Internal spiral heat exchanger

A heat exchanger, spiral technology, applied in the field of internal spiral heat exchangers, can solve the problems of height, fins can only be installed on the outer wall of the tube, overall performance is limited by conditions, unfavorable heat exchange, etc., to achieve product size The effect of high precision, increased length and area, and improved heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution will be described in detail below with reference to specific embodiments.

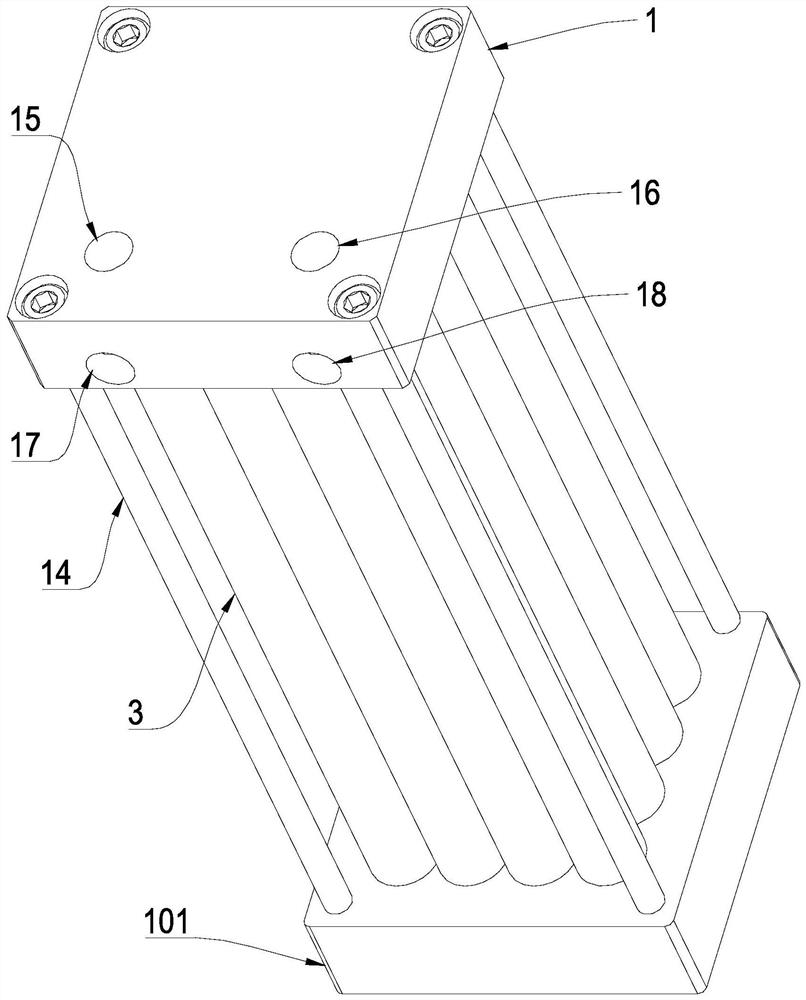

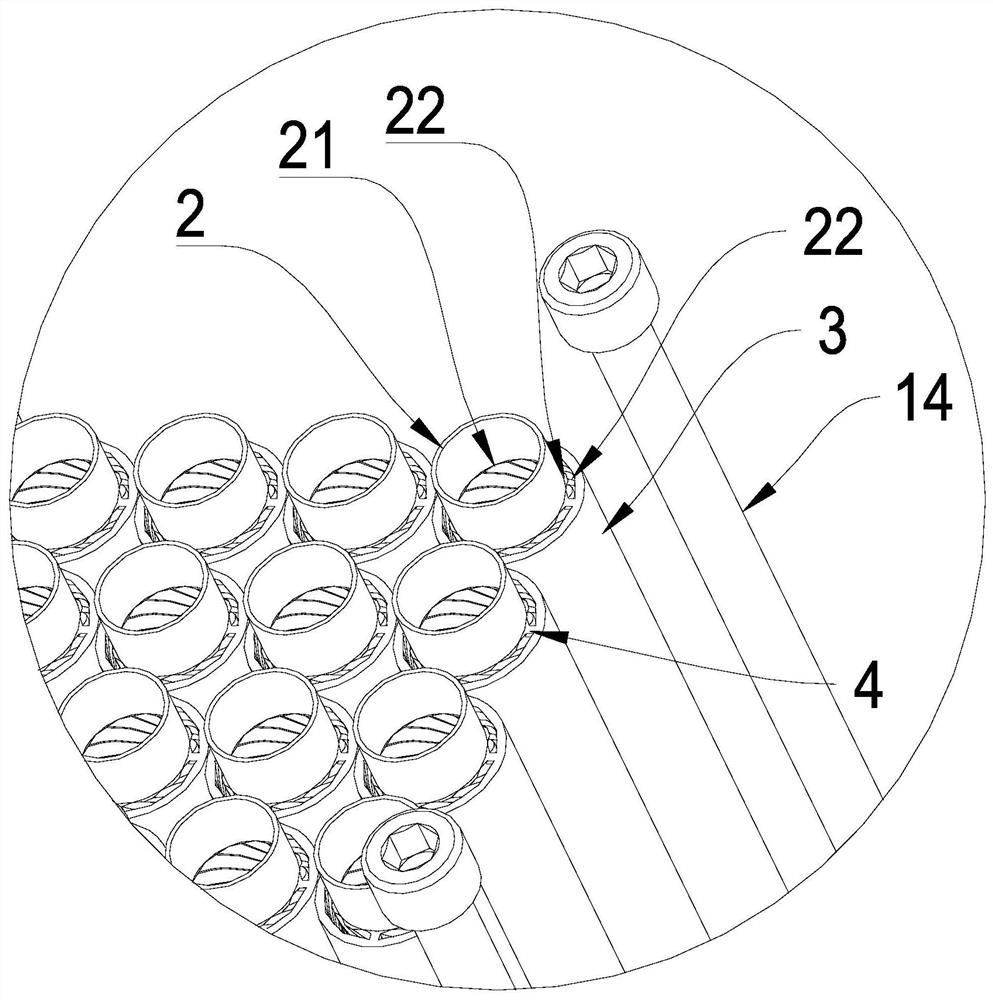

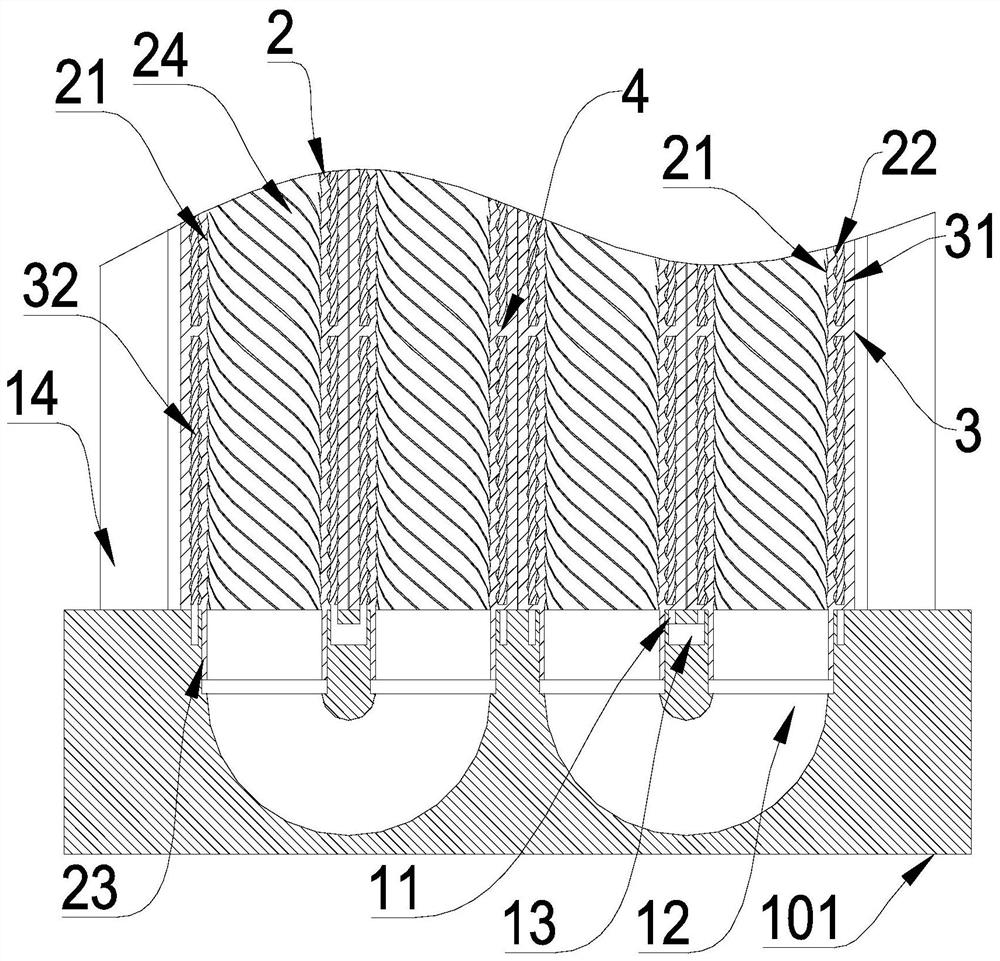

[0023] like Figure 1-3 As shown, the present invention discloses an internal spiral heat exchanger, which includes an upper cover 1 and a base 101, and is connected to a middle section between the upper cover 1 and the base 101, wherein 16 middle sections are selected, and they are 4×4 The array is vertically arranged between the upper cover 1 and the base 101, and two independent heat exchange channels are formed between the upper cover 1, the base 2 and the middle section, which are the refrigerant flow channel 32 and the refrigerant flow channel 24 respectively. .

[0024] Further, the middle section includes an inner tube 2 and an outer sleeve 3. The upper cover 1 and the base 101 are provided with a bend 12 opening on the upper cover 1 and the base 101, and on the upper cover 1 and the base 101. A ring groove 11 is arranged around the opening of the bend 12 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com