Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120results about How to "Increase heat transfer temperature difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

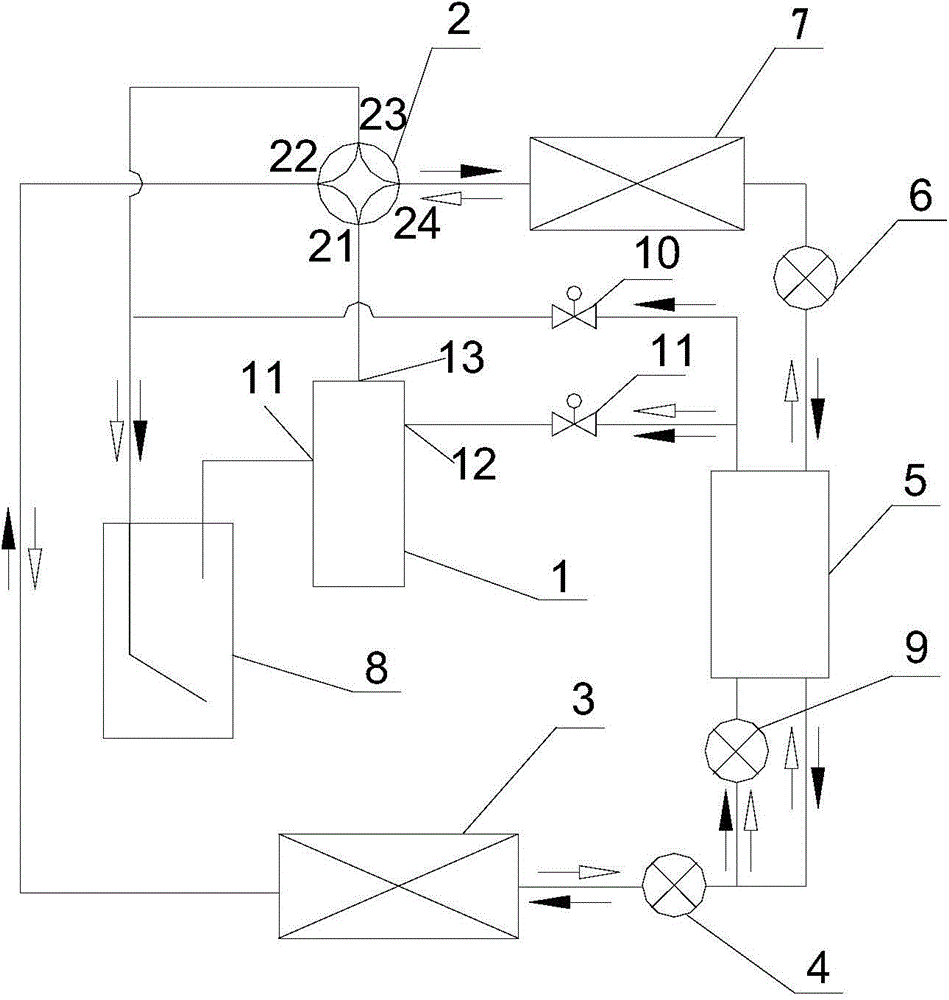

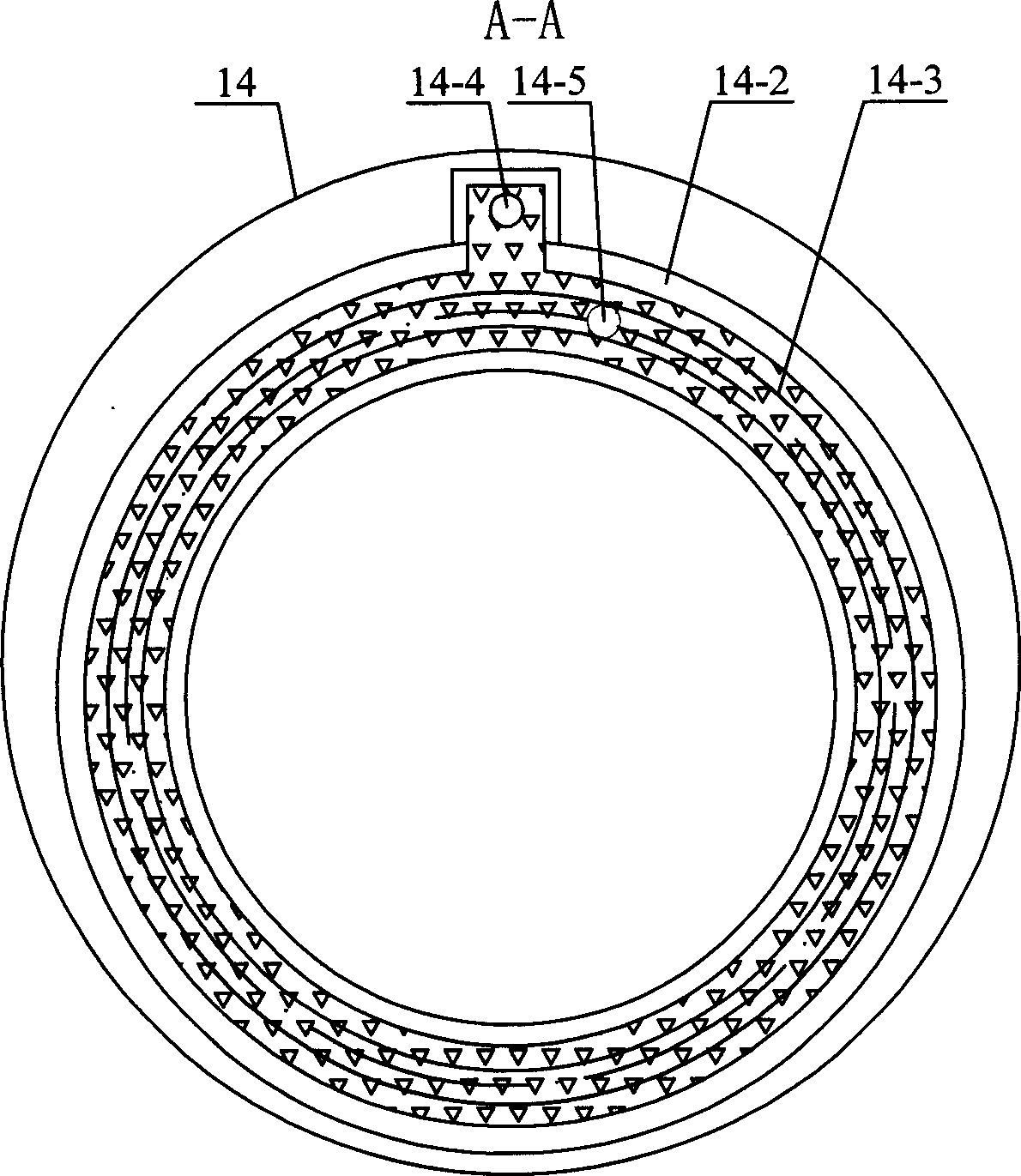

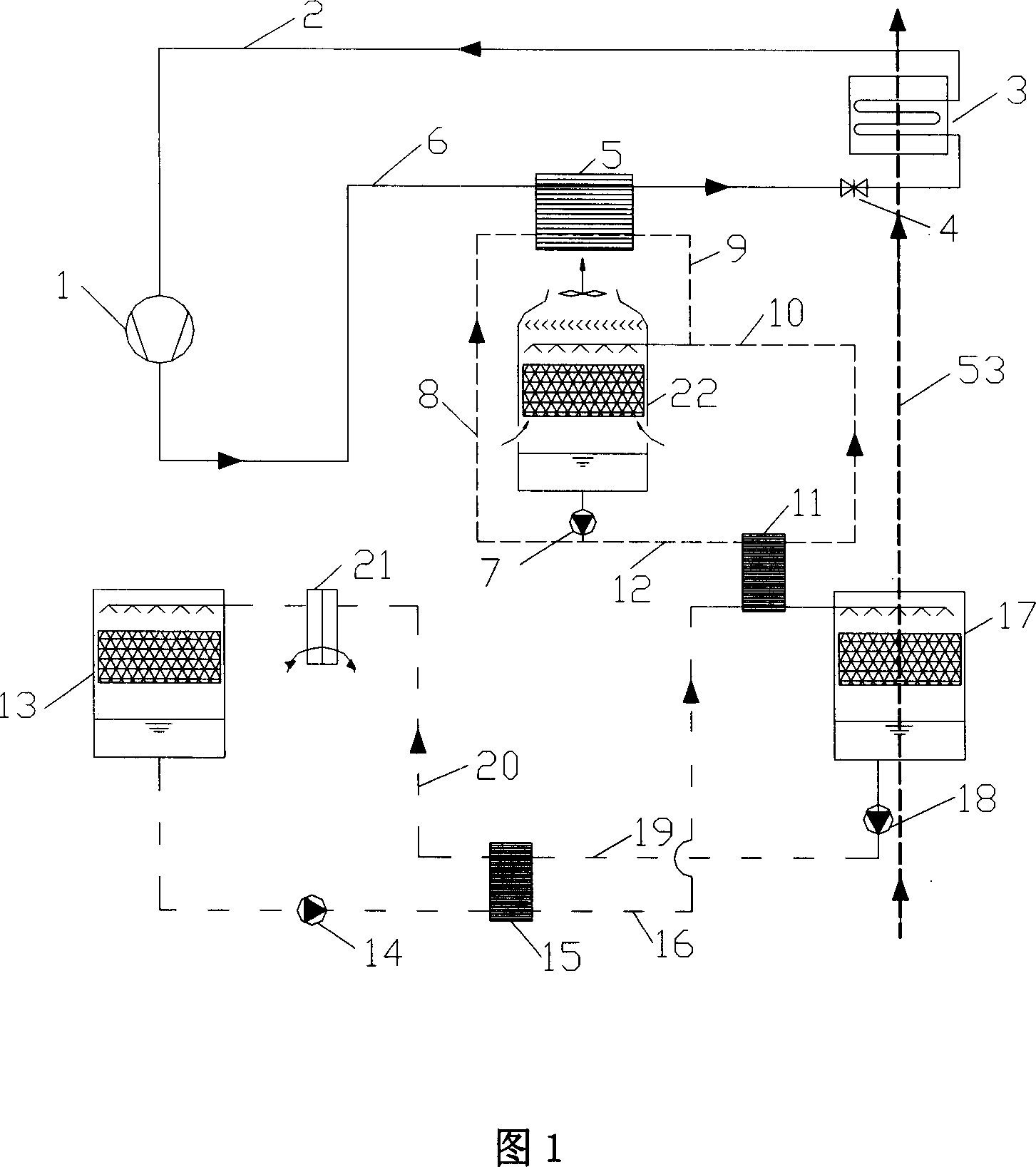

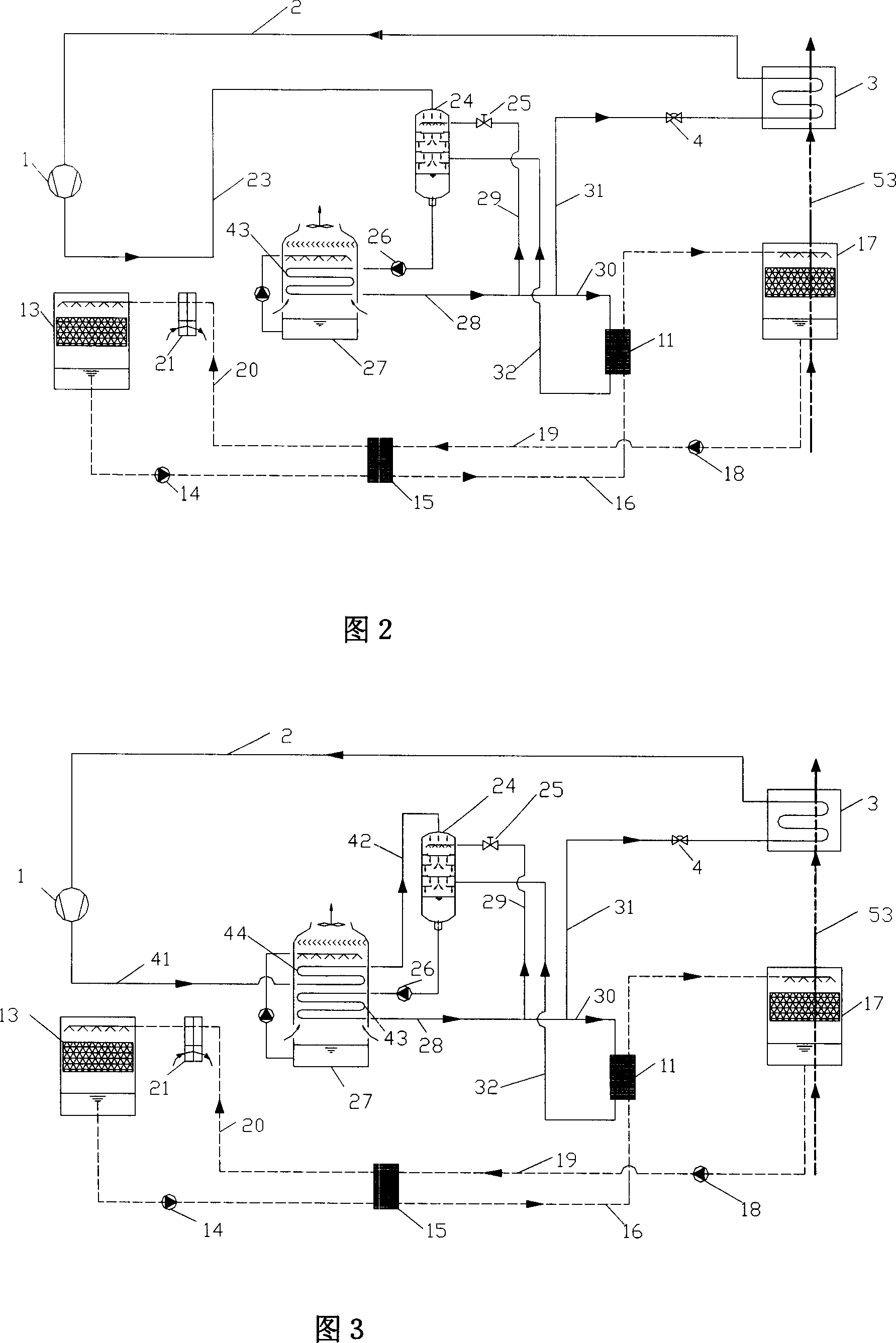

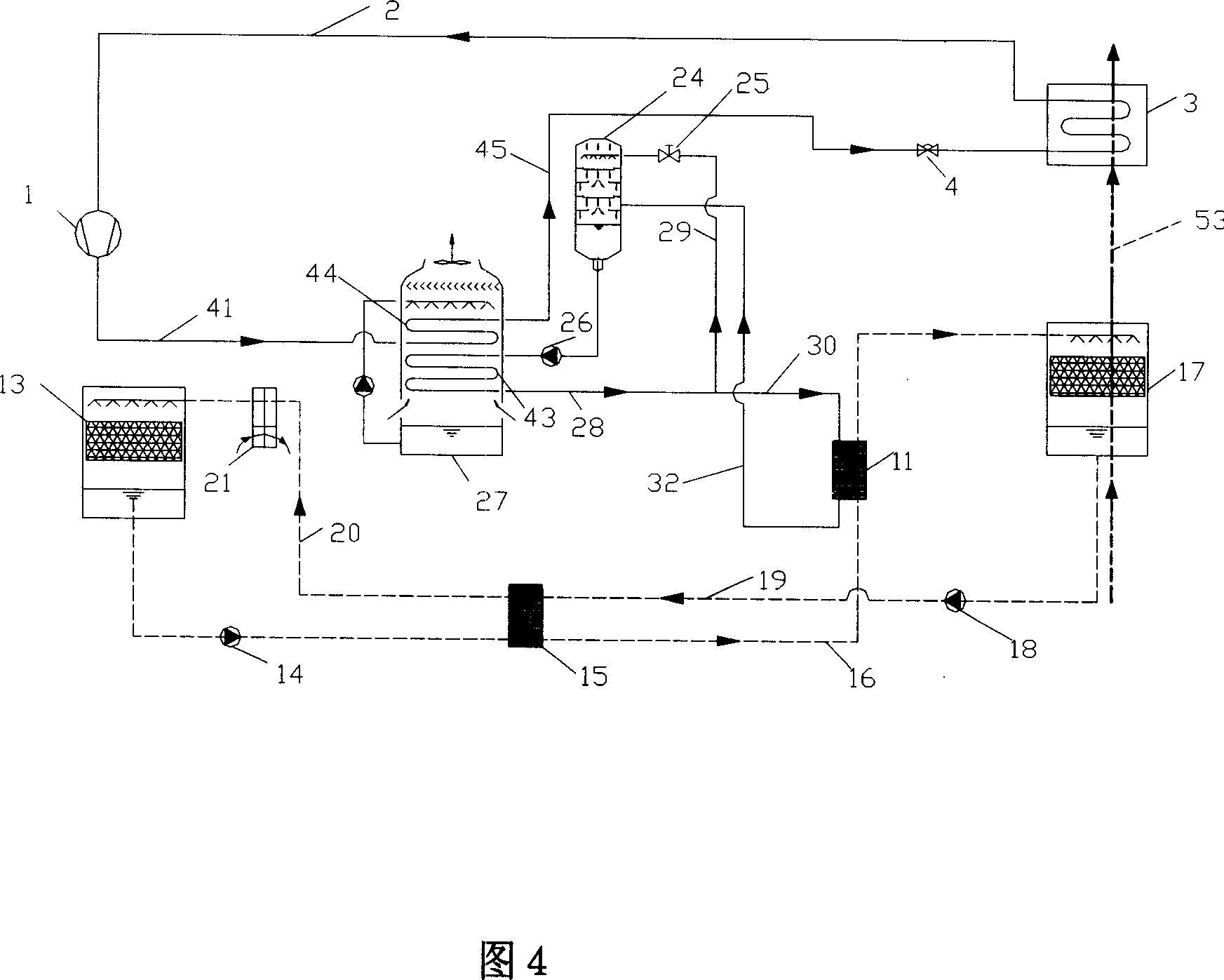

Heat pump air conditioner system

InactiveCN104613665AIncrease heat transfer temperature differenceDelay performance decayMechanical apparatusFluid circulation arrangementVapor–liquid separatorSolenoid valve

The invention discloses a heat pump air conditioner system. The heat pump air conditioner system comprises a compressor, an indoor heat exchanger, a first throttling device, an economizer, a second throttling device, an outdoor heat exchanger, a gas-liquid separator and an enhanced vapor injection refrigerating / heating circulating loop partially or totally composed in a third throttling device. The heat pump air conditioner system further comprises a first solenoid valve and a second solenoid valve. A connector of an auxiliary loop of the economizer and a vapor injection opening of the compressor is further communicated with an inlet of the gas-liquid separator through a pipe. The first solenoid valve is arranged on a connection pipe between the auxiliary loop of the economizer and an inlet of the gas-liquid separator. The second solenoid valve is arranged on a connection pipe between the auxiliary loop of the economizer and the vapor injection opening of the compressor. By means of the heat pump air conditioner system, the heat exchange temperature difference between the gas side and the liquid side of the economizer is increased, and higher heat exchange efficiency is achieved; the condensate depression of the system is improved in the refrigerating operating process, and capacity attenuation of unit long piping in the mounting process is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

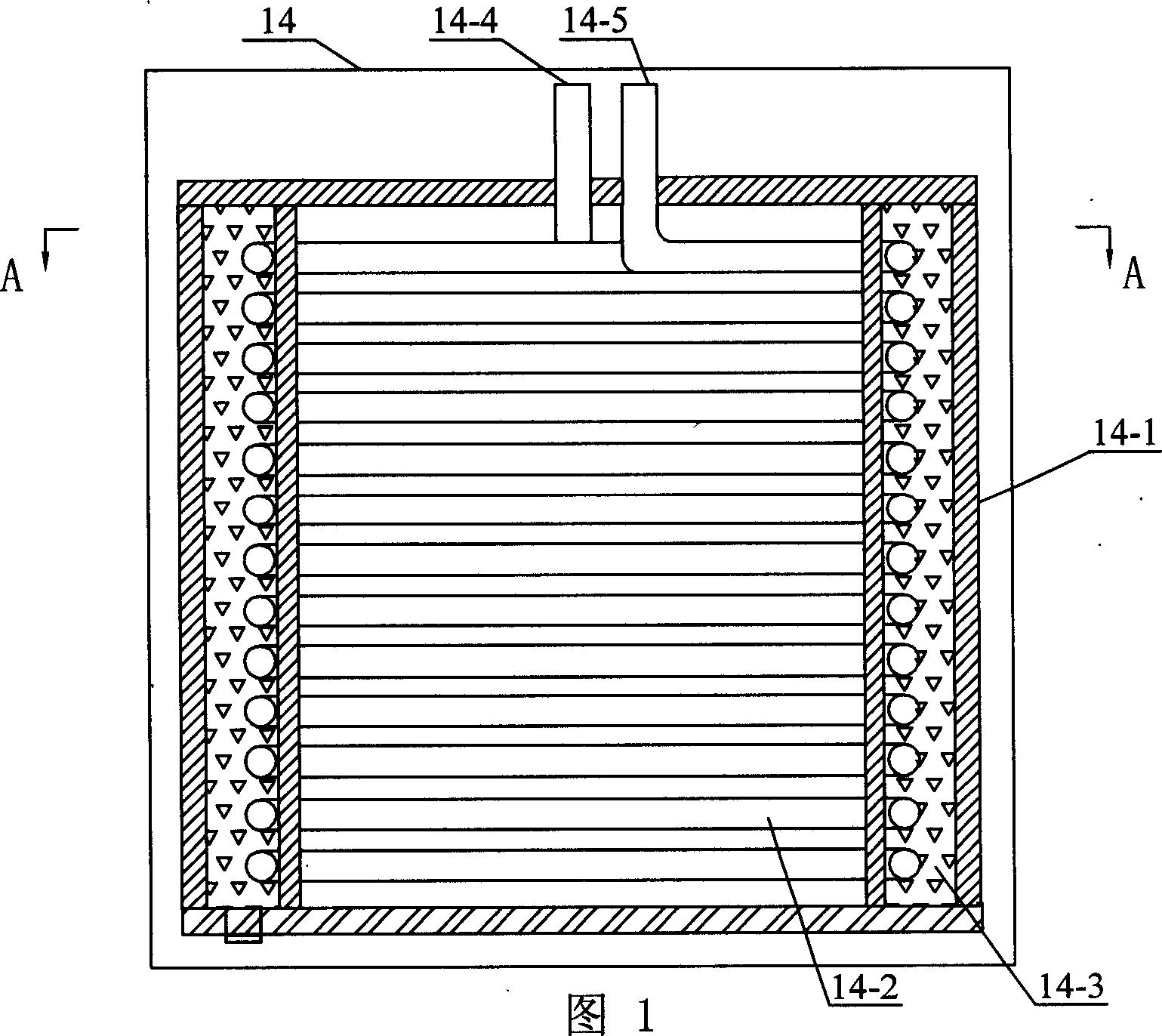

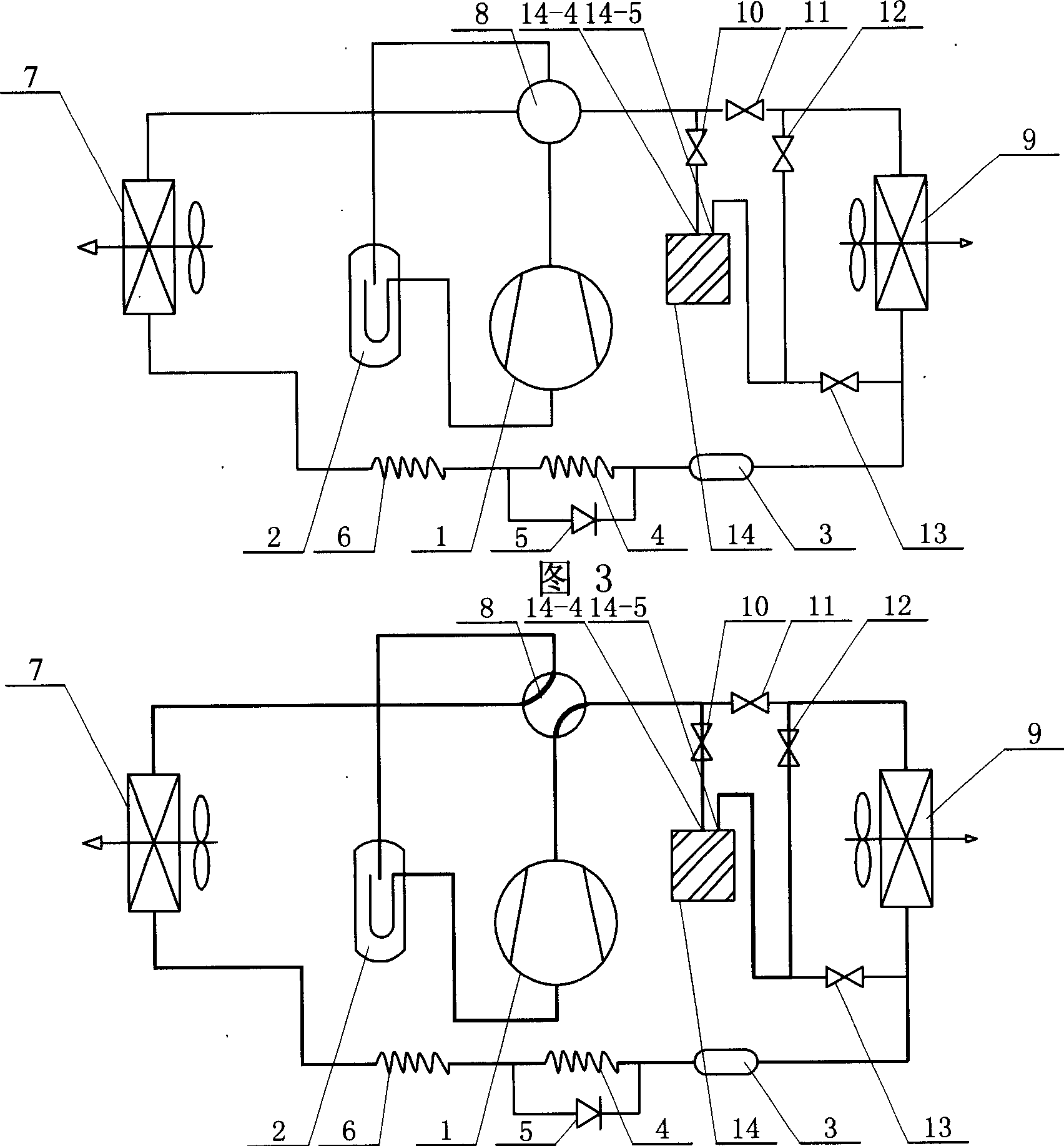

Accumulation phase-change material, and defrosting system of accumulation type air-source heat pump of using the material

InactiveCN1687297AShorten defrosting timeReduce energy lossCorrosion preventionHeat-exchange elementsChemical compositionEngineering

The present invention to an energy-storing phase change material and energy-stored air source heat pump defrosting system, belonging to the field of refrigeration equipment technology. The chemical component of said energy-storing phase change material is formed from CaCl2.6H2O and nucleating agent. Said invention also provides the concrete structure of said system. Said system can implement the function conversion from system heat production, waste heat energy storage, energy-releasing defrosting and heat production.

Owner:HARBIN INST OF TECH

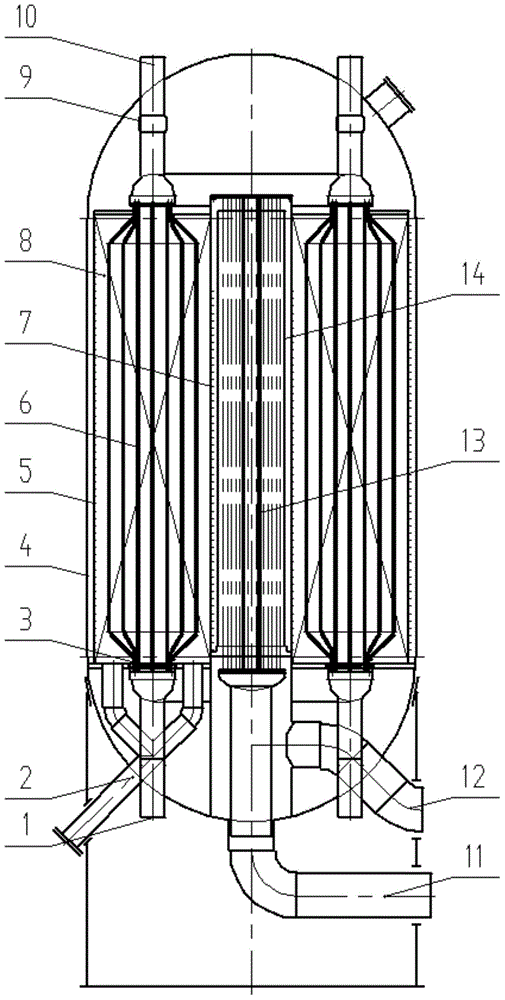

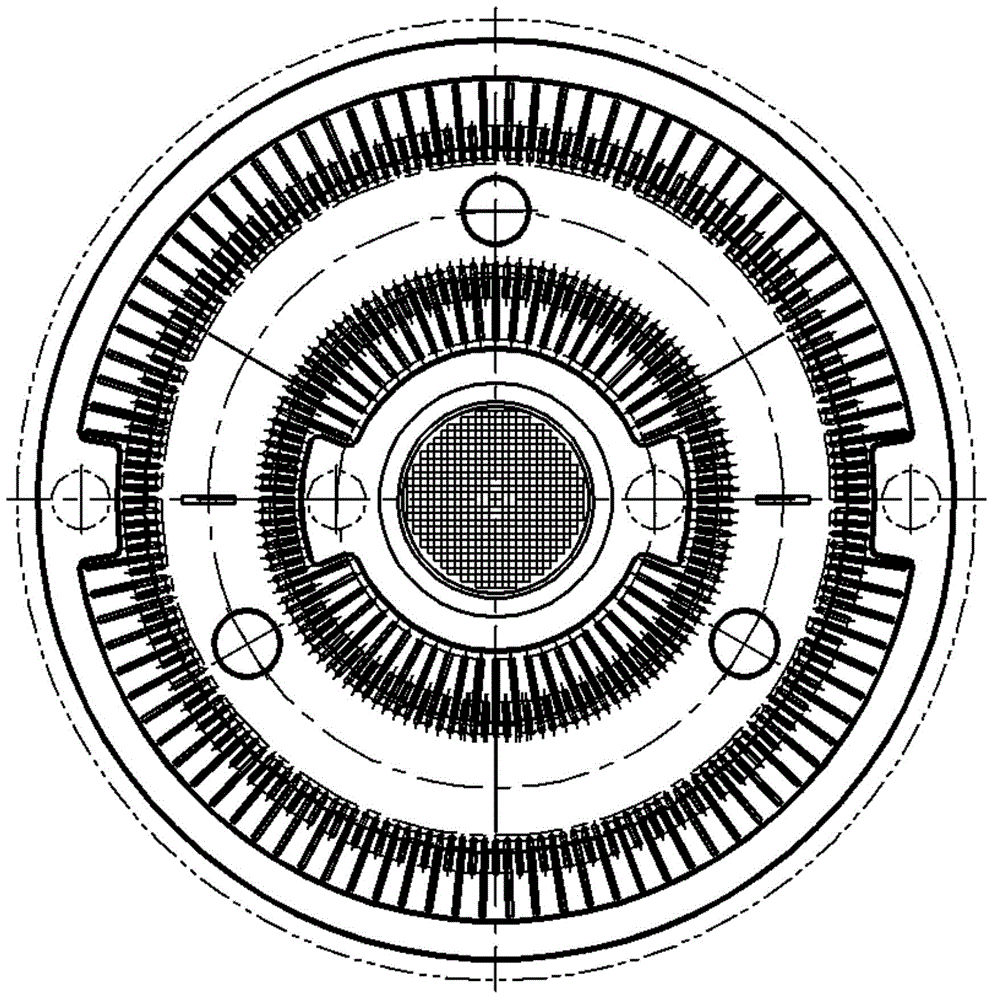

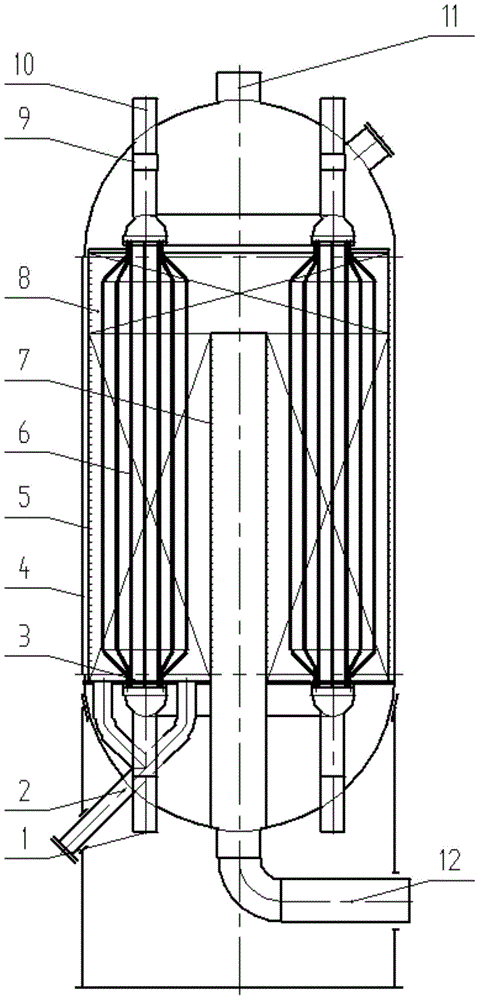

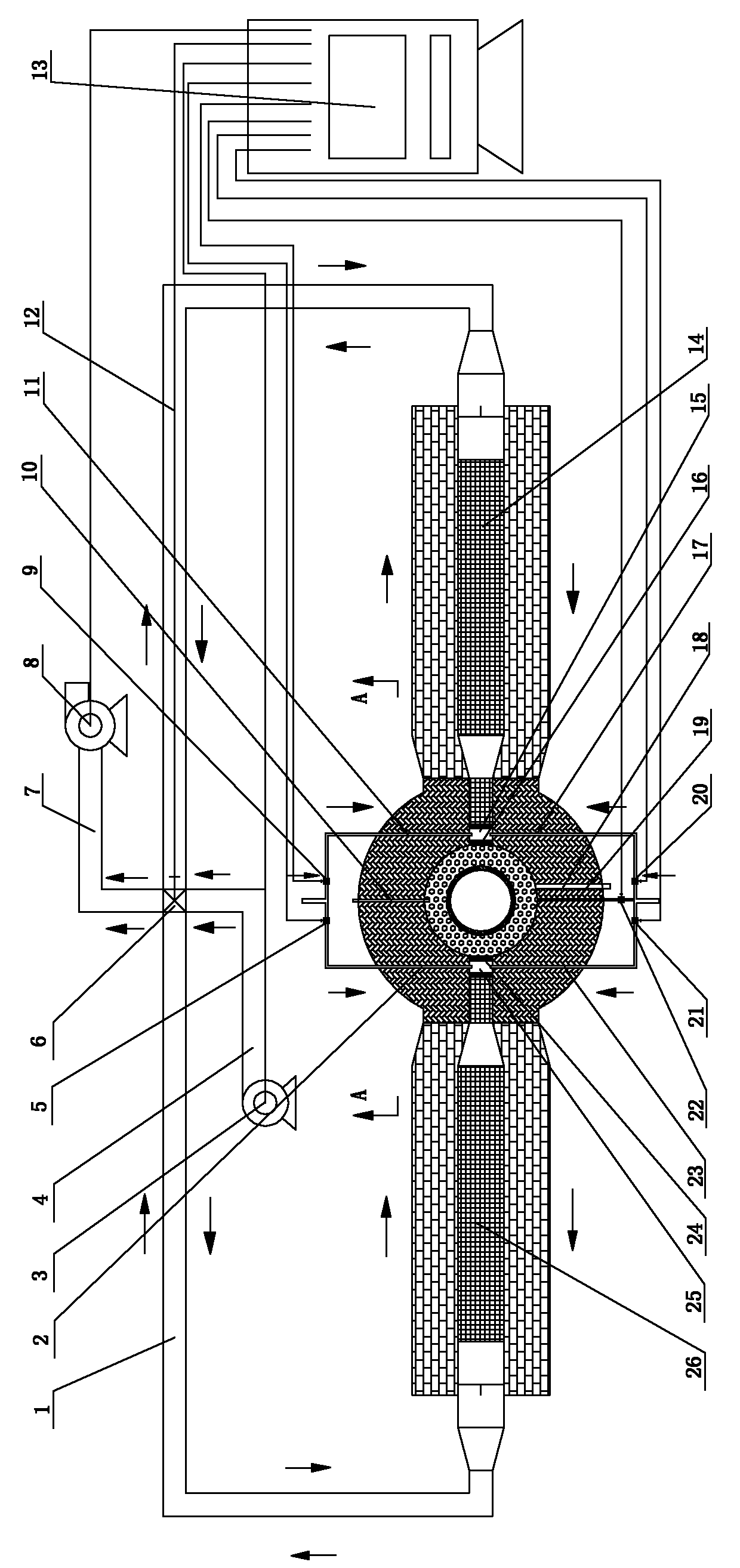

Pipe-bundle-builtin isothermal-shift reactor

ActiveCN105457563AFrom burningExtend your lifeHydrogenChemical/physical processesEngineeringHigh heat

The invention relates to a pipe-bundle-builtin isothermal-shift reactor. According to the pipe-bundle-builtin isothermal-shift reactor, axial annular pipe bundles, which are builtin and are uniformly distributed in a catalyst bed layer along circumferential direction, are adopted to shift out heat of reaction, so as to realize isothermal shift; and a central pipe bundle which is built in a central pipe is adopted to preheat raw material gas entering the reactor, so as to realize the builtin of a gas-gas heat exchanger. The isothermal-shift reactor comprises a pressure-bearing shell, a catalyst basket, the axial annular pipe bundles, the central pipe and the central pipe bundle; and the axial annular pipe bundles consist of upper and lower annular pipe boxes, upper and lower annular pipe sheets and heat exchange tubes. According to the pipe-bundle-builtin isothermal-shift reactor, due to builtin pipe bundles, the manufacturing cost of equipment is effectively reduced; due to an end-part bent structure for the heat exchange tubes, the size of the pipe sheets is effectively reduced; due to a heat insulating layer laid between the pipe sheets and the high-temperature catalyst bed layer, the contact between pipe end weld spots and a bed layer high-temperature area is effectively isolated, the probability of leakage is lowered, and the reliability of equipment is improved; and the pipe-bundle-builtin isothermal-shift reactor is compact in structure, low in manufacturing cost, relatively easy in maintenance, high in reliability, complete in function and high in applicability.

Owner:CHANGZHENG ENG

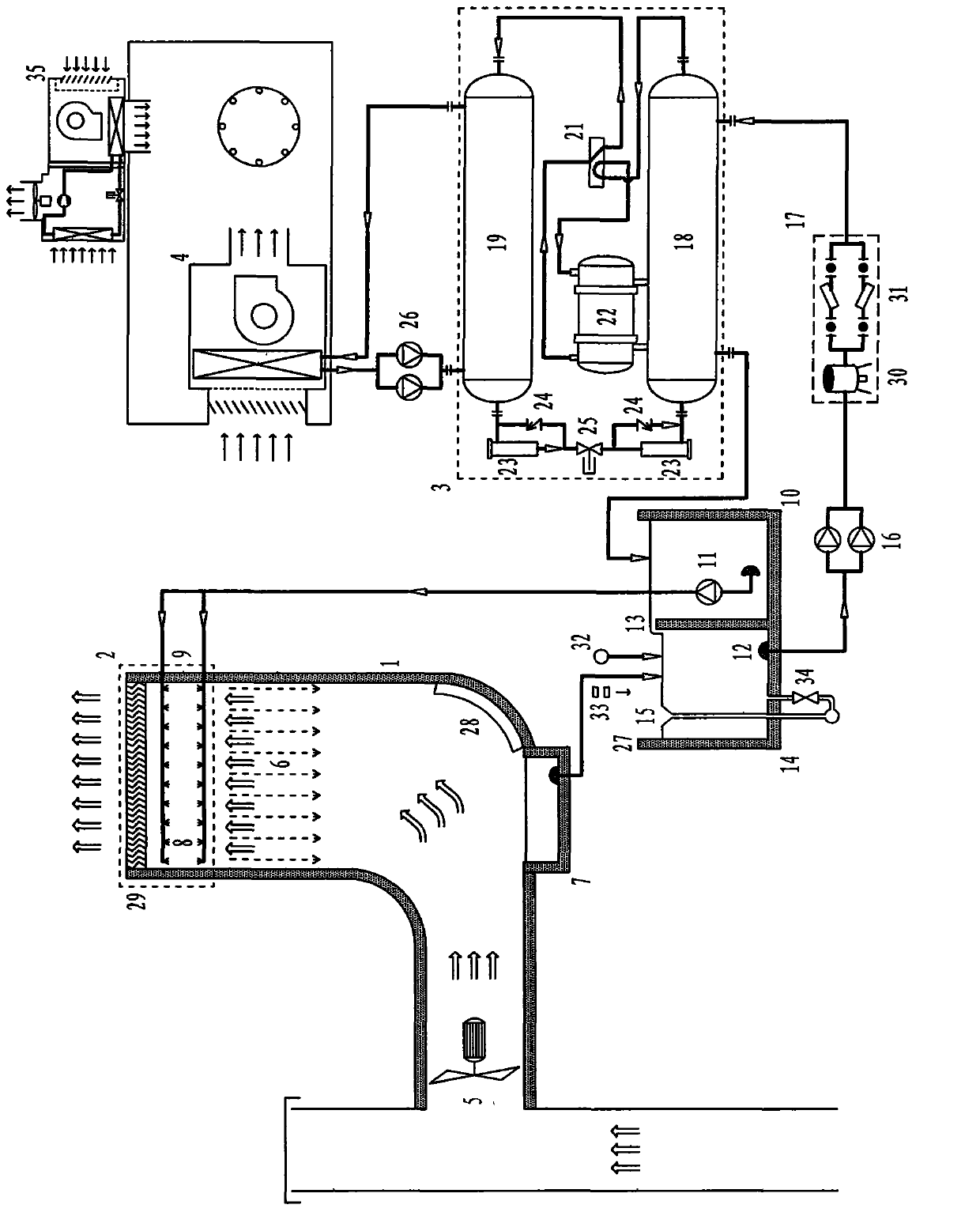

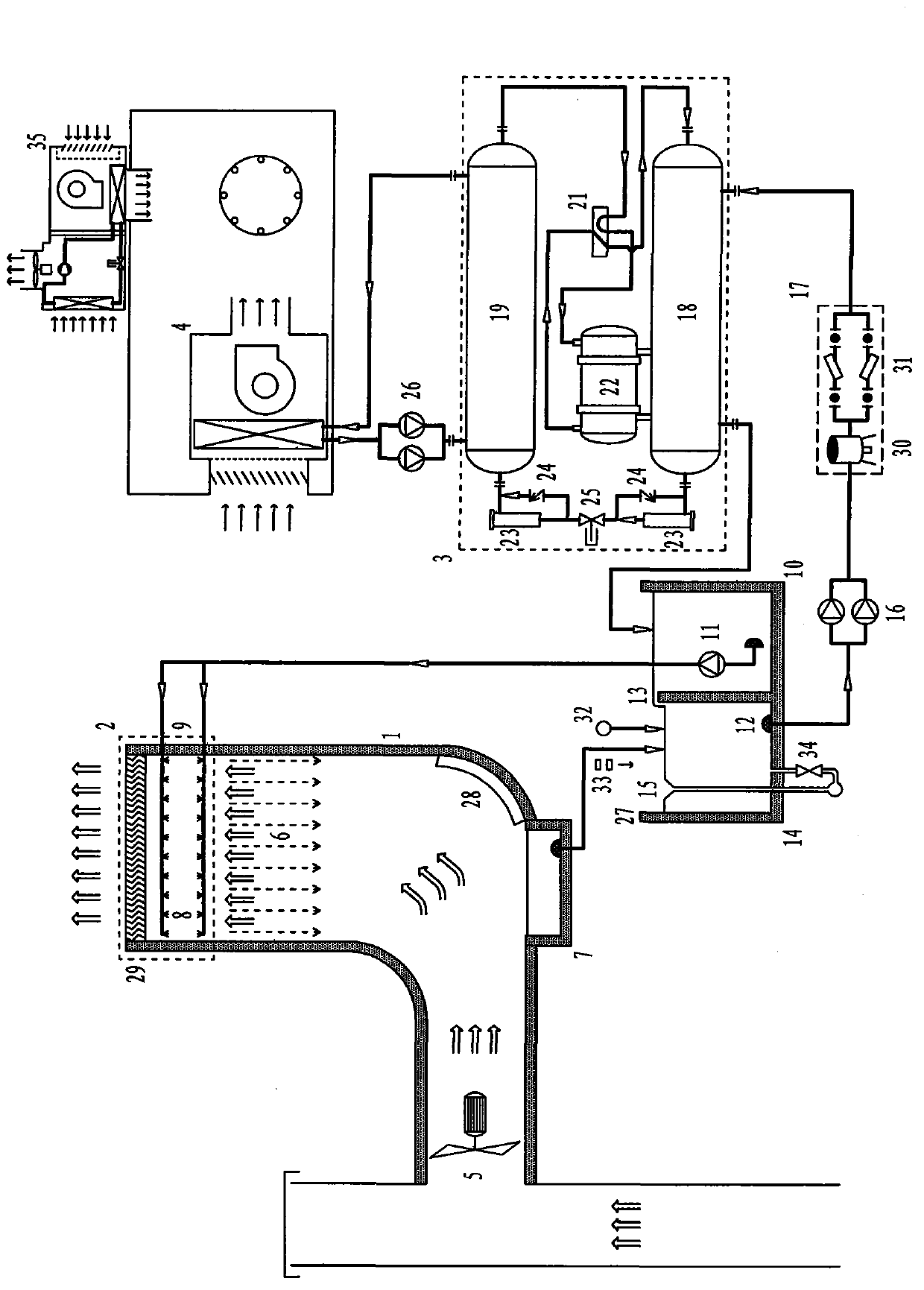

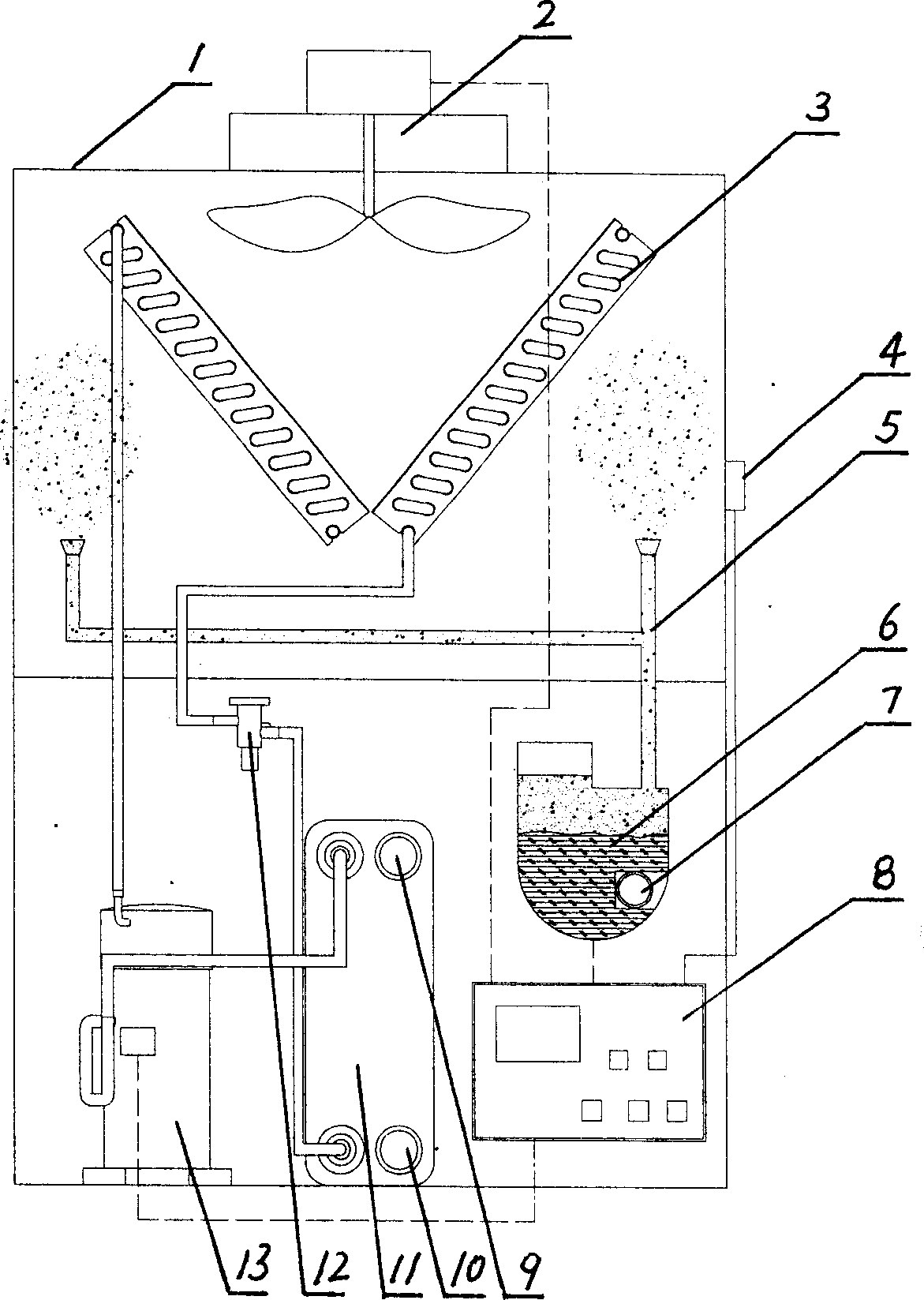

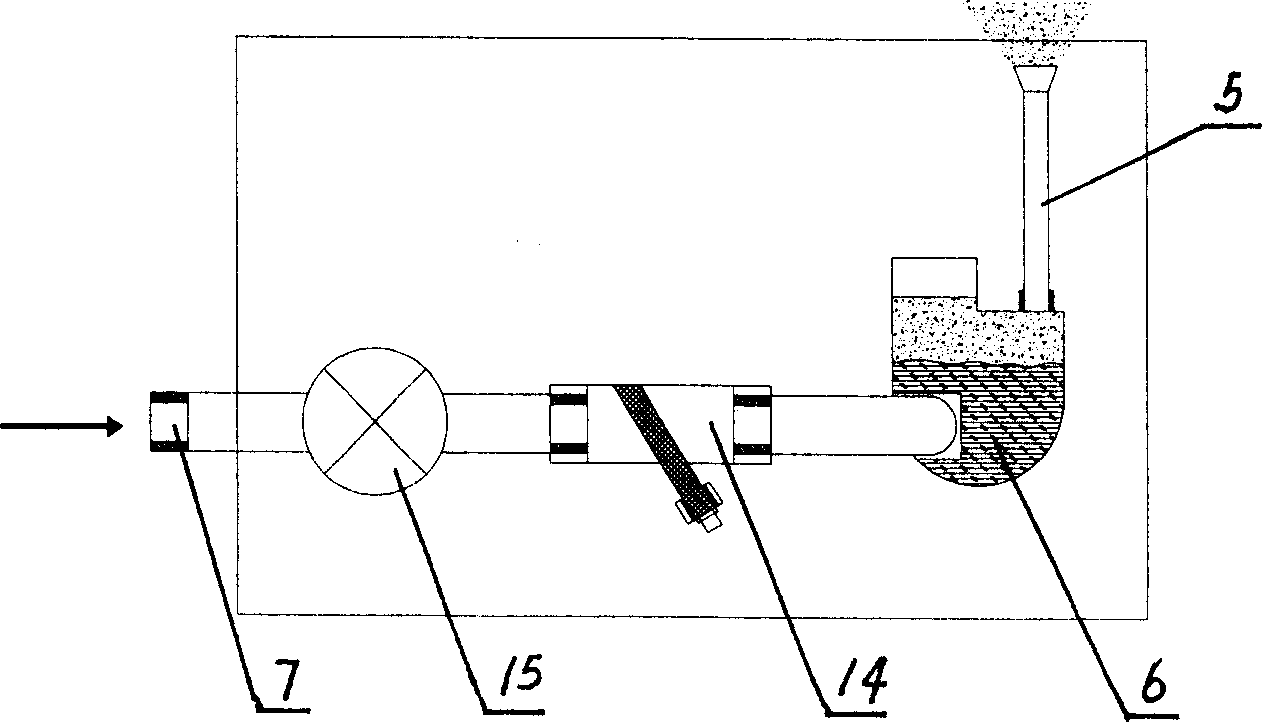

Low-temperature exhaust air source spray heat capturing efficient water source heat pump fresh air system

InactiveCN102778082APrevent freezingGood energy saving and emission reduction effectHeat pumpsWater source heat pumpWater source

The invention relates to a low-temperature exhaust air source spray heat capturing efficient water source heat pump fresh air system. The low-temperature exhaust air source spray heat capturing efficient water source heat pump fresh air system has the advantages that antifreeze fluid is sprayed to capture heat from a low-temperature exhaust air source, and the heat is boosted to be the heat of high quantity by a water source heat pump and then used for heating fresh air of a mine, so that the freezing of spray water is avoided; the heat pump absorbs heat in a high flow manner so as to increase evaporating temperature and energy efficiency; a fluid supply pool and a fluid return pool are subjected to cold-hot separation, and the heat pump is enabled to obtain fluid from the fluid supply pool which is heated after spray heat capturing, so as to increase the evaporating temperature and the energy efficiency; a spraying chamber is enabled to obtain fluid from the fluid return pool which is cooled after the heat pump carries out evaporating heat absorption, so as to increase heat exchange temperature difference and heat capturing efficiency; the temperature of supply water of the heat pump is reduced so as to increase heating efficiency; and the heat pump supplies heat in a low flow manner so as to reduce circulatory pumping power.

Owner:合肥天鹅制冷科技有限公司 +1

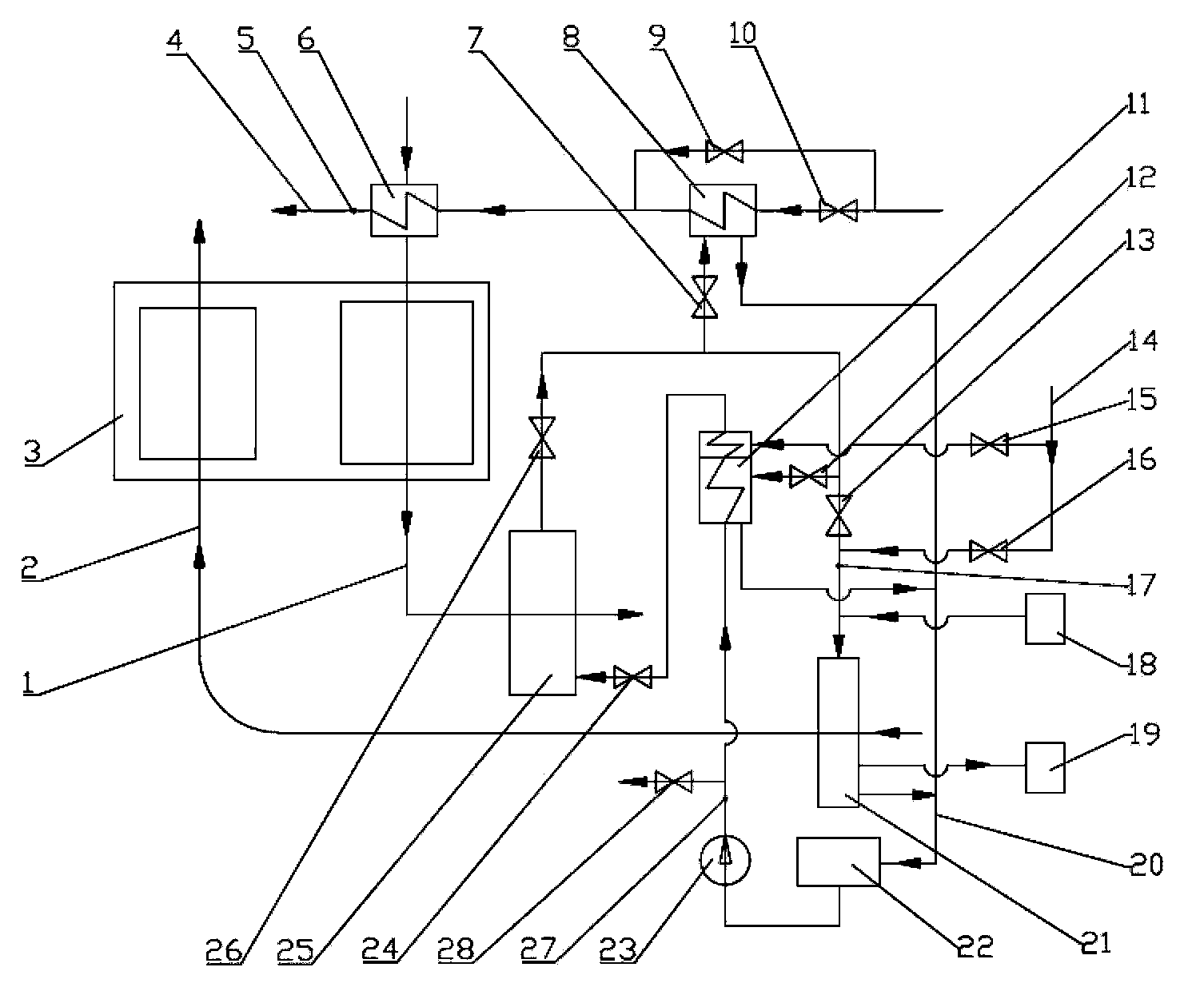

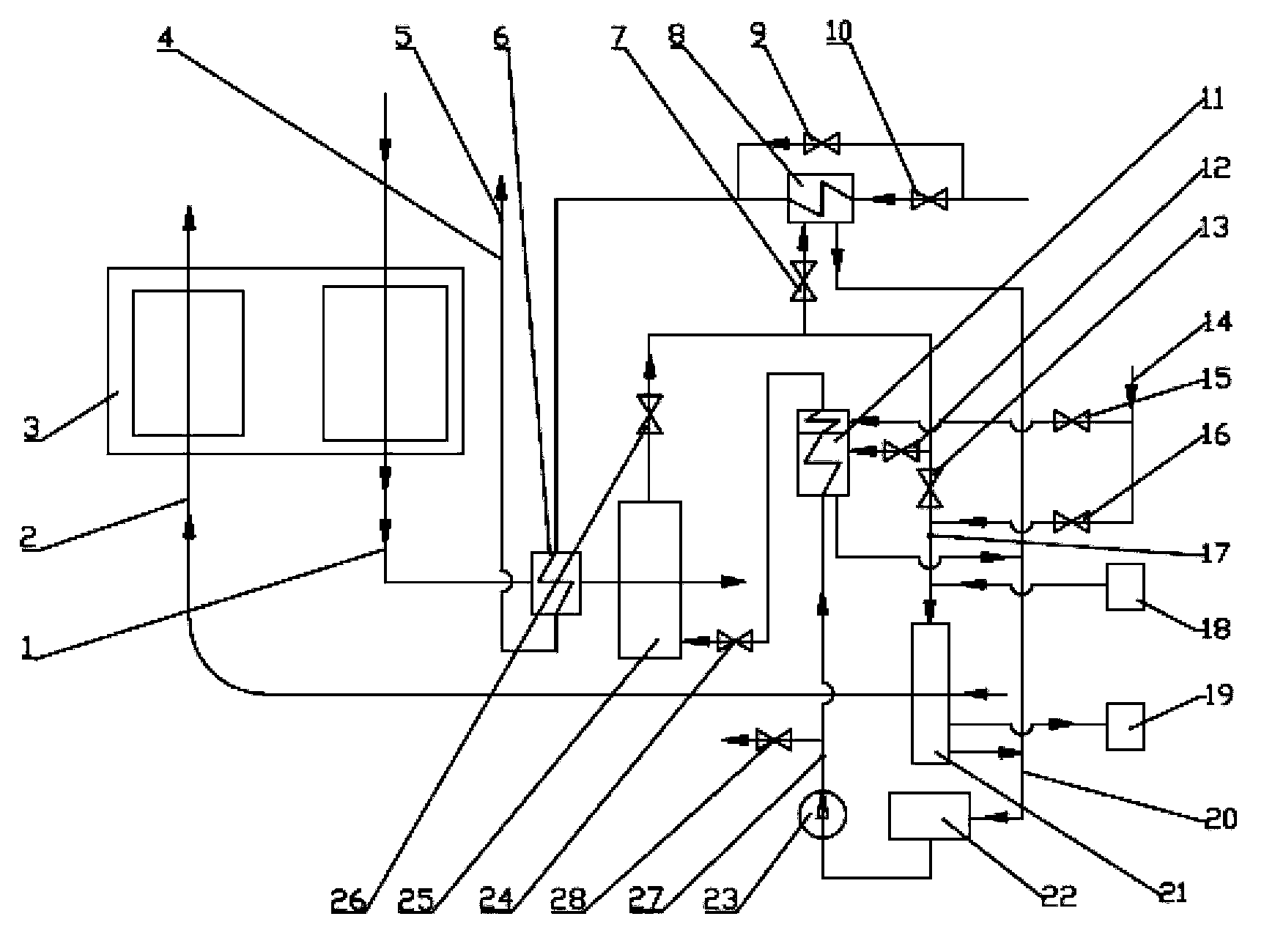

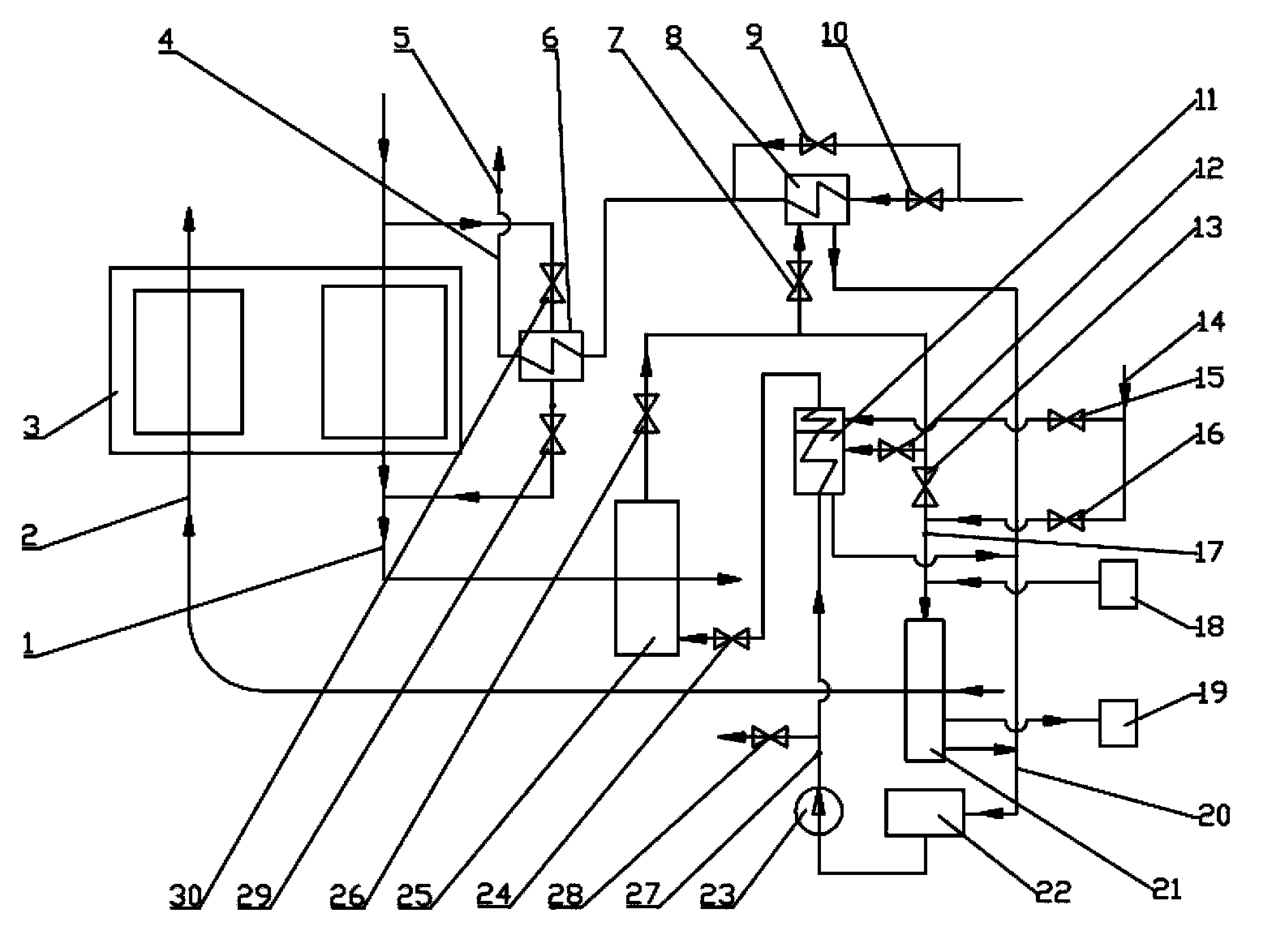

Method and device for preparing hydrogen and carbon monoxide by efficient synthesis gas separation

The invention relates to a method and a device for preparing hydrogen and high-purity carbon monoxide by efficient synthesis gas separation. Continuous rectification is performed by a methane washing tower (C1 tower) with an intermediate heat exchanger and a tower bottom reboiler, a deoxidation-methane tower (C2 tower) with an overhead condenser and a tower pot reboiler and a denitrification tower (C3 tower) with an overhead condenser and a tower pot reboiler to prepare the hydrogen and the high-purity carbon monoxide. According to the method and the device for preparing the hydrogen and the carbon monoxide by efficient synthesis gas separation, the methane washing tower with the reboiler and an intermediate cooler are applied, synthesis gas in which hydrogen content is smaller than 0.5% can be obtained by a single tower pot, hydrogen content of the tower pot is low so that a stripping tower is never required, meanwhile, the hydrogen and the carbon monoxide can be prepared by low energy consumption, 99.9% and over 99.999% of carbon monoxide products can be prepared, and a carbon monoxide compressor is never required when the pressure is larger than 0.2MPa during carbon monoxide preparation so that purposes of saving energy and investments and enhancing operation safety can be achieved.

Owner:SHANGHAI QIYUAN GAS DEV

Sub-control phase-change heat exchange system and method based on grading combination heat exchange

InactiveCN103808178AIncrease temperatureImprove energy qualityIndirect heat exchangersAir preheaterHigh energy

The invention discloses a sub-control phase-change heat exchange system based on grading combination heat exchange. The sub-control phase-change heat exchange system comprises a flue, an air channel, an air pre-heater, an external water pipeline, a steam supply valve of a low-temperature water heater, the low-temperature water heater, a water inlet valve of the low-temperature water heater, a steam-liquid heat exchanger, a steam supply valve of the steam-liquid heat exchanger, a steam supply valve of an air channel heat exchanger, an external steam supply valve of the air channel heat exchanger, a main water draining pipeline, the air channel heat exchanger, a water tank, a water pump, a water inlet valve of a flue heat exchanger, the flue heat exchanger, and a steam outlet valve of the flue heat exchanger. According to the sub-control phase-change heat exchange system, heat release exchangers which utilize the waste heat of recycled flue gas are arranged in a grading combination mode; according to different situations such as ambient air temperature, operating conditions and the like, the waste heat can be utilized to heat boiler supplied air, condensed water on the side of a steam turbine and the like in a combination mode; meanwhile, the temperature of the condensed water is improved through grading heating, higher energy quality is obtained, and the optimal economic benefit of recycling the waste heat is achieved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Micropower heat dissipating cabinet

InactiveCN103402334AChange cooling methodImprove bindingCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersHoneycombTemperature difference

The invention discloses a micropower heat dissipating cabinet, which comprises a cabinet body used for placing electronic equipment, a cabinet main door and a cabinet backdoor, wherein honeycomb ventilation holes are formed in the cabinet main door; the cabinet backdoor is provided with fans; one or more micro-channel heat exchangers are arranged on side, close to the cabinet backdoor, of the cabinet body; a refrigerant pipe joint for connecting external water and Freon heat exchangers are arranged on each micro-channel heat exchanger; ventilation holes or ventilation gaps are formed in each micro-channel heat exchanger; a water-collection tray is arranged below the micro-channel heat exchangers. The cabinet solves the problems existed in a project or an air condition system of a conventional machine room, releases machine room air-conditioner zone area for mounting electronic information equipment, improves the utilization ratio of the machine room, improves the heat exchange temperature difference and can extend the use time of outdoor cold sources as the air exhausting temperature of the cabinet is high, and greatly saves the energy consumption of the air condition system.

Owner:CHINA INFOMRAITON CONSULTING & DESIGNING INST CO LTD

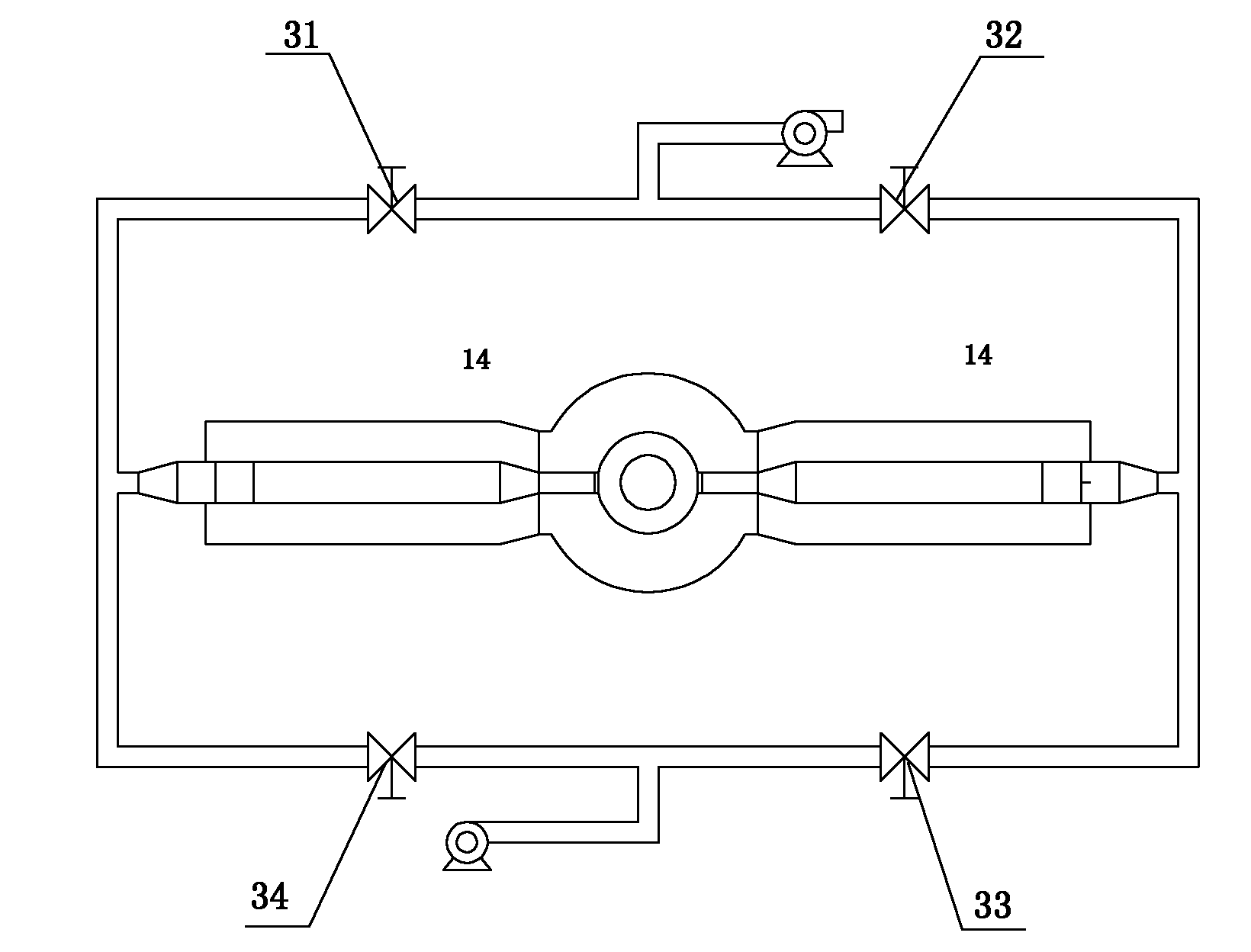

Cooling/heating double circulation system for heat management of power battery pack

ActiveCN108550948ASimple structureGuaranteed uptimeSecondary cellsThermal management systemEngineering

The invention belongs to the field of power battery pack, and in particular, relates to a heat management system for a power battery pack, wherein the heat management system includes a cooling circuitand a heating circuit; the cooling circuit is formed by a heat exchanger, a condenser and a liquid storage device and is connected to the battery pack; the heating circuit is formed by a heat exchanger, a bubble pump and a gas-liquid separator; a liquid outlet of the gas-liquid separator is connected with the liquid storage device by a pipeline. The liquid storage device is connected with the bubble pump by a pipeline to supplement a liquid cooling working medium for the bubble pump. The heat management system comprises the technical effects that high-efficient heat transfer is achieved, a heat exchange coefficient is greatly improved by working medium phase change heat transfer; compared with a traditional wind cooling heat transfer coefficient, the heat exchange coefficient is increasedby two orders of magnitude and is increased by one order of magnitude as compared with liquid cooling; and heat dissipation and cooling double circulation is achieved, heat dissipation circulation omits power components of a traditional liquid cooling system, and heat dissipation and heating are combined into a system, the structure is simpler and the operation is more reliable.

Owner:HENAN UNIV OF SCI & TECH

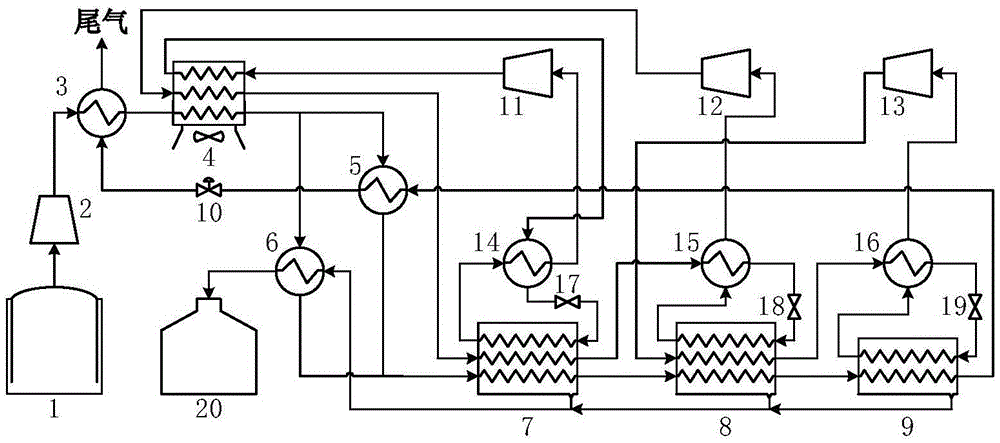

Pressurizing multi-grade condensation type oil gas recycling method

ActiveCN105536282AImprove energy efficiency ratioTake advantage ofMultiple-effect/fractional condensationLiquid hydrocarbon mixture recoveryRecovery methodAtmospheric layer

The invention discloses a pressurizing multi-grade condensation method for recycling oil gas. An air compressor is used for pressurizing the oil gas; cold quantity needed by each grade is provided for a pressurizing oil gas cooler through air cooling heat exchangers and a three-grade overlapping type refrigeration system. The pressurized oil gas passes through the air cooling heat exchangers and then is divided into two paths to be subjected to heat exchange with two heat exchangers which are arranged in parallel to recycle the cold quantity in liquid-state oil and tail gas respectively; then the oil gas sequentially passes through cooling heat exchangers of 2 DEG C, -30 DEG C and -80 DEG C, and the liquid-state oil and the tail gas are condensed and separated grade by grade. The tail gas is throttled to normal pressure before being exhausted to an atmospheric layer, and is subjected to heat exchange with the oil gas from the cooling heat exchangers to recycle the cold quantity again. The method disclosed by the invention has the three advantages that the water removing rate and the oil gas recycling rate can be easily improved after pressure is improved; the two parallel heat exchangers can be used for improving a heat transferring temperature difference and the cold quantity in the liquid-state oil and the tail gas is recycled to the greatest extent; the air cooling heat exchangers also can be used as overlapped refrigerating cycle condensers, so that a refrigerating system is relatively compact and efficient.

Owner:SOUTHEAST UNIV

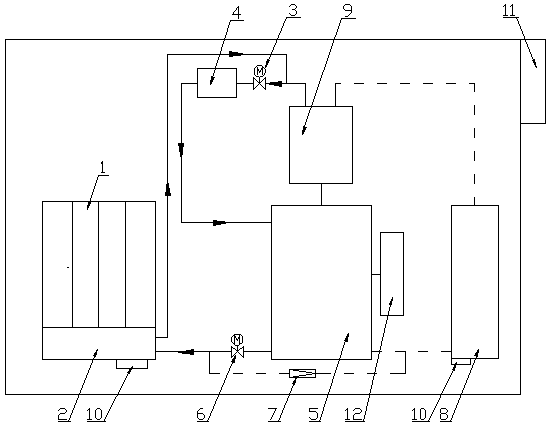

A refrigeration system suitable for a container-type data center

PendingCN108990382AMeet the needs of useIncrease heat transfer temperature differenceCooling/ventilation/heating modificationsData centerEvaporation

The invention relates to a refrigeration system suitable for a container-type data center. The container-type data center comprises a container, an air conditioning system and a cabinet arranged in the container. The container is provided with a heat channel and a cold channel separated from each other. The heat channel and the cold channel are adjacent to the cabinet. The air conditioning systemcomprises a condensing heat exchange module and an evaporating heat exchange module, wherein the evaporating heat exchange module comprises an evaporator for heat exchange and a first fan, an air return port of the evaporating heat exchange module is communicated with the heat passage, and an air outlet port of the evaporating heat exchange module is communicated with the cold passage; The condensation heat exchange module comprises a condenser for heat exchange, a refrigerant outlet of the condenser is connected with a refrigerant inlet of the evaporator, and a refrigerant outlet of the evaporator is connected with a refrigerant inlet of the condenser. As that contain data center is arranged in a totally closed, hot and cold channel, the heat exchange temperature difference of the evaporation heat exchange module of the air conditioning system is improved, the high-efficiency heat exchange is realized, and the use requirement of the container data center is met.

Owner:SHENZHEN ITEAQ NETWORK POWER TECH CO LTD

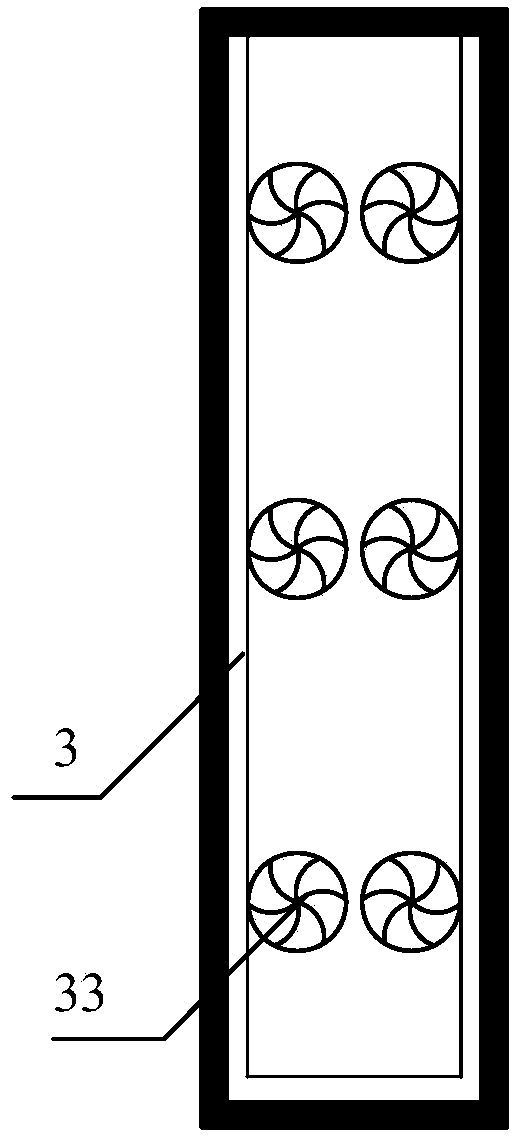

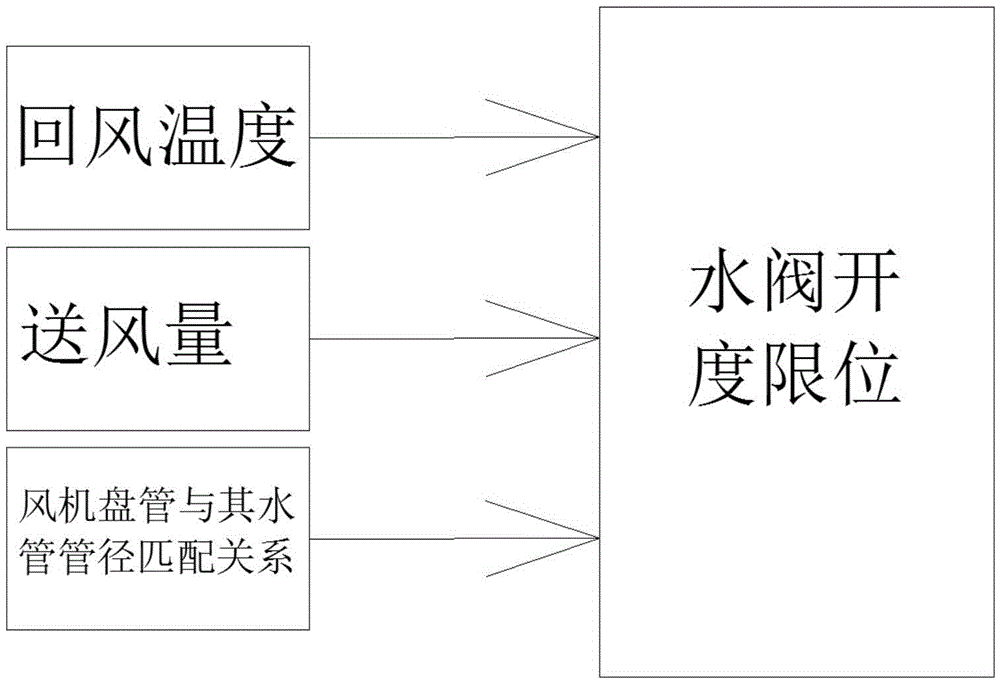

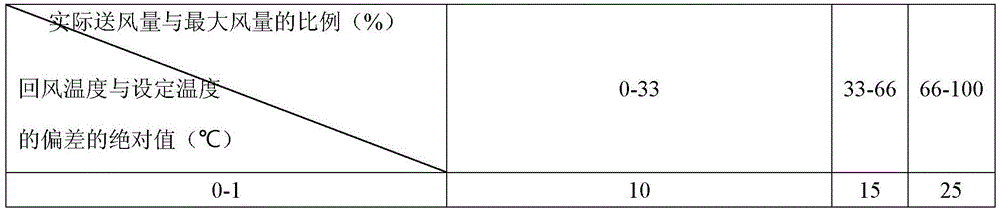

Fan coil temperature control device based on pipe diameter matching relation between fan coil and water pipe and controlled by return air temperature and air supply volume

InactiveCN105588208ASolve the problem of control stabilityImprove stabilityMechanical apparatusSpace heating and ventilation safety systemsTemperature controlAir volume

The invention relates to a fan coil temperature control device based on the pipe diameter matching relation between a fan coil and a water pipe and controlled by the return air temperature and the air supply volume. The fan coil temperature control device comprises the fan coil, an electric water valve, a controller and a control panel. A draught fan is arranged in the fan coil. The fan coil temperature control device is characterized in that the electric water valve is installed at the water inlet end of the fan coil; the model of the fan coil is matched with the pipe diameter of the water pipe so that the maximum limitation of the opening degree of the electric water valve can be controlled; the controller controls the opening degree of the electric water valve to be adjusted within the opening degree limiting range; a fan coil temperature control structure for automatically regulating the opening degree of the electric water valve according to the pipe diameter matching relation between the fan coil and the water pipe is formed; the control panel comprises multiple control signal output ends and feedback signal input ends, and a structure for automatically regulating the rotating speed of the draught fan and the opening degree of the electric water valve according to the return air temperature and the air supply volume is formed; and the model of the fan coil is FC800, or the model of the fan coil is FC400. According to the fan coil temperature control device, the maximum limitation of the opening degree of the eclectic water valve is controlled by the controller according to the pipe diameter matching relation between the fan coil and the water pipe, and the beneficial effects that the flow of the water pipe of the fan coil is accurately regulated and the stability of a chilled water system is improved are achieved.

Owner:GUANGZHOU DESIGN INST

Refrigerating unit of air condition by dehumidifying, evaporative cooling solution

InactiveCN101004277AReduce intermediate heat exchange linksCompact structureLighting and heating apparatusAir conditioning systemsStrong solutionsEvaporation

The present invention discloses a solution dehumidification evaporation cooling air-conditioning refrigeration equipment. It includes compressor, evaporator, throttling mechanism, solution cooling device, regenerator, strong solution pump, dehumidifier dilute solution pump and heater. It is characterized by that a direct contact type heat exchanger and an evaporation type heat exchanger are added in said equipment.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

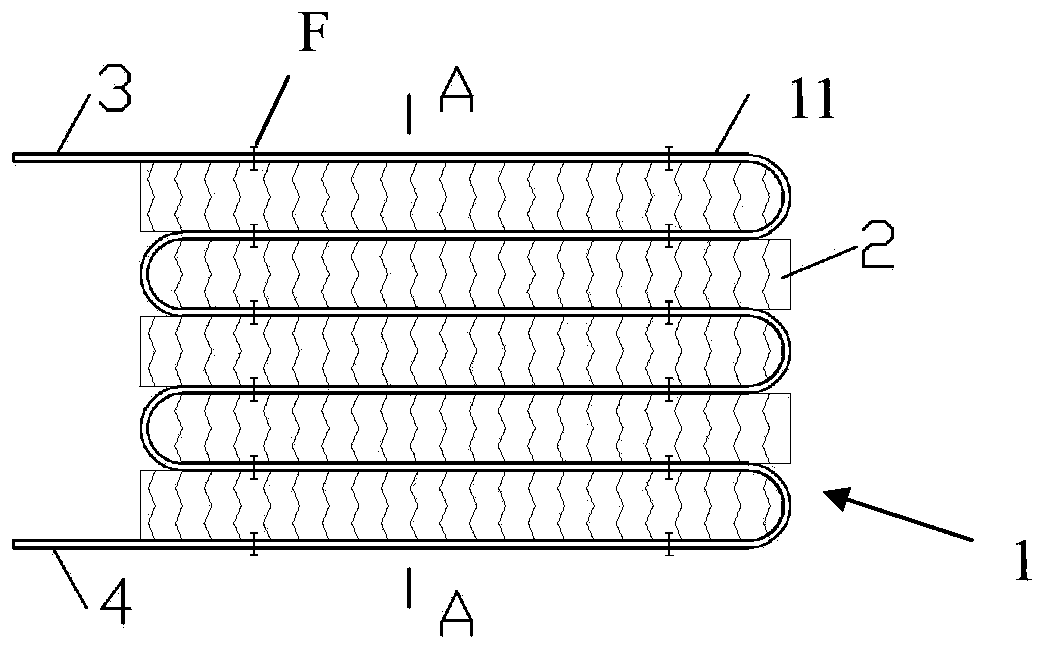

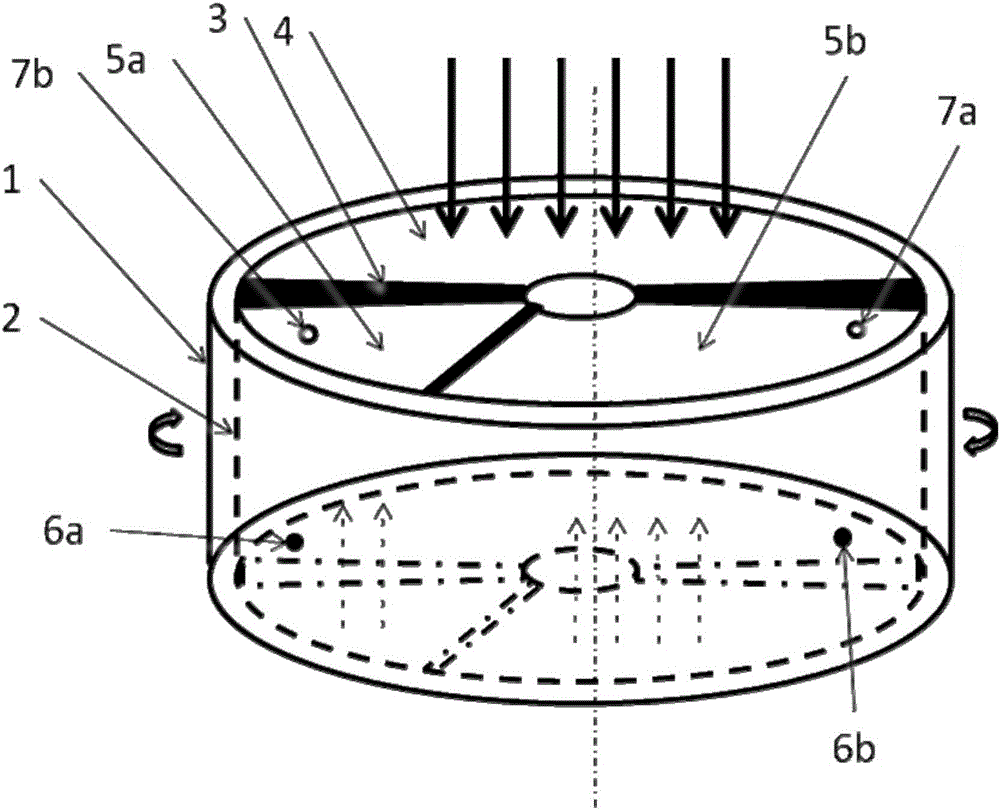

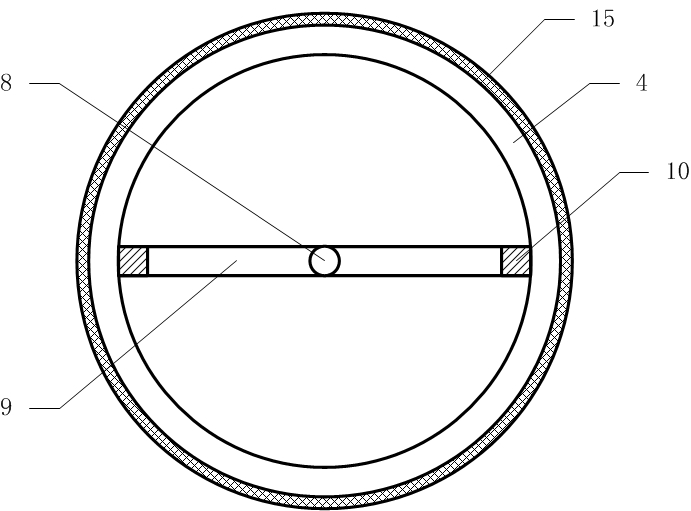

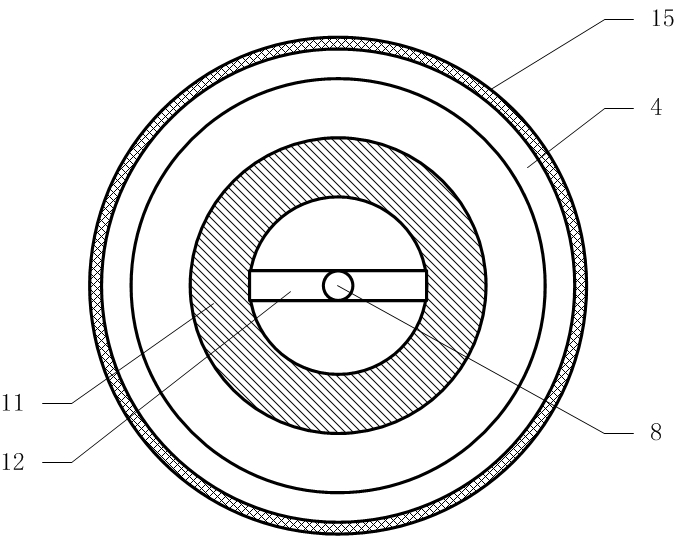

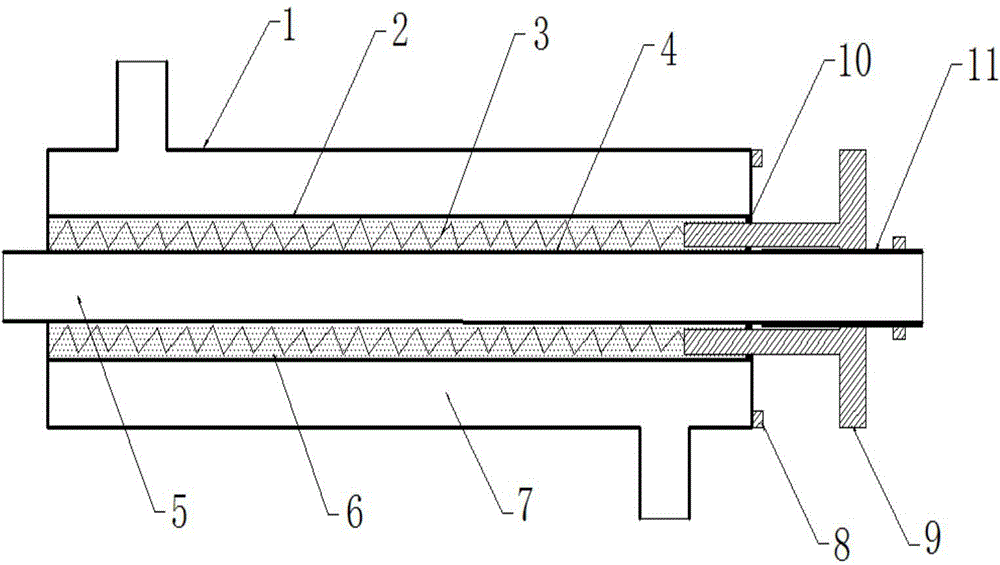

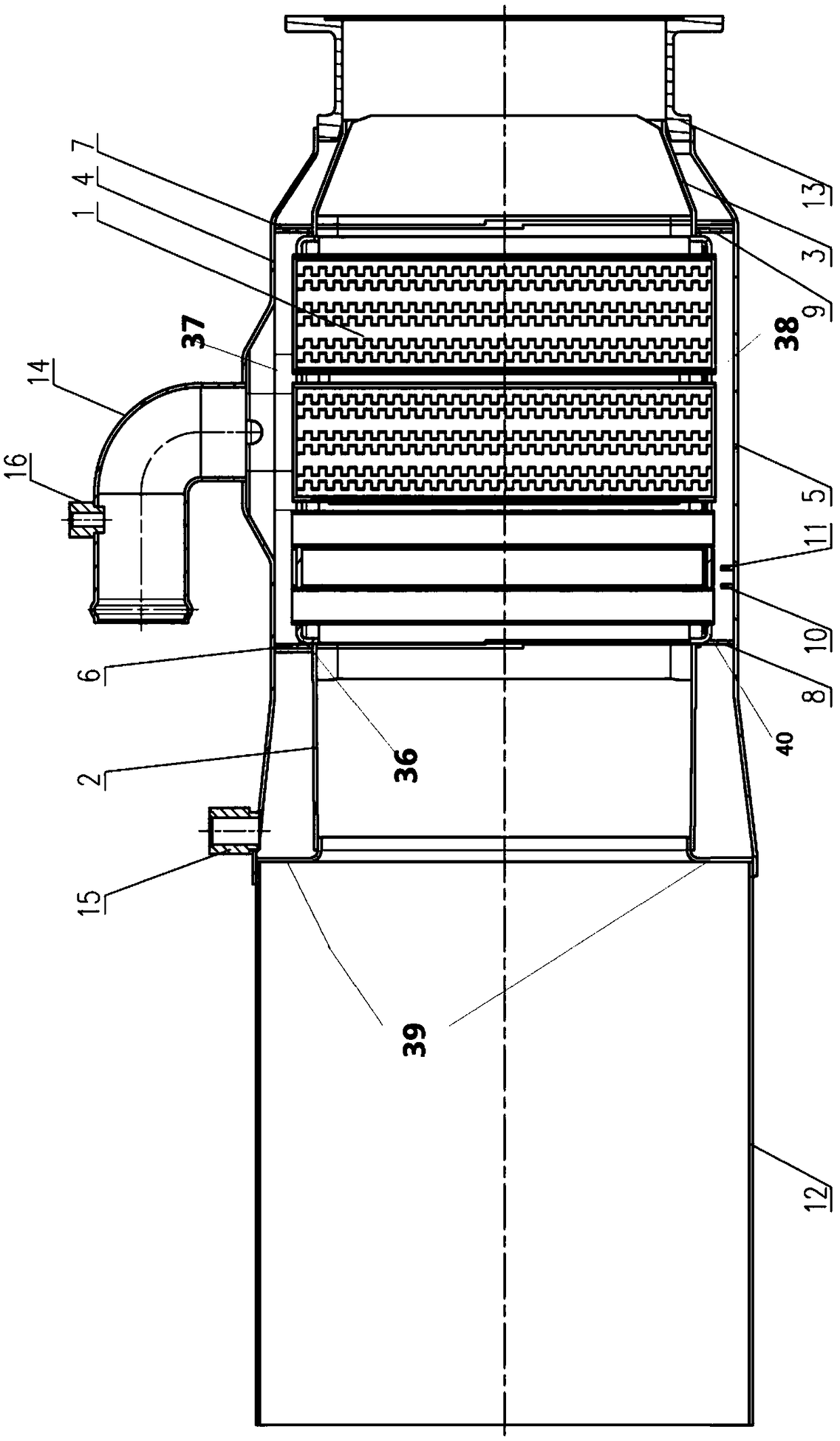

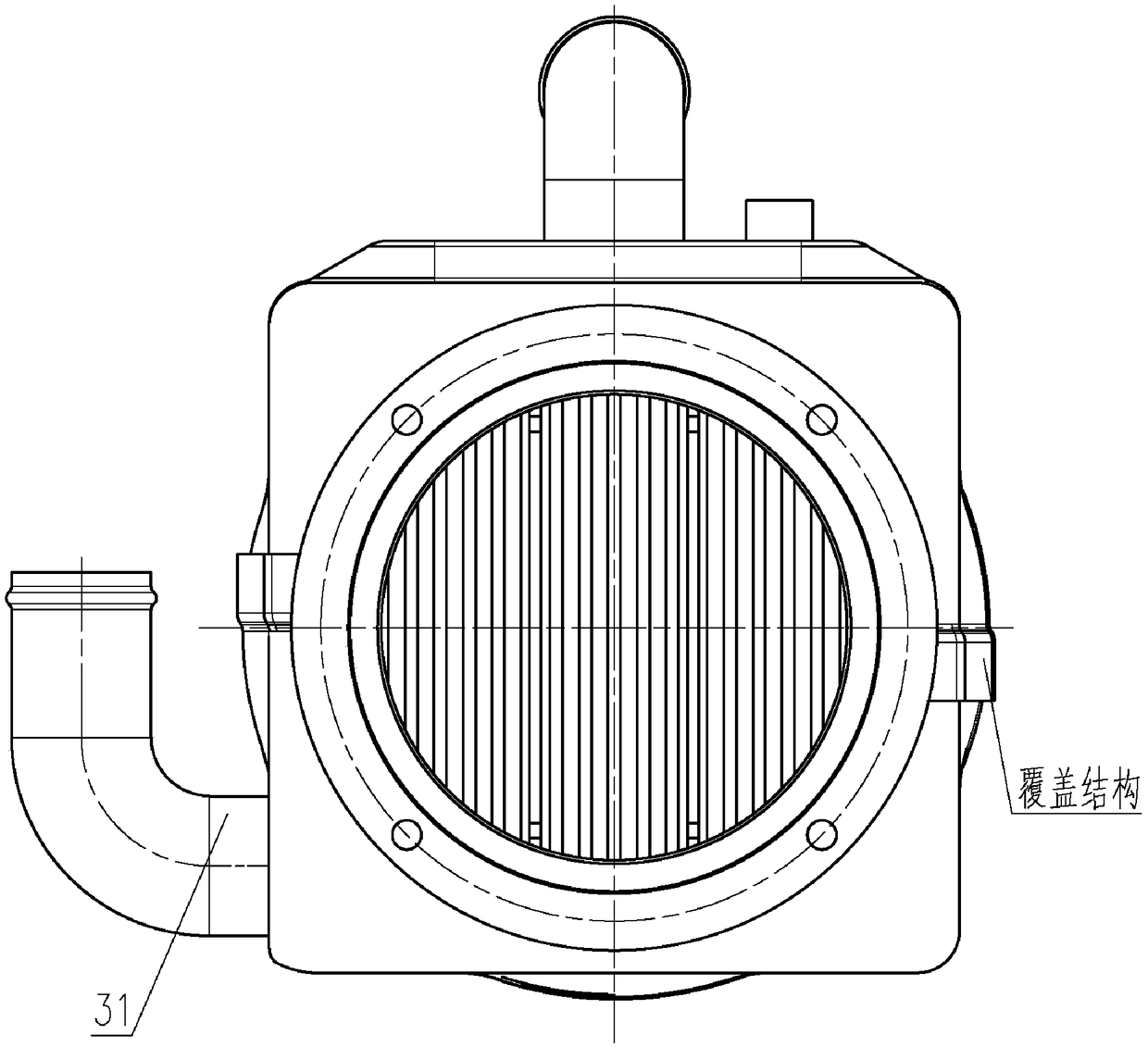

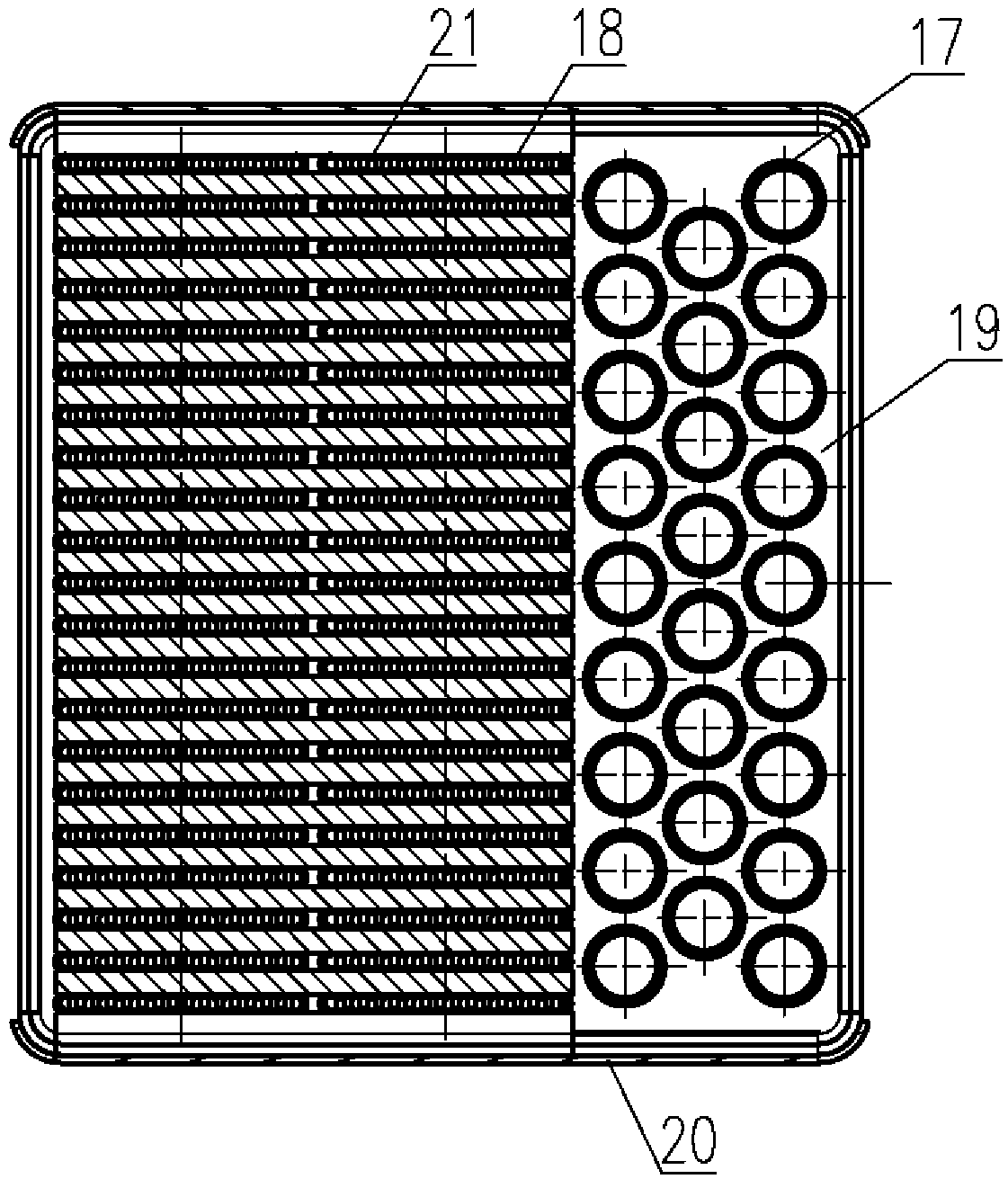

Efficient heat exchange tube fin for filler coupling coil evaporative condenser

InactiveCN103575132AReduce stayReduce driftEvaporators/condensersStationary conduit assembliesCouplingWater flow

A high-efficient heat exchange tube piece for a filler coupling coil evaporative condenser comprises a coil (1) formed of heat exchange tubes coiled into an S shape. The coil (1) is provided with at least one layer of filler (2) for guiding spraying cooling water to flow from an upper layer heat exchange tube to a lower layer heat exchange tube. The filler (2) is arranged between adjacent heat exchange tubes (11), and connects the heat exchange tubes (11) to form a continuous water flow surface. The heat exchange tube is capable of lowering the temperature of cooling water in a cooling coil, and improving water distribution coverage of cooling water sprayed from the cooling coil and the heat exchange efficiency.

Owner:GUANGZHOU WIDE IND

Air-cooling hot-pump water cooler set for decreasing working environment temperature

InactiveCN1818511AReduce air temperatureReduce condensing pressureCompression machines with non-reversible cycleMachines using refrigerant evaporationWater filterSprayer

The invention relates to an air-cooled heat pump water cooler set, in which is disposed a water sprayer made up of a magnetic valve, a water filter, a water atomizer and a spray-transfer device connected in order. The spray-transfer device is used as the outlet of the system and the magnetic valve is used as the inlet of the system. Outside the casing is disposed a moisture-temperature sensor connected with a electric control system. The inventive water sprayer can act for reducing the air intake temperature on the condenser side can be reduced by the spray evaporation to increase heat-exchange temperature difference between the condenser and the air, so as to improve the heat-exchange environment and effect of the condenser side.

Owner:NINGBO HICON IND

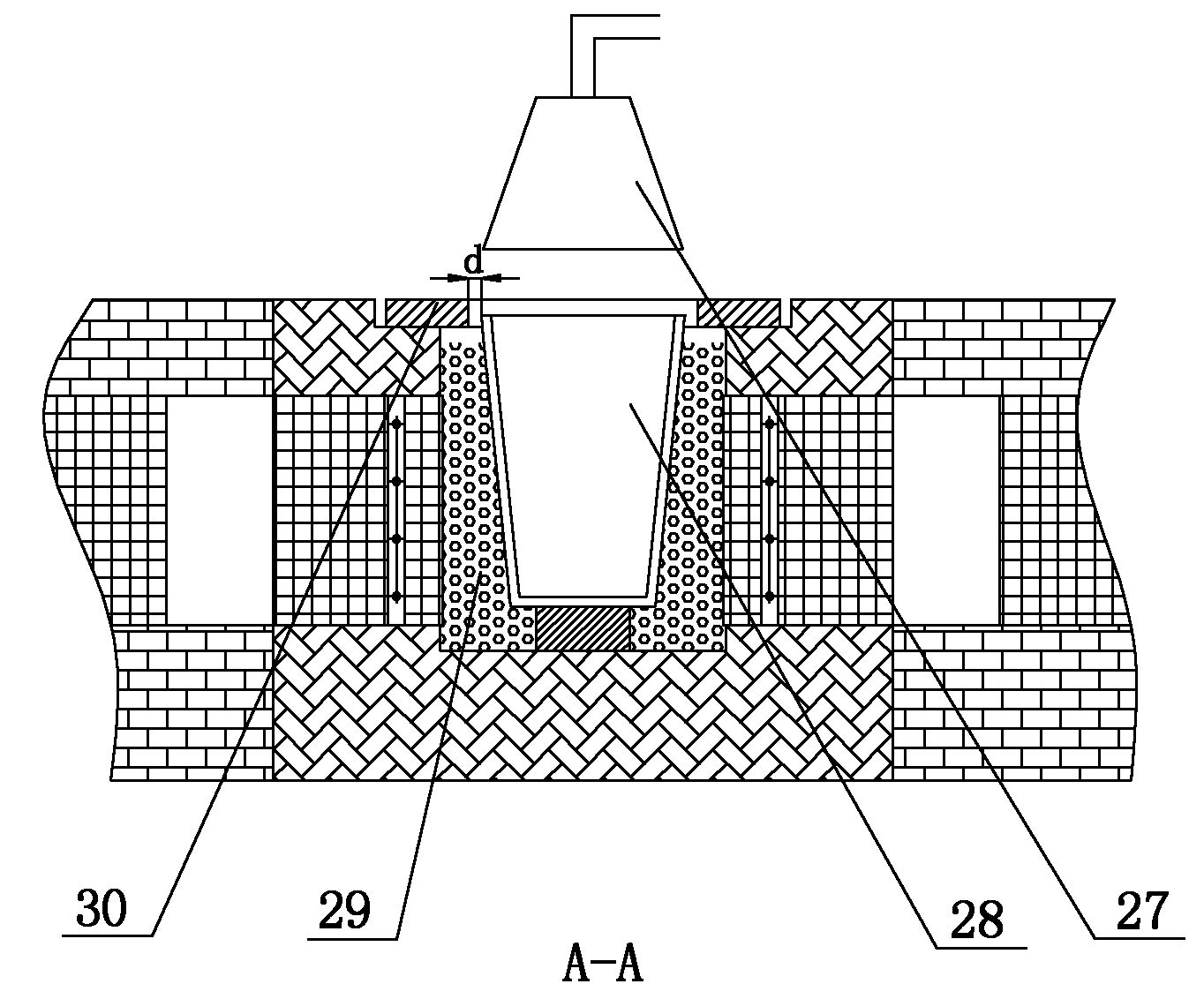

Reciprocating type porous medium gas burning metal smelting furnace

InactiveCN102243016AIncrease temperatureAchieve recyclingCrucible furnacesWaste heat treatmentPeriodic alternatingCombustion chamber

The invention discloses a reciprocating type porous medium gas burning metal smelting furnace which comprises a burning chamber and a metal accommodating container arranged in the burning chamber, wherein the burning chamber is connected with a first gas channel and a second gas channel, a first porous medium regenerative chamber is arranged in the first gas channel, and a second porous medium regenerative chamber is arranged in the second gas channel; the first gas channel and the second gas channel are evenly connected with a periodically reversing air supply mechanism, and the periodicallyreversing air supply mechanism comprises an air-smoke change valve controlled by a controller and is connected with an air supply channel and a smoke channel; and the combustion air and the high-temperature smoke are periodically and alternately reversed to flow through a porous medium high-efficient heat retainer, and the smoke waste heat is utilized to heat the combustion air. The metal smelting furnace provided with the invention has the advantages of short metal melting time, obvious energy-saving effect, high combustion efficiency, effective waste heat limited recycle, low energy consumption and low pollutant discharge.

Owner:ZHEJIANG UNIV

Heat exchange device utilizing combustion waste heat with variable distances of heat exchange structures

InactiveCN107270747AReduce film boilingReduce heat loadHeat exchanger casingsStationary tubular conduit assembliesCombustionEngineering

The invention provides a heat exchange device utilizing combustion waste heat. The heat exchange device comprises a heat exchange core; the heat exchange core is arranged in a waste gas flue and comprises circular tubes; the circular tubes are arranged perpendicular to the flowing direction of waste gas; a plurality of scattered heat exchange structures are arranged in the round tube at intervals; a plurality of dispersion heat exchange structures are arranged in the circular tubes in a segmented mode in the flow direction of fluid in the circular tubes; the distances between every two adjacent dispersion heat exchange structures become smaller and smaller from inlets of the circular tubes to outlets of the circular tubes. The heat exchange device has the advantages that the distances of the dispersion heat exchange structures in the circular tubes is continuously decreased along with the distance from the inlets of the circular tubes, and therefore the film boiling phenomenon on the water side can be effectively reduced, the convective heat exchange intensity of the water side can be increased, the heat load of the heat exchange core can be reduced, and the heat exchange efficiency can be improved.

Owner:CHINA NORTH VEHICLE RES INST

Boiler flue gas waste heat circulating heat-supply system

ActiveCN105570956AEfficient removalSave energyEmission preventionWaste gas energyProcess engineering

The invention relates to a boiler flue gas waste heat circulating heat-supply system. The boiler flue gas waste heat circulating heat-supply system is characterized by comprising an air inlet pipeline, an air blower, a dust removal device, a boiler flue gas waste heat heating tank, an air outlet pipeline, a cold water pipeline, a chimney, a drying device, a hot water circulating heating pipeline, a hot water tank, a hot water pipeline, a catalysis heating device and a water outlet pipeline; a catalyst is arranged in the air blower, the air inlet end of the air blower is connected with the air inlet pipeline, and the air outlet end of the air blower is connected with one end of the dust removal device; a curved flue gas heating pipeline is arranged in the boiler flue gas waste heat heating tank; one end of the curved flue gas heating pipeline is connected with the other end of the dust removal device; the other end of the curved flue gas heating pipeline is connected with one end of the air outlet pipeline; a water inlet of the boiler flue gas waste heat heating tank is connected with one end of the cold water pipeline, and a water outlet of the boiler flue gas waste heat heating tank is connected with one end of the water outlet pipeline; a catalysis tank is arranged in the catalysis heating device, and the hot water circulating heating pipeline is arranged in the catalysis heating device and on the outer surface of the catalysis tank in a surrounding mode.

Owner:HEBEI UNIV OF TECH

Heat recovering fresh air machine

InactiveCN106679132AIncrease air temperatureIncrease humidityEnergy recovery in ventilation and heatingHeat recovery systemsDevice formThin layer

The invention discloses a heat recovering fresh air machine which comprises a return air inlet, a return air channel, a fresh air channel, a heat exchange core body, a wet film and a water mist spraying device, wherein the return air channel communicates with the return air inlet; the heat exchange core body is used for realizing heat exchange between return air in the return air channel and fresh air in the fresh air channel; the wet film is arranged in the return air channel and is located in a part between the return air inlet and the heat exchange core body; the water mist spraying device is arranged in the return air channel and is located in a part between the wet film and the heat exchange core body; in the heat exchange core body, fresh air and return air flow in a cross flow manner and are separated through a hydrophilic aluminum foil, the fresh air is in direct contact with one face of the hydrophilic aluminum foil while the return air is in contact with another face of the hydrophilic aluminum foil, and the wet film and water mist generated by the water mist spraying device form a liquid thin layer on the surface of the other surface of the hydrophilic aluminum foil. By adopting wet film pre-cooling combined with indirect evaporative cooling, the heat recovering efficiency is improved. Compared with a conventional sensible heat recovering fan, the all heat recovery efficiency in a refrigerating working condition in summer can be increased from 30% to 80%, and the sensible heat recovery efficiency is increased from 65% to 140%.

Owner:SICHUAN INSITITUTE OF BUILDING RES

Iron-containing red mud coal-based direct reduction process and system

PendingCN111763791AEfficient reductionGuarantee normal productionRotary drum furnacesProcess efficiency improvementIron oxideHeat transfer efficiency

The invention discloses an iron-containing red mud coal-based direct reduction process and system. Drying and levigating are carried out on red mud and high-volatile coal, blending is carried out on the red mud, the high-volatile coal, a binder and a metal aggregating agent according to the mass ratio of 1: 0.25-0.35: 0.01-0.03: 0.01-0.03, water is added for pelletizing after uniform mixing, carbon-containing pellets with particle size being 20 mm-25 mm are obtained; and the carbon-containing pellets are dried and then conveyed to a rotary hearth furnace, reduction roasting is directly carriedout, reducing is carried out on the red mud through H<2> generated through sufficient pyrolysis of the high-volatile coal and H<2> generated through a carbon gasification reaction with H<2>O as a gasifying agent, the hearth temperature is controlled to be 1250 DEG C-1280 DEG C, the roasting time is controlled to be 30 min-35 min, and the red mud can be sufficiently reduced. According to the iron-containing red mud coal-based direct reduction process and system, the red mud is efficiently reduced by adopting a hydrogen metallurgy process, and the iron-containing red mud coal-based direct reduction process and system have the advantages of high hearth heat transfer efficiency, high iron oxide reduction speed, high single-furnace capacity, high product quality and essential emission reduction.

Owner:JIUQUAN IRON & STEEL GRP

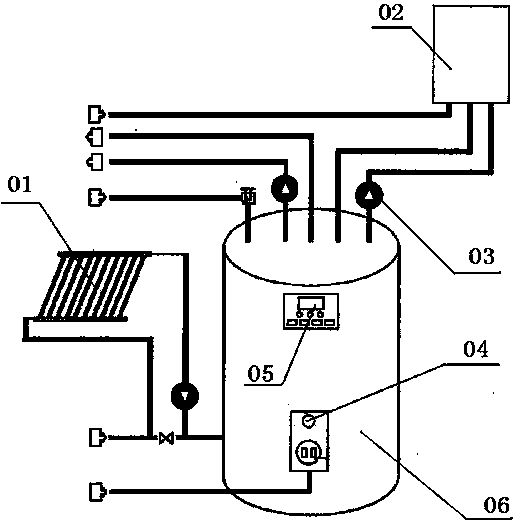

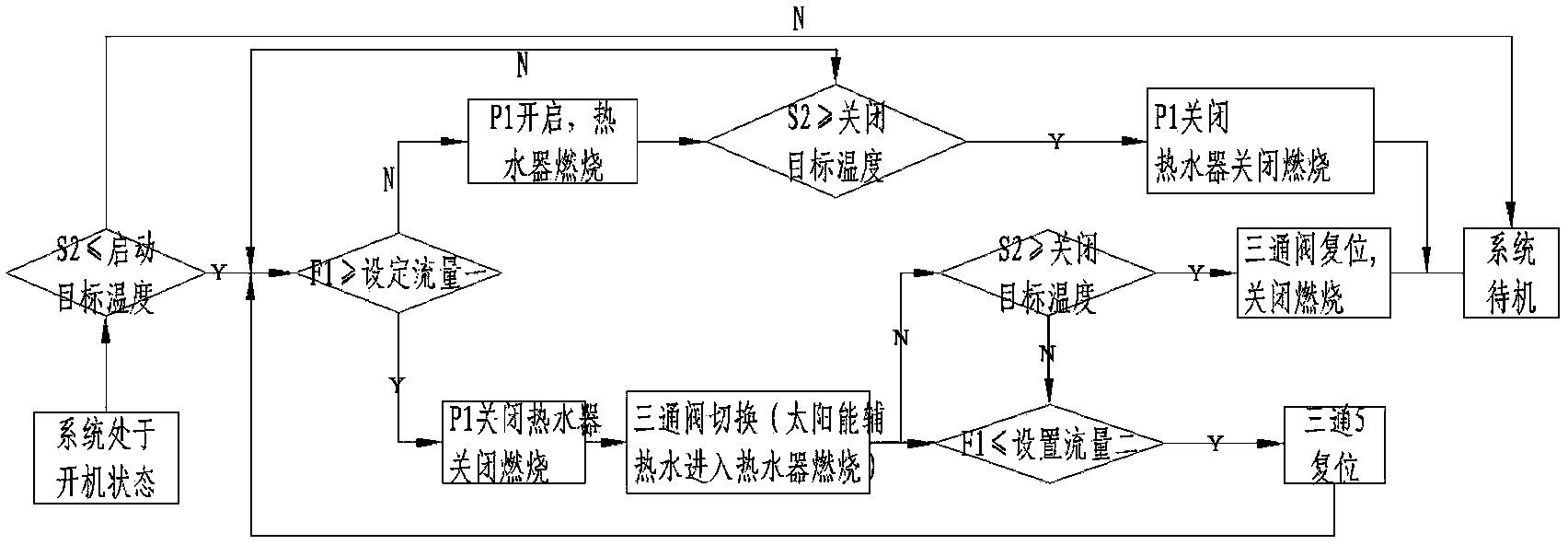

Solar gas composite energy water heating system and use method

ActiveCN103836715AIncrease heat transfer temperature differenceIncrease profitLighting and heating apparatusSpace heating and ventilation detailsEngineeringWater heating

The invention relates to the field of water storage heaters and discloses a solar gas composite energy water heating system. The system comprises a solar heater, a gas water heater, a water tank, a central hot water circulating circuit and a control system and is characterized in that the water tank comprises a constant temperature tank and a heat storage tank, wherein the constant temperature tank is directly connected with the central hot water circulating circuit, and the heat storage tank forms a solar circulating circuit with the solar heater. A first water outlet in the upper end of the constant temperature tank is connected with a water inlet of the gas water heater, and a first water inlet in the upper end of the constant temperature tank is connected with a water inlet of the gas water heater to form a heating and circulating circuit. A water outlet of the heat storage tank is connected with a second water inlet in the lower end of the constant temperature tank and a water inlet of the gas water heater. Compared with the prior art, the solar gas composite energy water heating system has the advantages that the solar utilization rate is high, the heating rate is high, and continuous large flow constant temperature water supplying capacity can be obtained through little heat output of a gas heating device. The invention further provides a control method based on the water heating system.

Owner:GUANGDONG MACRO GAS APPLIANCE

Heat exchange system of demethanizer and heat exchange method

ActiveCN107285981AReduce the temperatureIncrease heat transfer temperature differenceHydrocarbon purification/separationHydrocarbonsGas phaseTemperature difference

The invention discloses a heat exchange system of a demethanizer and a heat exchange method. The heat exchange system adopts one of the following manners: A, a branch separated from an outlet pipeline at the bottom of a 1# hydrogen-methane separation tank is connected with the demethanizer or a demethanizer return tank; B, an aftercooler is arranged at the top of the demethanizer return tank, and a branch separated from the outlet pipeline at the bottom of the 1# hydrogen-methane separation tank is connected with the aftercooler and then connected with the demethanizer return tank; C, a gas-liquid separation tank is arranged behind a cooling box, a gas phase outlet of the demethanizer return tank is connected with the cooling box and then connected with the gas-liquid separation tank, and the bottom of the gas-liquid separation tank is connected with the demethanizer return tank. Under the condition that the coolant level and compressor outlet pressure are unchanged, the gas phase at the top of the demethanizer return tank is cooled by use of local rich cold energy through reasonable optimization of matching of self cold energy of deep cooling, the heat transfer temperature difference of a condenser of the demethanizer is increased, and the loss of ethylene is reduced.

Owner:SINOPEC ENG +1

Zero emission treatment system and zero emission treatment method for desulfurization waste water from ultra-supercritical circulating fluid bed (CFB) boiler

PendingCN108558110AEfficient use ofIncrease heat transfer temperature differenceSludge treatmentWater contaminantsFiltrationHigh energy

The invention discloses a zero emission treatment system and a zero emission treatment method for desulfurization waste water from an ultra-supercritical circulating fluid bed (CFB) boiler. The zero emission treatment system comprises a chemical pretreatment system, a membrane filtration system, an electrodialysis system, a desulfurization waste water preheating system, a desulfurization waste water evaporator, a solid-liquid separation device and a vapor condensation device. High-temperature flue gas at an exit position of a cyclone separator of the ultra-supercritical CFB boiler is used as aheat source to evaporate and crystallize the desulfurization waste water, superheated steam at an inlet header of a rear platen superheater of the super-supercritical CFB boiler is used as a heat source for the preheated desulfurization waste water, and the membrane filtration system provided with a microfiltration device and the electrodialysis system used for concentration reduction are additionally arranged, so that the defects of high energy consumption and high equipment investment cost of the existing multi-effect evaporation technology are overcome, the desulfurization efficiency can be improved, equipment scaling is effectively avoided, system handling load is reduced, economic benefit is significantly improved, the energy is saved, and the operating cost is reduced.

Owner:XI AN JIAOTONG UNIV

Rotary hearth furnace and electric furnace reduction treatment process for stainless steel dedusting ash

InactiveCN111763792AEfficient recycling and utilizationMeet environmental protection requirementsRotary drum furnacesProcess efficiency improvementBrown coalNickel chromium alloy

The invention discloses a rotary hearth furnace and electric furnace reduction treatment process for stainless steel dedusting ash. The process mainly comprises the steps that after being fully slakedand dried, the stainless steel dedusting ash is compounded and mixed with brown coal and a binding agent; a mixture is produced into carbon-containing pellets with the diameter ranging from 18 mm to25 mm; after being dried through a drier, the pellets are laid on the furnace bottom of a hydrogen metallurgy rotary hearth furnace, and the thickness of a fabric is controlled to range from 60 mm to70 mm; reduction is conducted on the pellets in the furnace for 50-60 minutes at the temperature of 1250-1280 DEG C, and Fe, Cr and Ni in the stainless steel dedusting ash can be obtained through reduction; and after being discharged through a discharging end of the rotary hearth furnace, a high-temperature reduction material in the hot state is directly delivered into an electric furnace for deepreduction and melting separation, and molten iron containing 4-6% of Ni, 10-15% of Cr and 0.5-1.0% of C can be obtained. By means of the process, metal materials, such as iron, nickel and chromium, in the stainless steel dedusting ash can be obtained through reduction at the low cost; the utilization rates of nickel and chromium raw materials are effectively increased; the yields of a nickel alloy and a chromium alloy are effectively increased; and meanwhile, environmental pollution is reduced.

Owner:JIUQUAN IRON & STEEL GRP

Mechanical vapor recompression drying system and method

PendingCN111908764AReduce consumptionReduce evaporation lossSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesCooling towerSludge

The invention discloses a mechanical steam recompression drying system and method. The system comprises a sludge storage tank, a sludge injection pump, a thin-layer evaporation dryer, an extrusion slitting forming machine, a mesh belt dryer, a dry sludge bin, a steam compressor, a cyclone dust collector, a washing dust collector, a condensate water buffer tank and a vacuum pump which is connectedwith the condensate water buffer tank and used for sucking system air to maintain vacuum and discharging non-condensable gas. A large amount of energy consumption and cooling water system consumptioncan be saved. No waste gas is discharged in the process, the system is free of a cooling water system, and water evaporation loss of the cooling tower is reduced.

Owner:苏州翔云节能科技有限公司

Multichannel rotating type air preheater

InactiveCN105042621AReduce circumferential temperature deviationSmall heat transfer temperature differenceCombustion processIndirect carbon-dioxide mitigationCold airAir preheater

The invention provides a multichannel rotating type air preheater which comprises an air preheater shell, a rotor arranged in the shell, flue gas channels, air channels and sealing plates arranged between every two adjacent channels. At least two flue gas channels are arranged, and the number of the air channels is larger than or equal to that of the flue gas channels. The air channels are formed between every two adjacent flue gas channels, that is, the flue gas channels are partitioned by the air channels. Corresponding flue gas inlet / outlet connection plates and air inlet / outlet connection plates correspond to the flue gas channels and the air channels. By means of the multichannel rotating type air preheater, hot flue gas and cold air pass through the rotor of the air preheater frequently, so that lower smoke temperature peripheral deviation and air temperature peripheral deviation are achieved, the lowest exhaust smoke temperature and the lowest rotor temperature are increased under the same exhaust smoke temperature condition, it is avoided that part of flue gas in the flue gas channels of the air preheater enters a dew point area too early, and the problems of dew formation, ash sticking, corrosion, blocking and the like of a cold-end heat storage piece are reduced. Through optimal design, the temperature of exhaust smoke of a boiler can be further lowered, and the efficiency of the boiler is improved.

Owner:TSINGHUA UNIV +2

Viscous material cooling reactor

InactiveCN108671864BExtended storage timeSufficient heat exchangeChemical/physical/physico-chemical stationary reactorsChemical industryThermodynamics

The invention provides a reaction kettle for cooling a viscous and dense material. The reaction kettle comprises a kettle body, a jacket, a stirring paddle, a scraper, a shunt plate, a suction paddle,a thermometer and the like. The stirring paddle and the scraper are designed integrally to ensure that the viscous and dense material has axial and radial flows at the same time; and the scraper continuously scrapes away heat-exchanged materials to ensure that the viscous and dense material can fully exchange heat, the temperature distribution is uniform, and the cooling speed and efficiency areeffectively improved. The shut plate settles the cooled viscous and dense material at the bottom of the kettle body in sections, and the suction paddle assists in axial circulation to improve the heatexchange efficiency and realize continuous discharge in a cooling process. The reaction kettle solves environmental protection problems during filling and natural cooling of materials with high temperatures, and meanwhile greatly shortens the production period, effectively prolongs the storage time of materials and improves the quality of products. The reaction kettle has the characteristics of simple structure, low cost and convenient operation. The reaction kettle can be widely applied in food, feed, chemical industry, pharmacy and other fields requiring rapid cooling of viscous and dense materials.

Owner:荣成惠德环保科技有限公司

Heat transfer coefficient adjustable heat-exchange device

InactiveCN104634813AHeat transfer coefficient adjustmentImprove securityMaterial heat developmentHeat transfer efficiencyEngineering

The invention discloses a heat transfer coefficient adjustable heat-exchange device which comprises an outer tube, a middle tube, an inner tube, an elastic device and a driving mechanism. The heat transfer coefficient adjustable heat-exchange device is characterized in that heat conductive powder is arranged between the middle tube and the inner tube; and under the actions of the driving mechanism and the elastic device, the heat conductive powder can be compressed and loosened. By virtue of the combination of multiple layers of tubes and by adding the elastic device and the driving mechanism, the heat-exchange device disclosed by the invention can avoid mutual leakage and contact between two heat-exchange mediums, so that the safety of a system is enhanced; and under the actions of the driving mechanism and the elastic device, the heat conductive powder can be compressed and loosened to regulate the heat transfer coefficient of the heat-exchange device, so that the heat power of the heat-exchange device is adjustable.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

A heat exchange device for utilization of combustion waste heat with grid-distributed heat exchange structure

InactiveCN107270746BReduce film boilingReduce heat loadHeat exchanger casingsStationary tubular conduit assembliesGratingCombustion

The invention provides a heat exchange device utilizing combustion waste heat. The heat exchange device comprises a heat exchange core; the heat exchange core is arranged in a waste gas flue and comprises circular tubes; the circular tubes are arranged perpendicular to the flowing direction of waste gas; a plurality of dispersion heat exchange structures are arranged in the circular tubes in a segmented mode; each dispersion heat exchange structure comprises a core and a shell, wherein the core is arranged in the shell; the shells are fixedly connected to the inner walls of heat exchange tubes; each core is formed by arranging and combining a plurality of grating sheets; and the grating sheets are mutually connected to form grating holes. The heat exchange device has the advantages that the grating type dispersion heat exchange structures are arranged in the heat exchange tubes so as to separate a steam-water mixture in the heat exchange tubes, and therefore the film boiling phenomenon on the water side can be effectively reduced, the convective heat exchange intensity of the water side can be increased, the heat load of the heat exchange core can be reduced, and the heat exchange efficiency can be improved.

Owner:CHINA NORTH VEHICLE RES INST

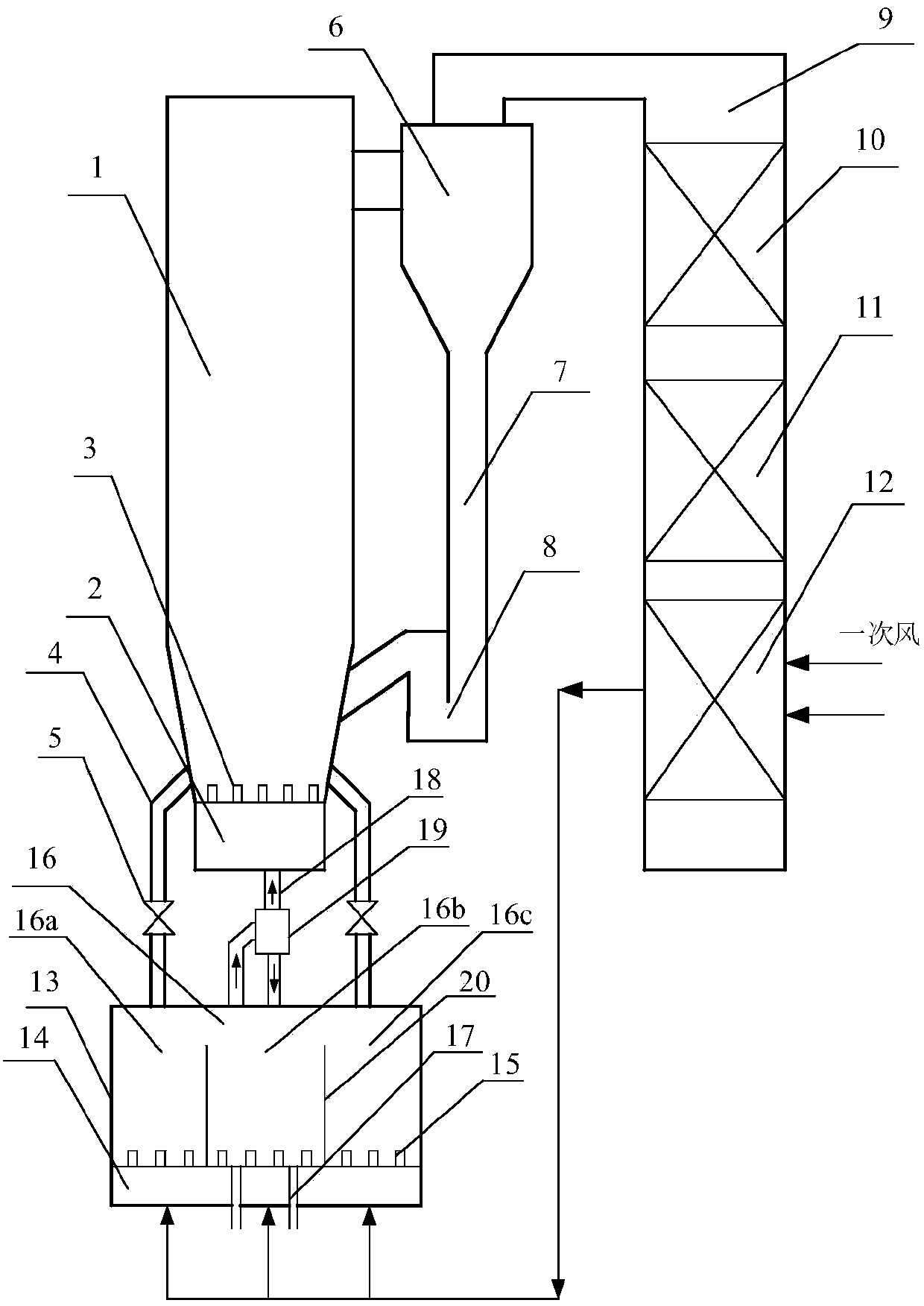

Circulating fluidized bed boiler for burning low-heat-value high-ash fuel

PendingCN107631294AHigh thermal efficiencyIncrease the flow distanceFluidized bed combustionIndirect carbon-dioxide mitigationAir preheaterSlag

A circulating fluidized bed boiler for burning low-heat-value high-ash fuel contains a hearth, a primary air chamber, a cyclone separator, a cyclone separator, a charge leg, a return valve, a slag discharge pipe, a tail flue and a gas-solid heat exchange bed. The gas-solid heat exchange bed is arranged below the primary air chamber and connected with the hearth through a connection pipe and a gas-solid separation device. The hearth is connected with the gas-solid heat exchange bed through the slag discharge pipe. The gas-solid heat exchange bed comprises a heat exchange bed air chamber, a heatexchange bed air cap, a heat exchange bed heat exchange chamber and a heat exchange bed slag discharge pipe. The heat exchange bed air chamber is connected with an air preheater through a gas pipeline. A large quantity of high-temperature ash residues in the hearth are discharged into the gas-solid heat exchange bed through the slag discharge pipe, and primary air is heated by the air preheater,is led into the gas-solid heat exchange bed and then enters the primary air chamber. By means of the circulating fluidized bed boiler, the temperature of the primary air can be greatly improved, and the requirement for stable burning of the low-heat-value high-ash fuel is met; and on the other hand, the heat of the large quantity of ash residues of the high-ash fuel can be recycled, the slag discharge heat loss is reduced, and thus the overall heating efficiency of the boiler is improved.

Owner:TSINGHUA UNIV

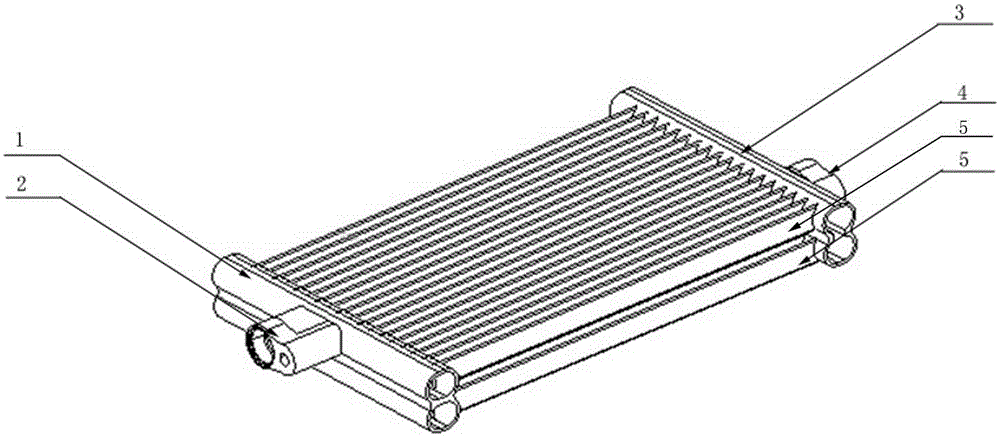

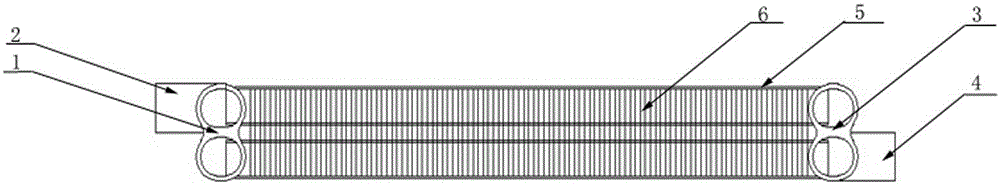

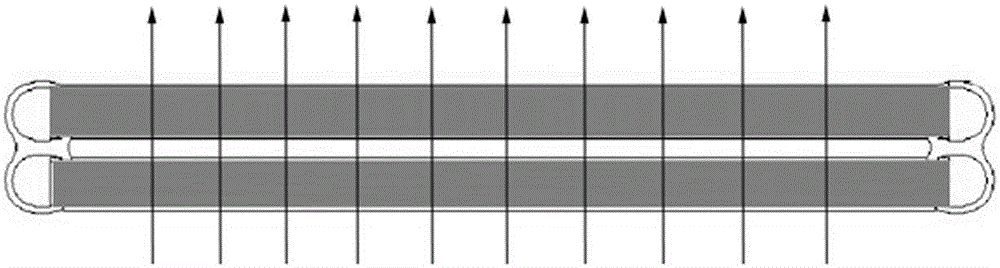

Double-layer parallel flow condenser for integrated passenger car air conditioner

InactiveCN105180520AEfficient use ofImprove heat transfer effectEvaporators/condensersEngineeringTemperature difference

The invention provides a double-layer parallel flow condenser for an integrated passenger car air conditioner. The double-layer parallel flow condenser comprises a double-layer heat transfer system. The double-layer heat transfer system is composed of a left double-hole header, a right double-hole header, a refrigerant inlet formed in an upper pipe of one double-hole header, a refrigerant outlet formed in a lower pipe of the other double-hole header, two layers of horizontal heat transfer flat pipes connected with the two double-hole headers, and heat transfer fins arranged on the heat transfer flat pipes. The upper pipes and the lower pipes of the double-hole headers are communicated through conduction holes. The layering heat transfer technology is adopted, effective utilization of the temperature gradient is achieved, and the heat transfer temperature difference is effectively improved. The heat exchange amount of the parallel flow condenser is greatly increased, the breakthrough of the heat exchange amount is achieved, and compared with a current traditional double-D type header condenser, better pressure resistance is achieved. According to integrated welding molding, the machining cost is reduced, and the market vacancy is filled up. The double-layer parallel flow condenser has the beneficial effects of being small in structural size, high in efficiency, low in cost, wide in application range and the like.

Owner:ZHENGZHOU KELIN VEHICLE AIR CONDITIONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com