Preparation method and application of YSZ ceramic chip

A technology of chips and ceramics, which is applied in the field of preparation of YSZ ceramic chips, can solve the problems that ceramic chips are prone to cracks, pits and curls, and is not friendly to the environment, so as to achieve good market prospects, good compactness, and overcome the problems of unfriendly environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

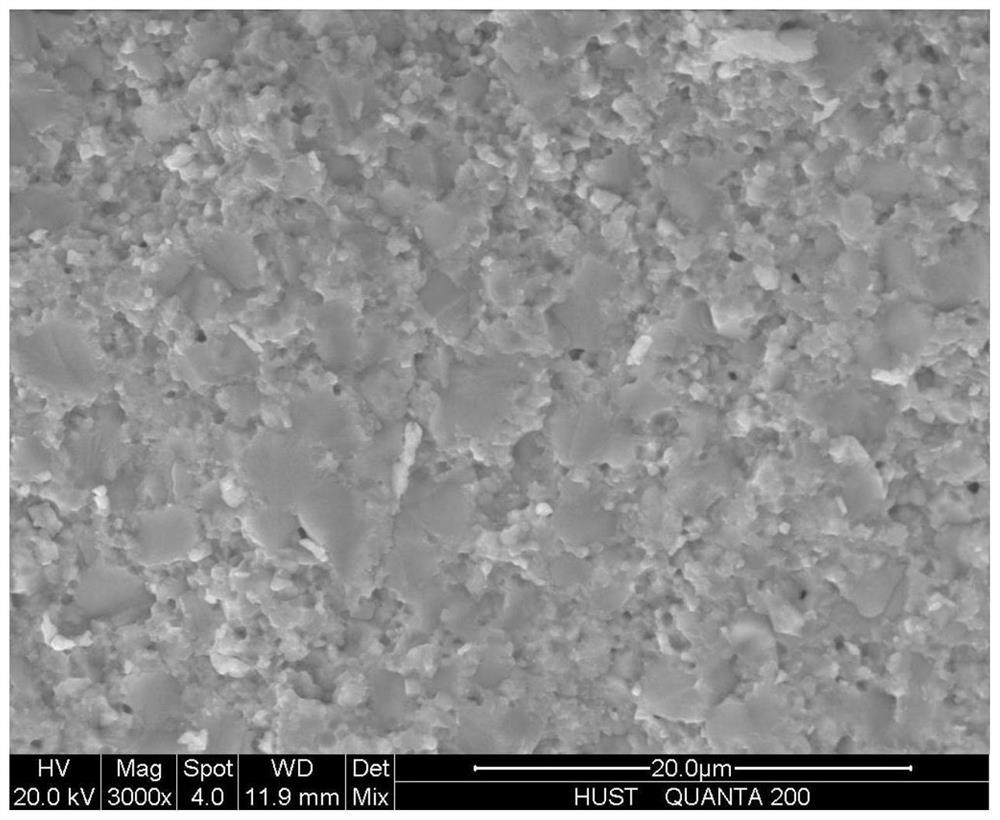

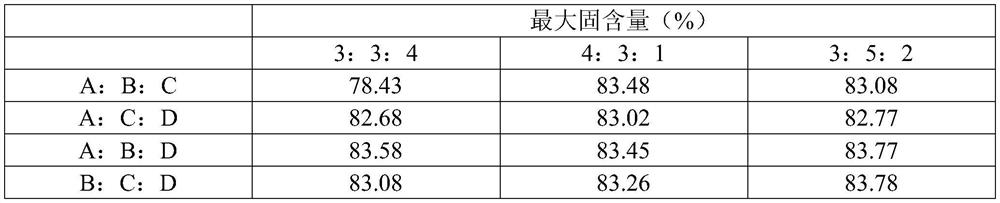

[0028] The proportioning optimization of the YSZ powder of different particle sizes and the solid content optimization of the YSZ powder of embodiment 1

[0029] YSZ powder with a particle size of 0.1-0.2 μm, YSZ powder with a particle size of 0.3-0.6 μm, YSZ powder with a particle size of 0.8-0.9 μm and YSZ powder with a particle size of 1.2-1.5 μm were respectively set For groups A, B, C, and D, choose one, two, three or four YSZ powders with different particle sizes for mixing, the total mass is 100g, add 15g of absolute ethanol to dissolve and stir, and then continue to use the glue head Add absolute ethanol drop by dropper and stir, find the critical inflection point, calculate the total mass of absolute ethanol used, calculate the solid content at this time is the maximum solid content, and the proportion of YSZ powder with different particle sizes corresponding to the maximum solid content , which is the optimal ratio.

[0030] Three kinds of YSZ powders with different...

Embodiment 2

[0054] A preparation method of a YSZ ceramic chip, comprising the steps of:

[0055] S1. Mix the powder with a particle size of 0.3-0.6 μm, the powder with a particle size of 0.8-0.9 μm and the powder with a particle size of 1.2-1.5 μm in a mass ratio of 3:5:2, and then add Triethanolamine and absolute ethanol, the addition of described triethanolamine is 0.7% of the total amount of the ceramic slurry, and the addition of the absolute ethanol is 37.3% of the total amount of the ceramic slurry, and then the first Second ball milling, the parameters of the first ball milling are as follows: ball milling 8-10h, ball milling speed is 300-350r / min, after ball milling, polyvinyl butyral and dibutyl phthalate are added again, the described The addition of polyvinyl butyral is 3.5% of the total amount of the ceramic slurry, and the addition of the dibutyl phthalate is 1.5% of the total amount of the ceramic slurry, followed by the second Ball milling, the parameters of the second bal...

Embodiment 3

[0061] A preparation method of a YSZ ceramic chip, comprising the steps of:

[0062] S1. Mix the powder with a particle size of 0.3-0.6 μm and the powder with a particle size of 1.2-1.5 μm in a mass ratio of 4:1, then add tributyl phosphate and absolute ethanol, the triphosphate The addition of butyl ester is 0.7% of the total amount of the ceramic slurry, and the addition of the absolute ethanol is 37.3% of the total amount of the ceramic slurry, followed by ball milling for the first time, the ball milling for the first time The parameters are as follows: ball milling for 8 to 10 hours, the ball milling speed is 300 to 350r / min, after the ball milling, polyvinyl butyral and polyethylene glycol are added again, and the amount of polyvinyl butyral added is the 3.5% of the total amount of the ceramic slurry, the addition of the polyethylene glycol is 1.5% of the total amount of the ceramic slurry, and then the second ball milling is carried out, and the parameters of the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com