Plastic flat filament production unit

A technology of plastic flat wire and unit is applied in the field of plastic making, which can solve the problems such as troublesome blade adjustment, and achieve the effect of good fixing effect, long heating path and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

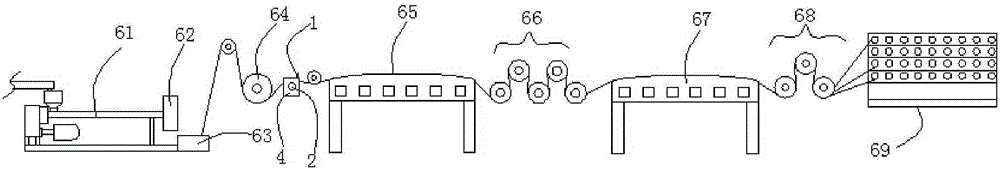

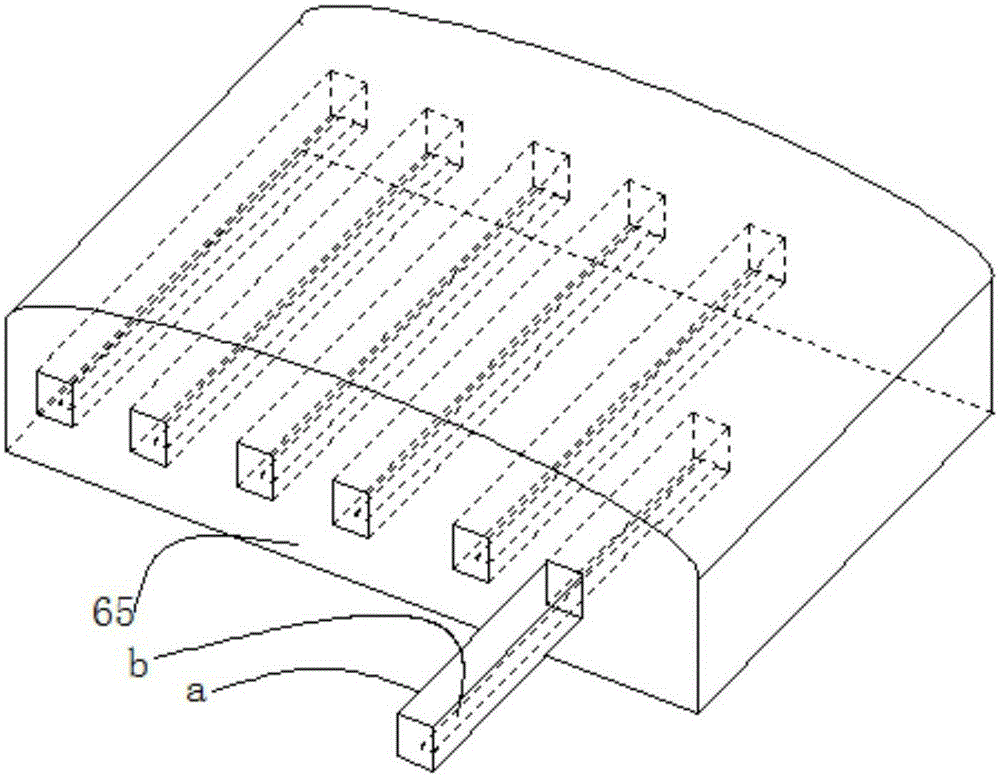

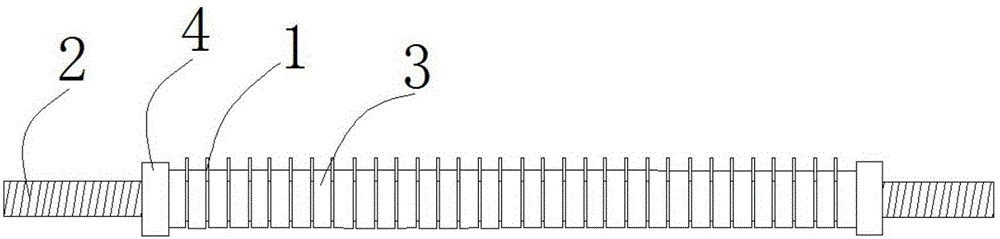

[0032] Such as figure 1 Shown, a kind of production unit of plastic flat yarn comprises extruding mechanism 61, T-shaped die head 62, cooling mechanism 63, drying mechanism 64, splitting mechanism, arc drafting baking plate 65, stretching mechanism 66, arc Shape setting baking plate 67, traction mechanism 68, wire receiving mechanism 69.

[0033] The raw material is in a molten state through various physical conditions in the extrusion mechanism 61, and then extruded by the T-shaped die head 62 and cooled by the cooling mechanism 63 to form a diaphragm; the diaphragm is cut by the splitting mechanism after being dried by the drying mechanism 64 Form the flat wire billet; the flat wire billet is stretched with the stretching mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com