Hydraulic control apparatus for automatic transmission

An automatic transmission and oil pressure control technology, which is applied in the direction of engine control, transmission control, and components with teeth, etc., can solve the problems of large-scale automatic transmission and complex oil circuit structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] follow below Figure 1 ~ Figure 4 Embodiments of the present invention will be described.

[0029] [Outline structure of automatic transmission]

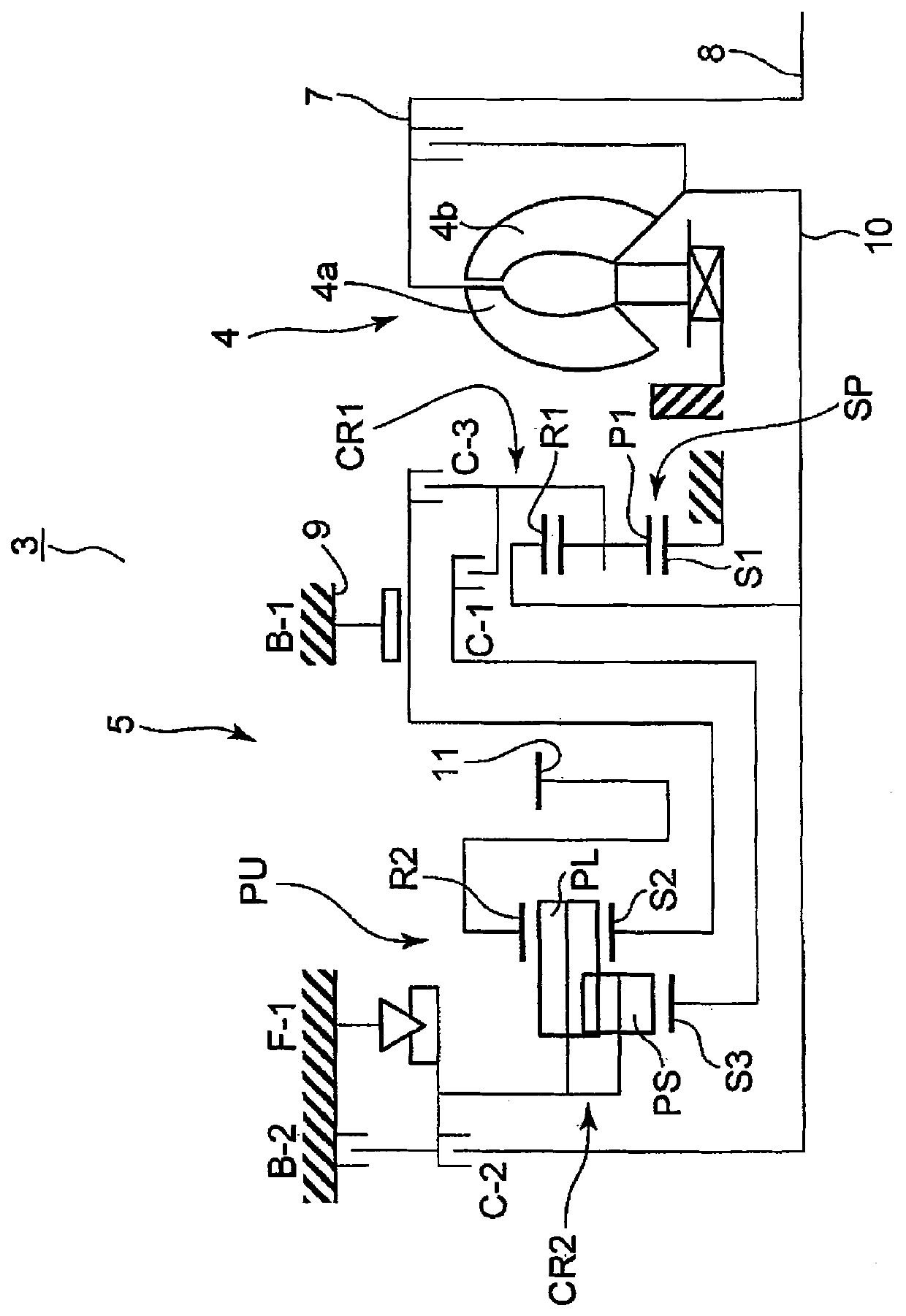

[0030] First, follow the figure 1 A schematic structure of the automatic transmission 3 to which the present invention can be applied will be described. Such as figure 1 As shown, for example, an automatic transmission 3 suitable for FF type (front-engine, front-wheel drive) vehicles has an input shaft 8 of the automatic transmission 3 that can be connected to an engine (not shown), and the axial direction of the input shaft 8 It has a hydraulic torque converter 4 and an automatic transmission mechanism 5 at the center.

[0031] The torque converter 4 has a pump impeller 4 a connected to the input shaft 8 of the automatic transmission 3 and a turbine 4 b that transmits the rotation of the pump impeller 4 a via a working fluid, and the turbine 4 b is connected to the input shaft of the automatic transmission mechanism 5 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com