Hogging moment rebar suspension construction control protection layer device and construction method thereof

A negative moment reinforcement, control and protection technology, applied to the processing of building materials, structural elements, building components, etc., can solve the problems of uneven spacing of reinforcement bars, low pad strength, and uneven force on the board, so as to reduce investment, The structure of the device is simple and light, and the effect of improving the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

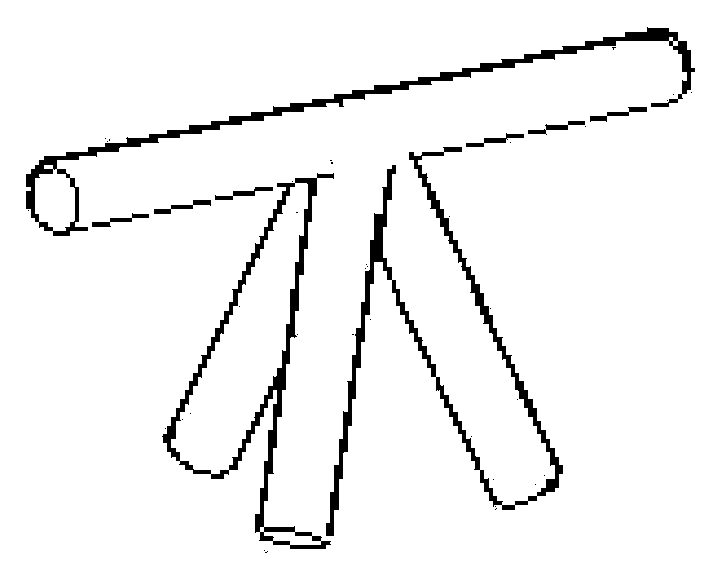

[0034] See figure 1 , is a structural schematic diagram of the device of the present invention, including a tripod support base 1 , a horizontal fixed beam 2 , and a fixed binding wire 3 .

[0035] See figure 2 , is a schematic diagram of the structure of the device tripod support seat of the present invention, and the tripod support seat 1 is made of steel bars, preferably For the above steel bars, the upper end of the triangular support is concentratedly welded on the support beam, the lower fulcrum is evenly distributed along the circumferential direction on the same horizontal plane, and the bottom is a triangular stable support;

[0036] See Figure 3-Figure 4 , is a schematic diagram of installation of the device of the present invention, the horizontal fixed beam 2 is made of steel pipe or square wood, preferably The steel pipe is er...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com