Air intake valve of screw air compressor

A technology of air compressors and intake valves, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as high cost, complex structure, and high probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

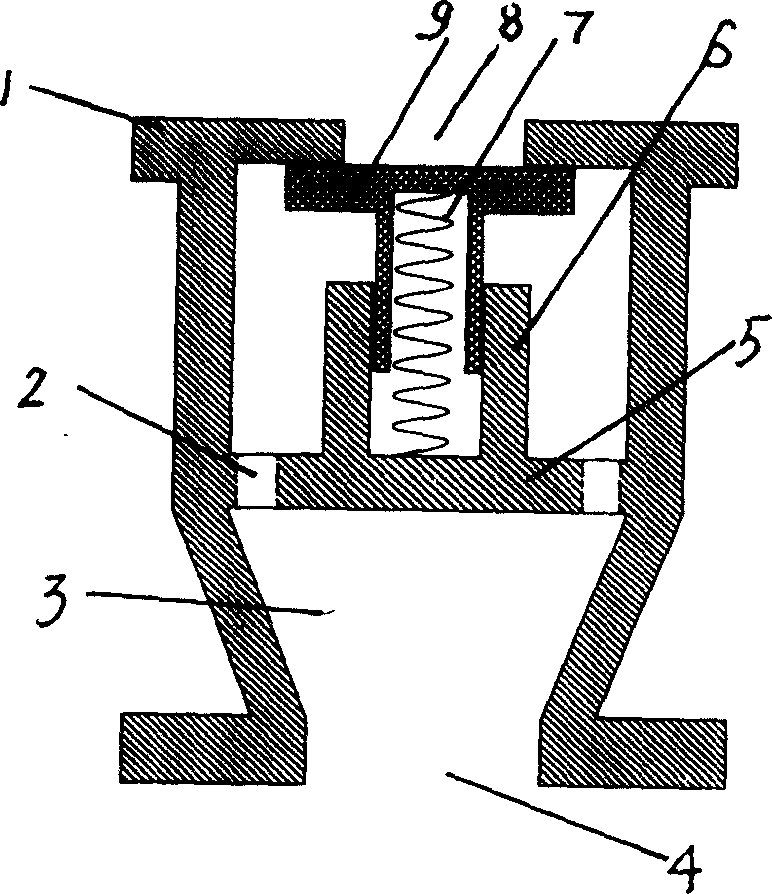

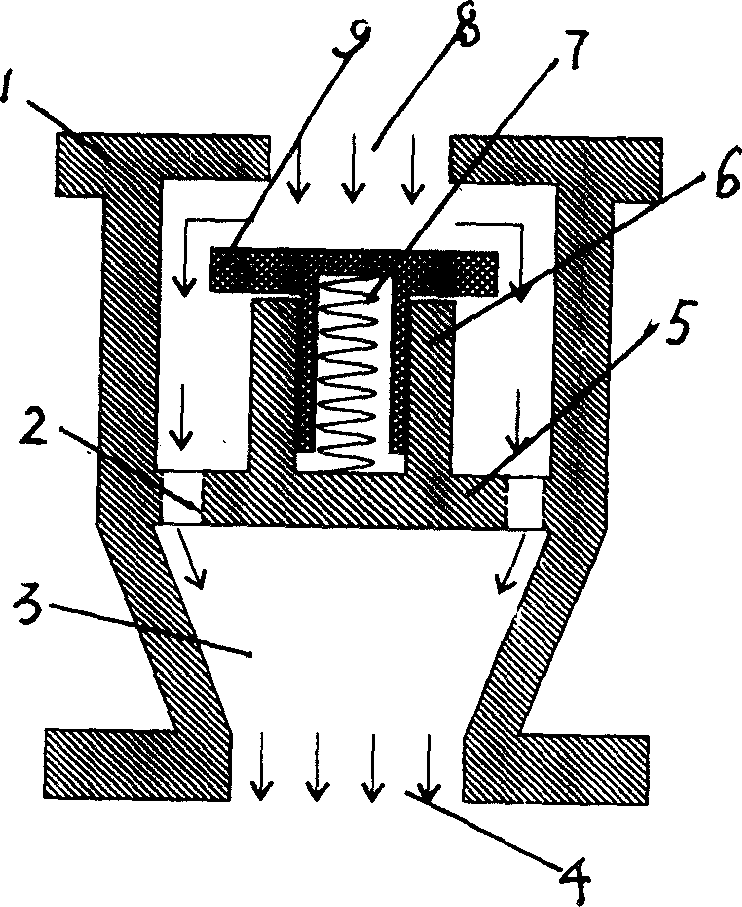

[0012] see figure 1 , figure 2 And Fig. 4, a kind of novel air inlet valve of screw air compressor, comprises the casing 1 that has air inlet 8, inner cavity 3 and air outlet 4, and there is a disc 5 in inner cavity 3, and the periphery of disc 5 Evenly distributed with some air holes 2, the center of the disc 5 is provided with a cylinder 6, the upright part of the T-shaped movable door cover 9 is hollow, and the spring 7 is placed in the upright part of the T-shaped movable door cover 9, and the T-shaped movable door cover 9 is upright Partially inserted into the cylinder 6, the T-shaped movable door cover 9 covers an area greater than that of the air inlet 8, and the housing 1, the disk 5 and the cylinder 6 are integral and form a valve body.

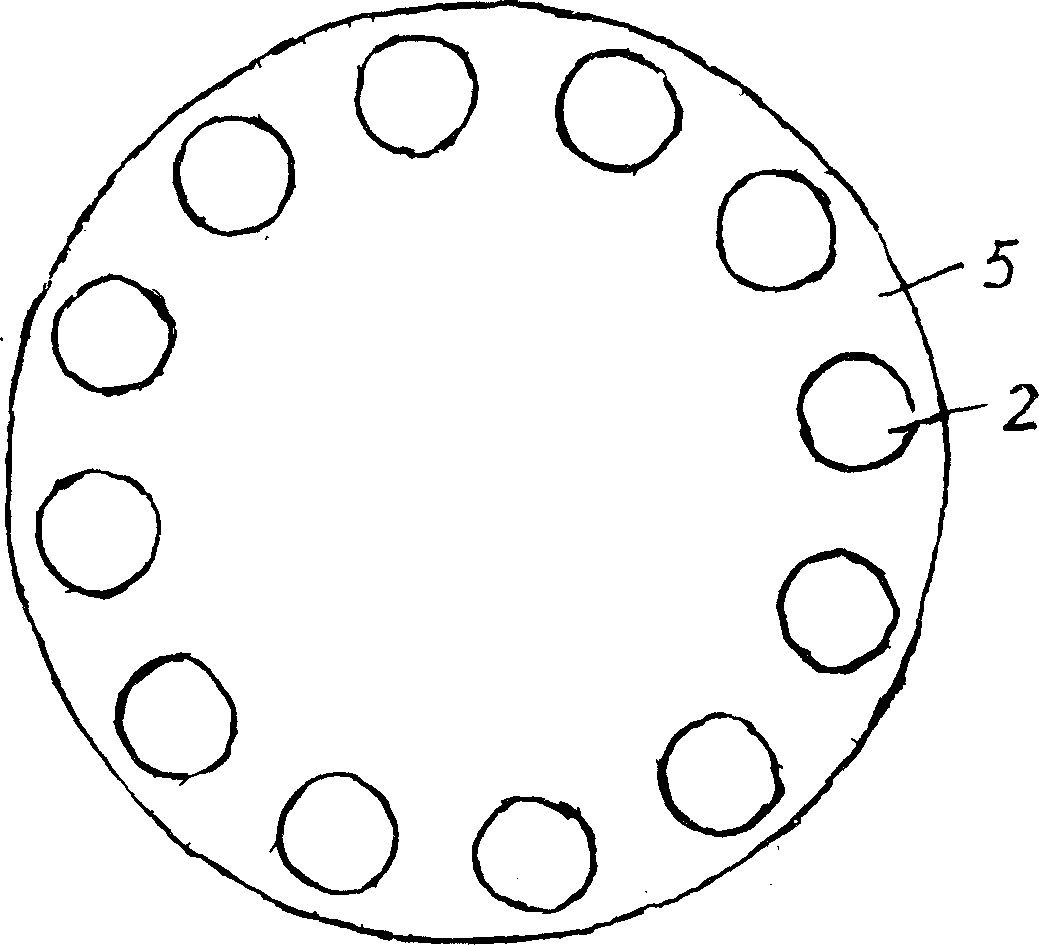

[0013] see image 3 , there are twelve air holes 2 in total.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com