Rock coarse fracture seepage simulation model and making method

A technology of simulation model and production method, which is applied in the fields of permeability/surface area analysis, suspension and porous material analysis, instruments, etc., which can solve the problem of not being able to fully and accurately reflect the structural surface characteristics of rock mass fissures, large gaps between fissures and actual engineering, gap and other issues, to achieve the effect of rapid integrated molding, reduced test cost, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing of description, the present invention will be further described.

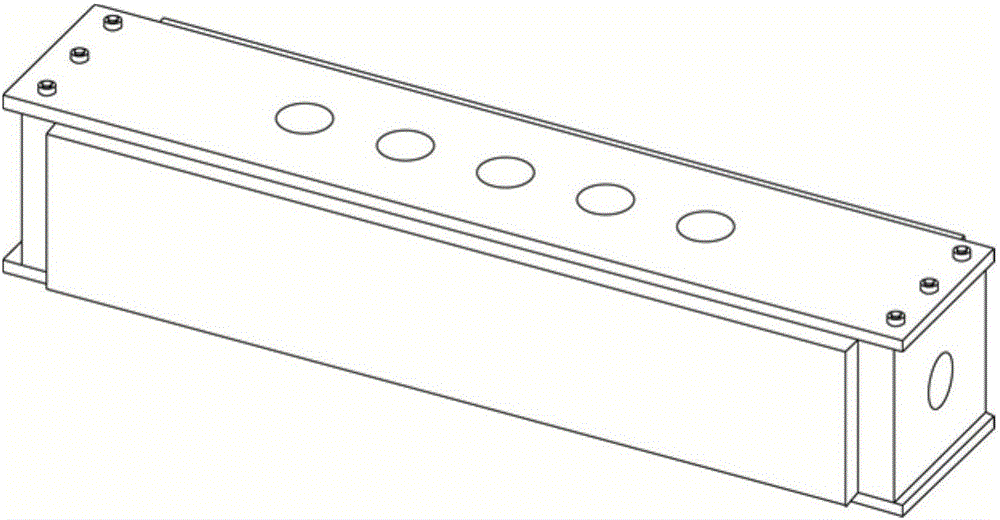

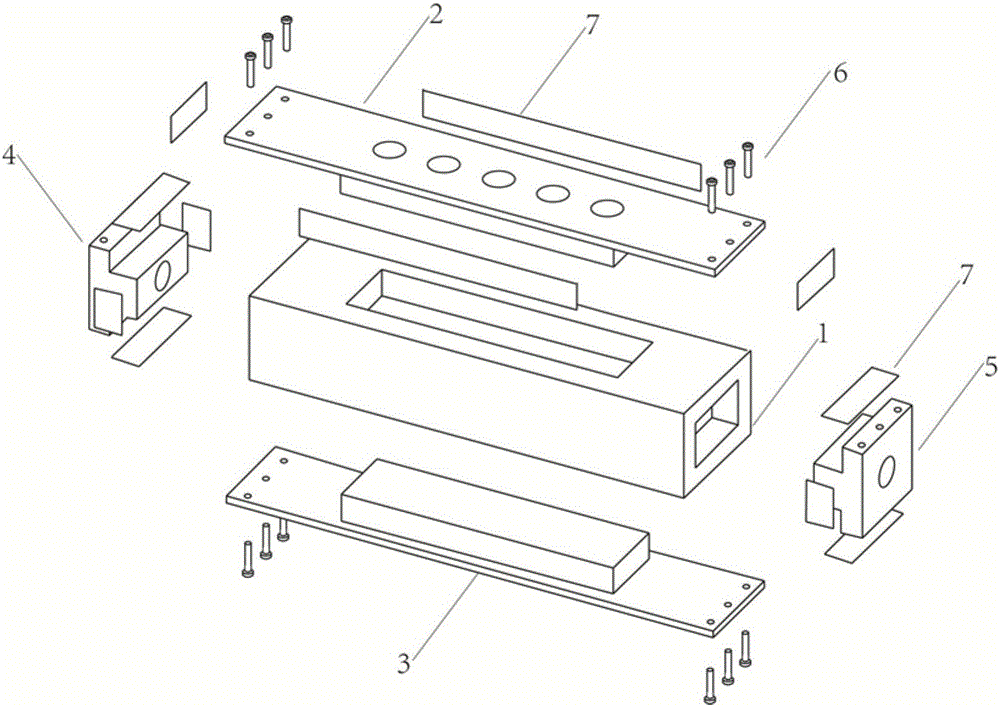

[0038] Such as figure 1 , figure 2 A rough crack seepage simulation model of rock mass is shown, including a crack main board 1, an upper installation board 2, a lower installation board 3, a left installation board 4, a right installation board 5, a fixing bolt 6 and a rubber pad 7; the crack main board is a cuboid structure, the upper surface and lower surface of the cuboid structure are respectively matched with the upper mounting plate and the lower mounting plate; the left and right surfaces are respectively matched with the left mounting plate 4 and the right mounting plate 5, and the upper mounting plate 2, the lower mounting plate There is also a rubber pad 7 at the matching position between the board 4, the right mounting board 5 and the cracked main board 1, and each is connected by a fixing bolt 6;

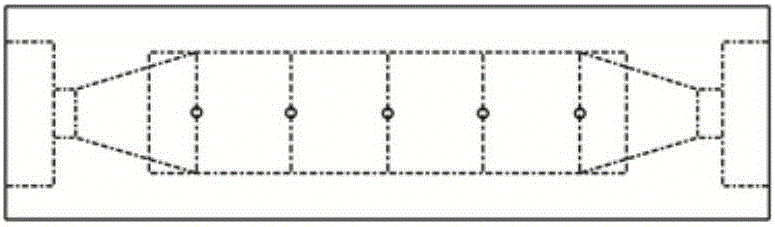

[0039] Such as Figure 3-1 to Figure 3-4 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com