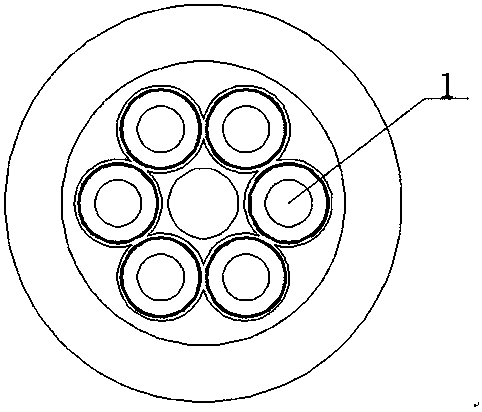

A plum blossom tube core mold

A plum blossom tube and mandrel technology, which is applied in the field of plastic machinery, can solve the problems of slow cooling speed, achieve the effects of reducing cooling time, changing cooling methods, and increasing processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

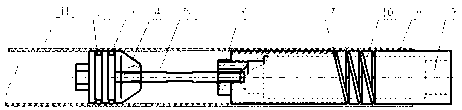

[0010] Embodiment of the present invention: the outer diameter of the plug 4 is equal to the outer diameter of the hollow cylinder 8, the plug 4 is provided with a groove 2 in the circumferential direction, and a sealing ring 3 is installed in the groove 2. One end of the hollow cylinder 8 has a water outlet 6, the other end has a water injection hole 9, the outer wall of the hollow cylinder 8 has a water outlet 7, the water outlet 7 is a spiral groove, and the spiral groove is provided with a small water outlet 10. One end of the water outlet hole 6 is arranged on the plug 4 and the hollow cylinder 8 through the connecting rod 5 to connect together.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com