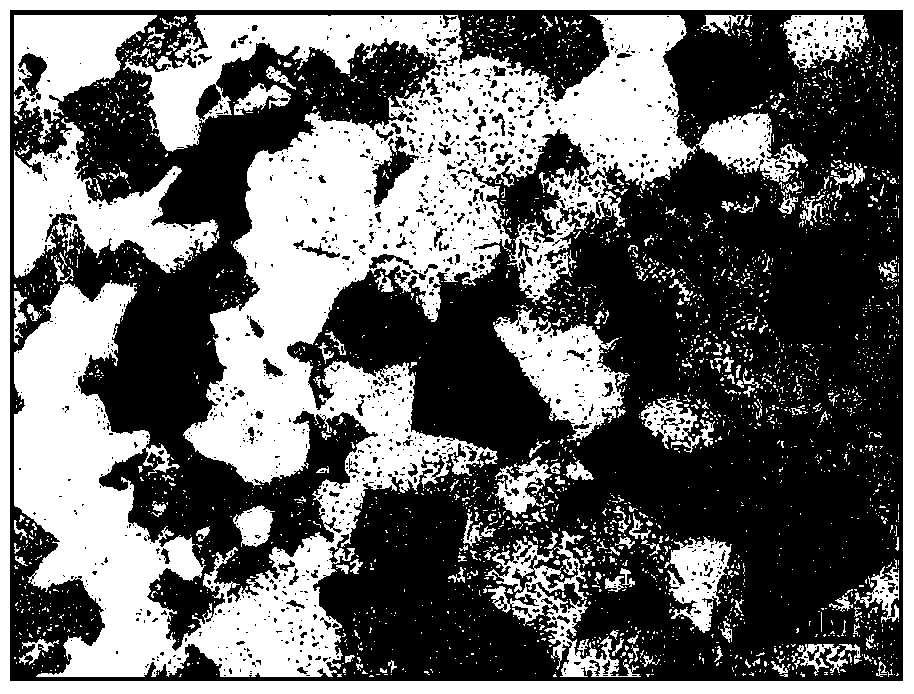

Nanostructured pure titanium plate preparation method

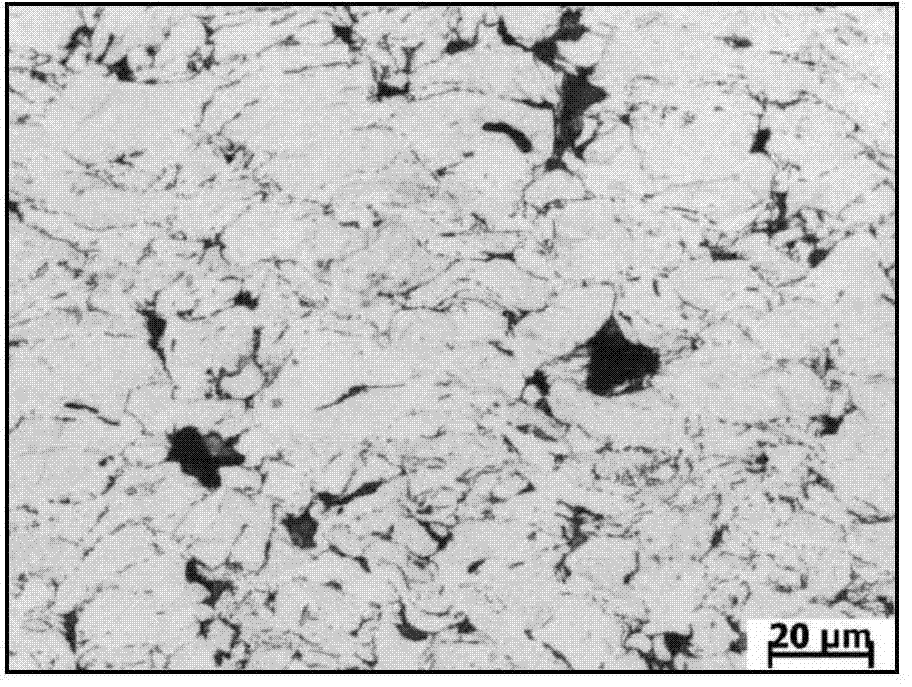

ActiveCN104846363AUniform tissueImprove performanceMaterial nanotechnologyPressure inorganic powder coatingBiocompatibility TestingNanostructure

The invention relates to a nanostructured pure titanium plate preparation method which includes the following phases: (1) selection of titanium powder particles, to be more specific, low oxygen and low hydrogen high purity titanium powder particles are selected, and the titanium powder particle size distribution range is 5-200 microns; (2) preparation of a pure titanium plate blank by high speed spray deposition method, to be more specific, titanium powder particles are accelerated, by collision of the high speed titanium powder particles and a substrate, a pure titanium plate blank is prepared by deposition caused by strong plastic deformation of the titanium powder particles; (3) plate blank heat treatment, to be more specific, and heat treatment of the prepared pure titanium plate blank is performed; and (4) hot rolling. The crystalline grain size of the pure titanium plate prepared by the method is small, the crystalline grain is nanocrystalline, uniform in organization, and excellent in performance, the shortcoming of low strength of the pure titanium plate is overcome, the hardness is 2 times greater than that of ordinary pure titanium plates, at the same time, the advantages of excellent corrosion resistance, heat resistance and biocompatibility and the like of the ordinary pure titanium plates are inherited. The nanostructured pure titanium plate preparation method is simple in process, good in controllability, and high in production efficiency, and helps to industrial application.

Owner:BAOSHAN IRON & STEEL CO LTD

Compact siro spinning dacron viscose high-count yarn and production method thereof

The invention relates to a compact siro spinning dacron viscose high-count yarn and a production method thereof, belonging to the field of textile processing. The invention aims at providing a compact siro spinning dacron viscose high-count yarn and a production method thereof, which overcome the bad problems that the traditional ring spun yarn feathers are more, the strength is low and the like. By adopting dacron fibers and viscose fibers as raw materials, the product has higher strength and fewer feathers, and the product has finer, softer and more comfortable characteristics. By adopting the method, the problems that the feathers of the traditional ring spun yarn are more, the strength is low, and the like can be overcome, in addition, by adopting dacron fibers and viscose fibers as raw materials, the product has higher strength and fewer feathers, and the product has finer, softer and more comfortable characteristics, and the compact siro spinning dacron viscose high-count yarn is more suitable for producing underwear and high-grade clothes on a water-jet loom.

Owner:JIANGNAN UNIV

High-performance glass fiber composite baseball bat and manufacturing method thereof

The invention discloses a high-performance glass fiber composite baseball bat. The composite baseball bat is prepared from, by weight, 15-30 parts of modified bamboo fibers, 20-40 parts of glass fibers, 20-50 parts of polypropylene, 1-4 parts of isobutyl triethoxy silane, 20-40 parts of maleic anhydride grafted polypropylene, 1-10 parts of epoxy resin, 1-6 parts of an antioxidant and 10-20 parts of filler. The invention further discloses a manufacturing method for the high-performance glass fiber composite baseball bat. The baseball bat is high in strength and toughness, long in service life, simple in manufacturing process and easy to operate.

Owner:安徽宁国市伟诚纤维制品有限公司

Polypropylene non-woven fabric and making method thereof

ActiveCN104250883ARaise the crystallization temperatureFast crystallizationNon-woven fabricsPolymer scienceNonwoven fabric

The invention provides a polypropylene non-woven fabric and a making method of the polypropylene non-woven fabric. The molecular weight distribution index of polypropylene in the polypropylene non-woven fabric is 2.5-5.5, and the high molecular trailing index PIHT in molecular weight distribution width is greater than 1.9. The polypropylene non-woven fabric has high strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

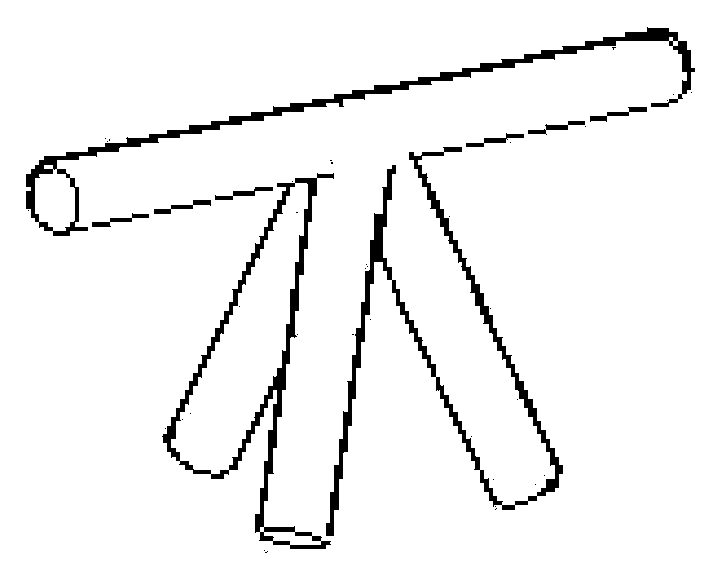

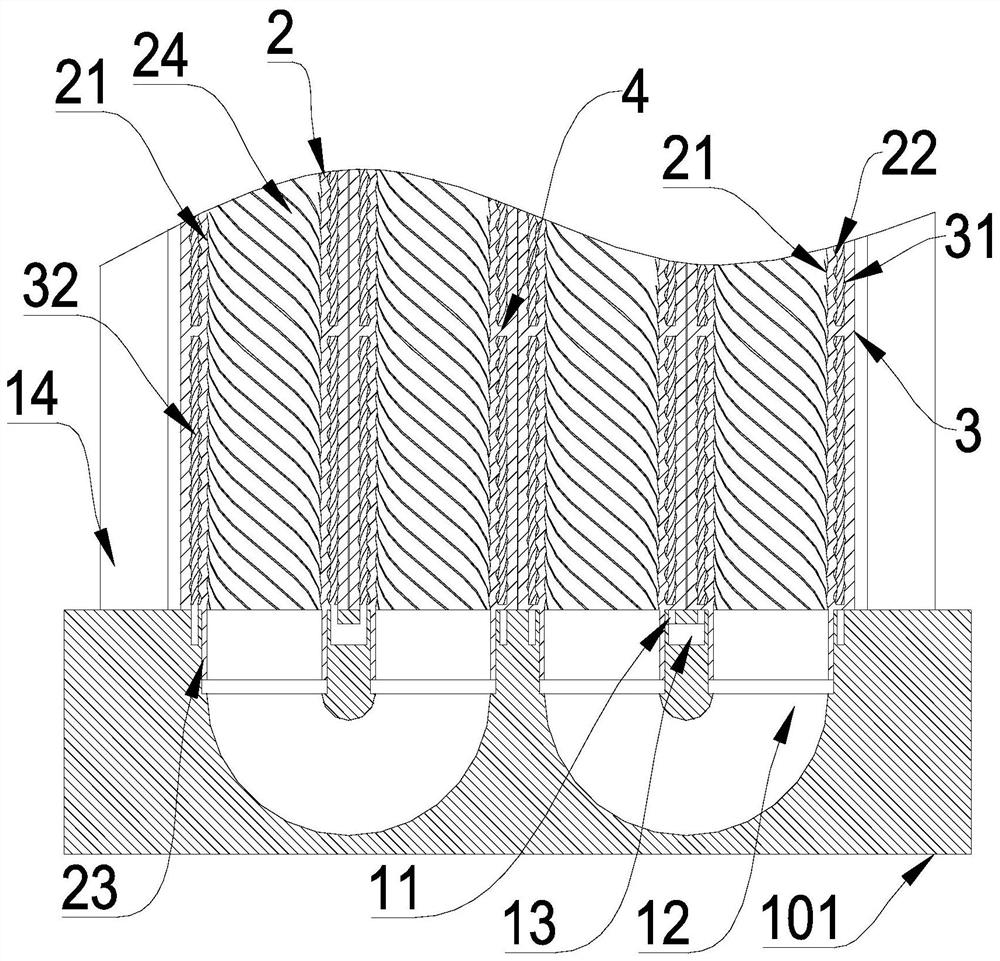

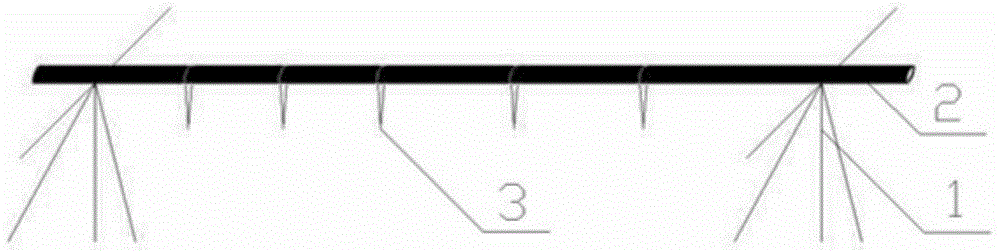

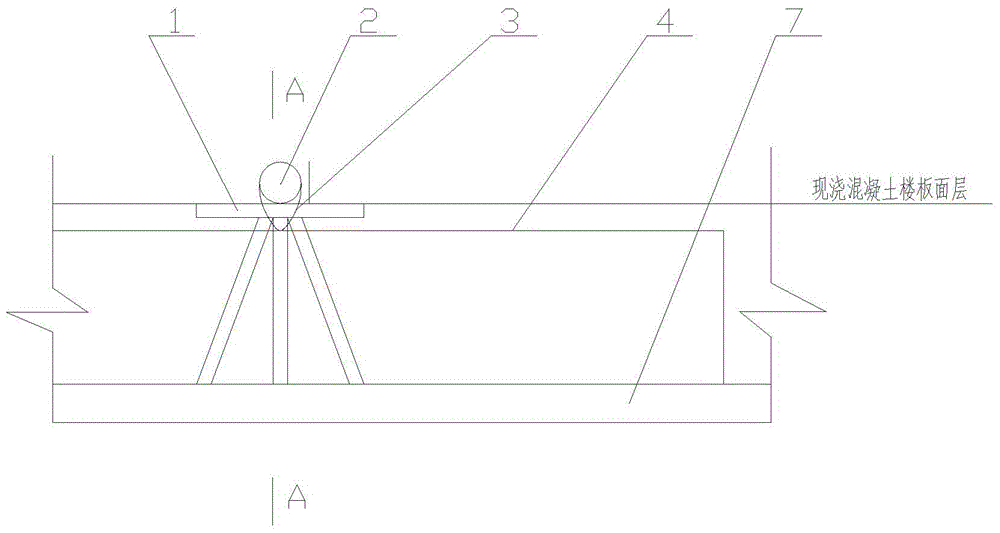

Hogging moment rebar suspension construction control protection layer device and construction method thereof

ActiveCN103669880AReduce investmentLight structureBuilding reinforcementsBuilding material handlingRebarUltimate tensile strength

The invention relates to a hogging moment rebar suspension construction control protection layer device and a construction method thereof. The device comprises tripod supporting bases, a horizontal fixing beam and a fixation binding line. The method includes the following steps that firstly, the thickness of a cast-in-place concrete plate is determined; secondly, the position and the use number of tripod supporting bases are determined and the tripod supporting bases are manufactured in batches; thirdly, the tripod supporting bases are placed in the middle of adjacent hogging moment rebar; fourthly, the horizontal fixing beam is arranged on the tripod supporting bases in an erected mode; fifthly, the hogging moment rebar is suspended on the horizontal fixing beam through the fixing binding line to be bound and fixed; sixthly, the surface of concrete on the lower portion of the horizontal fixing beam after casting is floated; seventhly, after concrete reaches the design strength, the upper portion horizontal fixing beam is detached. Compared with the prior art, the hogging moment rebar suspension construction control protection layer device and the construction method of the hogging moment rebar suspension construction control protection layer device have the advantages that the structure is simple and light, the device is convenient to use and low in investment cost and the situation that the position of the stressed rebar in a concrete structure is accurate and the thickness of the hogging moment rebar protection layer conforms to the requirements is effectively ensured.

Owner:CHINA THIRD METALLURGICAL GRP

Durable fragrant ceramic decorative plate and preparation method thereof

The invention provides a fragrant ceramic decorative plate and a preparation method thereof. The fragrant ceramic decorative plate is obtained by infiltrating a solid fragrant substance into a porousceramic plate through a melt impregnation process; and the porous ceramic plate is prepared from kaolin, calcined bauxite, a mineralizing agent, a sintering aid and a reinforcing agent. The preparation method of the fragrant ceramic decorative plate comprises the steps of ball milling, spray drying, compression molding, first firing, ink-jet printing and glazing, second firing, fragrance infiltration and surface treatment. The high-strength and high-porosity ceramic plate is prepared under the condition of no pore-forming agent by virtue of the enhancement effect of in-situ synthesized mullitewhiskers, a storage carrier with excellent performance is provided for fragrance substances, and the defect of low strength of a traditional fragrance ceramic carrier is overcome; and solid fragrancesubstances are infiltrated and surface treatment is performed through melt impregnation operation, so that a large amount of fragrance can be stored and slowly released, and lasting release of the fragrance is guaranteed.

Owner:新明珠(广东)新材料有限公司 +2

Preparation method of high-strength fully-recycled coarse aggregate concrete

ActiveCN102887679BHigh strengthImprove workabilitySolid waste managementSuperplasticizerUltimate tensile strength

The invention discloses a preparation method of high-strength fully-recycled coarse aggregate concrete, belonging to the technical field of recycled coarse aggregate concrete. According to the preparation method, a proper amount of superplasticizer, first-level coal ash and mineral powder are added at a water-gel ratio of 0.36-0.44 to prepare the high-performance fully-recycled coarse aggregate concrete which is good in working property, high in early-stage strength and good in later-stage strength development. The strength of the existing fully-recycled coarse aggregate concrete is low, and the compression strength of the fully-recycled coarse aggregate concrete provided by the invention is over 50Mpa according to actual measurement in 28 days.

Owner:BEIJING UNIV OF TECH

Steel slag-based pervious concrete

InactiveCN112094099AEasy to operateOvercome the disadvantage of low strengthSolid waste managementSlagEconomic benefits

The invention discloses a steel slag-based pervious concrete. The concrete comprises, by weight, 100 parts of steel slag, 15-30 parts of phosphate, 1-5 parts of a retarder and 50-150 parts of steel slag aggregate. When in use, the concrete materials are uniformly stirred and mixed with water, the obtained mixture is formed and naturally cured. The concrete has the excellent properties of high early strength, high low-temperature setting speed, small volume deformation, wide environmental adaptability, good water permeability and the like; and the defect that traditional pervious concrete is low in strength is overcome, meanwhile, a large amount of waste steel slag can be effectively treated, energy conservation, consumption reduction and emission reduction are achieved, and certain environmental protection and economic benefits are achieved.

Owner:KUNMING UNIV OF SCI & TECH

Pervious concrete and preparation method thereof

The invention provides pervious concrete and a preparation method thereof. The pervious concrete is prepared from, in parts by weight, 200-300 parts of cement, 30-80 parts of mineral powder, 30-80 parts of fly ash, 1400-1700 parts of gravel, 1-5 parts of rubber powder, 0.5-5 parts of cellulose and cellulose ether, 0.5-5 parts of starch ether, 3-4 parts of an additive and 57-84 parts of water. The raw materials used in the pervious concrete are common and easy to obtain, the production process is simple, and cellulose / cellulose ether and starch ether are added as thickening and water-retaining agents, so that the produced pervious concrete is suitable for long-distance transportation, high-strength pervious concrete can be prepared while good pervious rate is met, and the pervious concrete is suitable for production of common commercial concrete mixing plants.

Owner:长春冀东水泥混凝土有限公司

A kind of high-strength self-healing material and its preparation method

ActiveCN108659167BLower glass transition temperatureImprove self-healing abilityPolymer sciencePolyamide

The invention relates to a high-strength self-healing material and a preparation method thereof. The high-strength self-healing material adopts a structural formula as follows: FORMULA, wherein a lateral group R1 adopts a structural formula of -OCOR1' or -OH, and n is greater than or equal to 5 and smaller than or equal to 500. The high-strength self-healing material is prepared by polymerizing the same polyamide monomer under vacuum or copolymerizing different polyamide monomers under vacuum. The high-strength self-healing material synthesized by the preparation method provided by the invention has a large number of non-covalent bonds and relatively low glass transition temperature, so that the high-strength self-healing material has excellent autonomous healing ability; moreover, the high-strength self-healing material adopts a unique chemical structure, and has a large number of reversible non-covalent bonds and a large number of uniformly distributed nanocrystalline regions, so that the defect of low strength of an autonomous healing material is overcome.

Owner:ANHUI AGRICULTURAL UNIVERSITY

A simulation model of seepage in rough cracks of rock mass and its manufacturing method

ActiveCN106353233BReduce intensityOvercome the disadvantage of low strengthPermeability/surface area analysisEngineeringMotherboard

The invention discloses a rock coarse fracture seepage simulation model and a making method. The rock coarse fracture seepage simulation model comprises a fracture main board, a left mounting board, a right mounting board, an upper mounting board and a lower mounting board, the fracture main board is of a cuboid structure, a hydrophobic area is arranged on one side of the cuboid structure, a water gathering area is arranged on the other opposite side, the hydrophobic area is communicated with the water gathering area, the outer side of the hydrophobic area is matched with the left mounting board, and the outer side of the water gathering area is matched with the right mounting board; the upper surface and the lower surface of the cuboid structure are respectively matched with the upper mounting board and the lower mounting board, and a pressure measuring hole communicated with a communicating area between the hydrophobic area and the water gathering area is formed in the upper mounting board. 3D printing technology is adopted to manufacture the fracture main board which is fixed through the upper, lower, left and right mounting boards, and a bolt or a water pressure sensor is mounted on each mounting board, so that the making method of the rock coarse fracture seepage simulation model is simple to make, convenient to experiment and capable of reflecting rock fracture seepage characteristics more really and more accurately.

Owner:SHANDONG UNIV

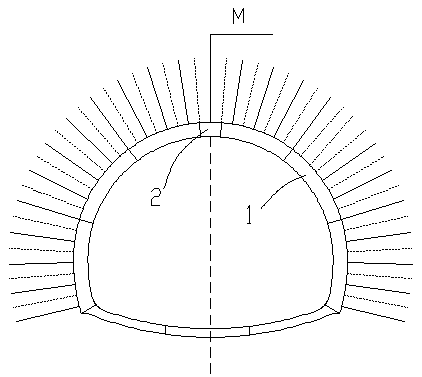

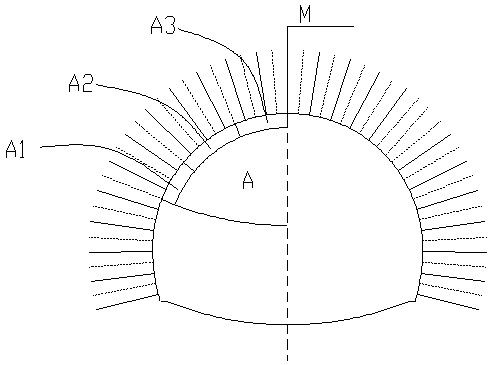

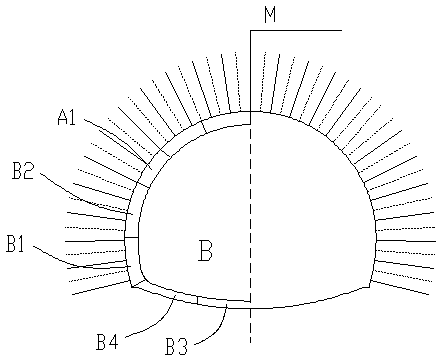

A Tunnel Assembled Primary Support Method

ActiveCN105952459BImprove construction safetyEasy to doUnderground chambersTunnel liningWorking environmentSurface construction

The invention relates to a splicing-type primary support method for a tunnel. Therefore, constructions in special sections of weak geological conditions can be effectively supported when a shield method for construction is not adopted for tunnels excavated by a mining method and primary support of underground construction. The splicing-type primary support method comprises an overall support and partial excavation support and is characterized in that based on a tunnel section form, a support member is divided into multiple blocks; on the site, the multiple blocks are attached to the excavation surface for splicing into a ring so that surrounding rock deformation is controlled; in the method of partial excavation support, rings are formed by partial excavation so that overall connection is formed. The surrounding rocks are supported timely and deformation is controlled. The working environment is improved. The primary support time is shortened and safety coefficients of the working surface construction are improved. Stress is more uniform. The construction quality of a water-proof layer is ensured. Mechanical installation is achieved and high efficiency is obtained. The splicing-type primary support method is used more flexible and has a broad application scope. The support cost is low.

Owner:CHINA RAILWAY 24TH BUREAU GRP ZHEJIANG ENG CO LTD

A kind of polypropylene non-woven fabric and preparation method thereof

ActiveCN104250883BOvercome the disadvantage of low strengthHigh strengthNon-woven fabricsPolymer scienceNonwoven fabric

The invention provides a polypropylene non-woven fabric and a making method of the polypropylene non-woven fabric. The molecular weight distribution index of polypropylene in the polypropylene non-woven fabric is 2.5-5.5, and the high molecular trailing index PIHT in molecular weight distribution width is greater than 1.9. The polypropylene non-woven fabric has high strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

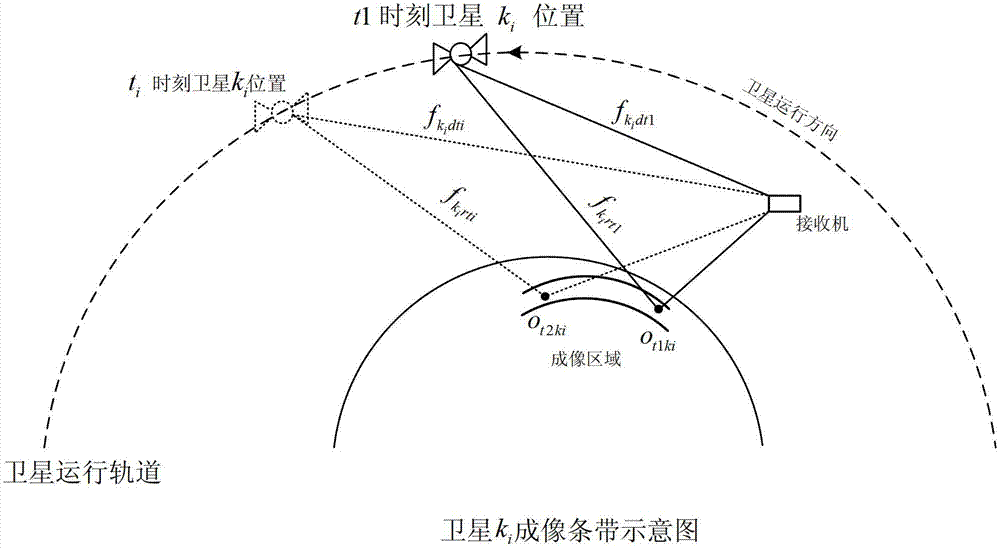

Multi-channel time delay Doppler two-dimensional partition mapping multi-satellite and multi-time image enhanced imaging device

ActiveCN102721962BOvercome the disadvantage of low strengthIncrease signal strengthRadio wave reradiation/reflectionTime delaysEarth surface

The invention discloses a multi-channel time delay Doppler two-dimensional partition mapping multi-satellite and multi-time image enhanced imaging device, wherein a navigation satellite, an imaging device and an earth surface reflection surface form a reflection surface imaging system. A satellite direct signal is received by a right-handed antenna of a receiver, and a satellite reflected signal is received by a left-handed antenna of the receiver. When the satellite is in the range of field of vision of the receiver, specular reflection points of the satellite signal are tracked by the corresponding left-handed antenna to acquire signals, and a signal acquisition region forms a band. According to the imaging device, a plurality of satellites can be tracked at the same moment to form a plurality of bands, the bands formed by tracking each satellite signal have an overlapped region; and the device is used for processing each satellite signal acquired from the overlapped region, and the band region is imaged by utilizing reflection surface characteristic information included by the reflected signal.

Owner:ZHEJIANG BEITE ELECTRONICS TECH

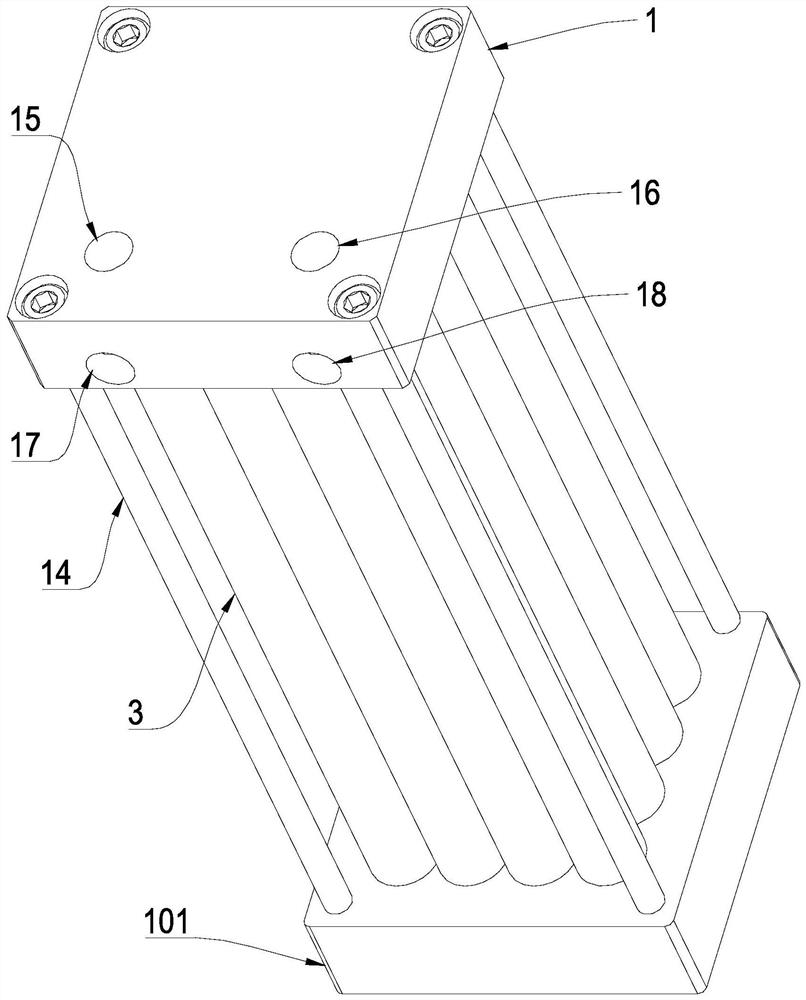

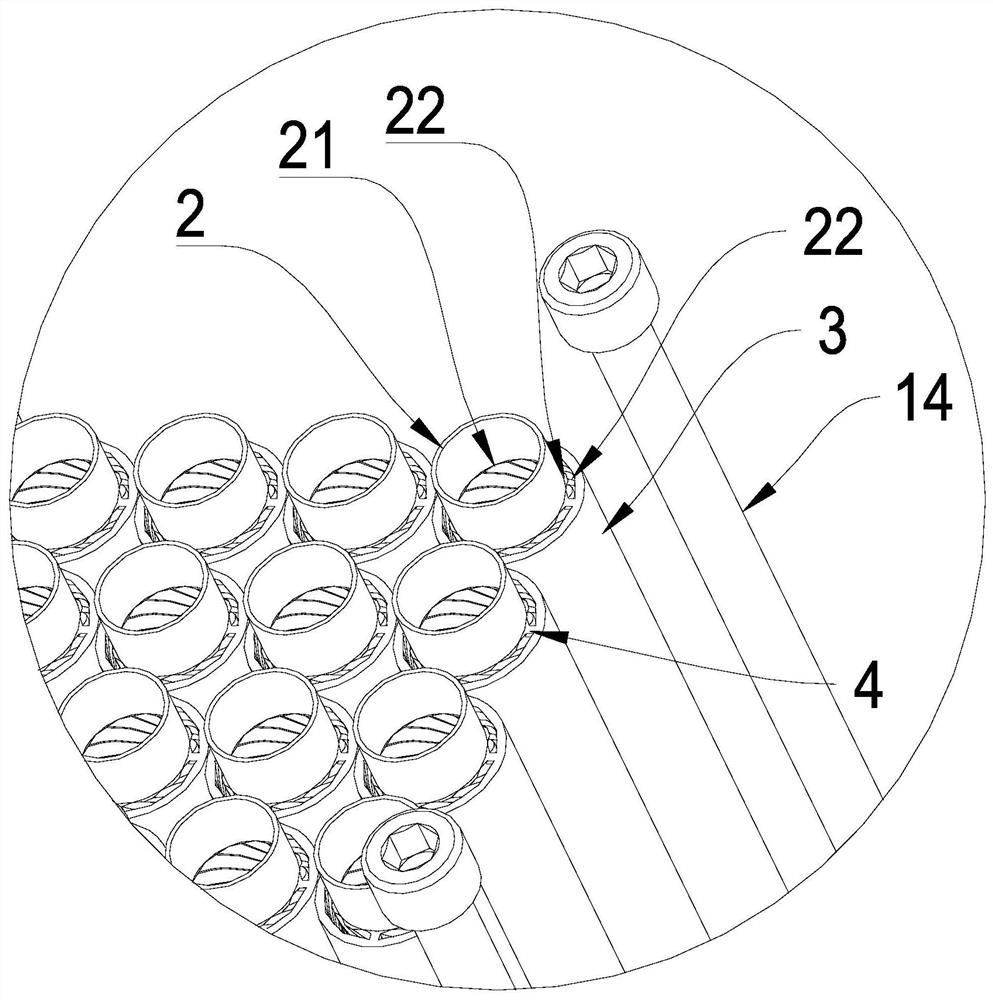

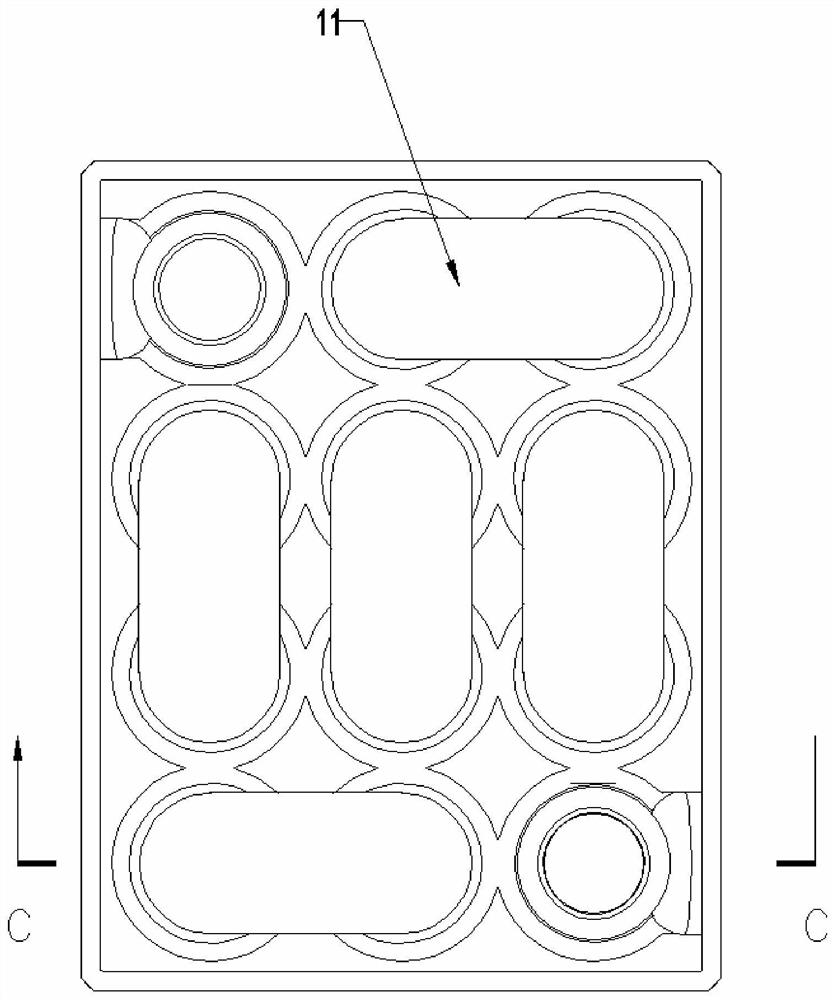

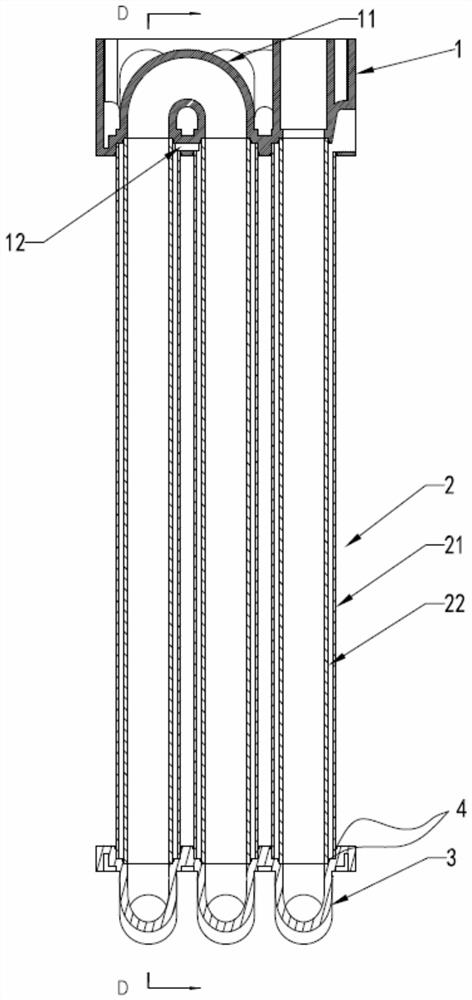

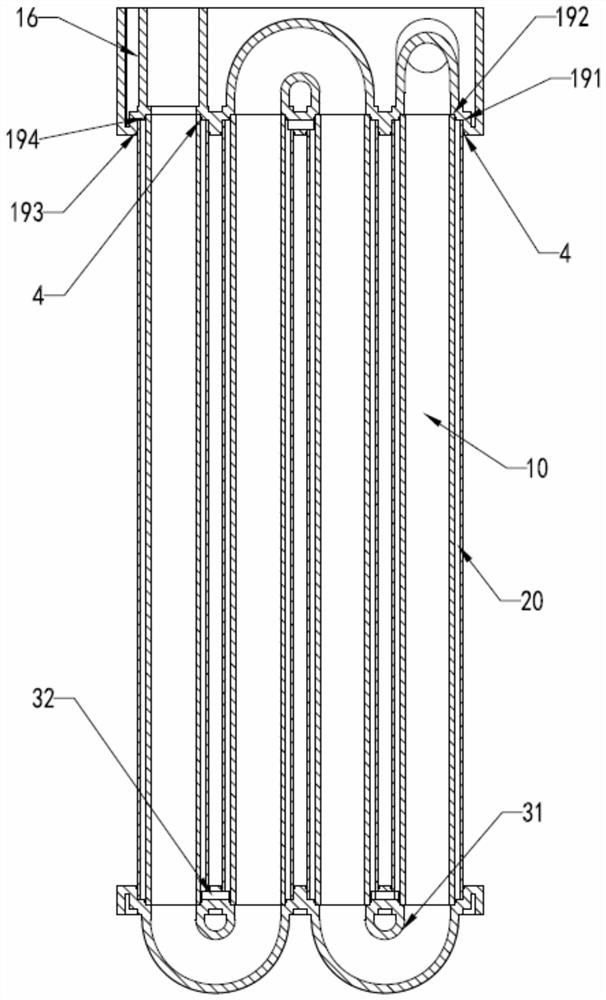

Internal spiral heat exchanger

PendingCN112985116AOvercome the disadvantage of low strengthSolve the problem of short heat exchange strokeHeat exchanger casingsStationary tubular conduit assembliesEngineeringRefrigerant

The invention discloses an internal spiral heat exchanger. The heat exchanger comprises an upper cover, a base and middle sections connected between the upper cover and the base, each middle section comprises an inner pipe and an outer sleeve, the upper cover and the base are provided with elbows with openings formed in the plate face of the upper cover and the plate face of the base, annular grooves are formed in the plate face of the upper cover and the plate face of the base and surround the opening portions of the elbows, openings in the two ends of the elbows are connected with the inner pipes of the adjacent middle section, interlayers are formed among the outer sleeves, the inner pipes and the annular grooves, communicating cavities are formed in the upper cover and the base to enable the two adjacent interlayers close to the elbows to communicate, the upper cover and the base are formed through metal injection molding, first threaded ribs are arranged on the inner wall face of the inner pipes, the thread pitch L1 of the first threaded ribs meets the condition that L1 is smaller than 0.028 Re*D1, Reynolds number Re=, v is the average flow velocity of fluid on the inner walls of the inner pipes, D1 is the diameter of the inner walls of the inner pipes, and mu is the current kinematic viscosity coefficient of the fluid on the inner walls of the inner pipes. A roundabout heat exchange structure with a long route is formed in the heat exchanger, and sufficient heat exchange between a refrigerant and a secondary refrigerant can be achieved.

Owner:SHUNDE POLYTECHNIC

Device and construction method for negative moment steel bar suspension construction control protective layer

ActiveCN103669880BReduce investmentLight structureBuilding reinforcementsBuilding material handlingEngineeringRebar

The invention relates to a hogging moment rebar suspension construction control protection layer device and a construction method thereof. The device comprises tripod supporting bases, a horizontal fixing beam and a fixation binding line. The method includes the following steps that firstly, the thickness of a cast-in-place concrete plate is determined; secondly, the position and the use number of tripod supporting bases are determined and the tripod supporting bases are manufactured in batches; thirdly, the tripod supporting bases are placed in the middle of adjacent hogging moment rebar; fourthly, the horizontal fixing beam is arranged on the tripod supporting bases in an erected mode; fifthly, the hogging moment rebar is suspended on the horizontal fixing beam through the fixing binding line to be bound and fixed; sixthly, the surface of concrete on the lower portion of the horizontal fixing beam after casting is floated; seventhly, after concrete reaches the design strength, the upper portion horizontal fixing beam is detached. Compared with the prior art, the hogging moment rebar suspension construction control protection layer device and the construction method of the hogging moment rebar suspension construction control protection layer device have the advantages that the structure is simple and light, the device is convenient to use and low in investment cost and the situation that the position of the stressed rebar in a concrete structure is accurate and the thickness of the hogging moment rebar protection layer conforms to the requirements is effectively ensured.

Owner:CHINA THIRD METALLURGICAL GRP

Prepn process of microcapsule containing Hansa yellow 100 electrophoresis liquid

InactiveCN1313196COvercome the disadvantage of low strengthSimple processMicroballoon preparationNon-linear opticsEpoxyElectrophoresis

The present invention discloses the preparation process of microcapsule containing Hansa yellow 10G electrophoresis liquid, and belongs to the field of the preparation technology of electronic ink microcapsule. The preparation process includes: adding Hansa yellow 10G into solvent including toluene to compound dispersant solution and adding surfactant including Span-80 and grinding to prepare suspended electrophoresis liquid; compounding water solution of gelatin and Arabic gum separately; mixing the suspended electrophoresis liquid and epoxy resin to form homogeneous dispersant liquid, dispersing the dispersant liquid into water solution of Arabic gum, adding water solution of gelatin, dropping acid to regulating pH and to take re-condensation reaction, cooling, adding formaldehyde or glutaraldehyde for cross-linking solidification, adding CMCNa, dropping NaOH to regulate pH, and heating to react to obtain the microcapsule containing Hansa yellow 10G electrophoresis liquid.

Owner:TIANJIN UNIV

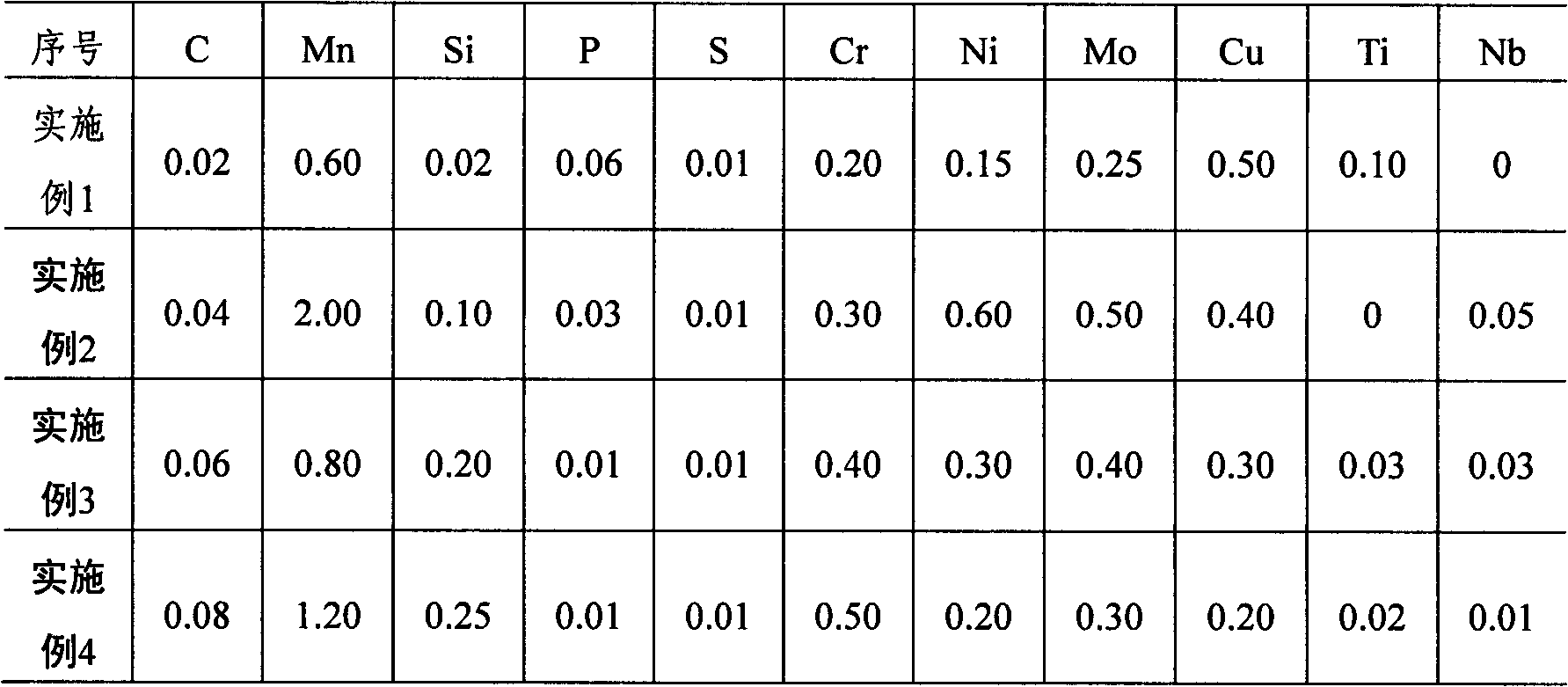

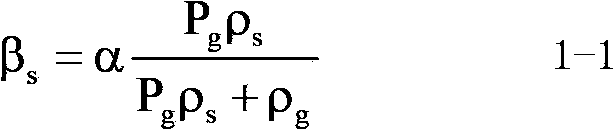

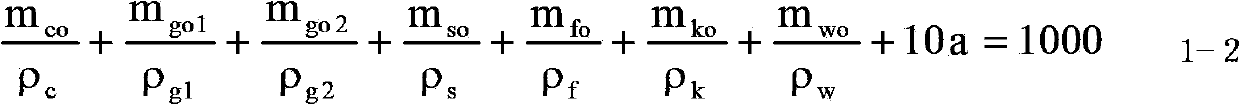

Tin-zinc hot dipping fuel-tank high-strength steel plate with good corrosion resistance and manufacturing method thereof

ActiveCN102828127BOvercome the disadvantage of low strengthImprove corrosion resistanceHot-dipping/immersion processesFurnace typesTinningFuel tank

The invention discloses a tin-zinc hot dipping fuel-tank high-strength steel plate with good corrosion resistance and a manufacturing method thereof. The steel plate comprises the following elements of: by weight, 0.02-0.10% of C, Si being less than or equal to 0.30%, 0.20-2.50% of Mn, P being less than or equal to 0.10%, S being less than or equal to 0.05%, 0.05-0.50% of Cr, 0.02-1.00% of Ni, 0.02-0.50% of Cu, 0.02-0.50% of Mo, Ti being less than or equal to 0.15%, Nb being less than or equal to 0.15%, and the balance Fe and other unavoidable impurities. The steel plate is prepared by process route of smelting, casting, hot rolling, cold rolling and continuous tin-zinc hot dipping. During the continuous annealing process, a steel band is heated to a two-phase region and is insulated for 10-100s while the temperature is 700-850 DEG C; then, the steel band is rapidly cooled to 300+ / -50 DEG C at the cooling rate of 10-100 DEG C / s, is insulated for 0-150s, undergoes tin-zinc hot dipping at the temperature of 280+ / -30 DEG C, and is finally air-cooled to room temperature after the plating process. The invention has the following advantages and effects: the disadvantage that a traditional lead-containing coated steel plate is harmful to the environment and a IF steel plate has low strength is overcome, and simultaneously the high-strength steel plate provided by the invention has good corrosion resistance and formability.

Owner:ANGANG STEEL CO LTD

Method for preparing high-strength semi-regenerative coarse aggregate concretes

ActiveCN102923997BHigh strengthImprove workabilitySolid waste managementRubber materialPolymer science

The invention discloses a method for preparing high-strength semi-regenerative coarse aggregate concretes, and belongs to the technical field of regenerative coarse aggregate concretes. The preparation method comprises the step of preparing the high-performance semi-regenerative coarse aggregate concretes with good working performance, high early strength and good development in long-term strength by regulating the mixing amount of additives, mineral powder and coal ash in reference to the using amount of rubber materials of the common concretes.

Owner:BEIJING UNIV OF TECH

A kind of preparation method of nanostructure pure titanium plate

ActiveCN104846363BUniform tissueImprove performanceMaterial nanotechnologyPressure inorganic powder coatingBiocompatibility TestingNanostructure

Owner:BAOSHAN IRON & STEEL CO LTD

Heat exchanger with spring rib structure

PendingCN112985117AOvercome the disadvantage of low strengthSolve the problem of short heat exchange strokeHeat exchanger casingsStationary tubular conduit assembliesHeat flowEngineering

The invention discloses a heat exchanger of a spring rib structure. The heat exchanger comprises a first end cover and a second end cover and further comprises a heat exchange sleeve, the heat exchange sleeve comprises inner pipes and outer sleeves, the first end cover and the second end cover are provided with bottom plates, an elbow and a communicating groove are integrally formed in each bottom plate in a metal injection mode, the two ends of the elbows are opened in the bottom plates, the communicating grooves are formed in the plate wall portions, connected with the two opening portions of the elbows, of the bottom plates, the openings in the two ends of the elbows are connected with inner pipes of the two adjacent heat exchange sleeves, outer sleeve interlayers of the two adjacent heat exchange sleeves connected with the elbows communicate through the communicating grooves, and therefore, two independent heat exchange runners are formed between the first end cover and the heat exchange sleeves and between the second end cover and the heat exchange sleeves. According to the heat exchanger, the metal injection molding technology is applied, the reasonable and mature brazing welding technology is additionally adopted, integral forming of s bent pipe and a sleeve can be achieved in a simple and effective mode, a spring is installed in a pipe body, the screw pitch L of the spring meets the condition that L is smaller than 50*D, so that additional heat resistance is reduced, and the heat exchange effect is better.

Owner:SHUNDE POLYTECHNIC

A kind of martensitic stainless steel seamless steel pipe for oil and gas development and its manufacturing method

ActiveCN104988403BHigh strengthOvercome the disadvantage of low strengthChemical compositionMetallurgy

The invention discloses a martensitic stainless steel seamless steel tube for oil and gas exploitation and a manufacturing method thereof. The seamless steel tube comprises, by weight, 0.20% to 0.60% of C, 0% to 1.00% of Si, 0% to 1.00% of Mn, 12.0% to 14.0% of Cr, 0% to 0.01% of S, 0% to 0.02% of P, 0% to 0.60% of Ni and the balance iron and unavoidable impurities. The manufacturing method includes the main steps that molten steel is smelted firstly according to chemical components, a billet is formed by the molten steel in a pouring mode and forged to be a solid circular tube blank, then the circular tube blank is extruded to be a seamless steel tube in the required specification, and the high-strength, high-tenacity and corrosion-resistant martensitic stainless steel seamless steel tube meeting the use requirement can be obtained after the tempering process and the follow-up finishing process.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

A kind of reed stalk aluminum plate composite plate and preparation method thereof

InactiveCN103753653BRetain structural strengthHigh strengthLaminationLamination apparatusEnvironmental resistanceWood shavings

The invention discloses a reed rod aluminum plate composite board and a manufacture method thereof. Different from the traditional method that a wood shaving board is made after reeds are smashed, the reeds stems are directly ground, adhered and rolled into reed stem shells for lamination, and then the reed stem shells are laminated into a reed rod composite layer. The structural strength of the reed stems is sufficiently maintained, and the defect that the strength of a composite board made through the smashing processing mode is low is overcome. According to the composite board, the reed stem composite layer is adhered to an aluminum base plate, and a waterproof board wraps the reed stem composite layer, so that interlamination sliding or coming-off of the reed stem composite layer after long time utilization are avoided, the reed stem composite layer is prevented from deteriorating and being rotted due to the fact that the reed stem composite layer is affected with damp, and the composite board which is light, large in strength, endurable and capable of protecting the environment is obtained.

Owner:SUZHOU UNIV OF SCI & TECH

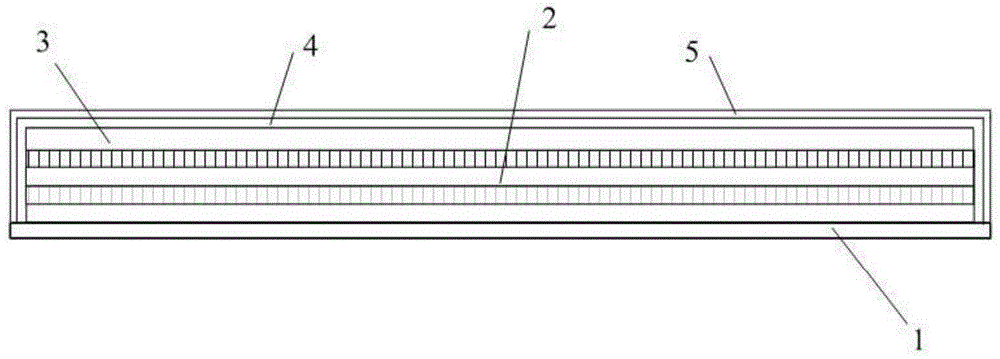

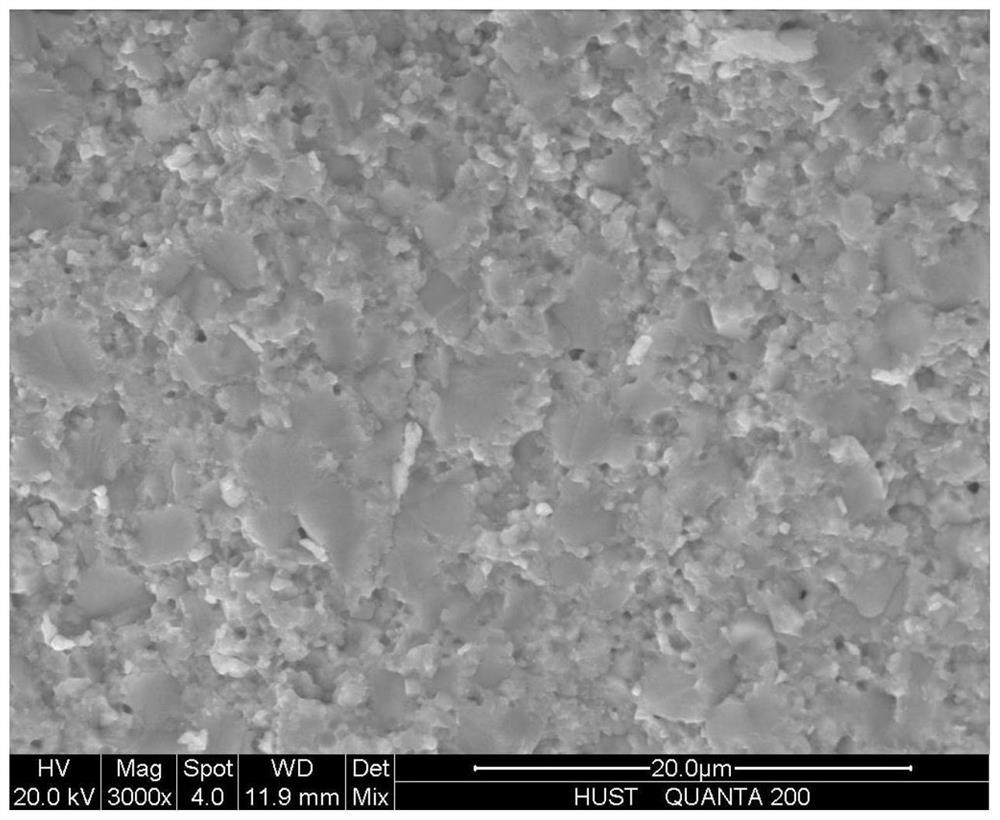

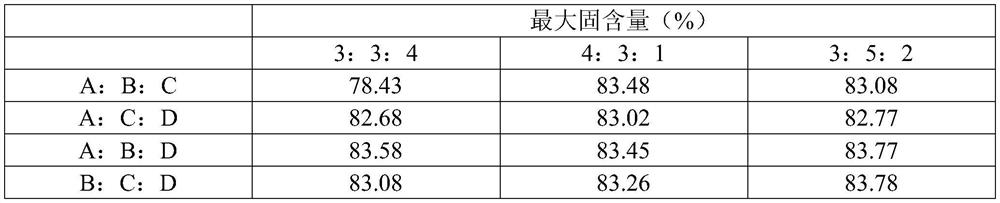

Preparation method and application of YSZ ceramic chip

The invention discloses a preparation method and application of a YSZ ceramic chip, specifically, YSZ powder with different particle sizes is selected and mixed, the large-particle-size YSZ powder is used as a framework, gaps among the large-particle-size YSZ powder are filled with small-particle-size YSZ powder, and obtained ceramic slurry is high in solid content, so that the prepared ceramic chip is better in compactness and smaller in shrinkage, and the thickness of the ceramic chip is smaller. In addition, absolute ethyl alcohol is used as a solvent, the defects that water-based tape casting is low in drying speed and a tape casting sheet is low in strength are overcome, the problem that traditional non-water-based tape casting is not environmentally friendly is solved, cost is low, and good market prospects are achieved. Glass phases such as SiO2, P2O5, K2O, CaO, TiO2, Fe2O3 and As2O3 exist in the cast sheet and the ceramic slurry, finally, degreasing and sintering are adopted for impurity removal, heat preservation is carried out at different temperature points, and the impurity glass phases are volatilized; and by adopting a sectional and gradual heating method, the defects of bending, cracking and the like of the chip can be prevented.

Owner:湖北丹瑞新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com