Viscous material cooling reactor

A technology for reactors and materials, which is applied in the field of special reactors and cooling reactors, can solve the problems that viscous materials cannot be cooled quickly and evenly, and achieves the convenience of manual control and automatic control, shortens the production cycle, and prolongs the storage time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The present invention will be further described in detail below in conjunction with the drawings:

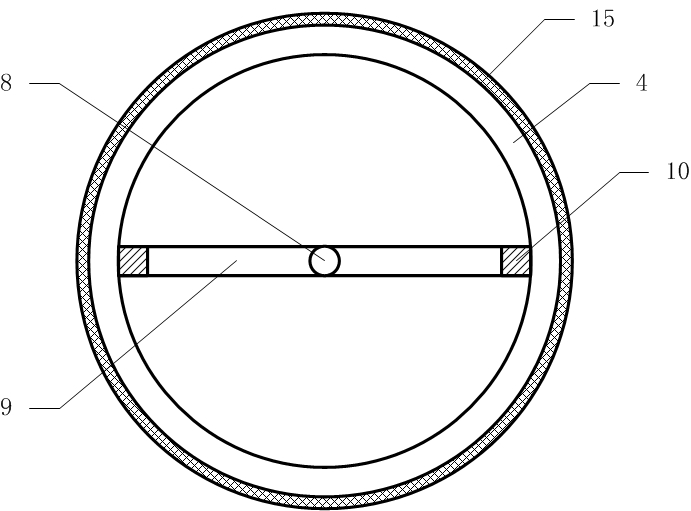

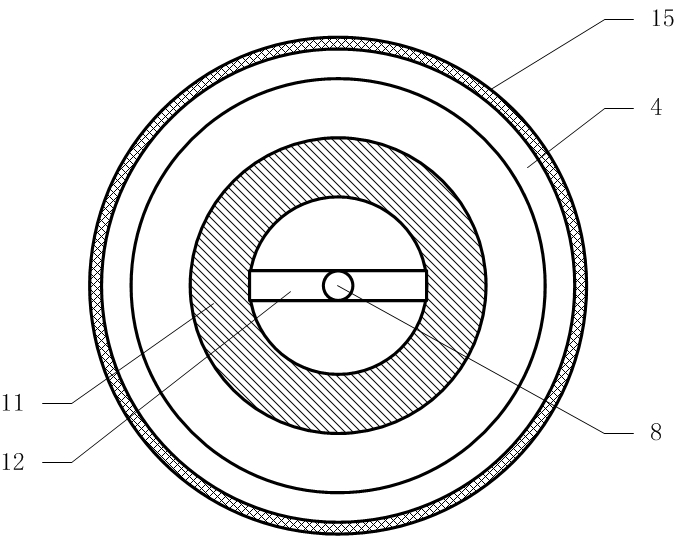

[0022]Such asfigure 1 Shown is the front view of the reactor for cooling viscous materials. The reactor for cooling viscous materials includes a kettle body (1), a feed port (2), a feed port (3), a jacket (4), Refrigerant inlet (5), refrigerant outlet (6), motor (7), stirring shaft (8), stirring paddle (9), scraper (10), splitter plate (11), suction paddle (12), thermometer (13), temperature probe (14), insulation layer (15).

[0023]figure 1 In the medium, after the material with higher temperature enters the kettle body (1) through the feed port (2), the motor (7) drives the stirring shaft (8) to drive the stirring blade (9) to rotate and stir the material; the blades of the stirring blade (9) have The vertical inclination angle is generally 45 degrees, so that the material can form an axial flow in the kettle body (1), and form a radial flow under the action of the scraper (10), so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com