Lithium ion battery silicon oxygen anode paste, preparation method thereof, battery anode and lithium ion battery

A lithium-ion battery and negative electrode slurry technology, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of small particle size, large specific surface area, and difficult dispersion, and achieve high first effect and good dispersion , the effect of cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

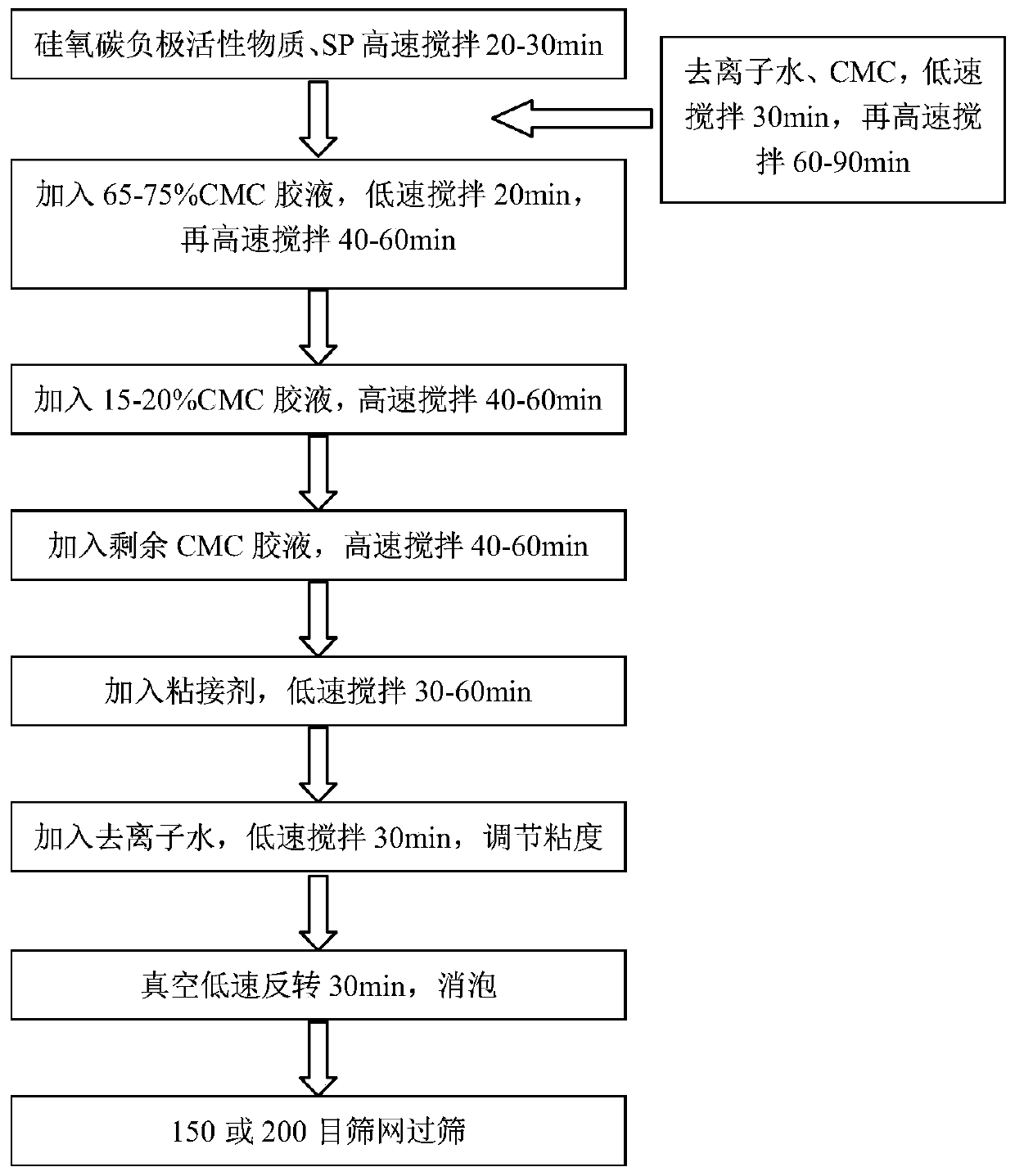

[0046] Such as figure 1 As shown, the present invention also provides a preparation method of silicon-oxygen negative electrode slurry for lithium-ion batteries, comprising the following steps:

[0047] 1) Preparation of glue: Add appropriate amount of deionized water (accounting for 40%-80% of the volume of the stirred tank) in the stirred tank, add 1.5-1.8% solid content CMC (solid content=CMC quality / (CMC quality+deionized Water quality)), first stir at low speed for 30min, open the stirring tank for scraping if necessary, scrape the undispersed CMC powder sticky on the paddle and the kettle wall into the kettle; then stir at high speed for 60-90min, until the CMC is completely dissolved In the deionized water, a transparent and viscous CMC glue is formed; in this process, in order to prevent the temperature from being too high, the water can be turned on to cool the circulating water so that the temperature in the stirring tank does not exceed 40°C; take out the prepared C...

Embodiment 1

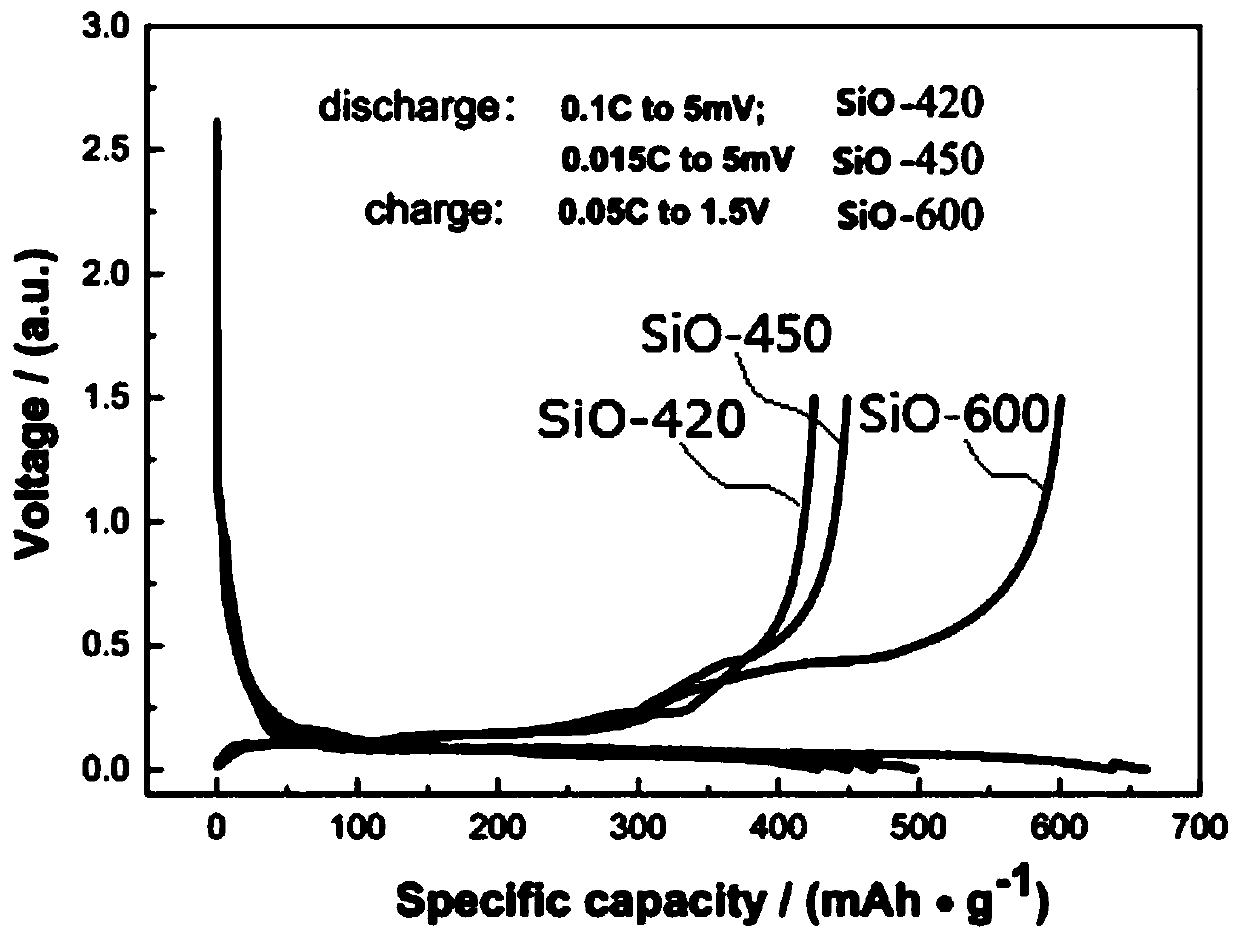

[0057] The main material of negative electrode slurry: gram capacity 420mAh / g silicon oxide negative electrode active material; the weight ratio of each component is negative electrode active material: SP: CMC: SBR (solid part) = 96: 1.0: 1.2: 1.8, that is, the weight of all materials is 100 In terms of parts, the negative electrode active material accounted for 96 parts, SP accounted for 1 part, CMC accounted for 1.2 parts, and SBR (solid part) accounted for 1.8 parts.

[0058] The particle size of the silicon-oxygen negative electrode active material described therein includes D10: 5 microns, D50: 11 microns, D90: 25 microns, and the ratio of the three is 1:0.3:0.2, and the specific surface area is 3.0m 2 / g, the tap density is 1.2g / cm 3 . According to the conversion of the ratio of D10:D50:D90 to weight percentage, D10: 66.67%, D50: 20%, D90: 13.33%, the degree of substitution of CMC A=0.5*66.67% / (20%+13.33%)= 1.0, the value range of K here is 0.5.

[0059] Further, the ...

Embodiment 2

[0068] The main material of the negative electrode slurry: the gram capacity of 500mAh / g silicon oxide negative electrode active material; the weight ratio of each component is the negative electrode active material: SP: CMC: PAA (solid part) = 95.0: 1.1: 1.4: 3.5, that is, the weight of all materials is 100 In terms of parts, the negative electrode active material accounted for 95.0 parts, SP accounted for 1.1 parts, CMC accounted for 1.4 parts, and PAA (solid part) accounted for 3.5 parts.

[0069] The particle size of the silicon-oxygen negative electrode active material described therein includes D10: 8 microns, D50: 16 microns, D90≤30 microns, and the ratio of the three is 1:0.5:0.2, and the specific surface area is 1.5m 2 / g, the tap density is 0.98g / cm 3 . According to the conversion of the ratio of D10:D50:D90 to the percentage by weight, D10: 58.82%, D50: 29.41%, D90: 11.77%, the degree of substitution of CMC A=0.9*58.82% / (29.41%+11.77%)= 1.32, the value range of K ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com