Method for producing processed food for heating

A technology for processing food and manufacturing method, applied in food preparation, food preservation, protein-containing food ingredients, etc., can solve the problems of high moisture content, uneven heating, long cooking time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Manufacture of antifreeze protein solution

[0052]700 g of commercially available Brassica juncea (trade name; mustard sprouts, manufactured by Murakami Farm) was added to 2.5 liters of distilled water, and hot water extraction was performed at 105° C. for 1 hour. After filtering with filter paper (manufactured by Advantec, retained particle size: 5 μm), about 2 liters of the extract was concentrated under pressure using an ultrafiltration concentration device (manufactured by Advantec, UHP-150) to obtain 200 ml of a concentrate. The concentrate was centrifuged at 10000 xg for 10 minutes, and the supernatant was recovered. The protein concentration of the supernatant was measured by the BCA method (BCA kit, manufactured by Pierce Co.), and found to be 5 mg / ml. Thus, the concentration of the antifreeze protein solution was 0.5%.

[0053] (2) Manufacture of frozen rice

[0054] 750 mL of tap water mixed with 1.5 mg (in terms of protein amount) of the extract obtai...

Embodiment 2

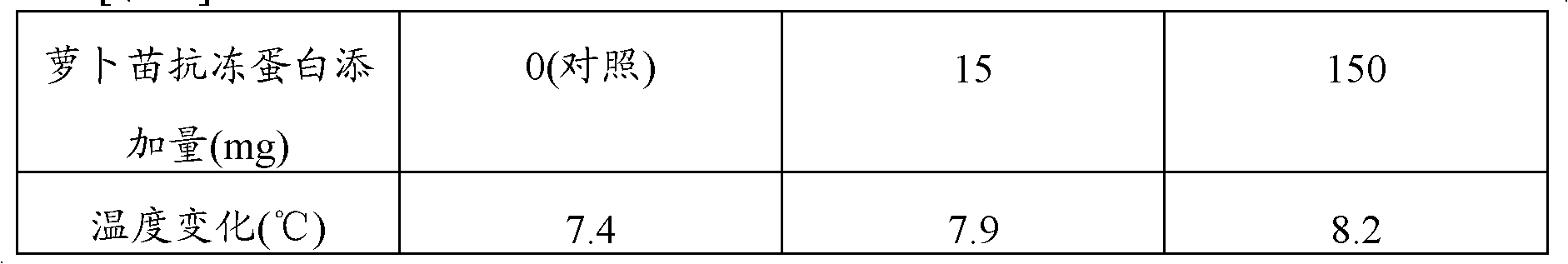

[0063] Add 15 mg and 150 mg of commercially available radish seedlings (カイワレ 大根) antifreeze protein (manufactured by Big World) to 0.72 L (4 pieces) of "Akitakomachi" (produced in Akita Prefecture) (calculated as the amount of protein) ) of tap water 750 mL, cooked rice in the same manner as in Example 1 (2). After the rice cooking was finished, the small portion of rice divided into 100 g in each container was stored in a freezer at -20°C.

Embodiment 3

[0072] In 380g of commercially available sterilized curry paste, add 20g of tap water mixed with commercially available radish seedling antifreeze protein 12mg (converted by protein amount), stir and mix until the hot water bath temperature is 80°C. After preparation, the curry paste that is divided into 100 g in each container is put into a freezer and stored at -20°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com