Substrate cartridge, substrate cartridge system, and substrate fitting system

A technology for assembling equipment and storage systems, applied in lighting and heating equipment, transportation and packaging, storage devices, etc., can solve problems such as damage to circuit boards, difficult to take out, etc., to achieve the effect of permanent connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

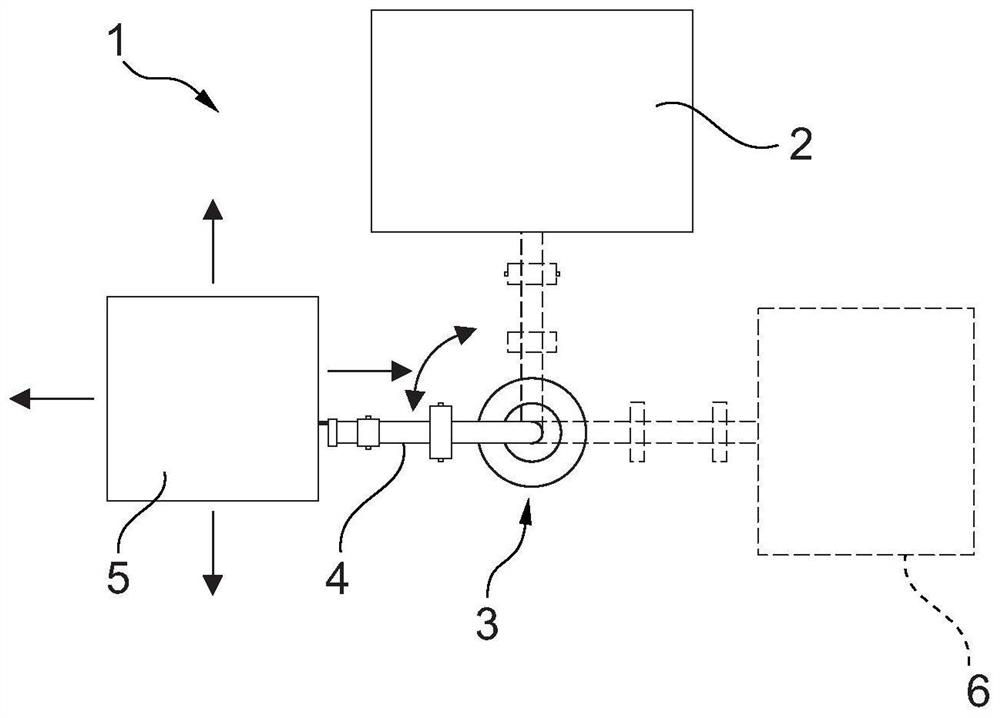

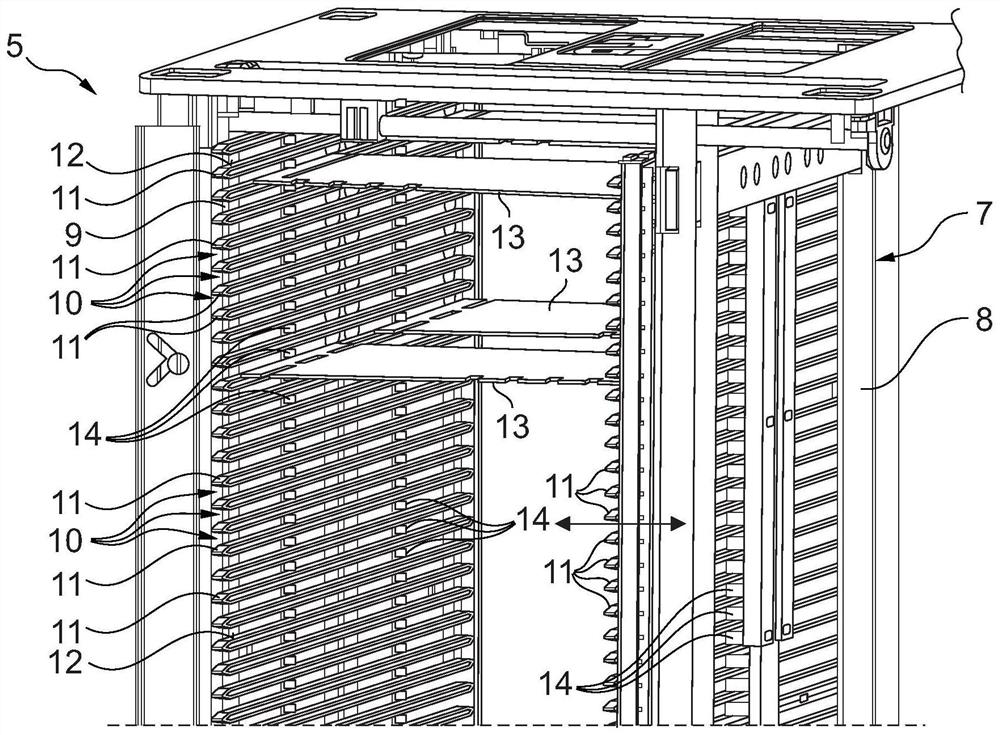

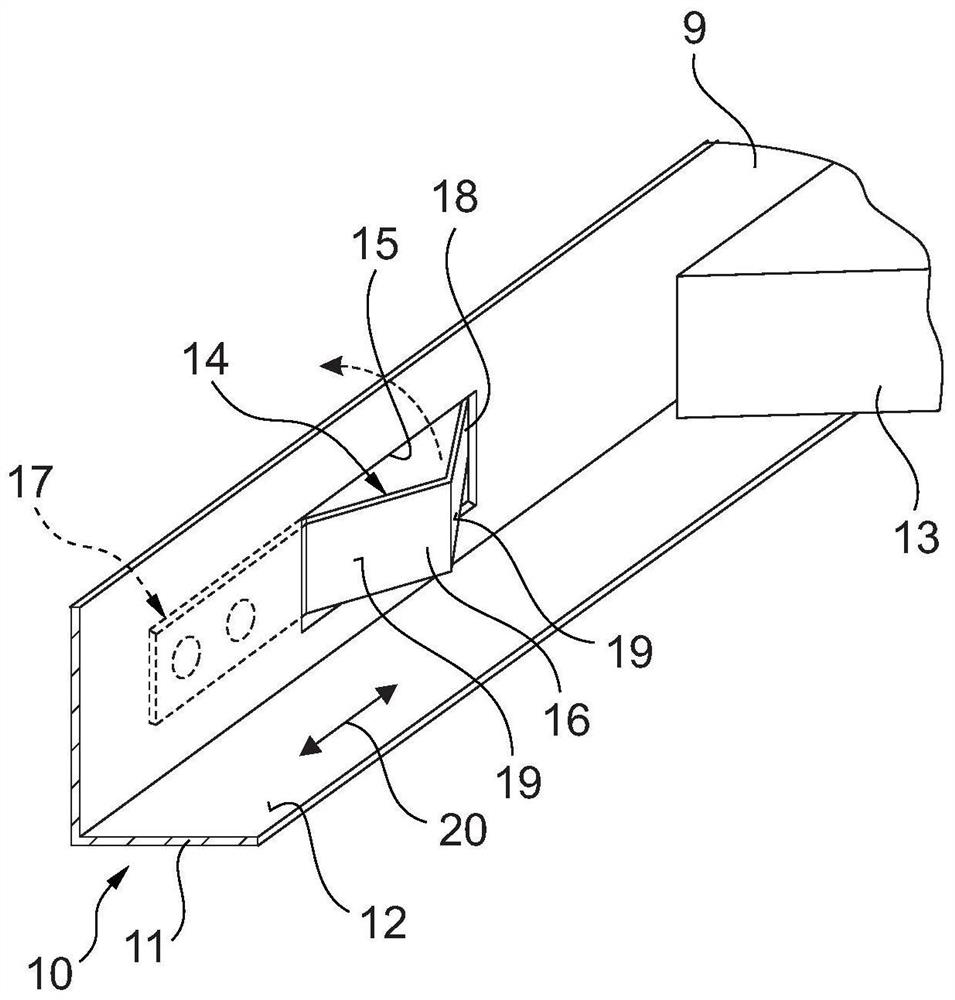

[0028] figure 1 In a simplified perspective plan view, a substrate assembly device 1 is shown, which has a substrate assembly device 2, by means of which substrates, in particular circuit boards, wafers, solar cells, The carrier, in particular a carrier plate or a carrier slot or the like, is equipped with identical or different, in particular electrical / electronic components. The substrate assembly device 1 also has a device 3 for transporting the substrate to be assembled to the assembly device 2 and away, wherein the device 3 is configured as a robot arm 4 here. The substrate assembly apparatus 1 also has a storage section 5 for accommodating substrates to be assembled. The substrate storage 5 is used for supplying and / or for receiving substrates to be mounted or mounted. Optionally, the assembly device 1 has a further substrate storage 6, whereby, for example, substrates to be assembled can be removed from the substrate storage 5, transported to the assembly device 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com