Novel forming heating plate

A molding heating and heating plate technology, which is applied in the field of parts and components, can solve the problems of poor molding effect, uneven heating of the stretch film, affecting the appearance and sealing effect, etc., to achieve the best heating effect and easy to attach and heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

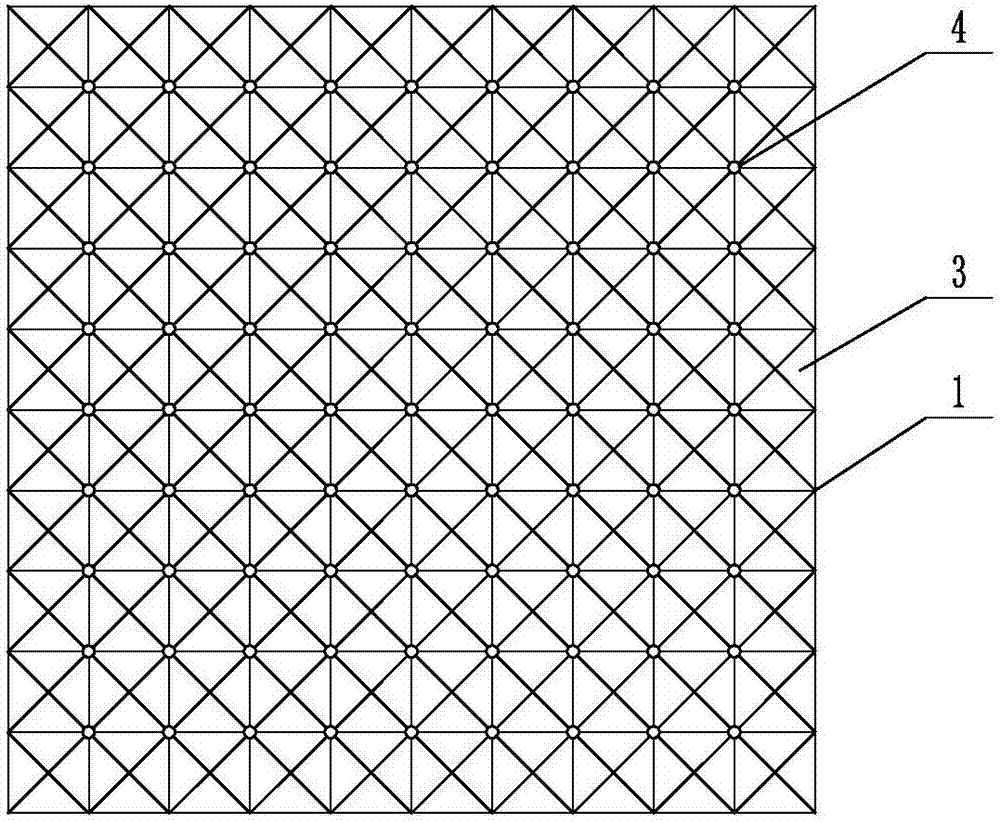

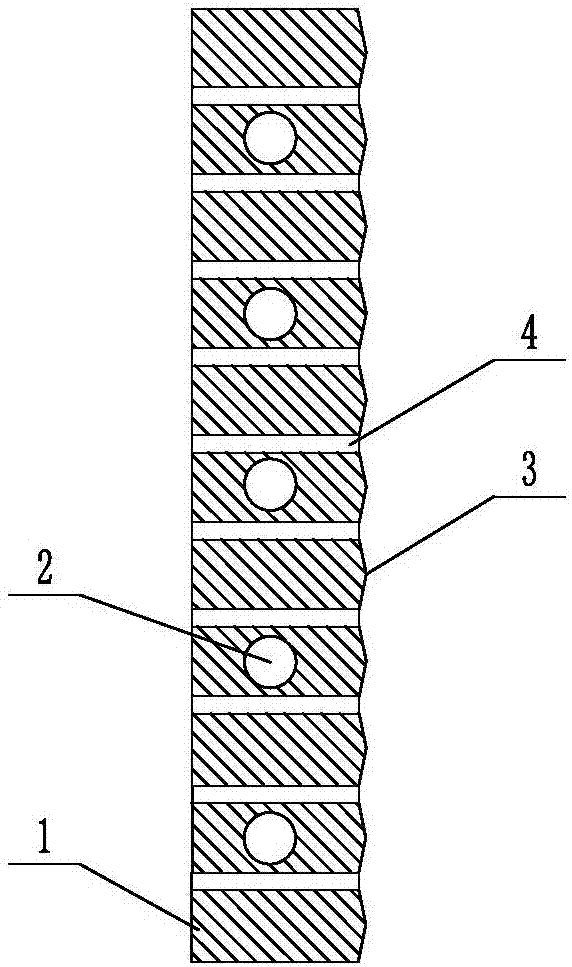

[0013] Such as figure 1 , 2 As shown, the present invention includes a heating plate 1, heating rods 2 uniformly distributed inside the heating plate 1, the surface of the heating plate 1 is provided with uniformly distributed protrusions 3, the protrusions 3 are square pyramids, and The four corners of the bottom surface of 3 are provided with exhaust holes 4 that run through the heating plate 1 .

[0014] The length of the base of the protrusion 3 is 18-22 mm, and the height of the protrusion 3 is 1.3-1.7 mm.

[0015] Preferably, the length of the base of the protrusion 3 is 20 mm, and the height of the protrusion 3 is 1.5 mm.

[0016] Working principle: under the heating of the heating rod 2, the heating plate 1 expands evenly after being heated, which avoids the appearance of traces caused by local uneven heating or uneven expansion of the material itself. The setting of the exhaust hole 4 realizes the heating plate 1 The flow of gas between the film and the stretch fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com