Connector of infusion bag

An infusion bag and connecting port technology, which is applied in the field of infusion bag production, can solve the problems of uneven heating, high cost, water leakage and seepage, and achieve the effects of reducing production cost, good heat sealing quality and saving materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

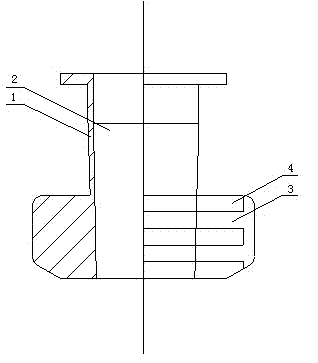

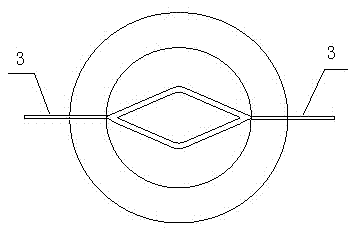

[0017] As shown in the figure, an infusion bag connection port of the present invention includes an interface body 1, one end of the interface body 1 is the outlet end, and the other end is the connection end with the infusion bag; the interface body 1 is provided with a longitudinal Through hole 2, the two sides of the port at the end where the interface body 1 is connected to the infusion bag are respectively provided with inline thin wings 3, and the length of each inline thin wing 3 is 1.2cm, and the thickness is 0.75mm; One corner of the lower end of the font-shaped thin wing 3 is provided with a chamfered edge; the end of the through hole 2 connected to the infusion bag is diamond-shaped.

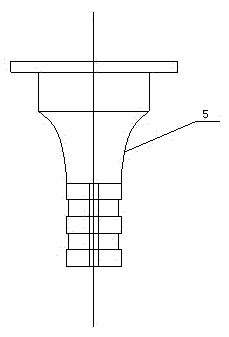

[0018] In the middle of the interface body 1 there is a transitional surface 5 from a circle to a rhombus; each of the inline thin wings 3 is provided with a rib 4 .

Embodiment 2

[0020] As shown in the figure, an infusion bag connection port of the present invention includes an interface body 1, one end of the interface body 1 is the outlet end, and the other end is the connection end with the infusion bag; the interface body 1 is provided with a longitudinal Through hole 2, the two sides of the port at the end where the interface body 1 is connected to the infusion bag are respectively provided with inline thin wings 3, and the length of each inline thin wing 3 is 1.8cm, and the thickness is 1.2mm; each one One corner of the lower end of the font-shaped thin wing 3 is provided with a chamfered edge; the end of the through hole 2 connected to the infusion bag is diamond-shaped.

[0021] In the middle of the interface body 1 there is a transitional surface 5 from a circle to a rhombus; each of the inline thin wings 3 is provided with a rib 4 .

Embodiment 3

[0023] As shown in the figure, an infusion bag connection port of the present invention includes an interface body 1, one end of the interface body 1 is the outlet end, and the other end is the connection end with the infusion bag; the interface body 1 is provided with a longitudinal Through hole 2, the two sides of the port at the end where the interface body 1 is connected to the infusion bag are respectively provided with inline thin wings 3, and the length of each inline thin wing 3 is 1.5 cm, and the thickness is 0.9 mm; each one One corner of the lower end of the font-shaped thin wing 3 is provided with a chamfered edge; the end of the through hole 2 connected to the infusion bag is diamond-shaped.

[0024] In the middle of the interface body 1 there is a transitional surface 5 from a circle to a rhombus; each of the inline thin wings 3 is provided with a rib 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com