Energy-saving rotary two-way balancing valve

A two-way balance valve, energy-saving technology, applied in the field of hydraulic valves, can solve the problems of poor reliability and stability, and achieve the effect of stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

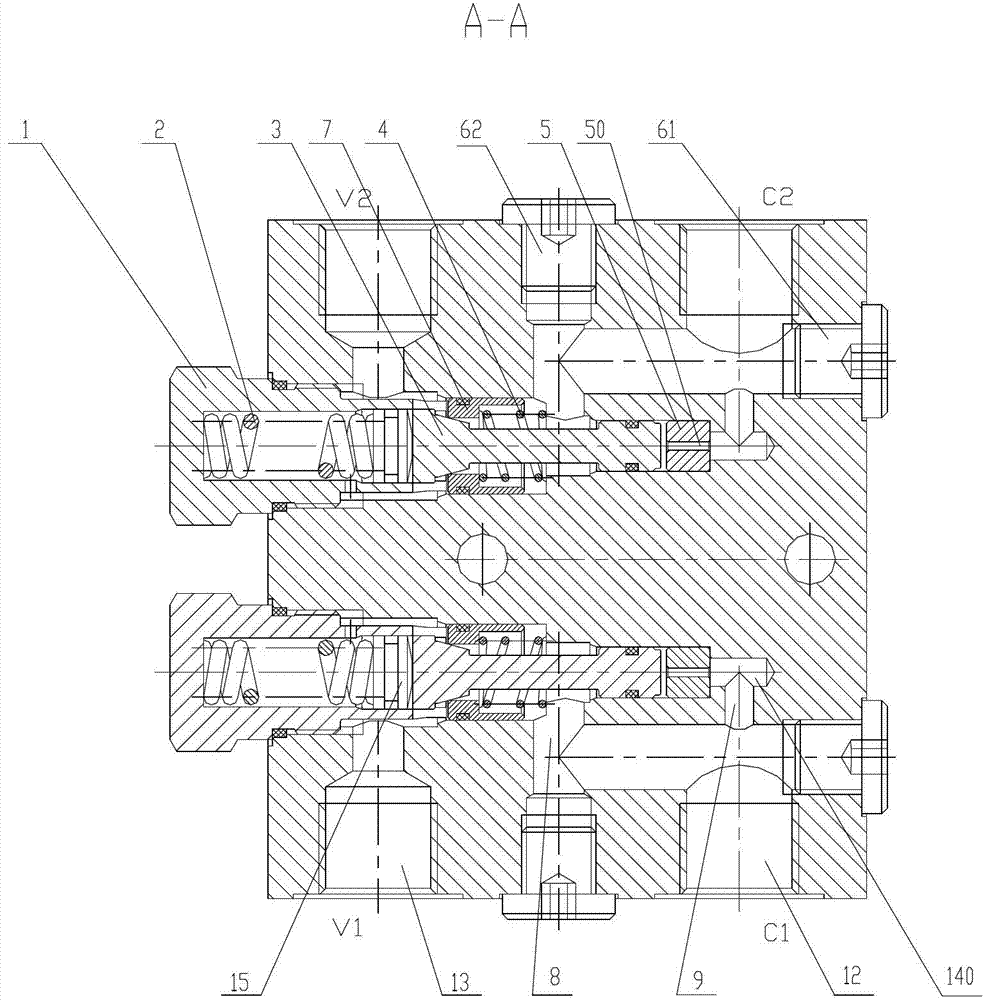

[0028] The present invention as Figure 1-6 As shown, it includes a valve body 14 and a pair of valve core assemblies. The valve body 14 is provided with a pair of symmetrical stepped valve chambers. The end faces of the valve body 14 are respectively provided with oil ports communicating with the valve chambers 12 and oil port two 13;

[0029] The valve cavity includes a horizontal main hole 140, a main flow channel 8 and a control flow channel 9, and the oil port 12 communicates with the main flow channel 8 and the control flow channel 9 respectively. The first head 61 and the second plug 62 are used to close the oil channel between the first control oil port 12, the main flow channel 8 and the control flow channel 9; The main hole 140;

[0030] The valve core assembly is arranged in the main hole 140, and the valve core assembly sequentially includes a throttle plug 5, a valve stem 3, a spring 4, a valve seat 7, a spring seat 15, a pressure regulating spring 2 and a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com