High-vacuum distillation purification device

A high-vacuum, distillation kettle technology, applied in distillation separation, molecular distillation, distillation in boilers/distillates, etc., can solve the problems of unclean removal of light components of products, easy oxidation of materials, and small processing capacity, etc. Low price, fast evaporation, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

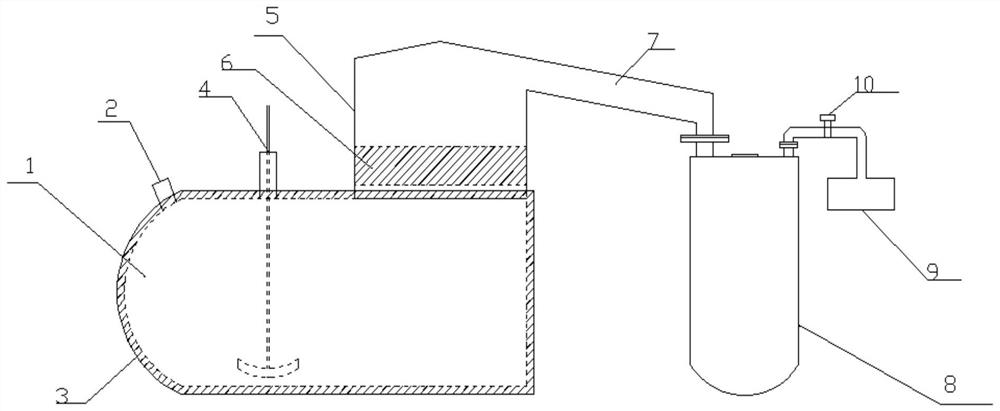

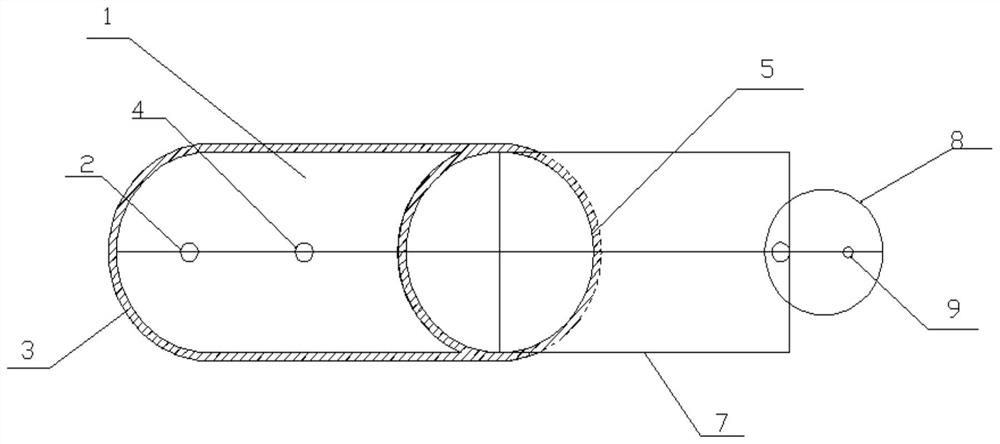

[0013] like figure 1 and figure 2 As shown, a high-vacuum distillation and purification device provided in this embodiment at least includes a feed port 2 for convenient direct feeding, a distillation still 1 with a stirring shaft 4, a fully wrapped jacket heating layer 3, a large-diameter Column 5 with packing 6, condenser 7, flanged receiving tank 8 and vacuum unit 9.

[0014] The shell of the still 1 except the feeding port 2, the stirring shaft 4, and the place where the column 5 and the still 1 are welded are all wrapped with the jacket type heating layer 3. First, the jacket is heated, which completely wraps the still still. The advantage of this is that the whole material in the still can be heated evenly under the condition of stirring. In addition, the jacket heating also facilitates the use of different heat sources. It is possible to use steam or heat transfer oil to heat the still, and it is also convenient to distill according to the material. Different heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com