Durable fragrant ceramic decorative plate and preparation method thereof

A technology for durable fragrance and decorative plates, which is applied in the field of architectural ceramic decoration, and can solve the problems of inapplicability, short fragrance emission time, and low strength of porous ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

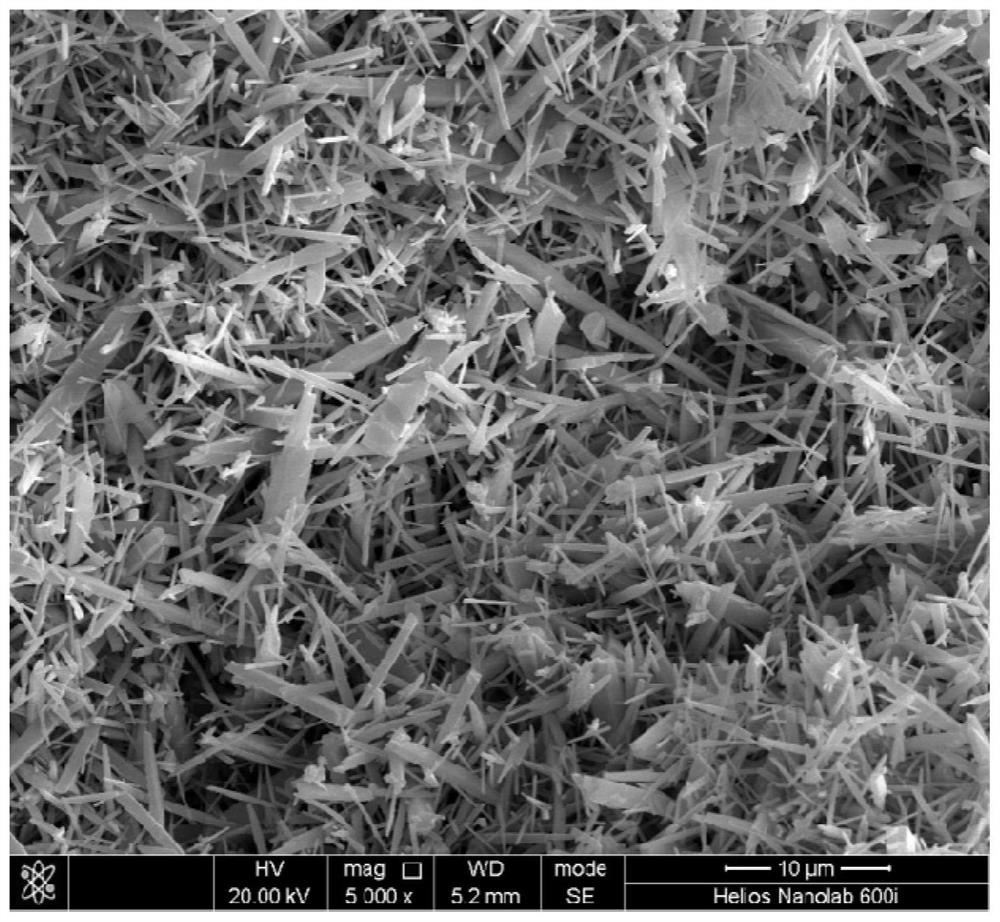

Image

Examples

Embodiment 1

[0037] Preparation of fragrance ceramic decorative plate:

[0038] (a) Weigh 300kg of kaolin, 150kg of calcined bauxite, 18kg of mineralizing agent aluminum fluoride, 18kg of sintering aid molybdenum oxide and 24kg of reinforcing agent silicon carbide (average particle size is 10 μm), put them in a ball mill jar, add water and ball milled for 12 hours to obtain a ceramic slurry with a median diameter of 7.0 μm, which was then dried by a spray tower to obtain green body powder. Wherein, the mass fraction of alumina in the chemical composition of kaolin is higher than 32%, while the mass fraction of alumina in the chemical composition of the calcined bauxite is between 55% and 80% (mass fraction), and the content of titanium oxide and iron oxide The total is less than 4% (mass fraction).

[0039] (b) Press the green body powder obtained in step (a) into a ceramic green body by a press, the pressing pressure is 30MPa, and the holding time is 6s.

[0040] (c) The ceramic green b...

Embodiment 2

[0046] Preparation of fragrance ceramic decorative plate:

[0047] (a) Weigh 300kg of kaolin, 150kg of calcined bauxite, 13kg of mineralizing agent aluminum fluoride, 22kg of sintering aid cerium oxide and 24kg of reinforcing agent silicon carbide (average particle size is 10μm), place them in a ball mill jar, add water and ball milled for 20 hours to obtain a ceramic slurry with a median diameter of 5.2 μm, which was then dried by a spray tower to obtain green body powder. Wherein, the mass fraction of alumina in the chemical composition of kaolin is higher than 32%, while the mass fraction of alumina in the chemical composition of the calcined bauxite is between 55% and 80% (mass fraction), and the content of titanium oxide and iron oxide The total is less than 4% (mass fraction).

[0048] (b) Press the green body powder obtained in step (a) into a ceramic green body through a press, the pressing pressure is 20 MPa, and the holding time is 8 s.

[0049] (c) Dry the ceramic...

Embodiment 3

[0055] Preparation of fragrance ceramic decorative plate:

[0056] (a) Weigh 300kg of kaolin, 150kg of calcined bauxite, 18kg of mineralizing agent aluminum fluoride, 18kg of sintering aid molybdenum oxide and 24kg of reinforcing agent silicon carbide (average particle size is 10 μm), put them in a ball mill jar, add water and ball milled for 12 hours to obtain a ceramic slurry with a median diameter of 7.0 μm, which was then dried by a spray tower to obtain green body powder. Wherein, the mass fraction of alumina in the chemical composition of kaolin is higher than 32%, while the mass fraction of alumina in the chemical composition of the calcined bauxite is between 55% and 80% (mass fraction), and the content of titanium oxide and iron oxide The total is less than 4% (mass fraction).

[0057] (b) Press the green body powder obtained in step (a) into a ceramic green body through a press, the pressing pressure is 30 MPa, and the holding time is 8 s.

[0058] (c) Dry the cera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com