Magnetic valve for a fuel injection system and high pressure fuel pump

A technology of fuel injection system and solenoid valve, applied in the direction of fuel injection pump, fuel injection device, charging system, etc., which can solve the problems of solid sound undesired emission, material wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] figure 1A schematic overview of a fuel injection system 10 of an internal combustion engine is shown, which delivers fuel 12 from a fuel tank 14 to injectors 22 via a prefeed pump 16 , a high-pressure fuel pump 18 and a high-pressure fuel accumulator 20 , The injector then injects fuel 12 into the combustion chamber of the internal combustion engine.

[0039] Fuel 12 is introduced into high-pressure fuel pump 18 via inlet valve 24 , is discharged under pressure from high-pressure fuel pump 18 via outlet valve 26 , and is delivered to high-pressure fuel accumulator 20 .

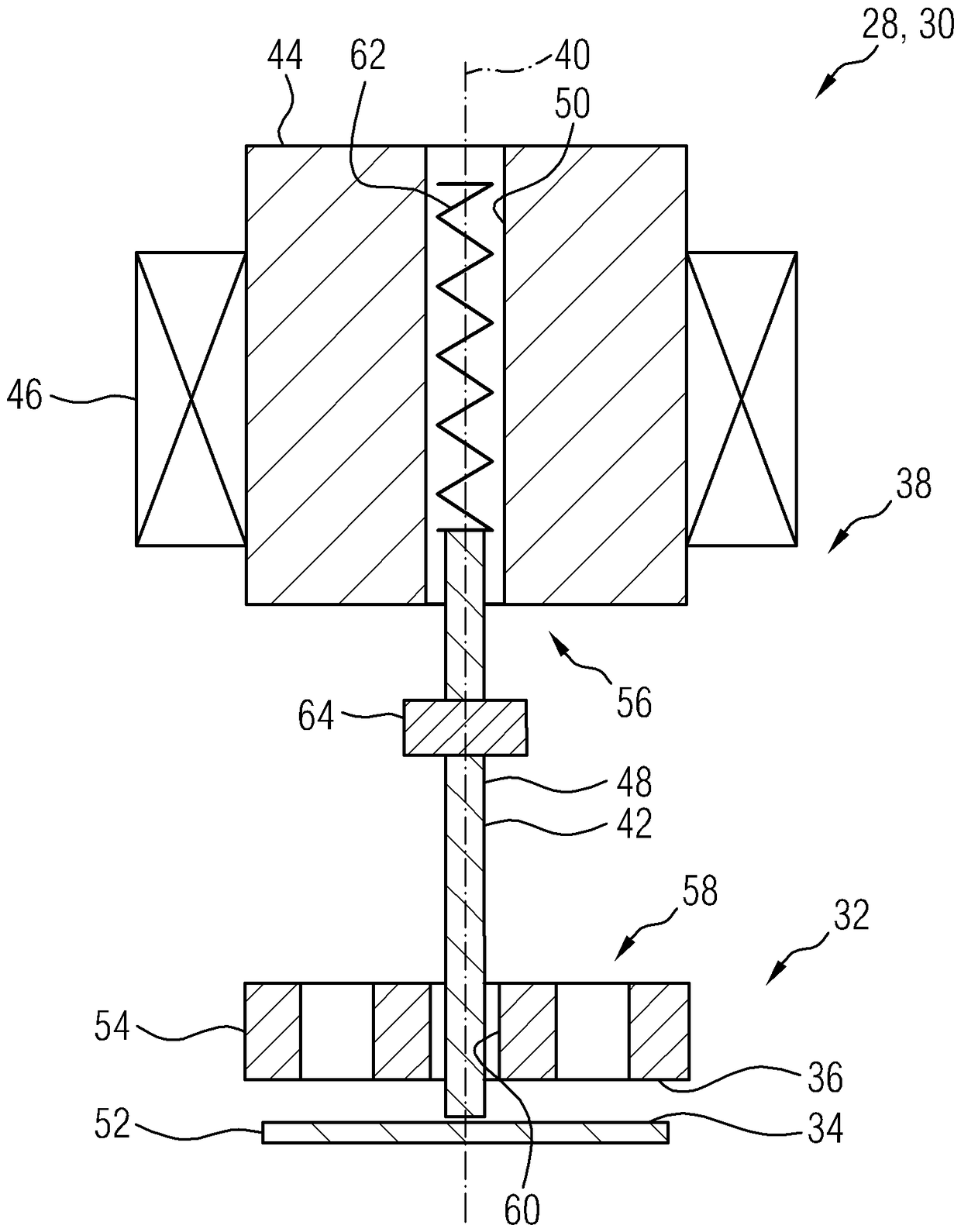

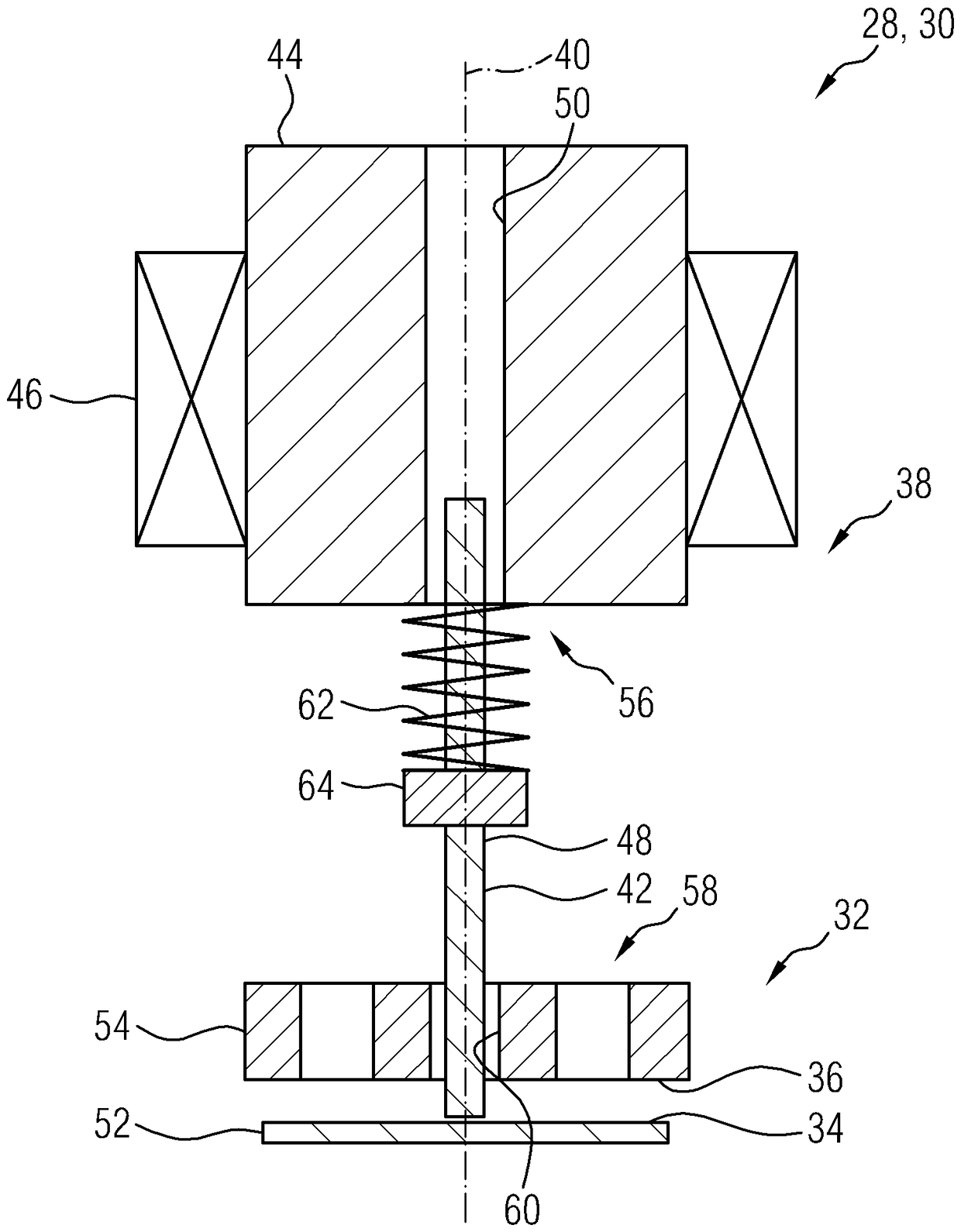

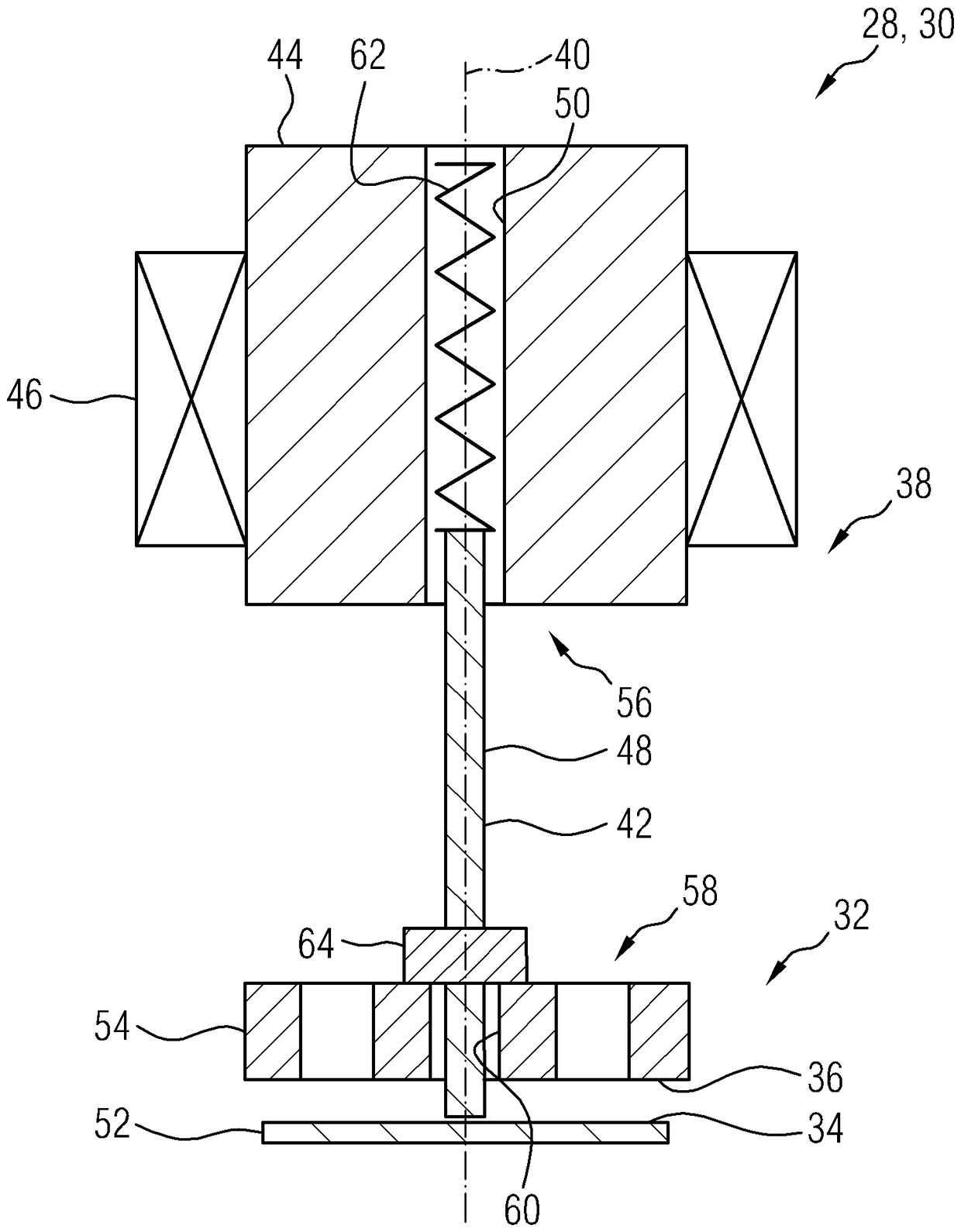

[0040] The inlet valve 24 is designed as a solenoid valve 28 , in particular as a volume flow control valve 30 , and can thus actively regulate the delivery of fuel 12 in the high-pressure fuel pump 18 by targeted changes in the closing or opening times. Spend.

[0041] exist Figure 2 to Figure 7 In , the solenoid valve 28 is shown in more detail in schematic cross-sectional views in different embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com