Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "No uneven heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

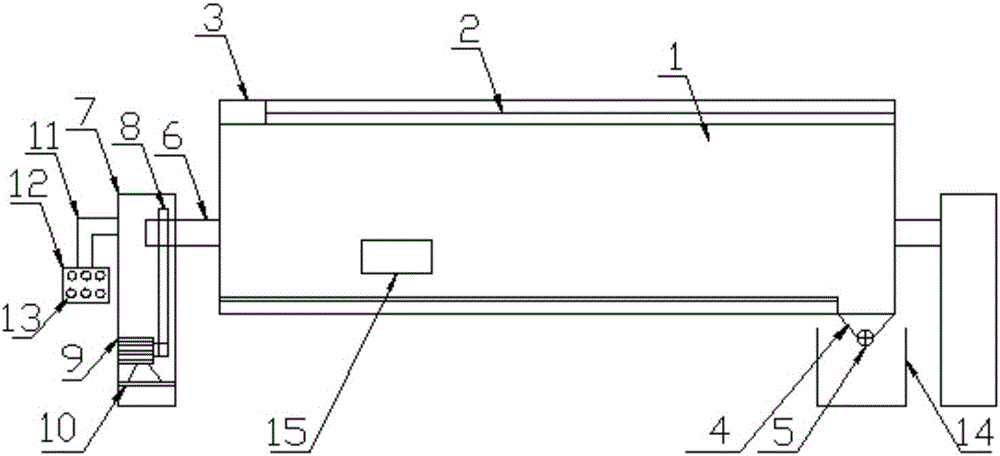

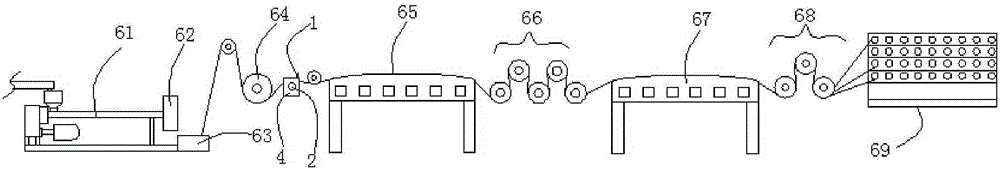

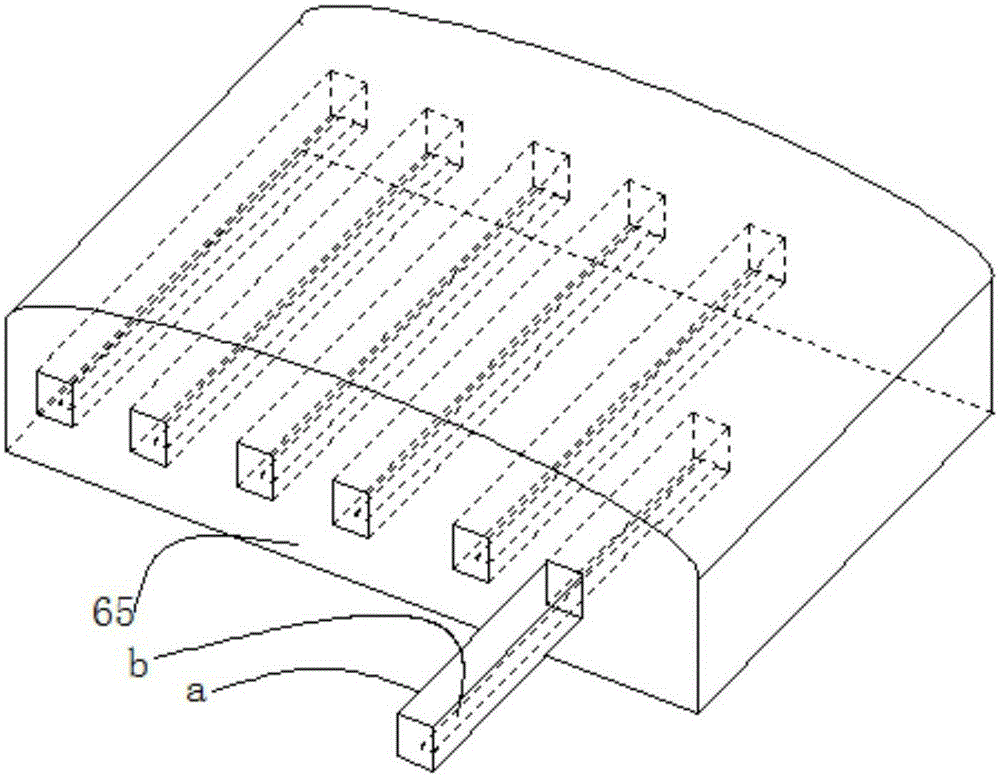

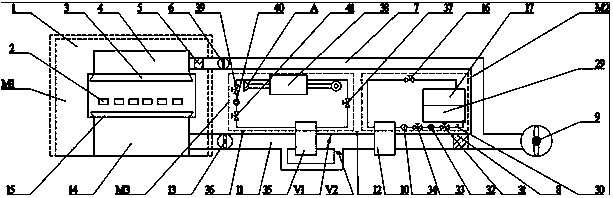

Shoe material thermal-laminating process, shoe material thermal-laminating device and production line thereof

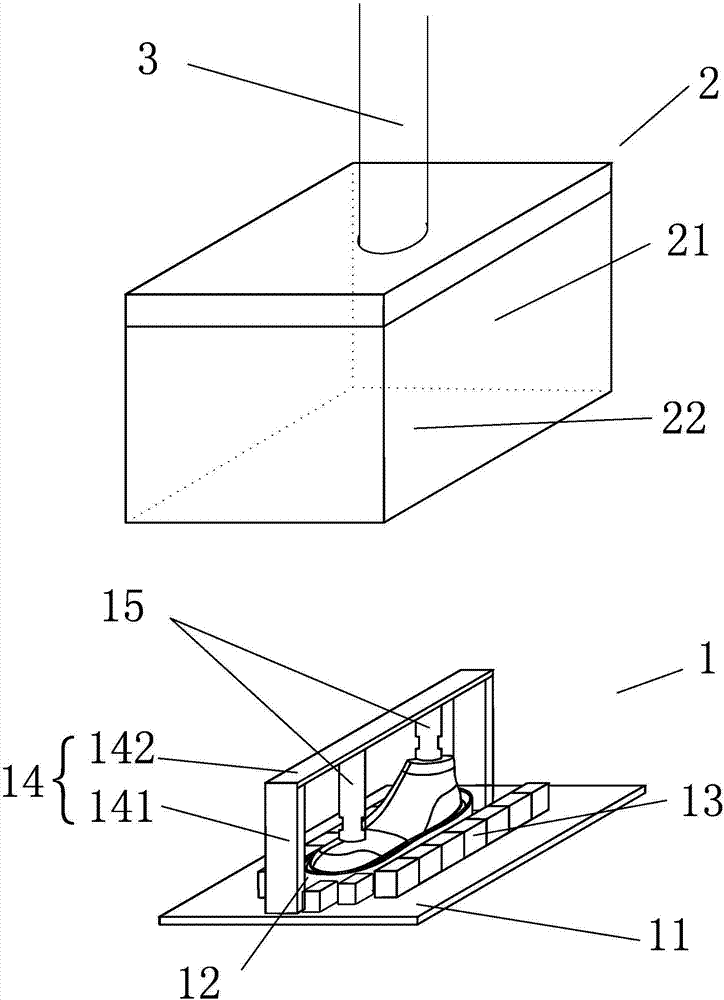

The invention discloses a shoe material thermal-laminating process. The shoe material thermal-laminating process comprises the following steps that 1, shoe materials to be processed are prepared, wherein the shoe materials include a first shoe material and a second shoe material which are to be laminated, a zone to be laminated of the first shoe material and / or a zone to be laminated of the second shoe material undergoes adhesive coating treatment, an adhesive layer is formed through the adhesive coating treatment, and the zones to be laminated and / or an adhesive contain moisture; 2, the zone to be laminated of the first shoe material and / or the zone to be laminated of the second shoe material obtained in the step 1 are correspondingly adhered, and adhesion is kept to obtain a shoe material adhered part; 3, the shoe material adhered part in the step 2 is subjected to microwave heating heat treatment through a microwave heating device to make the first shoe material and the second shoe material bonded and fixed together, and then the first shoe material and the second shoe material which are bonded and fixed together are subjected to low-temperature cold-shaping treatment. The shoe material thermal-laminating process has the advantages of being short in consumed time and simple and reducing the energy consumption.

Owner:SINCETECH FUJIAN TECH CO LTD

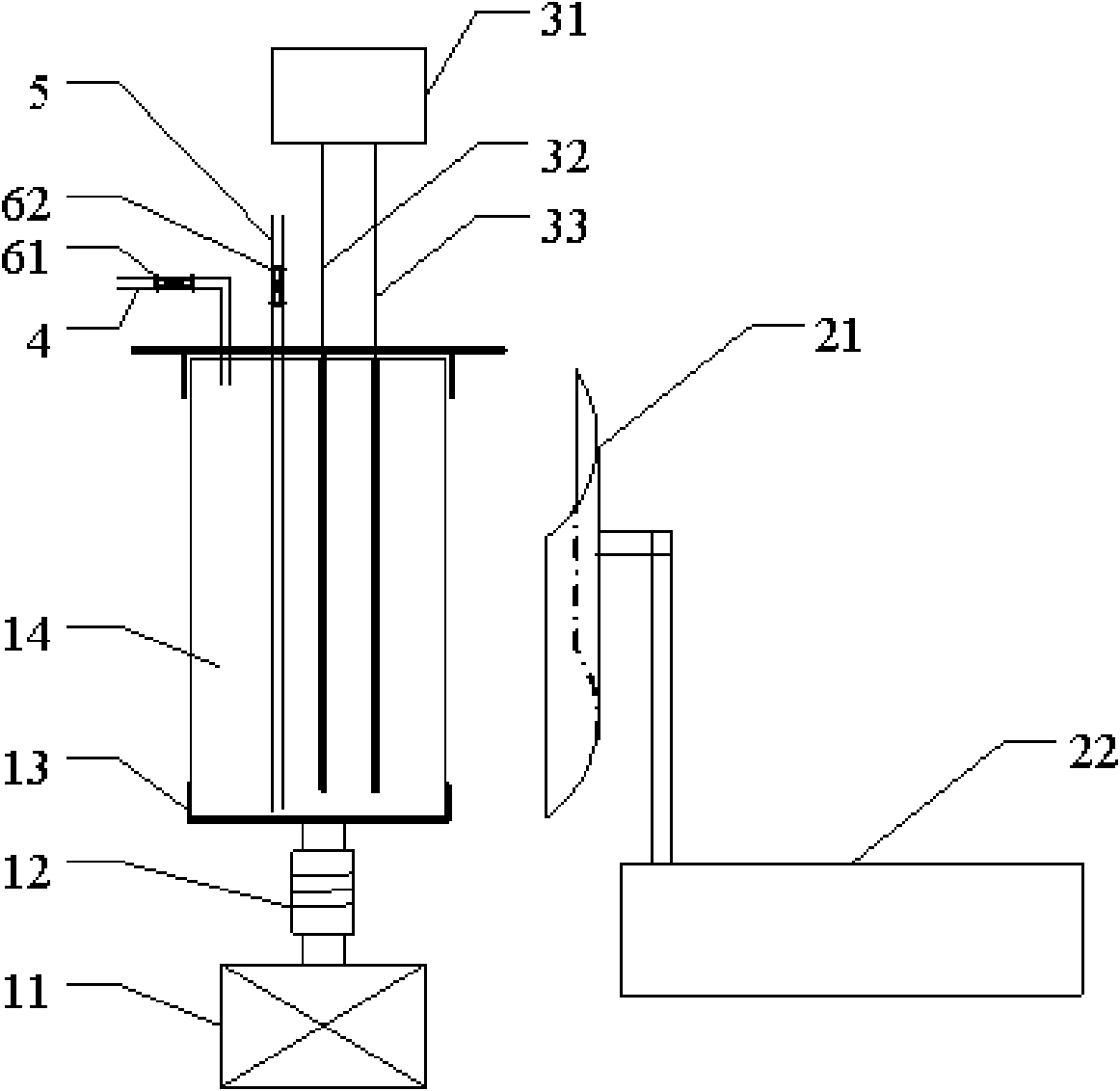

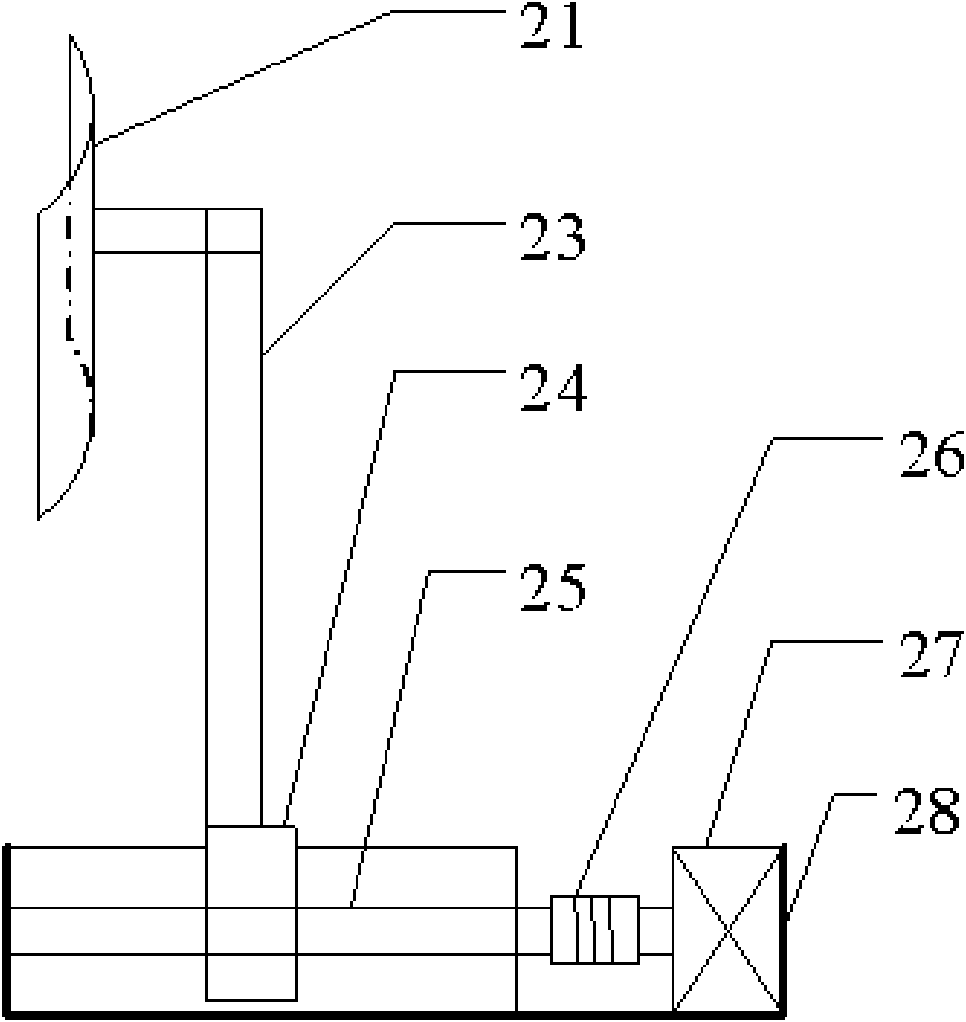

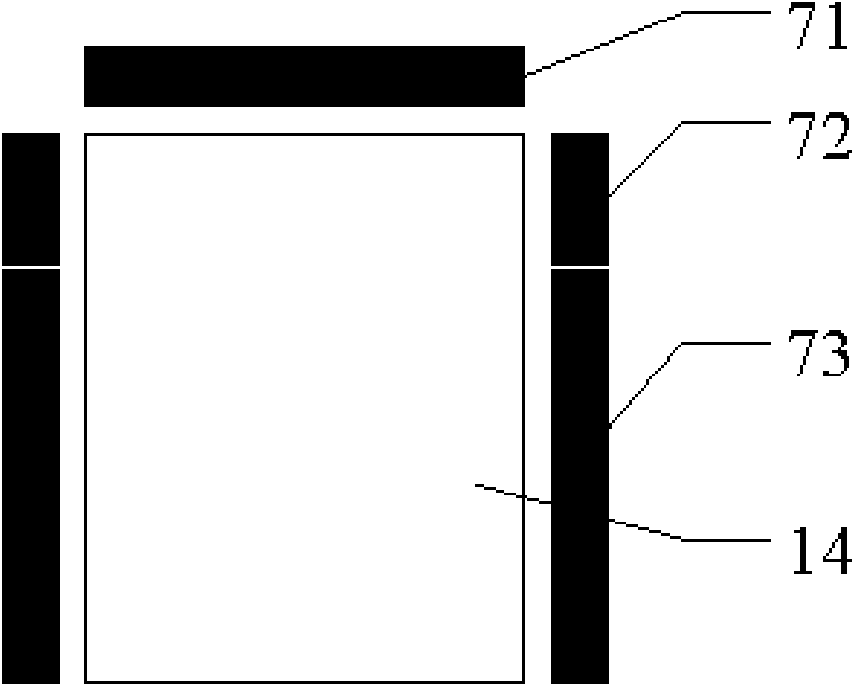

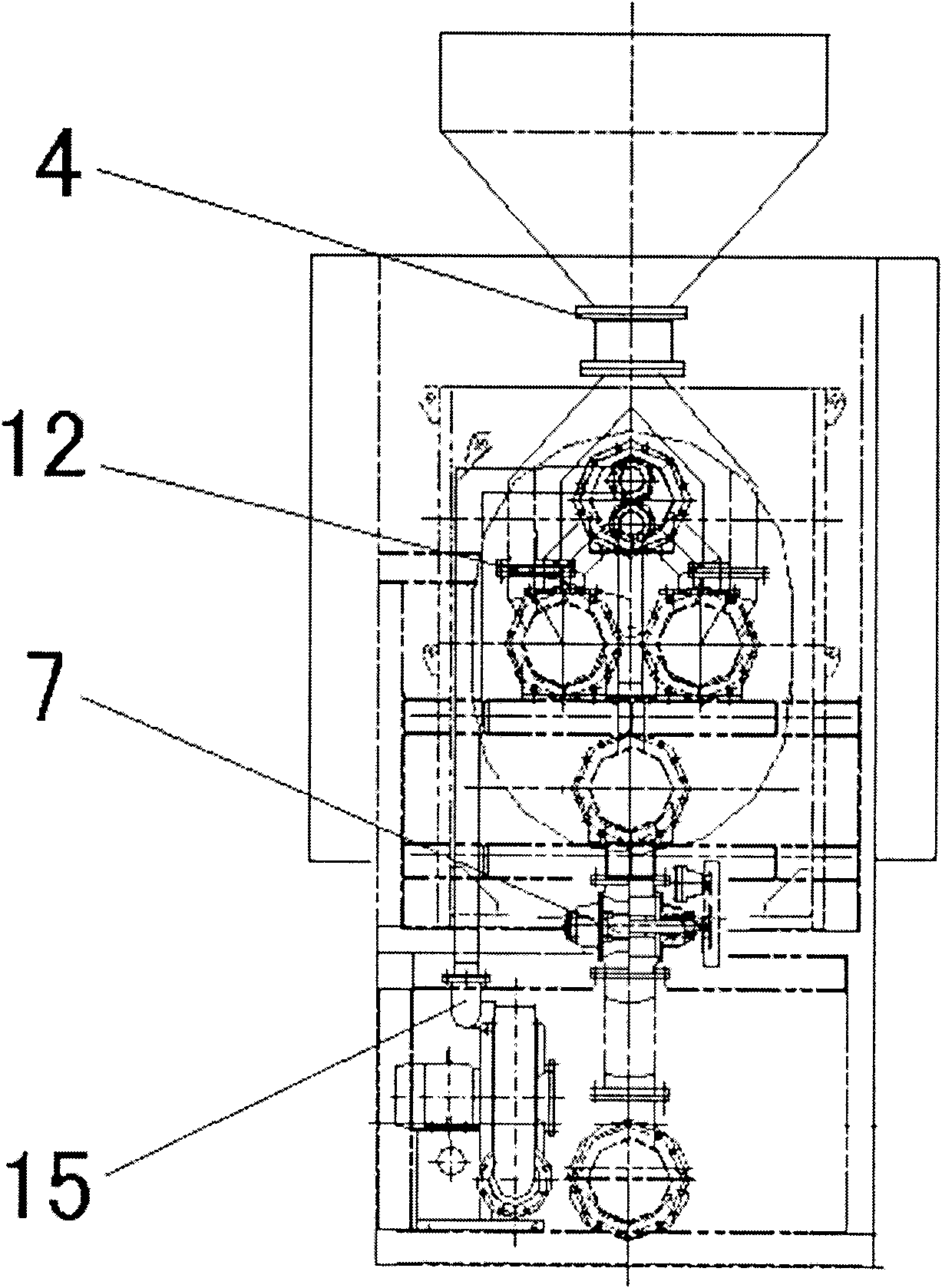

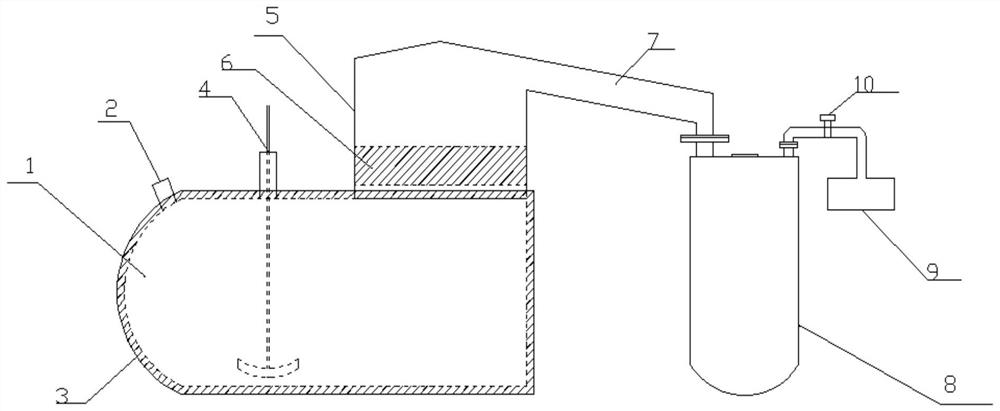

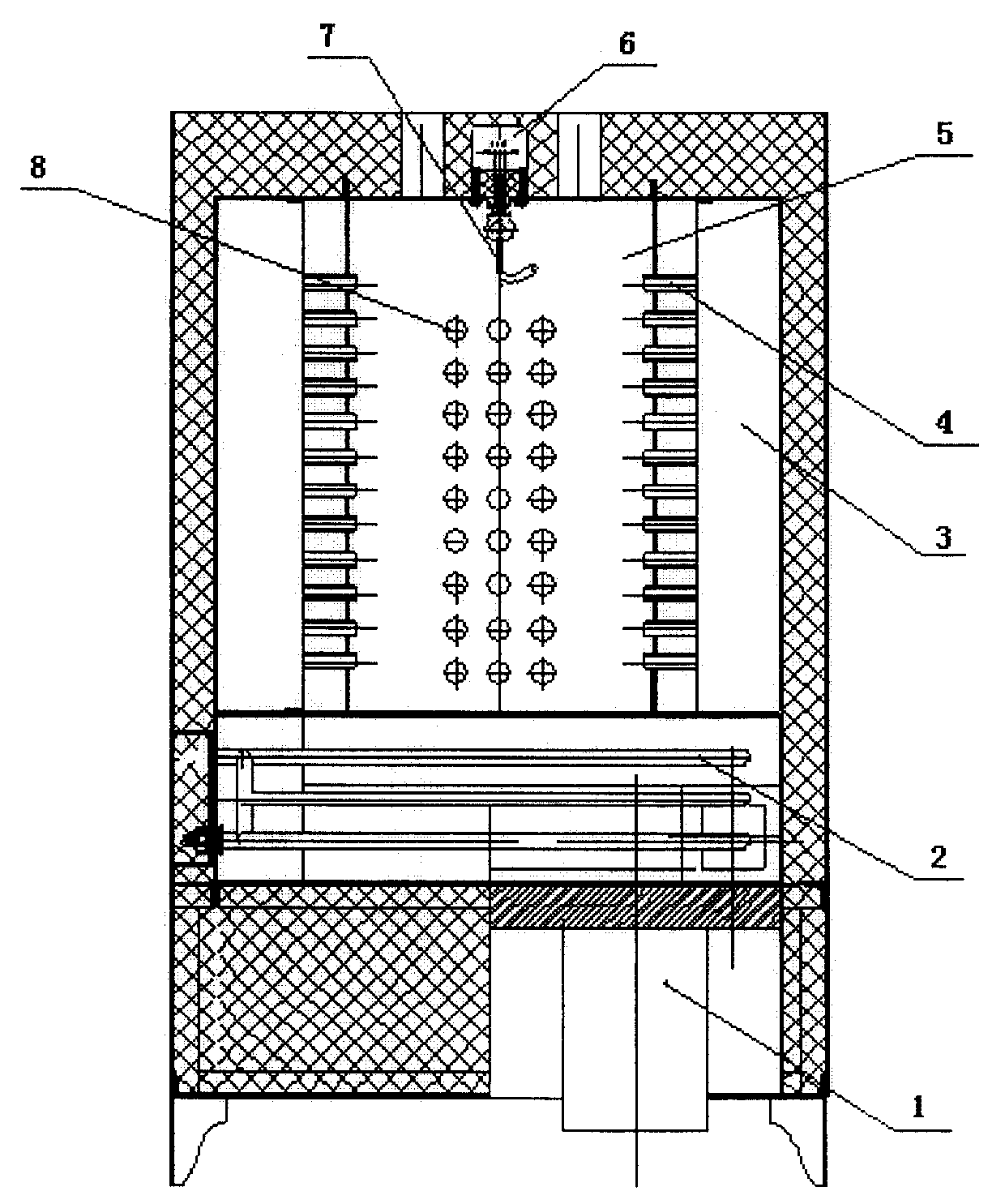

Bioreactor applied to magnetic nano-catalyst

InactiveCN101654655ASuppress foamReduce damageStress based microorganism growth stimulationNano catalystMagnet

The invention discloses a bioreactor applied to magnetic nano-catalyst which has the structure that one end of a first shaft coupling is connected with an output shaft of a first motor and the other end is connected with a connecting disc; a reaction vessel is installed on the connecting disc, provided with an input pipe and an output pipe with valves, and is installed with a temperature control apparatus. In use, the magnetic nano-catalyst is arranged in the reaction vessel and is adsorbed on the wall of the reaction vessel by means of a magnet. The magnetic nano-catalyst is uniformly mixed and conveniently recycled and and has the advantages of improving the catalyst using efficiency, flexibility to different technologies and reducing pollution.

Owner:HUAZHONG UNIV OF SCI & TECH

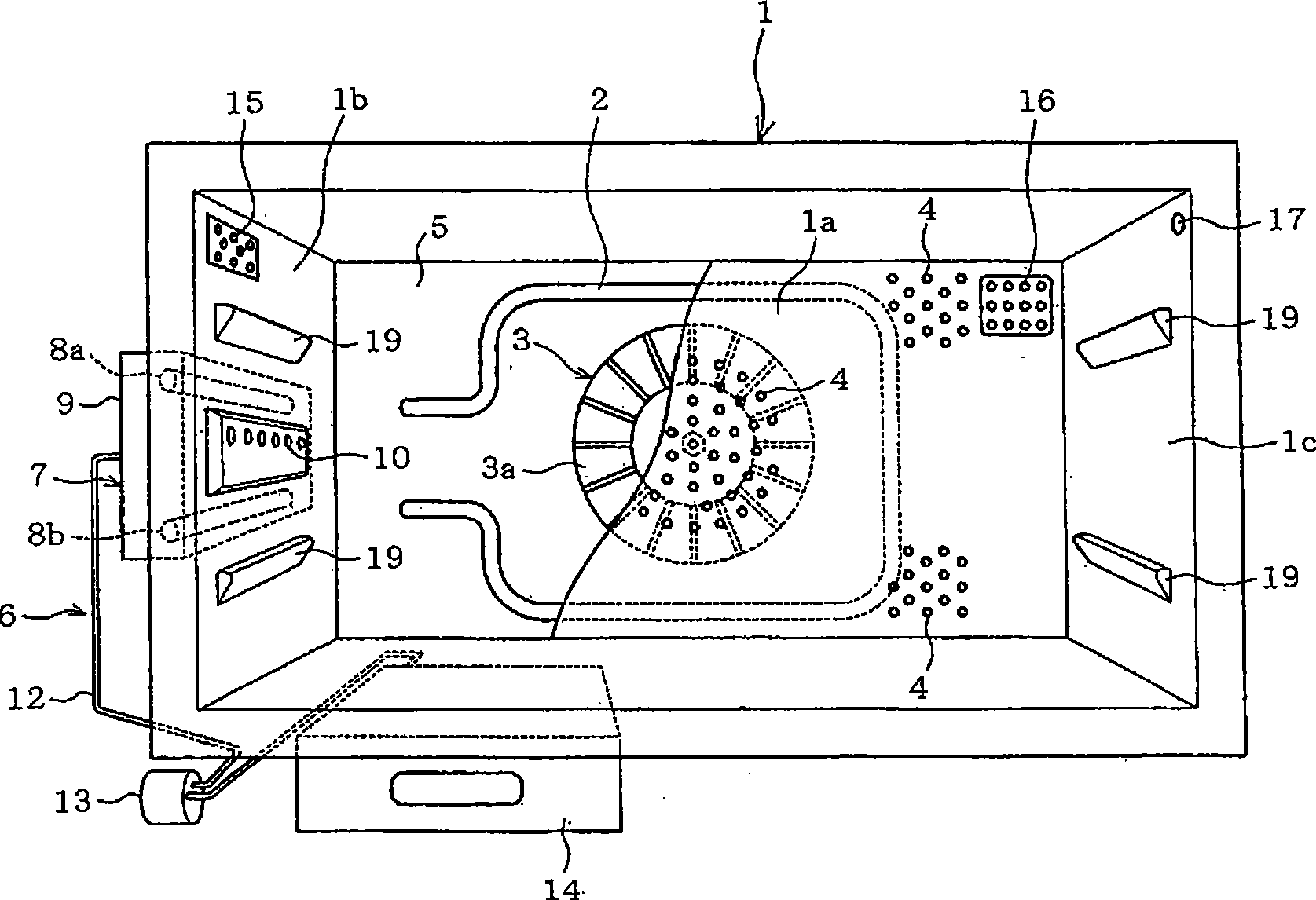

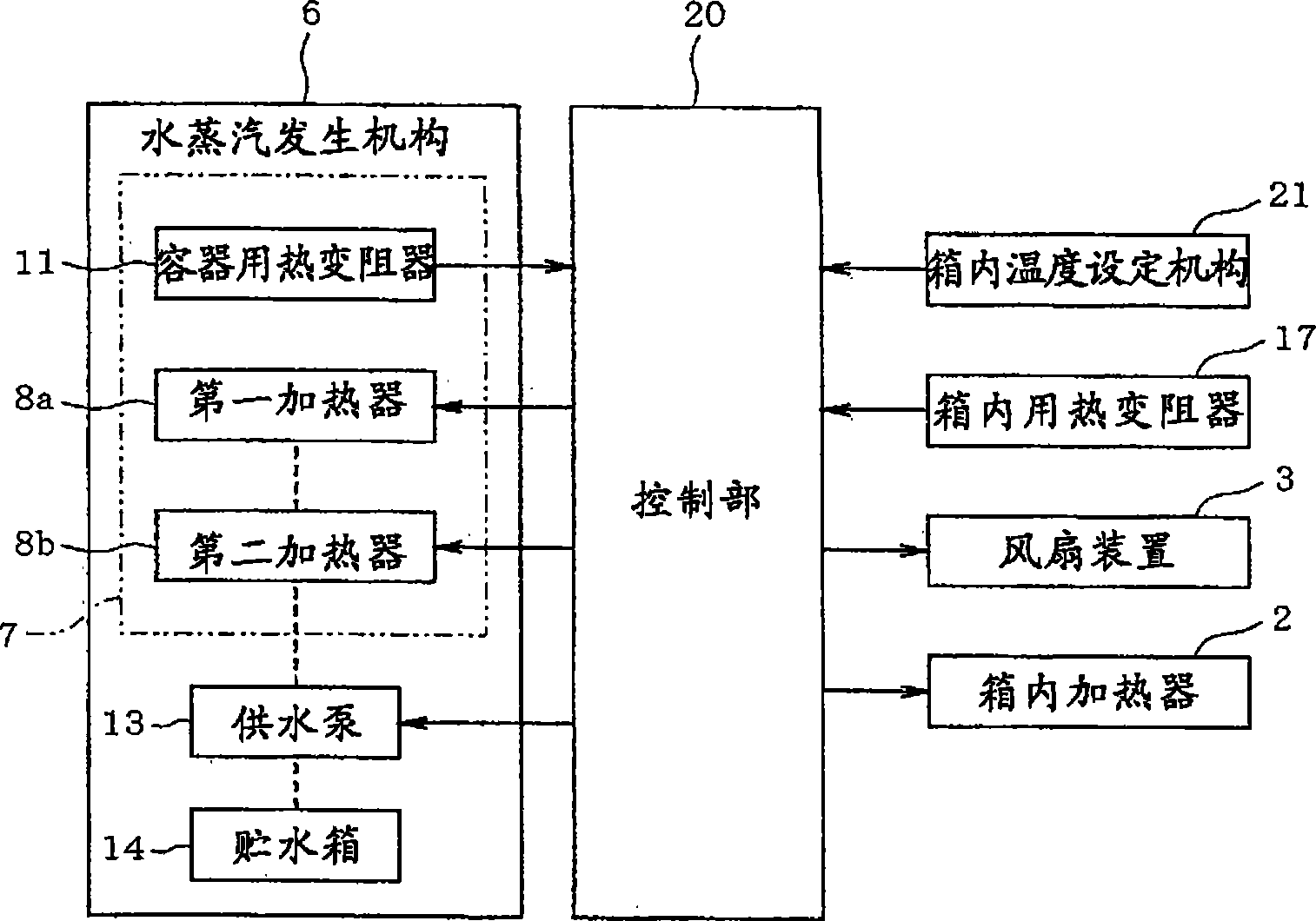

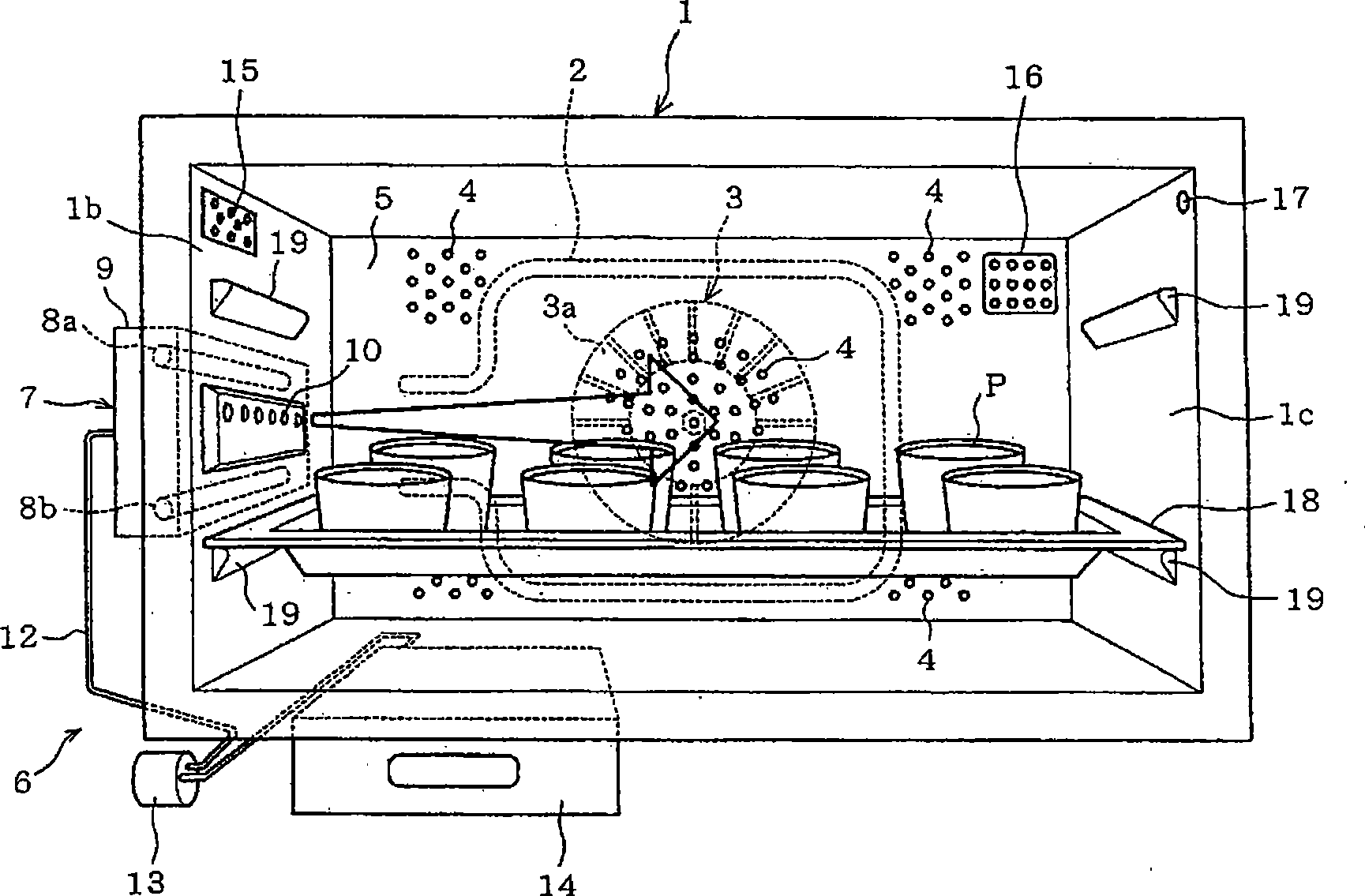

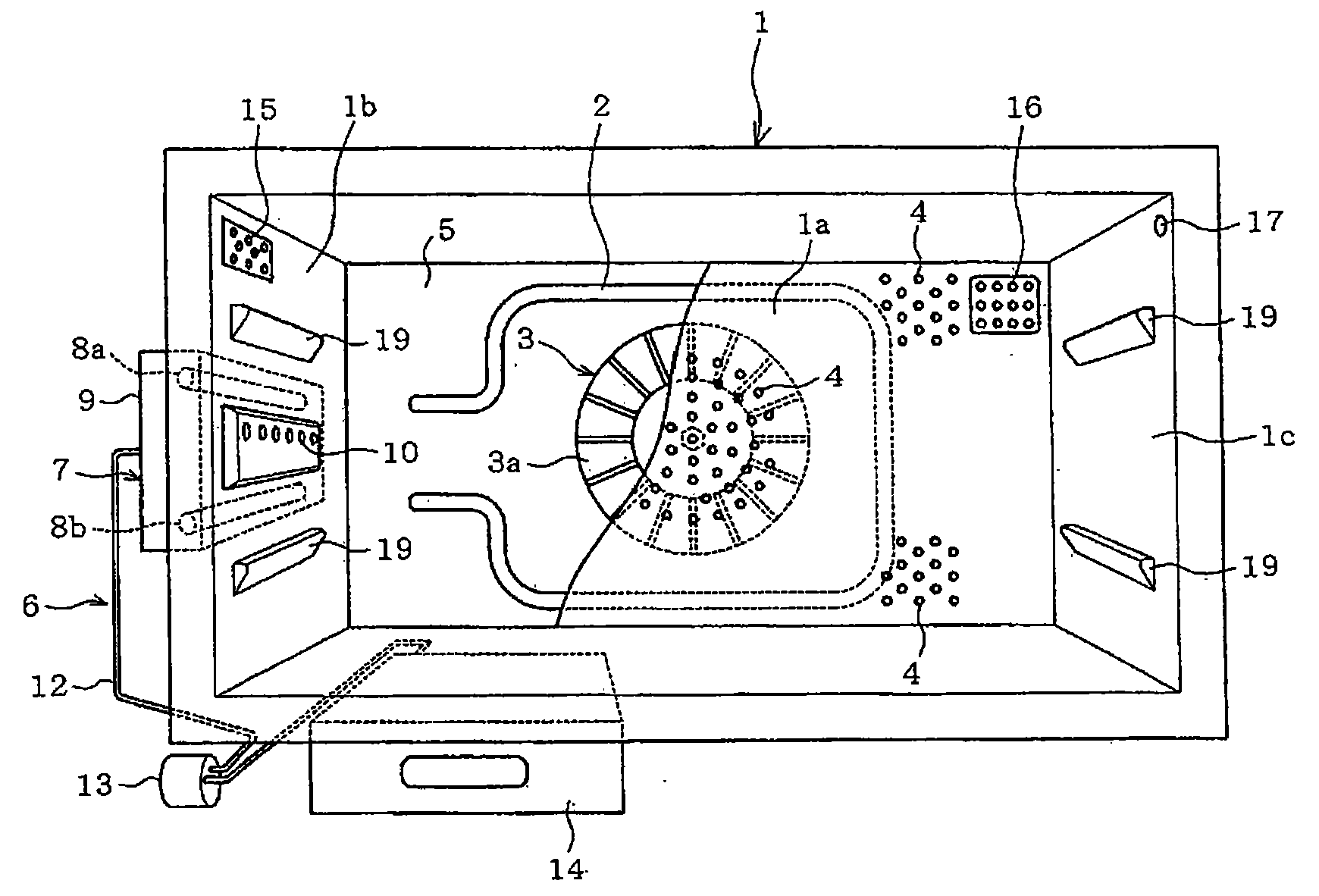

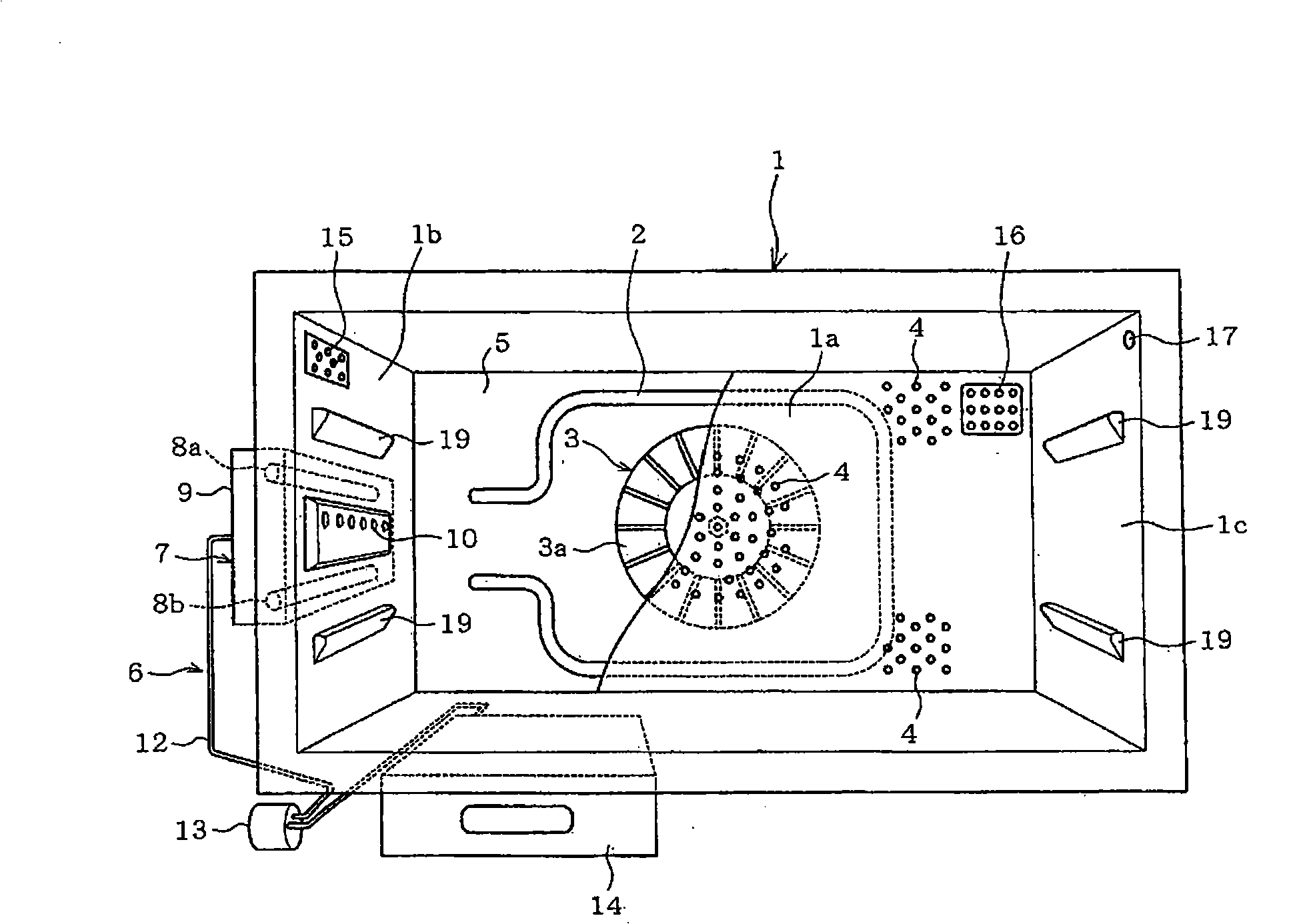

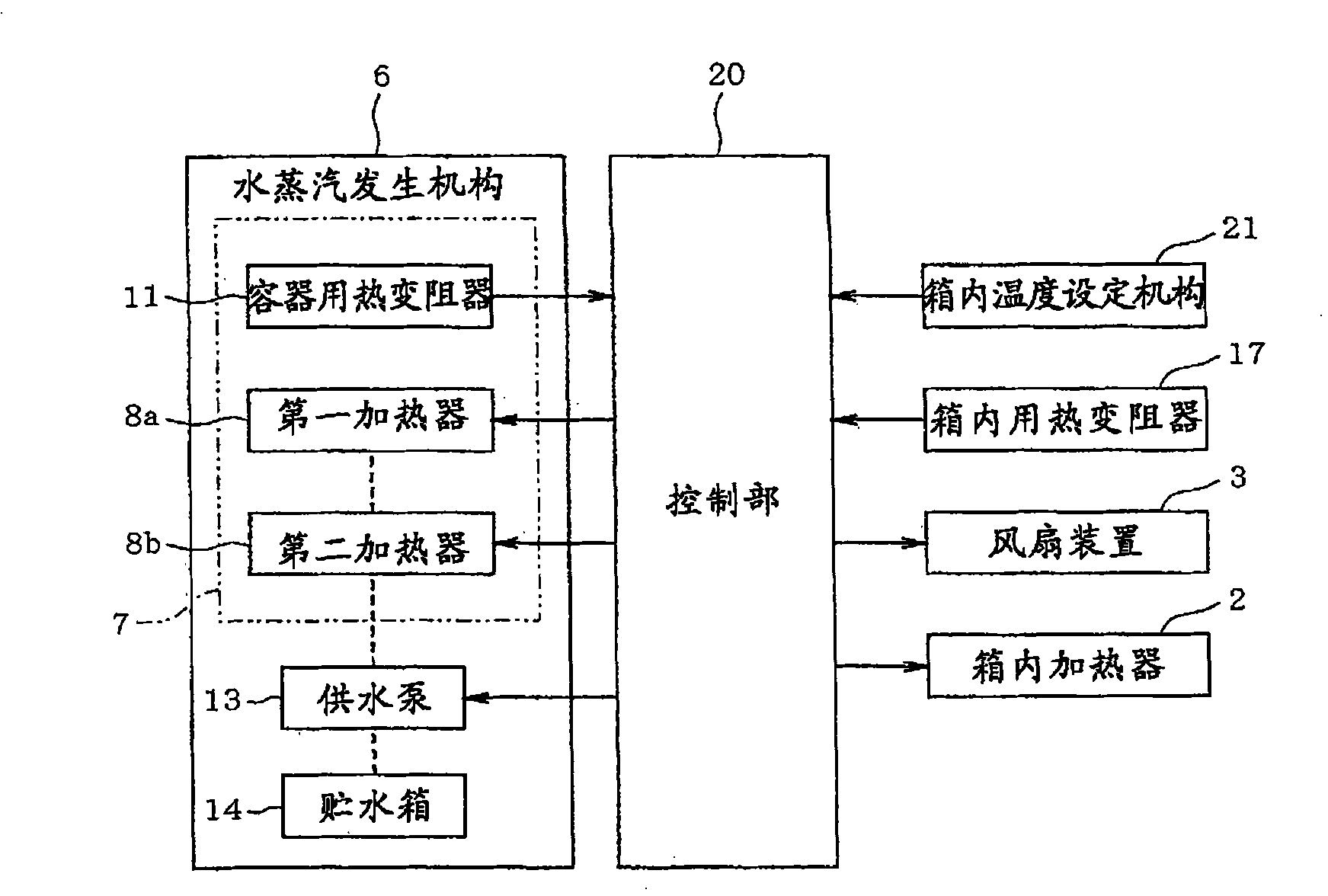

Heating cooking device

ActiveCN101377317ANo uneven heatingGood heat cookingDomestic stoves or rangesLighting and heating apparatusCookerEngineering

The invention provides a heating cooker, capable of realizing heating cooking without disproportion heating based on uniform heating in the box, in a heating cooking wherein the temperature in the box is set to below100 DEG C. The heating cooker includes an inside heating mechanism, a water vapor generating mechanism and a control section for controlling them. The heating steps controlled by the control section includes a first step when the temperature inside the box raises until it reaches the setting value; and a second step of maintaining the setting value in the box, in the second step, the supply power input to the water vapor generating mechanism is set to be larger than the supply power input to the inside heating mechanism.

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP

Drum-type food drying machine

The invention discloses a drum-type food drying machine which comprises a food drying machine body and supporting legs. A feeding port is formed in the top end of the food drying machine body, a discharging port is formed in the bottom end of the food drying machine body, a discharging valve is arranged at one end of the discharging port, a heater is arranged inside the food drying machine body, an observing port is formed in the surface of the food drying machine body, the food drying machine body is connected with the supporting legs through a rotary shaft, the rotary shaft is connected with a motor through a belt, a supporting plate is arranged at the bottom end of the motor, a connecting rod is arranged on one side of one supporting leg, a control panel is arranged at one end of the connecting rod, and buttons are arranged on the surface of the control panel. The drum-type food drying machine facilitates even food heating during food drying performed by people and is simple in structure and suitable for popularization, the control panel can also control the rotation speed of the motor and the temperature of the heater, and adjustment can be performed according to different crops.

Owner:合肥朝霞机械科技有限公司

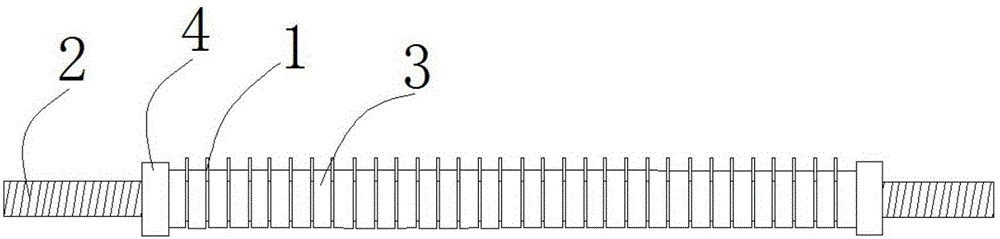

Plastic flat filament production unit

The invention provides a plastic flat filament production unit which includes a filament dividing mechanism; the filament dividing mechanism further comprises spacer rings; a plurality of holes are formed in the surface of a shaft in the axial direction; the hole midpoint connecting line is parallel with the axis of the shaft; a blade is inserted in each hole; each spacer ring sleeves the shaft and is positioned between two adjacent blades; fastener groups are arranged at the two ends of the shaft, so as to enable the spacer rings and the blades to squeeze and get close to each other tightly and enable the blades to be fixed on the shaft. Compared with the prior art, the blades can be fixed on the shaft through the cooperation of the spacer rings and the holes and the squeezing by the fastener groups at the two ends of the shaft, without needing extra fixture; rubber bulges are arranged on the side walls of each spacer ring, so that the friction force between the spacer rings and the blades is increased, and the fixing effect is better.

Owner:泗县鸿盛塑业股份有限公司

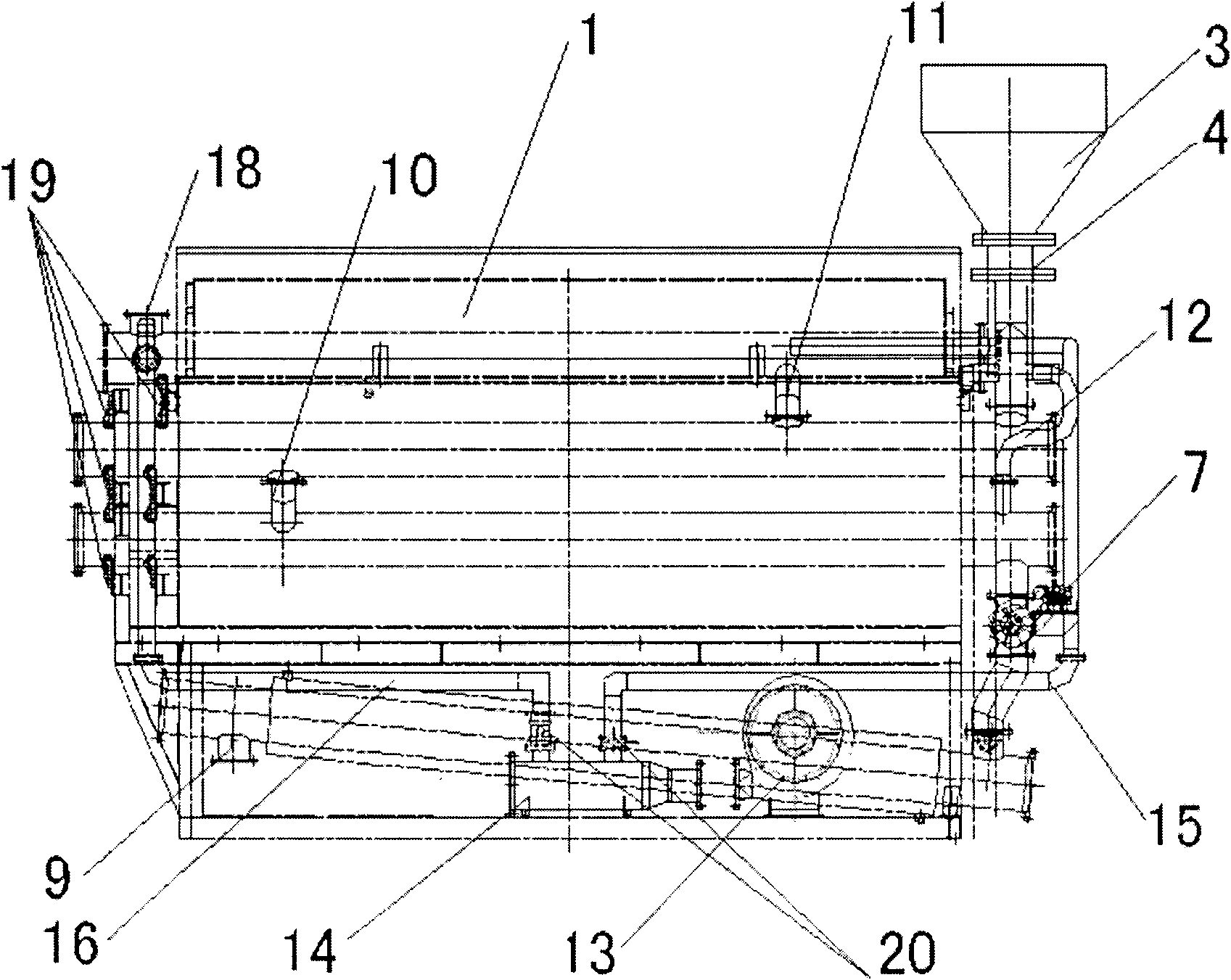

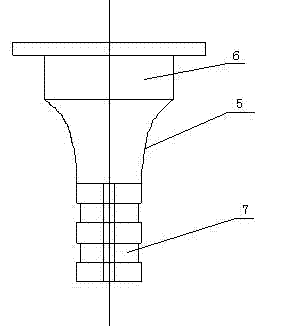

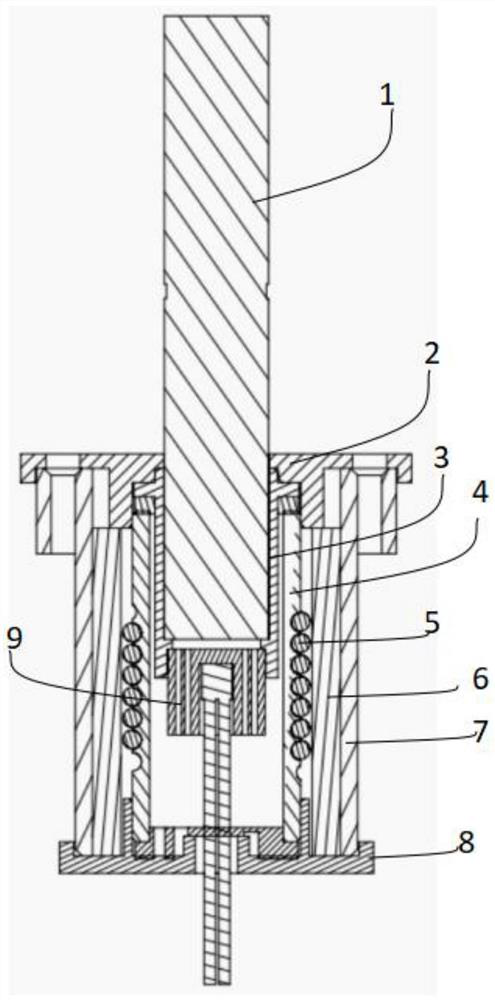

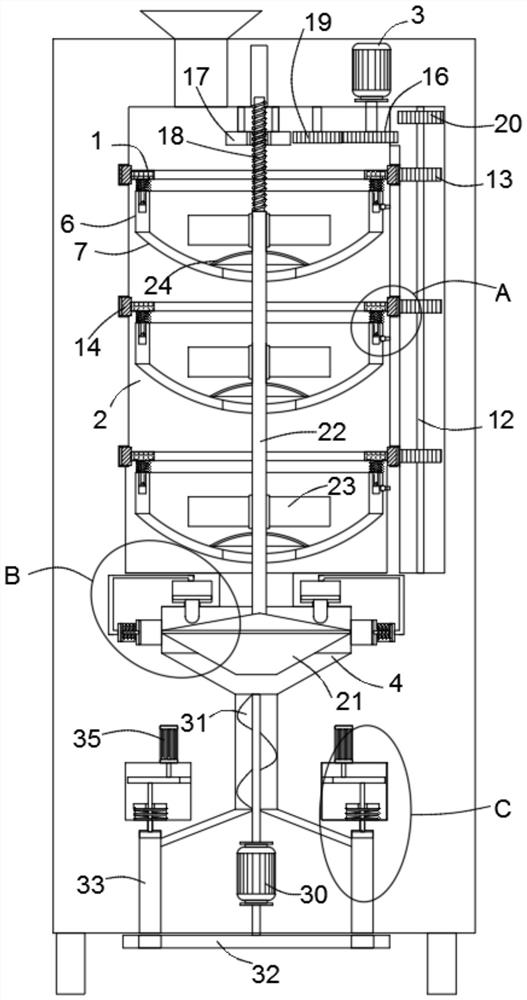

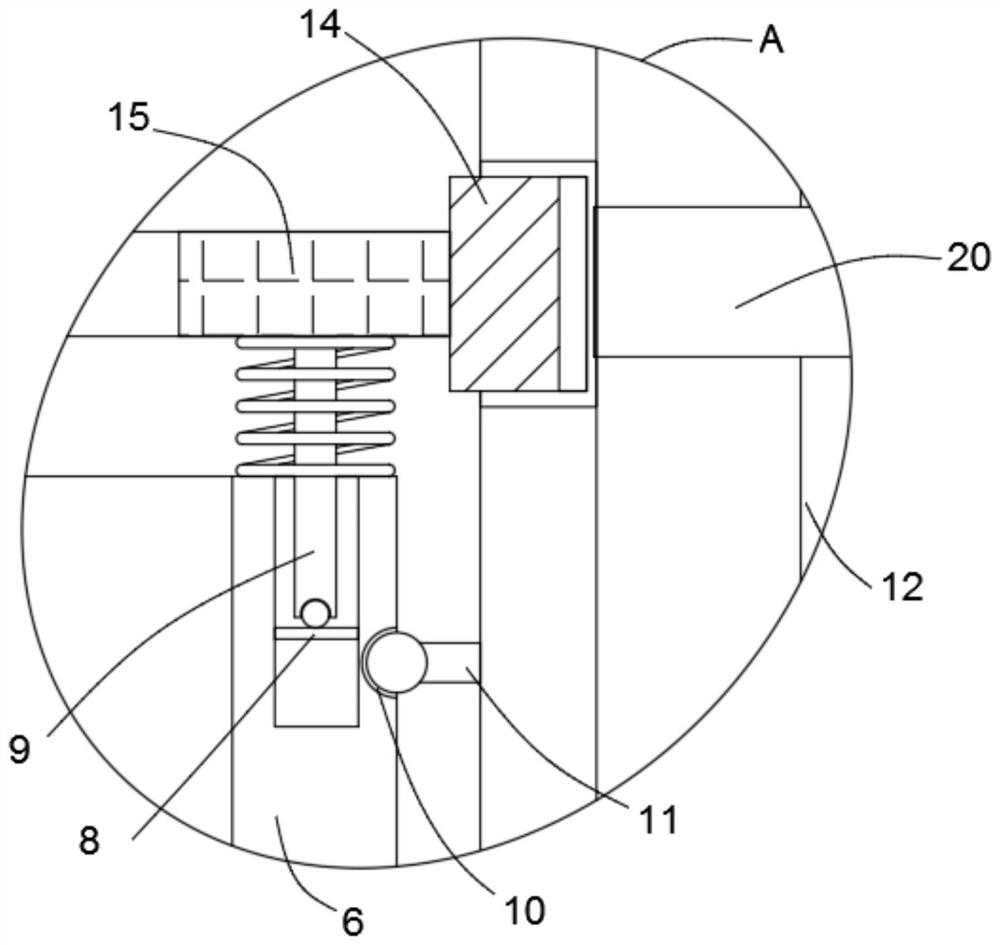

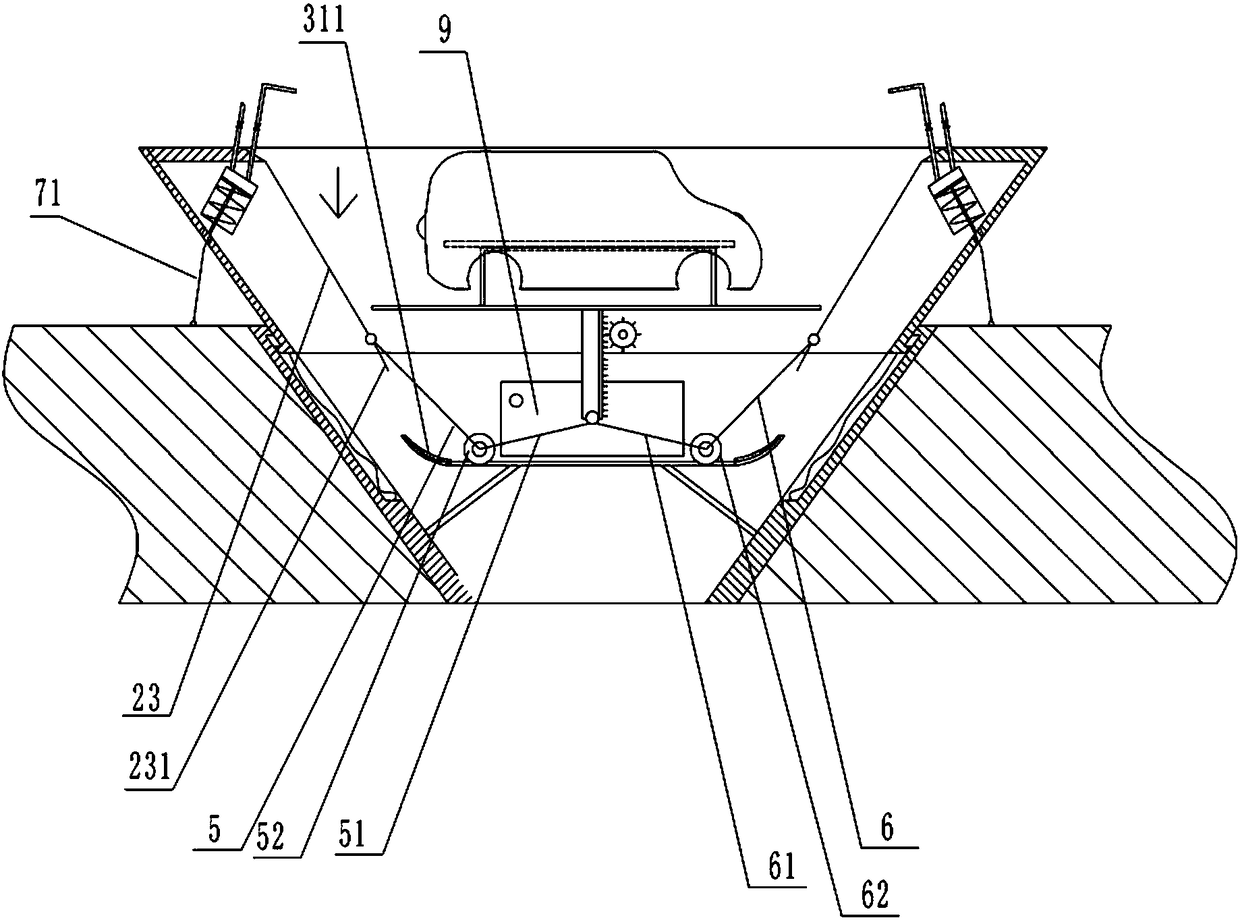

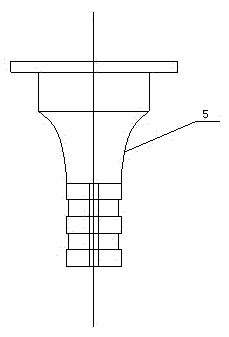

Equipment for carbonization treatment of sludge and its using method

InactiveCN102372413AHigh reduction rateNothing producedSludge treatment by thermal conditioningReduction rateResource utilization

The invention discloses equipment for carbonization treatment of organic sludge and its using method. The equipment comprises a drying machine and a carbonization furnace. The carbonization furnace further includes a top (1), an inner wall (2), a furnace chamber, a hopper (3), an anti-blocking rotary valve (4), preheating and auxiliary carbonization pipes (5), a main carbonization pipe (6), a high temperature rotary valve (7), a cooling pipe (8), a material outlet (9) and a gas pipe (17). The top (1) is detachable, and is convenient for the maintenance and replacement of internal parts. The inner wall (2) is an insulation material, and the upper part of the inner wall (2) is combined with the top (1) together and is in a cover opening structure. The equipment and method of the invention overcome the problems of no maximum resource utilization and secondary pollution during treatment in prior art, and can enhance the quantitative reduction rate of a treated substance, stabilize the finished product, and realize resource utilization. And the treatment process can be harmless.

Owner:QINGDAO BIOMASS ENVIRONMENTAL PROTECTION TECH

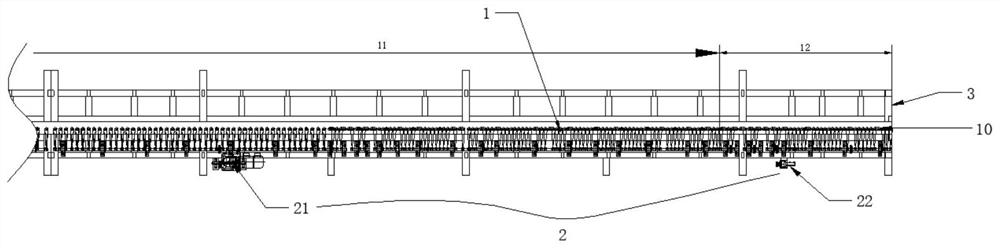

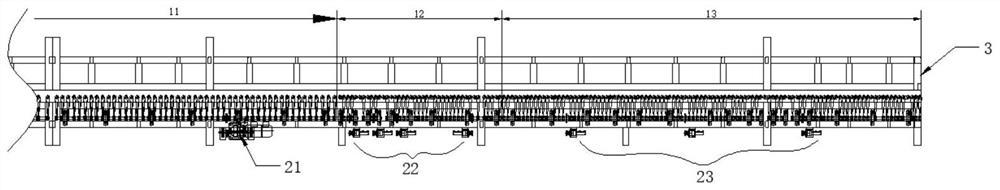

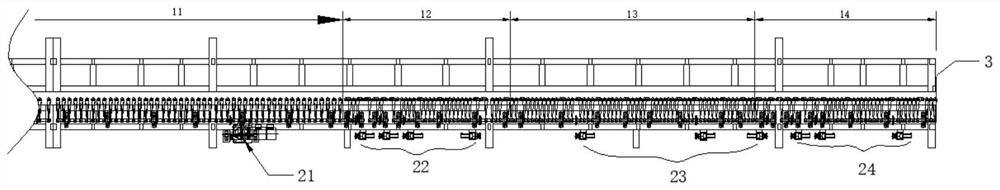

Conveying method of heating furnace in continuous glass toughening furnace

PendingCN111908781AReduce the deformationImprove the defects that are prone to "wavy lines"Glass transportation apparatusGlass tempering apparatusTemperingHeating furnace

The invention provides a conveying method of a heating furnace of a continuous glass toughening furnace, and belongs to the field of glass toughening. According to the method, a heating furnace conveying line is divided into a normal-speed section, an acceleration section and a rapid section, wherein in the normal-speed section, the glass is driven to be conveyed at a constant speed at the speed of V flat; in the rapid section the glass is driven to be conveyed at a constant speed at the speed of V<rapid>, V<rapid> being larger than V<normal>; and in acceleration section, variable-speed conveying of the glass is controlled, and the glass is limited at the temperature required by heating to tempering in the rapid section. According to the invention, the accelerating section on the conveyingline of the existing heating furnace is advanced, and meanwhile, the quick section is added behind the accelerating section, so that the glass is limited at the temperature required by the quick section to be heated to be tempered, i.e., the glass is completely heated in the quick moving process and moves in a quick passing manner before being heated to a softening point; as a result, the deformation amplitude of the glass is effectively reduced, so that the defect that raised grains are likely to appear on the surface of the glass is overcome, the effect is more obvious especially for ultrathin glass with the glass thickness smaller than or equal to 2.5 mm, and the flatness of the glass can reach 0.2 mm or below.

Owner:宣城吉鼎玻机械有限公司

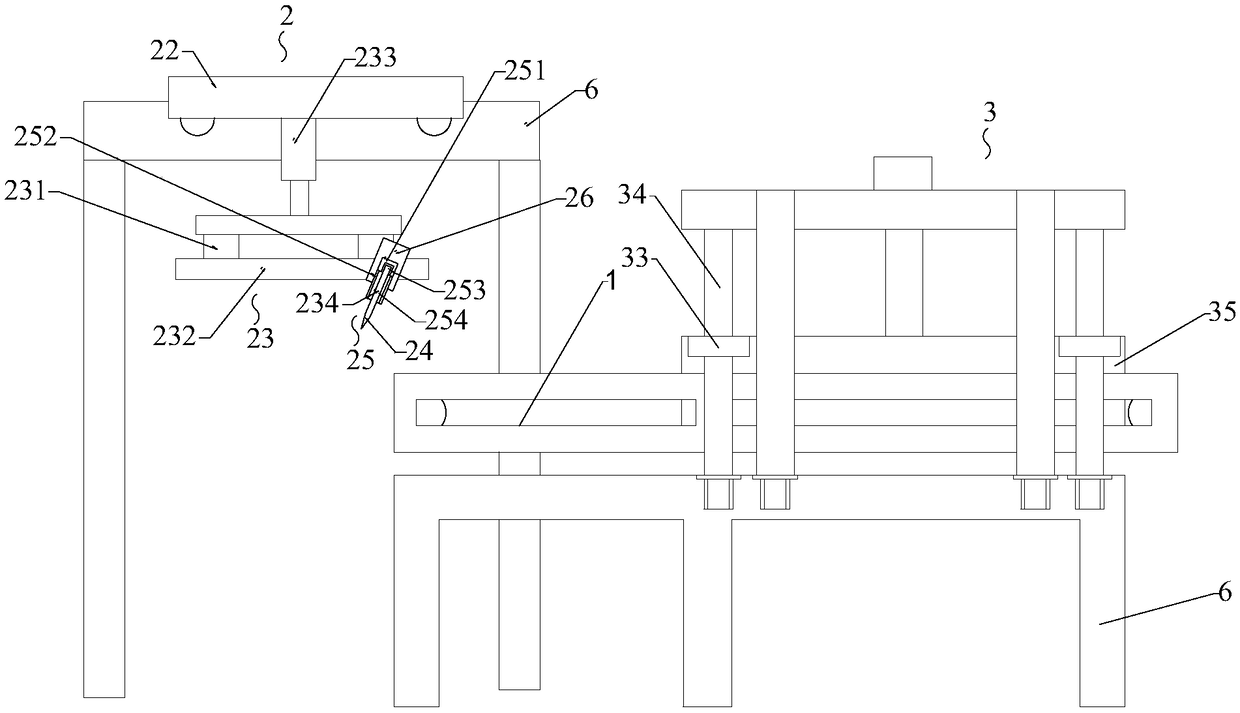

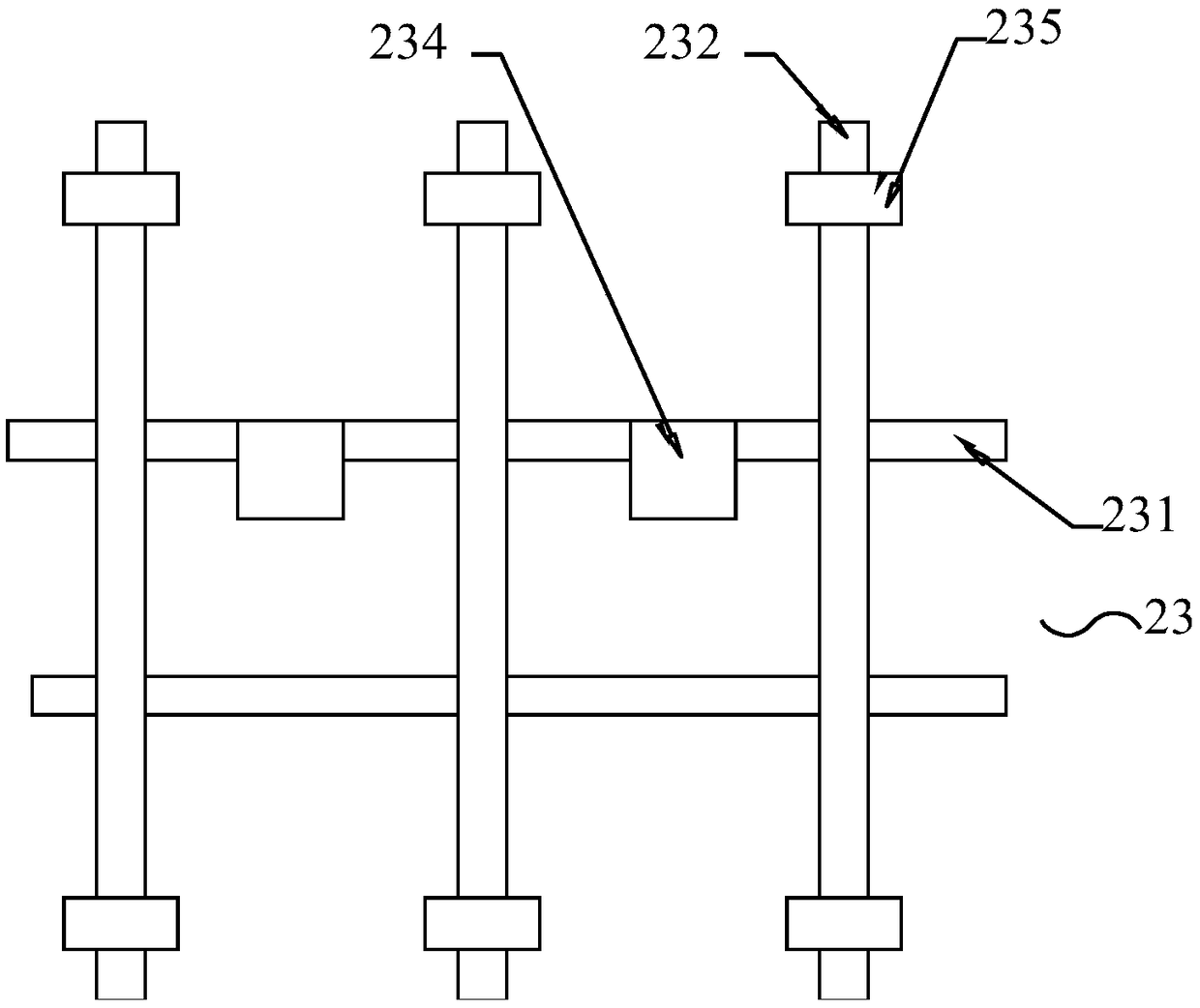

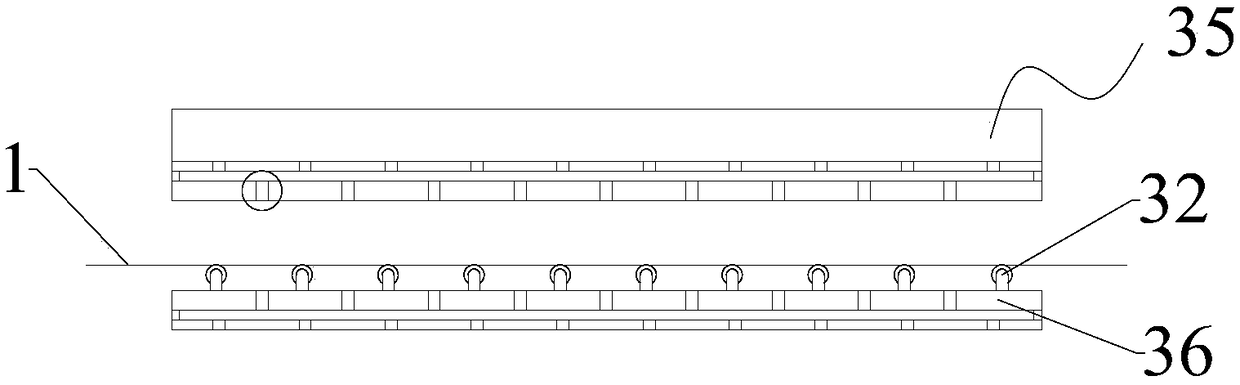

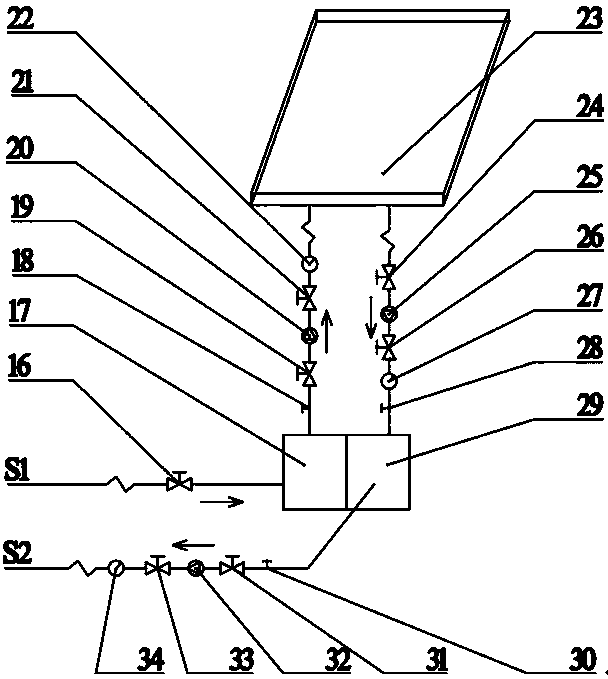

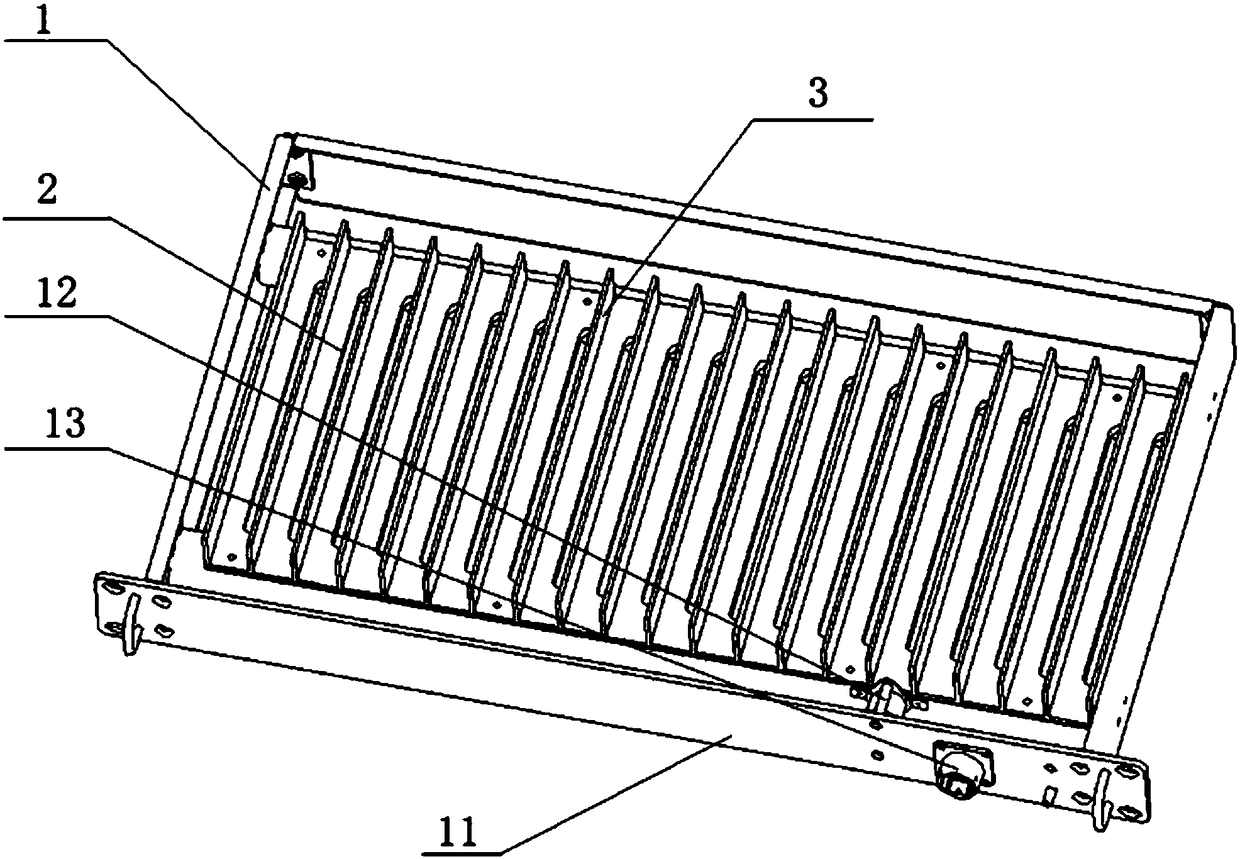

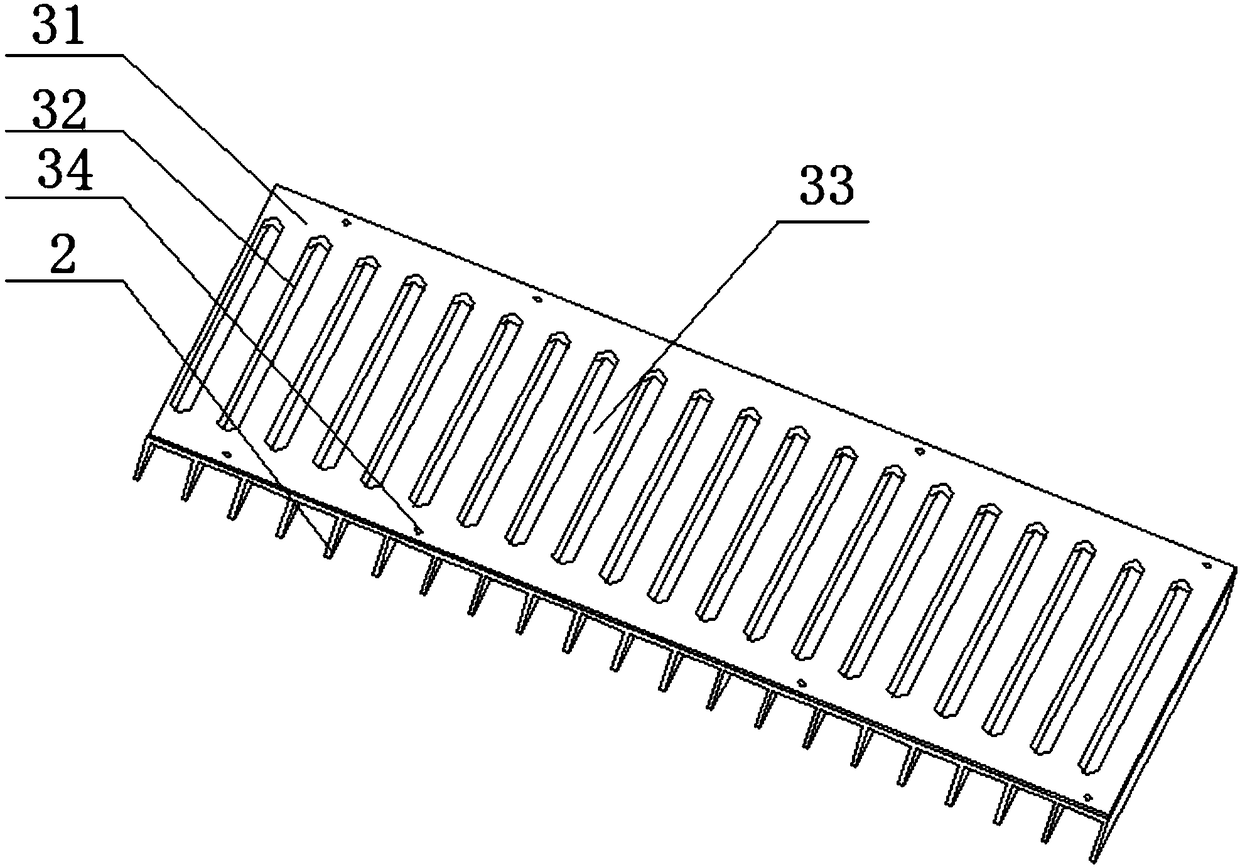

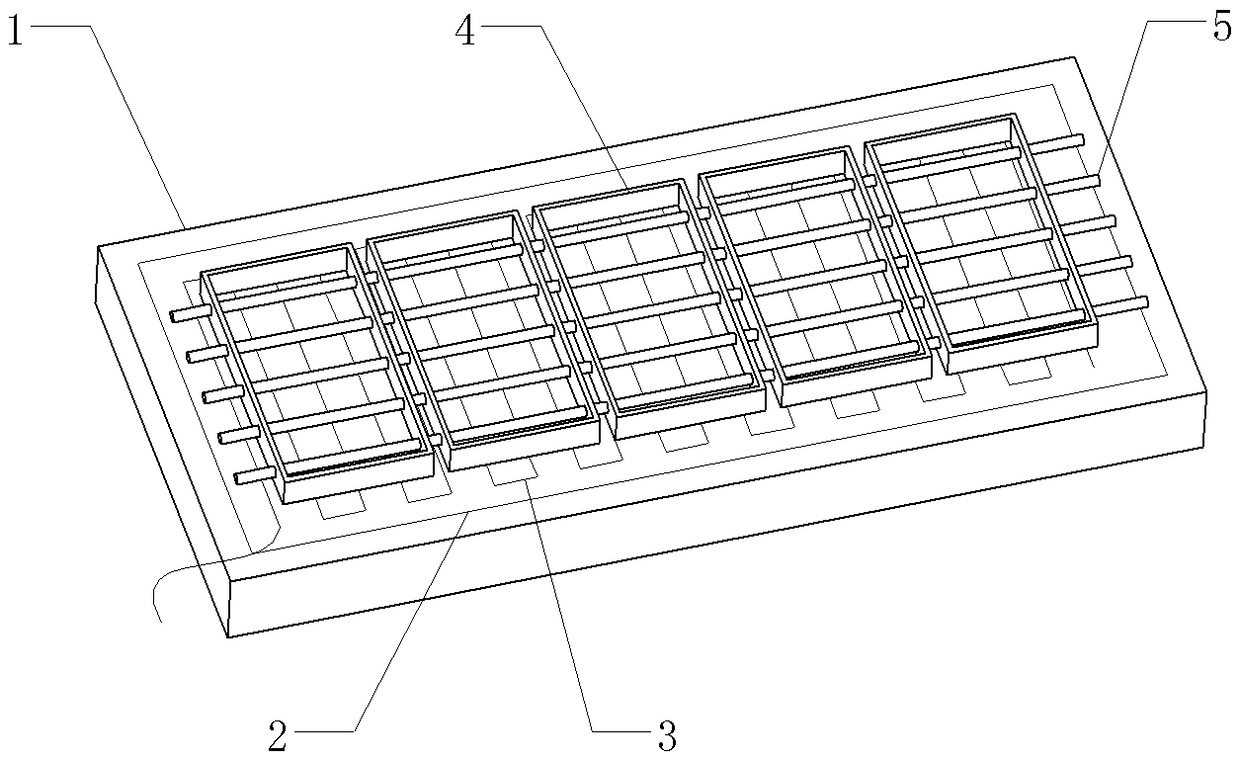

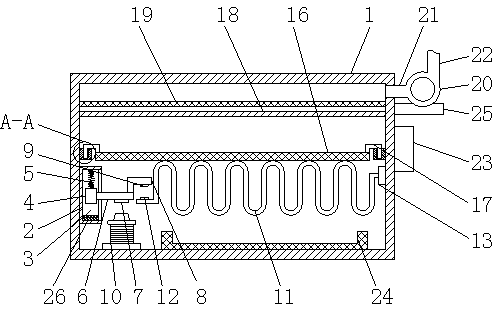

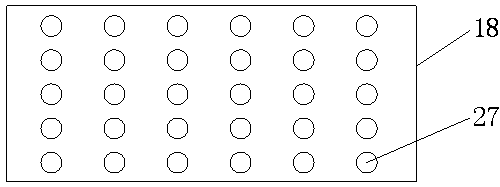

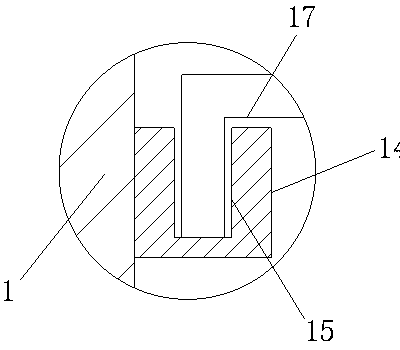

Die pressing production line

The invention belongs to the technical field of sound-absorbing cotton, and provides a die pressing production line. The die pressing production line comprises a rack. The rack is provided with a feeding device, a baking box and a die pressing machine, all of which are sequentially distributed and connected through a conveying belt. The feeding device comprises a material taking device arranged onthe rack. The material taking device comprises transverse parts connected with the rack through a walking device. Longitudinal parts and a first grabbing device are arranged at the bottoms of the transverse parts. Second grabbing devices are arranged at the two ends of the longitudinal parts. The transverse parts are connected with the walking device through a telescopic rod. The 2-5 longitudinalparts are arranged, and the first grabbing device is arranged in the center of the area defined by the second grabbing devices. The first grabbing device is a needle type inserting rod, and the second grabbing devices are suction cups or mechanical arms. A conical inserting head is arranged at one end of the first grabbing device, and a connecting part is arranged at the other end of the first grabbing device, wherein the connecting part is connected with the transverse parts through an installing base. The die pressing production line solves the technical problems that in the prior art, a sound-absorbing cotton production line is simple in structure, and usage is not convenient.

Owner:保定棉金汽车饰件制造有限公司

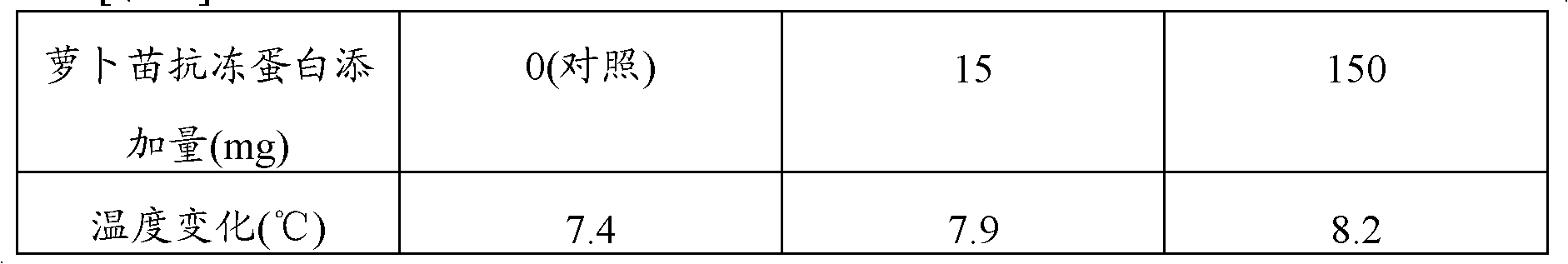

Method for producing processed food for heating

InactiveCN102427734AImprove heat treatment effectHeating evenlyFood ingredient as anti-freezing agentFood preservationMicrowave ovenHeating time

Owner:KANEKA CORP

Methods for producing roux and starting material thereof, roux, cream source and frozen food

Provided is a method for producing a roux for preparing a cream sauce, said roux having a body taste inherent to butter, in particular a roasted feeling characteristic to roux and, when used in a frozen food, showing a high suitability for microwave cooking (for example, assuring uniform heating and easy re-gelatinization, i.e., quick reconstitution) and, after thawing and heating, showing a good texture (for example, a smooth texture). The method for producing a roux comprises: step (A) for stirring butter to give creamy butter; step (B) for mixing the creamy butter obtained in step (A) with active gluten to give a starting material of roux; step (C) for mixing the starting material of roux obtained in step (B) with processed starch to give a mixture; and step (D) for heating the mixture obtained in step (C) to the gelatinization temperature of the processed starch or higher to give a roux.

Owner:MEIJI CO LTD

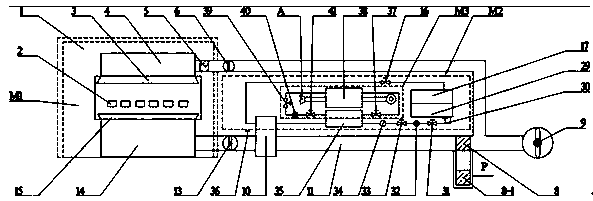

Rubber glove drying system utilizing solar heat pump

PendingCN110118475AReduce usageAvoid pollutionSolar heating energyHeat pumpsWater storage tankAir treatment

The invention relates to a rubber glove drying system, in particular to a rubber glove drying system utilizing a solar heat pump. The rubber glove drying system mainly comprises a drying room, a heatpump system module, a solar heat collecting module, a solar heating module and an air treatment module. A heat preservation layer and a hand die support are arranged at the upper portion in the dryingroom. The hand die support is arranged between an air supply port and an air outlet. An air supply box is arranged below the air supply port. An air outlet box is arranged above the air outlet. The connecting position of the fresh air pipe and an air return pipe is provided with a fresh air draught fan. A water storage tank cold water area and a water storage tank hot water area are arranged in the water storage tank. A water storage tank belongs to the heat collecting module and also belongs to the heating module. The hot water area belongs to the heat collecting module, and the cold water area belongs to the heating module. The rubber glove drying system utilizing the solar heat pump can solve the problems that according to a traditional drying manner, power consumption is large, the drying efficiency is low, the temperature is hard to control, glove heating is uneven, the finished product quality is poor, and dust pollution is caused.

Owner:JIANGSU UNIV OF SCI & TECH

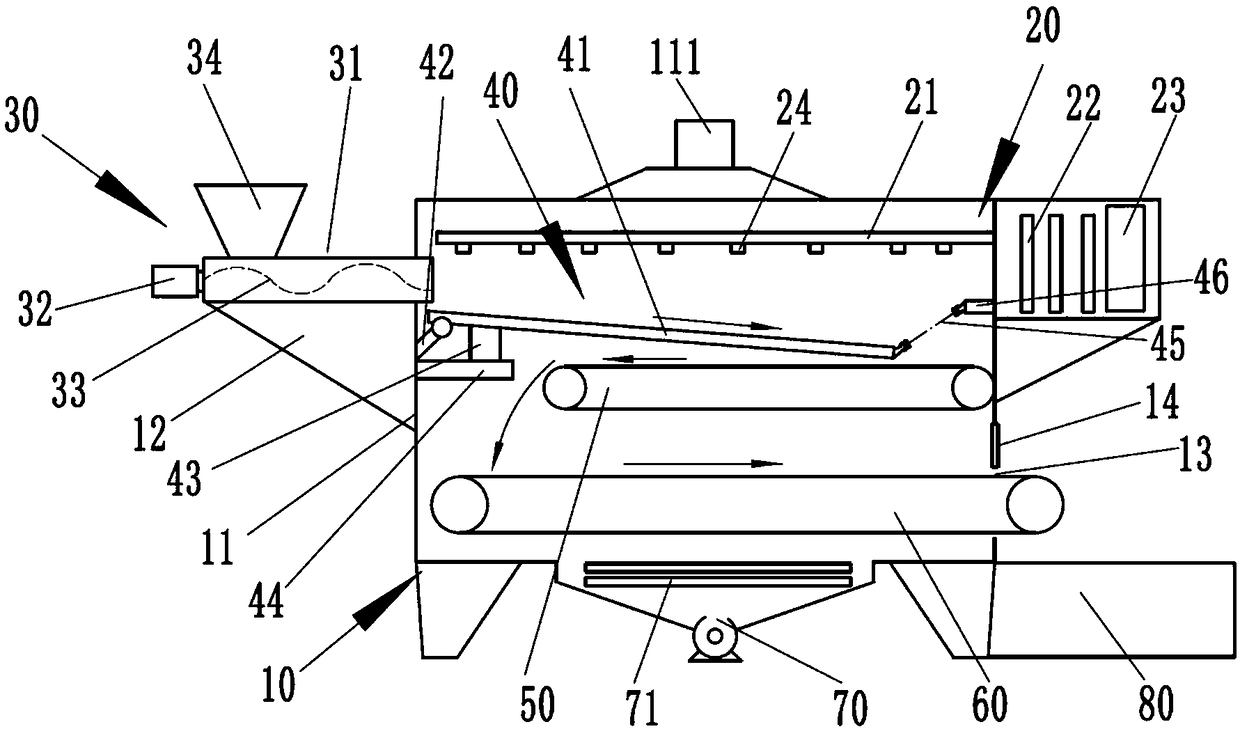

Tea drying machine

The invention discloses a tea drying machine. The machine comprises a frame, a drying box body, a feeding device, a heat supply device, an unloading mechanism, a conveying mechanism and a material containing box, the drying box body is arranged on the frame, the feeding device is arranged on the left side of the drying box body, the heat supply device is positioned on the right side of the feedingdevice, the unloading mechanism is arranged in the drying box body and is positioned below the heat supply device, the conveying mechanism is arranged below the unloading mechanism, a vibrating mechanism is arranged in the unloading mechanism and can spread the crowded tea leaves for more uniform heating, and the material containing box is arranged at the right lower part of the drying box body,and is positioned below the conveying mechanism. The machine can enable the tea leaves to be uniformly heated without breaking, so that the practicability of the machine is higher.

Owner:郑海东

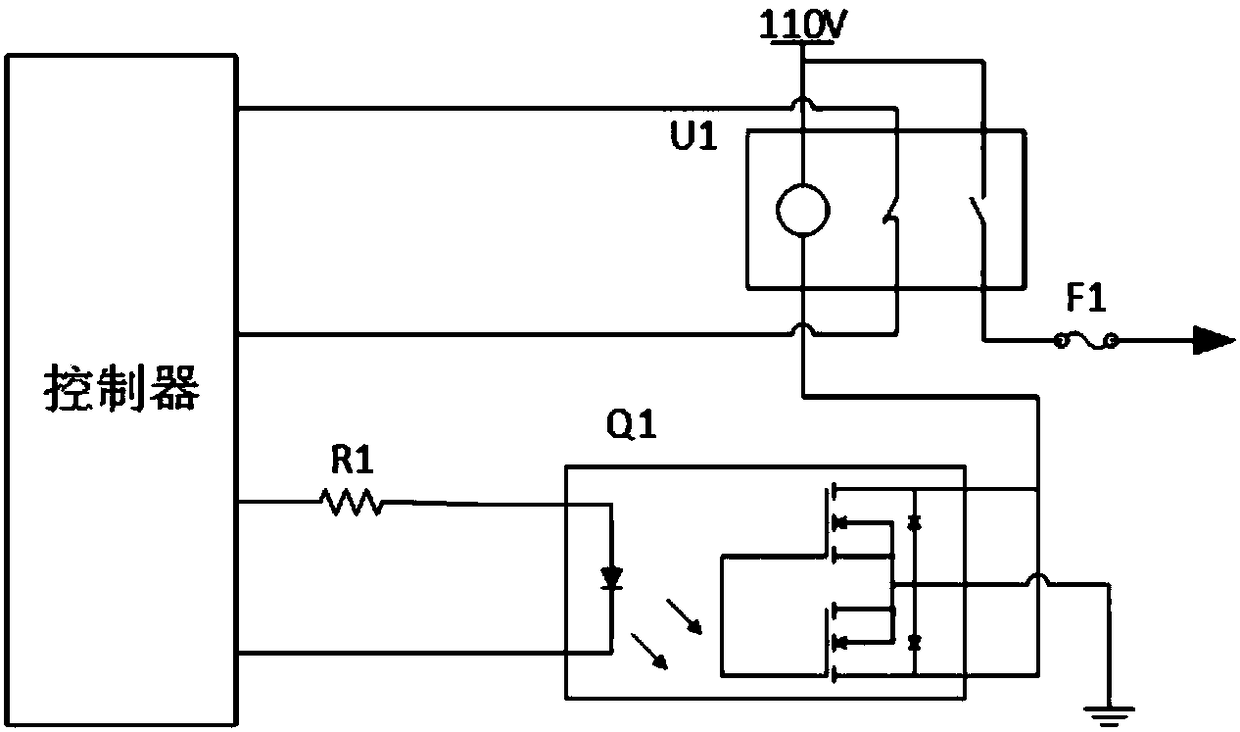

Heating system for driving equipment

InactiveCN108135107AReduce the temperatureUniform temperatureOhmic-resistance heatingCooling/ventilation/heating modificationsHeat conductingEngineering

The invention, which belongs to the heating field, provides a heating system for driving equipment. The heating system is composed of a heater and a control board for controlling the heating process of the heater. An external temperature sensor is also connected to the control board. The heater includes a frame; and a silica gel heating piece for electrification heating is fixed at the frame. Besides, a temperature controlled switch is also arranged and is connected with a temperature controller and is connected with the control board by a cable. Because the silica gel heating piece is used inthe heating system, compared with the metal heat pipe heater and the PTC heater, the silica gel heating piece has advantages of small size, simple process, great convenience in forming and opening, low-temperature starting, and energy conservation and the like. In addition, the highest temperature that the heating piece can reach is set by using the silica gel heating piece or PET electric heating film; and the heater and the cabinet frame are in thermal connection by a heat-conducting rubber mat to realize the conduction type heating dissipation with uniform heat conduction and high heat conduction efficiency, so that a phenomenon that the adjacent core device is damaged due to the too high local temperature is avoided.

Owner:ZHEJIANG UNIV +1

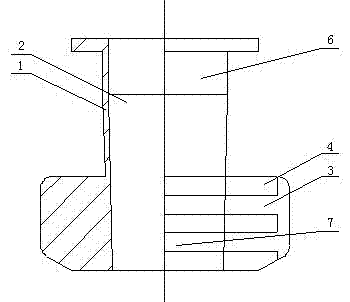

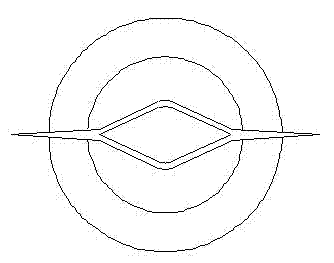

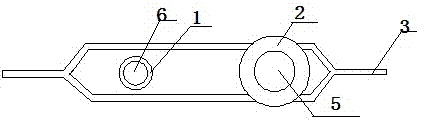

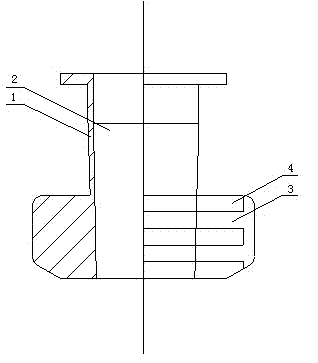

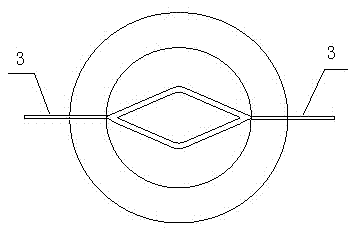

Connecting port of infusion bag

InactiveCN102247290AUniform thicknessNo uneven heatingPharmaceutical containersMedical packagingEngineeringRhomboid

The invention discloses a connecting port of an infusion bag, comprising a body, wherein the body is provided with a longitudinal through hole; a connecting part is arranged at one end of the body; an outlet part is arranged at the other end of the body; the connecting part is provided with two wings, and convex ribs are arranged on the two wings; one section of transitional part for connecting the outlet part with the connecting part is arranged in the middle of the body; the thickness wall of the transitional part is transitioned from thickness to thinness between the outlet part and the connecting part; a through hole is in a rhomboid shape in the connecting part; from top to bottom, the width of the through hole is transitioned from width to narrowness; and the two wings are thin wings. By adopting the rhomboid design and producing the two wings into the thin wings, the thickness of the side wall of the connecting part at the connecting port of the infusion bag is kept uniform; during heat sealing, the non-uniformity during heating is avoided, favorable heat sealing performance is obtained and materials are saved; meanwhile, by adopting the design of the transitional part, the materials are further saved.

Owner:江苏金扬子包装科技有限公司

Fish tank with heating and illuminating functions

The invention provides a fish tank with heating and lighting functions. Including cylinder body, cylinder head, low-voltage electric heating ceramic sheet, heating sheet carrier, electric contact mercury temperature controller, heating relay, heating power supply, power supply, waterscape lamp, photosensitive element circulating water system; among them, the upper part of the cylinder body is the cylinder head, The bottom of the tank is the bottom of the tank, and a screen is set inside the tank close to the bottom of the tank, and a water feature light groove is set on the bottom of the tank, which is a cylindrical groove, and a water feature light is installed in the water feature light groove; the above-mentioned fish tank A low-voltage electric heating ceramic sheet is provided, and the low-voltage electric heating ceramic sheet is fixed on the heating sheet carrier, and the heating sheet carrier is arranged in front of the last stage filter of the water tank, and the water tank is arranged in the fish tank body near the cylinder head; the two sides of the above water tank A water outlet is arranged on the water channel, and the water outlet is located near the tank wall; the circulating water pump of the fish tank is installed on the bottom of the tank body, and the upper water outlet of the circulating water pump is arranged on the side of the water tank away from the water outlet.

Owner:ZHAOQING CITY HI TECH ZONE XIAOJING TECH CO LTD

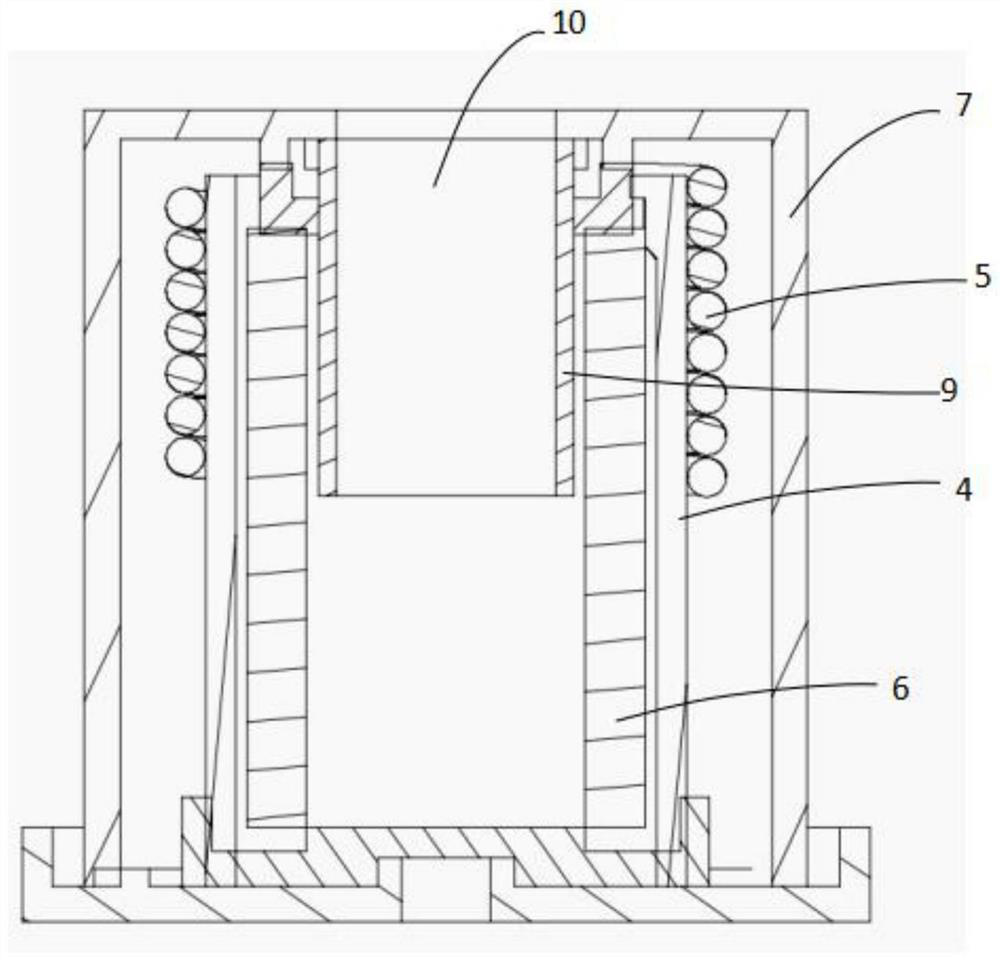

Electromagnetic induction heating aerosol forming device and application thereof

PendingCN114246367ALow efficiency due to eddy current effectReduced shieldingTobaccoMixed materialsMaterials science

The invention belongs to the field of heating appliances, and particularly relates to an electromagnetic induction heating aerosol forming device and application thereof. The aerosol forming device comprises a shell (7), a heating body (9) and a smoke cup (3), wherein the heating body (9) is internally provided with an air flow channel, and the heating body (9) contains a ceramic material and a soft magnetic material. In an existing electromagnetic induction heating mode, when a heating body (9) is only made of a soft magnetic material (such as an iron block), an eddy current effect can only be generated on the surface of the heating body (9), and the interior of the heating body (9) is shielded, so that the eddy current effect is low in efficiency. The heating body (9) is a mixed material of a soft magnetic material and a ceramic material, and after the soft magnetic material and the ceramic material are mixed, the shielding effect is reduced, so that the center of the heating body (9) can generate an eddy current effect, and the efficiency of the eddy current effect is enhanced.

Owner:SHENZHEN GEEKVAPE TECH CO LTD

Automatic drying injection molding machine used for computer connector

The invention discloses an automatic drying injection molding machine used for a computer connector. The machine comprises an injection molding machine body, a heating cavity is formed in the injection molding machine body, a layered heating device is arranged in the heating cavity, a transmission cavity is formed in the position, on one side of the heating cavity, of the injection molding machinebody, a transmission device is arranged in the transmission cavity, a push rod motor is arranged on the top of the injection molding machine body, the output end of the push rod motor is connected with an adjusting device, an annular cavity is formed in the position, located on an output opening, in the injection molding machine body, an injection device is arranged in the annular cavity, multiple layers of heating chassis rings which are heated gradually are arranged in the heating cavity, the material can be gradually heated, in the heating process, through device drive, rotation and turnover of the heating chassis rings can be achieved, it is ensured that the material in the heating chassis rings can be sufficiently heated, and the condition of uneven material heating can be avoided.

Owner:SHANDONG LABOR VOCATIONAL & TECHN COLLEGE

Heating cooking device

ActiveCN101377317BNo uneven heatingGood heat cookingDomestic stoves or rangesLighting and heating apparatusWater vaporEngineering

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP

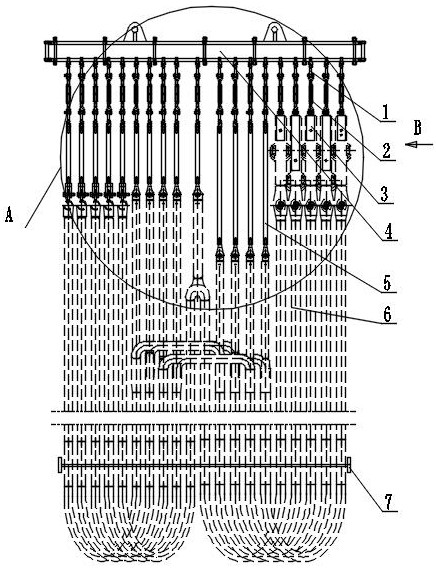

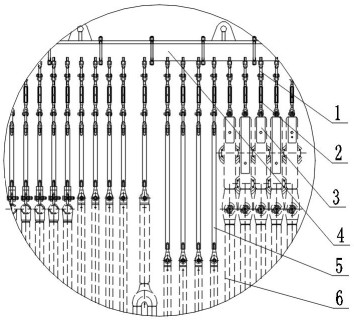

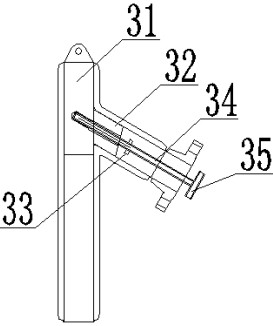

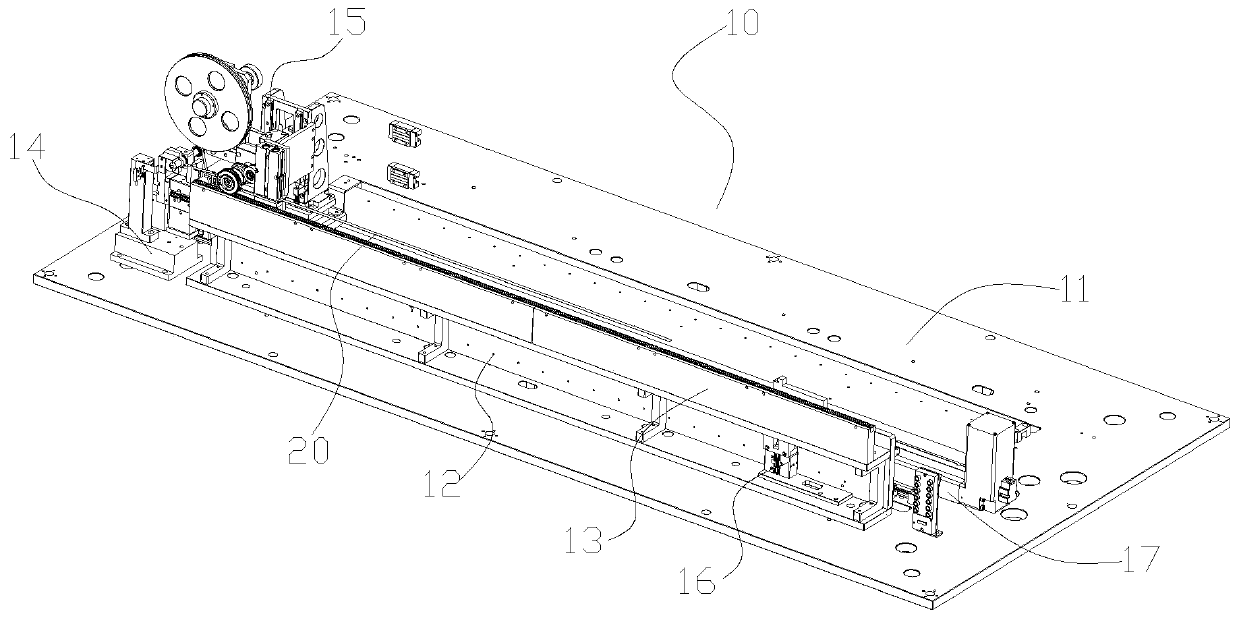

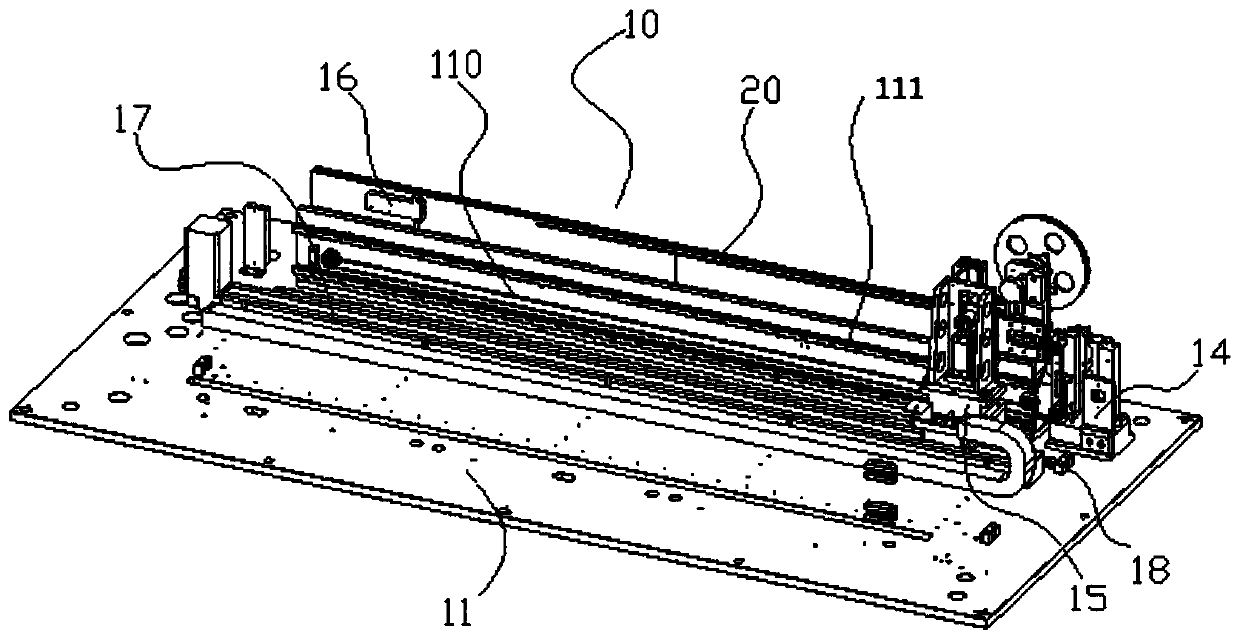

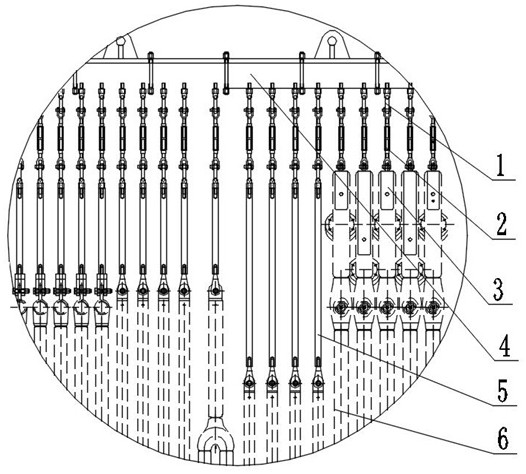

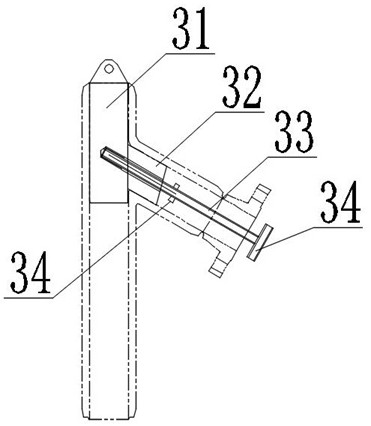

Universal ethylene cracking furnace coil hanging test equipment and test method

ActiveCN112249862BNo interferenceNo uneven heatingLoad-engaging elementsStructural engineeringMechanical engineering

The invention discloses a general-purpose ethylene cracking furnace coil hanging test tool, which includes a main suspension beam and a universal suspension ring. Several universal suspension rings are connected to the lower part of the main suspension beam, and UU-shaped turnbuckle screws are connected to the lower part of the universal suspension ring; The top of one end of the coil is connected to the UU-shaped turnbuckle through a bu-shaped pipe lifting rod tooling, and the top of the other end of the coil is connected to the UU-shaped turnbuckle through an intermediate connector; the lower part of the coil is provided with auxiliary tooling. The invention has the advantages of reasonable structure, convenient and simple operation, wide application range, greatly reduced cost and storage space for hanging test tooling, prolonged service life, greatly reduced labor force, and improved inspection accuracy.

Owner:JIANGSU BIAOXIN KUBOTA IND

Novel forming heating plate

Owner:诸城市昊坤装备科技有限公司

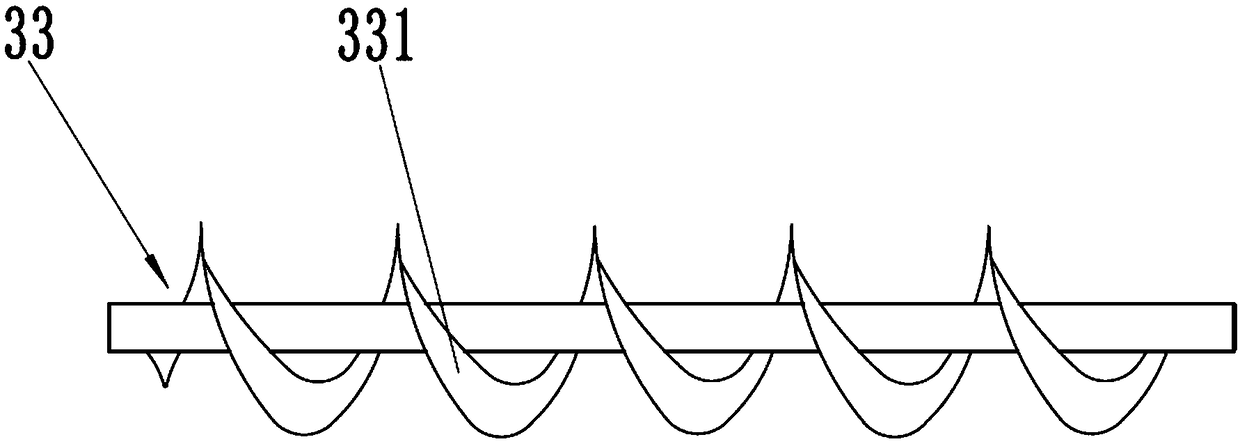

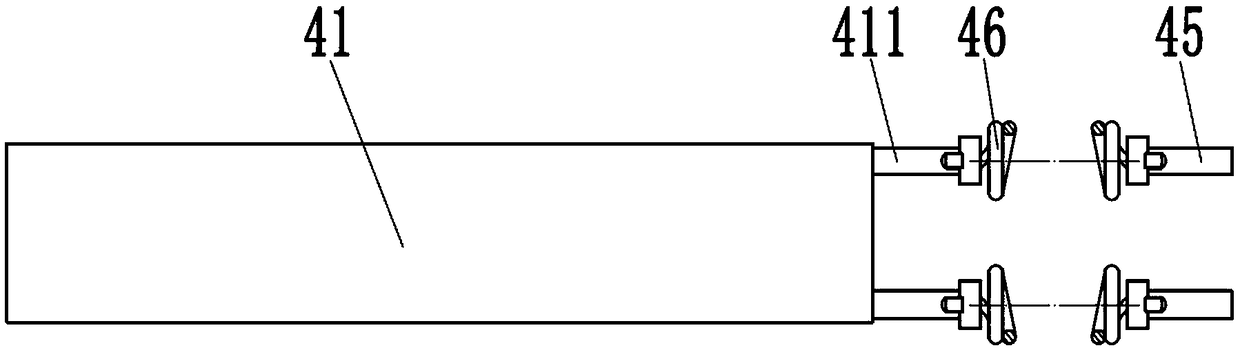

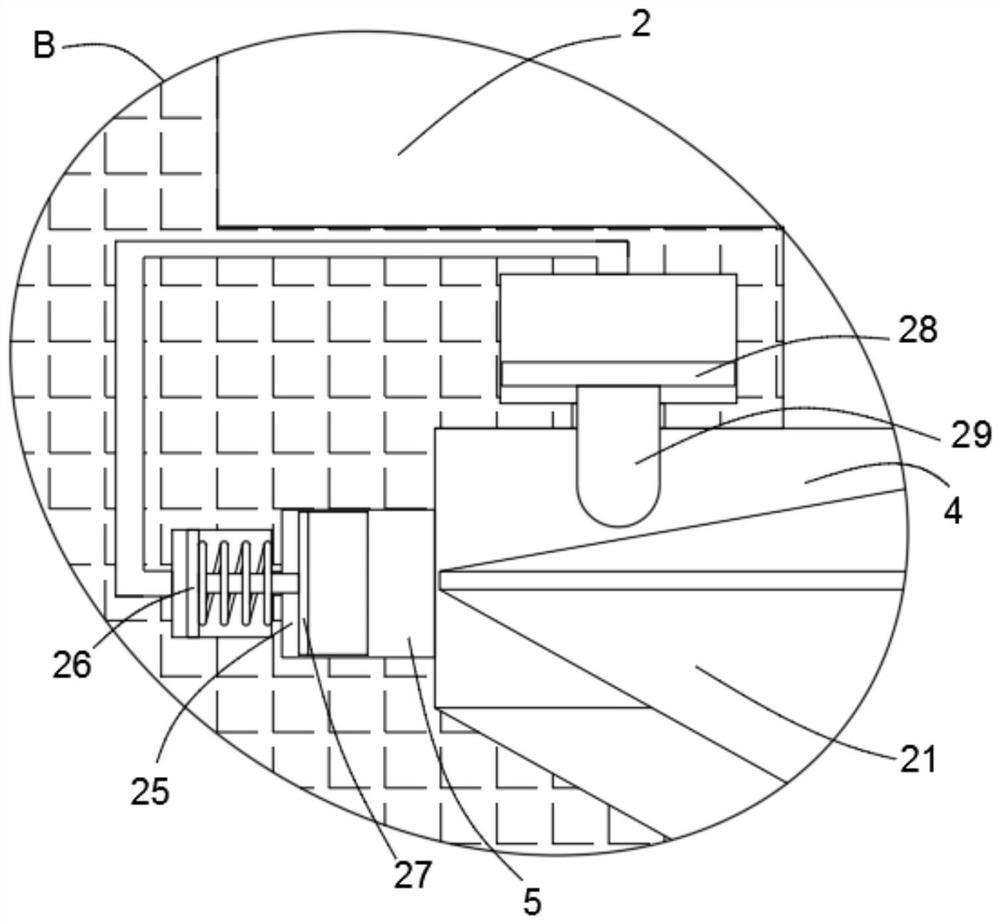

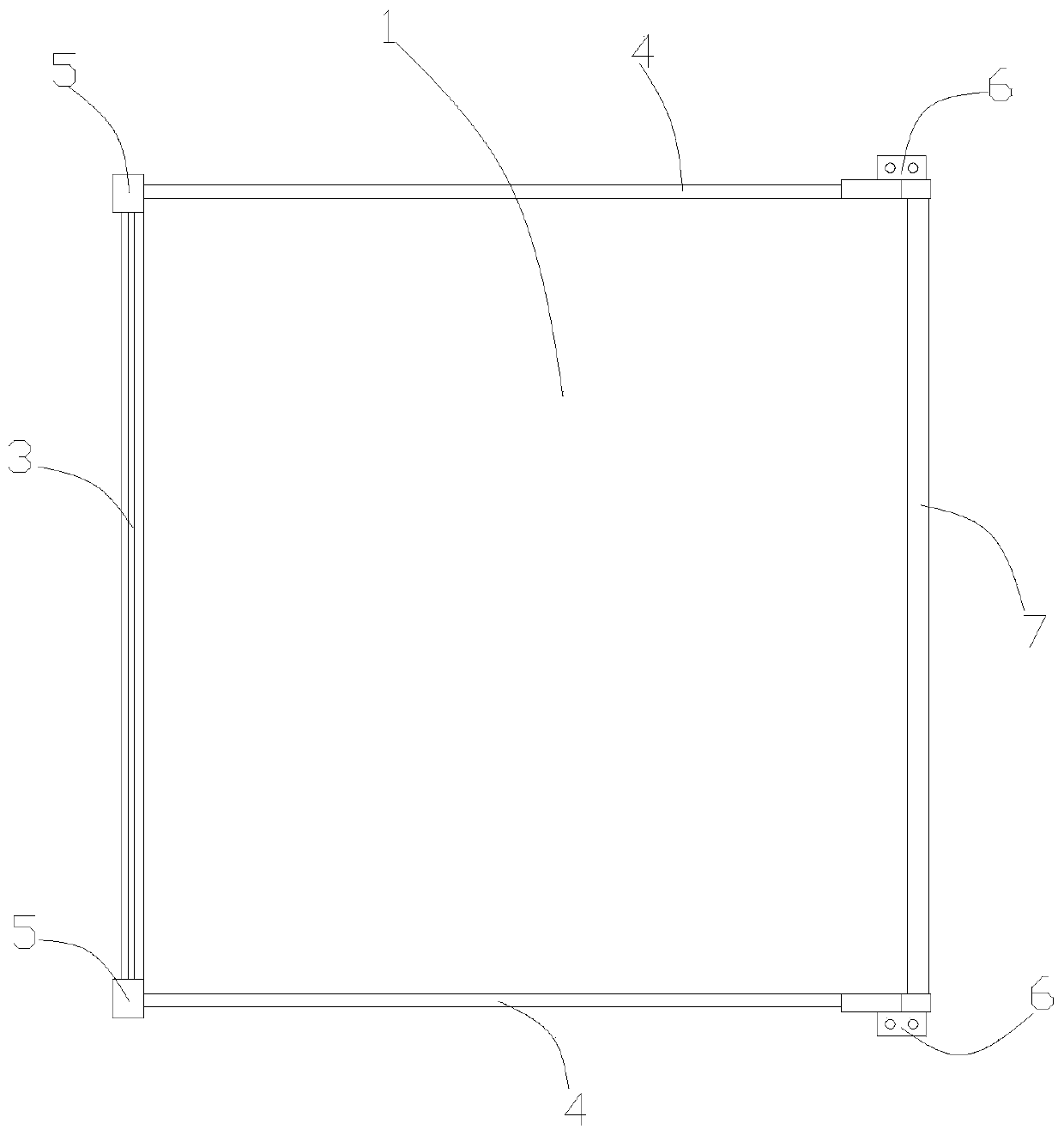

Coil spring glue laying device for sunshade curtain

ActiveCN107824381BRoll back smoothlyEasy to processLiquid surface applicatorsCoatingsCoil springSlide plate

Owner:科德汽车零部件(长春)有限公司

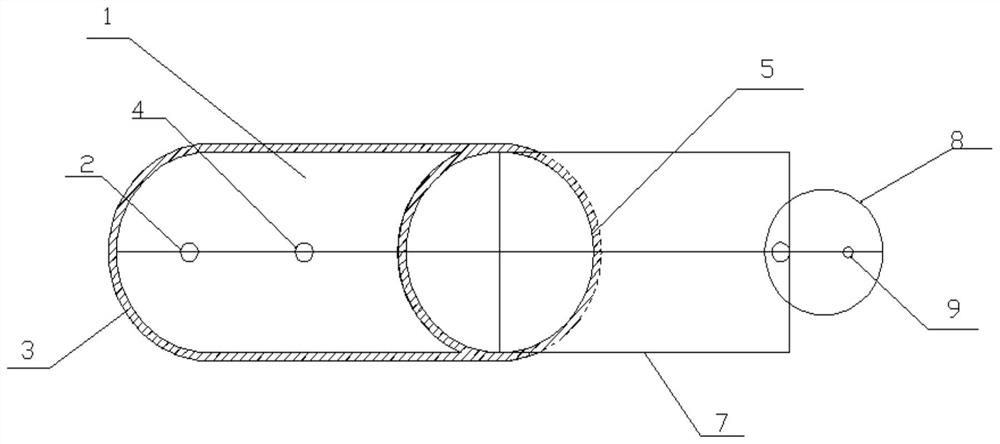

High-vacuum distillation purification device

PendingCN114768286AEvenly heatedNo uneven heatingDistillation in boilers/stillsVapor condensationEngineeringVALVE PORT

The invention discloses a high-vacuum distillation and purification device which is suitable for separation of high-boiling-point and heat-sensitive materials. The device at least comprises a distillation still with a stirring shaft, a feeding port is formed in a distillation still shell, a column and the distillation still are directly welded at 90 degrees, and the distillation still shell except for the feeding port, the stirring shaft and the position where the column and the distillation still are welded is all wrapped by a jacket type heating layer; the front end of the condenser is welded with the top end of the column and inclines downwards, and the tail end of the condenser is connected with the receiving tank through a flange; a vacuum pipeline is arranged on the upper portion of the receiving tank, the vacuum unit is connected with the receiving tank through the vacuum pipeline, and a vacuum valve is arranged on the vacuum pipeline to control the opening degree of the vacuum unit. The device has the characteristics of high vacuum degree, low distillation temperature and high evaporation speed, and is simple to operate and low in equipment price.

Owner:张博申

Double-mouth pipe of transfusion bag

InactiveCN102366347AAvoid breakingAvoid cross contaminationPharmaceutical containersMedical packagingMaterial consumptionEngineering

The invention provides a double-mouth pipe of a transfusion bag. The double-mouth pipe comprises a medicine distribution pipe and a transfusion pipe, wherein the medicine distribution pipe and the transfusion pipe are vertically fixed on a double-pipe body seat; a medicine distribution pipe through hole and a transfusion pipe through hole are separately arranged on the medicine distribution pipe and the transfusion pipe; the aperture of the medicine distribution pipe through hole is smaller than that of the transfusion pipe through hole; a gasket is arranged inside the top end of the medicine distribution pipe through hole; a rubber plug is placed on the gasket; two sides of the double-pipe body seat are in an elongated and thin wing shape, and four corners of the double-pipe body seat are all chamfers; and multiple convex ribs are arranged outside the double-pipe body seat. The double-mouth pipe of the transfusion bag has the advantages that: the transfusion pipe and the medicine distribution pipe are separated, thus cross infection is avoided when medicine liquid is used; the aperture of the medicine distribution pipe hole is smaller than that of the transfusion pipe hole, thus the material consumption is reduced and the production cost is lowered; and two sides of the double-pipe body seat are in an elongated and thin wing shape, and four corners of the double-pipe seat are all chamfers, thus bag breakage and liquid leakage caused by excessive extension of the membrane at the transfusion bag joint are avoided.

Owner:江苏金扬子包装科技有限公司

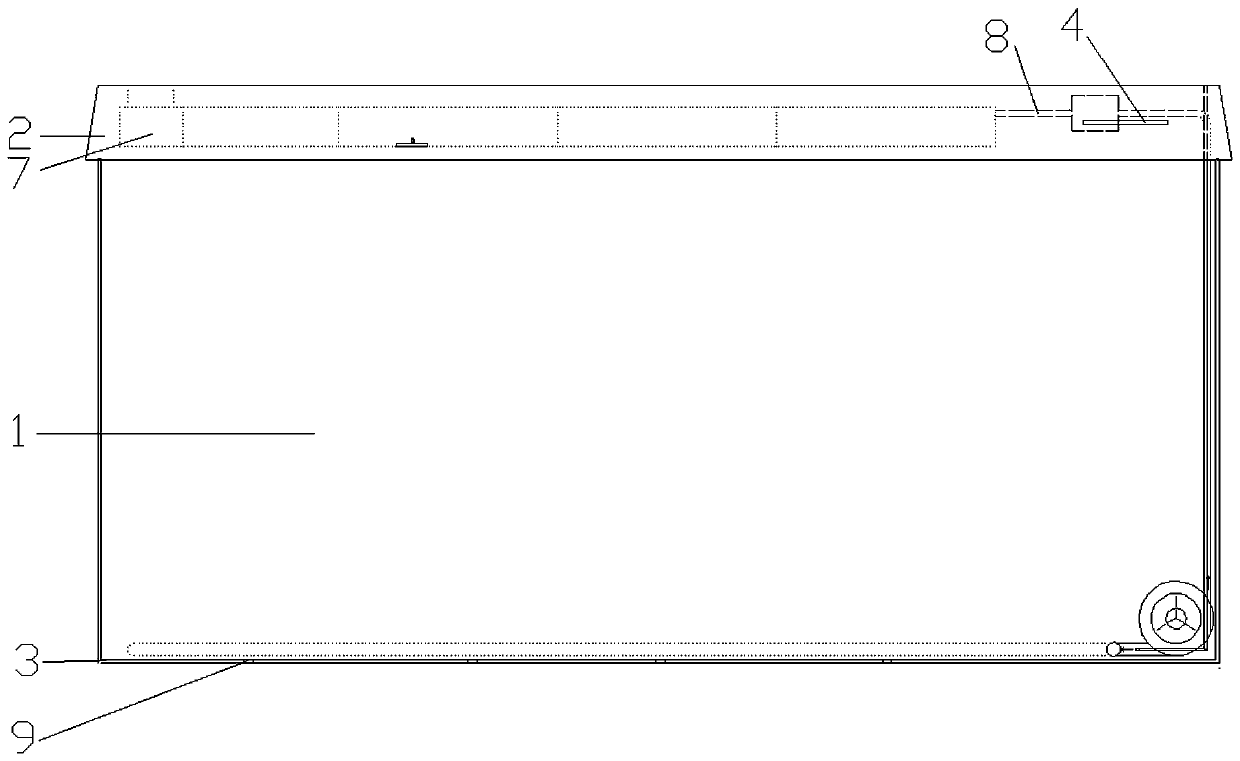

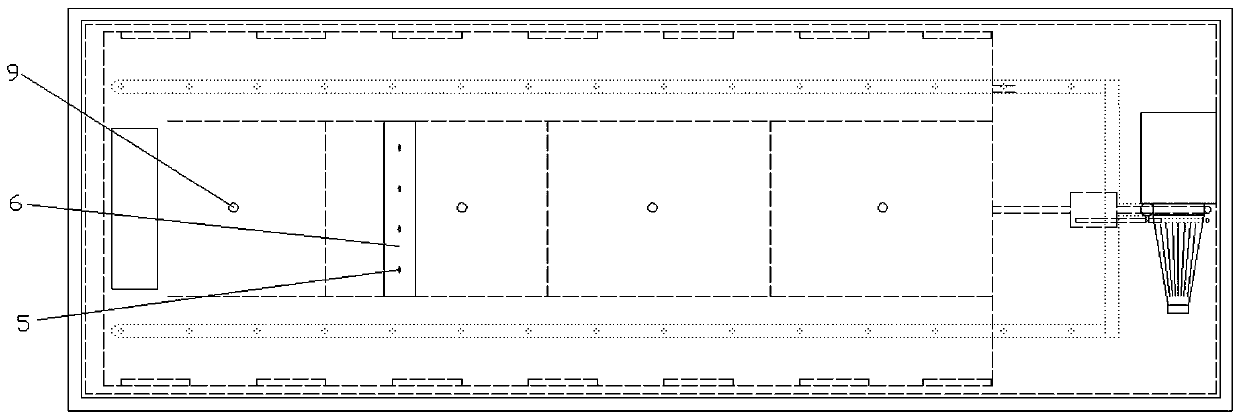

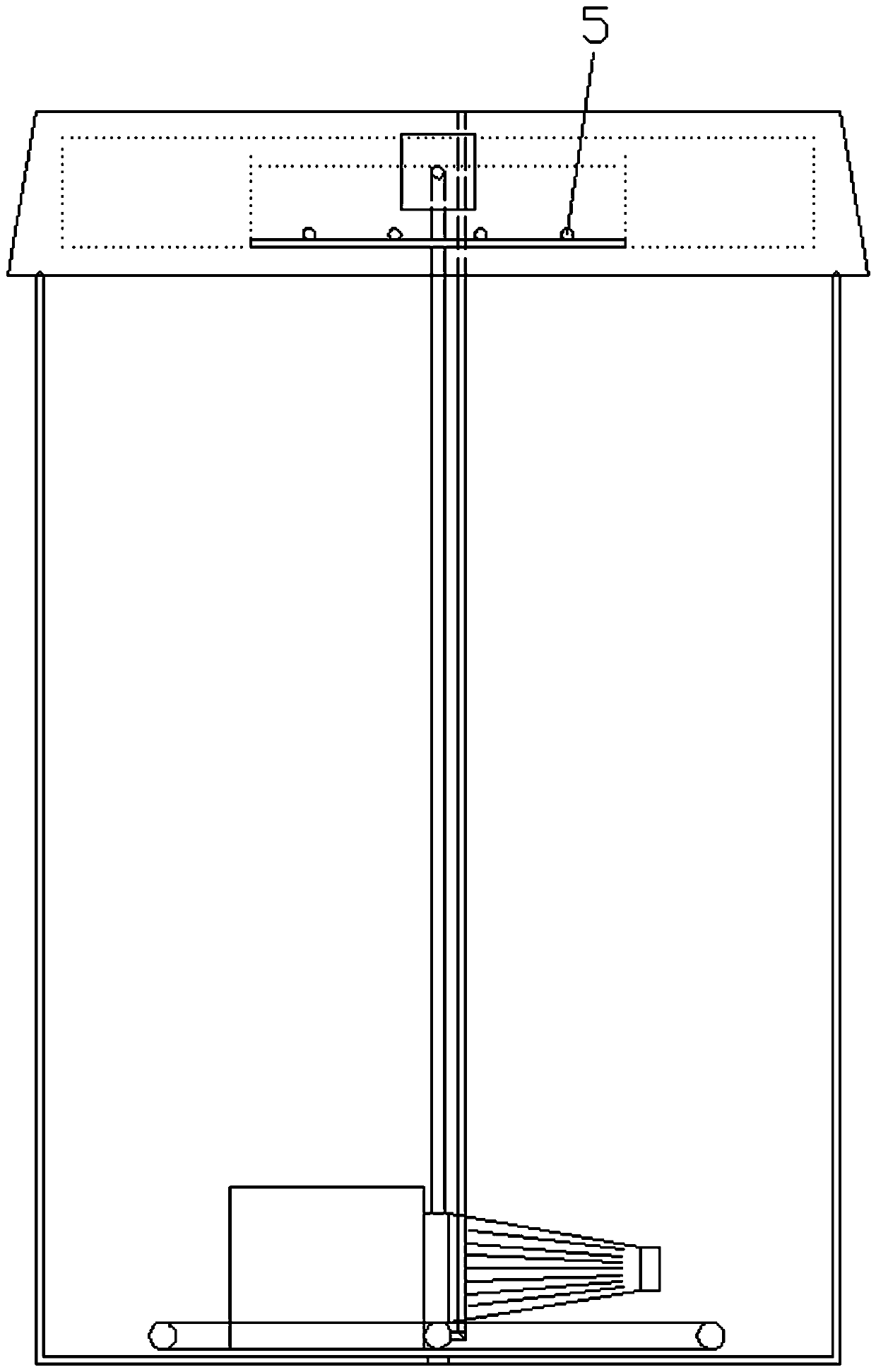

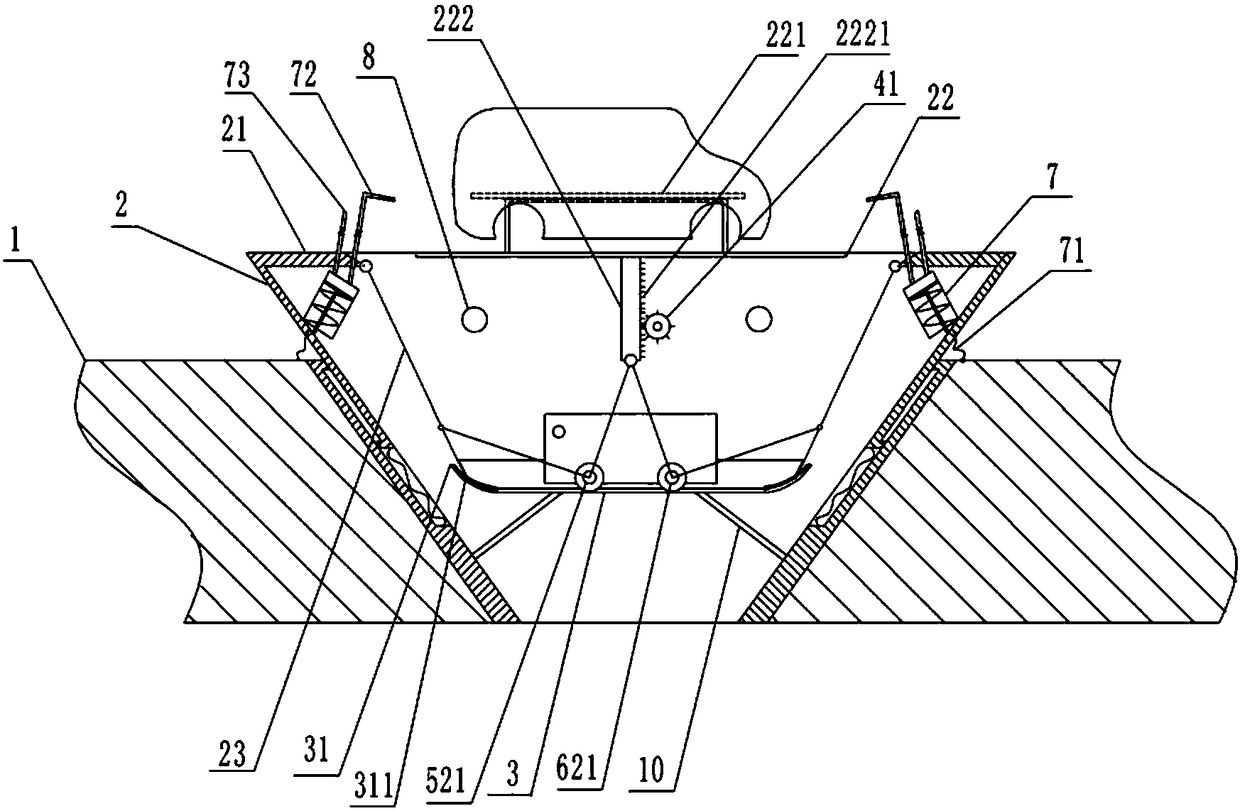

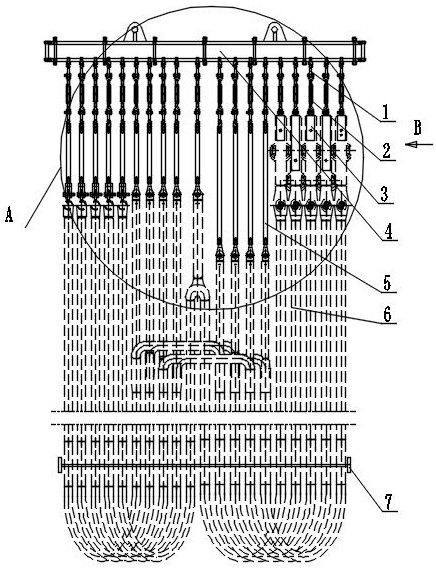

Duck Roasting process and device by air jet impacting

InactiveCN100348130CCreate pollutionNo uneven heatingFood preparationRoast chickenPulp and paper industry

The present invention aims at providing duck roasting process and roaster with homogeneous heating, homogeneous product appearance and color, standard operation and no pollution. The technological process features that the prepared duck is roasted in airflow of 120-150 deg.c temperature and 5-20 m / s speed for 30-60 min inside an airflow impacted duck roaster. The roaster includes roasting chamber with nozzles on two sides and waste air recovering channel, duck suspender, fan assembly and heater in the lower part of the roasting chamber, and rotating unit in the top center of the roasting chamber. The present invention has the features of homogeneous heating, no flame, no pollution, homogeneous color of the roasted product and standard operation. The present invention may be also used in producing roasted chicken, roasted sucking pig, roasted whole sheep, etc.

Owner:CHINA AGRI UNIV

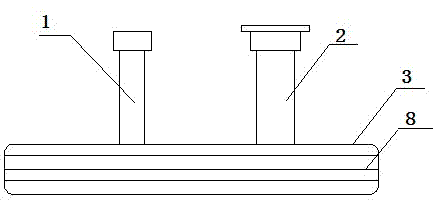

Working table convenient for automobile oil sludge model production

InactiveCN108297596AGuaranteed plasticityEasy to modifyWork benchesOther artistic work equipmentsOil sludgeCavity wall

The invention relates to the technical field of oil sludge production, in particular to a working table convenient for automobile oil sludge model production. The working table convenient for automobile oil sludge model production comprises a working table body, the working table body is provided with a machining cavity, and a sliding cover is slidably connected to the inner wall of the machiningcavity. The sliding cover is internally provided with a supporting platform, a suction part and supporting inclined plates, a heating part is arranged under the supporting inclined plates, and first contact points connected with a heating wire are arranged on the heating part. Second contact points connected to a power supply are arranged at the lower ends of the support inclined plates, and the second contact points can be in contact with the first contact points and electrify the heating wire. A support rod is fixed to the bottom surface of the supporting platform, and a rack is fixed to theside wall of the support rod. A rotating shaft is rotataly connected to the inner wall of an inner cavity of the machining cavity, and a gear is fixed to one end of the rotating shaft. A power part is arranged at the lower end of the support rod, and the power part drives the sliding cover to slide up and down under the push of the support rod. A fetching-placing part is arranged on the cavity wall of the machining cavity. Hot air pipes are further connected to the sliding cover in a communicating mode. The working table convenient for automobile oil sludge model production can recycle oil sludge and ensure the use efficiency of the oil sludge.

Owner:重庆中壹迪工业设计有限公司

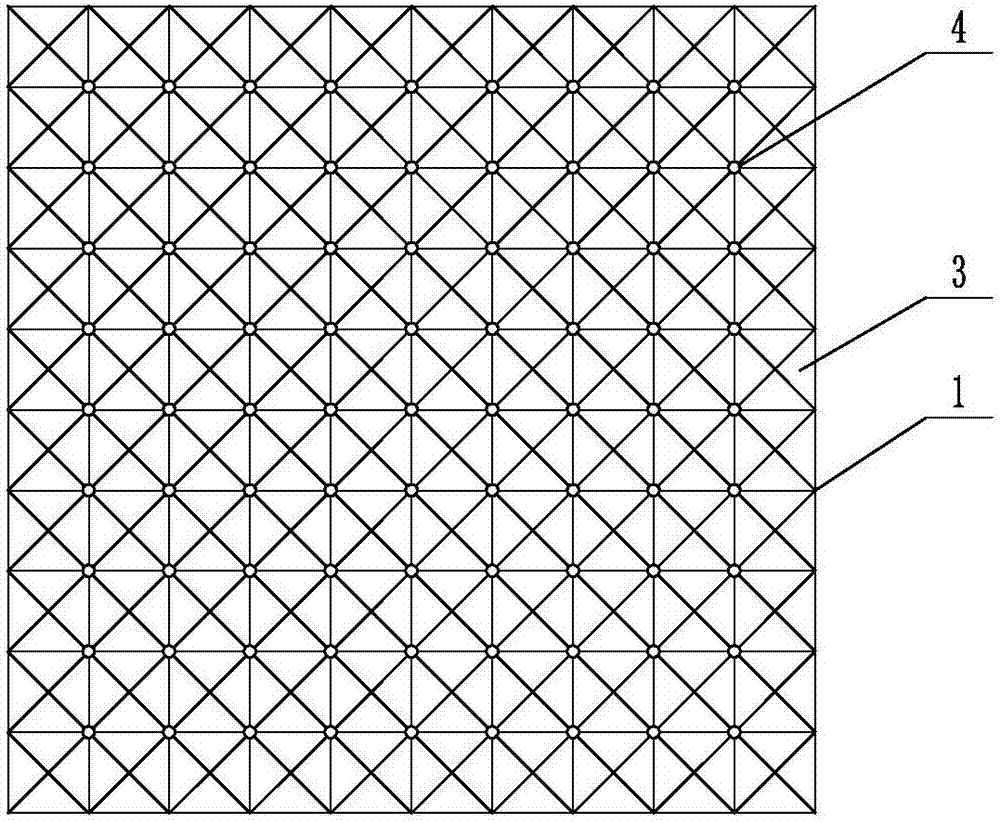

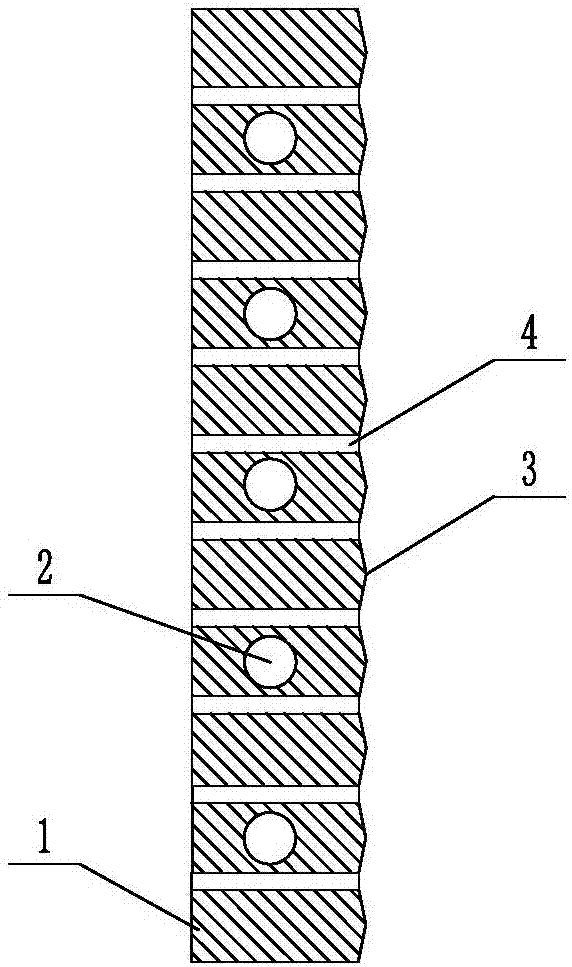

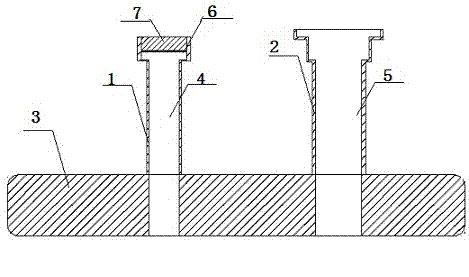

Concrete Prefabricated Component Manufacturing Process

ActiveCN106363790BFast preparationHeating fastCeramic shaping apparatusReinforced concreteTemperature difference

The invention discloses a manufacturing technique for precast concrete components, and relates to the technical field of precast reinforced concrete components. The manufacturing technique for the precast concrete components comprises the following steps that (1) a basic plane is cleaned; (2) electric heating wires and frame type formworks are arranged on the basic plane, and the electric heating wires are arranged in the frame type formworks; (3) the precast concrete components are poured in the frame type formworks; (4) the poured precast concrete components are heated by the electric heating wires; (5) the precast concrete components are cured to the hoisting strength; and (6) the precast concrete components are hoisted to be separated from the formworks and continue to be hardened, and thus the precast concrete components are manufactured. By adoption of the manufacturing technique, rapid manufacturing of small-thickness precast concrete components can be achieved. Integral heating of the small-thickness precast concrete components can be achieved through the electric heating wires on the basic plane, nonuniform heating or a too large temperature difference between the upper portion and the lower portion is avoided, and accordingly accelerated drying and hardening of the precast concrete components are achieved.

Owner:河北晶通建筑科技股份有限公司

Oven heating device

Owner:赵燕

Heating device for nylon heat insulation strip production and heating method thereof

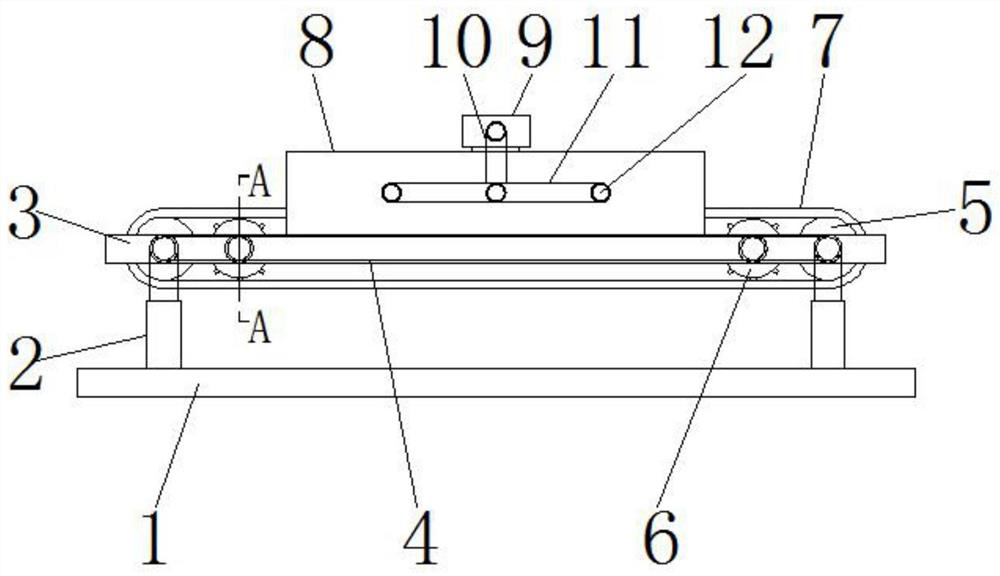

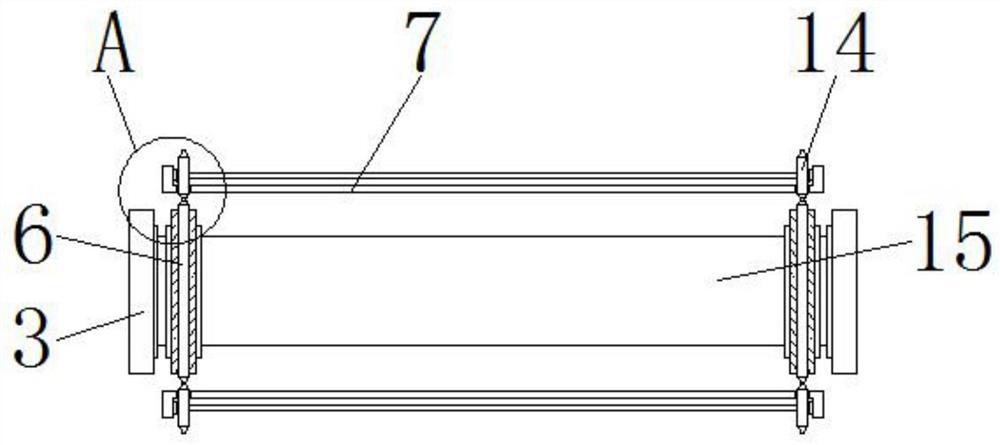

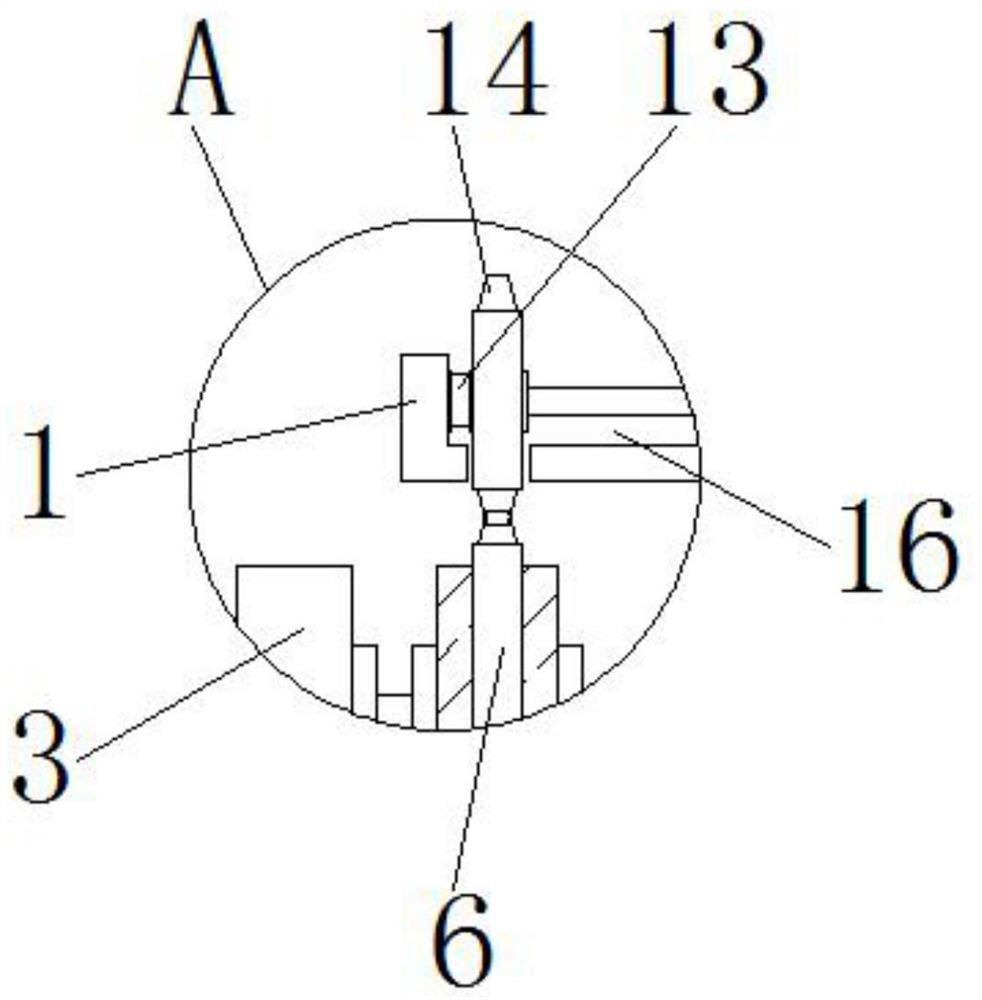

InactiveCN112093387AImprove heating efficiencyThere will be no serious lossConveyorsDrying gas arrangementsPhysicsElectric energy

The invention discloses a heating device for nylon heat insulation strip production. The heating device comprises a base, a supporting rod, a fixing plate, a belt, a roller body, a rotating gear and aconveying belt; the supporting rod is fixedly installed at the top end of the base, the top end of the supporting rod is connected with the bottom of the fixing plate, and the top end of a connectingshaft is connected with one side of a containing device; and a rotary gear is arranged at one side of the roller body, an intermediate shaft of the rotary gear penetrates through the fixing plate, and the outer portion of the intermediate shaft of the rotary gear is arranged at the inner side of the belt. When the heating device for nylon heat insulation strip production is used, the temperaturein a fixing cover in the whole device can be repeatedly utilized, the phenomenon of serious heat losses is avoided, and then the consumption of electric energy is indirectly reduced, so that the wholedevice is more energy-saving and environment-friendly when being used.

Owner:金寨宏伟新材料有限公司

Universal ethylene cracking furnace coil pipe hanging test tool and test method

ActiveCN112249862ANo interferenceNo uneven heatingLoad-engaging elementsStructural engineeringMechanical engineering

The invention discloses a universal ethylene cracking furnace coil pipe hanging test tool which comprises a main hanging beam and universal hanging rings. The lower part of the main hanging beam is connected with a plurality of universal hanging rings, and the lower parts of the universal hanging rings are connected with a UU-shaped turnbuckle; the top of one end of a coil pipe is connected with the UU-shaped turnbuckle through a lifting rod assembly of a pipe taking the shape of the Chinese character bo, and the top of the other end of the coil pipe is connected with the UU-shaped turnbucklethrough a middle connecting piece; and an auxiliary tool is arranged at the lower part of the coil pipe. The universal ethylene cracking furnace coil pipe hanging test tool is reasonable in structure,convenient and simple to operate and wide in application range, the cost and the space for storing hanging test tools are greatly reduced, the service life is prolonged, the labor force is greatly saved, and the testing accuracy is improved.

Owner:JIANGSU BIAOXIN KUBOTA IND

Connector of infusion bag

InactiveCN102247289AAvoid breakingAvoid broken bags and liquid leakagePharmaceutical containersMedical packagingEngineering

Owner:江苏金扬子包装科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com