Device for regulating a coolant flow and cooling system

A technology of cooling medium flow and cooling system, used in the control of coolant flow, engine cooling, non-variable-capacity pumps, etc., can solve problems such as hindering the heating of the combustion chamber, and achieve the effect of fail-safe functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

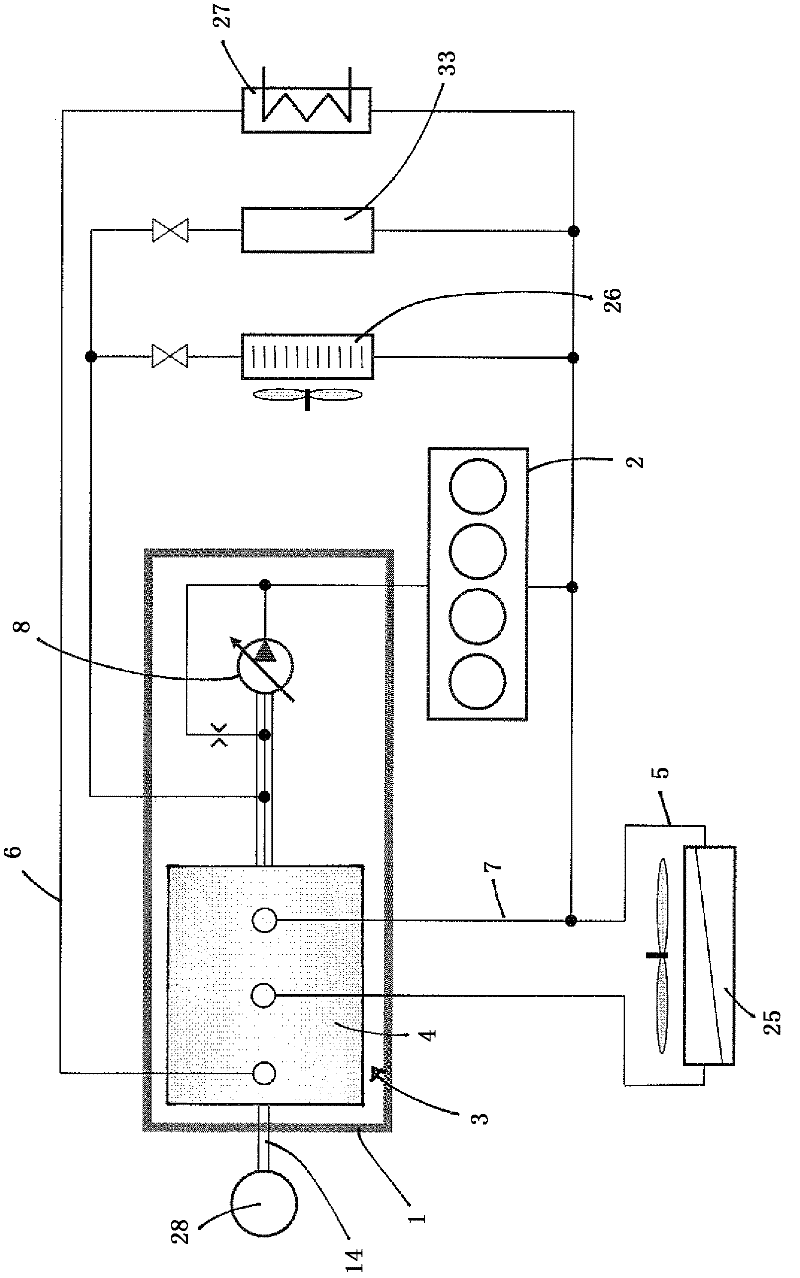

[0031] According to the cooling system of the present invention figure 1 The example shown in includes a device 1 for regulating a coolant flow, which device 1 can primarily be used for cooling an internal combustion engine 2 . Furthermore, an oil cooler 26 as a further consumer and a heating device 27 are connected to the cooling circuit. Furthermore, other components 33 can optionally be connected to the cooling system. In order to be able to achieve the desired distribution of the cooling medium flow, the cooling system also has various cooling circuits 5 , 6 and a bypass circuit 7 for enclosing the cooler 25 in the cooling circuit 5 . Thus, an uncooled coolant flow is already provided via the bypass circuit, which enables an optimum coolant temperature to be set. For this purpose, the cooling medium from the bypass circuit 7 is mixed with the cooling medium from the cooling circuit 5 . The mixing takes place via the valve system 3 , which is a component of the device 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com