Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100results about How to "Avoid decapitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of regenerative polyester bottle tablet for producing textile filament raw material

InactiveCN101831149AReduce lossAvoid decapitationPlastic recyclingMonocomponent polyesters artificial filamentPolyesterMaterial resources

The invention relates to a preparation method of a regenerative polyester bottle tablet for producing a textile filament raw material, belonging to the technical field of the processing of the raw spinning materials. The preparation method comprises the steps of: preparing raw materials, separating, removing labels, shearing, smashing once, evaporating, washing, dehydrating for drying, smashing for the second time and sieving. The technical scheme provided by the invention can ensure that the regenerative polyester bottle tablet has the impurity content decreased from 2 percent to less than 0.02 percent without containing polyester powder, thereby end breakage as well as ossified filaments and yarn variation of textiles can be avoided during spinning; and moreover, the process is short with less raw materials consumption, which is beneficial to saving energy source and materials resources.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV

Far infrared bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556275AImprove antibacterial propertiesSignificant far infrared health functionArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceFar infrared

The invention discloses provides a far infrared bamboo charcoal viscose fiber and a preparation method thereof, in order to make up for the blank of the conventional far infrared bamboo charcoal viscose fiber and solve the problem of poor spinnability of the bamboo charcoal viscose fiber. The far infrared bamboo charcoal viscose fiber is characterized in that the fiber comprises 1-10 percent by weight of far infrared ceramic powder and 0.1-10 percent by weight of bamboo charcoal, wherein the far infrared emissivity is greater than 80 percent, the ammonia absorption rate is greater than or equal to 50 percent, the permeability is greater than or equal to 500 mm / s, and the color fastness to washing is class 4-5. The far infrared bamboo charcoal viscose fiber has a heat insulation effect; the radiated far infrared also has the health-care functions of activating cell tissues and promoting the blood circulation.

Owner:YIBIN HIEST FIBER +1

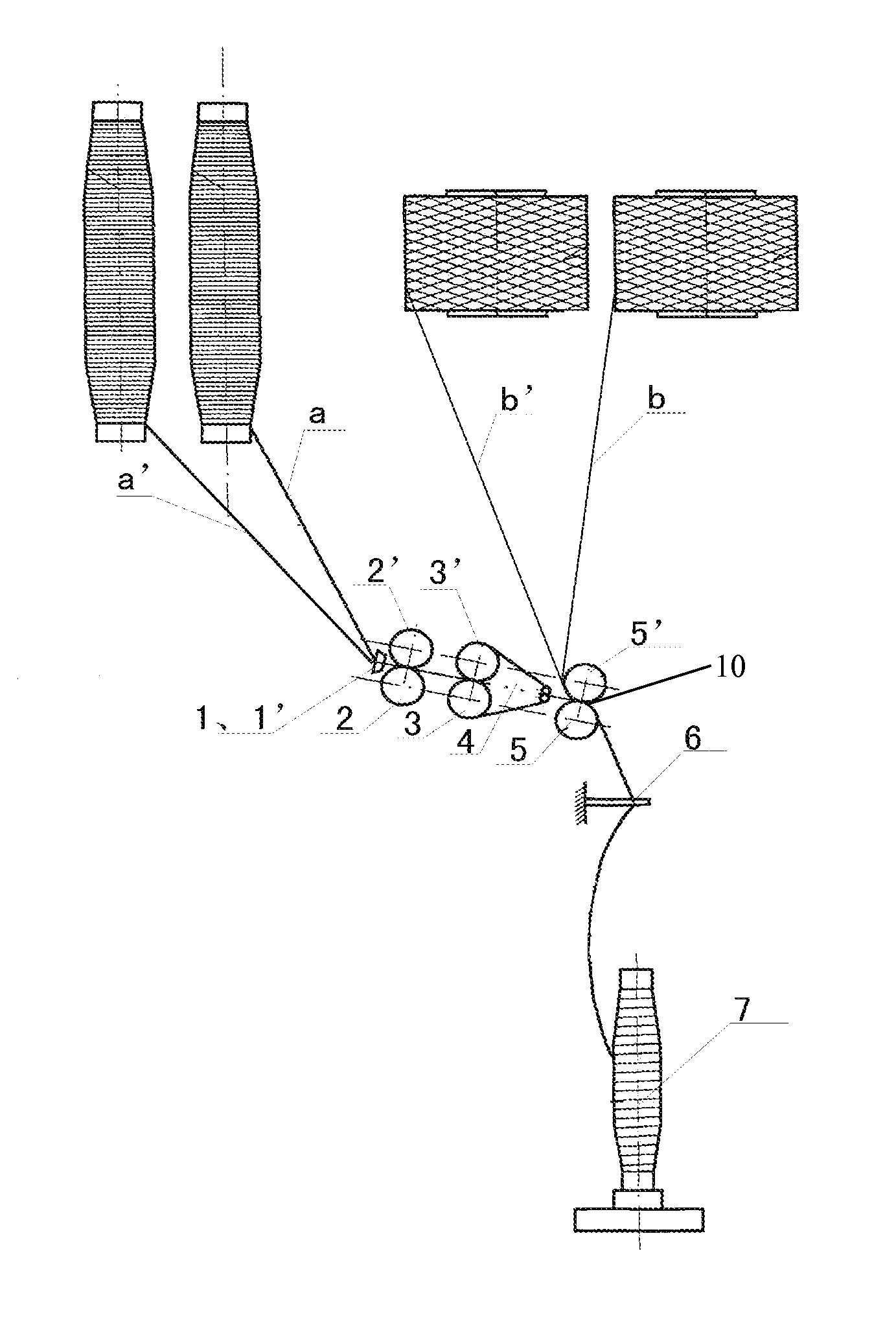

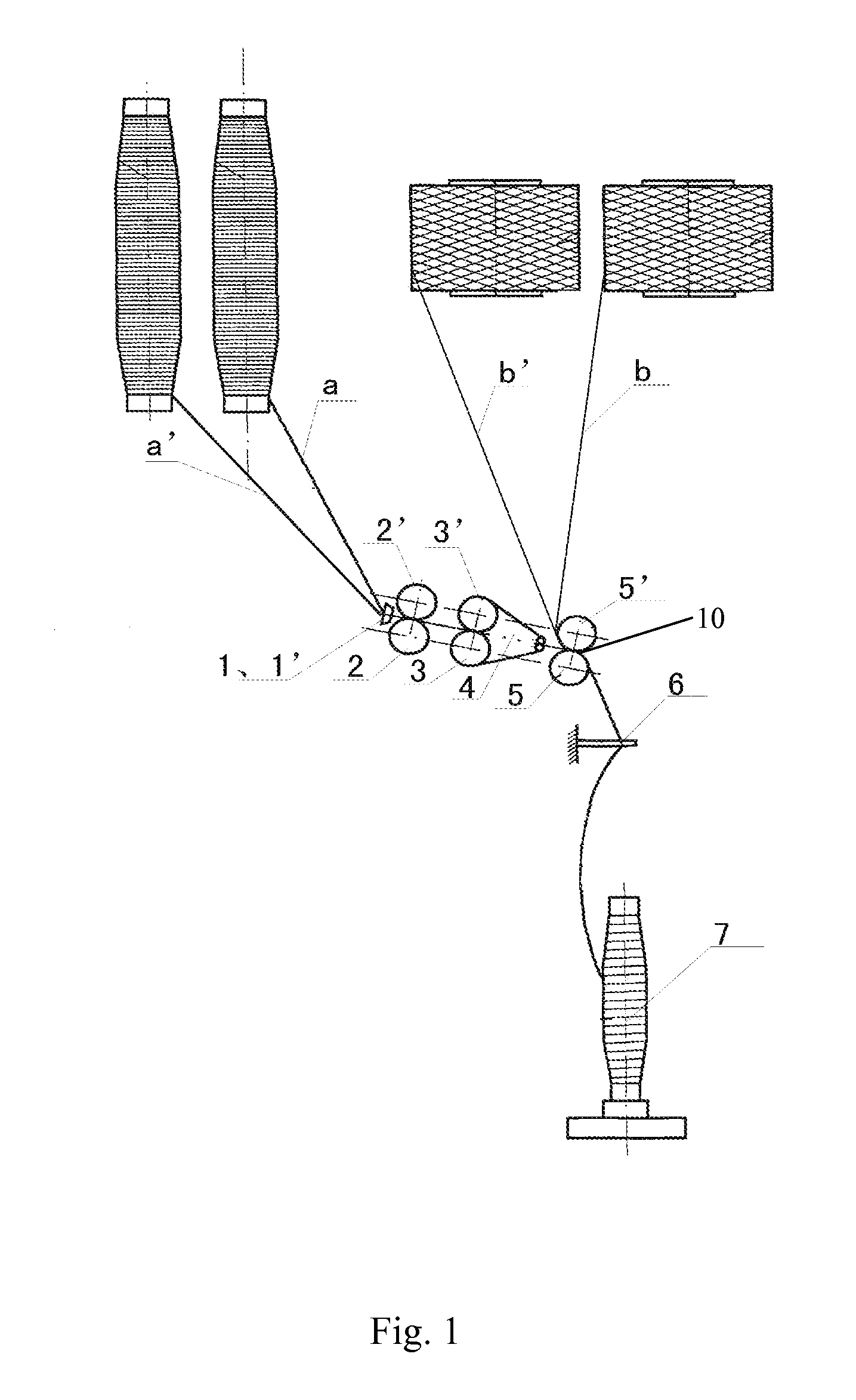

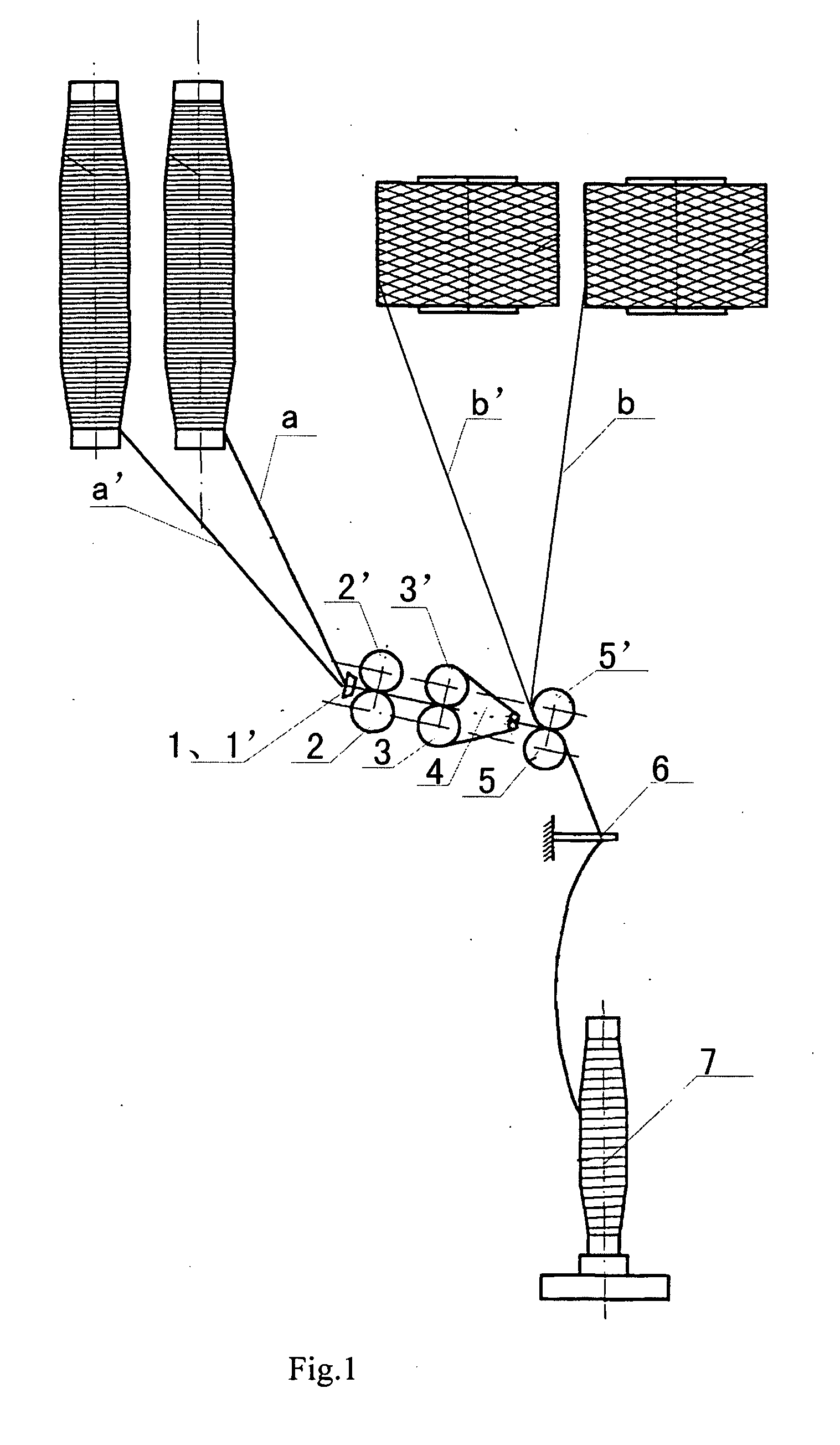

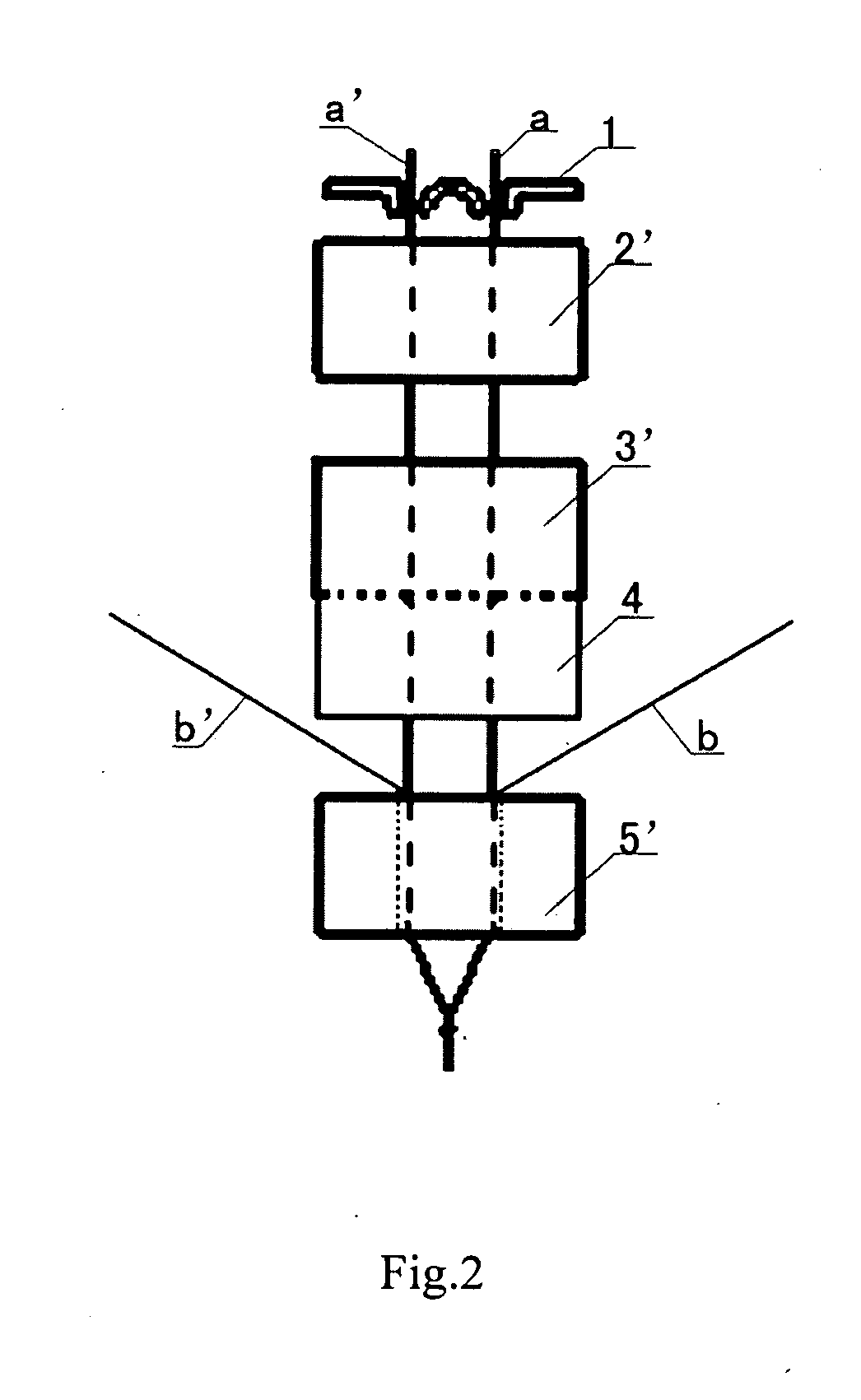

Embedded type system positioning spinning method

On each draft element of a ring spinning frame, two pieces of short-staple roving from the roving bobbin enter into the draft mechanism to be drafted though a guide funnel in parallel, two pieces of filament are fed from the back of the front roller, and combine with two pieces of roving at front jaw respectively. The drafted two pieces of roving and filament are output from the front jaw and enter into the twisting triangle area to be twisted, and then are wound onto a yarn bobbin to produce yarn. Based on the relative position of the two pieces of roving and two pieces of filament, different yarns can be produced. Furthermore, multi-component yarn, such as core structure, wrapped structure, strand-like structure, can be produced on a ring spinning frame. The structure of yarn can be precisely determined. Special fiber yarn can be produced on traditional spinning frame.

Owner:SHANDONG RUYI SCI & TECH GRP +2

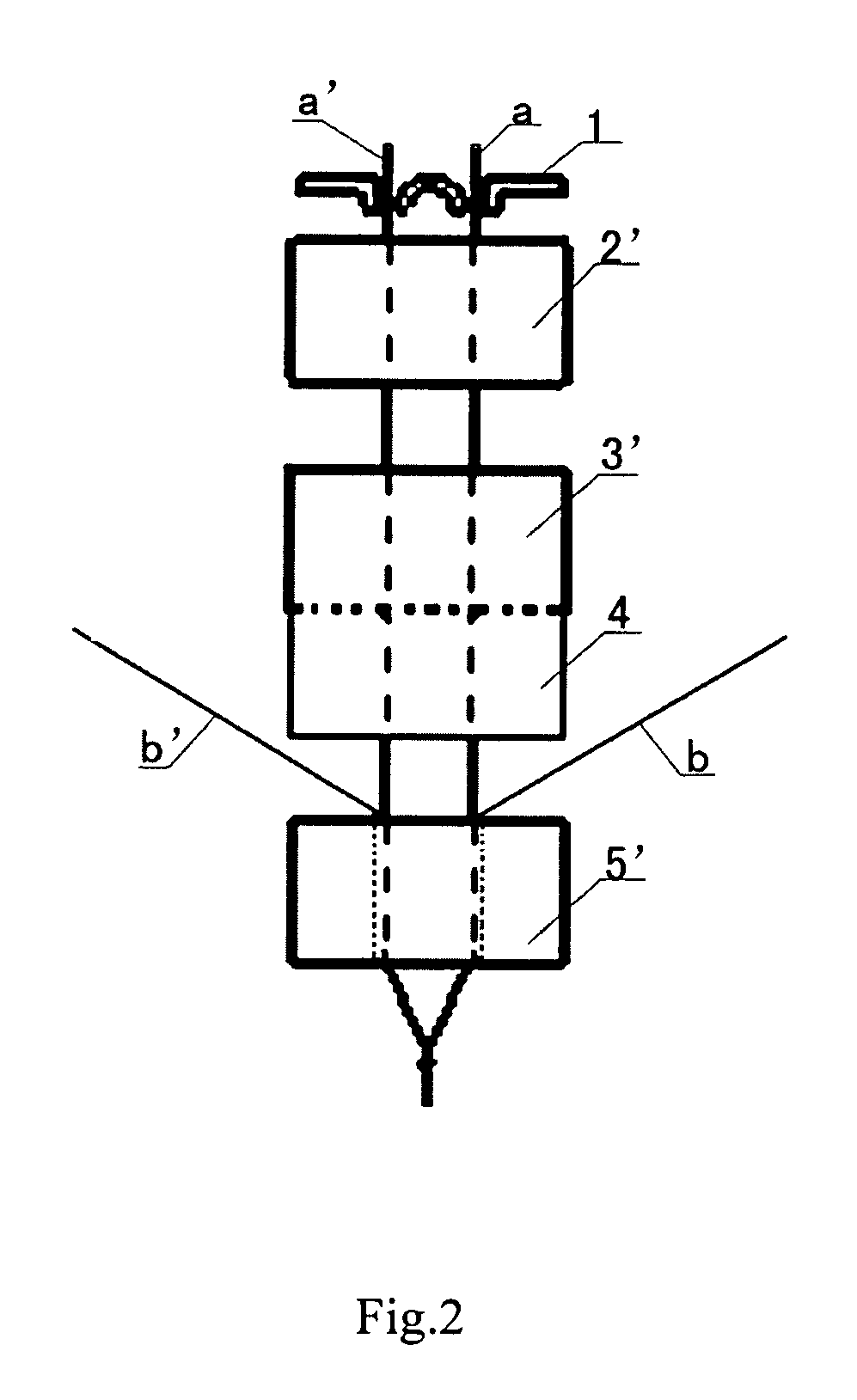

Method for preparing functional polyester masterbatch from regenerative polyester bottle chips and device for method

The invention discloses a method for preparing functional polyester masterbatch from regenerative polyester bottle chips and a device for the method, and belongs to the technical field of textile material processing. The method for preparing the functional polyester masterbatch from the regenarative polyester bottle chips comprises the following steps of: feeding the regenerative polyester bottle chips into a first screw extruder; melting the regenerative polyester bottle chips into polyester melt and extruding by using the first screw extruder; filtering the melt at the extruder discharge outlet of the first screw extruder by using a melt filter screen, making the filtered melt enter a blender, and adding a functional assistant into the polyester melt which enters the blender, and uniformly stirring to obtain functional polyester melt; and filtering the functional polyester melt with a filter screen, introducing the functional polyester melt into a second screw extruder, extruding the functional polyester melt by using the second screw extruder, and obtaining the functional polyester masterbatch through cutting, washing and drying. The purity of the obtained polyester master batch is improved, the problems such as end breakage, non-uniform evenness and poor intensity are solved in the subsequent spinning technology, and the polyester masterbatch has the performance such as heat retention, environmental protection and safety, and the like.

Owner:JIANGSU XINKAISHENG ENTERPRISE DEV

Extinction bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556261ASignificant shielding rateGood deodorizing functionArtificial filaments from viscoseWet spinning methodsChemistryComposite material

The invention provides an extinction bamboo charcoal viscose fiber and a preparation method thereof in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The extinction bamboo charcoal viscose fiber is characterized by comprising the components by weight percent: 0.01-10 percent of titanium dioxide and 0.1-10 percent of bamboo charcoal, wherein the ammonia absorption rate is more than or equal to 50 percent, the air permeability is more than or equal to 500mm / s, and the color fastness to washing is of 4-5 level. The extinction bamboo charcoal viscose fiber disclosed by the invention is a novel product, has the functions of bacterium and ultraviolet prevention and deodorization, is high in air permeability and moisture absorption, has soft handfeel and has an extinction function.

Owner:YIBIN HIEST FIBER +1

Steel wire connecting method

InactiveCN102873447AImprove toughnessGood elastic limitFurnace typesHeat treatment furnacesTwo temperatureFree cooling

The invention discloses a steel wire connecting method, and provides a steel wire connecting method capable of preventing end breakage of a welding position during a drawing process, and reducing end breakage rate. The method comprises the following steps of: clamping a polished welding seam at a tempering jaw, and raising the temperature intermittently for 4-5 times, with 1-2 seconds of interval between every two temperature rises, and stopping temperature rise when reaching 750-820 DEG C; continuously raising the temperature to 750-820 DEG C when naturally cooling to the temperature of 650 DEG C in the air, stopping temperature rise, repeating the above cooling-raising temperature process for three to four times, and then naturally cooling to 650 DEG C in the air; then continuously raising the temperature to 750-820 DEG C, and keeping the temperature for 1 minute through intermittent heating; and after naturally cooling to 570-590 DEG C, instantly electrifying and raising the temperature by 20-50 DEG C, and naturally cooling. The steel wire connecting method provided by the invention has the beneficial effects that through high temperature tempering processing at the weld part, the internal stress generated in welding is reduced, the tenacity of the welding part is improved, the phenomenon of end breakage at the welding position in the drawing process is prevented, and the end breakage rate is lowered.

Owner:天津市新天钢中兴盛达有限公司

Bamboo charcoal viscose fiber rich in nano-copper and preparation method of bamboo charcoal viscose fiber

ActiveCN103556272AImprove breathabilityHigh strengthArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceSpinning

The invention provides a bamboo charcoal viscose fiber rich in nano-copper and a preparation method of the bamboo charcoal viscose fiber in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The bamboo charcoal viscose fiber rich in nano-copper is characterized by being prepared by mixing a nano-copper bamboo charcoal solution with viscose throug injection before spinning, and carrying out wet spinning and post-treatment; the nano-copper bamboo charcoal solution is formed by mixing masterbatches containing the nano-copper and a bamboo charcoal solution. The fiber comprises the components by weight percent: 0.01-5 percent of nano-copper and 0.1-10 percent of bamboo charcoal; the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The bamboo charcoal viscose fiber rich in the nano-copper has functions of ultraviolet prevention and deodorization and is high in air permeability and absorptivity; furthermore, the antibacterial effect of the bamboo charcoal viscose fiber is better than that of the common bamboo charcoal fiber; the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

Embedded type system positioning spinning method

InactiveUS20100162677A1Enlarge rangeAlteration be simpleContinuous wound-up machinesYarnEngineeringBobbin

On each draft element of a ring spinning frame, two pieces of short-staple roving from the roving bobbin enter into the draft mechanism to be drafted though a guide funnel in parallel, two pieces of filament are fed from the back of the front roller, and combine with two pieces of roving at front jaw respectively. The drafted two pieces of roving and filament are output from the front jaw and enter into the twisting triangle area to be twisted, and then are wound onto a yarn bobbin to produce yarn. Based on the relative position of the two pieces of roving and two pieces of filament, different yarns can be produced. Furthermore, multi-component yarn, such as core structure, wrapped structure, strand-like structure, can be produced on a ring spinning frame. The structure of yarn can be precisely determined. Special fiber yarn can be produced on traditional spinning frame.

Owner:SHANDONG RUYI SCI & TECH GRP +2

Anti-ultraviolet bamboo charcoalviscose fiber and preparation method thereof

ActiveCN103556252AGood antibacterial effectGood deodorizing functionArtificial thread manufacturing machinesArtificial filaments from viscoseBamboo charcoalViscose fiber

The invention provides an anti-ultraviolet bamboo charcoalviscose fiber and a preparation method thereof in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoalviscose fiber is poor in spinning property. The anti-ultraviolet bamboo charcoalviscose fiber is characterized by being obtained by mixing an anti-ultraviolet bamboo charcoal solution with mucilage glue through spinning before injection, and carrying out wet spinning and post-treatment, wherein the anti-ultraviolet bamboo charcoal solution is formed by mixing an anti-ultraviolet masterbatches and a bamboo charcoal solution; the anti-ultraviolet masterbatches contain an anti-ultraviolet agent. The fiber comprises the components by weight percent: 0.01-10 percent of the anti-ultraviolet agents and 0.1-10 percent of bamboo charcoal; the ultraviolet shielding rate is more than or equal to 95 percent, the ammonia absorption rate is more than or equal to 50 percent, and the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The anti-ultraviolet bamboo charcoalviscose fiber has functions of ultraviolet prevention and deodorization and is high in air permeability and absorptivity; furthermore, the anti-ultraviolet effect of the anti-ultraviolet bamboo charcoalviscose fiber is better than that of the common bamboo charcoal fiber; the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

Preparation method of magnesium-carbon composite monolithic stopper rod for continuous casting

InactiveCN101722302AImprove thermal shock resistanceReduce generationMelt-holding vesselsCarbon compositesMaterials preparation

The invention belongs to the technical field of novel fire resistant material preparation and provides a preparation method of a magnesium-carbon composite monolithic stopper rod for continuous casting. The rod body of the monolithic stopper rod is made of an aluminum-carbon material, the rod head is made of a low carbon magnesium-carbon material, and the mixing transition of the aluminum-carbon material and the low-carbon magnesium-carbon material is adopted between the rod head and the rod body. A main raw material of the material of the rod head is fused magnesia, and 3-8 percent by weight of aluminum-silicon alloy power, 0.5-2 percent by weight of BN and 8-12 percent by weight of graphite are also added. The safety when in use is guaranteed through optimizing the grain composition of the graphite used by the magnesium-carbon material and adding the aluminum-silicon alloy capable of forming a ceramic binding phase in a heat treatment process and the BN capable of reducing the thermal expansion coefficient to improve the thermal shock resistance of the magnesium-carbon material. In addition, the uniform mixing transition between the rod head material and the rod body material is formed, and the generation of thermal stress is reduced as much as possible during thermal shocks so as to prevent end break phenomena when in use.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

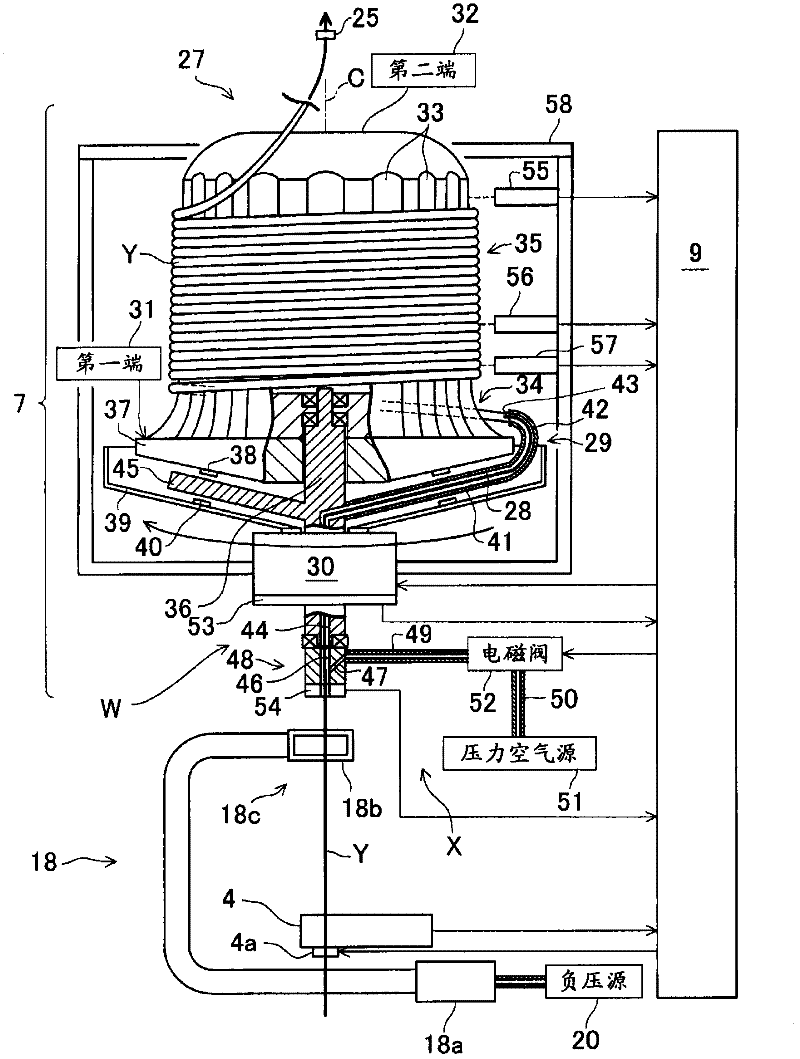

Yarn winder

ActiveCN102548884AExcellent power consumption reductionIncrease power consumptionFilament handlingYarnBobbin

Disclosed is a yarn winder capable of continuing winding yarn during knotting of the yarn. Specifically disclosed is a yarn winder which comprises a yarn supplying unit (3) that unwinds yarn (Y) from a yarn supplying bobbin (B); a yarn winding unit (5) that winds the yarn (Y) as a package (P); an accumulator (7) that is disposed between the yarn supplying unit (3) and the yarn winding unit (5) and that accumulates the yarn (Y); and a yarn end drawing mechanism (W) that draws an end of the accumulated yarn (Y) to the yarn supplying unit (3) when the yarn supplying bobbin (B) is changed, when the yarn is cut, or when the yarn runs out.

Owner:MURATA MASCH LTD

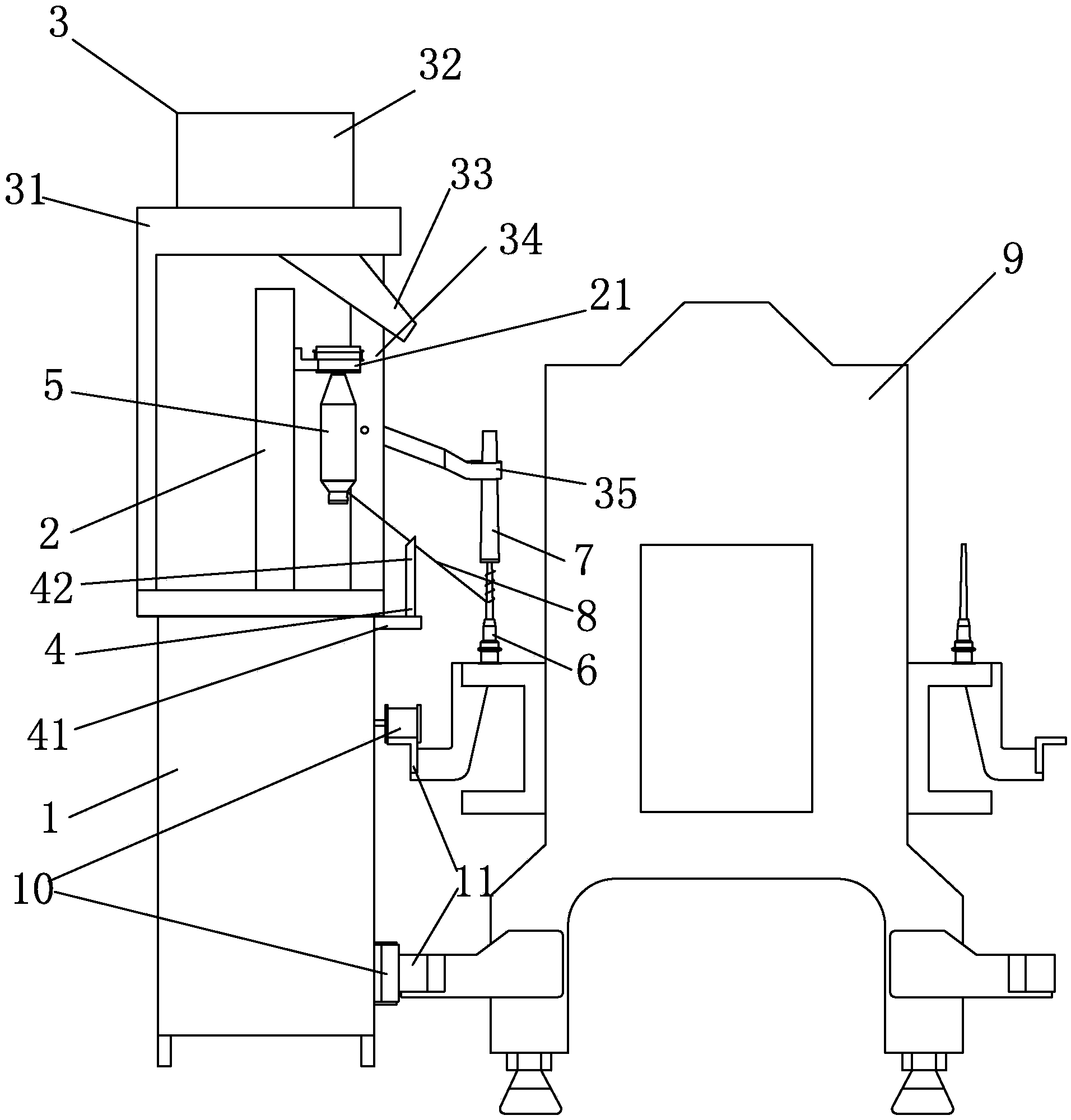

Doffing process used for ring-spinning doffer

The invention discloses a doffing process used for a ring-spinning doffer, relates to a doffing process of the doffer used for a ring-spinning spinning frame, and provides a doffing method of the doffer. According to the doffing method of the doffer, the labor cost can be reduced, and the production efficiency can be improved. The doffing process used for the ring-spinning doffer includes the steps of pulling a full bobbin away from a spindle blade through a bobbin pulling device on the doffer under the adjustment and control of a control system, then inserting an empty bobbin into the spindle blade of the spinning frame in a sleeved mode through a bobbin inserting device on the doffer, cutting off yarns connected between the spindle blade and the full bobbin through a yarn cutting device on the doffer, finally placing the full bobbin into the doffer through the bobbin pulling device on the doffer, in this way, repeating the motions, and achieving the aim that the empty bobbin is firstly inserted and then the yarns are cut. The production efficiency is accordingly improved.

Owner:TONGLING SOBONE INTELLIGENT EQUIP

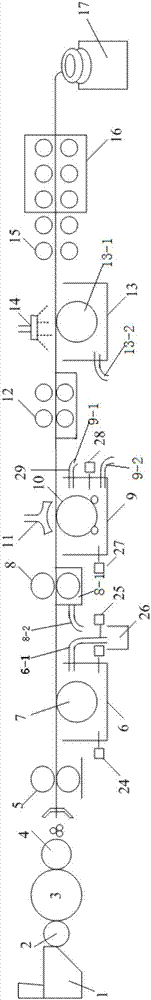

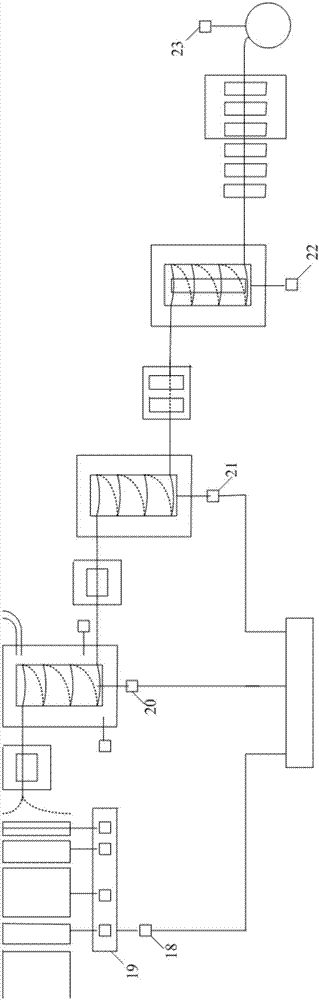

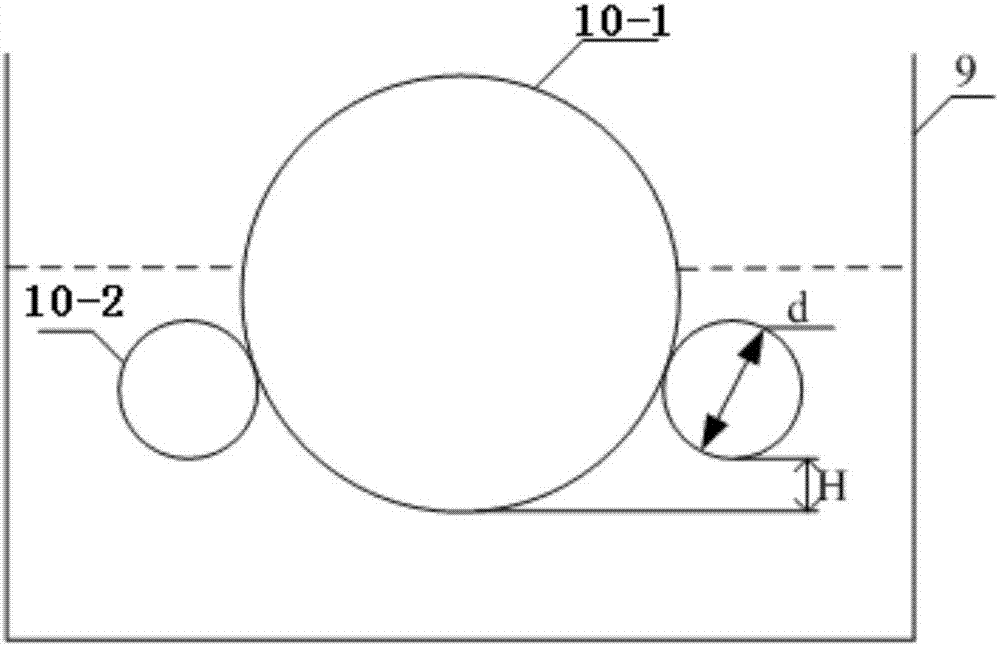

Continuous indigo dyeing device and dyeing method for cotton sliver

InactiveCN107059284AIncreased production flexibilityReduces unintended draft tension effectsLiquid/gas/vapor removal by squeezing rollersFibre cleaning/openingEngineeringPre treatment

The invention discloses a continuous indigo dyeing device for cotton sliver. The device comprises a pre-treatment device, a dyeing device, a raw cotton feeding device and a post-treatment device, all of which are orderly arranged. The pre-treatment device comprises the raw cotton feeding device, a loosening roll, a carding roll, a collection and slivering device, a cotton sliver wetting device, a scouring groove, a scouring rotary drum and a pair of liquid pressing rolls A. The continuous indigo dyeing device for cotton sliver has the following beneficial effects: sliver equipment, sliver scouring, sliver dyeing and water scrubbing and drying processes are effectively integrated so that phenomena in the prior art are avoided during a sliver processing and production process such as non-uniformity and broken ends due to accidental stretching; and high efficiency short-flow production of denim indigo is achieved. The invention further discloses a method for dyeing with the dyeing device.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Aromatic bamboo charcoal fiber and production process thereof

ActiveCN103541035AGood deodorizing functionGood air permeabilityArtificial filaments from viscoseWet spinning methodsAnti bacterialBamboo charcoal

The invention aims at meeting market customer demands of a product, solving the problem of poor spinnability of bamboo charcoal viscose fiber and providing aromatic bamboo charcoal fiber and a production process thereof. The aromatic bamboo charcoal fiber is characterized in that the fiber contains 0.01-10% by weight of aromatic fragrance and 0.1-10% of bamboo charcoal, the ammonia absorption rate is not less than 50%, the air permeability is not less than 500mm / s, and the color fastness to washing is level 4-5. The aromatic bamboo charcoal fiber provided by the invention has not only anti-bacterial, anti-ultraviolet and deodorizing functions, but also good air permeability and absorption, and can effectively and continuously emit aroma and realize the effects of relieving stress and refreshing people.

Owner:YIBIN HIEST FIBER +1

Antibacterial bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556278AImprove breathabilityImprove antibacterial propertiesArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceAnti bacterial

The invention provides an antibacterial bamboo charcoal viscose fiber and a preparation method thereof, which meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The antibacterial bamboo charcoal viscose fiber is characterized by being obtained by mixing an antibacterial bamboo charcoal solution with viscose through injection before spinning, and carrying out wet spinning and post-treatment, wherein the antibacterial bamboo charcoal solution is formed by mixing an antibacterial solution and a bamboo charcoal solution. The fiber comprises the components by weight percent: 0.01-10 percent of an antibacterial agent and 0.1-10 percent of bamboo charcoal; the bacteriostasis rate is more than or equal to 90 percent; the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The antibacterial bamboo charcoal viscose fiber has functions of ultraviolet prevention and deodorization and is high in air permeability and absorptivity; furthermore, the antibacterial effect of the antibacterial bamboo charcoal viscose fiber is better than that of the common bamboo charcoal fiber; the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

Two-for-one twister

InactiveCN1844521ADoes not affect strengthAvoid decapitationTextiles and paperYarnUltimate tensile strength

This invention relates to a two-for-one twister, which includes frame, at least two yarn storage canisters which are arranged on the frame, and the yarn guiding device which is arranged on the frame, and the wind device, wherein the yarn guiding device is arranged between the yarn storage canister and the wind device, and the frame between two adjacent yarn storage canisters is arranged with the yarn divider, and the yarn divider is the stainless steel broad whose surface is lubricous. This invention can avoid the great damage to the yarn when touching the yarn divider, and prevent the yarn from breaking, and it can be used for long time still with stainless and lubricous surface.

Owner:屠建文

Production method of super-strength chinlon 66 fiber

ActiveCN108441974AImprove spinnabilityUniform and stable viscosityMonocomponent copolyamides artificial filamentMelt spinning methodsFiberMaterials science

The invention discloses a production method for super-strength chinlon 66 fiber. The production method comprises the main steps of nylon 66 saline solution, concentration polymerization, spinning, cooling, oiling, drafting forming and winding. The production method is simple in technology and easy to implement, batched and continuous production of the super-strength chinlon 66 fiber can be achieved, the production efficiency is high, the yield is large, the performance of product batch pieces is uniform and stable, the breaking strength of the obtained super-strength chinlon 66 fiber reaches 10.0-10.4 g / d, the elongation at break reaches 16-22%, the elongation rate under the constant load reaches 10.5-13.5%, the dry hot shrinkage rate is 4.7-7.7%, the strength retention is larger than 90%,and the method has the advantages of being high in strength, low in unit weight, good in fatigue resistance, impact resistance, friction resistance and heat resistance and the like.

Owner:SHEN MA INDUSTRY CO LTD

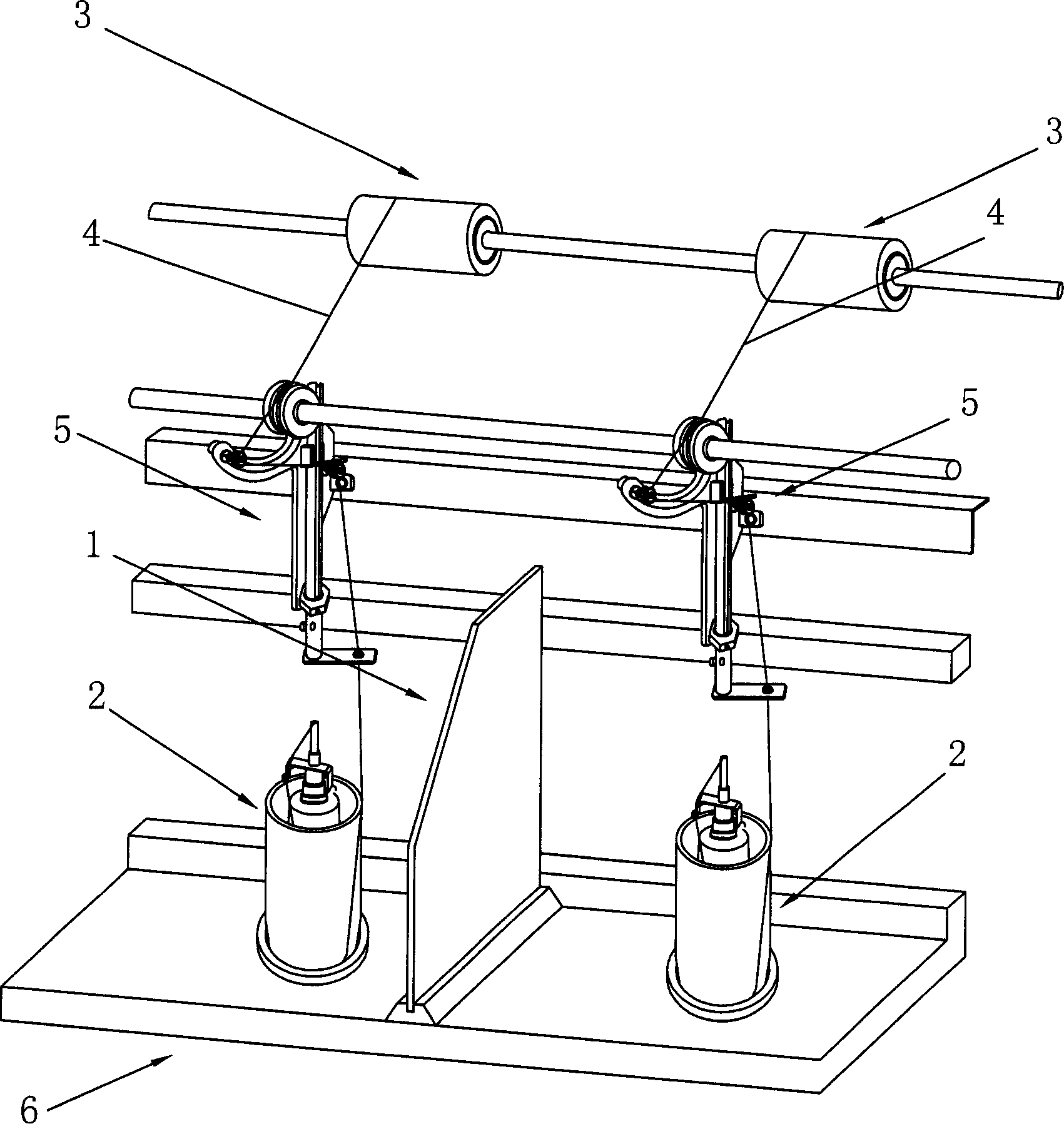

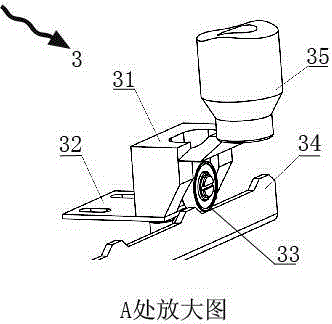

Spinning frame automatic doffing trolley

The invention relates to an automatic doffing trolley of a spinning machine. The automatic doffing trolley comprises a doffing trolley body and an automatic doffing device. The automatic doffing device is arranged on a bottom plate located on the upper portion of the doffing trolley body. A pre-loosening mechanism of the automatic doffing device is arranged on the bottom plate of the doffing trolley body through a spring steel plate. A pre-loosening block is fixed on the spring steel plate. When the trolley moves forwards, the pre-loosening block moves forwards along with the trolley, is inserted into the lower end of a bobbin, and enables the lower end of the bobbin to ascend along an oblique plane of the pre-loosening block. Then, under the action of a plane cam, the pre-loosening block abuts against the lower end of the bobbin, moves upwards in the direction parallel to the axis of a spindle blade and enables the full bobbin to break away from the spindle blade under the blocking action of a spindle hook. The bobbin bounced upwards enters a manipulator device. The upper ends of claws of the manipulator device clamp the upper end, without yarn, of the full bobbin and then pull the full bobbin out. The pre-loosening force of the pre-loosening mechanism is parallel to the axis of the spindle blade and has little influence on a spindle bearing. The manipulator device clamps the upper end, without the yarn, of the bobbin, and the quality index of the yarn can not be influenced.

Owner:SHANXI JINXIN CARD CLOTHING

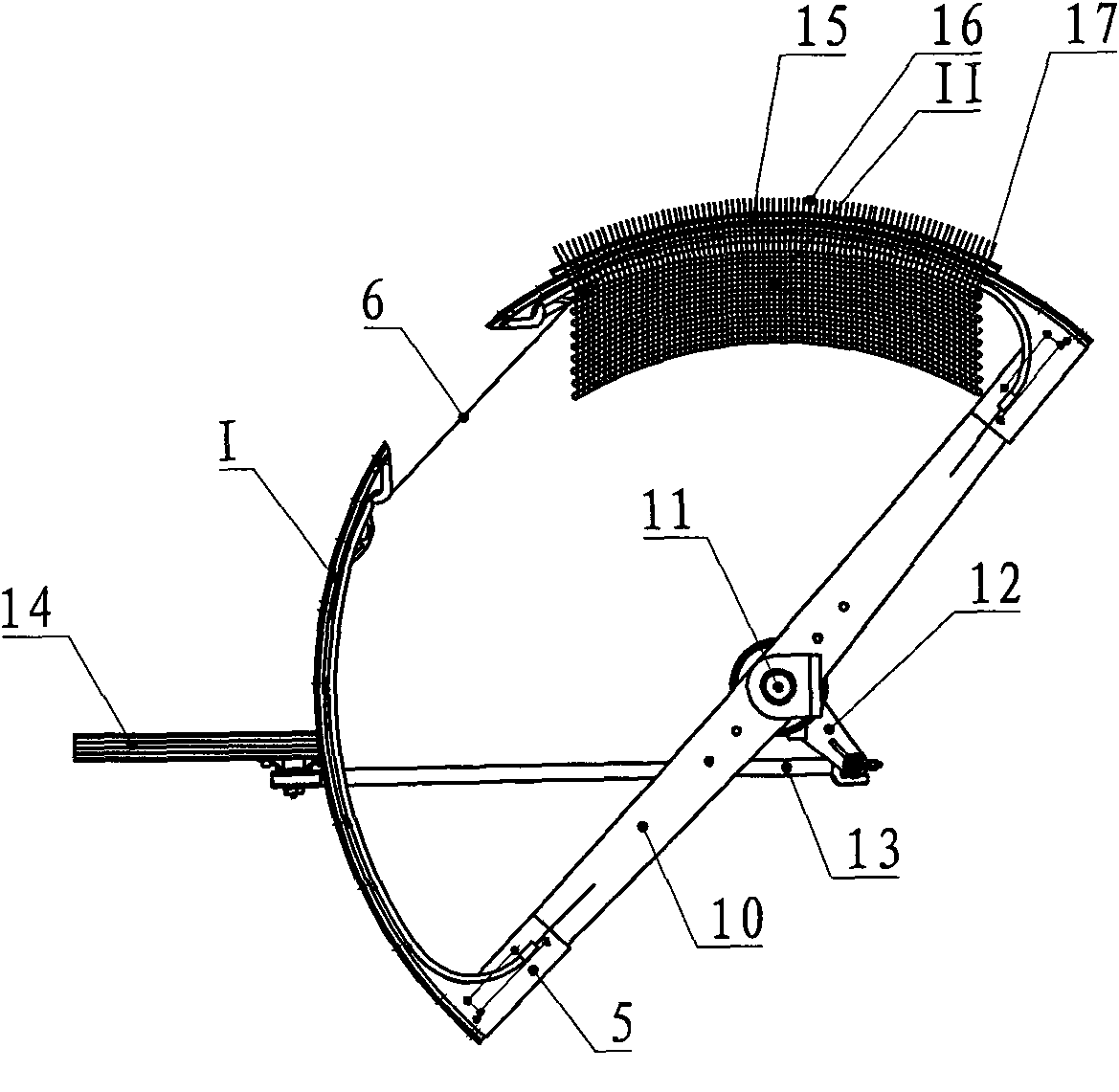

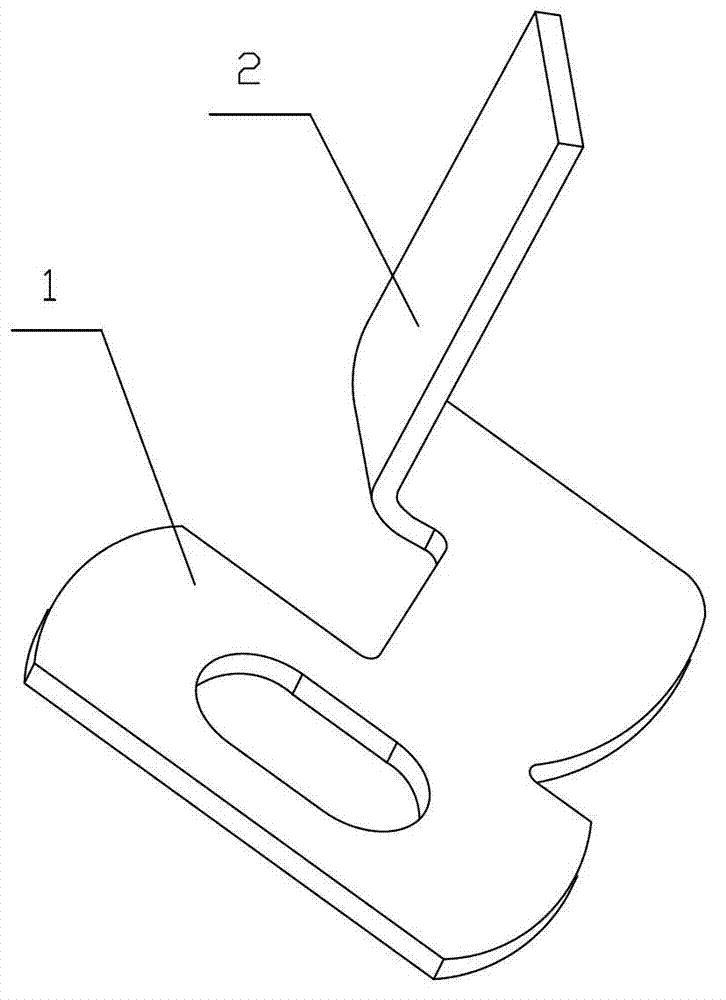

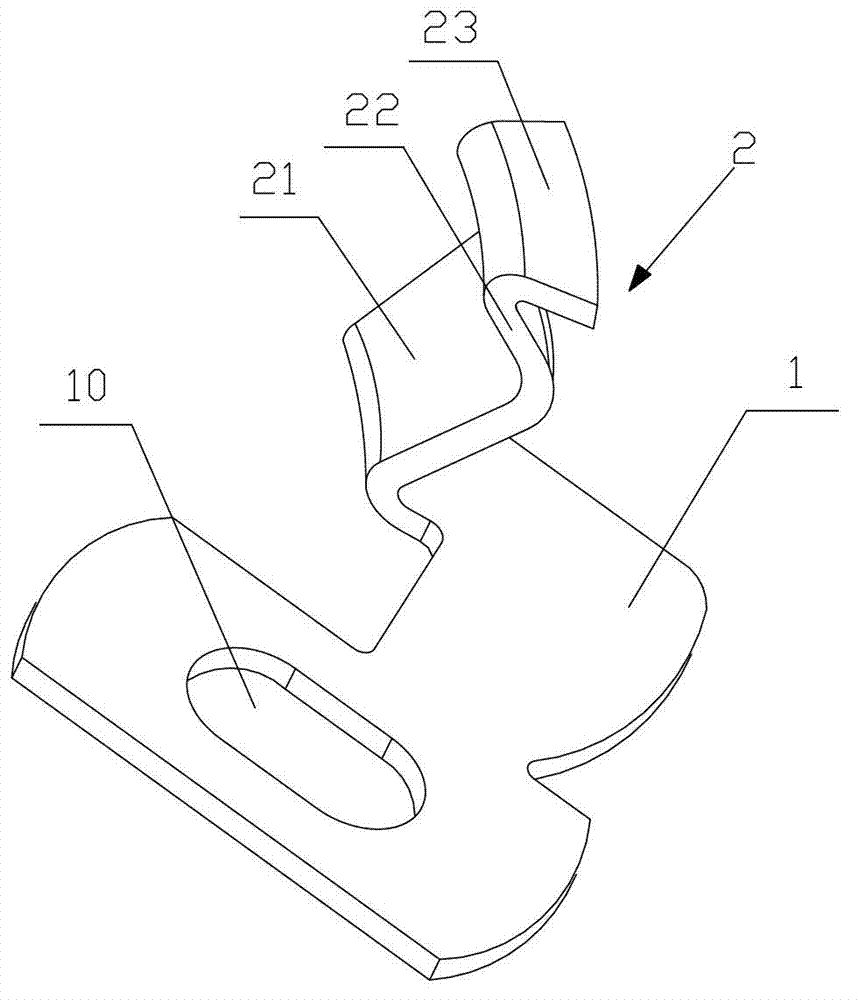

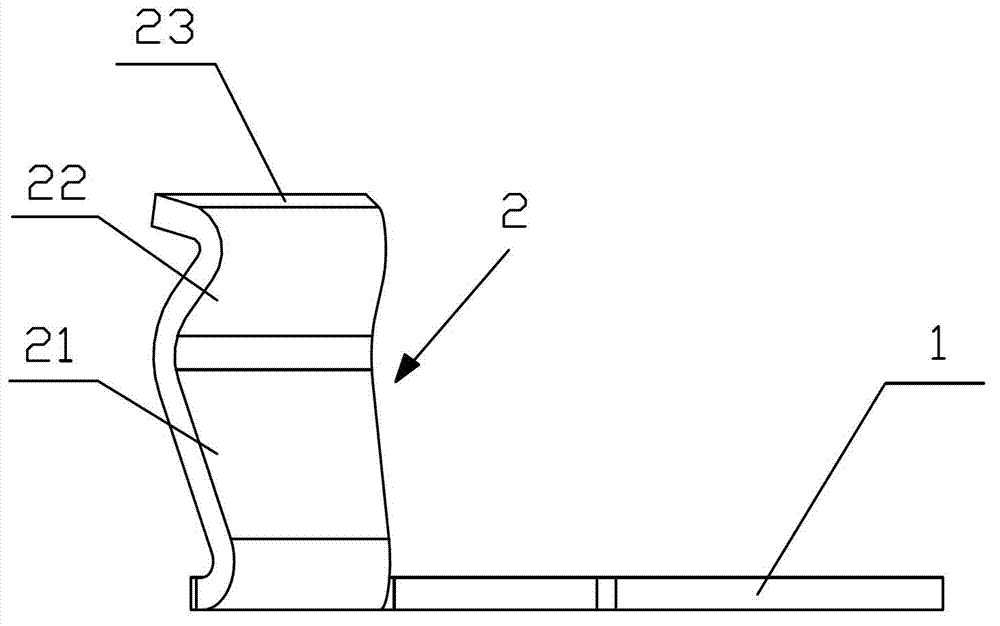

Sackcloth rapier loom

The invention provides a sackcloth rapier loom comprising a pair of rapiers (I), a heald frame and reeds (15). Either rapier (I) enables weft yarns to be woven into warp yarns (16) and is provided with a rapier head with a weft yarn outlet; the rapier heads of the rapiers (I) are mounted in opposite directions, wherein either rapier (I) is bent in an arc, and the weft yarn outlet is arranged at the inner side of the arc; the chord length of either rapier (I) is larger than the breadth of woven sackcloth (II); the two rapiers (I) are mounted on a central shaft (11) in the circle center of the arcs by rapier arms (10); the central shaft (11) and the heald frame lift the warp yarns (16) in parallel directions; a swinging arm (12) using the central shaft (11) as a rotating shaft is fixedly connected with the rapier arms (10); and a swinging angle of the swinging arm (12) is larger than a central angle occupied by the breadth of the woven sackcloth (II) on the trace of the rapier heads. Compared with the prior art, a pair of driving mechanisms can simultaneously drive the two rapiers to work, thereby the invention lowers noise, reduces energy consumption, improves the motion stability of the rapiers and also decreases the manufacture material consumption of the loom and the labor cost.

Owner:ZHEJIANG GOLDEN EAGLE

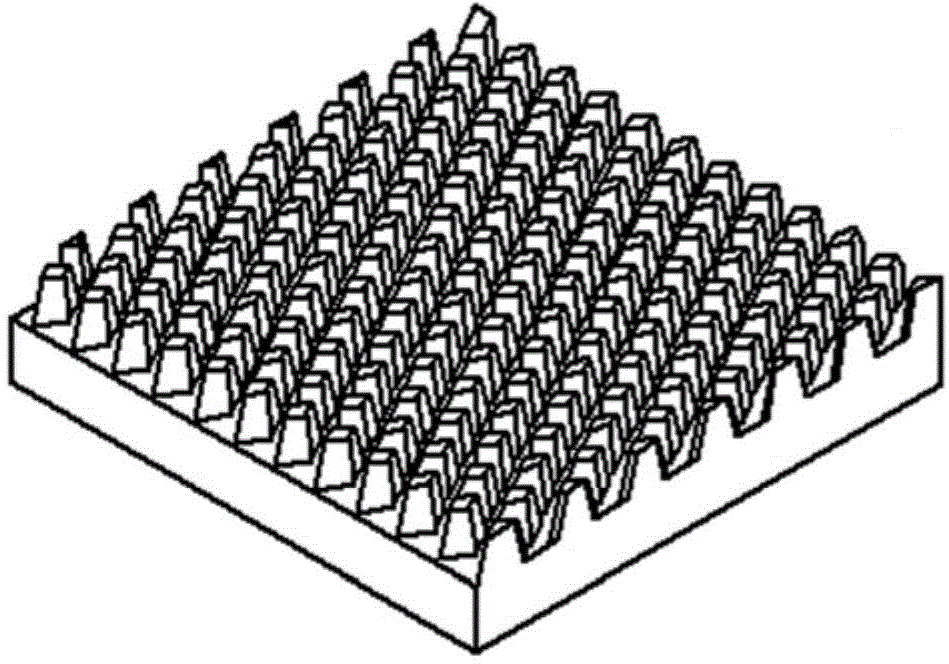

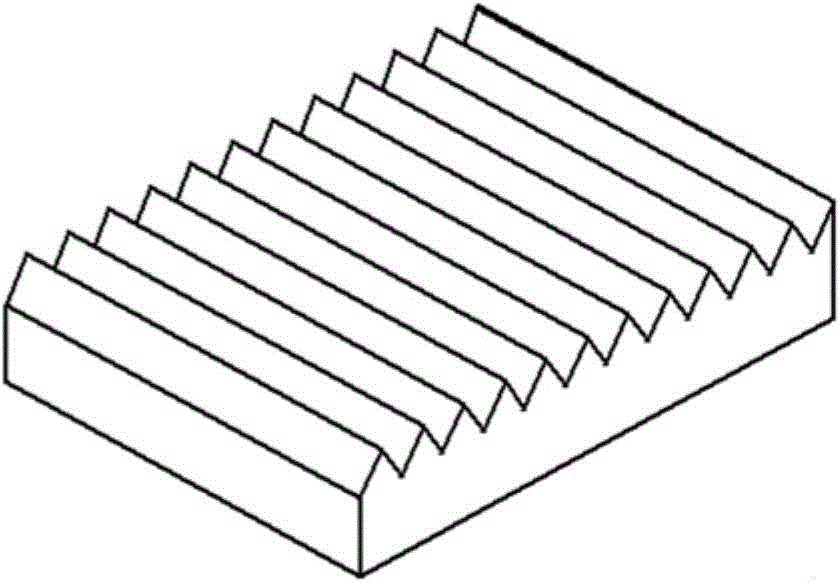

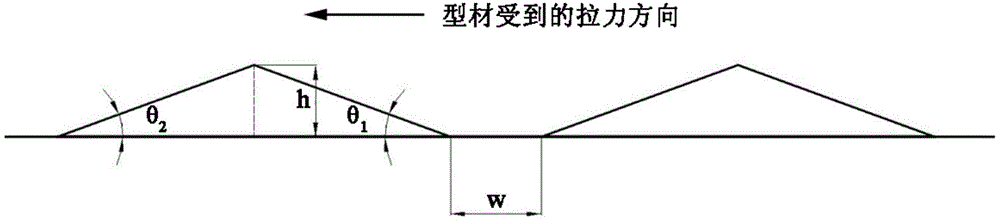

Anti-slip tooth design applicable to high-hardness metal sectional material stretching and straightening

The invention relates to an anti-slip tooth design applicable to high-hardness metal sectional material stretching and straightening. Anti-slip teeth arranged at a tong jaw of a stretching machine are straight teeth with isosceles-triangle-shaped cross sections, the extending direction of the teeth is vertical to the stretching direction, the height of the teeth is 2 to 5mm, the front bottom angle and the back bottom angle of the anti-slip teeth are 10 degrees to 80 degrees, and the width of a platform among the teeth is 0 to 50mm; or the anti-slip teeth of the tong jaw of the stretching machine are barb-shaped teeth, the extending direction of the teeth is vertical to the stretching direction, the height of the teeth is 2 to 5mm, the front bottom angle of the anti-slip teeth is 10 degrees to 80 degrees, the back bottom angle of the anti-slip teeth is 90 degrees to 170 degrees, and the width of the platform among the teeth is 0 to 50mm. When the anti-slip teeth designed by a method provided by the invention is adopted, the slippage between sectional materials and the tong jaw can be effectively avoided, so that the stretching can be smoothly carried out, and in the use process for high-hardness metal sectional material stretching and straightening, the biting depth of the teeth is proper, so that the fracture due to stress concentration is avoided, in addition, a proper gap is formed among the teeth, and the clamp head skin can be prevented from being easily peeled off.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

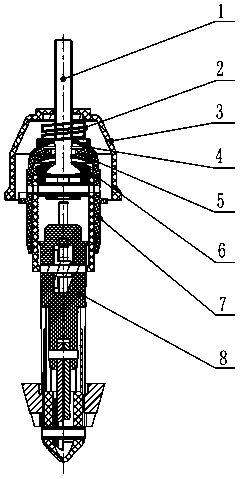

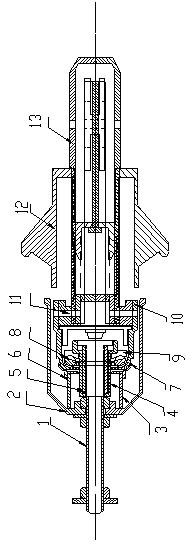

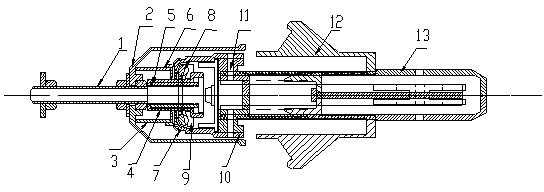

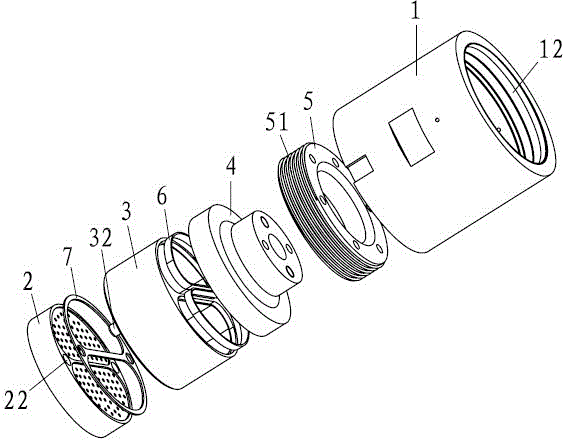

Magnetic levitation automatic constant yarn leading tension roving serial suspension spindle

InactiveCN104746187AConstant thread tensionLess rotational resistance and more stableContinuous wound-up machinesYarnSliding contact

The invention discloses a magnetic levitation automatic constant yarn leading tension roving serial suspension spindle. The suspension spindle comprises a suspension spindle body and a suspension spindle cap. A suspension rod bolt is fixed in the axial direction of the suspension spindle cap, the head portion of the suspension rod bolt is disposed on the outside of the suspension spindle cap, and the tail portion of the suspension rod bolt is disposed on the inside of the suspension spindle cap. A suspension spindle inner sleeve is arranged in the suspension spindle cap and is fixedly connected with the suspension spindle body through a pin, a group of Gaussian magnets opposite in SN polarity are sleeved on the tail portion of the suspension rod bolt in the axial direction and comprise floating sheets and bearing sheets. A damping ring in sliding contact is arranged above the suspension spindle inner sleeve, a damping spring is sleeved between the outside of the top of the damping ring and the inside of the top of the suspension spindle cap, and the suspension spindle cap is sleeved on the upper portion of the damping spring. The suspension spindle has the advantages of being applicable to all spun yarn leading tension conditions, enabling the yarn leading tension to be constant automatically along with the roving weight constant change during spinning, preventing breaking and falling during yarn leading and being simple in structure, convenient to promote and long in service life.

Owner:江阴市通隆纺织机械有限公司

Aromaticity bamboo charcoal fiber and preparation method thereof

ActiveCN103556264AImprove breathabilitySignificant shielding rateArtificial filaments from viscoseWet spinning methodsSpinningPulp and paper industry

The invention provides an aromaticity bamboo charcoal fiber and a preparation method thereof in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The aromaticity bamboo charcoal fiber is characterized in that a finished product is obtained by taking cellulose fiber pulp as a raw material, mixing an aromaticity bamboo charcoal solution and viscose through injection before spinning and performing wet spinning and post-treatment, wherein the aromaticity bamboo charcoal solution is prepared by mixing fragrant masterbatches and a bamboo charcoal solution; the fragrant masterbatches contain perfumes; the fragrant perfume content of the fiber is 0.01-10 percent; the bamboo charcoal content is 0.1-10 percent; the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The aromaticity bamboo charcoal fiber disclosed by the invention has the functions of bacterium and ultraviolet prevention and deodorization, is high in air permeability and hygroscopicity, can effectively and continuously scatter fragrance and has the effects of relieving pressure and enabling people to be invigorating.

Owner:YIBIN HIEST FIBER +1

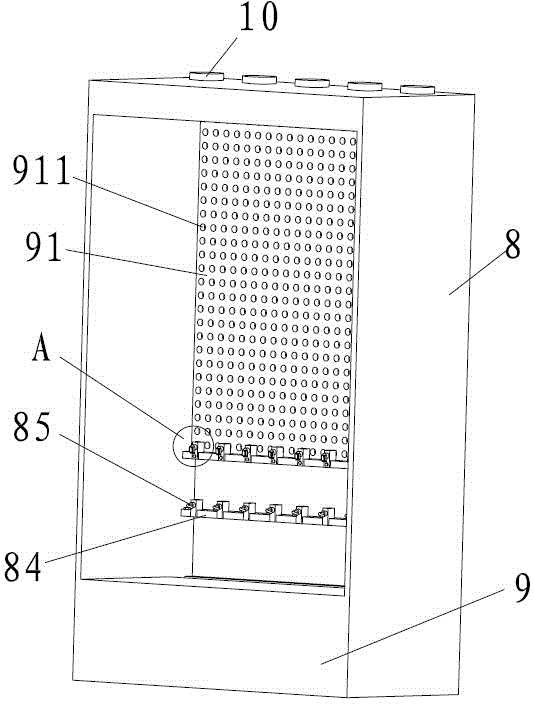

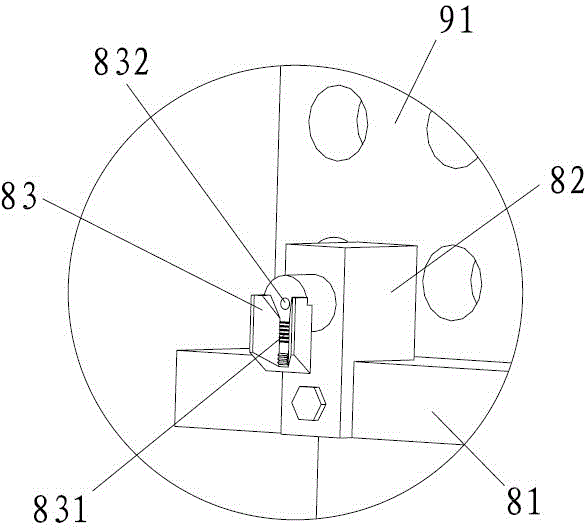

High-speed double-twisting machine

InactiveCN103572416ADoes not affect strengthAvoid decapitationContinuous wound-up machinesYarnStructural engineering

The invention relates to a high-speed double-twisting machine, comprising a machine frame, at least two yarn storage barrels, yarn guiding devices and friction rollers, wherein the yarn storage barrels, the yarn guiding devices and the friction rollers are installed on the machine frame in sequence from bottom to top; a segregation board is arranged between each two adjacent yarn storage barrels; the segregation boards are installed on the machine frame; particularly, the segregation boards are made from stainless steel and have a smooth surface respectively; each yarn guiding device comprises a tension frame and a yarn guiding wheel; a sliding groove is formed in each tension frame; the yarn guiding wheels are installed in the sliding grooves and can continuously slide along the sliding grooves. The high-speed double-twisting machine provided by the invention has multiple advantages that yarns can be effectively prevented from burring, the yarn guiding devices are convenient to adjust, and the like.

Owner:SHAOXING TEXTILE MACHINERY GRP

Antistatic bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556280ASignificant far infrared health functionSignificant UV shielding rateArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceMoisture absorption

The invention provides an antistatic bamboo charcoal viscose fiber and a preparation method thereof, which fill up the blank of the conventional antistatic bamboo charcoal viscose fiber and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The antistatic bamboo charcoal viscose fiber is characterized by comprising 1-10 percent of graphite and 0.1-10 percent of bamboo charcoal, wherein the volume resistivity is lower than 1,010 ohm.cm, the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s, and the color fastness to washing is of 4-5 level. The antistatic bamboo charcoal viscose fiber disclosed by the invention has the functions of bacterium and ultraviolet prevention and deodorization, is high in air permeability and moisture absorption and has soft handfeel; the antistatic effect is obvious and lasting.

Owner:YIBIN HIEST FIBER +1

Rough yarn-series suspended spindle capable of automatically keeping yarn leading tension constant

The invention discloses a rough yarn-series suspended spindle capable of automatically keeping yarn leading tension constant, which relates to the field of spinning machine components and is used for solving the problems of accidental micro-section traction and the formation of long snick yarn defects caused by easy falling of silvers when rough yarns approach a hollow tube since the yarn leading tension of the conventional suspended spindle cannot be kept constant and accidental extension and hard head projection are easily caused when a roving bobbin is filled with yarns. In a technology disclosed by the invention, a weight spring and a damping spring are arranged in a suspended spindle cap and used for adjusting the yarn leading tension; in a wide yarn leading tension range, a tension gear shifting device is arranged on the basis of the structure, fixed control force is pre-adjusted, and the spring is used for controlling the rest of the force value. The rough yarn-series suspended spindle has the characteristic of keeping the yarn leading tension of all common raw material-series rough yarns constant, and has the beneficial effects of simple structure, small increase in the cost and convenience for popularization.

Owner:江阴市通隆纺织机械有限公司

Spinning box

InactiveCN102912465AReduce frictionAvoid breakingSpinnerette packsArtificial thread manufacturing machinesYarnFiber

The invention relates to mechanical manufacturing of chemical fiber filament, in particular to a spinning box. According to the invention, the spinning box is achieved by the following technical scheme: the spinning box comprises a frame, a yarn spraying tank, an air blowing mechanism, a yarn guide module, a yarn leading module and a yarn collecting box, wherein the yarn spraying tank is arranged at the upper part of the frame; the air blowing mechanism is used for blowing air to yarns; the yarn guide module is arranged between the two sides of the frame; the yarn leading module is arranged between the two sides of the frame and positioned below the yarn guide module; the yarn collecting box is arranged below the frame; the yarn spraying tank comprises a tank cylinder and a yarn spraying plate, a yarn cup and a fluid passing body, wherein the yarn spraying plates are mounted in the tank cylinder and are provided with at least two yarn spraying areas with a plurality of fine holes; the yarn cup is provided with fluid passages corresponding to the yarn spraying areas one to one; the fluid passing body is provided with a fluid inlet and provided with shunting passages, which are communicated with the fluid inlet and corresponding to the fluid passages one to one; and the bottom of each fluid passage is a filter plate with a plurality of micro holes. According to the invention, the yarn spraying tank has no flowing dead point so that broken filaments and broken ends are prevented; moreover, as high yarn yield is obtained, the spinning box provided by the invention is beneficial for increasing production efficiency.

Owner:ZHEJIANG HUATESI POLYMER TECHN

Method for dyeing and finishing bamboo fiber fabric

InactiveCN107201666AGuaranteed water absorptionGuaranteed feelSingeingDry-cleaning apparatus for textilesFiberOxygen

The invention provides a method for dyeing and finishing a bamboo fiber fabric, and relates to an improvement of a method for treating a fabric, in particular to an improvement of the method for dyeing and finishing the bamboo fiber fabric. The method provided by the invention adopts a dyeing and finishing process comprising the steps of enzyme desizing, singeing, oxygen bleaching, unhairing enzyme finishing, dyeing, and after finishing. The step of dyeing adopts a vat dye, presetting is carried out before dyeing at 140-150 DEG C to ensure that a cloth cover is flat before dyeing, and drying fixation is carried out after dye dipping treatment during the presetting before dyeing; and the dye for dyeing contains X%(o.w.f) anhydrous sodium sulphate of Yg / L, a substitution alkali M-231P:2-2.5 g / L, and a cotton leveling agent M-230K of 1-2 g / L, the temperature and time are 60 DEG C and 30-60 min, the bath ratio is 1:(6-10), and the M-231P is a substituent alkaline agent for dyeing of a reactive dye. The method provided by the invention enables the bamboo fiber fabric to keep water absorption after use, thereby ensuring a use hand feeling of the bamboo fiber fabric and the service life of the bamboo fiber fabric. Through adoption of the method, process flows are simplified and energy sources are saved. The unhairing enzyme finishing after oxygen bleaching improves the chromaticity and glossiness of a product, and normal temperature pressure jig dyeing is adopted to avoid the condition that the tension of a textile is too large, and effectively avoid phenomena of broken ends, scratches and the like, thereby reliably ensuring the quality of a product.

Owner:HENAN XINYE TEXTILE

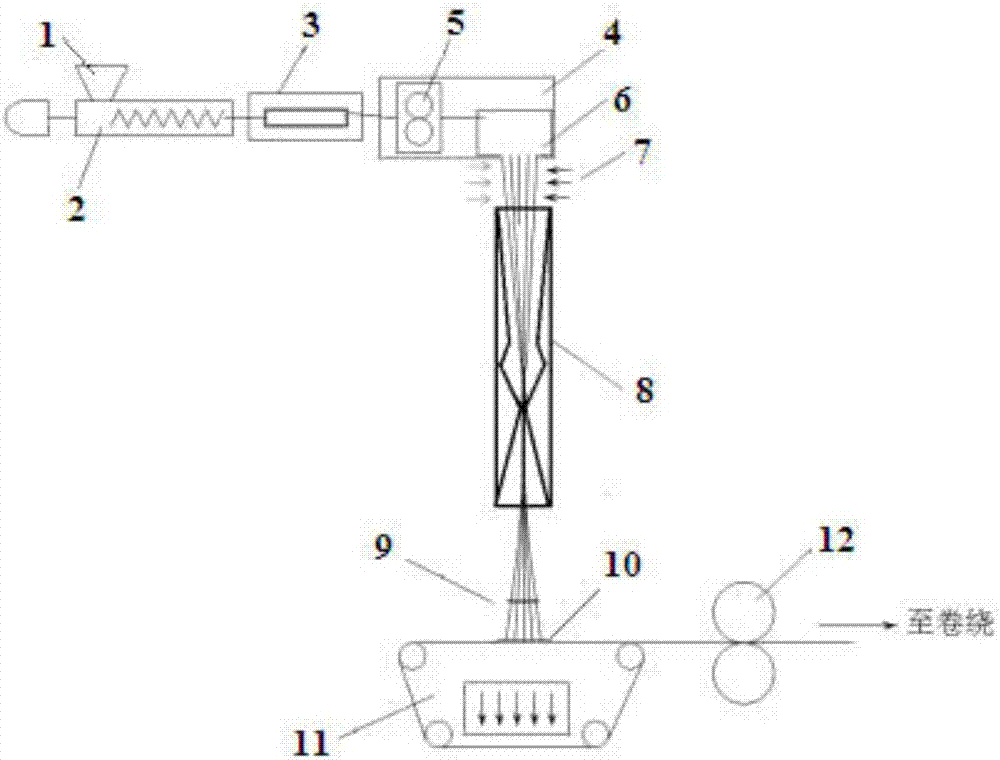

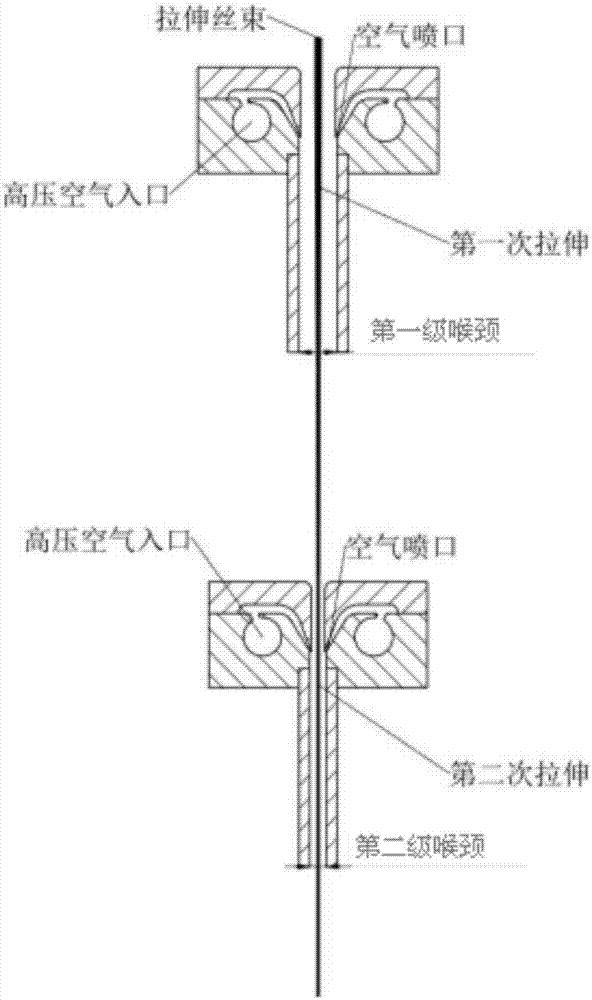

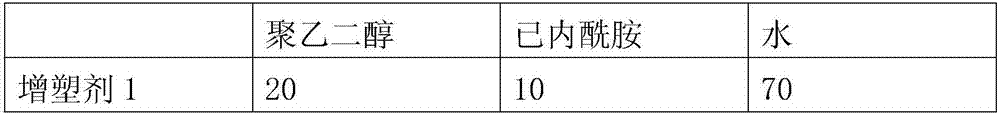

Manufacturing method and processing device for low-temperature water-soluble polyvinyl alcohol non-woven fabric

ActiveCN106948090AReduce phase separationAvoid phase separationArtificial thread manufacturing machinesSpinning head liquid feederPolyvinyl alcoholEngineering

The invention relates to the field of polyvinyl alcohol non-woven fabric, and especially relates to a manufacturing method and a processing device for a low-temperature water-soluble polyvinyl alcohol non-woven fabric. The device comprises a feeding opening, a screw extruder, a melt filter, a spinning manifold, a combined stretching slit, a silk reciprocator, an air suction device, and a reinforcing device. Through water plasticized melt-spinning, the fabric is directly formed, a manufacturing process of the polyvinyl alcohol non-woven fabric is greatly shortened, cost is reduced, and environmental pollution is reduced. The combination of the process and the device preferably solves a technical problem of low-temperature water-soluble polyvinyl alcohol non-woven fabric, and a polyvinyl alcohol non-woven fabric product whose water solution temperature is 20-40 DEG C is successfully manufactured. The method and the device are simple in process and low in cost, and are suitable for industrial production.

Owner:大连天马可溶制品有限公司

Preparation method of magnesium-carbon composite monolithic stopper rod for continuous casting

InactiveCN101722302BImprove thermal shock resistanceReduce generationMelt-holding vesselsCarbon compositesMaterials preparation

The invention belongs to the technical field of novel fire resistant material preparation and provides a preparation method of a magnesium-carbon composite monolithic stopper rod for continuous casting. The rod body of the monolithic stopper rod is made of an aluminum-carbon material, the rod head is made of a low carbon magnesium-carbon material, and the mixing transition of the aluminum-carbon material and the low-carbon magnesium-carbon material is adopted between the rod head and the rod body. A main raw material of the material of the rod head is fused magnesia, and 3-8 percent by weightof aluminum-silicon alloy power, 0.5-2 percent by weight of BN and 8-12 percent by weight of graphite are also added. The safety when in use is guaranteed through optimizing the grain composition of the graphite used by the magnesium-carbon material and adding the aluminum-silicon alloy capable of forming a ceramic binding phase in a heat treatment process and the BN capable of reducing the thermal expansion coefficient to improve the thermal shock resistance of the magnesium-carbon material. In addition, the uniform mixing transition between the rod head material and the rod body material isformed, and the generation of thermal stress is reduced as much as possible during thermal shocks so as to prevent end break phenomena when in use.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Textile flyings cleaner

InactiveCN103205828AClean up thoroughlyOperating speed effectTextiles and paperEngineeringYarn strength

The invention discloses a textile flyings cleaner which comprises a bottom plate and a cleaning plate. The bottom plate extends upwardly to form the cleaning plate, and the cleaning plate is transversely bent to form a first cleaning plate and a second cleaning plate by a preset included angle. During high-speed rotation of a steel wire ring, air flow is generated between the first and second cleaning plates, so that flyings on the steel wire ring can be thoroughly cleaned under impact of the air flow. On one hand, breakage of yarns due to flyings is avoided; on the other hand, the rotation speed of the steel wire ring is unaffected by the flyings, and accordingly, the service life of the steel wire ring is prolonged. Furthermore, yarn quality is protected from being affected by the flyings, and yarn strength is improved.

Owner:TIANCHANG LIHENG TEXTILE MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com