Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Overcome spring force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

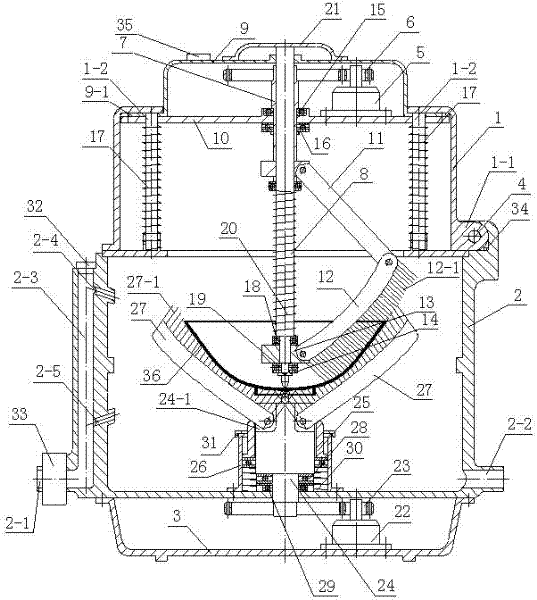

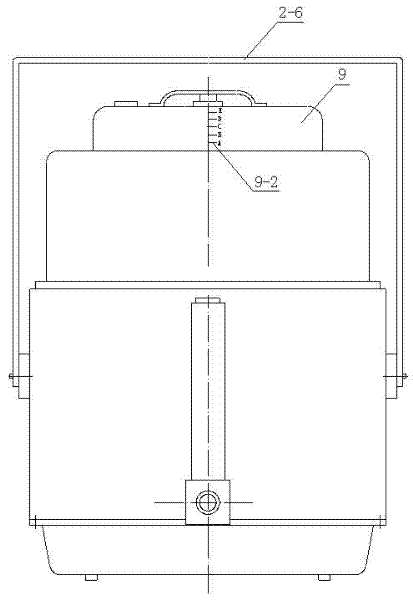

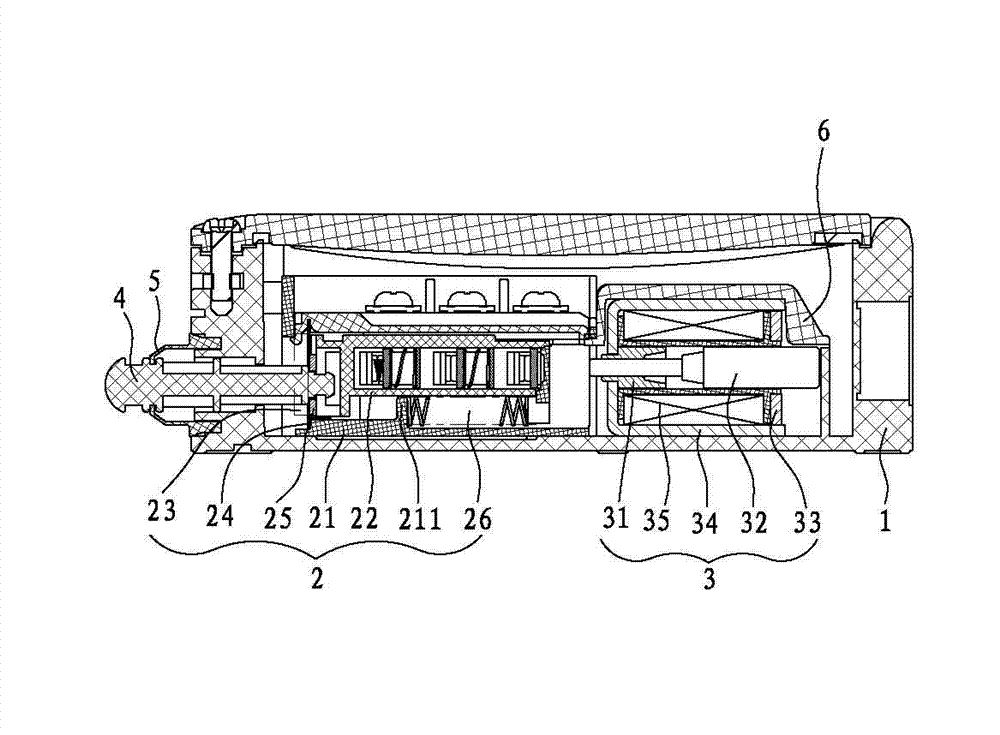

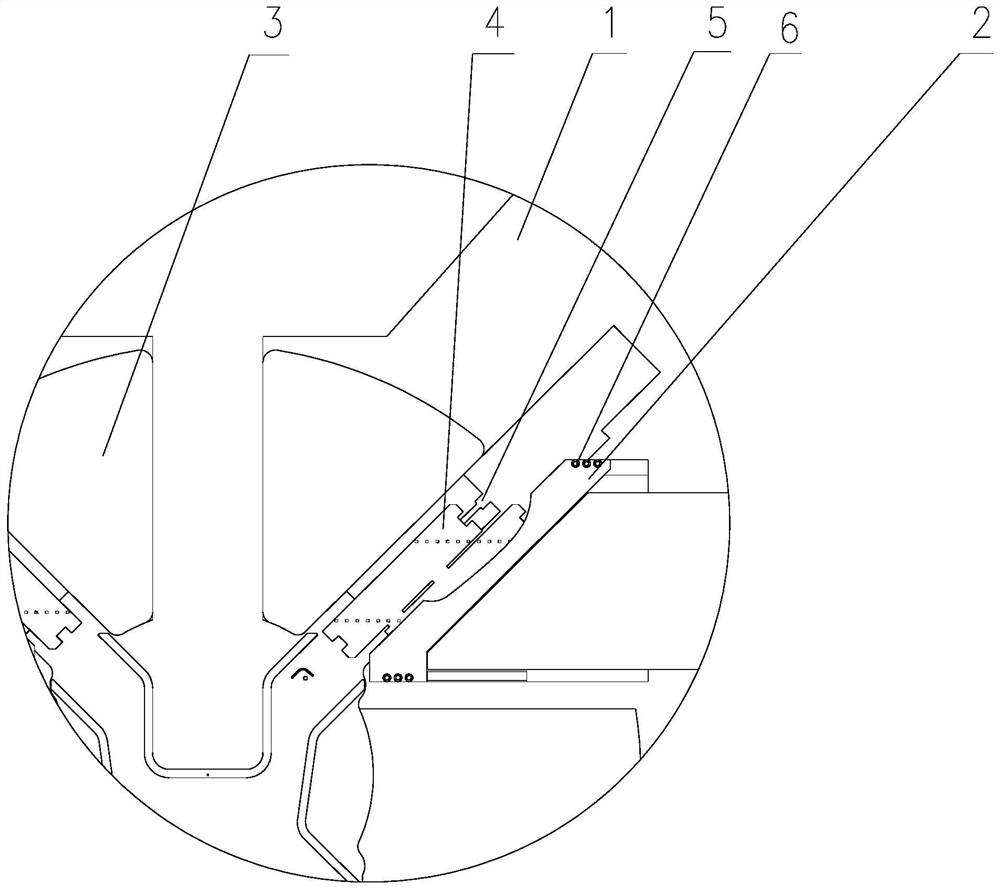

A household dishwasher

InactiveCN102293618AShort cleaning timeImprove efficiencyTableware washing/rinsing machine detailsDish washer applicanceElectricityEngineering

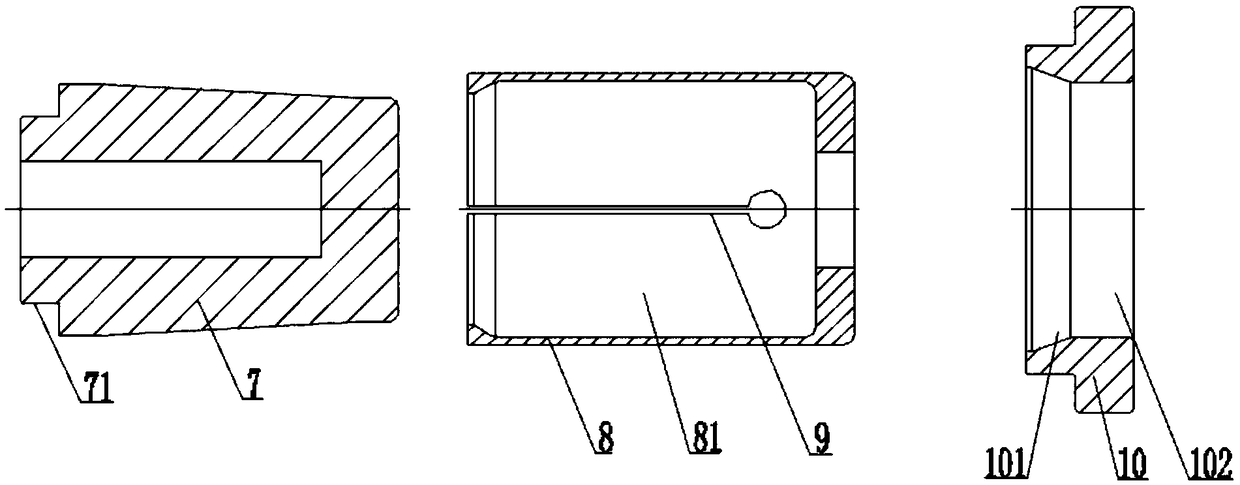

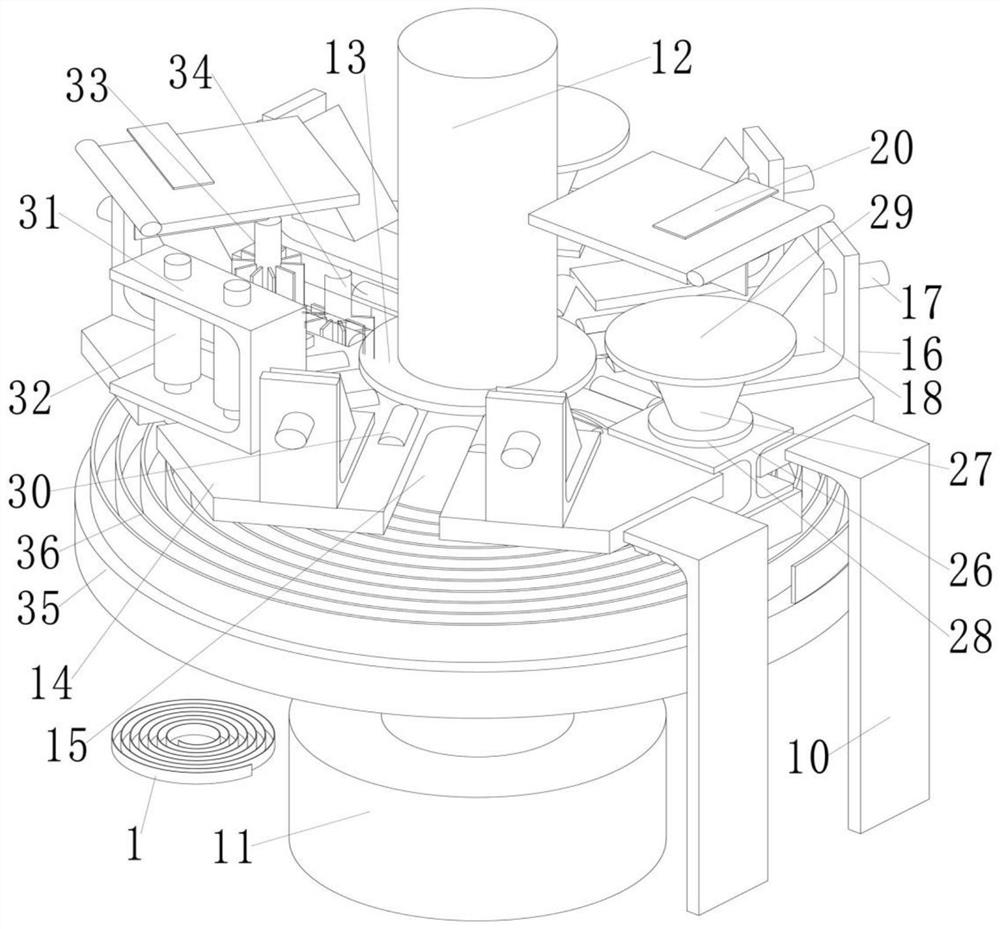

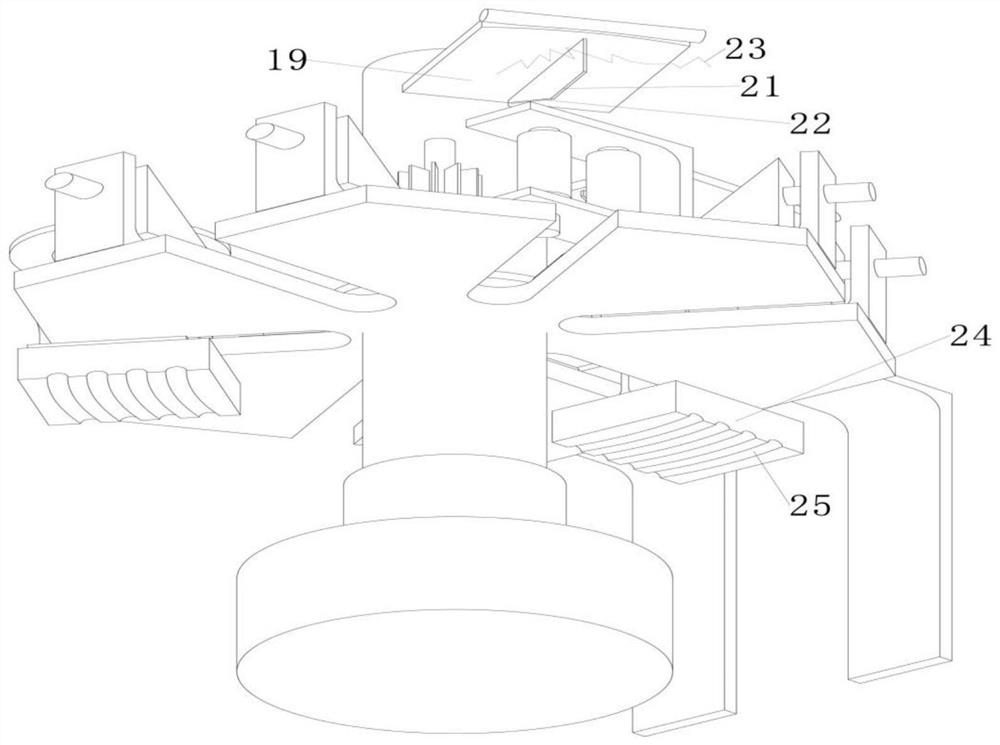

The invention relates to a domestic bowl washing machine, which comprises an upper cover, a tube body, a bottom case, an internal cleaning device and an external cleaning device, wherein the upper cover is overlapped on the upper end surface of the tube body, the lower edge of the upper cover is provided with a convex lug, the convex lug is rotatablely connected with the tube body, the bottom case is fixedly connected with the lower end of the tube body, the internal cleaning device is in contact with the upper cover, the external cleaning device is fixedly connected with the tube body and the bottom case, the internal cleaning device and the external cleaning device are coaxially arranged and are in contact with each other, and at least two symmetrically distributed guide posts are arranged in the upper cover. The domestic bowl washing machine has the advantages that the speed is high, the efficiency is high, the cleaning is clean, the effect is good, the function is complete, the electricity, the water and the time are saved, the structure is compact, the appearance is attractive, the operation is easy, the carrying and the placement are convenient, and the manufacturing cost islow.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

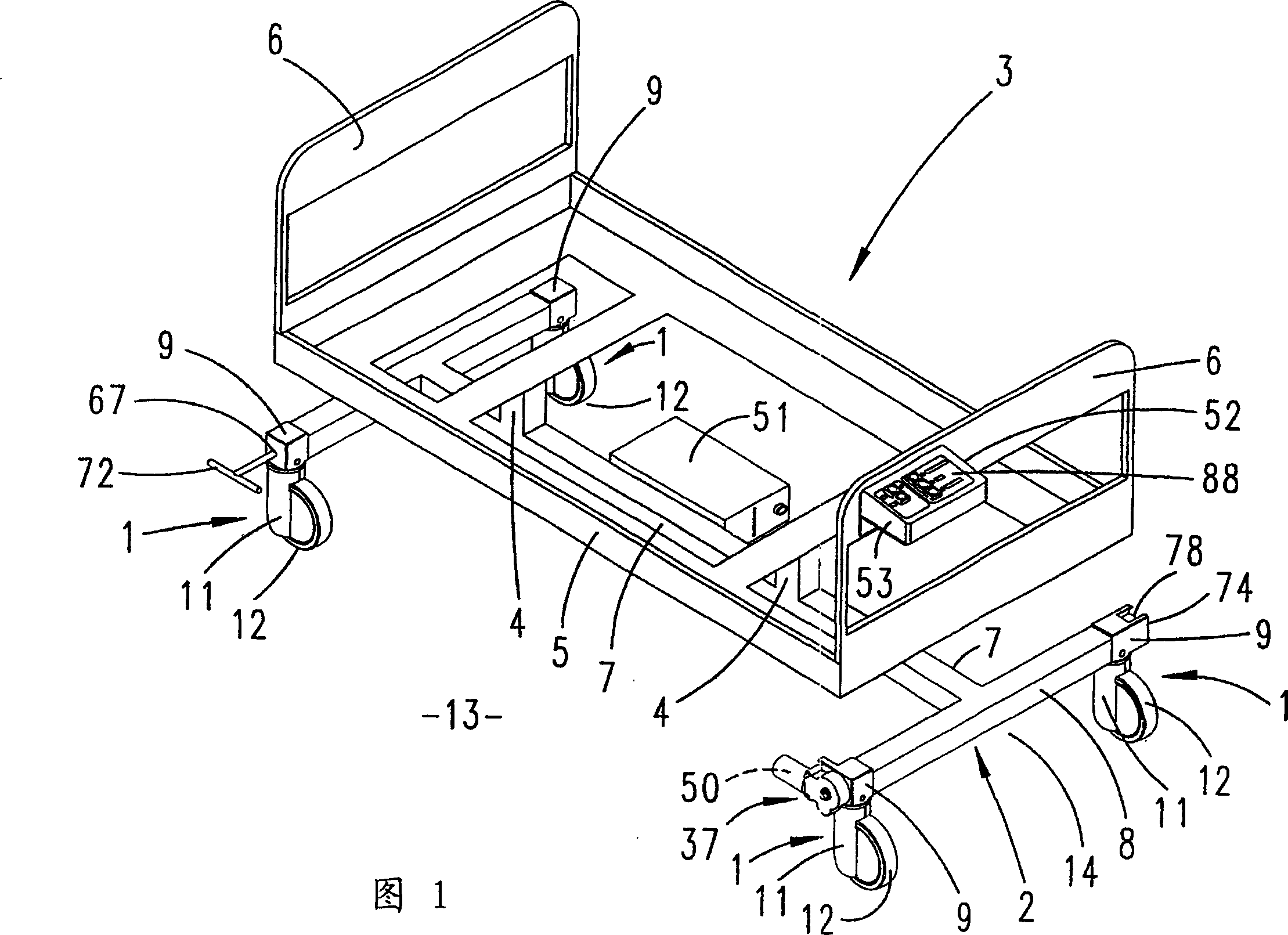

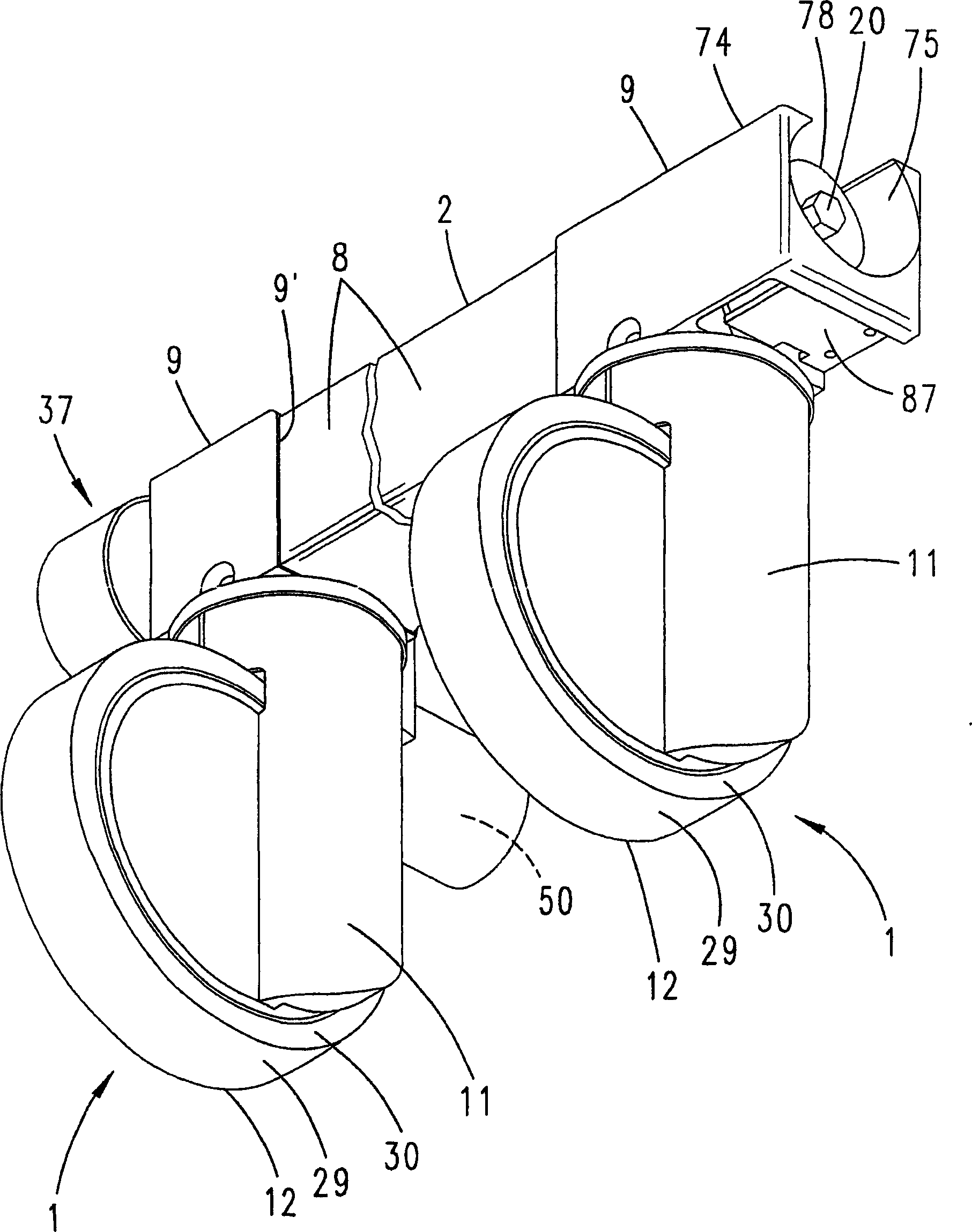

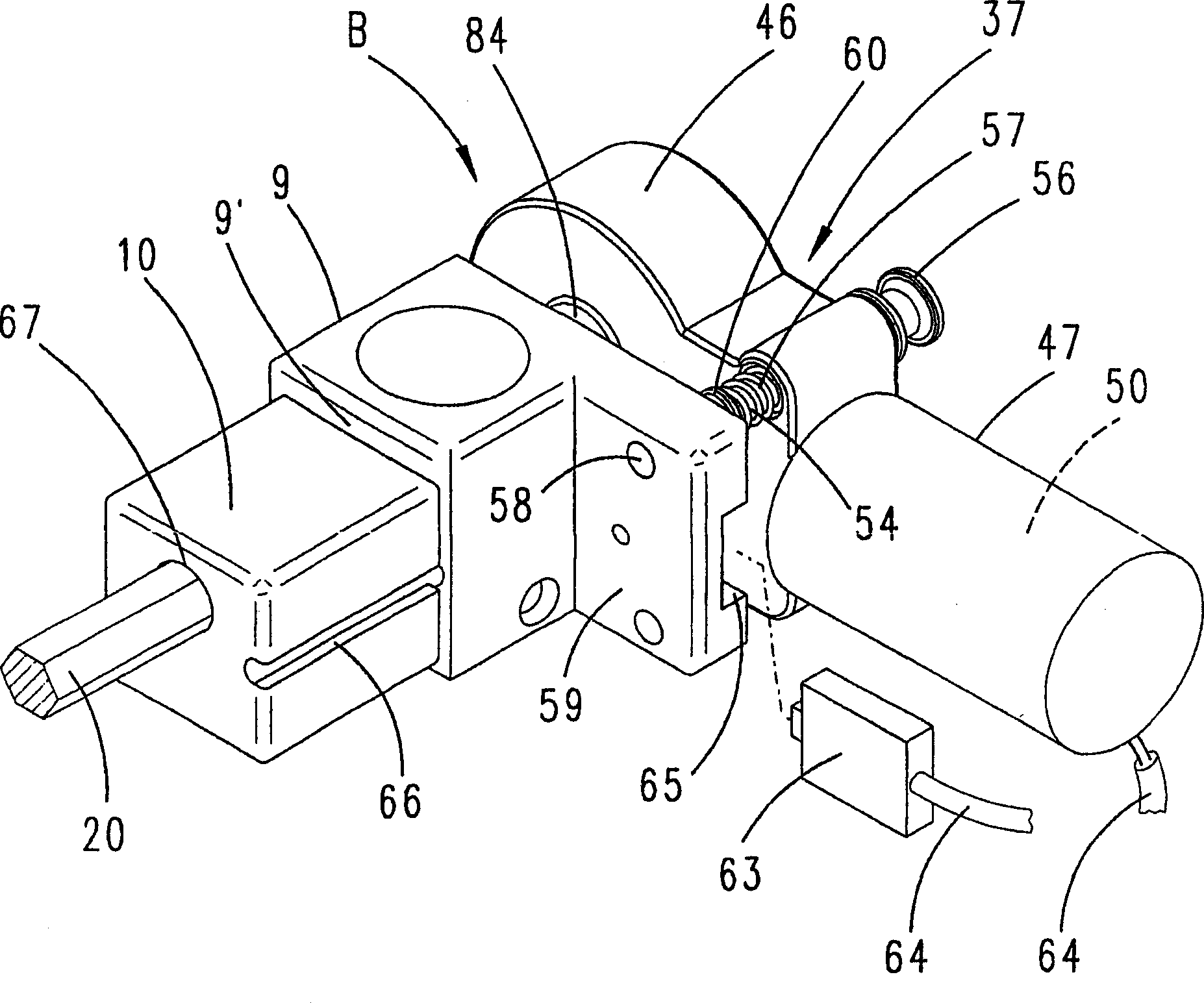

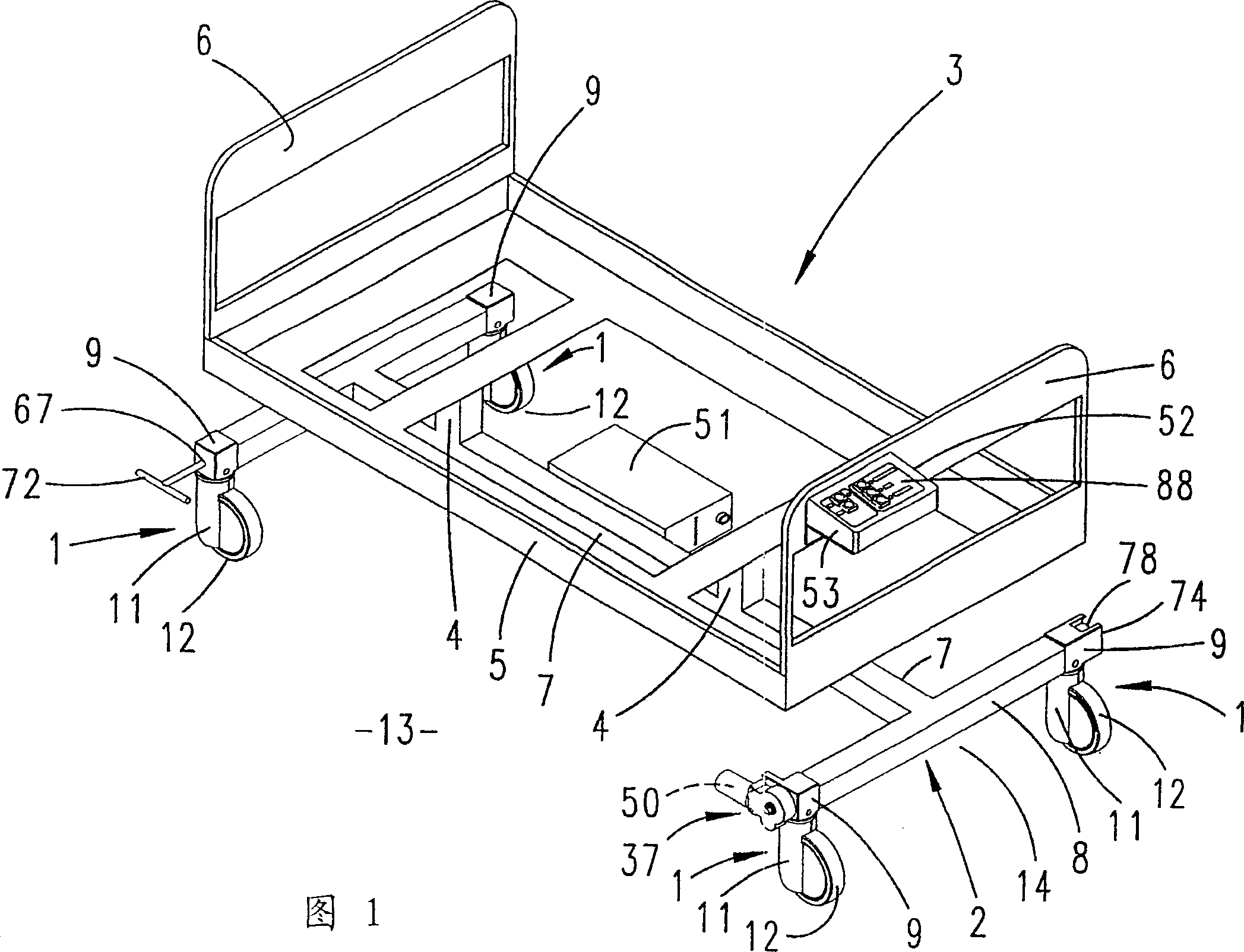

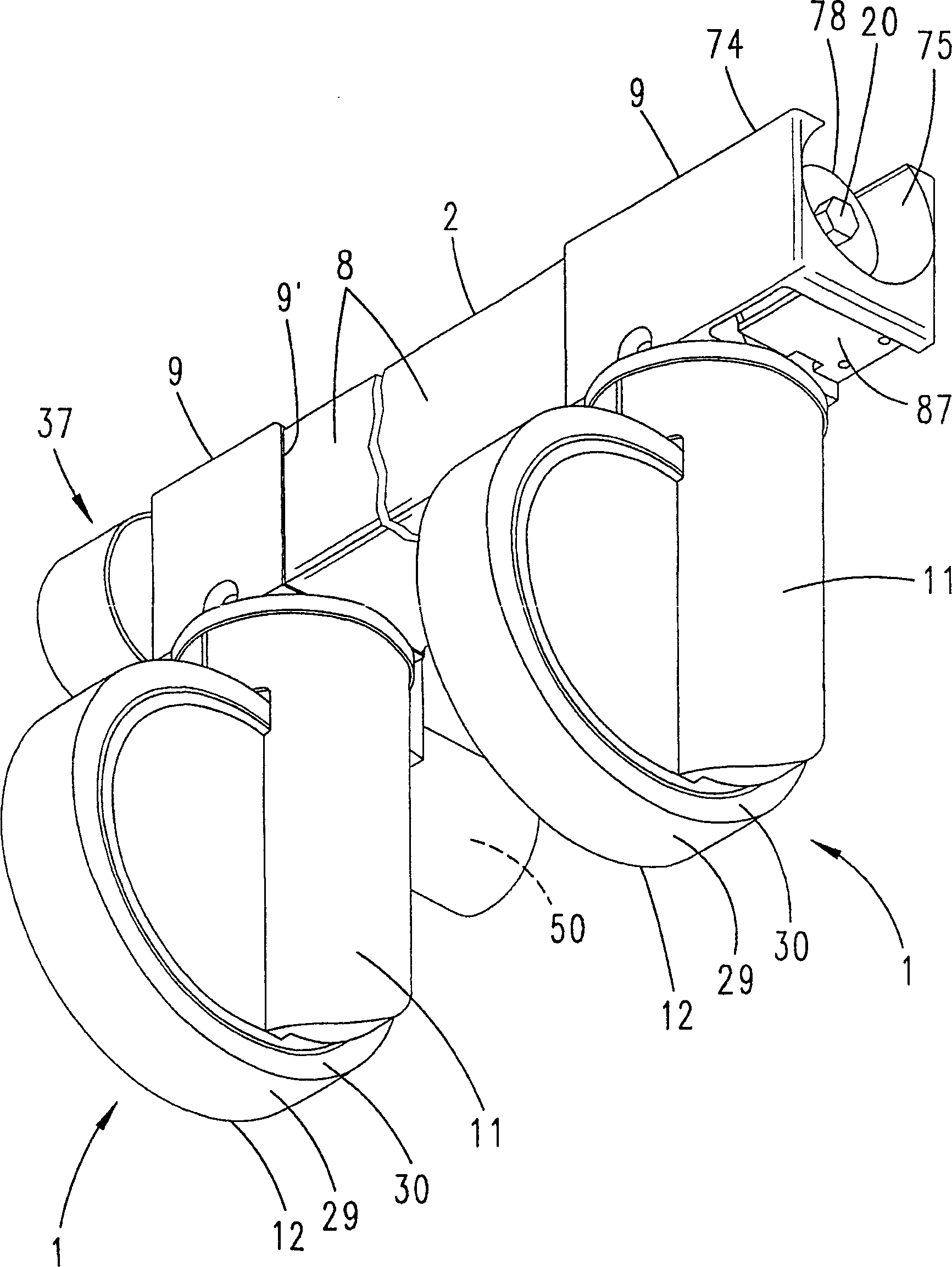

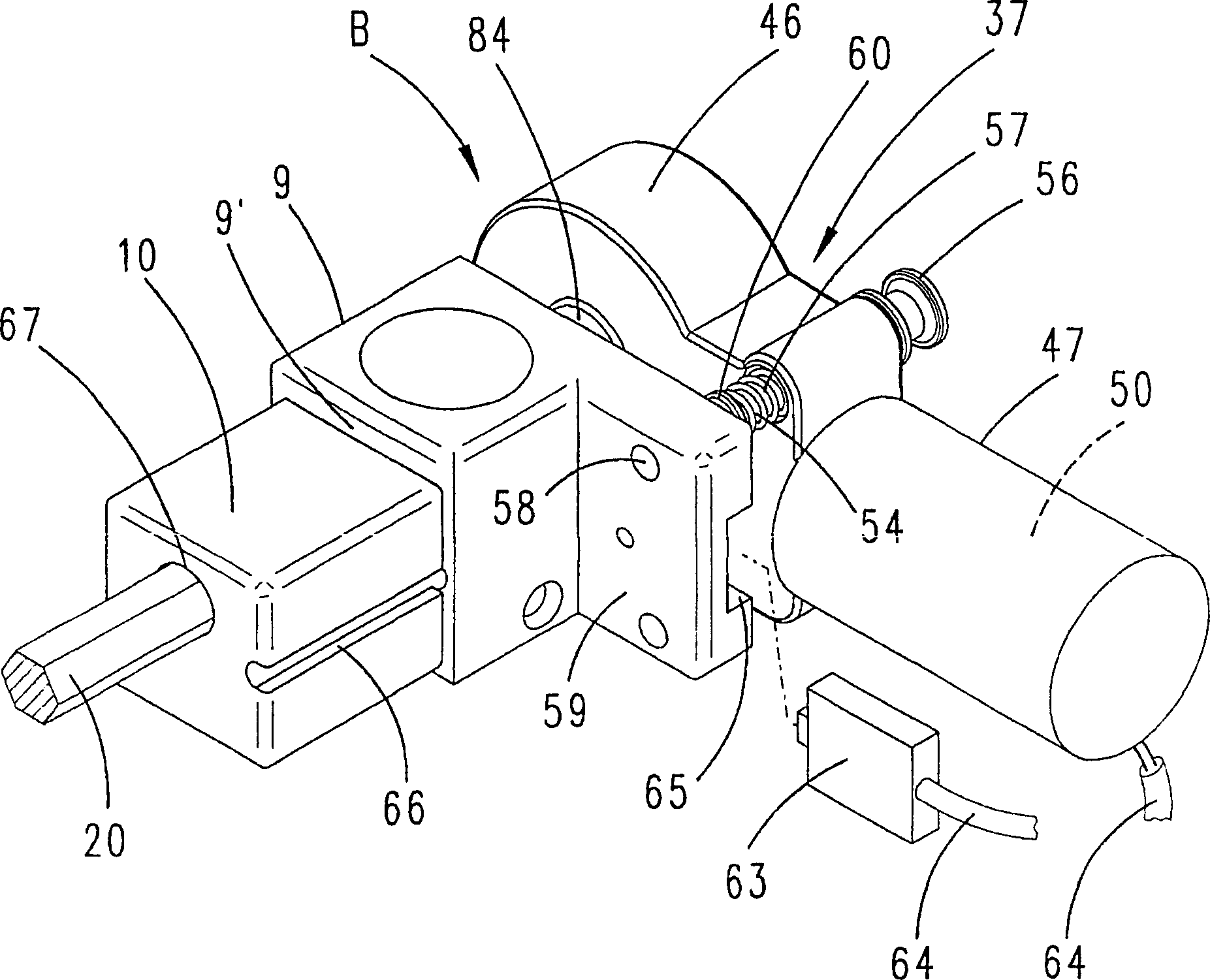

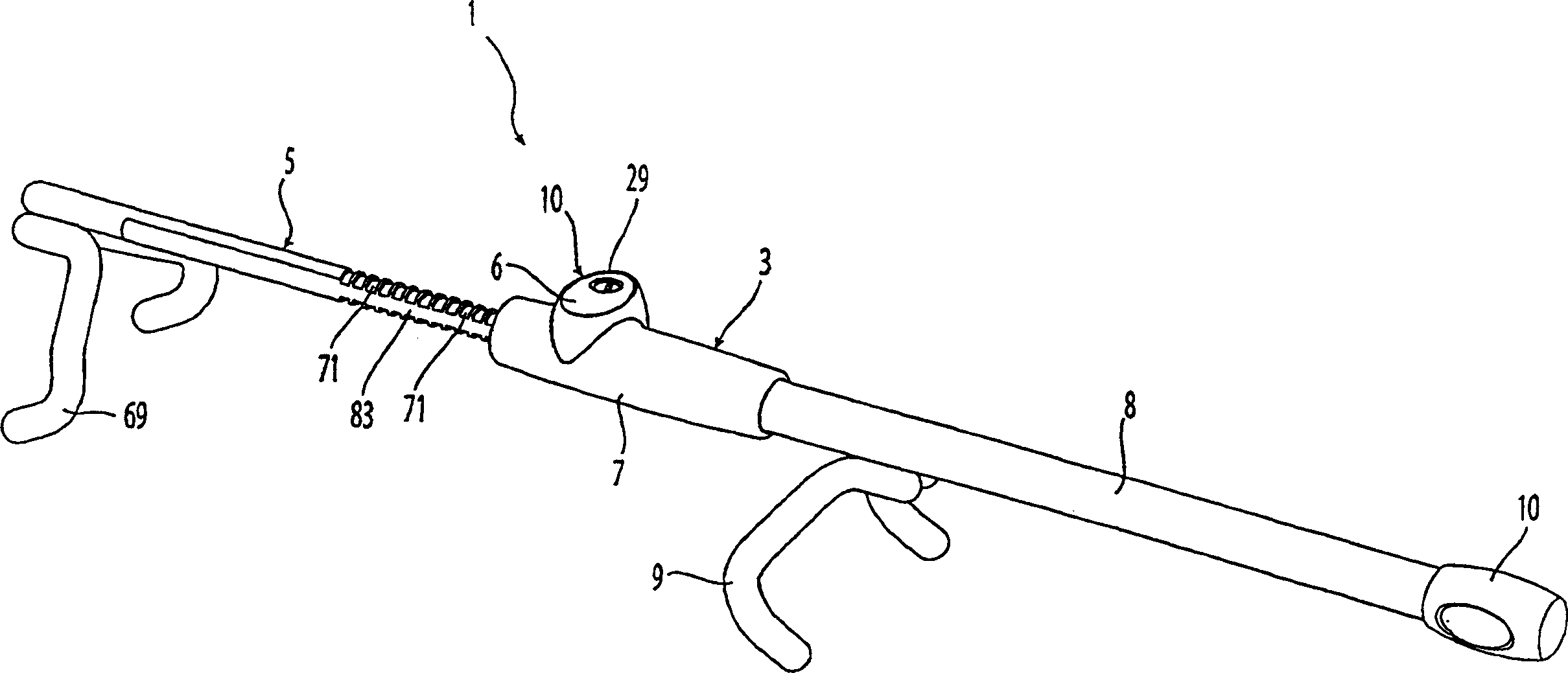

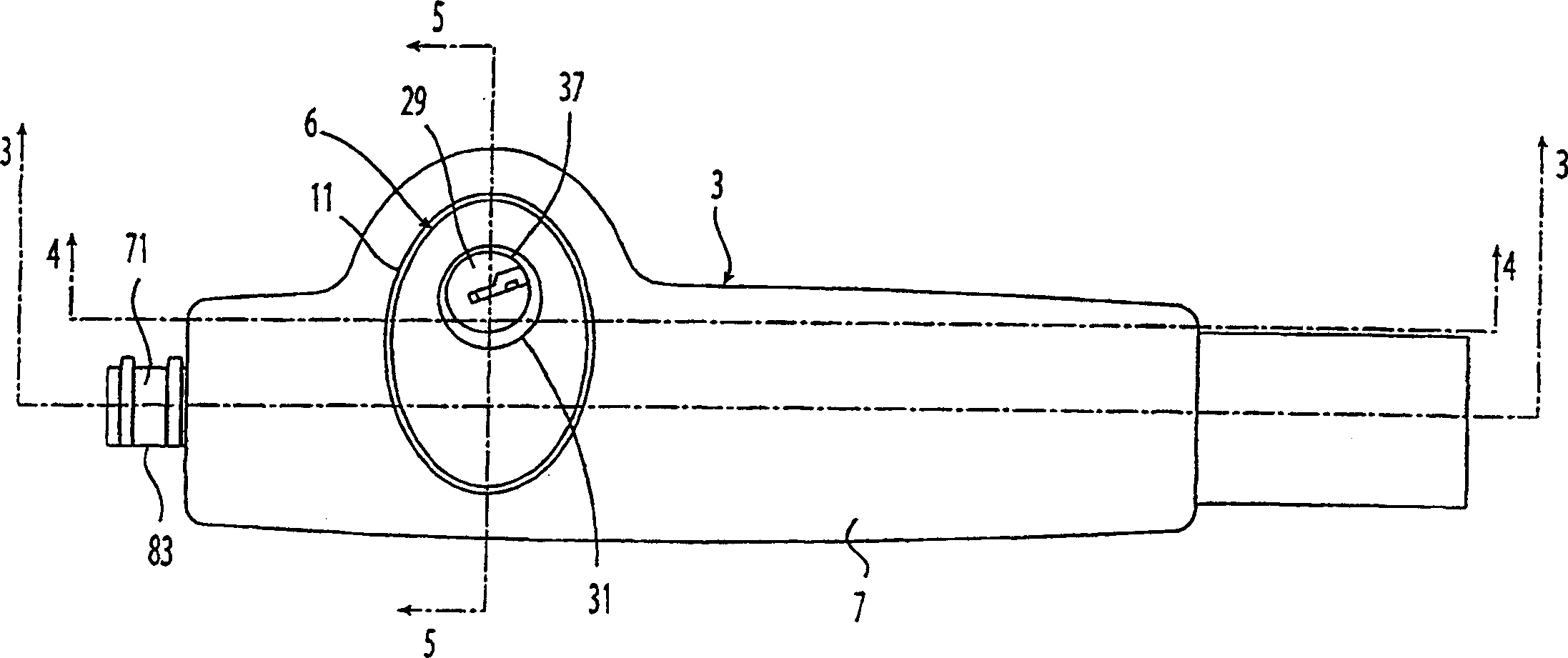

Castor type roller controlled by motor

InactiveCN1486251AEasy to operateSimple structureBraking element arrangementsToothed gearingsElectric machineEngineering

The invention relates to a roller (1),in particular, a castor. The rotation of the running wheel of said castor and optionally the pivoting motion of the running wheel (12) may be fixed, by means of an operating shaft (20), which moves a control cam (19) through the roller (1), with an electric motor (37) acting thereupon for operation thereof. According to the invention, the functional roller operation can be embodied with a more advantage operation, a simpler construction, yet of secure operation, whereby the electric motor (37) acts on the operating shaft (20) by means of an electric motor shaft (39) using a toothed gear (38).

Owner:TENTE

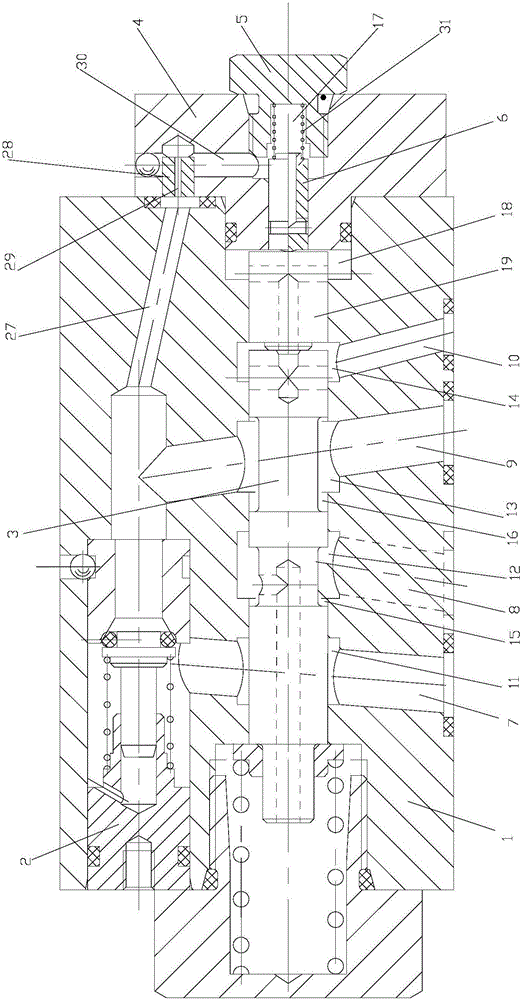

Fast-extending and slow-contracting hydraulic cylinder

InactiveCN105041769ACompressibleImplement soft start indentationFluid-pressure actuatorsHydraulic cylinderEngineering

The invention provides a fast-extending and slow-contracting hydraulic cylinder. The hydraulic cylinder mainly comprises a cylinder barrel, a piston rod, a piston, a buffer sleeve, a jet flow passage, an acceleration sleeve, a guide buffer sleeve, an end cover B and an end cover A. The fast-extending and slow-contracting hydraulic cylinder is characterized in that the piston rod can extend fast and contract slowly. According to the fast-extending and slow-contracting hydraulic cylinder, the buffer sleeve with one inwardly concave side and an angular jet flow passage are arranged, so that the slow contracting of the piston rod is realized; the parabola-shaped acceleration sleeve is arranged, so that the fast extending of the piston rod is realized; the parabola-shaped inwardly-concave guide buffer sleeve is arranged, and an annular blind hole is formed in the guide buffer sleeve, so that buffer stop of the acceleration sleeve is realized, the extension length of the piston rod is increased, and soft start contraction of the piston rod is realized; a check valve is arranged on the cylinder barrel, so that high-pressure air in the cylinder is discharged; elastic pads are arranged between the end cover B and the guide buffer sleeve, so that impact on the guide buffer sleeve generated by fluid is absorbed; oil grooves and sealing rings are arranged on the outer side surface of the piston, so that oil leakage, temporary storage of impurities in oil and sealing of the piston are realized.

Owner:UNIV OF JINAN

Stroke switch with remote control reset function

InactiveCN102737869ARealize resetOvercome spring forceContact operating partsSwitch power arrangementsElectromagnetic valveRemote control

The invention discloses a stroke switch with a remote control reset function, which comprises a shell body, a core part module, an electromagnetic valve, a plunger and a seal sleeve. The core part module and the electromagnetic valve are sequentially arranged in the inner cavity of the shell body; a push rod on the electromagnetic valve is jacked on the slow transmission rod of the core part module; the seal sleeve is sleeved on one end of the shell body; the plunger movably penetrates through the through hole of the seal sleeve; the outer end of the plunger goes out of the seal sleeve; and the inner end of the plunger is connected with one end of the slow transmission rod on the core part module which is fixedly connected with an armature. The stroke switch with the remote control reset function is provided with the core part module and the electromagnetic valve; the push rod on the electromagnetic valve is inserted and buckled on one end of the slow transmission rod on the core part module; the other end of the slow transmission rod is over against the plunger; and the push rod on the electromagnetic valve can drive the slow transmission rod to move back and forth in a core part shell, so that the spring force of a movable rod spring is overcome, a permanent magnet and the armature are close and are actuated and the plunger is reset. Because the electromagnetic valve can be controlled remotely, so that the stroke switch has the remote control reset function.

Owner:SUNS ELECTRIC ZHANGZHOU

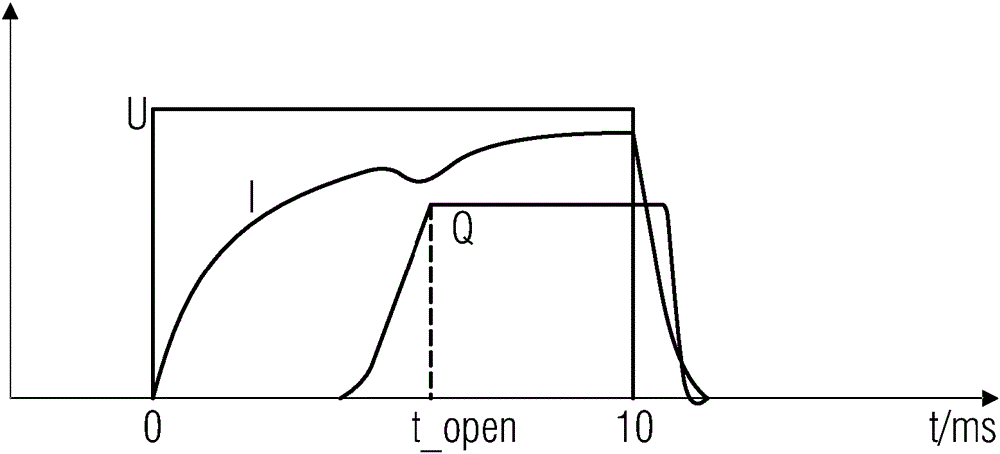

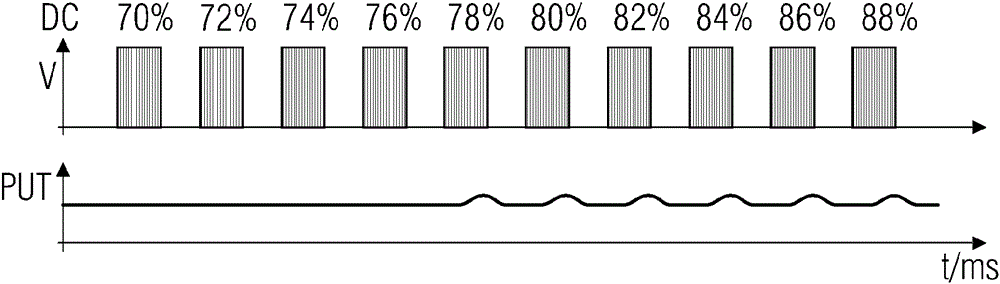

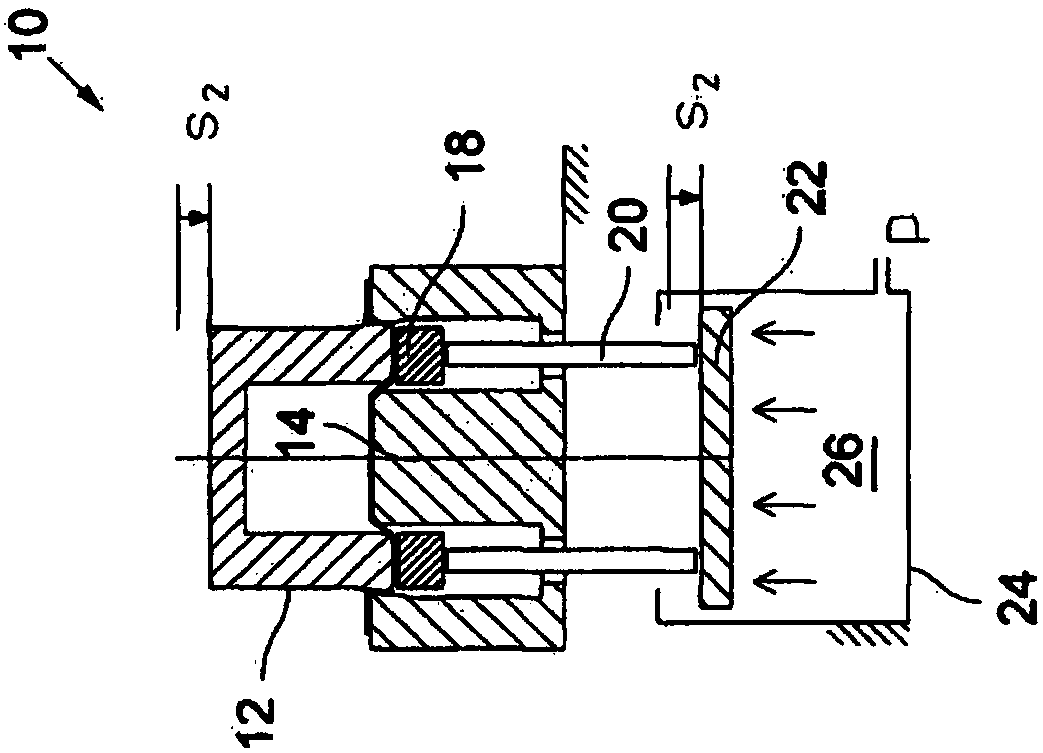

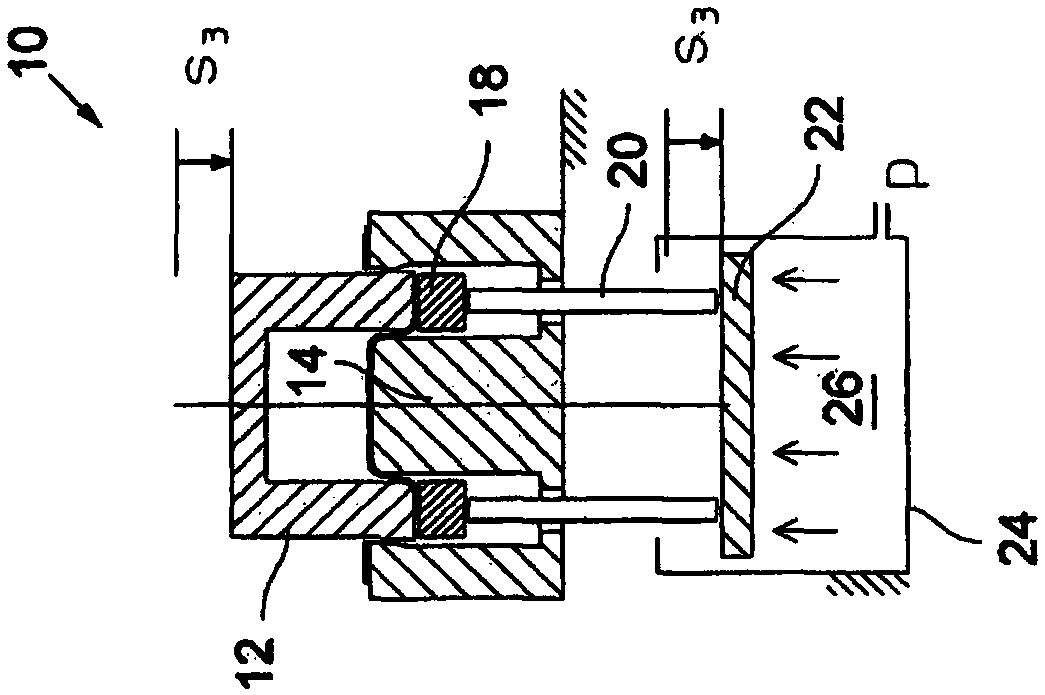

Method for operating a switch valve

ActiveCN105189988ADuty Cycle GuaranteedOvercome spring forceElectrical controlNon-fuel substance addition to fuelEngineeringPwm signals

The invention relates to a method for operating a switch valve (4) which opens and closes a fluid line (5). The switch valve (4) is actuated by means of a pulse width modulated (PWM) signal. The switch valve (4) is actuated outside of the active operating time of the switch valve using PWM signals with an increasing or decreasing duty cycle. The duty cycle in which the switch valve (4) is opened is determined, and the duty cycle corresponding to the opening time is then used to actuate the switch valve (4) in order to open and close the switch valve during the active operating time of same. In this manner, the switch valve (4) can be actuated in a particularly precise manner.

Owner:VTESCO TECH GMBH

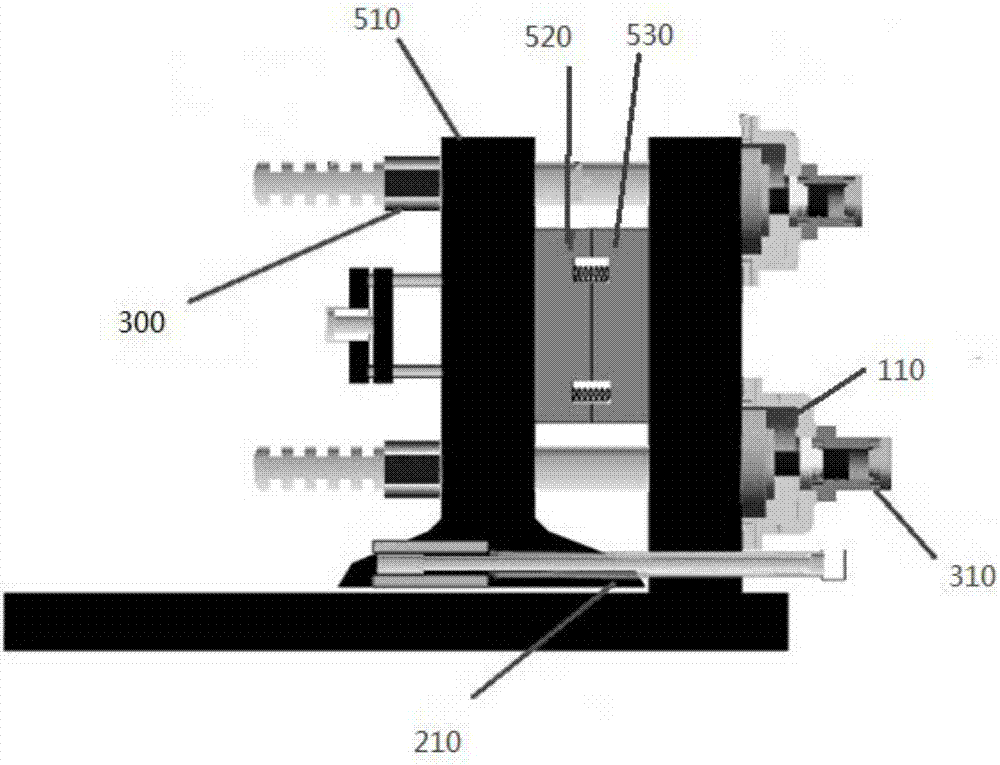

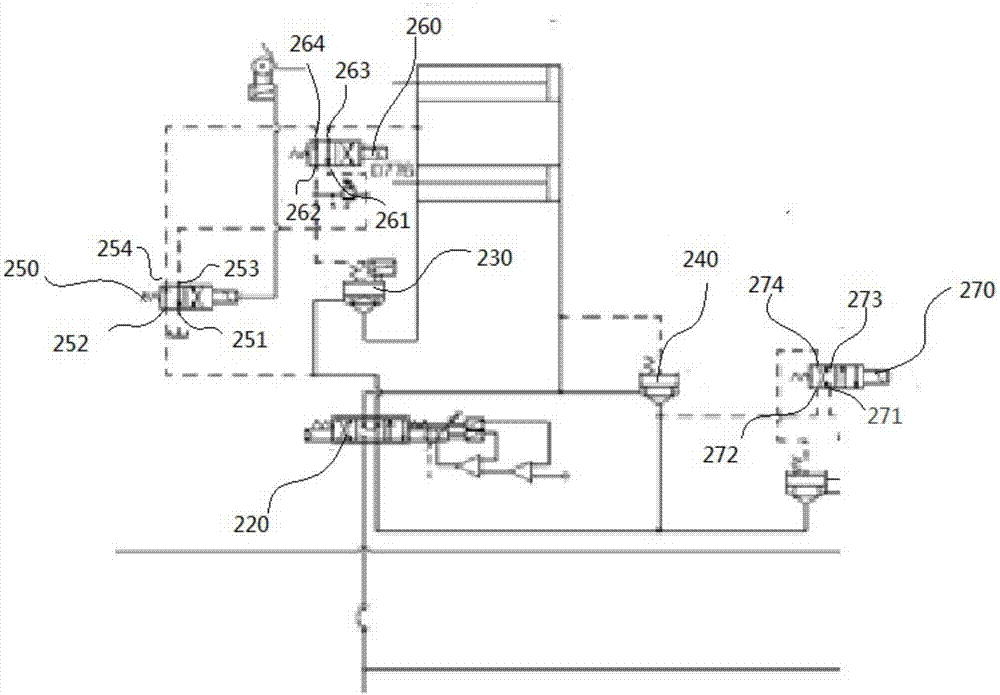

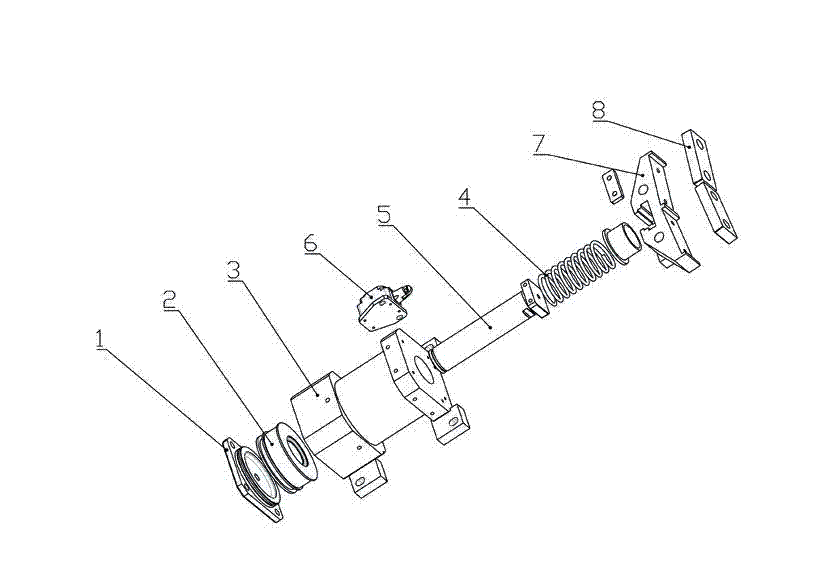

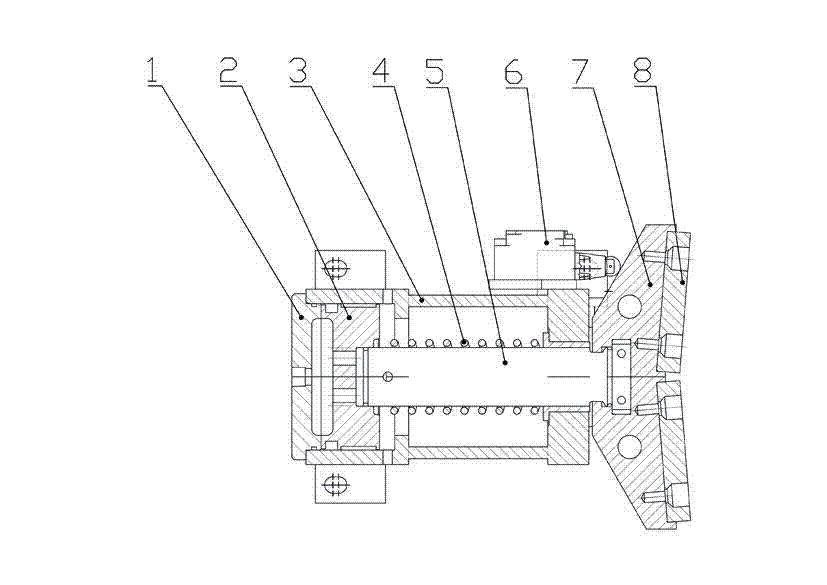

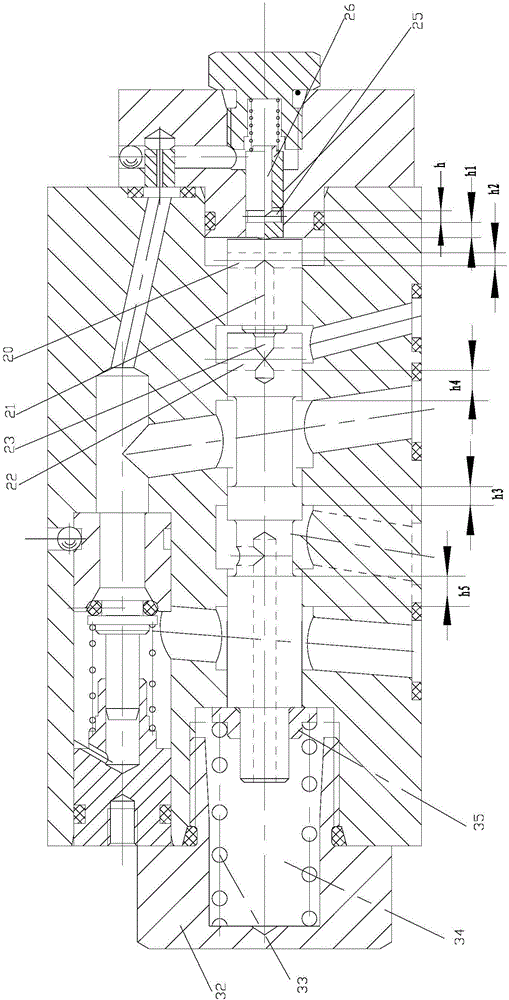

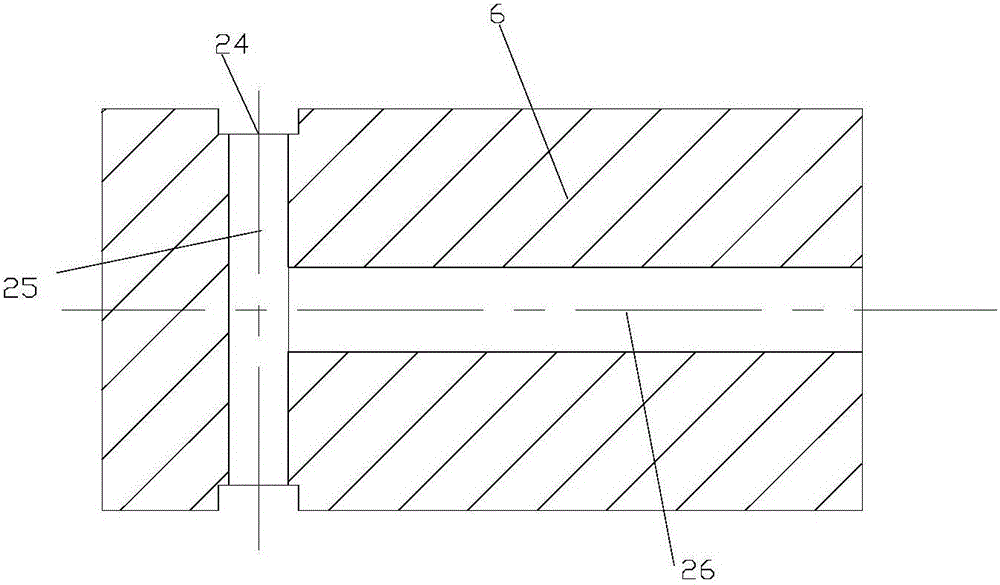

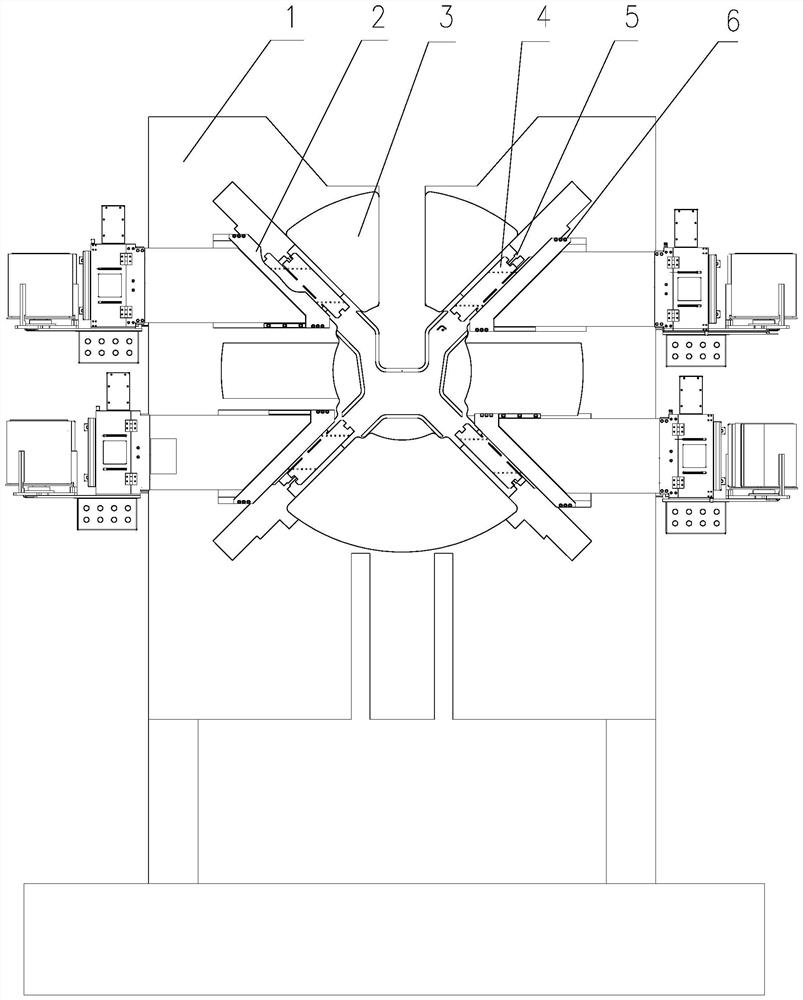

Die-opening method and driving system for spring die of two-plate injection molding machine

The invention discloses a die-opening method and a driving system for a spring die of a two-plate injection molding machine. The driving system is characterized in that the driving system comprises adie locking system, a die opening and closing system and a braking system. The die-opening method comprises the steps that 1, the die locking system relieves pressure to make die locking force of a male die and a female die be reduced to zero; 2, the die opening and closing system drives the spring die firstly to be broken and then outputs overcome force to overcome spring force of the spring dieto make the spring die to be assembled; 3, the braking system drives a brake machine to open a brake in place; and 4, the die opening and closing system drives the spring die to be opened. According to the die-opening method and the driving system for the spring die of the two-plate injection molding machine, die assembling motion exists in the die opening process, the spring force of the spring die is overcome by utilizing the overcome force provided by the die opening and closing system, the situation that the spring force acts on the brake machine is avoided, thus the brake machine can openthe brake smoothly, and the overcome force can be set according to the spring force.

Owner:HAITIAN PLASTICS MACHINERY GRP

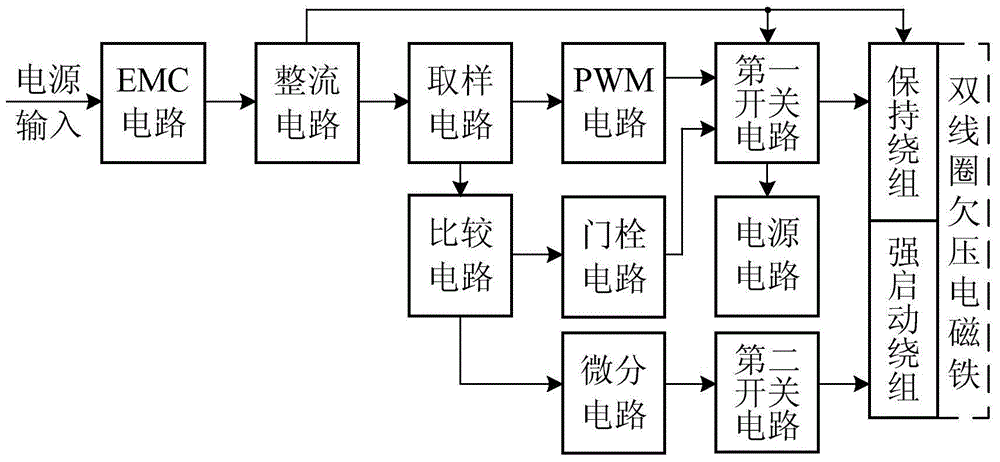

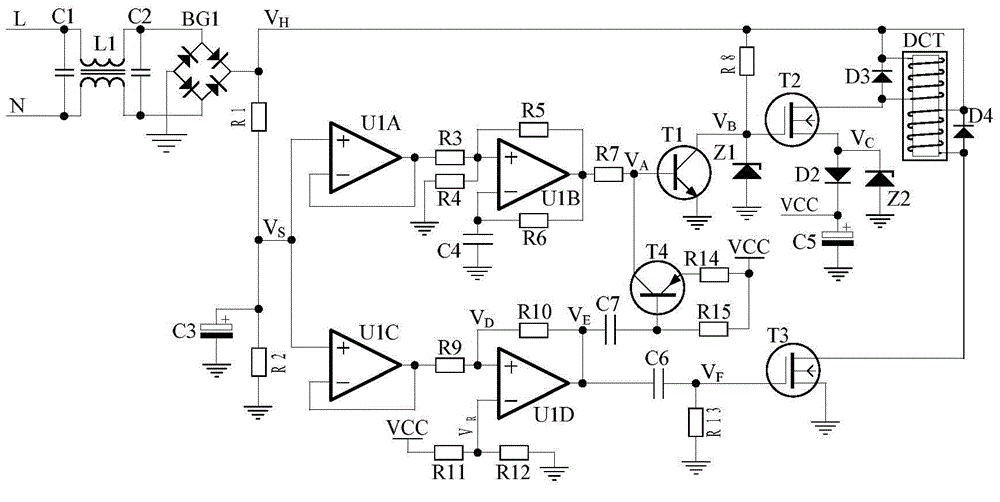

Double-coil undervoltage tripper

ActiveCN104659741AReduce the number of turnsThick wireArrangements responsive to undervoltagePower gridStartup winding

The invention discloses a double-coil undervoltage tripper. The double-coil undervoltage tripper comprises an EMC filter circuit, a rectifying circuit, a sampling circuit, a PWM circuit, a first switch circuit, a power supply circuit, a comparing circuit, a bolt circuit, a differentiating circuit, a second switch circuit and a double-coil undervoltage electromagnet, wherein the EMC filter circuit is used for bidirectionally inhibiting interference signals generated by a power grid and an internal circuit; the double-coil undervoltage electromagnet comprises a stabilizing winding, a strong starting winding and a movable iron core. According to the double-coil undervoltage tripper, the reliable pull-in when the voltage of the power grid is higher than 85% of rated voltage is guaranteed, and the reliable tripping when the voltage of the power grid is lower than 50% of the rated voltage is guaranteed; by virtue of relatively high power of the strong starting winding and relatively low power of the stabilizing winding, the high-reliability pull-in can be achieved, and the low-power operation is simultaneously considered, so that the heating of the electromagnet is avoided. Besides, after a power supply circuit of the double-coil undervoltage tripper is connected to the second switch circuit in series, the energy efficiency of the circuit is effectively improved when the integral circuit is adequately simplified.

Owner:美玛特电子科技(常州)有限公司

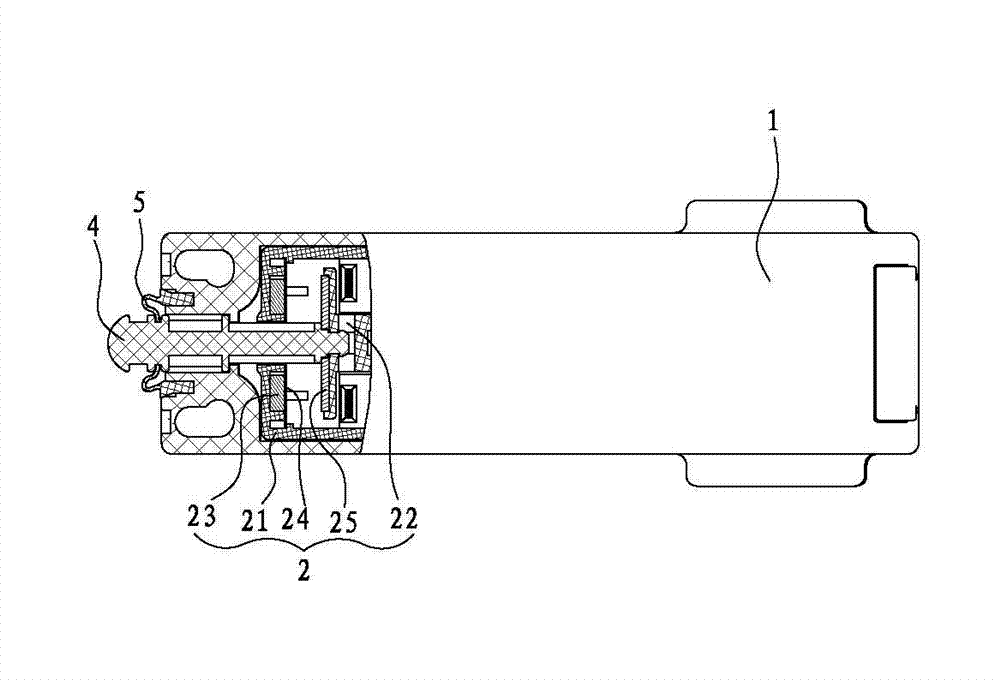

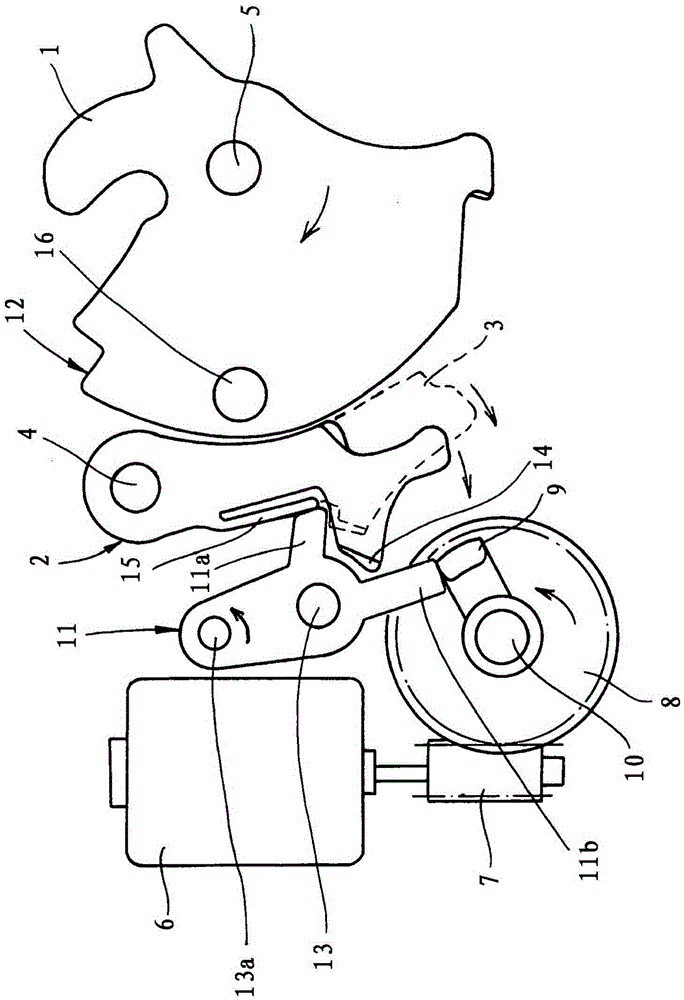

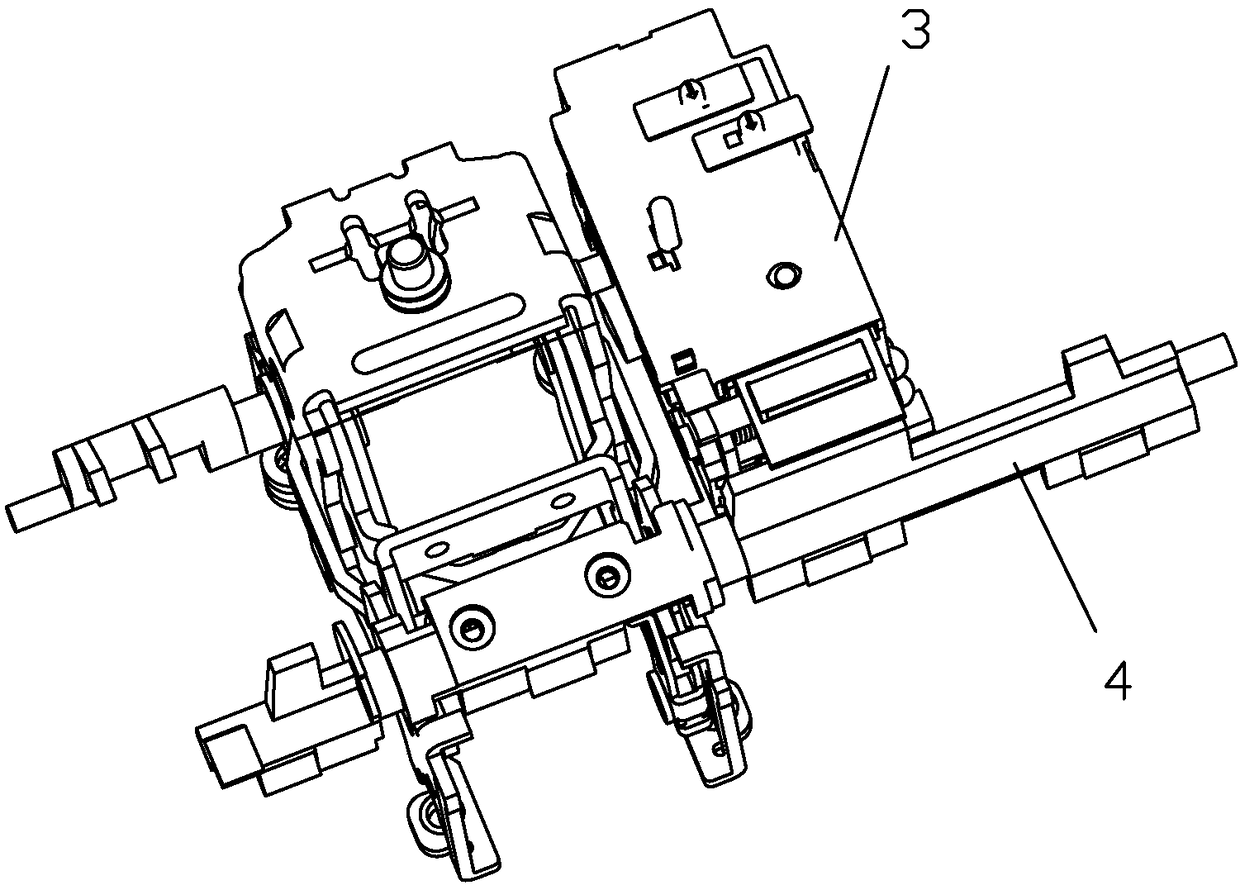

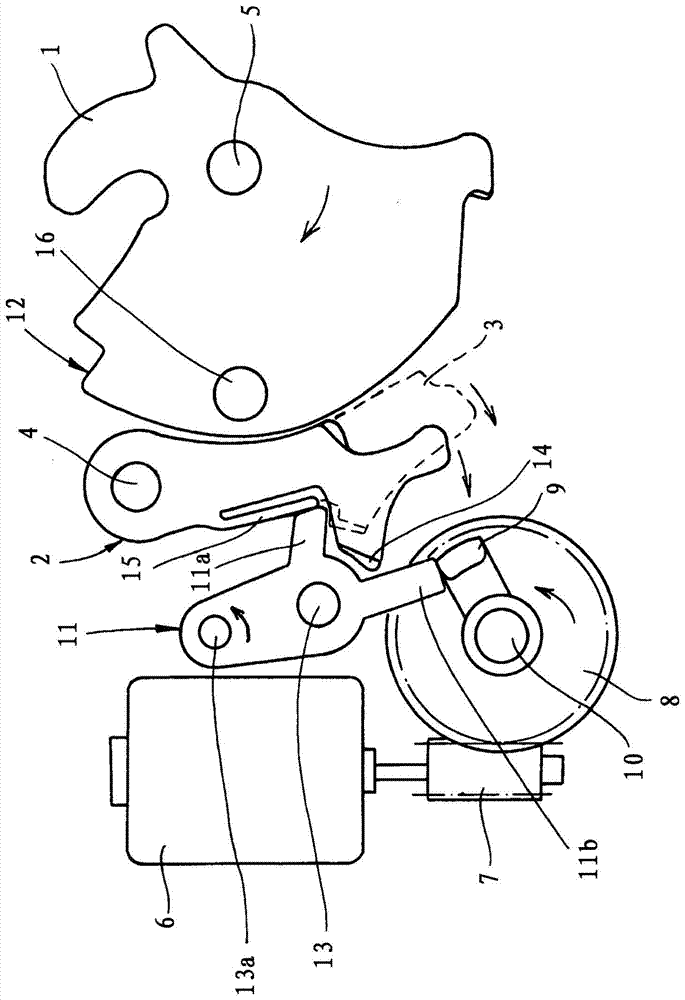

Motor vehicle door lock

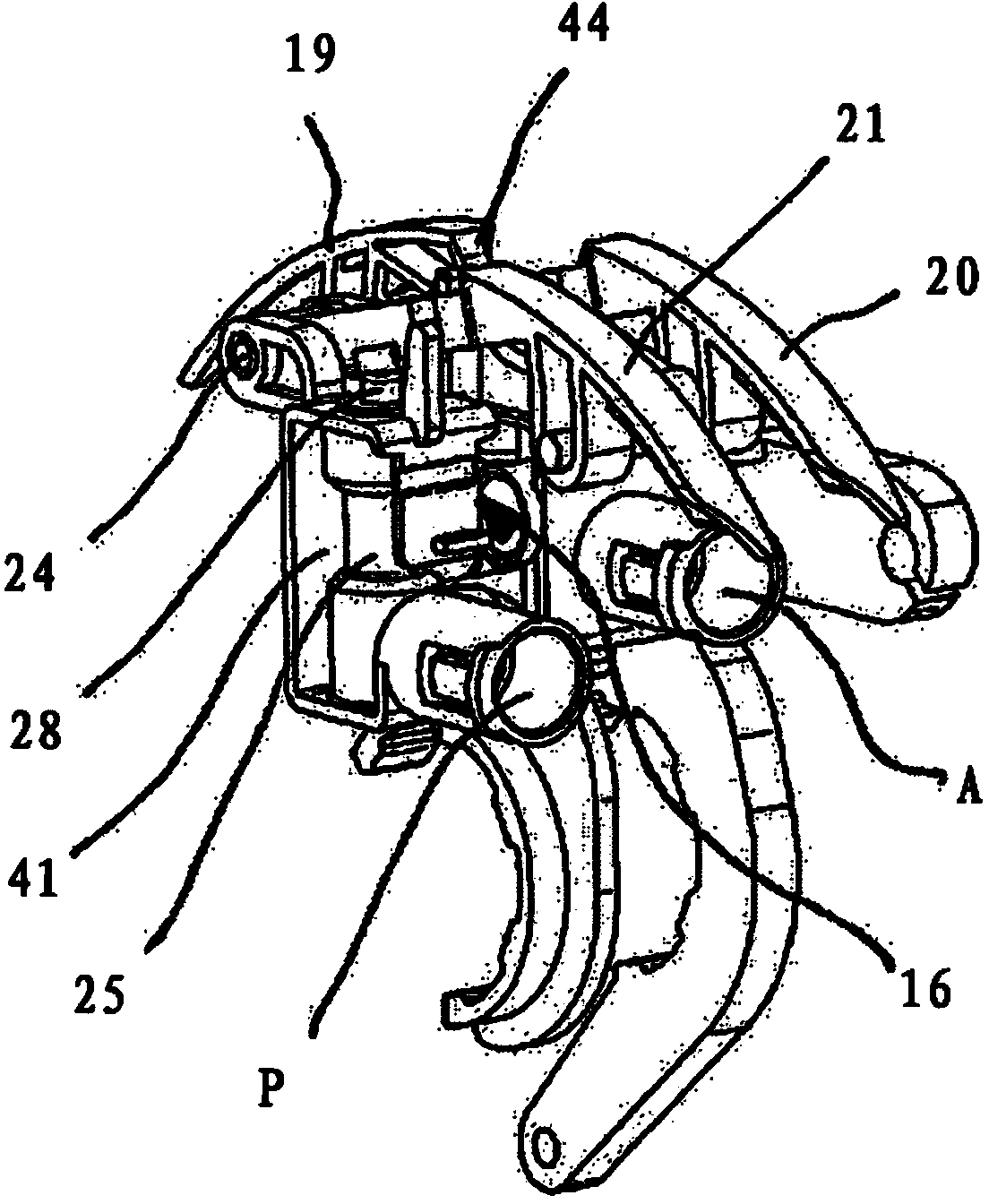

ActiveCN105264156ACompact costLow costNoise-prevention/anti-rattling lockingPower-actuated vehicle locksCar doorLocking mechanism

The invention relates to a motor vehicle door lock, having a locking mechanism (1, 2, 3) comprising substantially a rotary latch (1) and at least one pawl (2, 3). A drive (6 to 9) for acting on the locking mechanism (1, 2, 3) is also provided. A blocking element (11) which interacts with the pawl (2, 3) has at least one pawl arm (11a) which holds the pawl (2, 3) in a latching position. Finally, a stop arm (11b) is realized on the blocking element (11) and / or on the pawl (2, 3) and / or on a release element, said stop arm acting as a stop for the drive (6 to 9). According to the invention, the blocking element (11) is arranged on an edge which is averted from the rotary latch and also so as to laterally overlap the pawl (2, 3).

Owner:KIEKERT & KOMMANDITGES

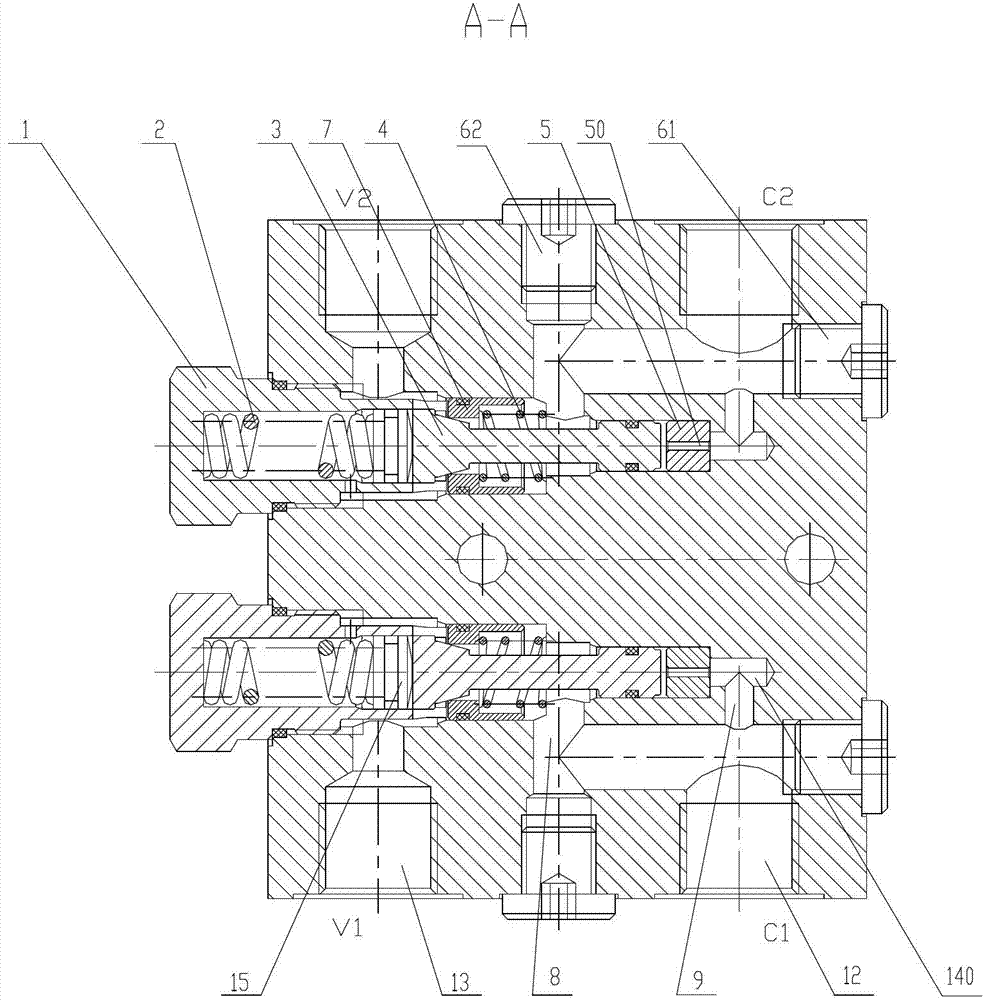

Energy-saving rotary two-way balancing valve

InactiveCN103291976AIncrease the amount of openingStable jobMultiple way valvesNegative feedbackEngineering

The invention provides an energy-saving rotary two-way balancing valve which is compact in structure and steady to operate and realizes energy conservation and consumption reduction. The energy-saving rotary two-way balancing valve comprises a valve body and a pair of valve spool components, a pair of symmetrical stepped valve cavities are formed in the valve body, a first oil port and a second oil port communicated with the valve cavities are respectively arranged on the end surface of the valve body, each valve cavity comprises a horizontal main hole, a main flow channel and a control flow channel, the first oil port is respectively communicated with the main flow channels and the control flow channels, the control flow channels, the main flow channels and the second oil ports are sequentially communicated with the main holes, the valve spool components are arranged in the main holes, and each valve spool component sequentially comprises an orifice plug, a valve rod, a spring, a valve seat, a spring seat, a pressure adjusting spring and a valve sleeve. By the aid of the hydraulic negative feedback principle, two sets of sequence valves and one-way valves with negative feedback are arranged in the valve body, so that a main engine can steadily work, and the balancing valve can function in saving energy and reducing consumption.

Owner:江苏鼎晟液压有限公司

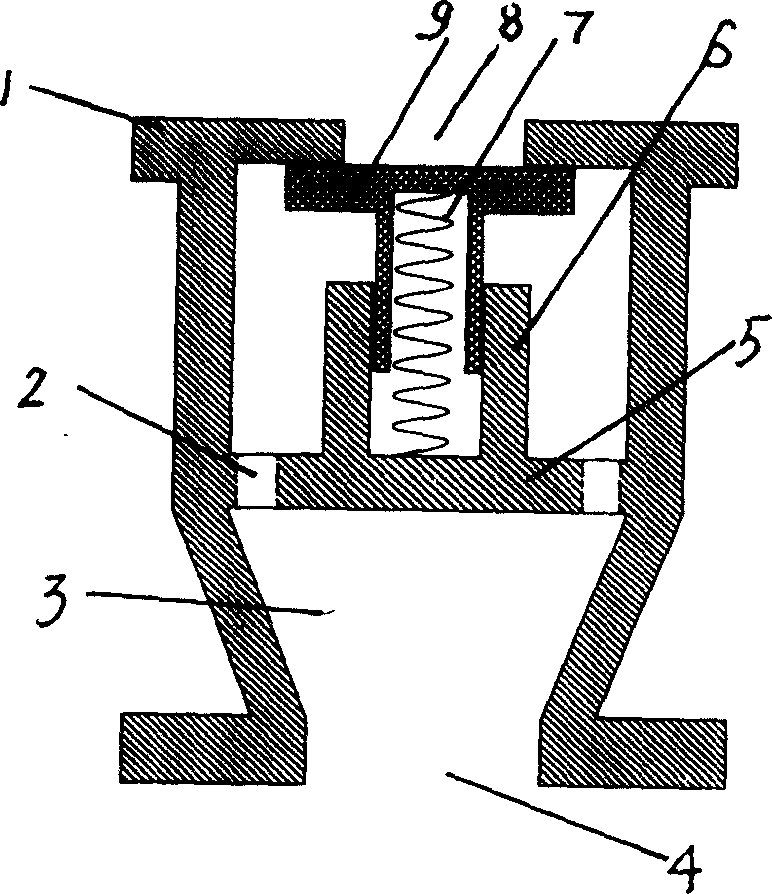

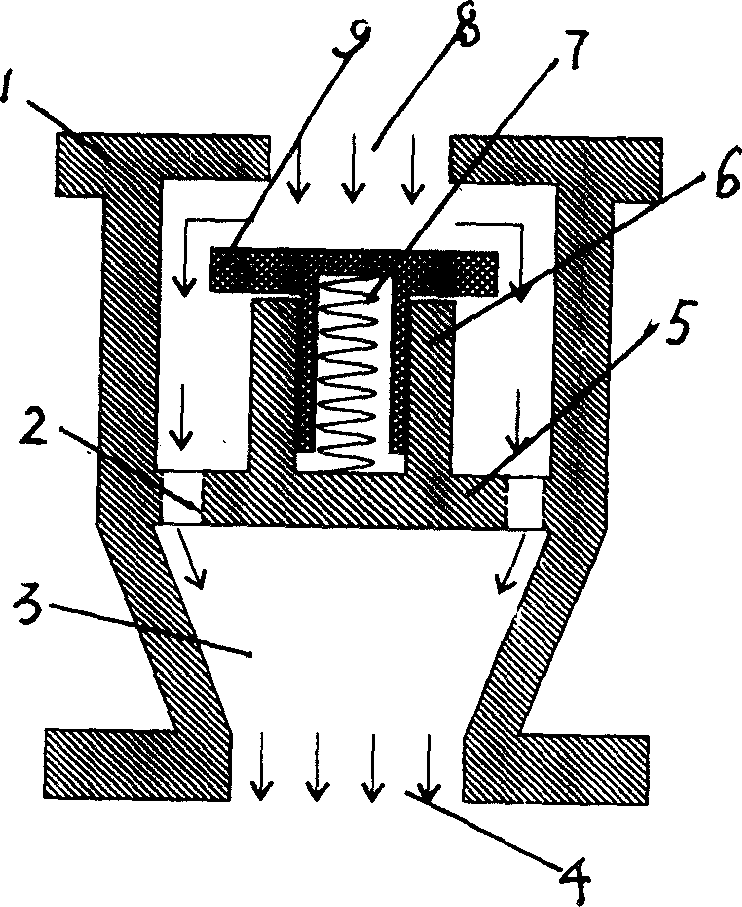

Air intake valve of screw air compressor

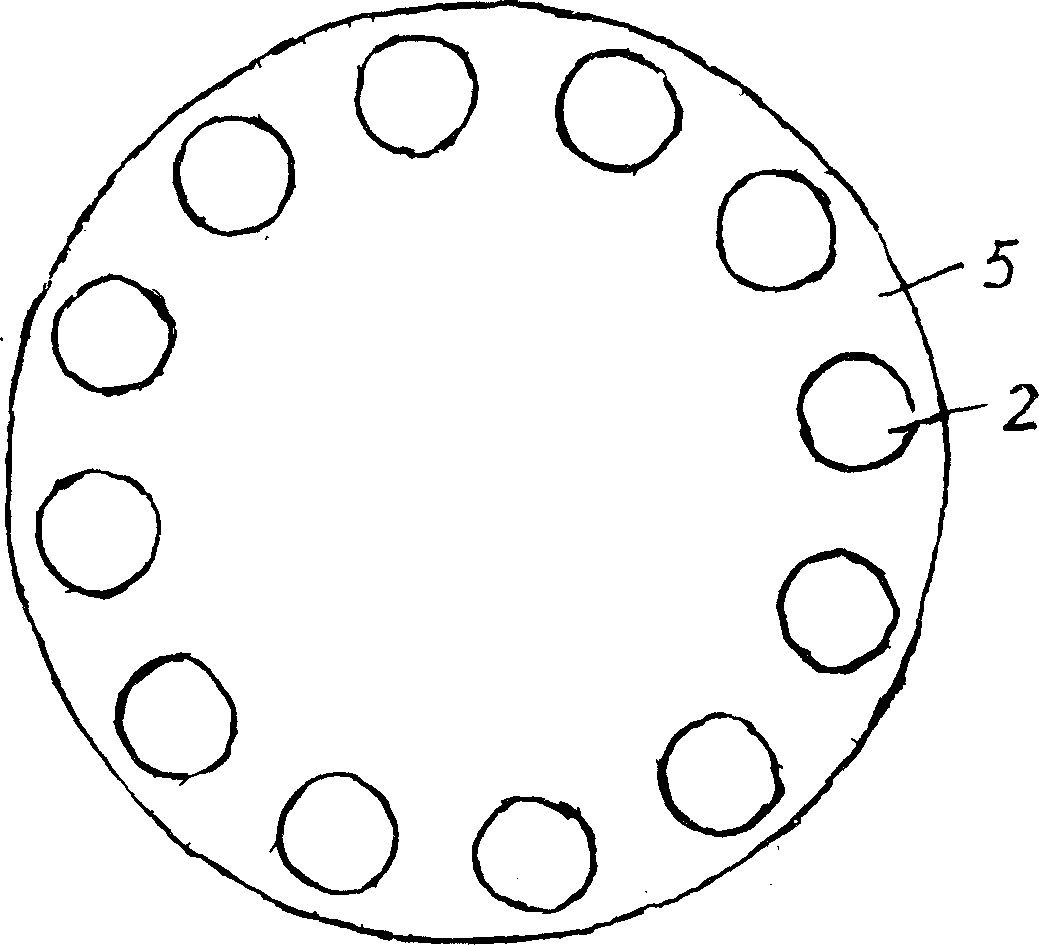

InactiveCN1877128ASimple structureLow costRotary piston pumpsRotary piston liquid enginesCircular discFailure rate

The invention relates to an air inlet valve of screw air compressor, which comprises an inlet, a chamber and an outlet mounted on the frame. Wherein, the chamber contains one round disc whose circumference is uniformly distributed with several vent holes; the center of disc has a cylinder; the upright part of T-shaped movable door cover is hollow that contains spring; the upright part is inserted into the cylinder; the area of door cover is larger than the inlet; the frame, round disc and cylinder are integrated to form a valve. The invention is simple with low cost and low failure rate.

Owner:朱祚睿

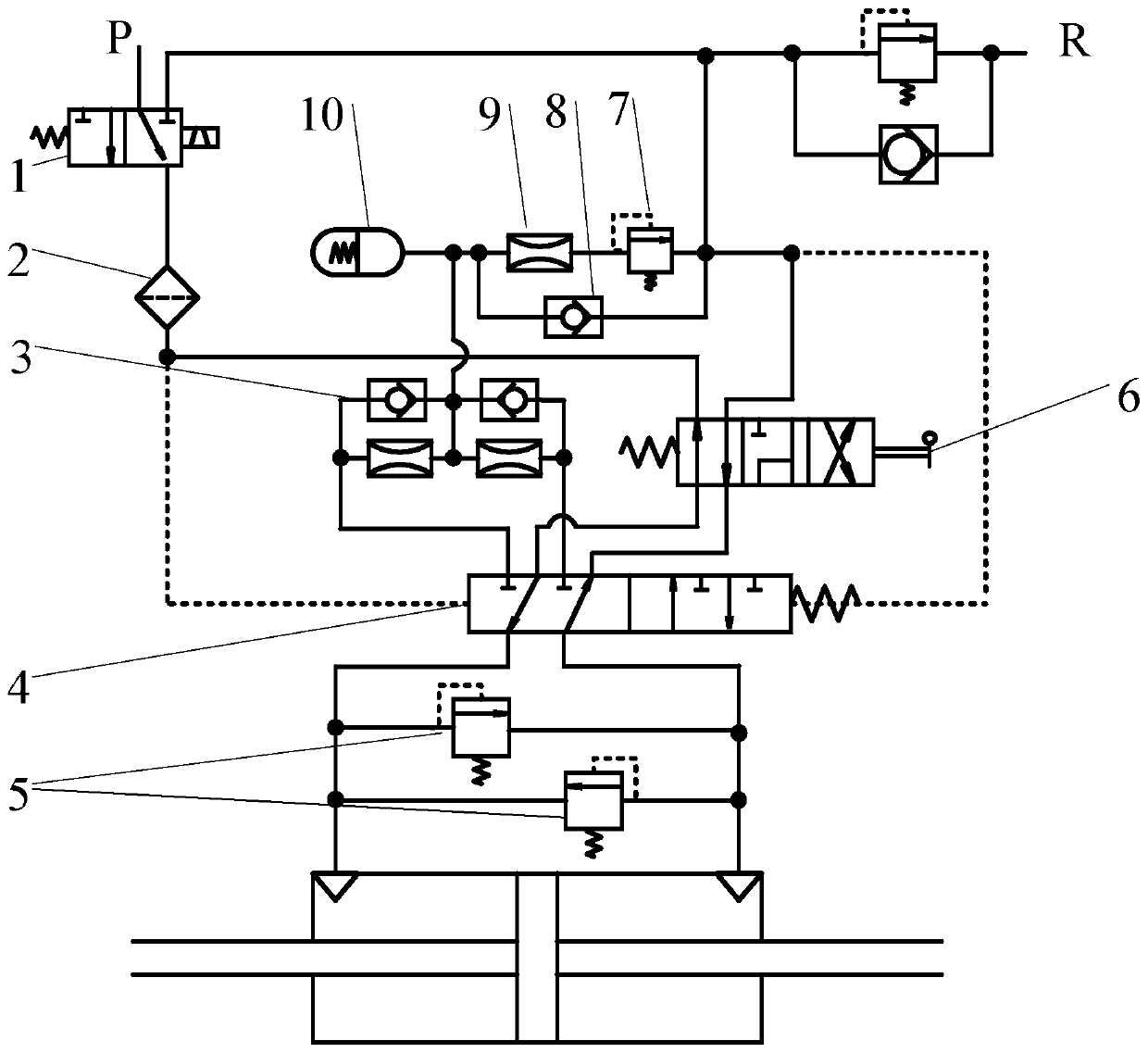

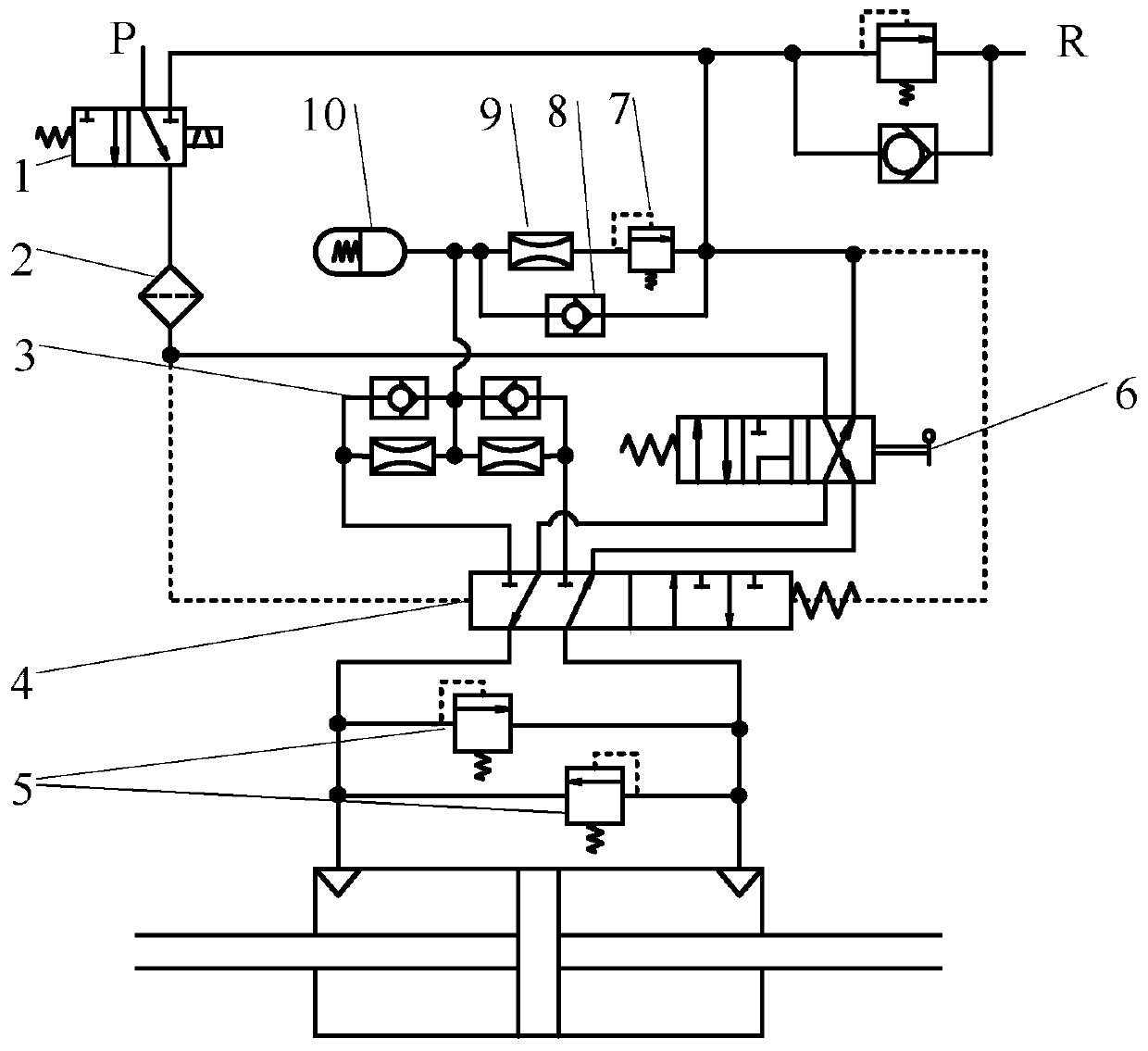

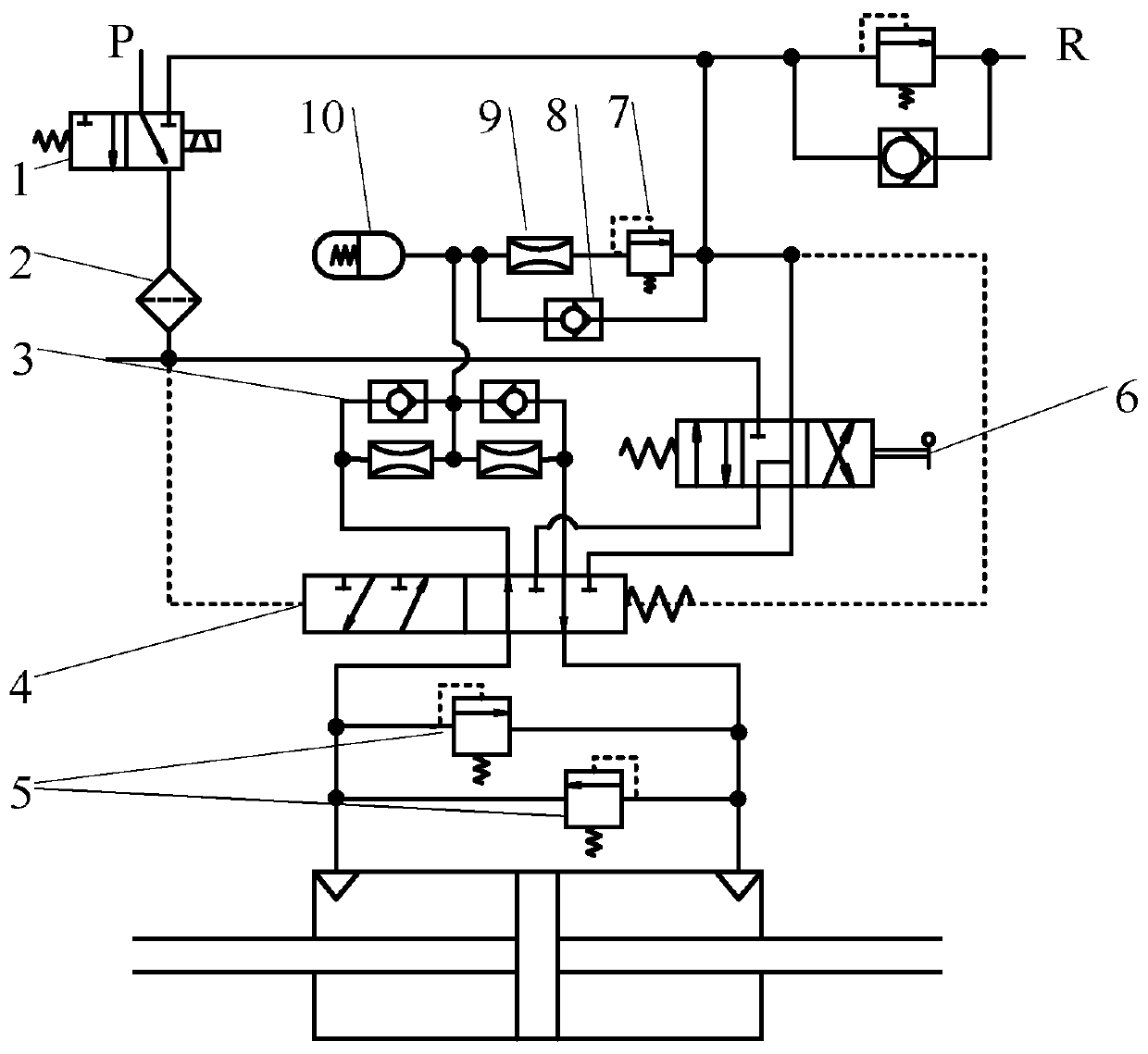

Mechanical-hydraulic aircraft nose wheel turning anti-swing system

PendingCN111071436AAvoid mutual interferencePrevent deviationAlighting gearSolenoid valveHydraulic circuit

The invention discloses a mechanical-hydraulic aircraft nose wheel turning anti-swing system, and aims to provide a multifunctional combination valve integrating reversing, damping, compensation and state conversion. The mechanical-hydraulic aircraft nose wheel turning anti-swing system is realized through the following technical scheme: the high-pressure oil is divided into two paths by an electromagnetic valve; one path is sent to a state conversion valve through a reversing valve; enters a safety valve to control an airplane front wheel turning actuator cylinder to overcome the state change-over valve spring force to allow the stating change-over valve to be in left-position machine energy, the change-over valve communicates with two cavities of an air aircraft front wheel turning actuator cylinder, the two cavities of the turning actuator cylinder are cut off by a one-way damping valve, and the other path of the turning actuator cylinder enters a swing-reducing oil return compensator through a closed-loop swing-reducing hydraulic loop connected beside an electromagnetic valve hydraulic pipeline; when the electromagnetic valve is powered off, high-pressure oil communicates withthe reversing valve, enters the shimmy damping oil return compensator through a bypass pipeline and communicates with the state change-over valve, the reversing valve and two cavities of the front wheel turning actuator cylinder are cut off, two cavities of the turning actuator cylinder communicate with the one-way damping valve, and the airplane front wheel is controlled to be in a shimmy dampingmode through the safety valve.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

Flywheel brake device for punch press

The invention discloses a flywheel brake device for a punch press. The flywheel brake device comprises a gland, an air cylinder and a friction block, wherein the gland is arranged on the outer side of the air cylinder; an air inlet for applying pressure to a piston in an inflation mode is formed on the gland; the air cylinder comprises a piston rod, the piston and a cylinder body; a spring is arranged in the cylinder body and is sleeved on the piston rod; one end of the piston rod butts against the piston, and the other end of the piston rod butts against the inner wall of the cylinder body; a friction block is arranged on a friction block base; the friction block base is arranged on the other side of the cylinder body; the free end of the piston rod is fixedly connected with the friction block base; and a contact switch for judging the position of the friction block base is arranged on the cylinder body of the air cylinder. The flywheel brake device achieves the function of stopping a flywheel quickly by virtue of a principle of converting mechanical energy into heat energy through adding resistance to quickly consume the energy of the flywheel, so that the whole process is fast and simple in, and the flywheel brake device is good in security and suitable for industrial popularization.

Owner:ZHEJIANG JINAOLAN MASCH TOOL CO LTD

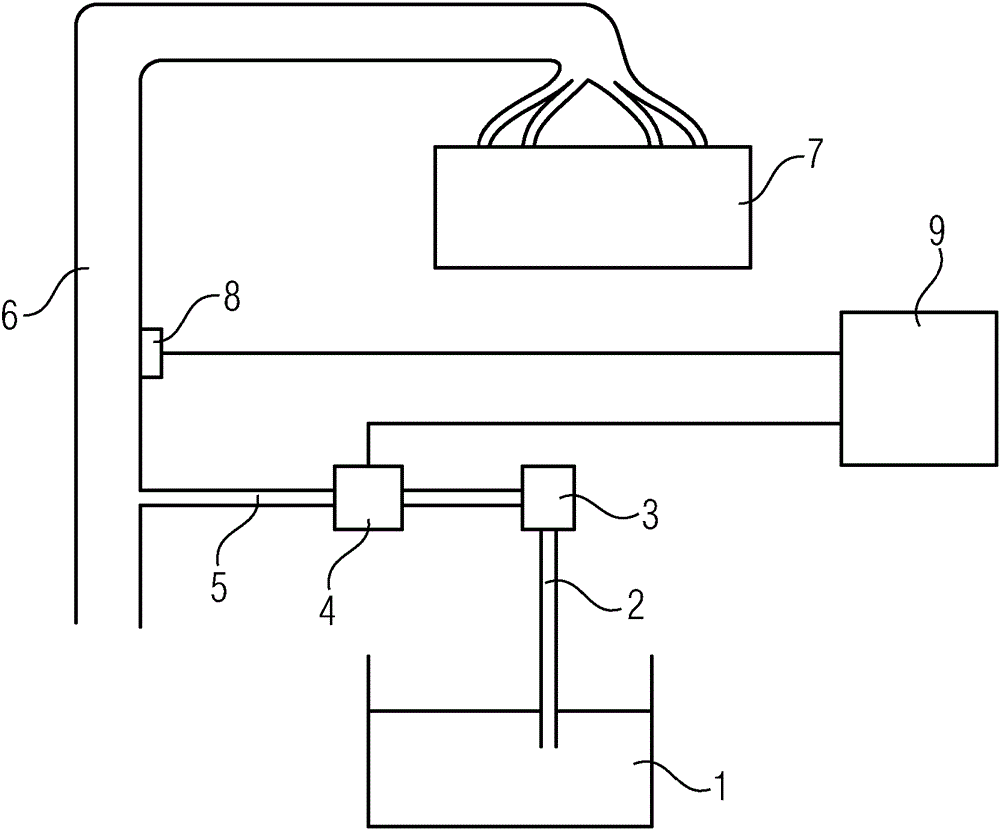

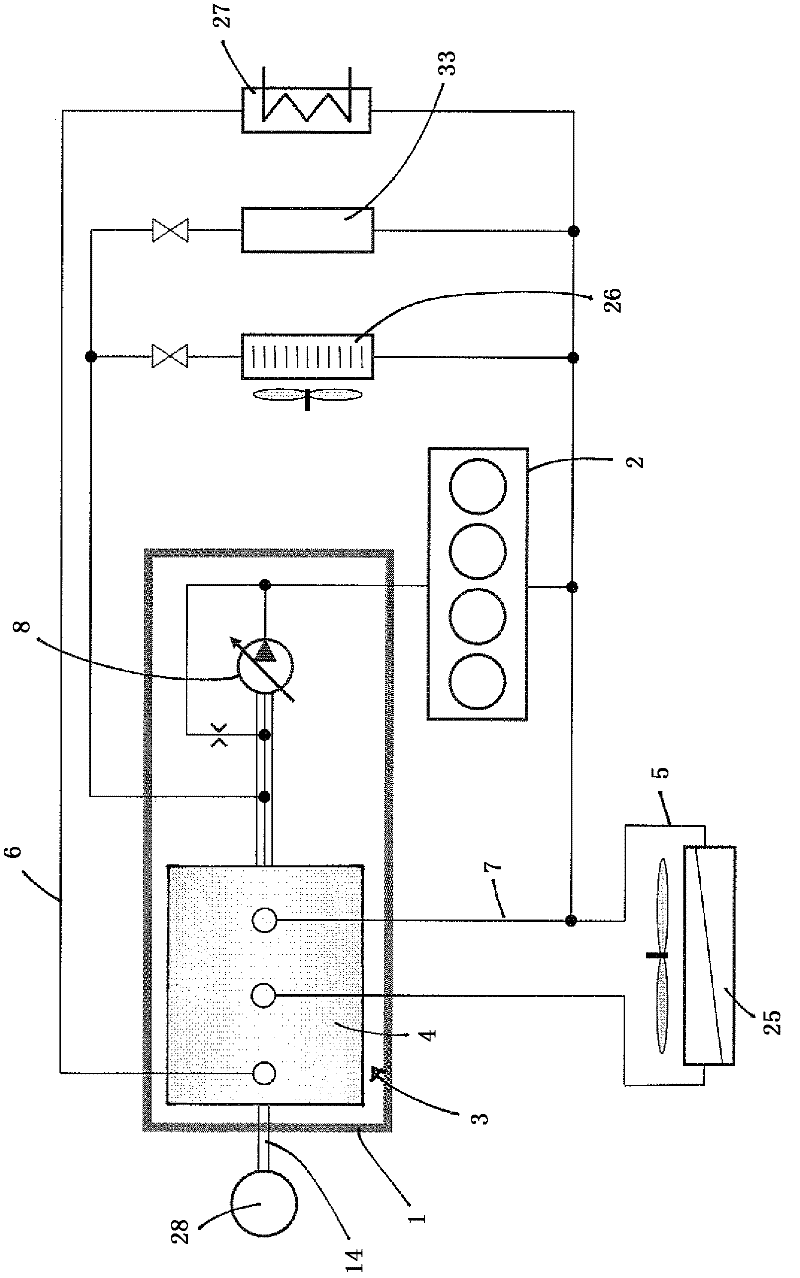

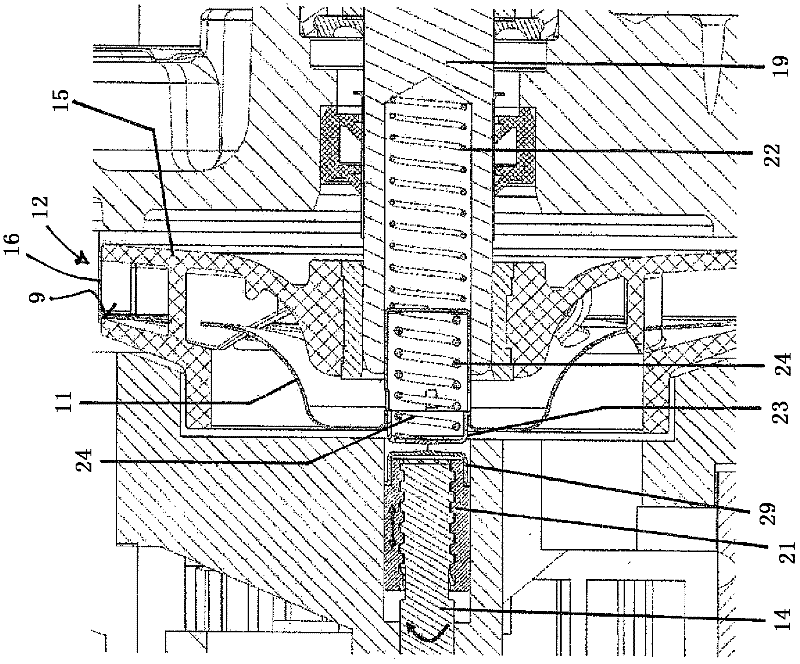

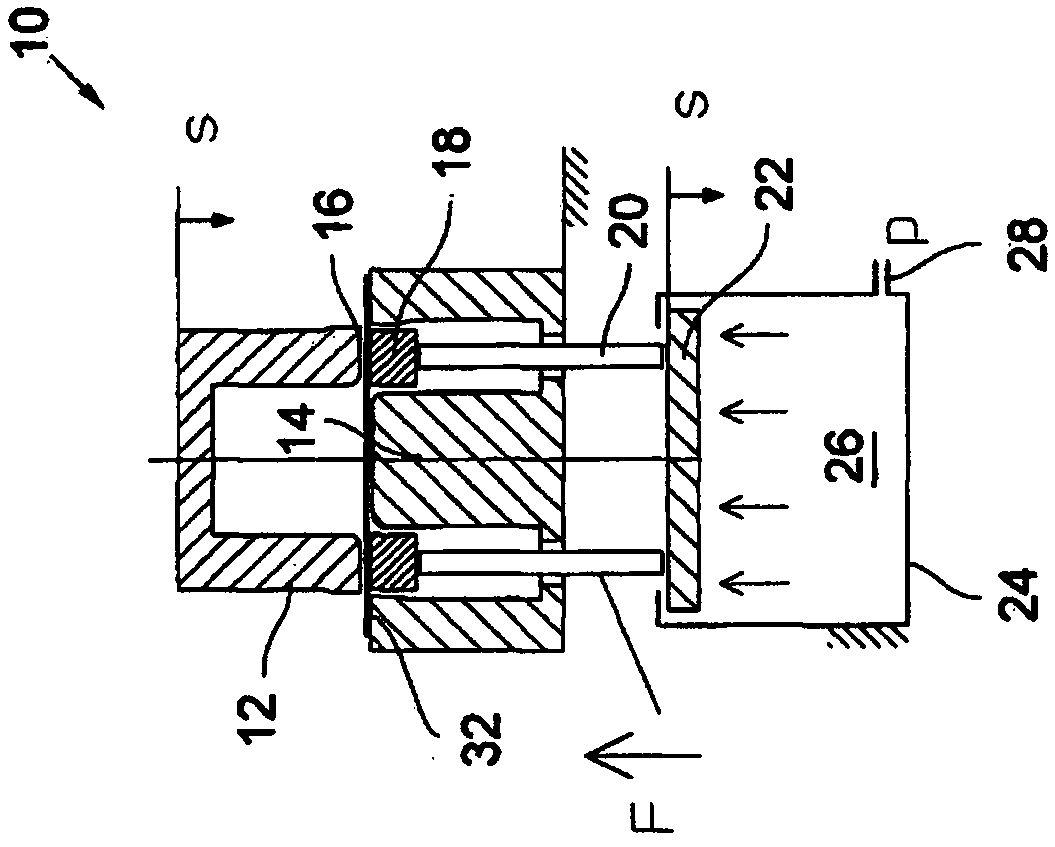

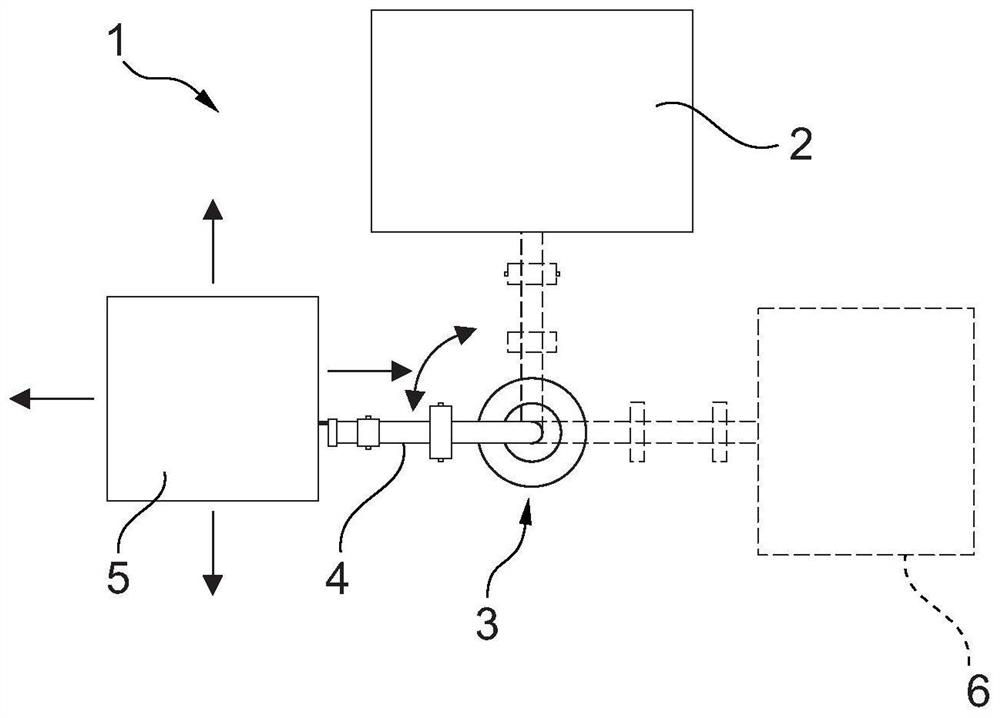

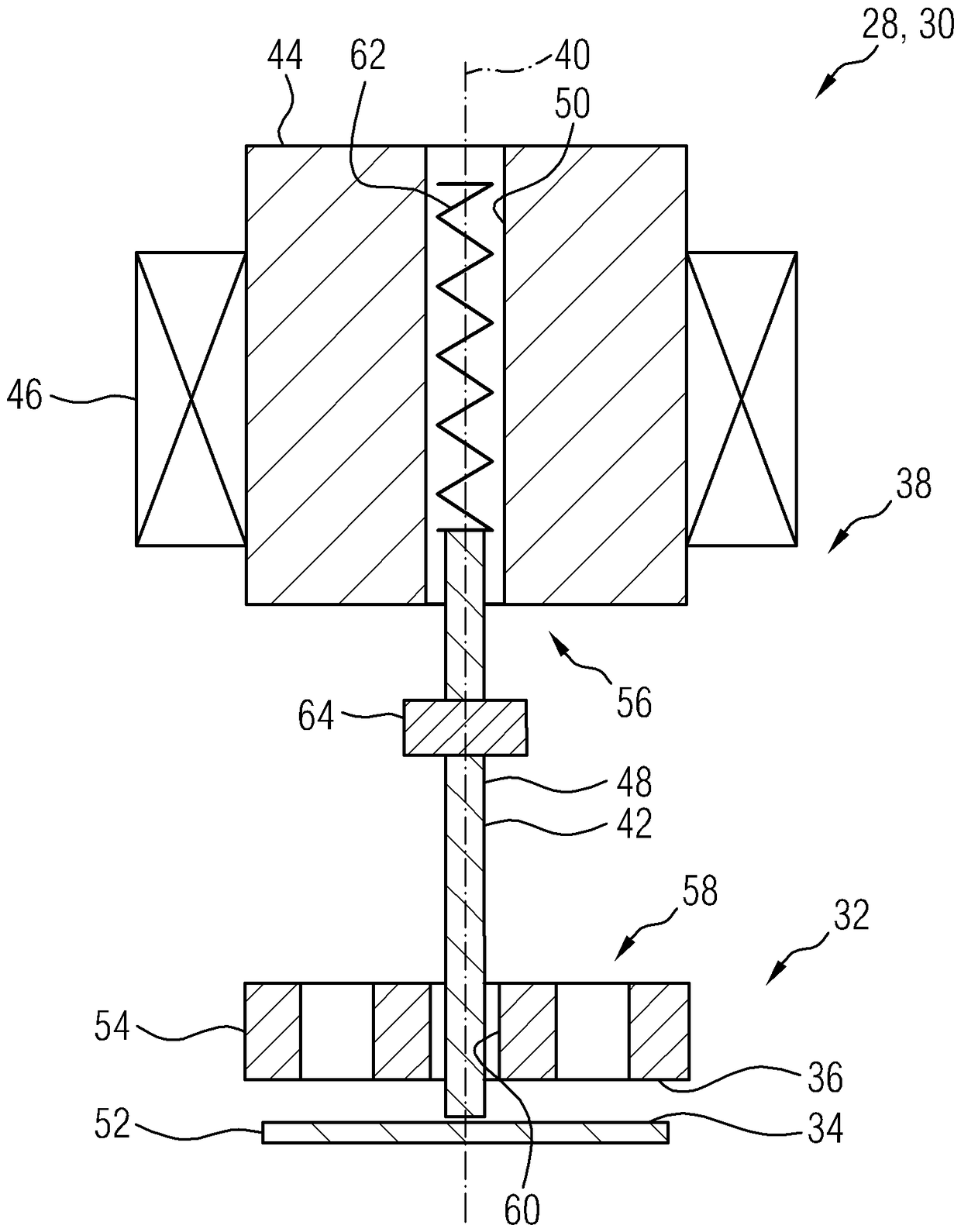

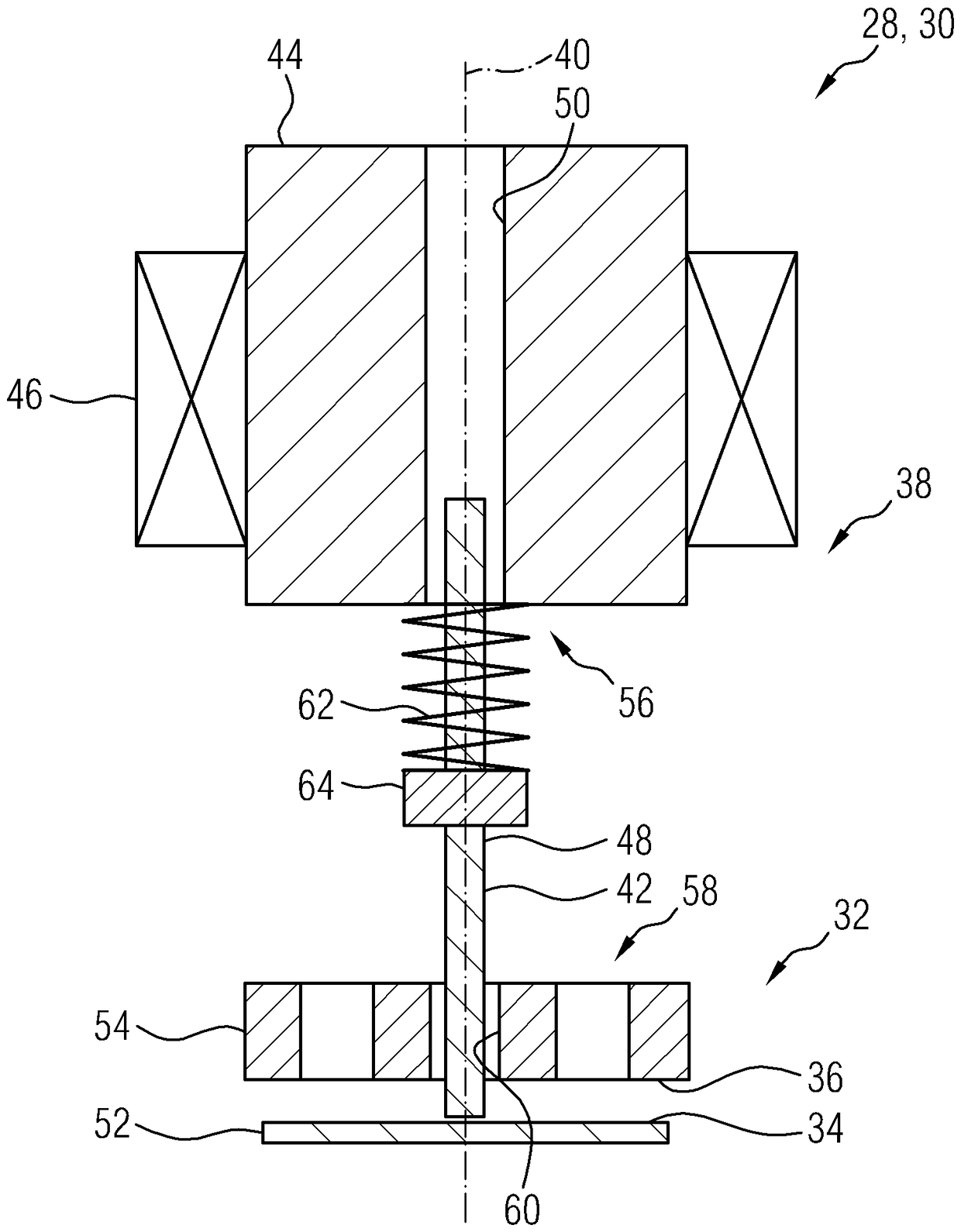

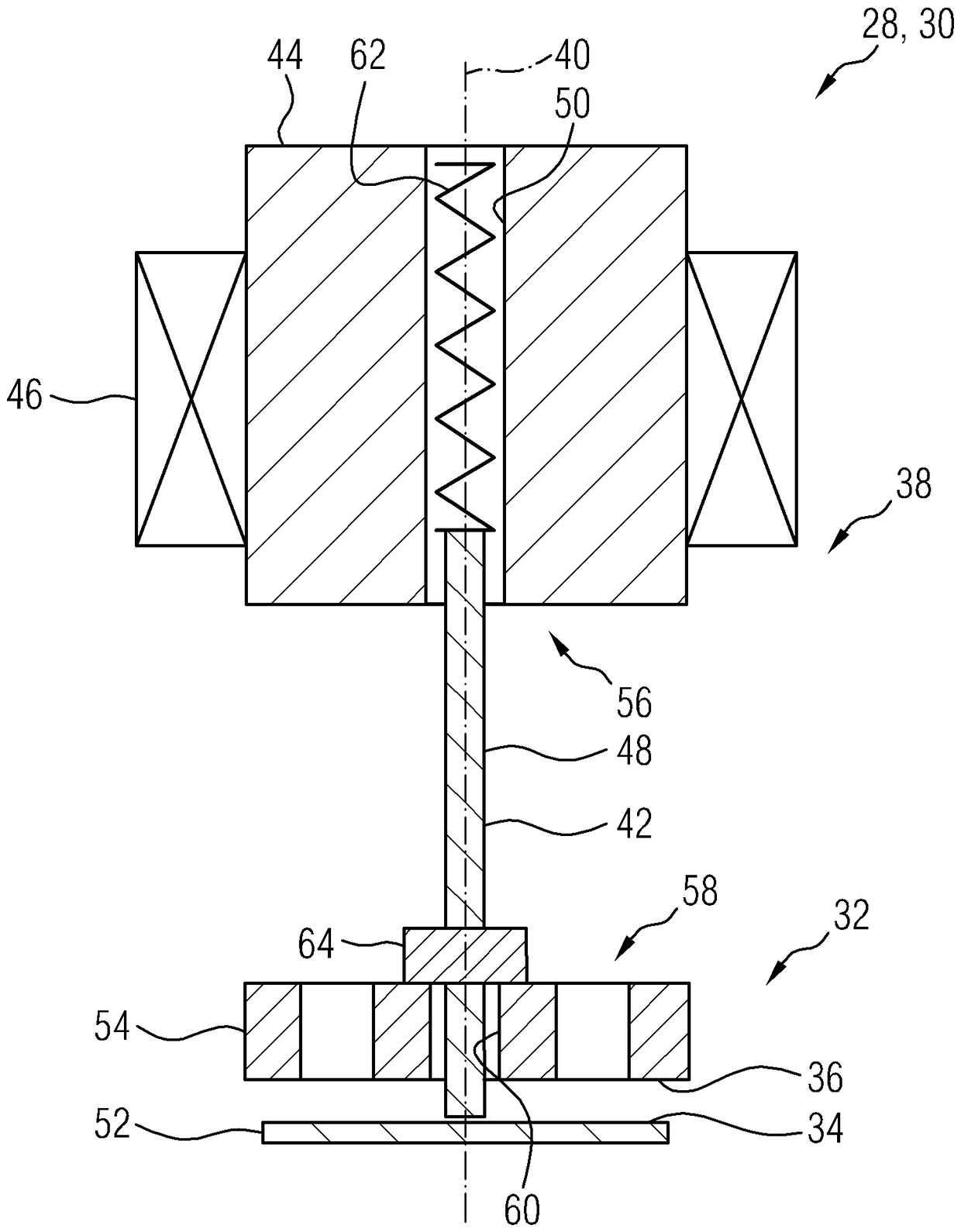

Device for regulating a coolant flow and cooling system

InactiveCN102454471AImplement fail-safe functionsOvercome spring forceCoolant flow controlPump controlImpellerEngineering

A device (1) for regulating a coolant flow in a cooling system of an internal combustion engine (2) with a valve arrangement (3) that includes a rotary disk valve (4) for switching at least one cooling circuit (5, 6) and / or a bypass circuit (7), as well as a coolant pump (8) that is constructed as an impeller pump and is connected on the suction side to the valve arrangement (3). The coolant pump (8) has an axial adjustable guide plate (11) on an inside between two end stops (9, 10) for closing and releasing a pump outlet (12). The guide plate (11) for the axial adjustment is indirectly coupleable by a lead screw thread (13) to a drive shaft (14) of the rotary disk valve (4). A cooling system for an internal combustion engine (2) with such a device (1) is also provided.

Owner:SCHAEFFLER TECH AG & CO KG

Device and method for cool drying a gas

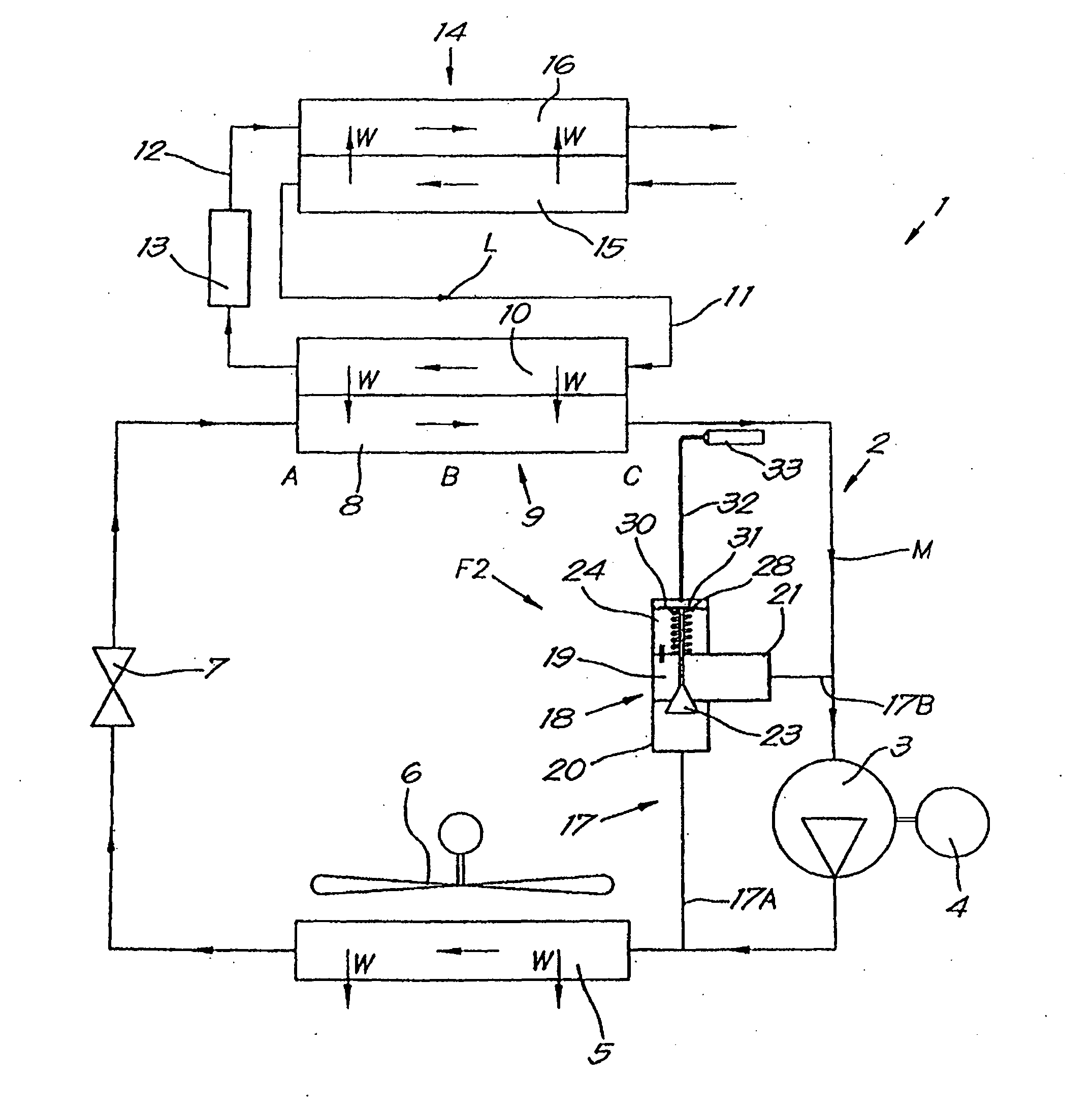

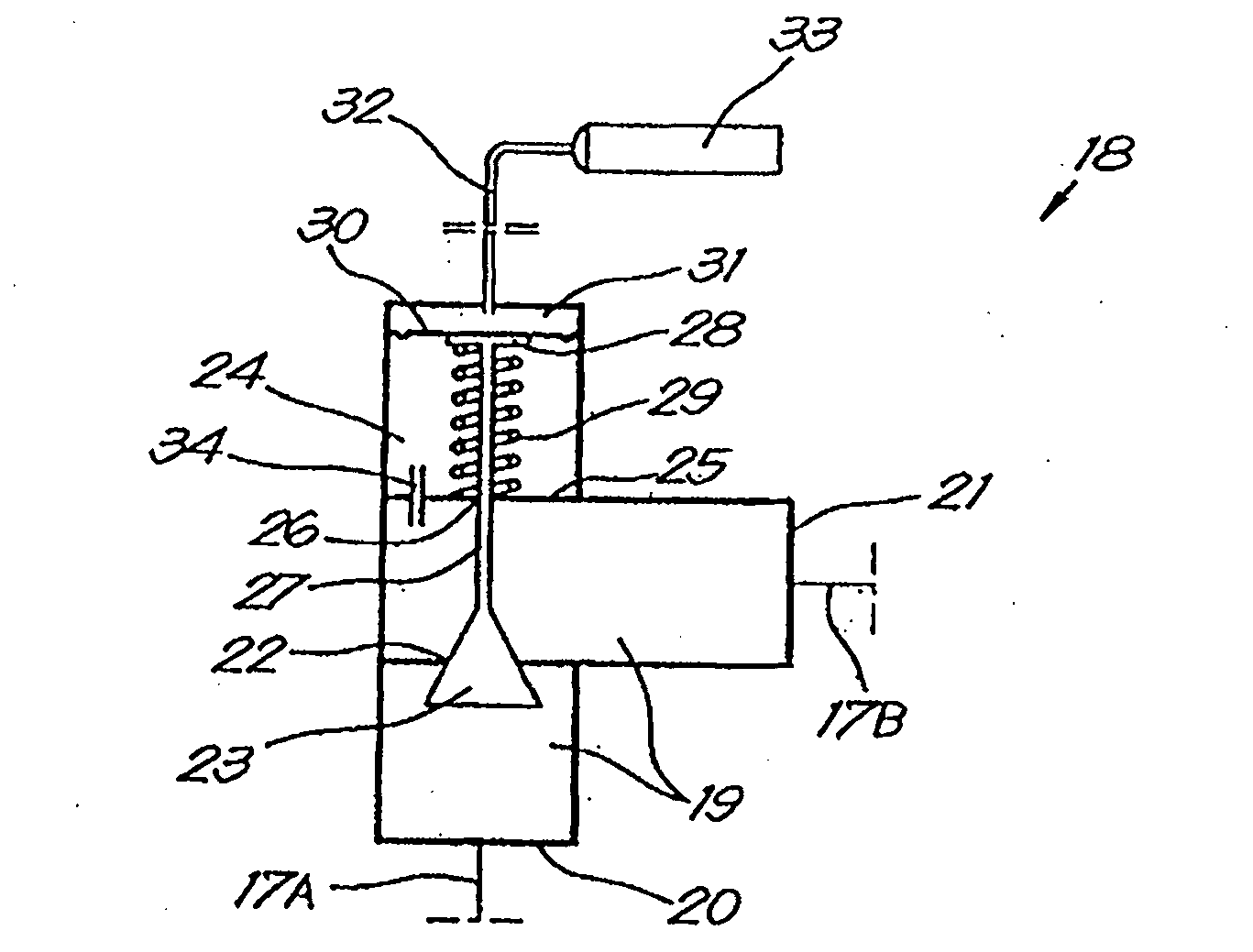

ActiveCN103209753AKeep dryLittle changeMechanical apparatusDispersed particle separationEngineeringProduct gas

Device for cool drying a gas that consists of a closed cooling circuit (2) with a compressor (3), and which further in the direction of flow (M) of the coolant successively contains a condenser (5), an expansion means (7) followed by an evaporator (8), that constitutes the primary part of a heat exchanger (9) with a secondary part (10) through which the gas to be dried is guided, and whereby there is a bypass pipe (17) in the cooling circuit (2) that can be closed by means of a bypass valve (18) with a valve element (23) and a pressure-sensitive element (30) acting on it that is exposed to a local control pressure in the cooling circuit (2), whereby the control pressure pipe (38) is connected to the closed cooling circuit (2) upstream of the outlet of the evaporator (8).

Owner:ATLAS COPCO AIRPOWER NV

Control valve for an air spring and motor vehicle seat having a control valve

ActiveCN104144821AEasy to controlSmall toleranceOperating means/releasing devices for valvesEqualizing valvesAir springEngineering

The invention relates to a control valve (16) for an air spring, comprising a housing (41), an exhaust duct that has an exhaust tappet (26) for opening of closing the exhaust duct, which exhaust tappet interacts with a first control means (19), a ventilation duct that has a ventilation tappet (27) for opening or closing the ventilation duct, which ventilation tappet interacts with a second control means (20), and a supplemental duct having a supplemental tappet (28) for opening or closing the supplemental duct, which supplemental tappet interacts with a third control means (21), wherein a first air connection A connects to the exhaust duct and a second air connection P connects to the exhaust duct together with the supplemental duct, wherein a first control means (19) and a second control means (20) are arranged to one another in such a manner that said control means cannot be actuated at the same time by an control element (18), and wherein the second control means (20) and the third control means (21) are arranged to one another in such a manner that the supplemental duct can only be opened when the ventilation duct is opened. The invention further relates to a motor vehicle seat comprising a mechanical swing system and an air spring, which motor vehicle seat has such a control valve.

Owner:GEBR ISRINGHAUSEN GMBH & CO KG

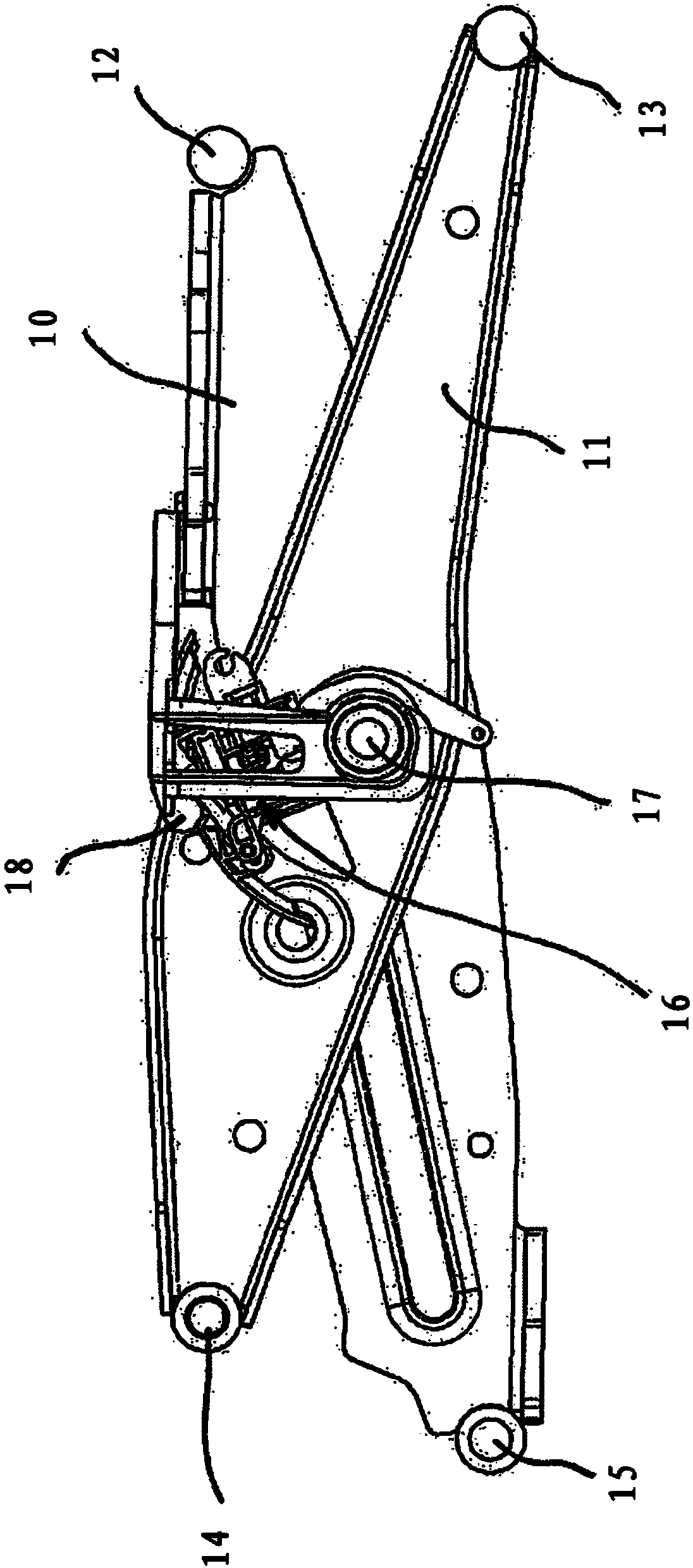

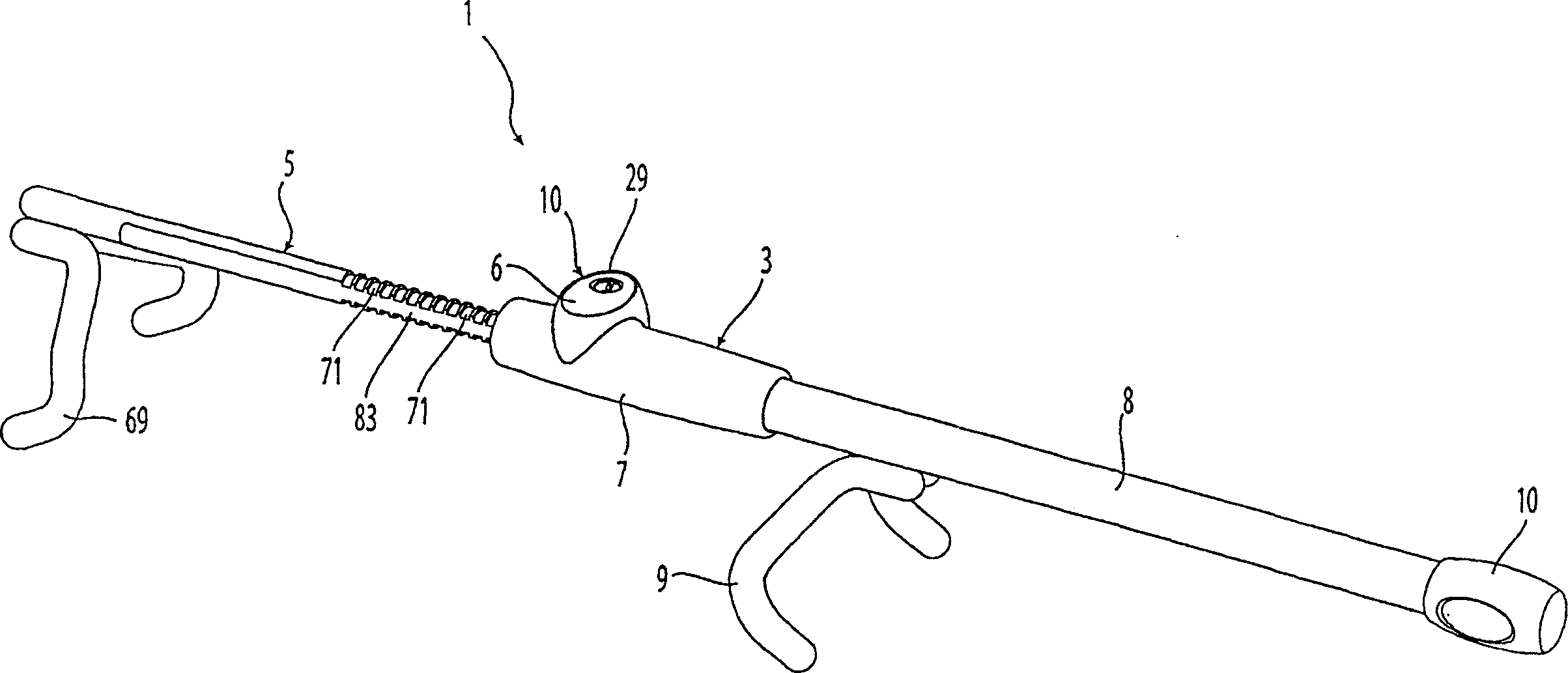

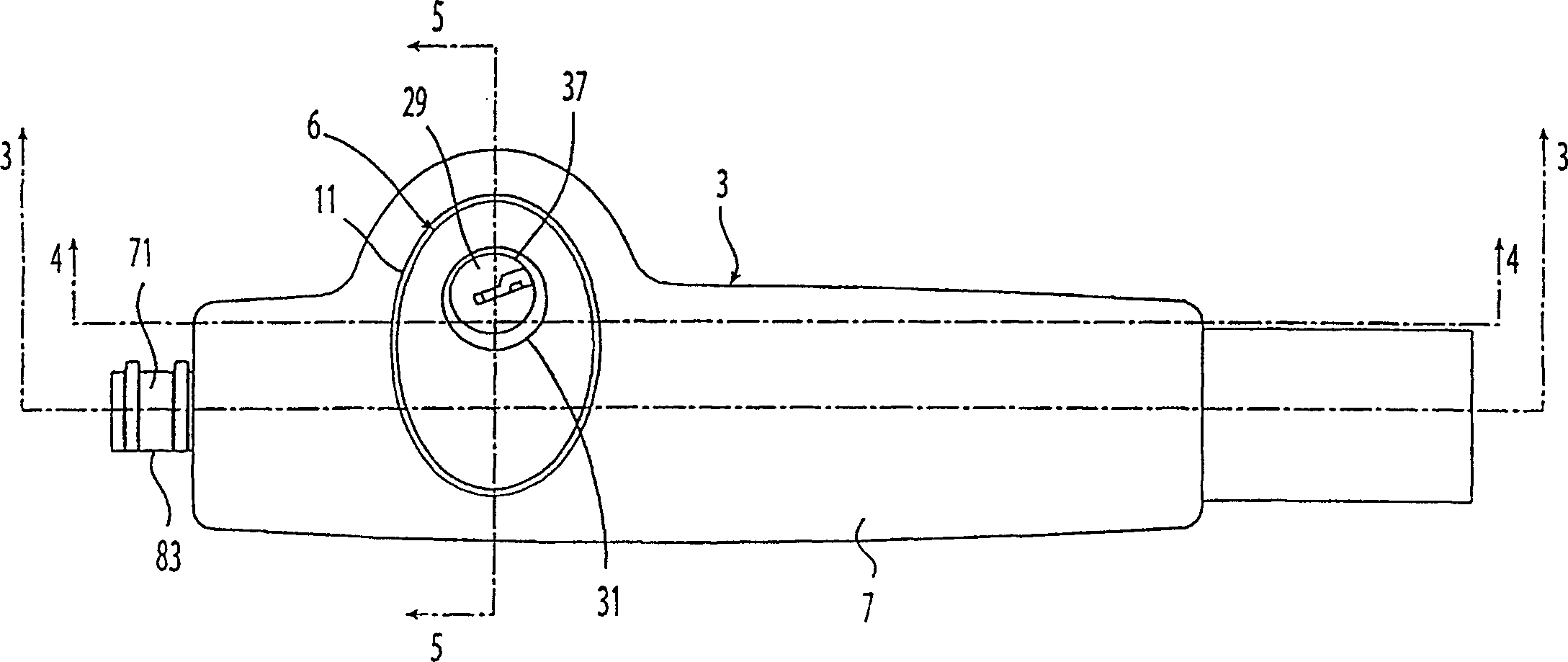

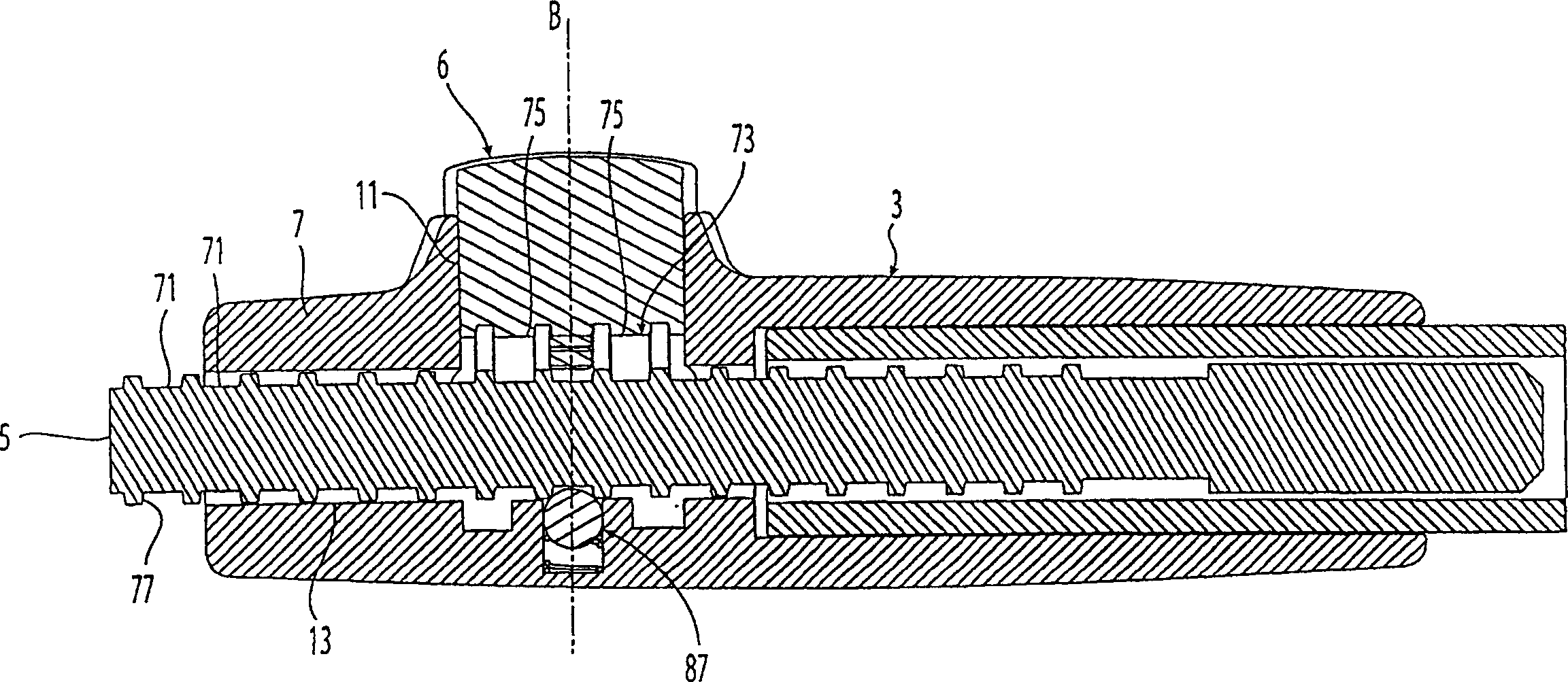

Castor type roller controlled by motor

InactiveCN1265980CEasy to operateSimple structureBraking element arrangementsCastorsGear wheelElectric machine

The invention relates to a roller (1),in particular, a castor. The rotation of the running wheel of said castor and optionally the pivoting motion of the running wheel (12) may be fixed, by means of an operating shaft (20), which moves a control cam (19) through the roller (1), with an electric motor (37) acting thereupon for operation thereof. According to the invention, the functional roller operation can be embodied with a more advantage operation, a simpler construction, yet of secure operation, whereby the electric motor (37) acts on the operating shaft (20) by means of an electric motor shaft (39) using a toothed gear (38).

Owner:TENTE

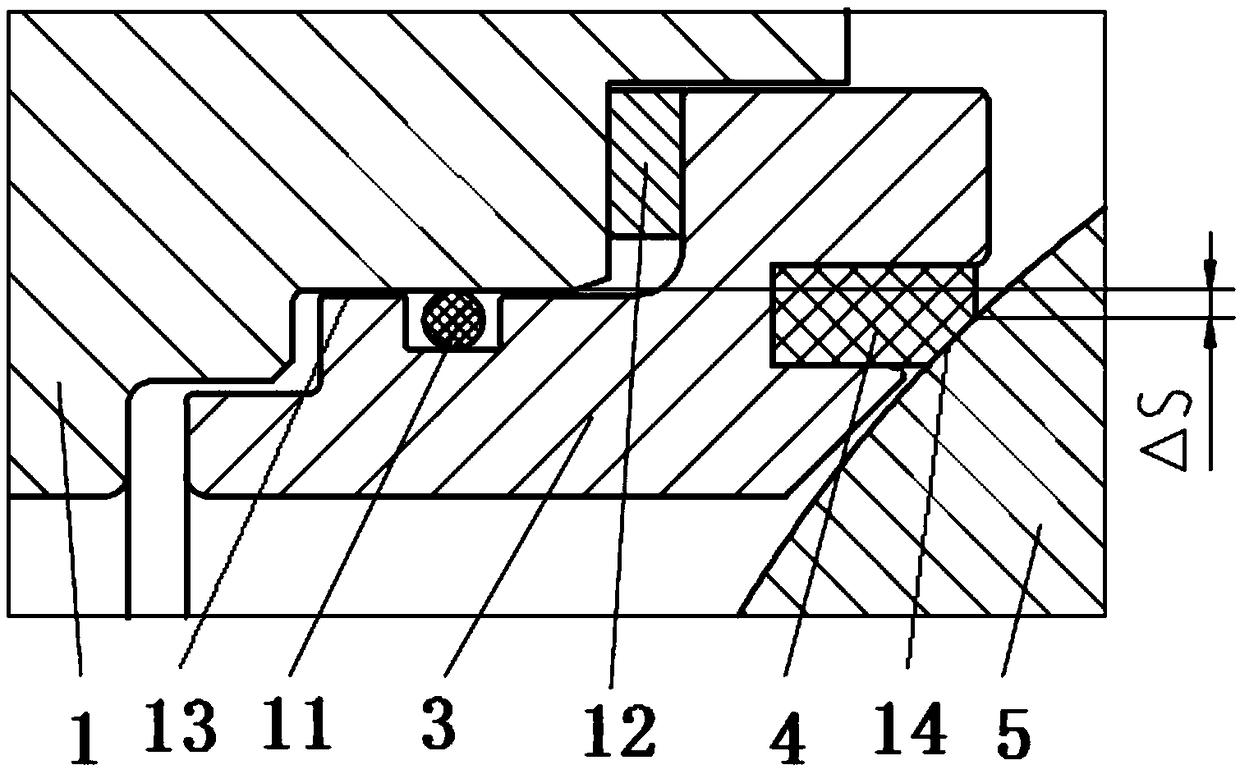

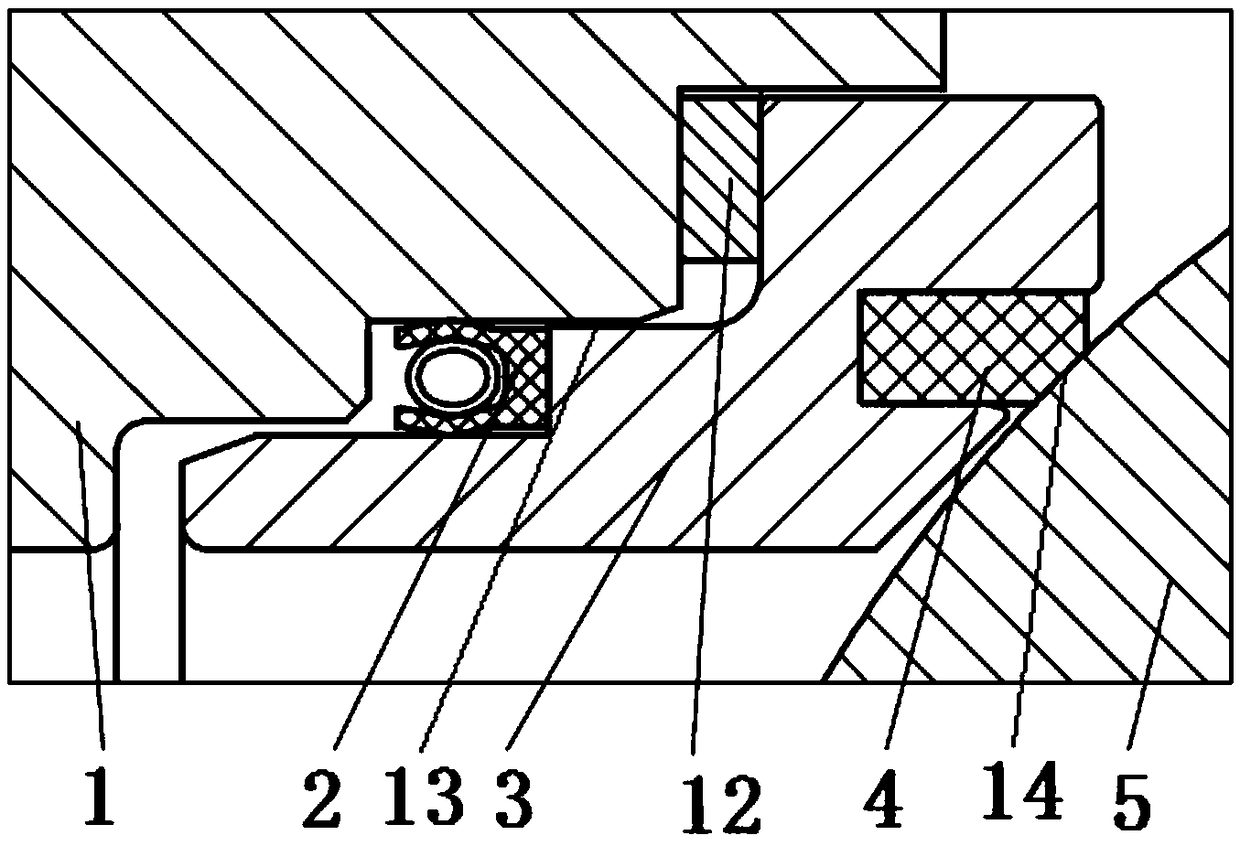

Positive and reverse rotation overload unloading valve

InactiveCN105736501AOvercome spring forceAvoid damageFluid-pressure actuator safetyServomotor componentsHigh pressureControl valves

The invention discloses a positive and reverse rotation overload unloading valve. The valve comprises a valve body (1), a one-way valve (2), a main valve core (3), an end cover (4), a plug (5), a control valve core (6) and a spring pressure regulating component, wherein an oil discharge duct (7), an oil return duct (8), an oil inlet duct (9) and a reverse oil duct (10) are formed in the valve body (1); the one-way valve (2) is communicated with the oil inlet duct (9) and the oil discharge duct (7); a runner structure used for unloading is arranged on the valve body (1); a first sealing oil cavity (17) is arranged between the control valve core (6) and the plug (5); a first oil duct mechanism is arranged between the oil inlet duct (9) and the first sealing oil cavity (17); a secondary pressure bearing valve core (19) is connected with the valve body (1) in a sliding manner. The valve can realize both positive oil duct high pressure self-control unloading and reverse low pressure control oil discharge duct oil return on one valve body.

Owner:宁波诚威液压科技有限公司

Assembling fixture of annular elastic structure, assembling method and ball valve

PendingCN109249341ASimple structureImprove installation efficiencyPlug valvesEngine sealsBall valveEngineering

The invention relates to the technical field of the annular structure assembly and in particular to an assembling fixture of an annular elastic structure. The assembling fixture of the annular elasticstructure comprises a frustum-shaped workpiece matched with a piece to be assembled, wherein the frustum-shaped workpiece has a conical surface of which a diameter is gradually increased along an axial direction from the first end away from the piece to be assembled to the second end adjacent to the piece to be assembled; a sliding workpiece, wherein the sliding workpiece is provided with a cavity matched with the conical surface of the frustum-shaped workpiece, and used for pushing the annular elastic structure placed on the first end of the frustum-shaped workpiece to a preset position of the piece to be assembled along the conical surface under the action of an external force; and a force applying workpiece, wherein the force applying workpiece has a force applying surface which is slid along the outer side wall of the piece to be assembled under the action of the external force so that an acting force opposite to a deformation direction thereof is applied to the annular elastic structure on the outer side wall. The invention further discloses an assembling method of the annular elastic structure and a ball valve. The assembling fixture is capable of solving defects in the prior art that annular elastic installation is difficult and assembling efficiency is low.

Owner:NEWAY VALVE SUZHOU

Machining and conveying method for bearing bush of marine diesel engine

InactiveCN112298949ARealize hot roll bendingOvercome spring forceConnecting rod bearingsBearing componentsMarine engineeringDieseling

The invention relates to a machining and conveying method for a bearing bush of a marine diesel engine. A conveying assembly (2) comprises a first conveying bottom (38) and first conveying output siderollers (37), wherein the input end of the first conveying bottom (38) is used for bearing the bottom of a bearing bush piece (1) which is unfolded to be linear, and the first conveying output side rollers (37) are vertically arranged on the two sides of the first conveying bottom (38) and used for making contact with the side portion of the bearing bush piece (1); the first conveying bottom (38)is provided with first bottom taper pair rollers (39) which are longitudinally distributed and symmetrically arranged; a first bottom center process groove (40) is formed between the first bottom taper pair rollers (39); the bearing bush piece (1) is located in the first bottom center process groove (40); the taper faces of the first bottom taper pair rollers (39) are used for making contact withthe lower edge of the bearing bush piece (1); and a first inner side longitudinal line pressing roller (41) and a first inner side transverse line pressing roller (42) are arranged on one side of thefirst conveying bottom (38). The machining and conveying method is reasonable in design, compact in structure and convenient to use.

Owner:烟台大丰轴瓦有限责任公司

Deep drawing tool and deep drawing process for deep drawing blanks

Owner:RAINER NAROSKA VERPACKUNGSMASCHEN

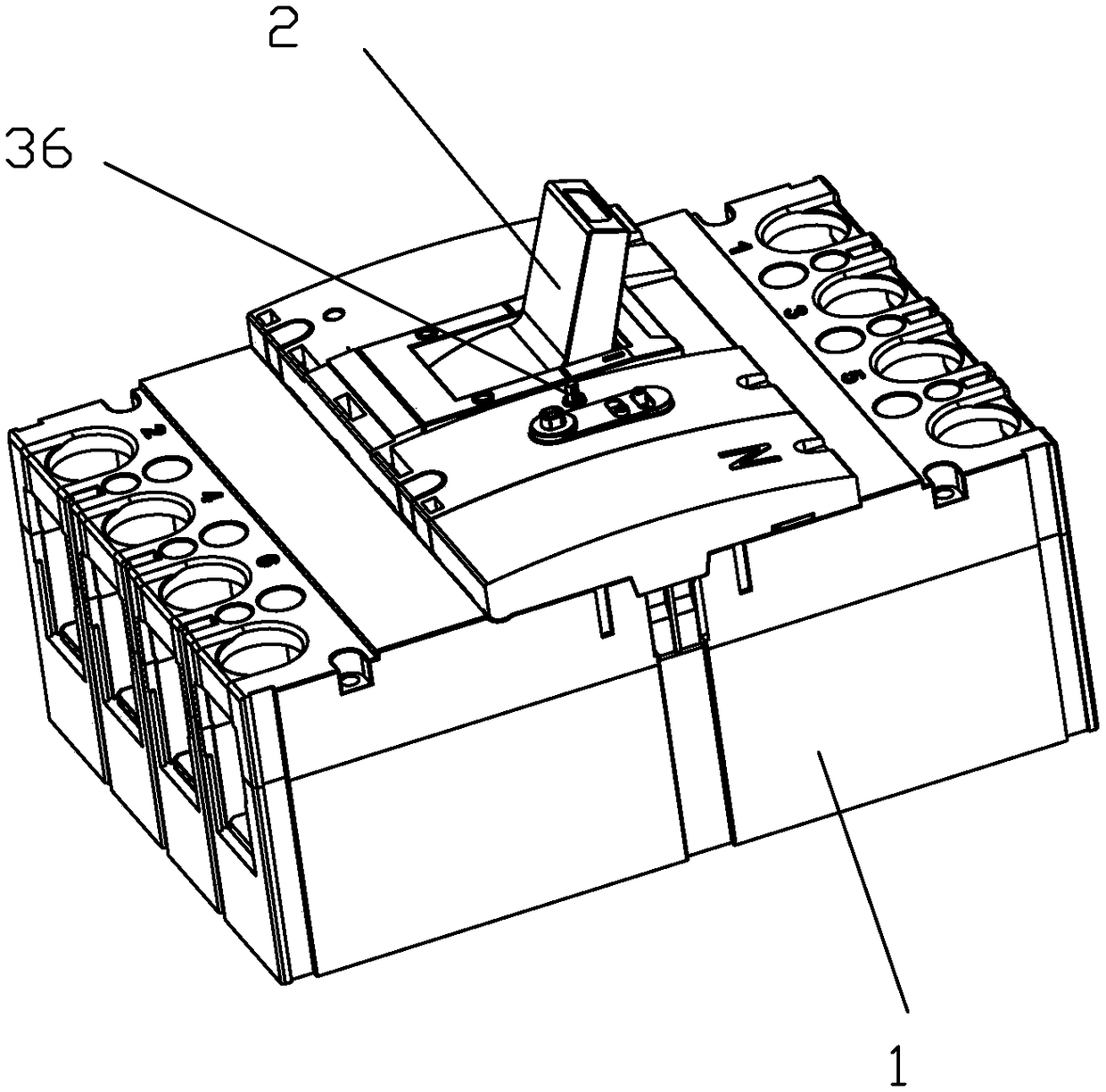

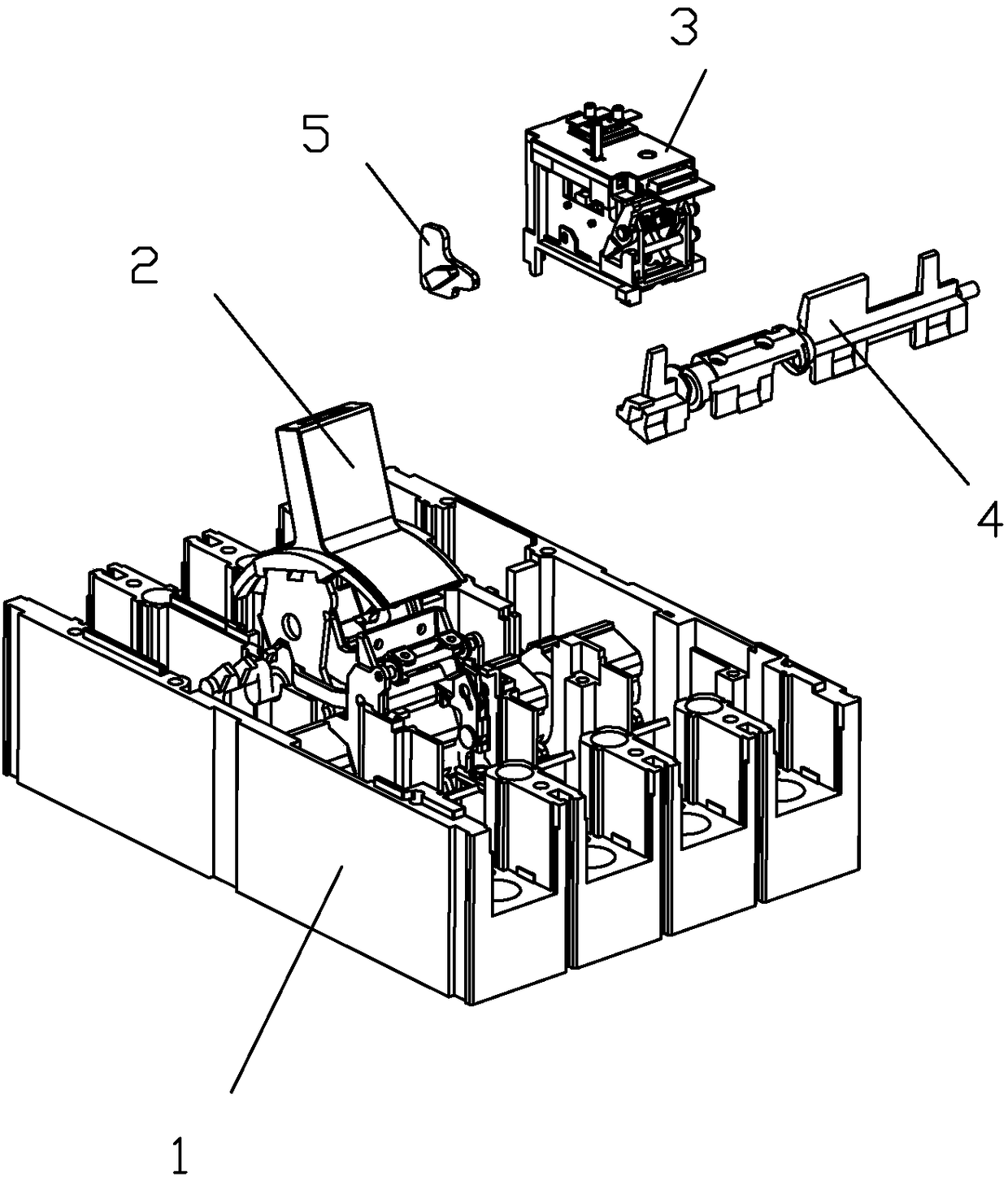

Molded case circuit breaker with residual current protection

PendingCN108321055ARapid responseImprove reliabilitySwitching device condition indicationProtective switch operating/release mechanismsEngineeringMotion direction

The invention discloses a molded case circuit breaker with residual current protection. The molded case circuit breaker comprises a base, a handle, a draw bar and a leakage release; the handle and thedraw bar are mounted on the base; the leakage release adopts a flux converter as a release drive component, and the leakage release and the handle are mounted on the same side of the base with respect to the draw bar side by side; the extension direction of a push rod of the flux converter and the release motion direction of the push rod are opposite, and are identical to the loading direction ofthe circuit breaker. The invention can achieve accurate quick and reliable leakage protection through structural improvement; and the molded case circuit breaker has a small size and a compact structure, and the leakage indication is not prone to jamming.

Owner:XIAMEN HONGFA ELECTRICAL SAFETY & CONTROLS CO LTD

Push-button steering wheel lock

InactiveCN1422219AAvoid breakingOvercome spring forceBuilding locksAnti-theft devicesSteering wheelPush-button

A push-button steering wheel lock for attachment to an automobile steering wheel is provided having a housing and a push-button assembly disposed in the housing. The assembly is positioned in either a locked position for securing the steering wheel lock to the steering wheel or an unlocked position. In the locked position, the push-button lock assembly engages a rod slideably disposed in the housing to prevent movement of the rod with respect to the housing. The push-button assembly also includes two levers, one each on either side of the assembly to engage two surfaces within the housing to retain the push-button assembly in the locked position and also to retain the push-button assembly in the housing.

Owner:MASTER LOCK CO INC

Liquid seasoning container

PendingCN106214027AImprove preservation qualityOutflow smoothlyKitchen equipmentEngineeringMechanical engineering

The invention discloses a liquid seasoning container. The liquid seasoning container comprises a container body (1) and a valve mechanism (2), wherein the valve mechanism (2) is communicated with the container body (1) through a pipeline (3), the valve mechanism (2) comprises a valve element (2.1), a spring (2.2) and a valve rod (2.3), the valve element (2.1) is located at the position of a liquid outlet (4) of the valve mechanism, the valve element (2.1) is sleeved with the spring (2.2), and the valve rod (2.3) is connected with the tail end of the valve element (2.1); a vent rod (5) is arranged in the container body (1), a vent hole is formed in the vent rod, a vent hole opening and closing rod (6) is connected with the valve rod (2.3), a hole plug is arranged on the vent hole opening and closing rod, and the hole plug (2.3) and the vent hole (5.1) are combined or separated under the driving of the valve rod (2.3). The liquid seasoning container has a reasonable ventilation structure and is airtight during seasoning pouring at a normal ventilating state, so that the storage quality of seasoning is improved.

Owner:赖季谷

Pressing strip structure of gasket roll channel of gasket placing machine of wire rod packing machine

ActiveCN113978787AGuaranteed uptimeStandardized and smooth pushBundling machine detailsWire rodEngineering

The invention relates to an improved mechanism of a machine tool in a packing process of processing steel bars to form wire rods in the field of ferrous metallurgy, further improves a gasket placing machine of a high-speed wire rod packing machine, and discloses a pressing strip structure of a gasket roll channel of the gasket placing machine of the wire rod packing machine. A pressing strip (2) is fixed at a notch position of a wire groove (5) of a pressing plate (1) in a floating manner through a spring (6) structure, when the outer back of the pressing strip (2) is pressed, the pressing strip (2) moves downwards, the inner wall of the pressing strip (2) abuts against a gasket (4) to be pressed on the pressing plate (1) of the packing machine, when the pressure of the outer back of the pressing strip (2) is released, the pressing strip (2) rises, and the gasket (4) can pass through the gap. The pressing strip structure is simple and ingenious in structure, low in cost, not prone to faults, beneficial to equipment operation and beneficial to creative popularization and application of the gasket placement improved mechanism CN109795755A, the special and excellent technical effect is achieved, and the common defects of traditional packing machines at home and abroad are overcome.

Owner:SHANGHAI WINLONG ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

Domestic bowl washing machine

InactiveCN102293618BShort cleaning timeImprove efficiencyTableware washing/rinsing machine detailsDish washer applicanceElectricityEngineering

The invention relates to a domestic bowl washing machine, which comprises an upper cover, a tube body, a bottom case, an internal cleaning device and an external cleaning device, wherein the upper cover is overlapped on the upper end surface of the tube body, the lower edge of the upper cover is provided with a convex lug, the convex lug is rotatablely connected with the tube body, the bottom case is fixedly connected with the lower end of the tube body, the internal cleaning device is in contact with the upper cover, the external cleaning device is fixedly connected with the tube body and the bottom case, the internal cleaning device and the external cleaning device are coaxially arranged and are in contact with each other, and at least two symmetrically distributed guide posts are arranged in the upper cover. The domestic bowl washing machine has the advantages that the speed is high, the efficiency is high, the cleaning is clean, the effect is good, the function is complete, the electricity, the water and the time are saved, the structure is compact, the appearance is attractive, the operation is easy, the carrying and the placement are convenient, and the manufacturing cost islow.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

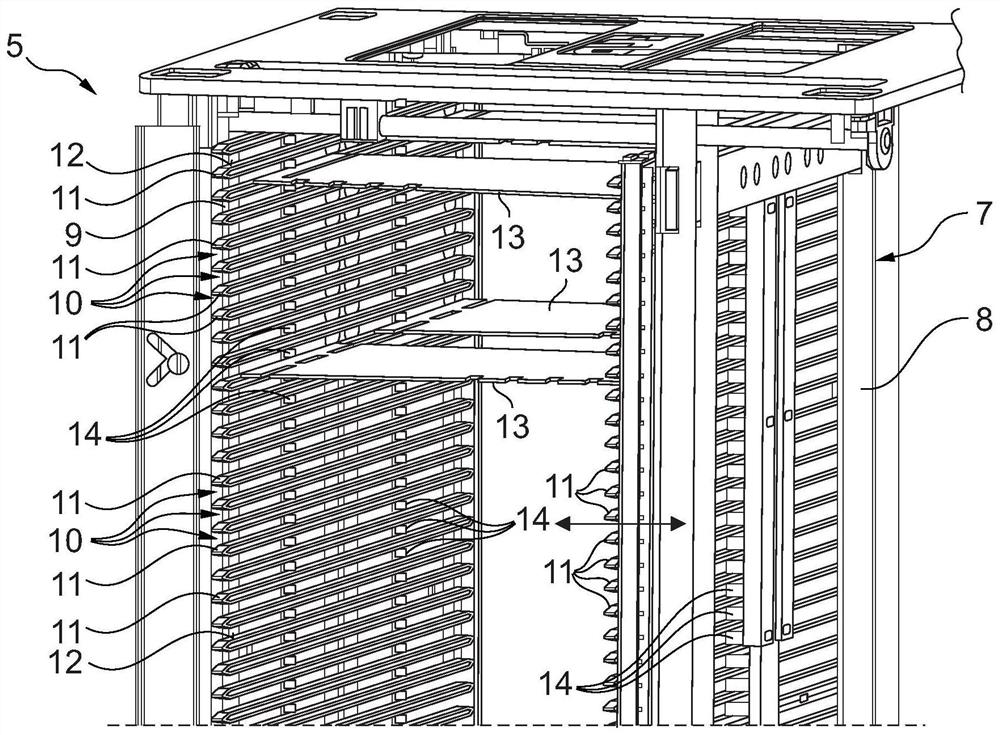

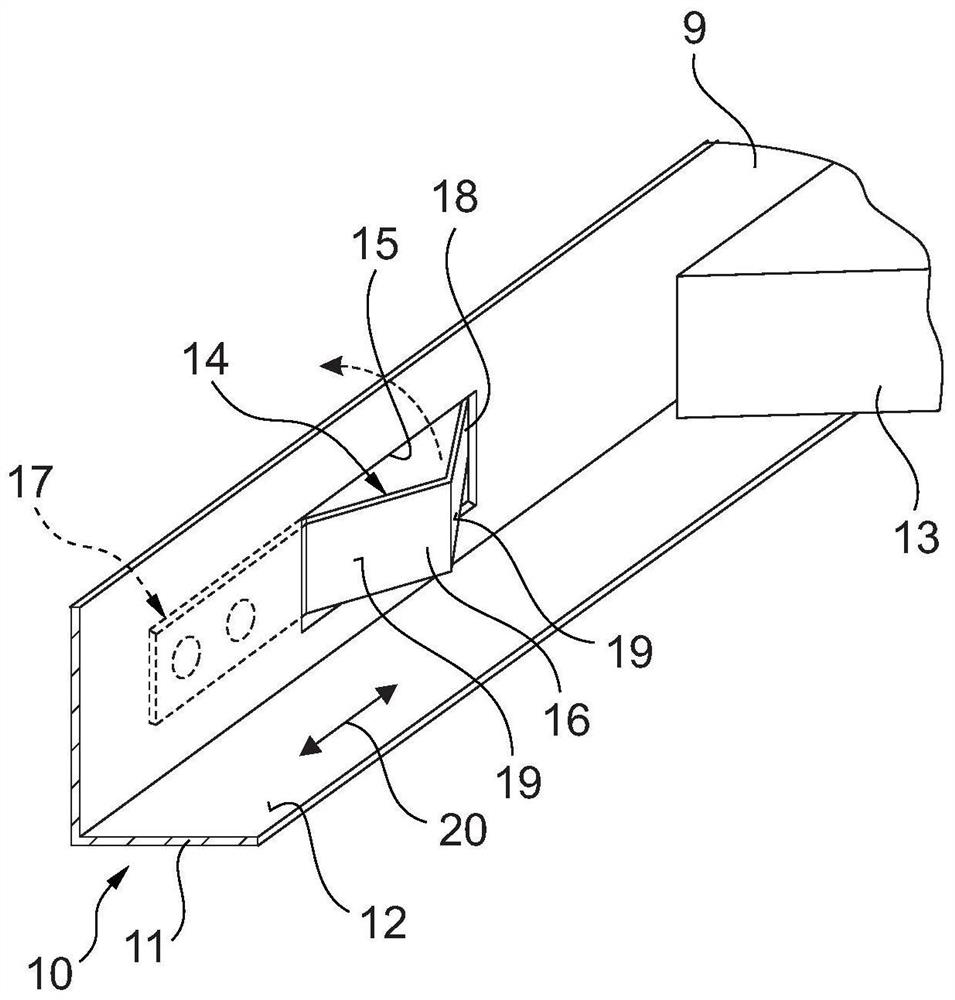

Substrate cartridge, substrate cartridge system, and substrate fitting system

PendingCN112298881AMake sure it's lockedImprove stabilityPrinted circuit board drawersCharge manipulationEngineeringStructural engineering

A substrate magazine (5) for a substrate insertion system (1), having a frame (7) in which several drawers (10) for receiving in each case at least one flat substrate (13) are arranged one above the other. Each drawer (10) is formed by two guide rails (11), arranged in parallel and at a distance from one another at the same height as that of the frame (7), each with a sliding surface (12) on whicha substrate (13) lying on the edge can be displaced. At least one elastically displaceable latching element (14) is assigned to each drawer (10). In a first, unloaded state, the at least one latchingelement extends at least partially over the sliding surface (12) of one (11) of the guide rails of the drawer (10) and, in a second, elastically deformed state, releases the sliding surface (12).

Owner:ASYS AUTOMATISIERUNGSSYST

Push-button steering wheel lock

InactiveCN1245301CAvoid breakingOvercome spring forceBuilding locksAnti-theft devicesSteering wheelPush-button

A push-button steering wheel lock for attachment to an automobile steering wheel is provided having a housing and a push-button assembly disposed in the housing. The assembly is positioned in either a locked position for securing the steering wheel lock to the steering wheel or an unlocked position. In the locked position, the push-button lock assembly engages a rod slideably disposed in the housing to prevent movement of the rod with respect to the housing. The push-button assembly also includes two levers, one each on either side of the assembly to engage two surfaces within the housing to retain the push-button assembly in the locked position and also to retain the push-button assembly in the housing.

Owner:MASTER LOCK CO INC

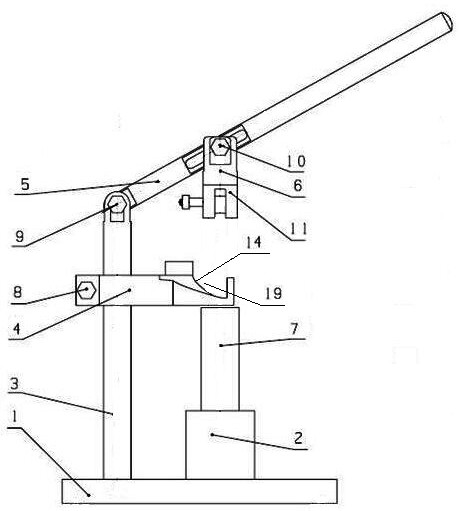

A method for press-fitting a gun frame balancer

ActiveCN110961893BEasy to operateReduce manufacturing costMetal working apparatusSet screwRotation - action

The invention discloses a method for press-fitting a gun rack balancer, which belongs to the technical field of firearm assembly, and is characterized in that it comprises the following steps: a. Putting the outer tube of the balancer into the outer tube fixing seat of the gun rack balancer press-fitting machine, Tighten the set screws, put the inner balance spring and the balance spring into the inner hole of the balancer outer tube in turn, and then insert the guide tube into the balancer outer tube; b. Then put the balancer inner tube into the guide tube, put the inner tube on Balance spring and balance spring, put the inner tube sleeve on the upper end of the balancer inner tube, adjust the direction of the roller shaft, press down the pressure rod connected with the inner tube sleeve; c, continue to press down the inner tube sleeve, when the balancer inner tube and the balancer After the outer tube is 90 degrees relative to each other, stop pressing down and rotating; d. Finally, lift the pressing rod up, take out the balancer assembly, and complete the assembly action. In the actual assembly process, the present invention is quite simple to operate, saves time and effort, is safe and reliable, can effectively improve assembly efficiency and assembly quality, and reduce tooling manufacturing costs.

Owner:CHONGQING JIANSHE IND GRP

Magnetic valve for a fuel injection system and high pressure fuel pump

InactiveCN108286483AQuality improvementReduce momentumElectrical controlWear reducing fuel injectionSolenoid valveEngineering

There is disclosed a solenoid valve (28) for a fuel injection system (10), in which a closing element (34) which interacts with a valve seat (36) in order to close and open the solenoid valve (28) isactuated by a control pin (42), wherein the control pin is formed by way of a solenoid plunger (48). Furthermore, a high pressure fuel pump (18) is disclosed which has a solenoid valve (28) of this type.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Motor vehicle door lock

ActiveCN105264156BLow costOvercome spring forceNoise-prevention/anti-rattling lockingPower-actuated vehicle locksLocking mechanismCar door

The invention relates to a motor vehicle door lock, which has a locking mechanism (1, 2, 3) mainly composed of a rotary locking fork (1) and at least one locking pawl (2, 3) for locking the Drive means (6 to 9) acting on the mechanism (1, 2, 3), locking element (11) interacting with the locking pawl (2, 3), the locking element having at least one locking pawl arm (11a) , the locking pawl arm keeps the locking pawl (2, 3) in the blocking position, the motor vehicle door lock also has a locking element (11) and / or on the locking pawl (2, 3) and / or on the triggering Stop arm ( 11 b ) on the element for stopping the drive ( 6 to 9 ), characterized in that the blocking element ( 11 ) is arranged at the edge remote from the rotary locking fork and is connected to the locking The claws (2, 3) overlap laterally.

Owner:KIEKERT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com