Heat exchanger with spring rib structure

A technology of heat exchanger and rib structure, applied in heat exchange equipment, heat exchanger type, heat exchanger shell, etc., can solve the problems of short heat exchange time, low refrigerant flow rate, short heat exchange flow distance, etc., to achieve Reduce the impact of heat exchange efficiency, high product size accuracy, and solve the effect of short heat exchange stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution will be described in detail below in conjunction with specific embodiments.

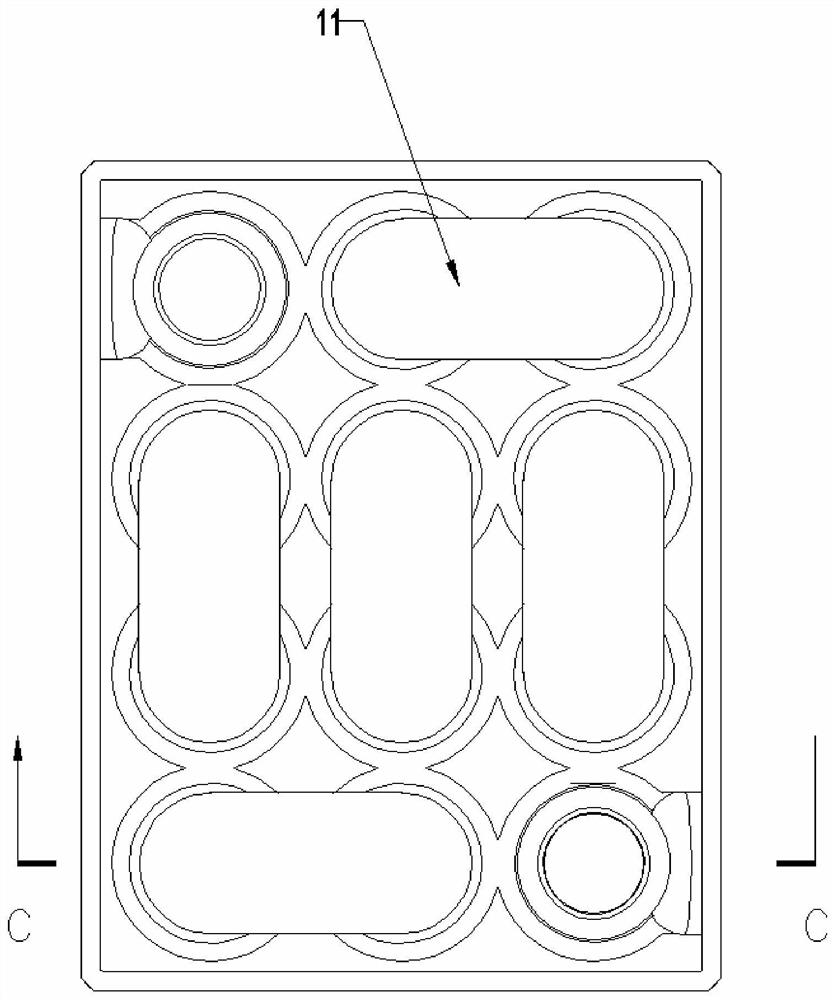

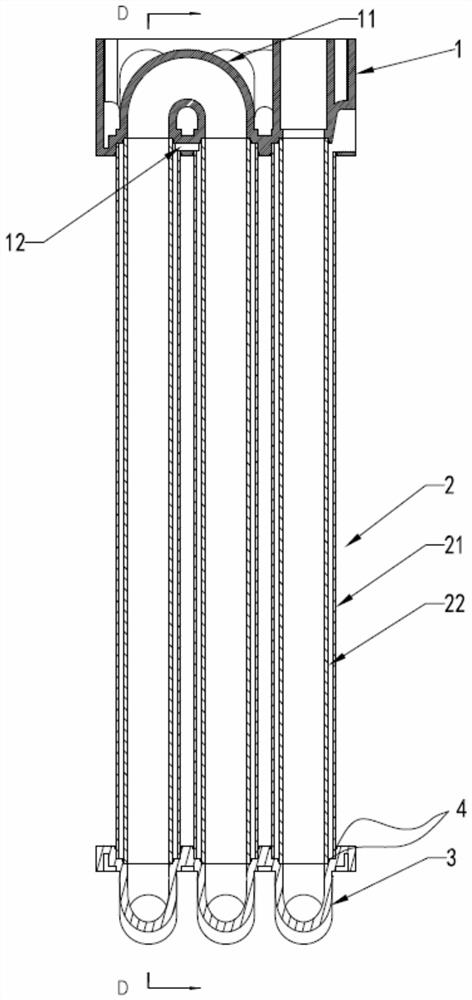

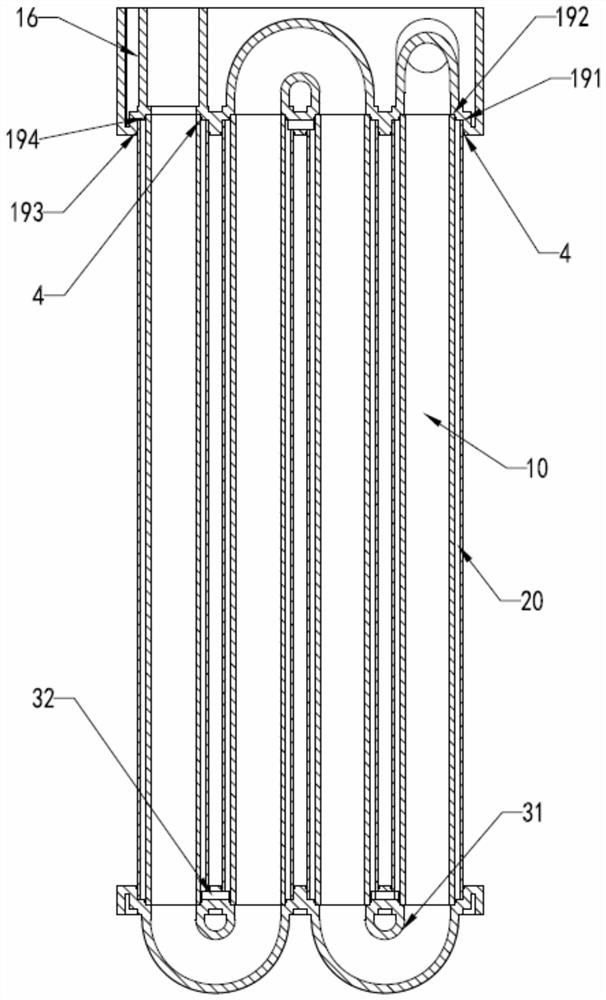

[0028] Such as Figure 1-10 As shown, the present invention discloses a heat exchanger with a spring rib structure, including a first end cover 1, a second end cover 3, a heat exchange sleeve 2, and a heat exchanger between the first and second end covers and the heat exchange sleeve. The two heat exchange channels formed are respectively the water channel 10 and the refrigerant channel 20 . The heat exchange sleeve 2 is composed of an inner tube 22 and an outer tube 21. As we know, in order to make the fluid heat exchange more fully, it can be realized by increasing the heat exchange area of the two fluids and prolonging the heat exchange time between the two fluids. However, the traditional sleeve-type heat exchanger cannot extend the length of the heat exchange flow path due to the limitation of the length of the tube body. Although the screw-wound tube heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com