Micropower heat dissipating cabinet

A technology of micro-power consumption and cabinets, which is applied in cooling/ventilation/heating transformation, electrical equipment shells/cabinets/drawers, electrical components, etc., and can solve the problems of increasing the power of a single cabinet, distributing difficult cabinets on demand, and difficult to install air conditioners, etc. problem, to achieve the effect of increasing installed power, saving energy consumption, and high exhaust temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

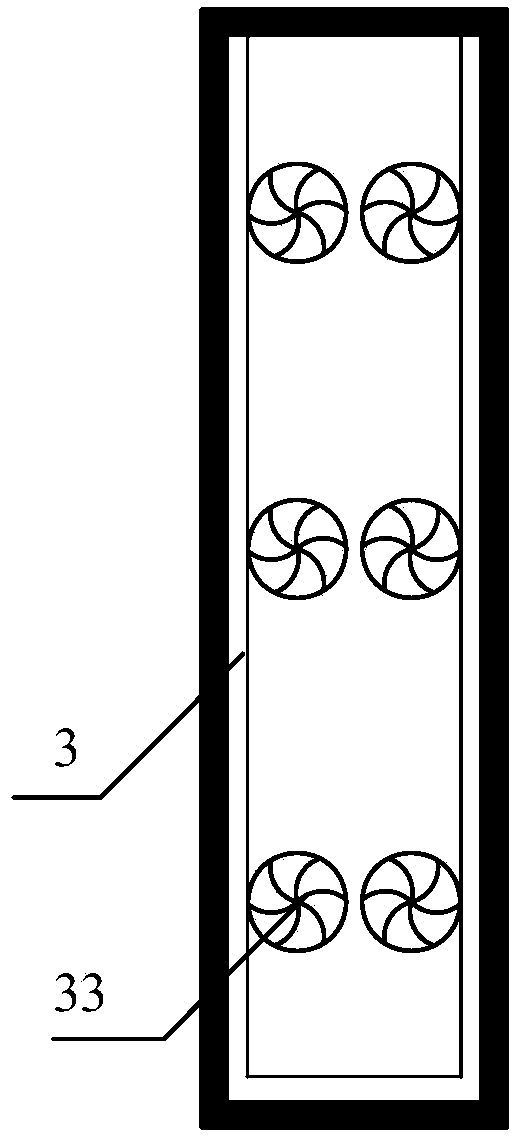

[0028] Such as Figure 1~4 as well as Figure 7 As shown, this embodiment includes a cabinet body 1, a cabinet front door 2, a cabinet back door 3, a first microchannel heat exchanger 31, a second microchannel heat exchanger 32, a fan 33, a water collecting tray 34, a first The refrigerant pipe interface 35 of the first microchannel heat exchanger, and the refrigerant pipe interface 36 of the second microchannel heat exchanger. The front door 2 of the cabinet is provided with a honeycomb vent 21 .

[0029] In this implementation, when the computer room is normally installed and running, the cabinet body 1 is used to install electronic information equipment, and the first microchannel heat exchanger refrigerant pipe interface 35 and the second microchannel heat exchanger in the cabinet back door 3 The refrigerant pipe interface 36 of the heat exchanger is respectively connected to two sets of water Freon heat exchangers in the external system, and there is a certain height di...

Embodiment 2

[0032] Such as Figure 5 As shown, in this embodiment, the width of the first microchannel heat exchanger is equal to the width of the second microchannel heat exchanger, and all air first passes through the first microchannel heat exchanger before entering the second microchannel heat exchanger. Heater, all the other are identical with embodiment 1.

Embodiment 3

[0034] Such as Figure 6 As shown, the width of the first microchannel heat exchanger in this embodiment is equal to the width of the second microchannel heat exchanger, but there is a gap space in the middle of the first microchannel, and part of the air can directly enter the second microchannel through the gap space. Two micro-channel heat exchangers, part of the air can be directly discharged to the machine room from both sides through the first micro-channel heat exchanger, part of the air first passes through the first heat exchanger and then passes through the second heat exchanger, and the rest Example 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com