Tin-zinc hot dipping fuel-tank high-strength steel plate with good corrosion resistance and manufacturing method thereof

A technology of high-strength steel plate and manufacturing method, applied in hot-dip galvanizing process, manufacturing tools, heat treatment furnace, etc., can solve the problems of complex shape, zinc clogged fuel filter, poor welding performance, etc., achieve good corrosion resistance, overcome harmful The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

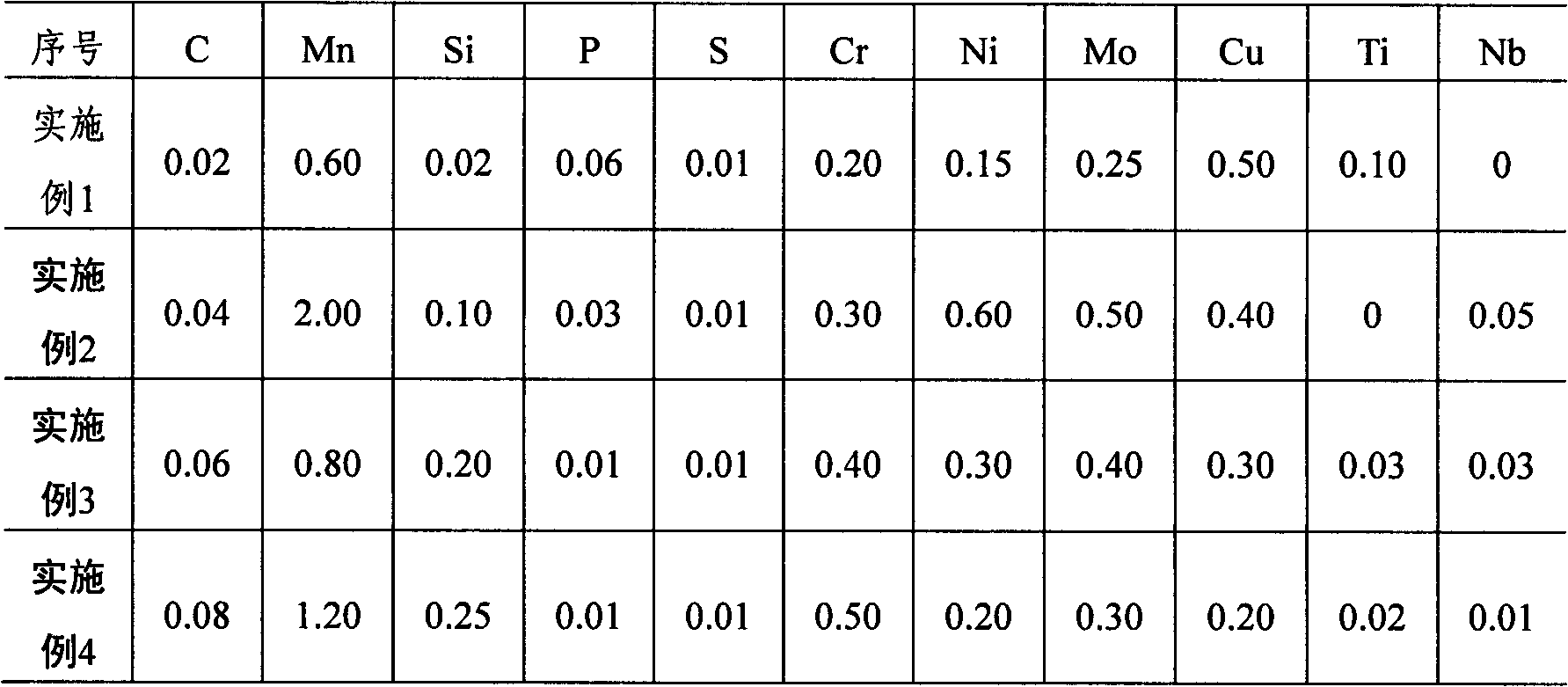

[0031] The chemical composition of the steel is shown in Table 1. The annealing process is 820°C for 20 seconds, cooled to 320°C at a rate of 50°C per second and held for 60 seconds, then hot-dipped. The temperature of the bath is 300°C, and the zinc content of the bath is 8wt. .%, the balance is tin and unavoidable impurities, air knife purging after leaving the plating solution, air cooling to room temperature, the structure is ferrite + bainite + austenite, and its volume content is 69%-83% %, 15%-23%, 2%-5%.

Embodiment 2

[0033] The chemical composition of the steel is shown in Table 1. The annealing process is 800°C for 40 seconds, cooled to 300°C at a rate of 20°C per second and held for 20 seconds, then hot-dipped. The temperature of the bath is 290°C, and the zinc content of the bath is 10 %wt.%, the balance is tin and unavoidable impurities, air knife purging after leaving the plating solution, air cooling to room temperature, the structure is ferrite + martensite + bainite, the volume content is 56% respectively -68%, 20%-30%, 5%-20%.

Embodiment 3

[0035] The chemical composition of the steel is shown in Table 1. The annealing process is 780°C for 60 seconds, cooled to 280°C at a rate of 70°C per second and held for 50 seconds, then hot-dipped. The temperature of the bath is 270°C, and the zinc content of the bath is 12wt. .%, the balance is tin and unavoidable impurities, air knife purging after leaving the plating solution, air cooling to room temperature, the structure is ferrite + bainite + martensite, and its volume content is 50%-80% %, 15%-25%, 15%-35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com