Pressing strip structure of gasket roll channel of gasket placing machine of wire rod packing machine

A technology of balers and gaskets, which is applied to the parts, packaging, transportation and packaging of strapping machines, can solve problems such as restricting the promotion and use of patents, affecting the operation of equipment and devices, and prolonging the deformation time, so as to achieve favorable equipment operation and excellent performance. Technical effects, effects that are less prone to failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

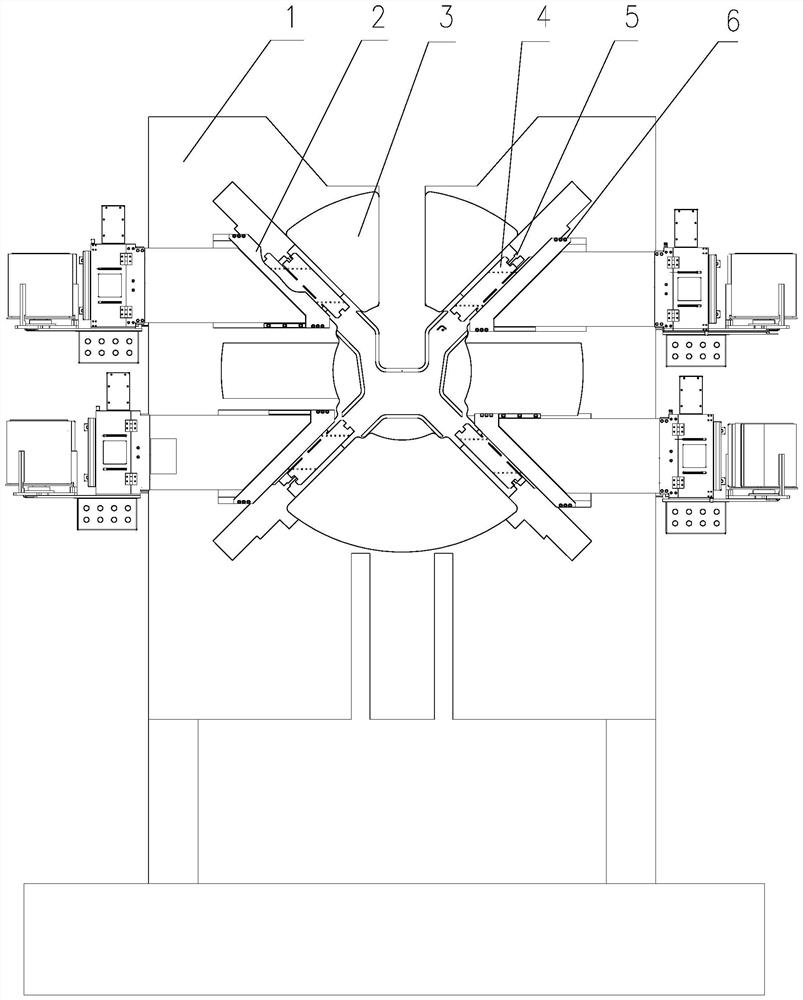

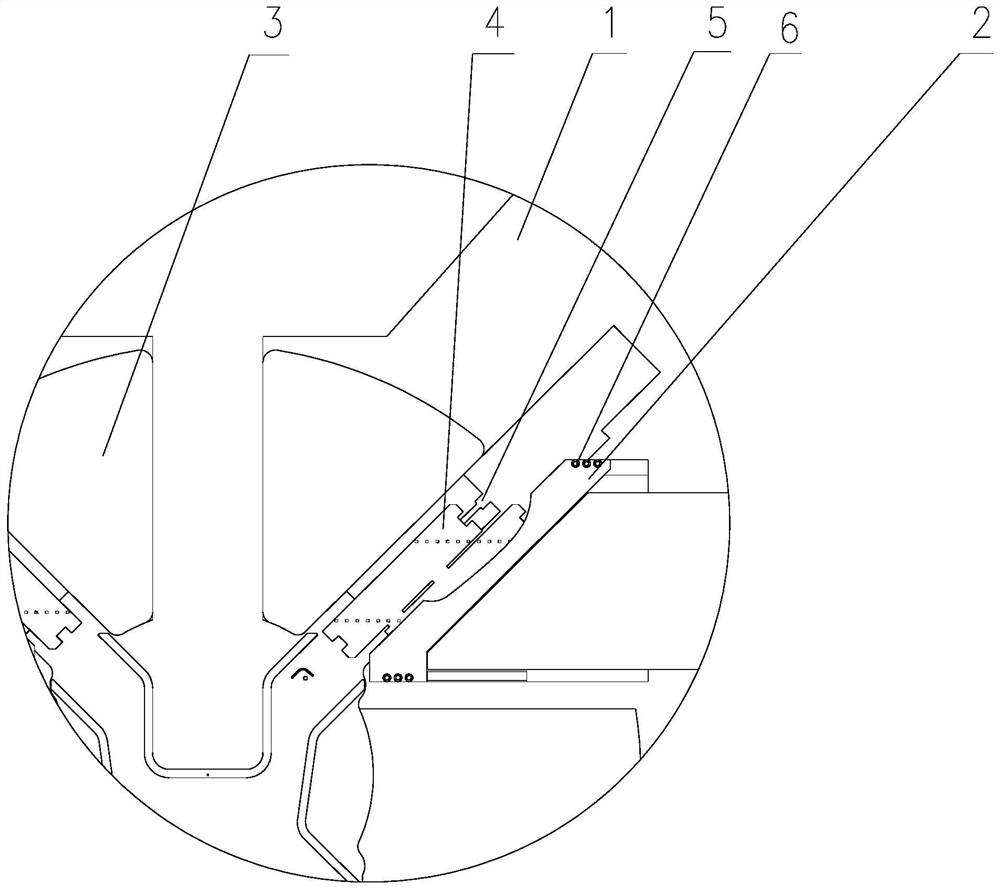

[0031] The utility model relates to a layering structure of a gasket roll channel of a gasket placement machine for a wire rod packing machine.

[0032] The four opposite corners of the platen 1 of the wire rod packing machine are respectively provided with a continuous pushing mechanism for the gasket, and the gasket rolls are continuously pushed one by one through the passage of the anti-frustration disc 3 to the position of the slot 5 of the press plate 1, and the slot 5 At the notch position, the bead 2 is set above the gasket 4;

[0033] It is characterized in that: the pressure bar 2 is floating and fixed on the notch position of the wire slot 5 of the pressure plate 1 with a spring 6 structure,

[0034] When the outer back of the bead 2 is under pressure, the bead 2 moves down, the inner wall of the bead 2 presses against the gasket 4 and presses on the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com