Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about How to "No beating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro line segment dynamic prospect control method and micro line segment dynamic prospect control device

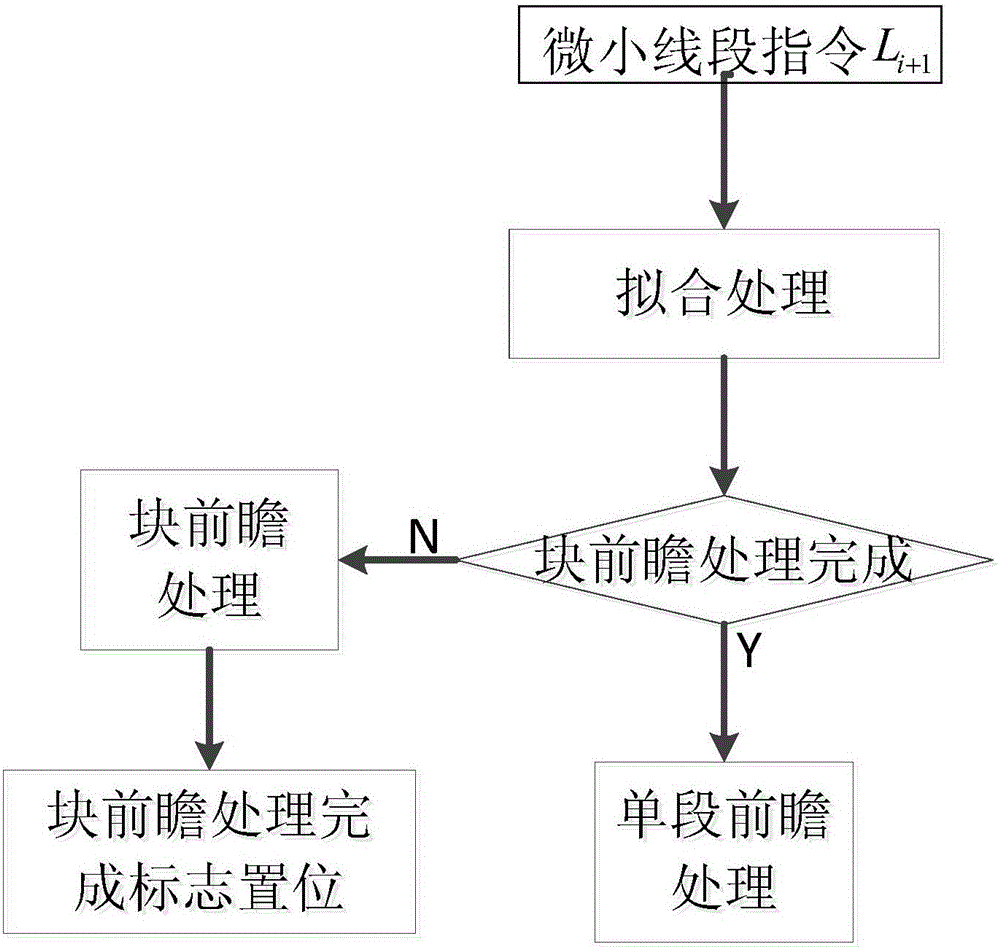

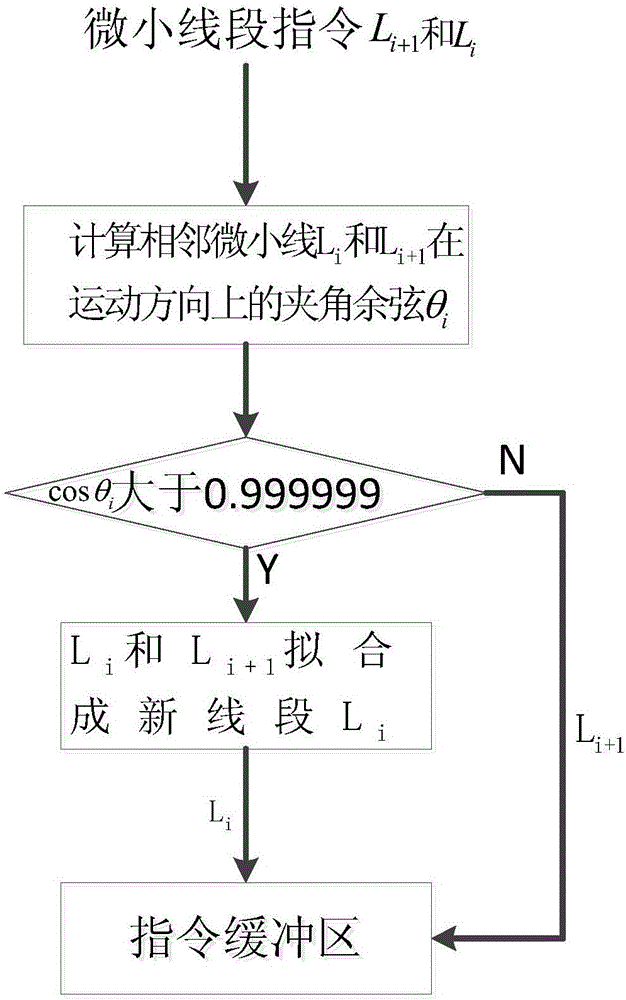

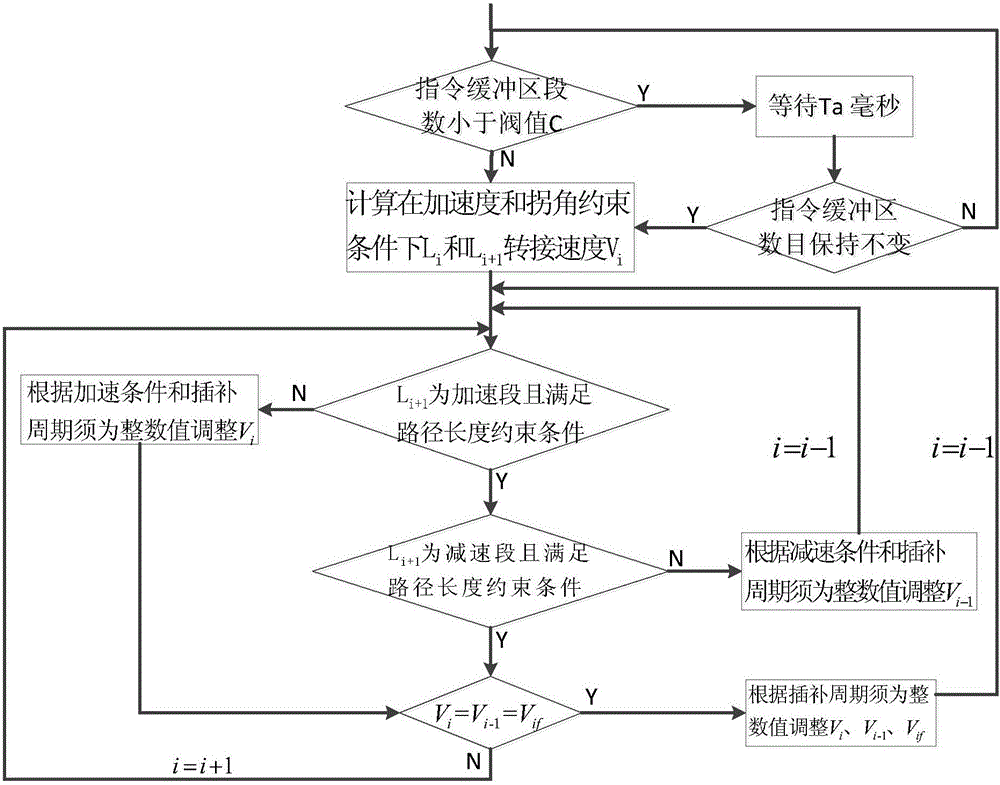

The invention discloses a micro line segment dynamic prospect control method and a micro line segment dynamic prospect control device. On the condition that an included angle between two adjacent line track segments is very small, the two line track segments are fitted for obtaining one straight line segment, thereby reducing prospect calculation time and improving switching speed. According to the micro line segment dynamic prospect control method and the micro line segment dynamic prospect control device, through block prospect processing, a motion control system does not require static or dynamic assignment for a prospect segment number, thereby improving integral interpolation efficiency, reducing storage space of the motion control system and reducing cost. Furthermore an interpolation period effect is considered in prospect calculation in advance, thereby reducing switching speed jump and improving processing precision. Furthermore segment prospect processing is performed for realizing a fact that the motion control system can dynamically determine whether the currently received track segment is a final segment, thereby setting the terminal point speed of the final track segment to zero.

Owner:SHENZHEN LEADSHINE INTELLIGENT CONTROL CO LTD

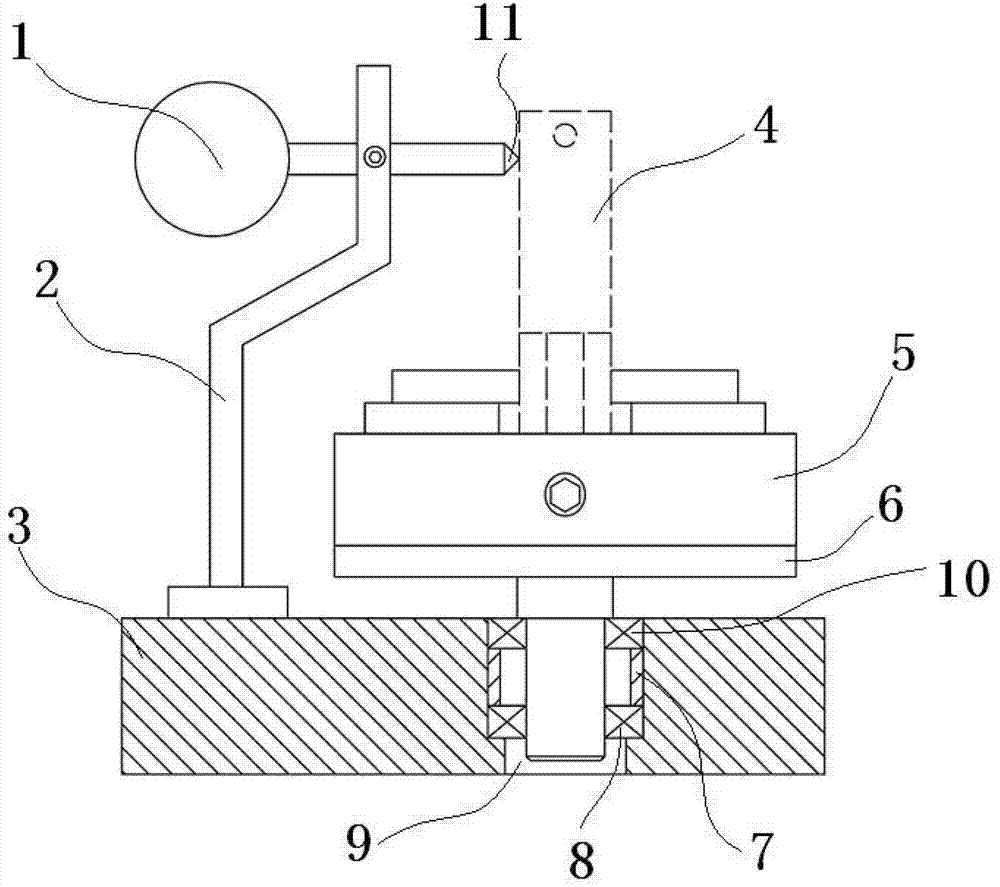

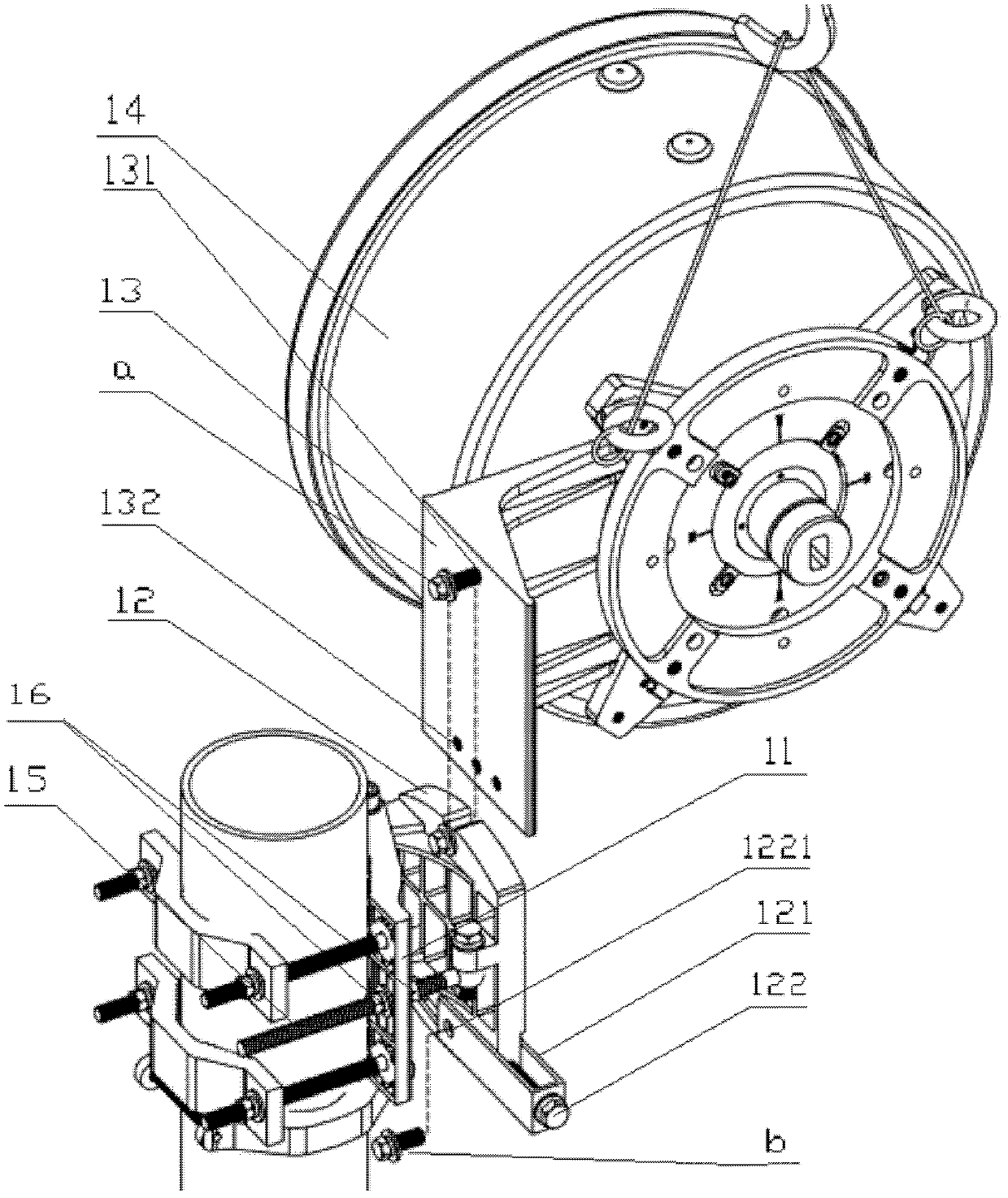

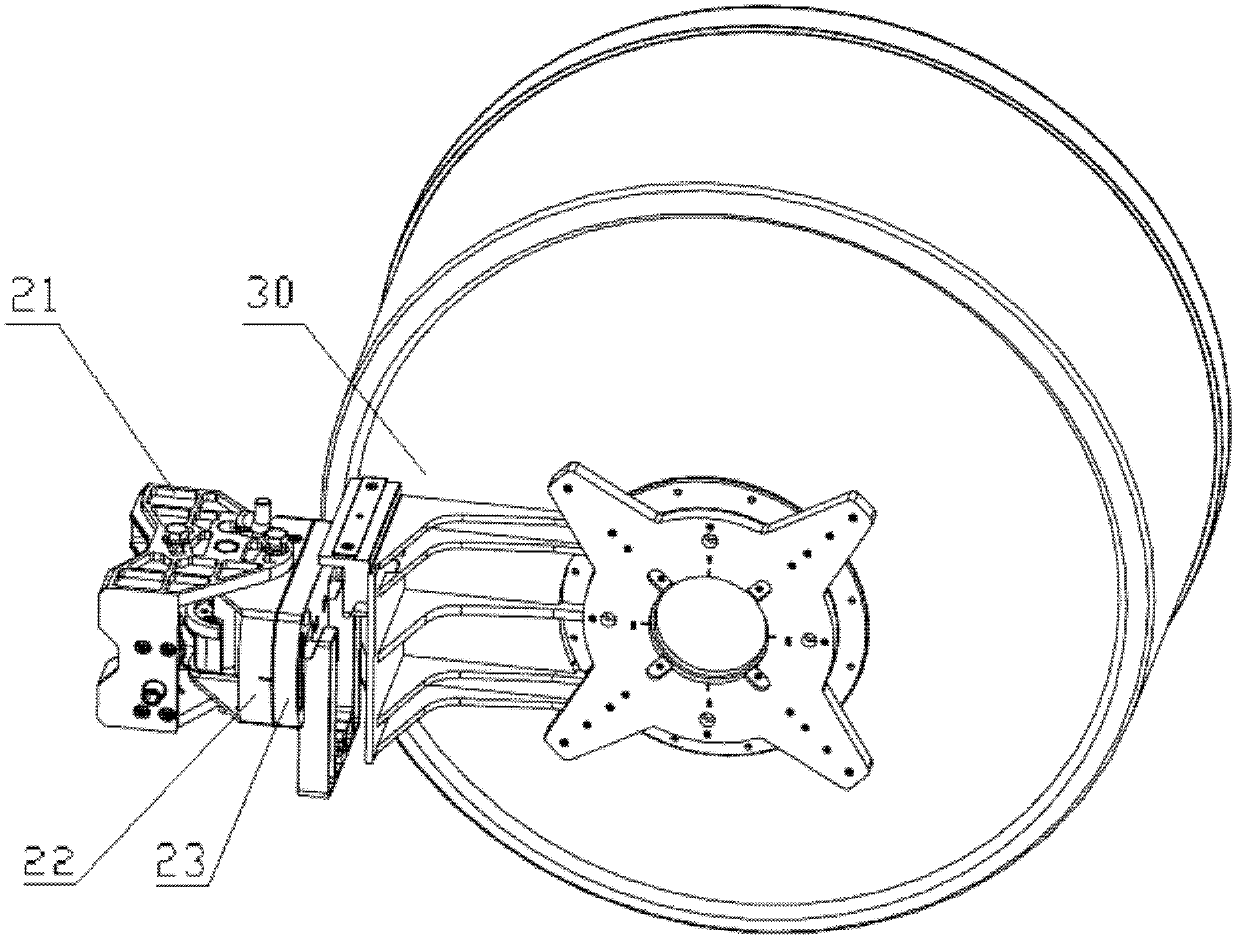

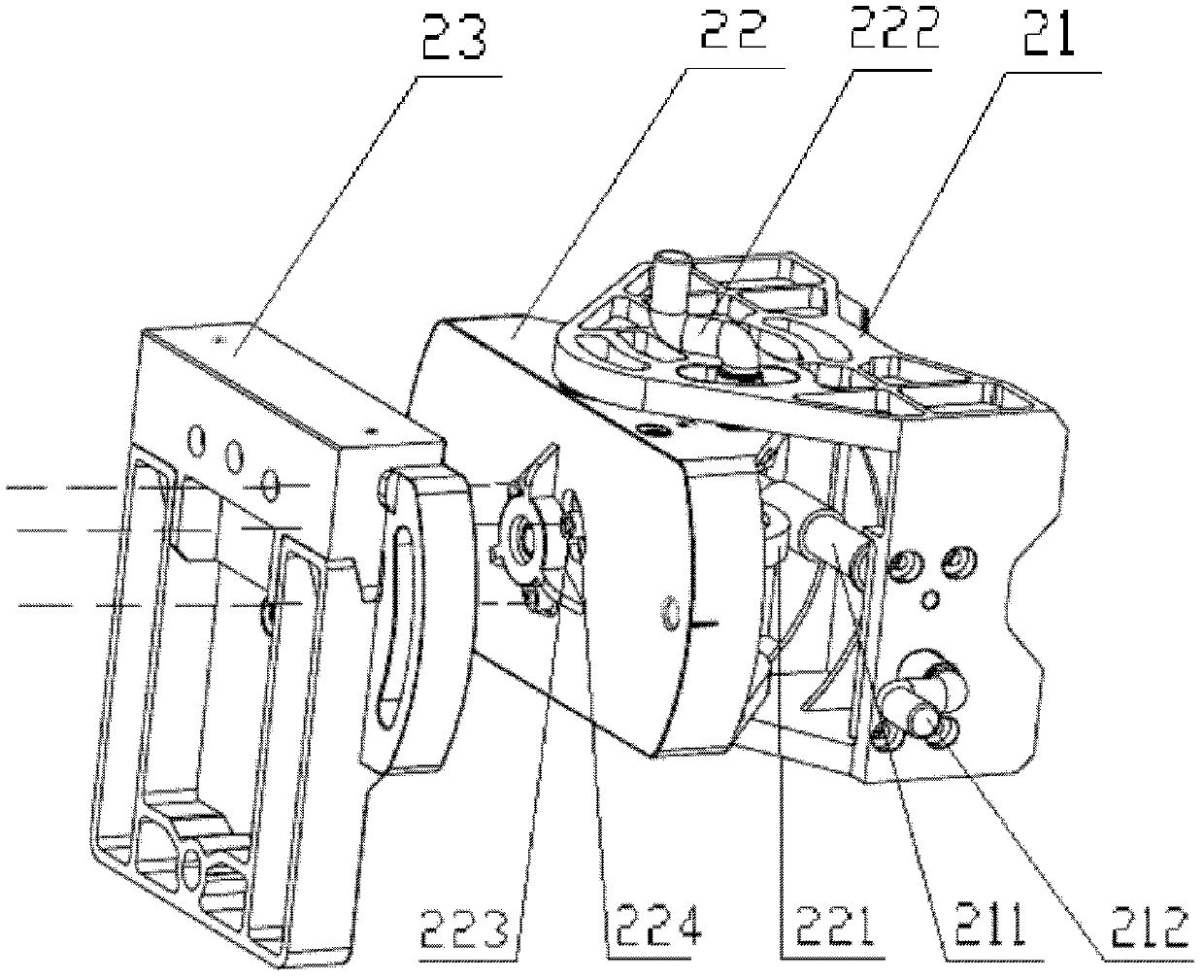

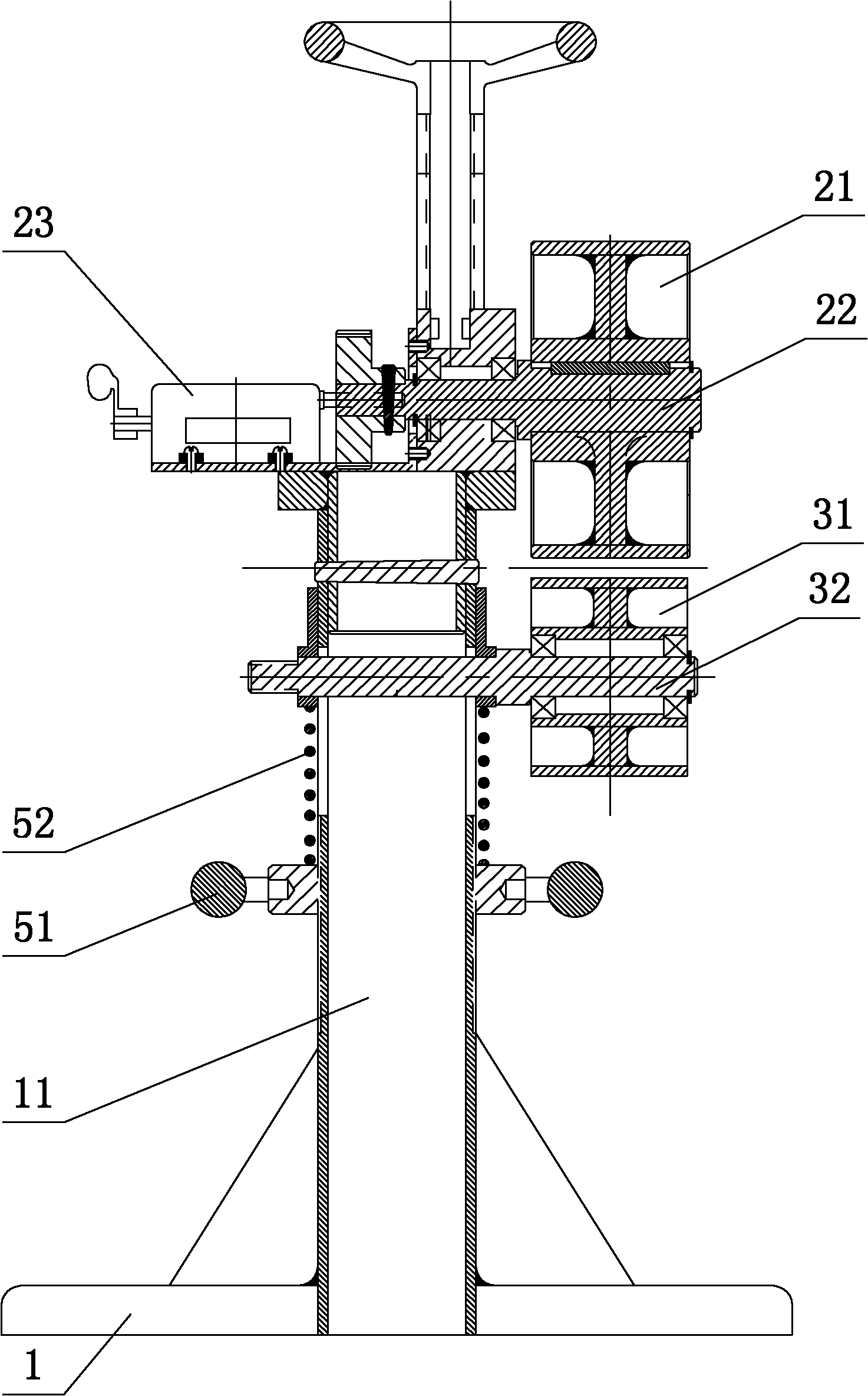

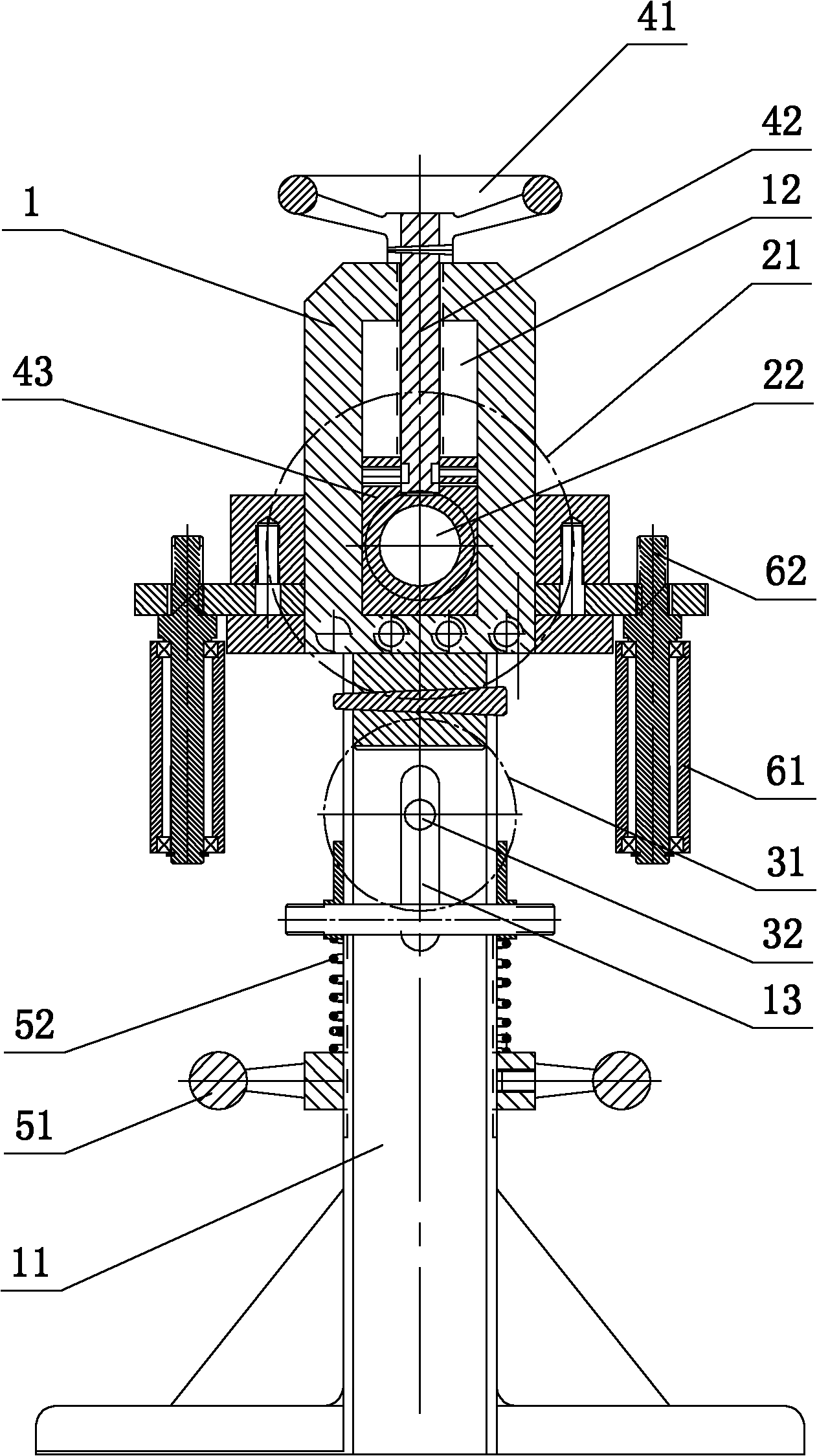

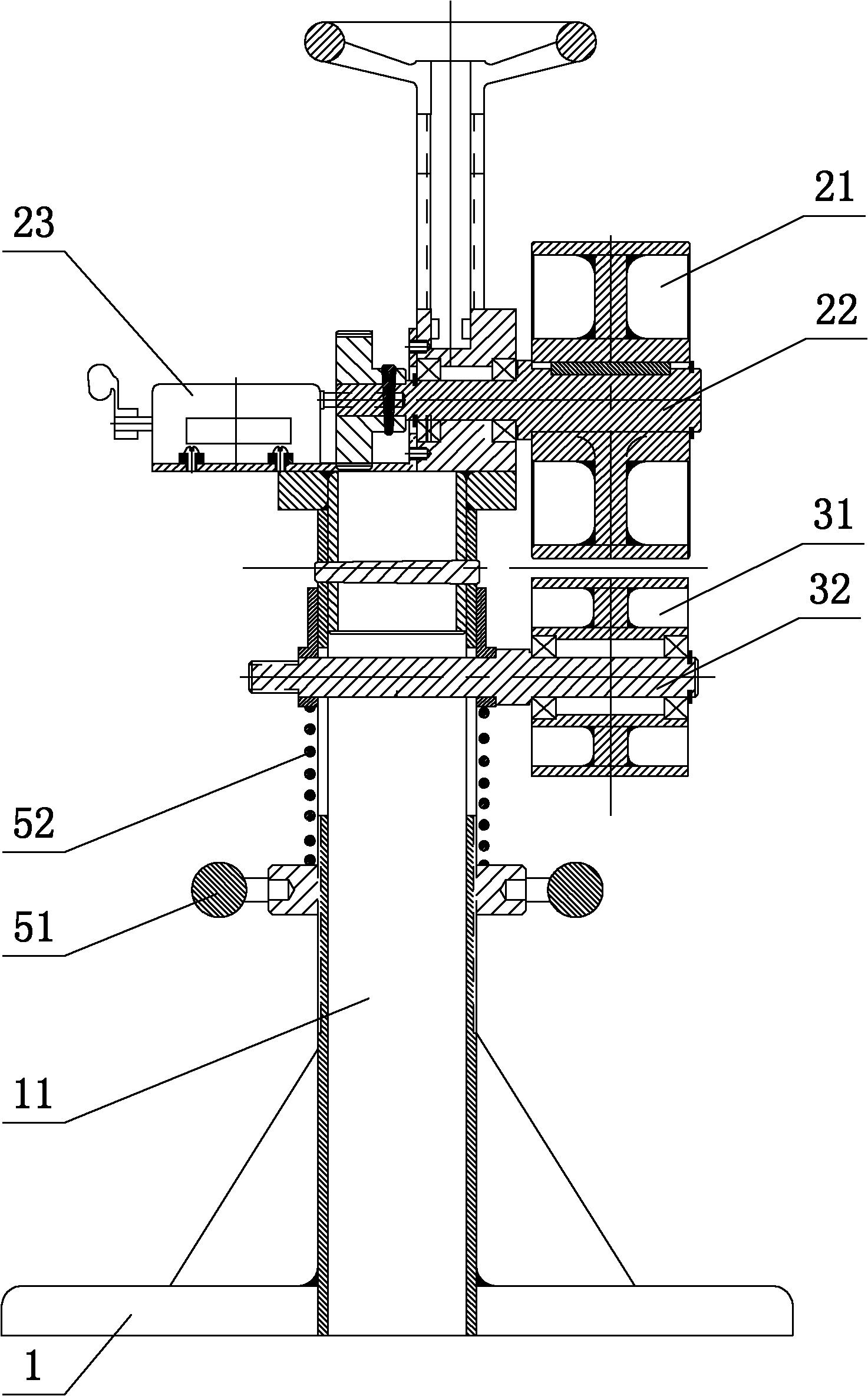

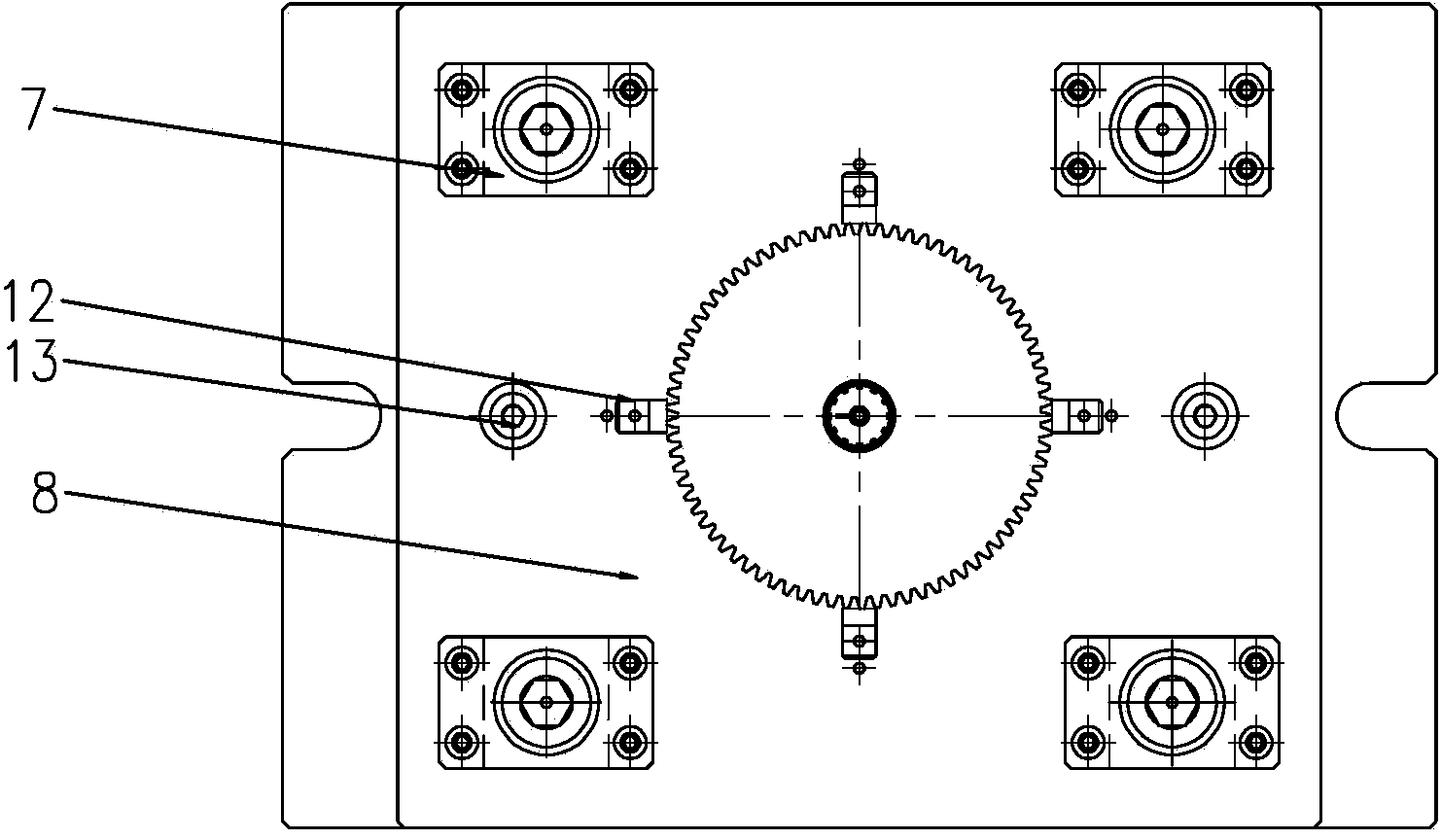

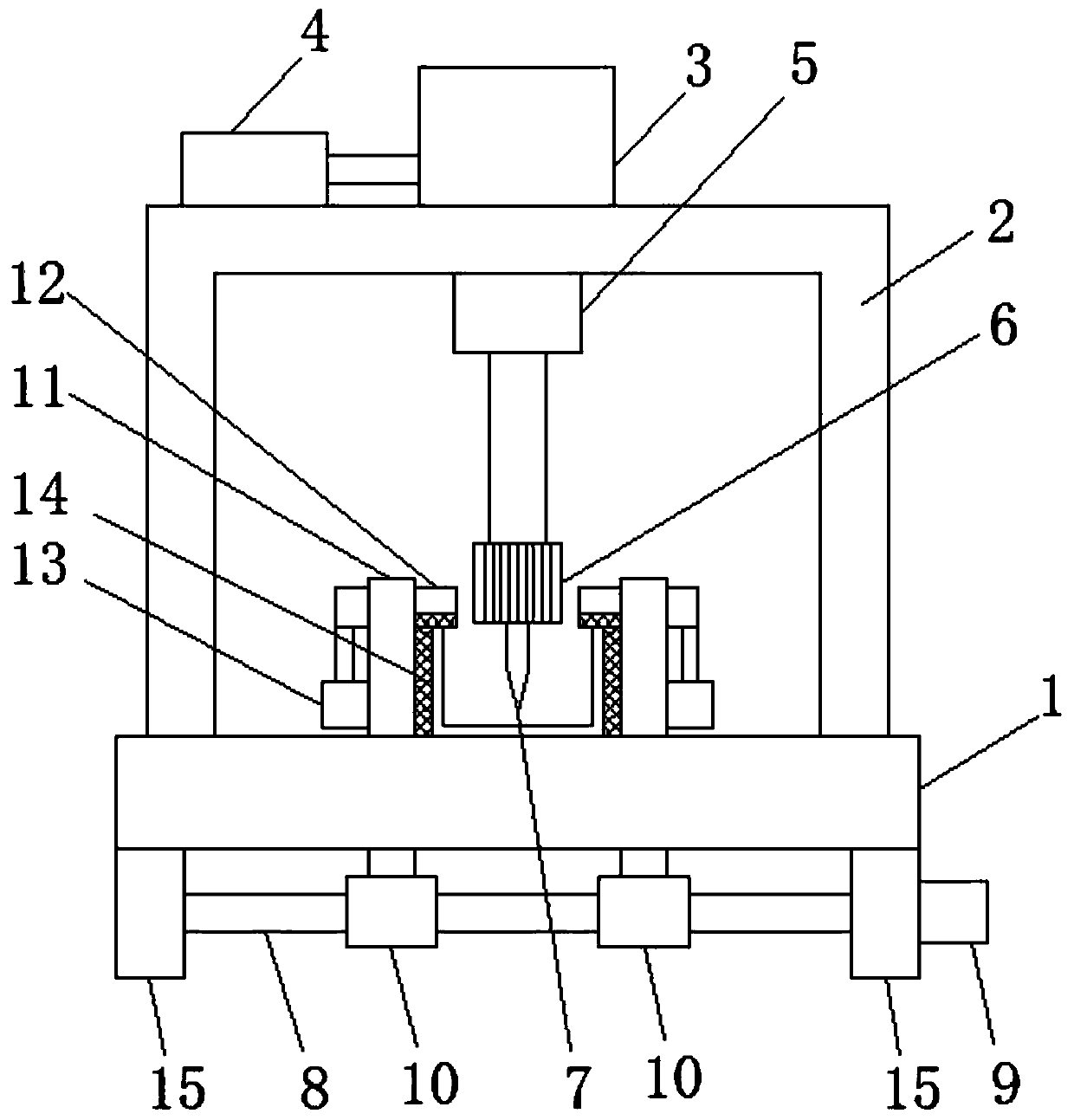

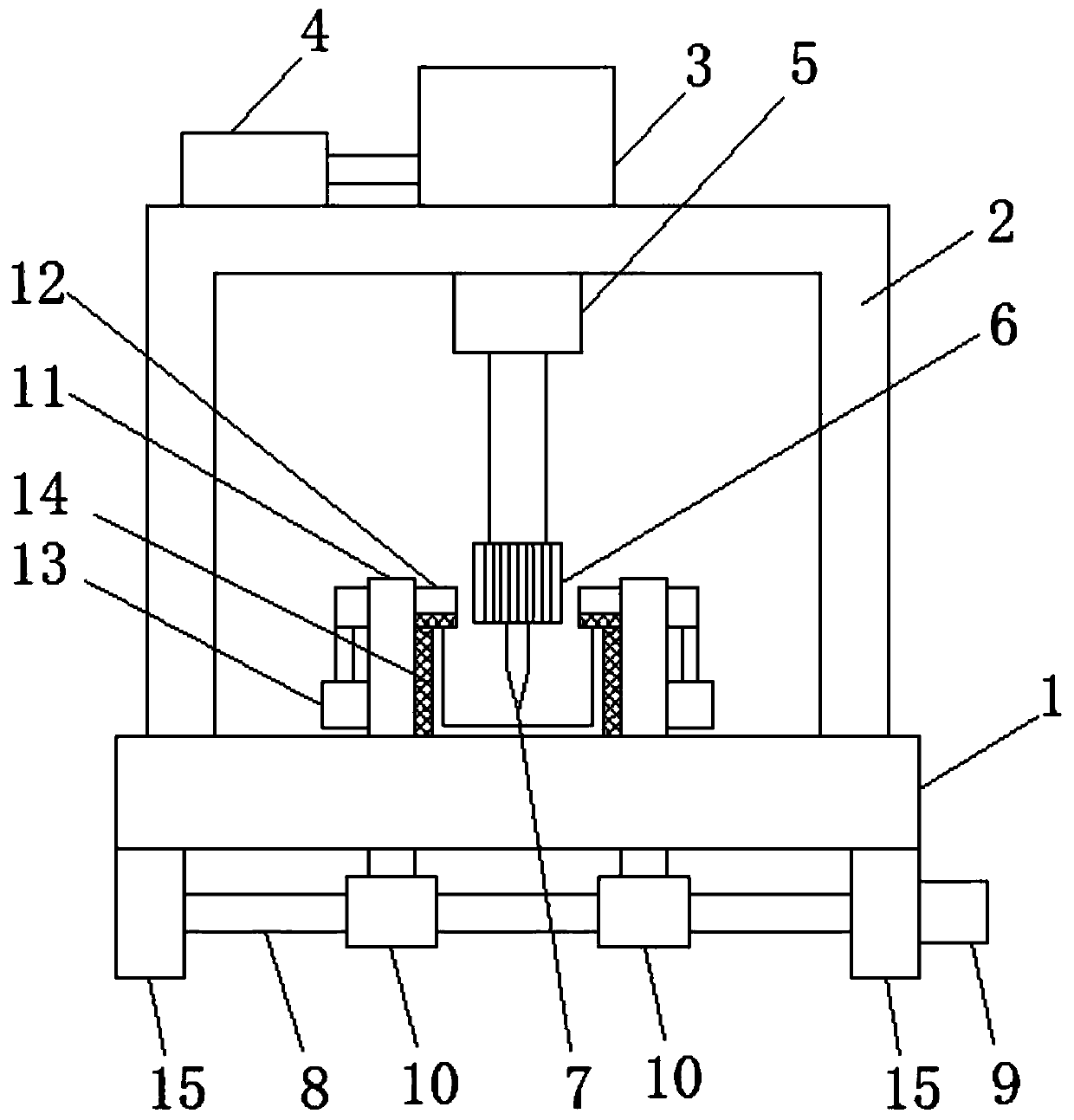

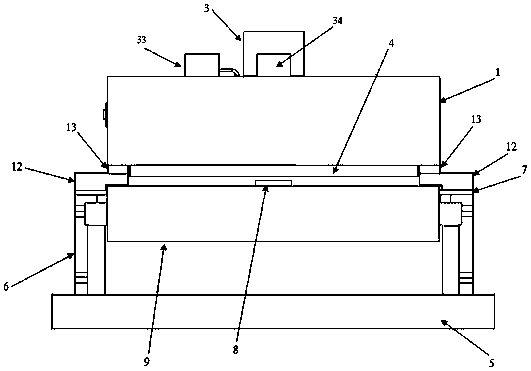

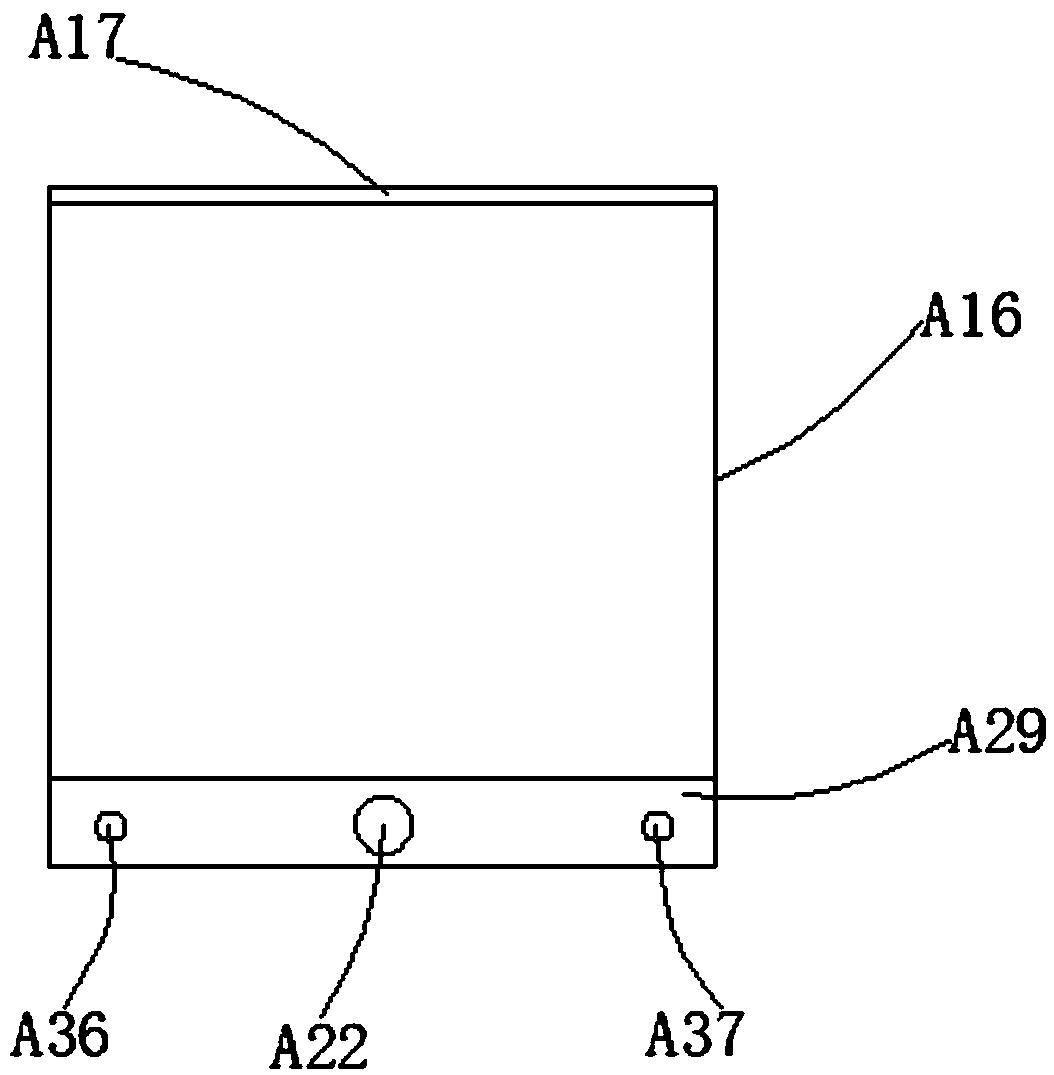

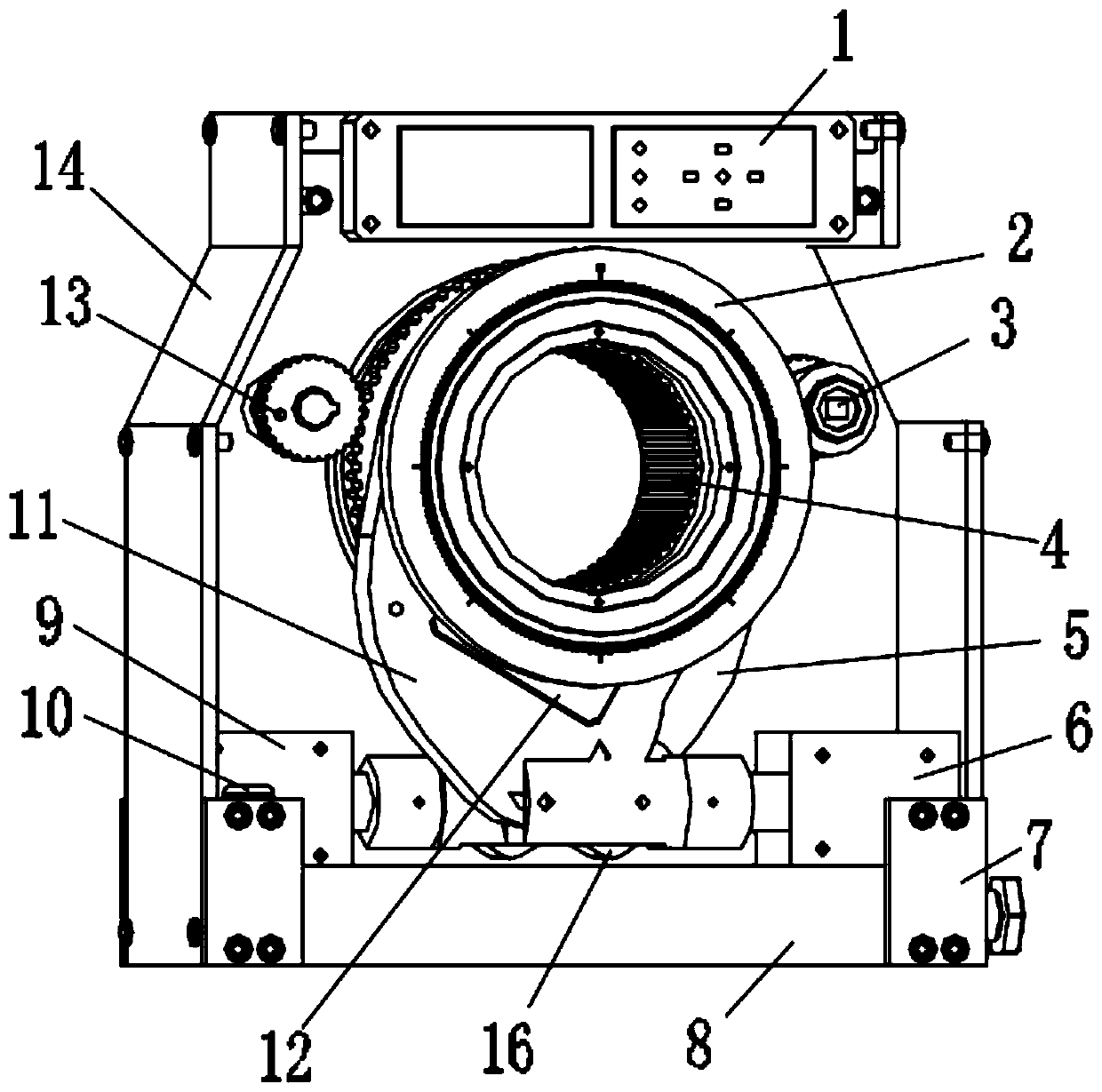

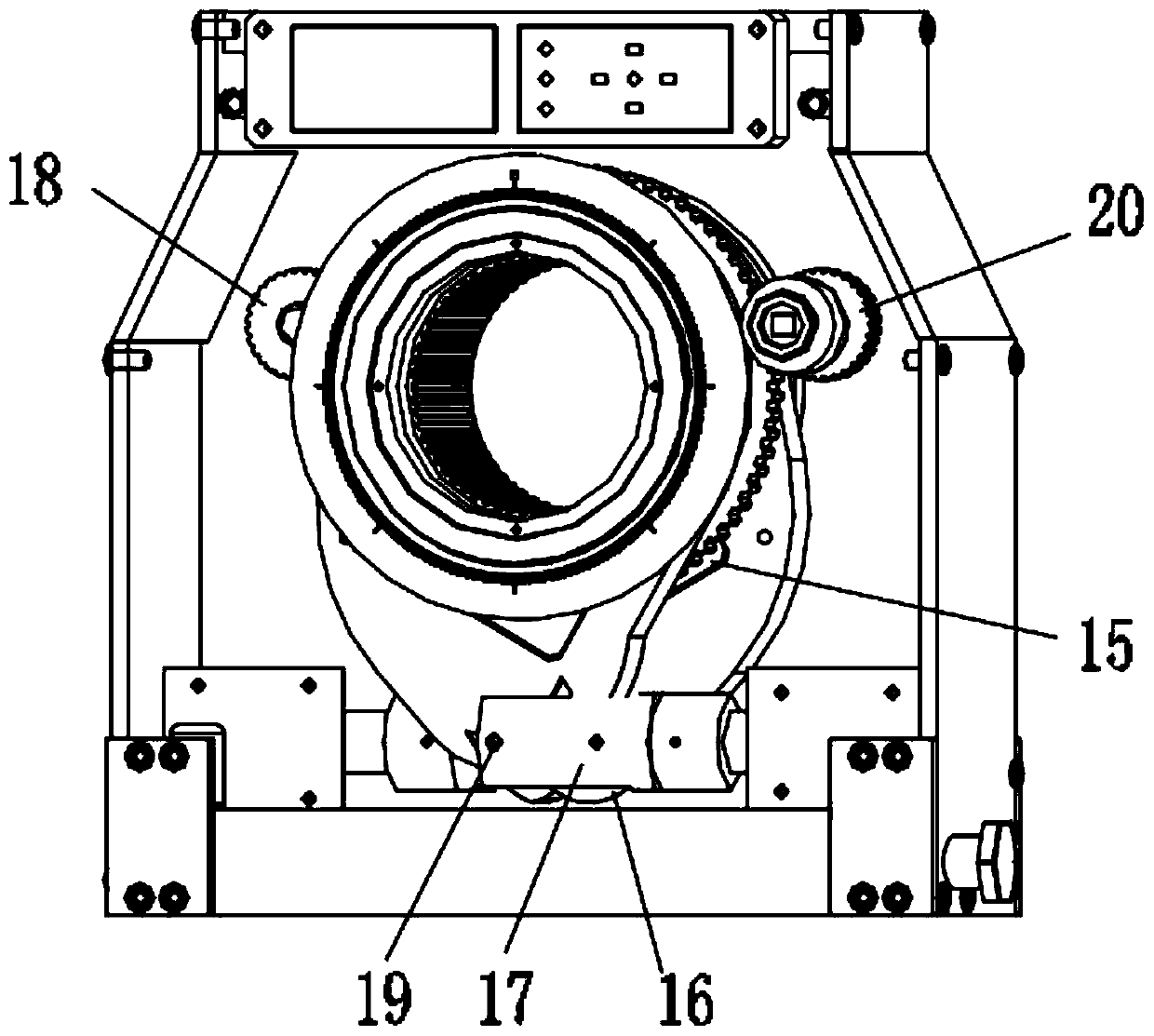

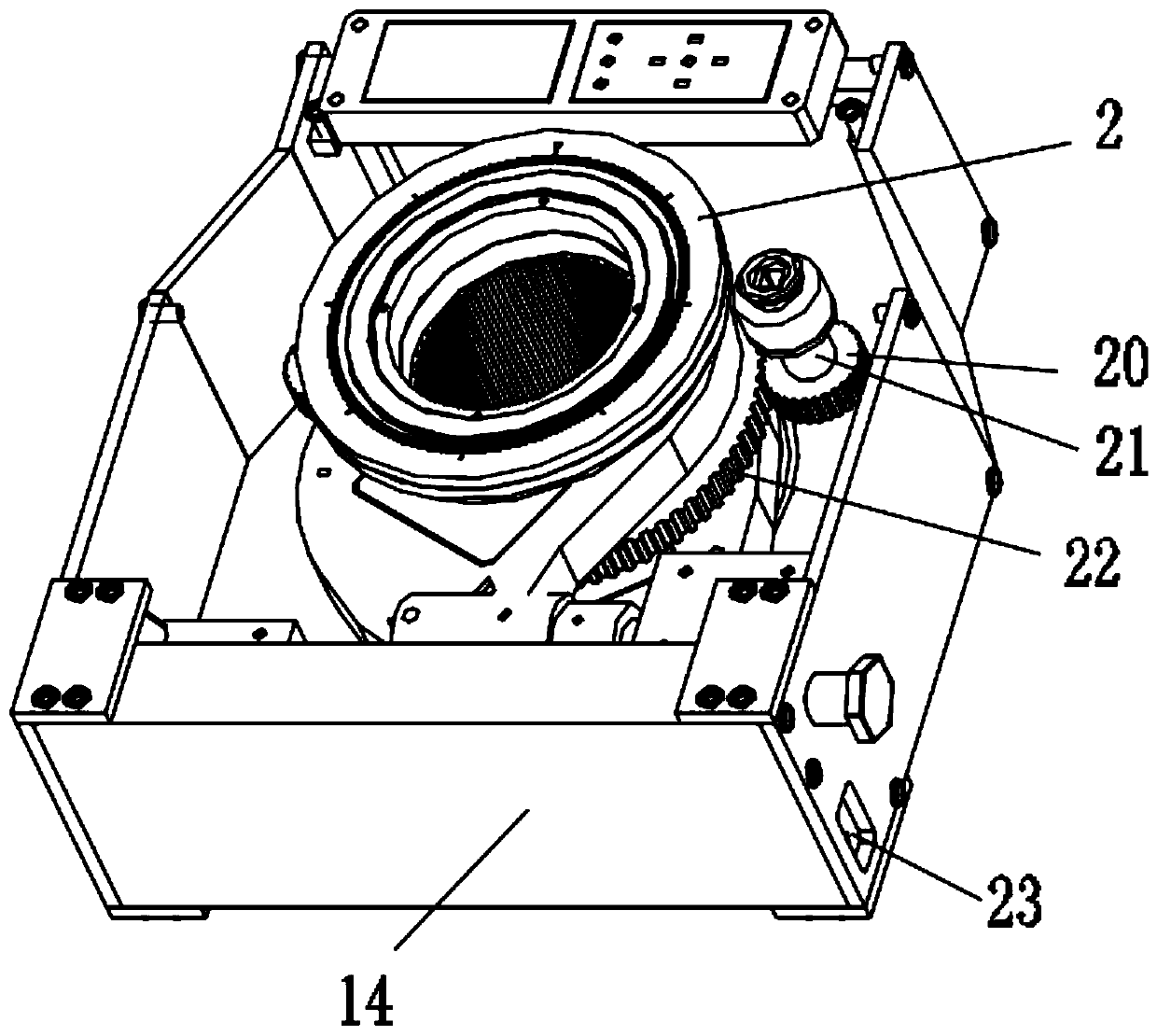

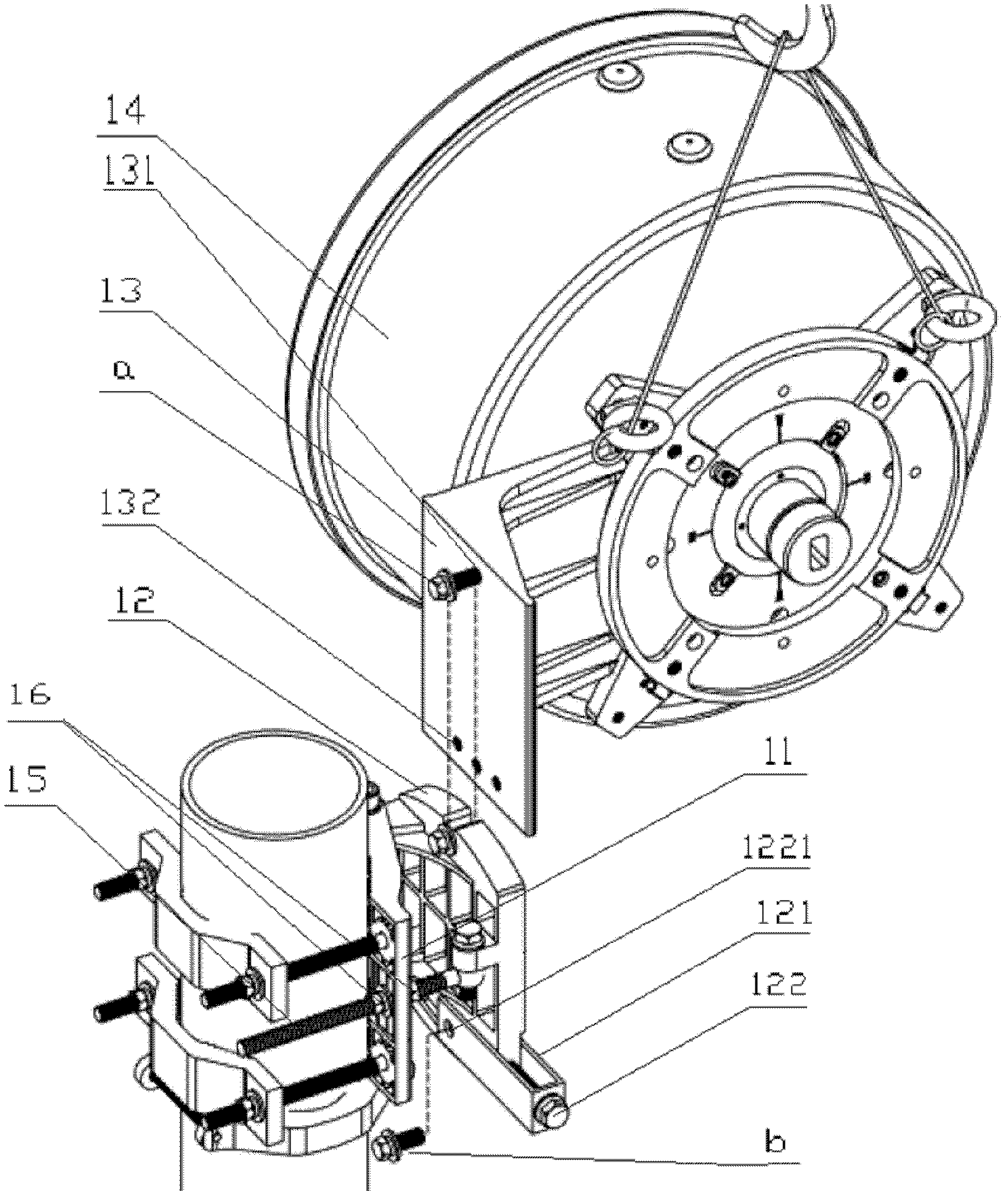

Coaxiality detector

InactiveCN102901433AEasy clampingEasy to disassembleMechanical measuring arrangementsEngineeringInstallation Error

The invention provides a coaxiality detector. The coaxiality detector is used for detecting the coaxiality of a hexagonal shaft, and comprises a base, a clamping mechanism, a slewing mechanism and a detection device, wherein the clamping mechanism is used for clamping the hexagonal shaft; the slewing mechanism is movably arranged on the base, and is used for supporting and driving the clamping mechanism to rotate around the central axis of the hexagonal shaft; and the detection device is arranged on the base and is used for detecting the coaxiality of the hexagonal shaft. The coaxiality detector provided by the invention adopts a precision three-jaw chuck and is connected with the base through a bearing, so that the precision three-jaw chuck cannot jump when the precision three-jaw chuck rotates in the center of the base freely; and simultaneously, the hexagonal shaft is clamped on and detached from the three-jaw chuck very conveniently; the installation error is low; and the detection precision is improved.

Owner:宁波培源股份有限公司

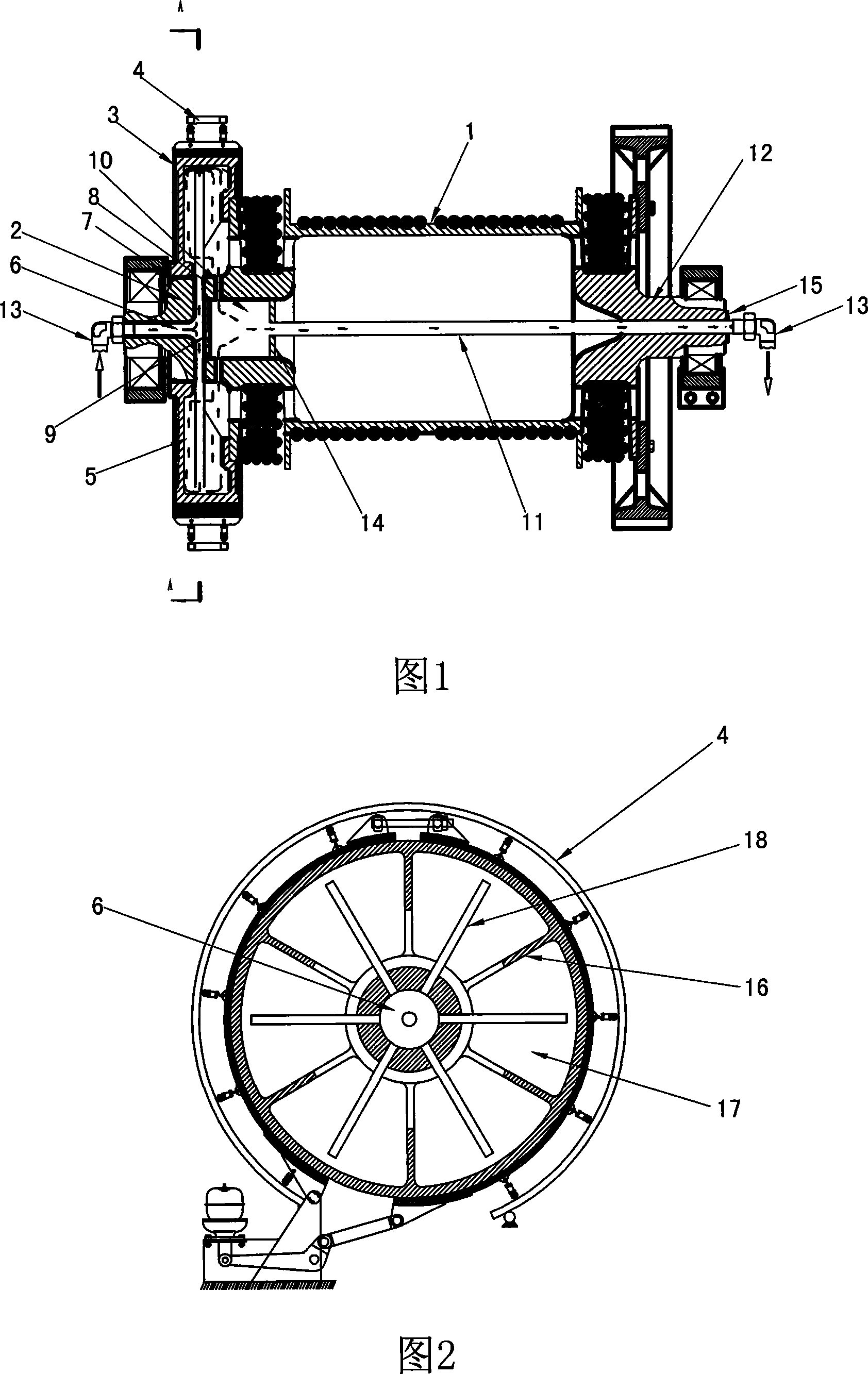

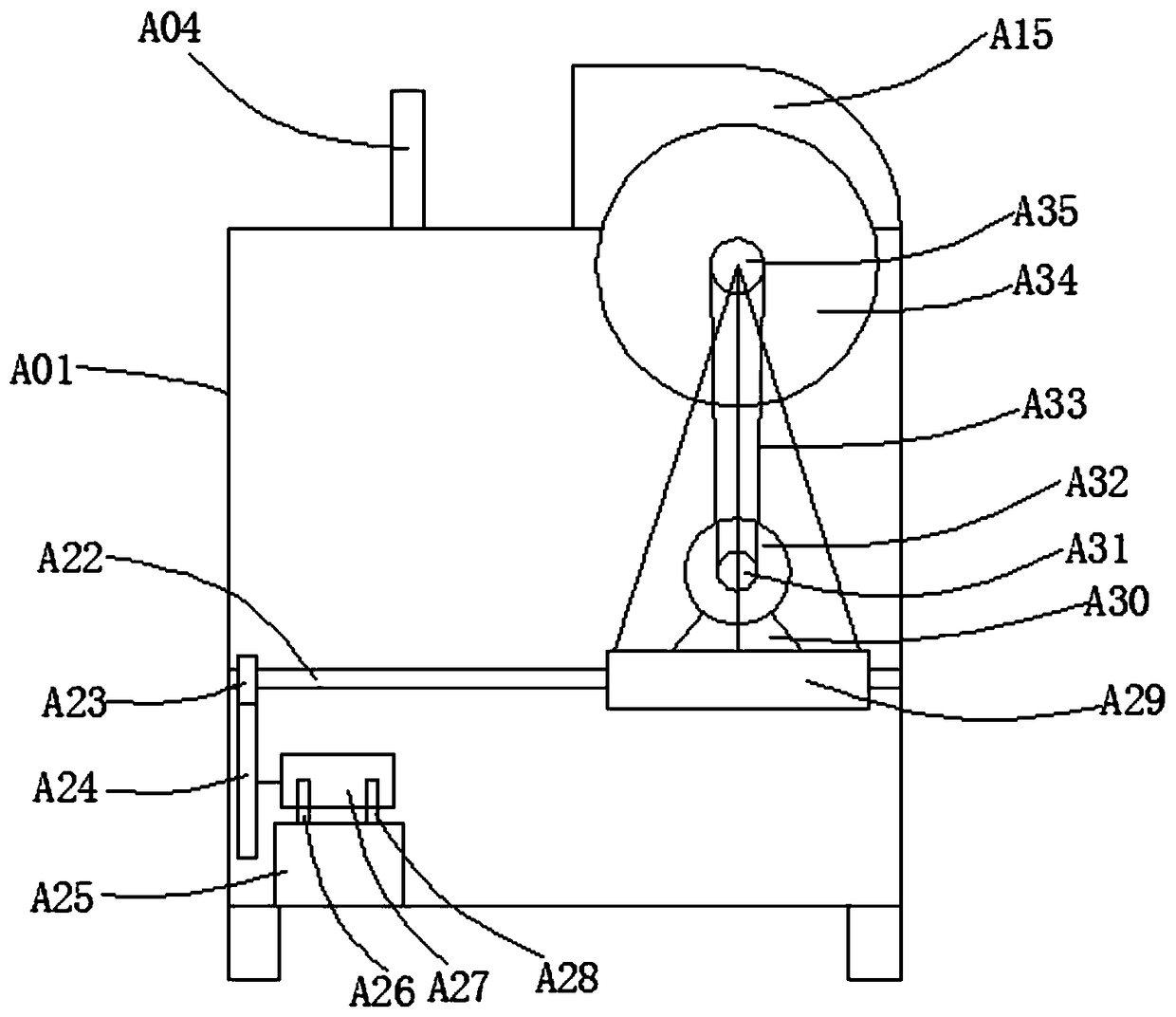

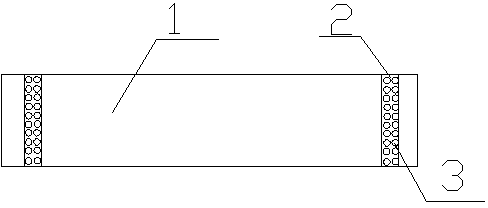

Water refrigerating device of exterior brake of grab bucket type grasping and digging crane

InactiveCN101219763APrevent leakagePrevent slippingBraking elementsHoisting equipmentsCooling chamberEngineering

The invention discloses an external brake water cooling device of a grabbing bucket typed grabbing and digging crane, characterized in that the device comprises a cooling chamber arranged inside a brake of a steel wire rope roller, an intake chamber and an outlet pipe communicated with the cooling chamber; the intake chamber is arranged inside a hub of the roller; one end of the outlet pipe is arranged inside another hub of the roller; an inlet end of the intake chamber and an outlet end of the outlet pipe are provided with rotating joints; the invention can timely take away the heat generated due to friction between an external brake assembly and the brake, prevent slipping phenomenon caused by heat accumulation between the external brake assembly and the brake, eliminate security hidden troubles, facilitate continuous work of the brake system, increase production efficiency, avoid wear of a friction belt of the external brake assembly and prolong the service life of the friction belt.

Owner:梁志庭

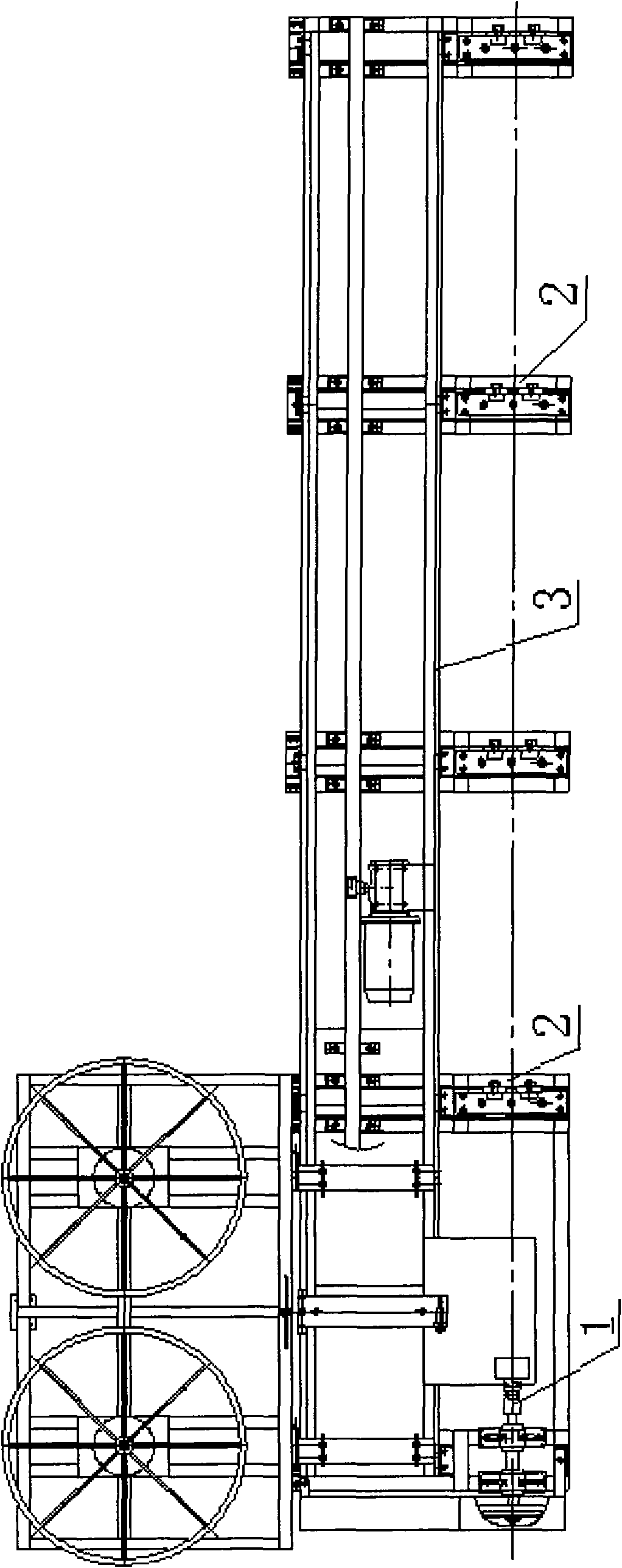

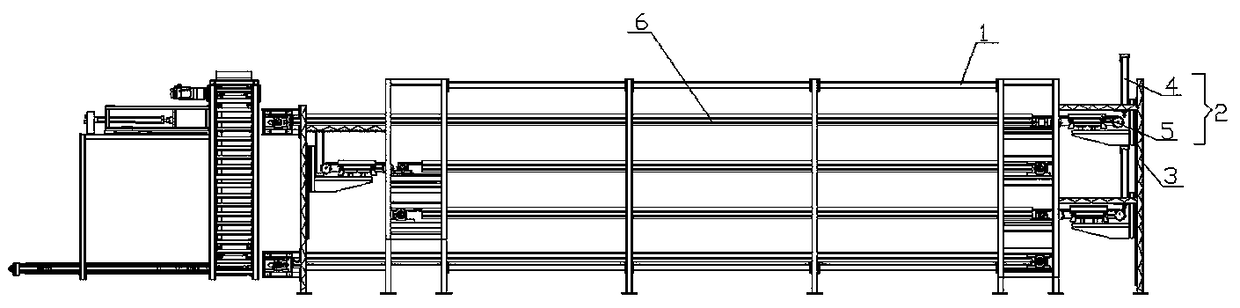

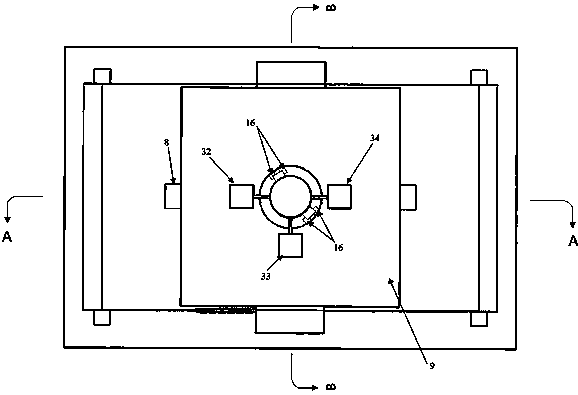

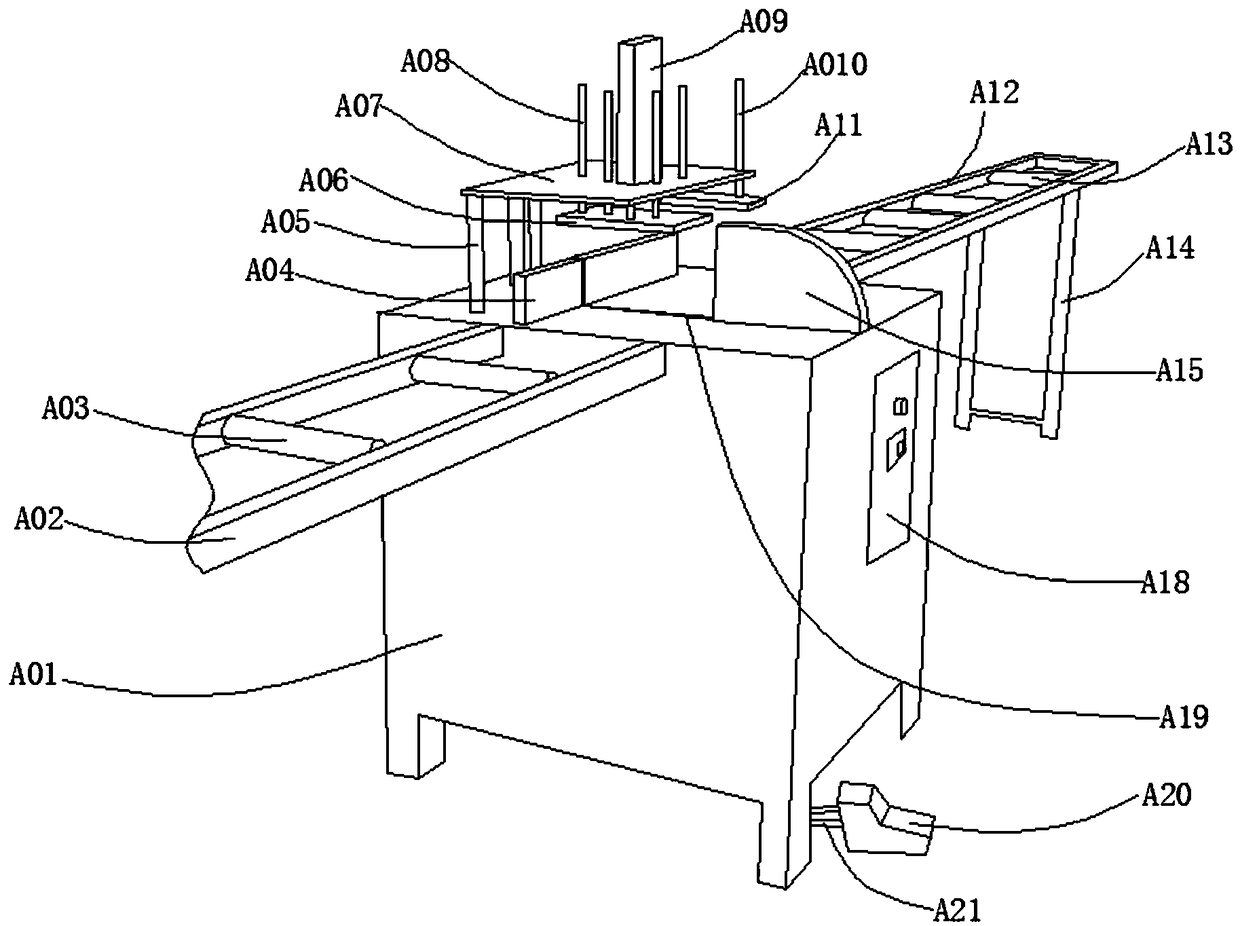

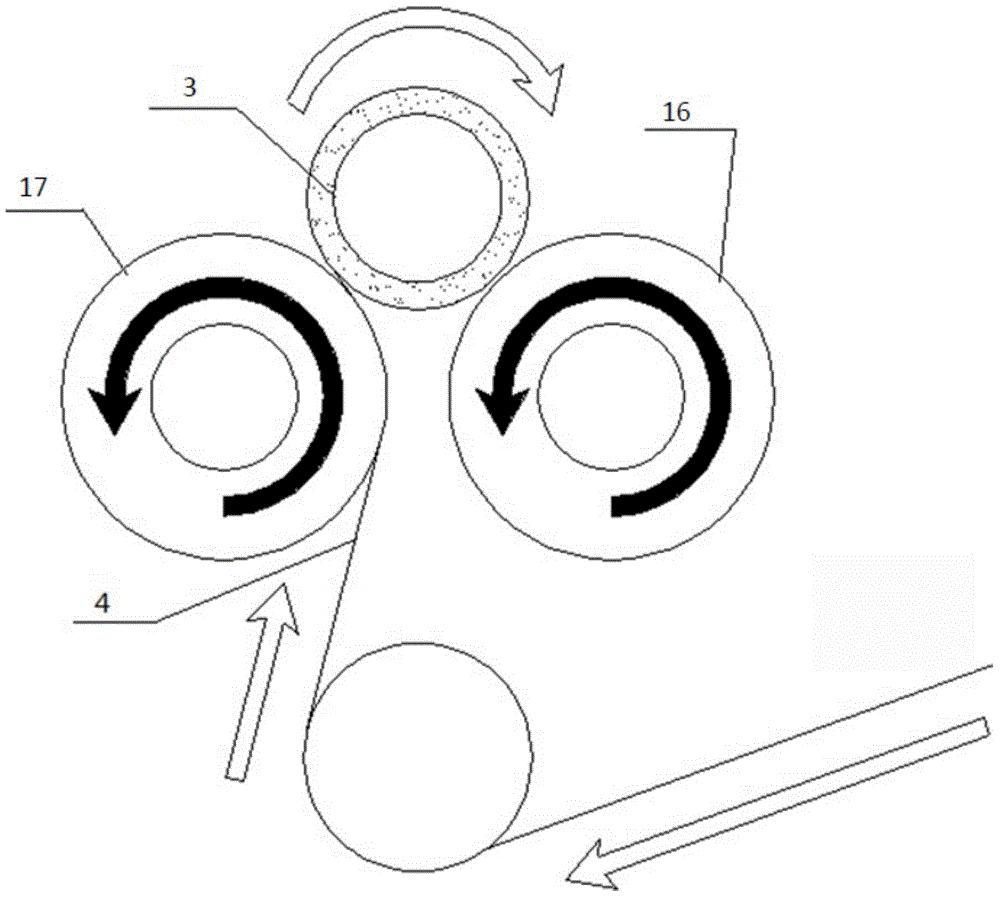

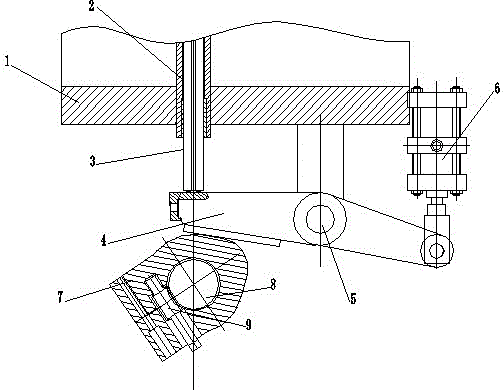

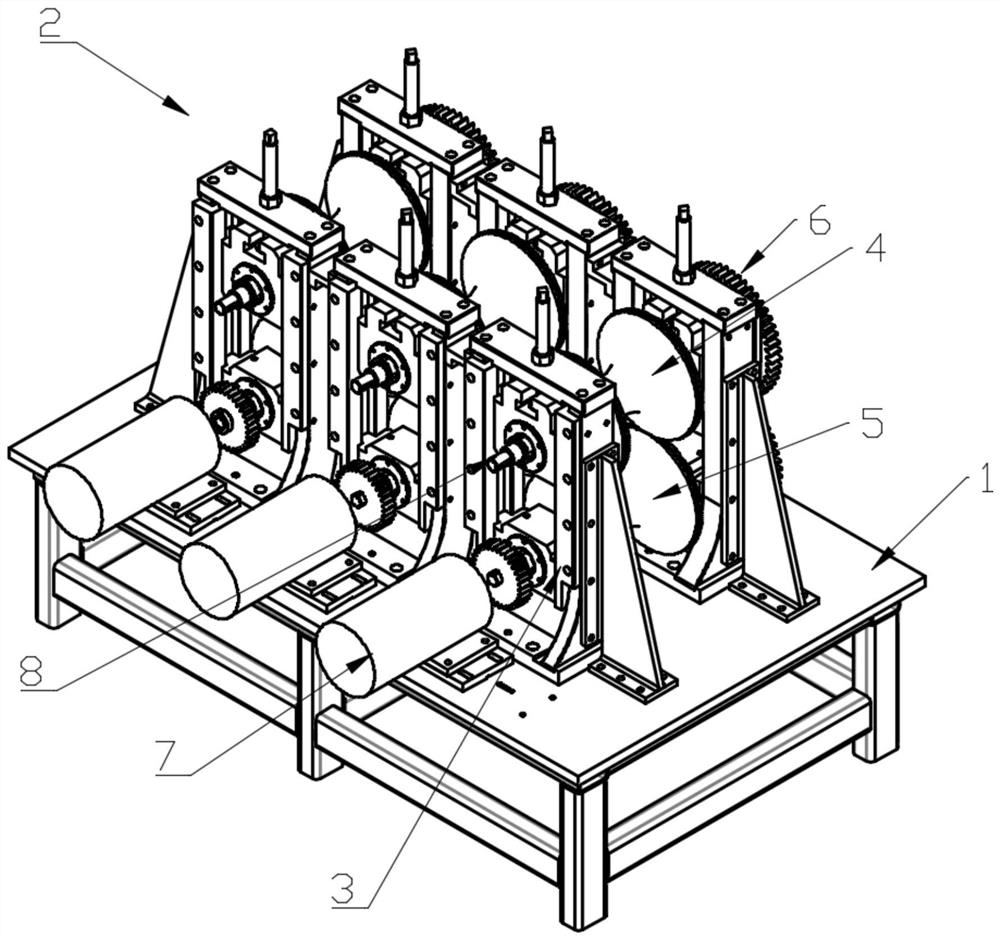

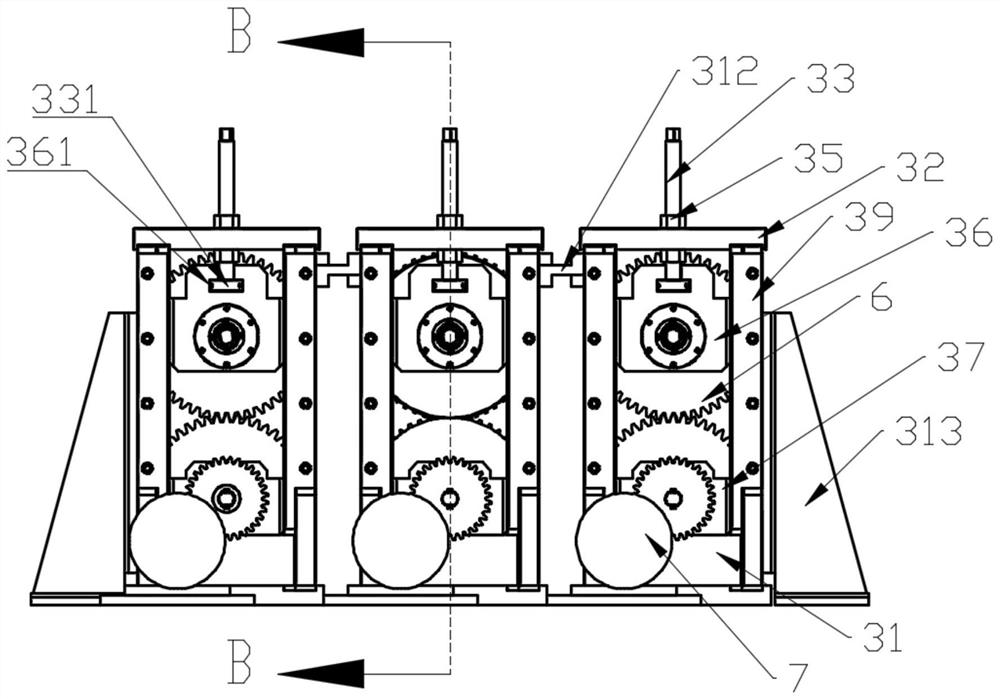

Long pipe surface thermal spraying device

ActiveCN101967620AContinuous and efficient automationContinuous High Efficiency Thermal SprayingMolten spray coatingThermal sprayingSolenoid valve

The invention relates to a long pipe surface thermal spraying device applied to a pipe outside surface thermal spraying protective layer. A track is horizontally fixed on a bracket, a walking trolley is arranged on the track and a thermal spraying system is fixed on the walking trolley. Four to six cylinder-type lifting mechanisms are fixed on a supporting seat at one side of the track; one end of a supporting seat of the cylinder-type lifting mechanism is fixed with a clamping rotation mechanism. Each group of control mechanisms consists of two travel switches, an electric relay and a solenoid valve, and the control mechanisms are fixed on the track. The invention has the advantages of realizing of continuously automatic and efficient thermal spraying on the outside surface of a longer pipe and completely continuous and efficient spraying process, solving the problem of a spraying leakage point caused by the blocking of a bearing support point by using the cylinder-type lifting mechanism and ensuring that the spraying process is complete, continuous and highly-efficient.

Owner:PETROCHINA CO LTD

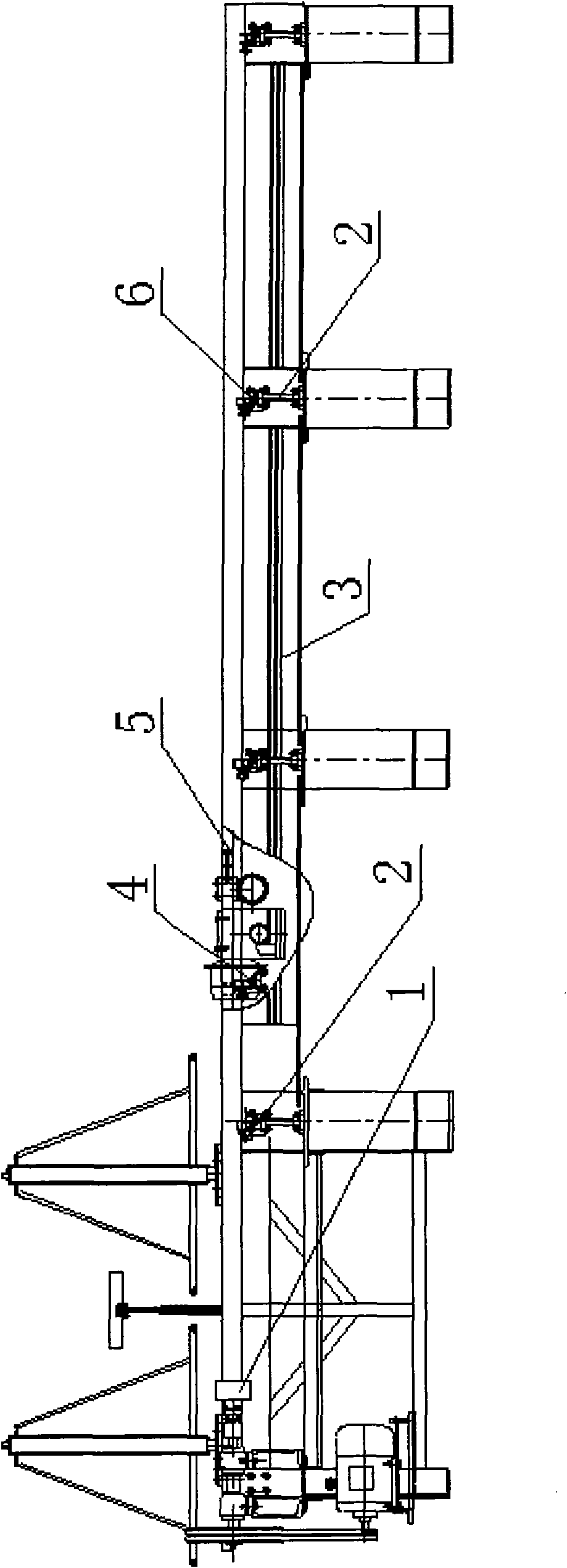

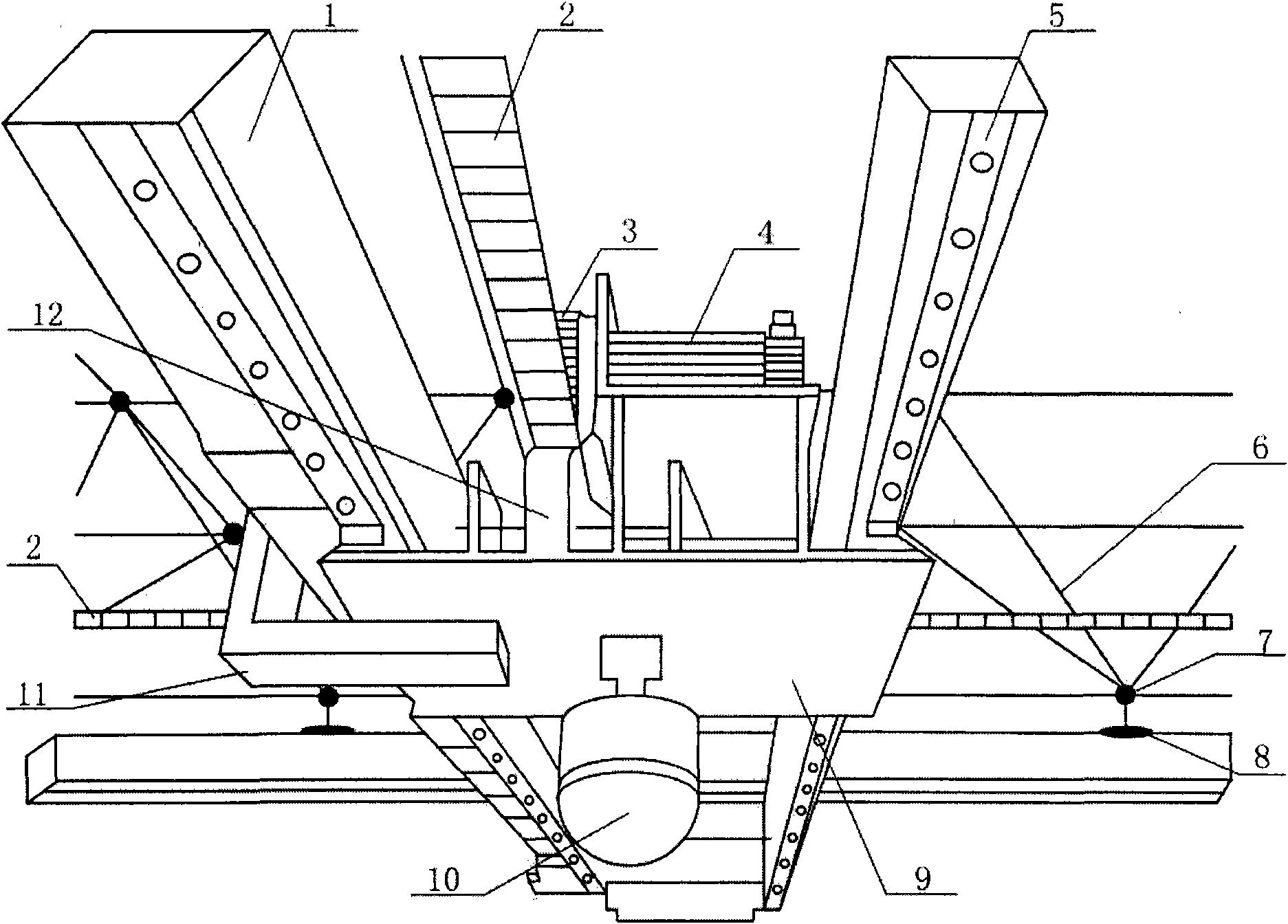

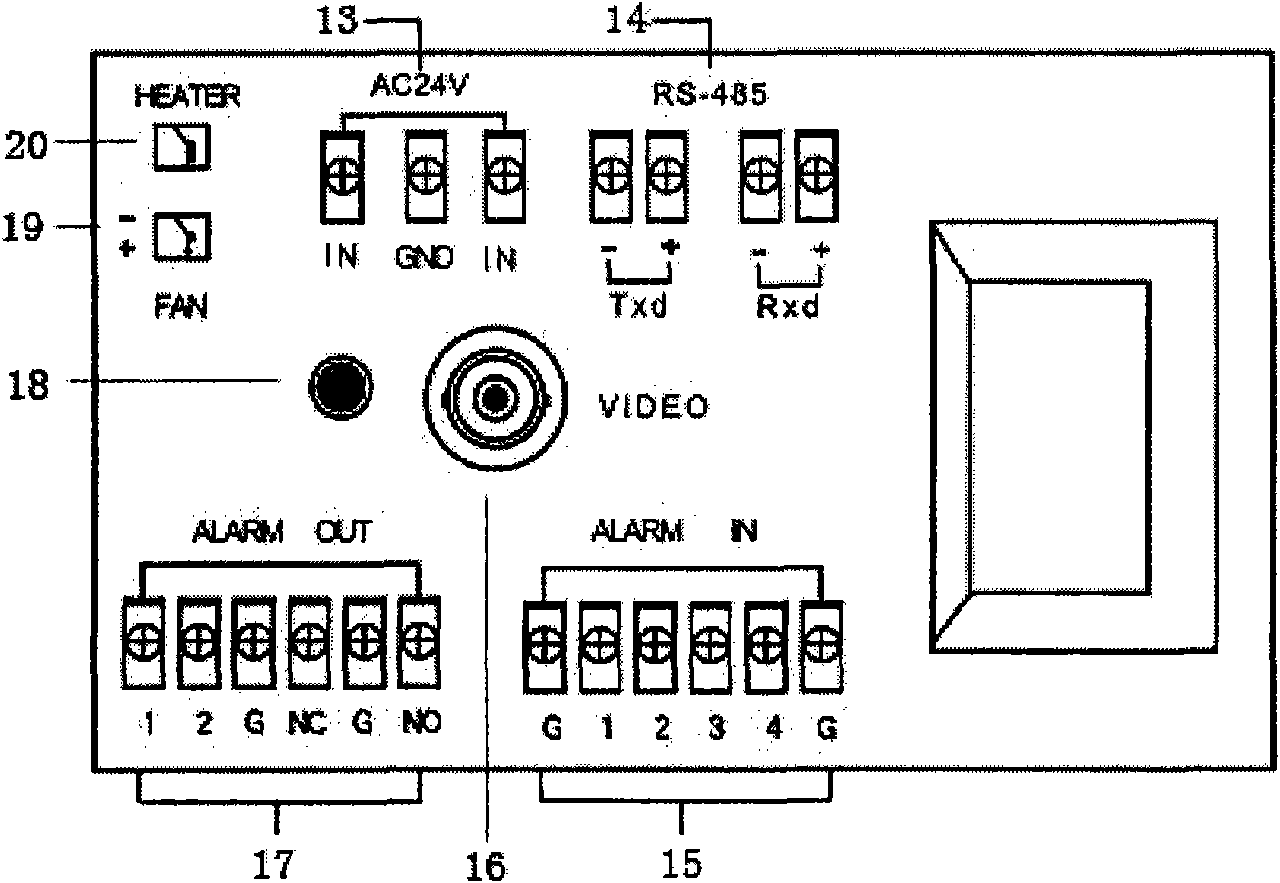

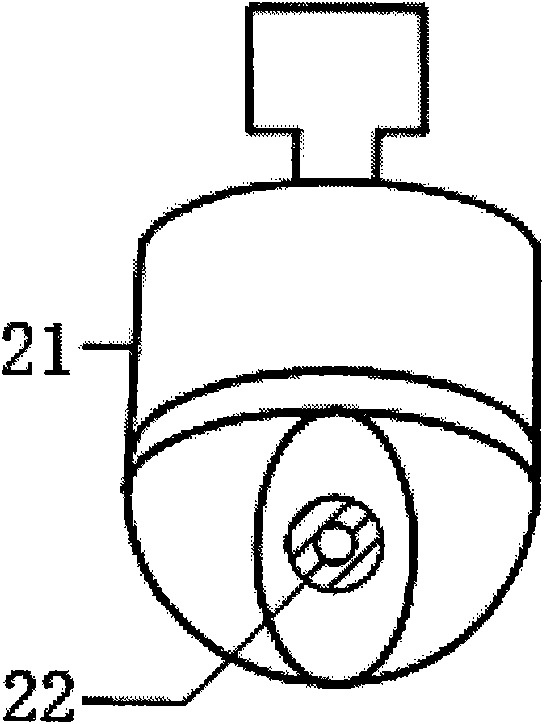

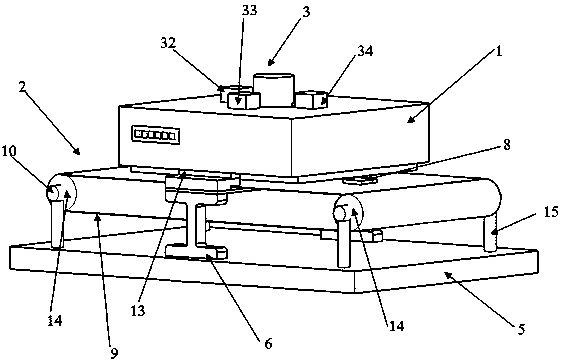

Terminal guidance section simulation system

InactiveCN101782354AExtended service lifeHigh cost performanceAmmunition testingSelf-propelled projectilesTransmission beltEarth surface

The invention relates to a terminal guidance section simulation system, which comprises a guidance head and a movement simulation platform, wherein the guidance head adopts a simulation guidance head and consists of a holder and a camera; the movement simulation platform is of a net-type supporting frame which is provided with a guide rail installation beam and a transmission belt, wherein a precise guide rail is installed on the bottom part of the guide rail installation beam, a large installation platform is installed between two guide rail installation beams, a small installation platform is installed on the side surface of the guide rail installation beam, a roll-over drag chain is installed at the left side of a stepper motor, and the simulation guidance head is installed below the large installation platform. By adopting the simulation guidance head, the terminal guidance section simulation system has the advantages of long service life, high cost performance and simple structure; and the movement simulation platform adopts a steel tube net rack as a supporting frame, adopts the precise guide rail as the movement restriction, adopts the large-power stepper motor, the high-strength transmission belt and the roll-over drag chain as the towing, and adopts the computer to carry out the movement control, so the simulation system has the advantages that the simulated range of the earth surface for missile to pass is large, the platform motion is stable and is free from jumping, and the computer can conveniently perform the precise control.

Owner:PLA AIR FORCE AVIATION UNIVERSITY

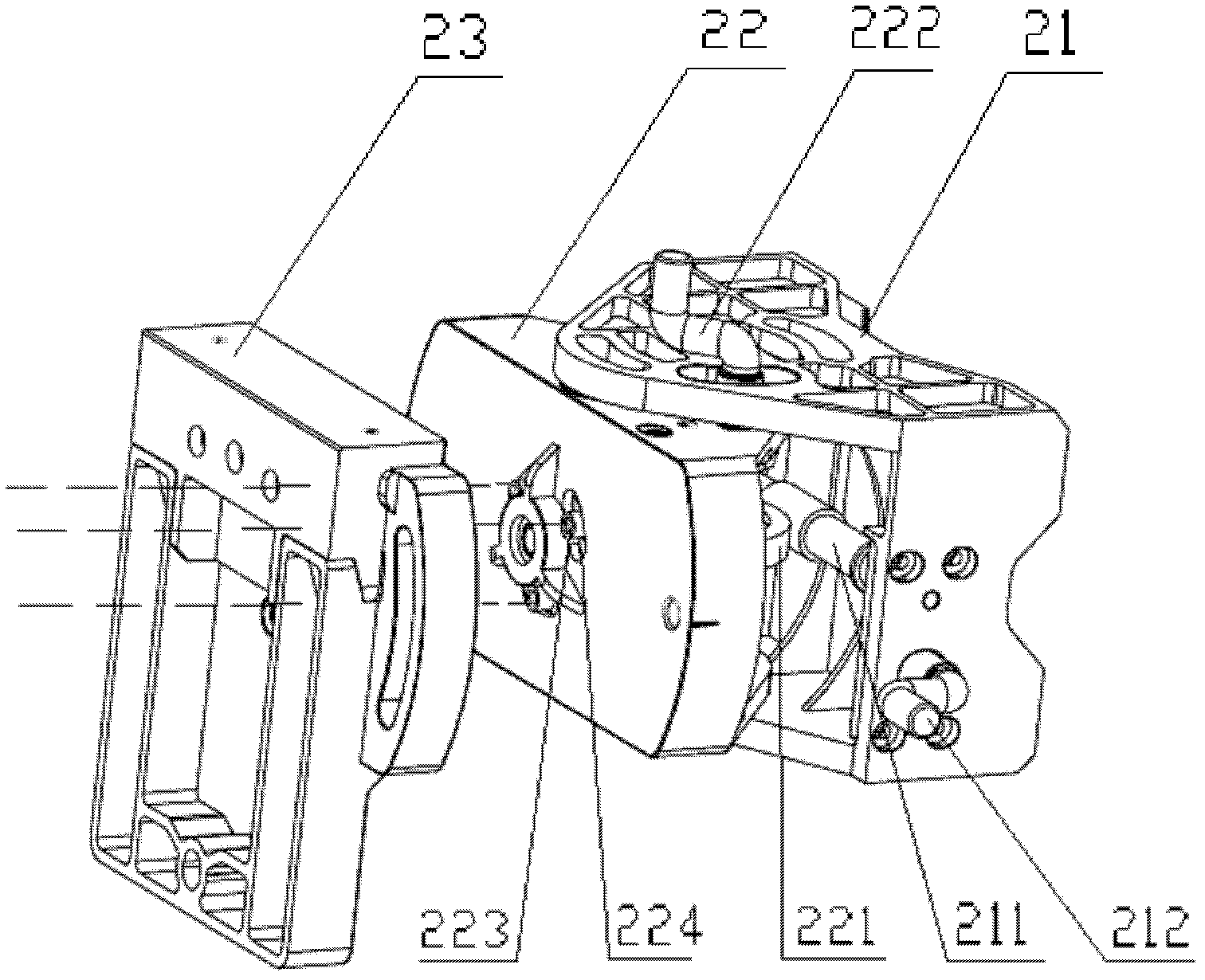

Adjusting device of microwave antenna

An adjusting device of a microwave antenna comprises a supporting member hinged via a first hinge shaft and a mounting member for connecting the microwave antenna, wherein, the supporting member is equipped with a first worm. The adjusting device also comprises a first worm wheel cooperated with the first worm and fixed with the mounting member, the rotary axis of the first worm wheel is overlapped with the axis of the first hinge shaft, and the adjusting device also comprises a first driving device for driving the first worm. The adjusting device drives the mounting member to rotate relative to the supporting member via a worm and worm wheel mechanism so as to drive the microwave antenna to rotate connected with the mounting member, being simple in operation. And the worm and worm wheel mechanism is in linear transmission, the position adjustment of the microwave antenna is a linear adjustment, and the change of the microwave signal is continuous, has no jumping and is high in adjustment precision. In addition, the adjustment of the worm and worm wheel mechanism is stable, relative to a threaded rod driving in the prior art, the scheme does not employ a threaded rod, and does not need to process an excessive through hole, thereby avoiding a signal compulsion generated by fastening bolts at the two sides of the excessive through hole.

Owner:HUAWEI TECH CO LTD

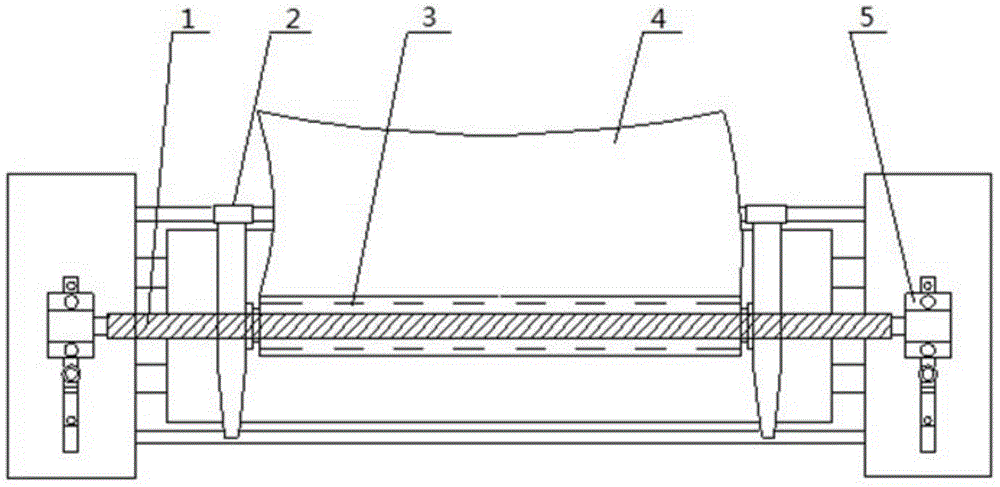

Vertical meter counting device

InactiveCN102121812AAccurate meter dataAdjustable distanceMechanical measuring arrangementsEngineeringMechanical engineering

The invention discloses a vertical meter counting device, which comprises a rack, a meter counter and riding wheel component, wherein the middle and lower parts of the rack are provided with a cylindrical central upright post; the meter counter is arranged on the upper part of the rack by a first longitudinal adjustment device; the riding wheel component is arranged on the rack by a second longitudinal adjustment device; the meter counter comprises a meter counting wheel, a meter counting wheel shaft and a counting device; the riding wheel component comprises a riding wheel and a riding wheel shaft; the riding wheel shaft is arranged horizontally; and the meter counting wheel shaft and the riding wheel shaft are arranged in the same vertical plane in parallel. The vertical meter counting device has the advantage that: a cable conductor is inserted between the riding wheel component and the meter counter, and fully contacts with the meter counting wheel without galloping by the riding wheel component, and simultaneously, a distance between the meter counter and the riding wheel component can be adjusted to make the cable conductor always in a horizontal linear state in releasing, meter counting and take-up, so meter counting data is more accurate.

Owner:PINGHU DIGONG MACHINERY MFG

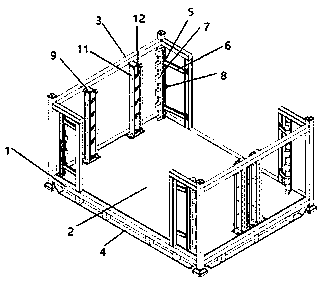

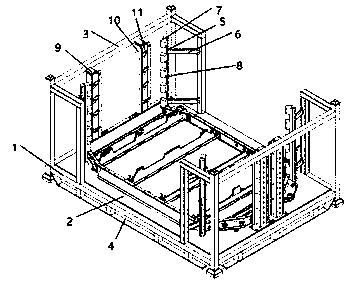

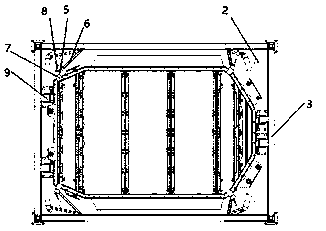

New energy vehicle battery frame base transfer loading shelf

InactiveCN110143363ANo beatingDoes not happenPackaging vehiclesContainers for machinesFrame basedNew energy

The invention discloses a new energy vehicle battery frame base transfer loading shelf. The new energy vehicle battery frame base transfer loading shelf comprises a shelf main body; the shelf main body consists of a rectangular base and two U-shaped flanges; the two U-shaped flanges are mounted on the base; stable brackets are mounted on all edges of the lower end of the base; pressing rod modulesare mounted on the side edges of two ends of the U-shaped flanges; the pressing rod modules consist of connecting frames and EVA racks; two support modules are mounted on two opposite short edges ofthe base; the upper ends of the support modules are connected with the upper side surfaces of the U-shaped flanges; and the support modules consist of frames and multiple overturning support plates. Through the mode, the new energy vehicle battery frame base transfer loading shelf has no obstacle on two sides to achieve the manipulator operation; and by dint of linkage structures of four support modules on two sides of the battery frame base, the production loading demands are met.

Owner:CHANGSHU TONGRUI LOGISTICS EQUIP CO LTD

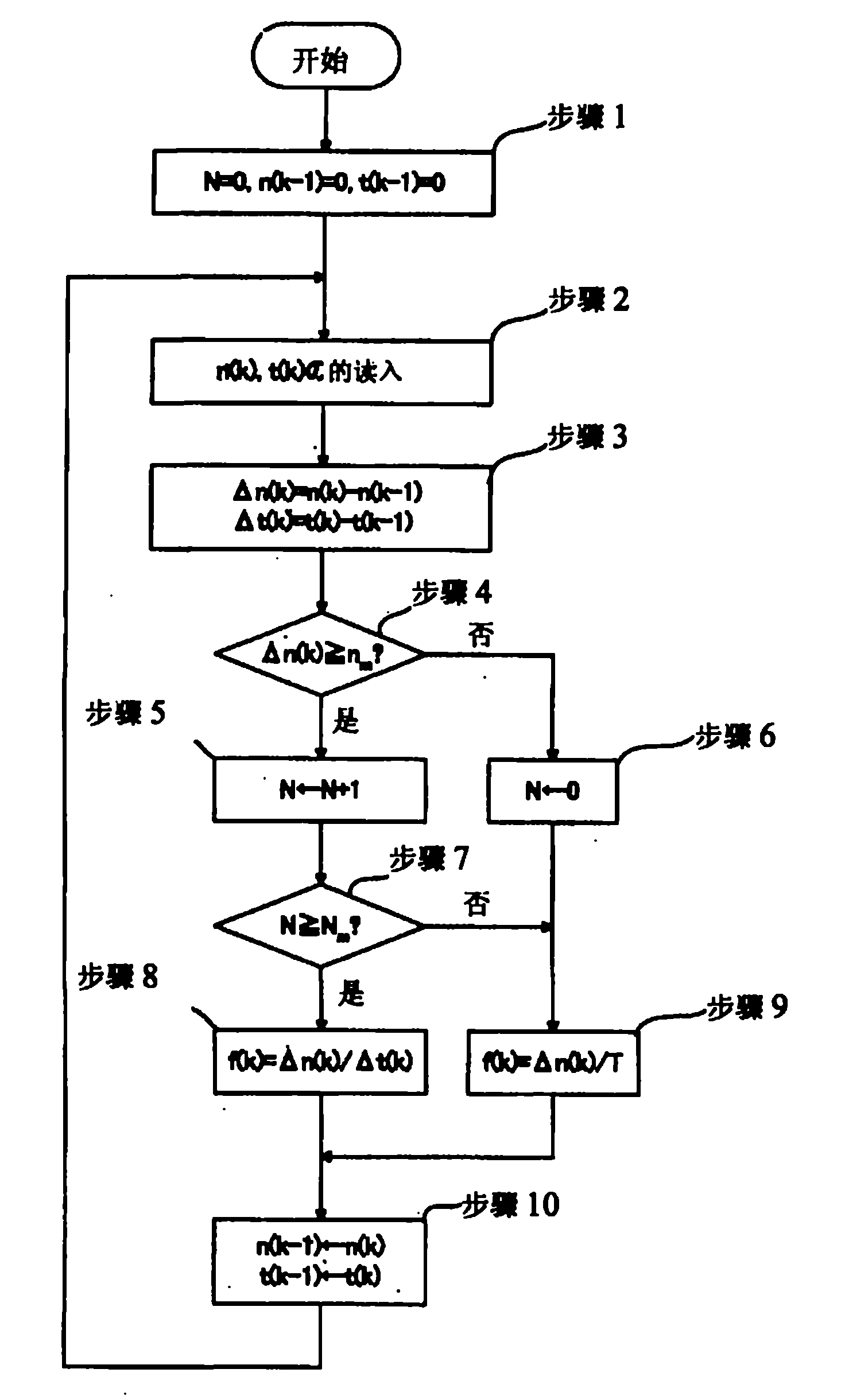

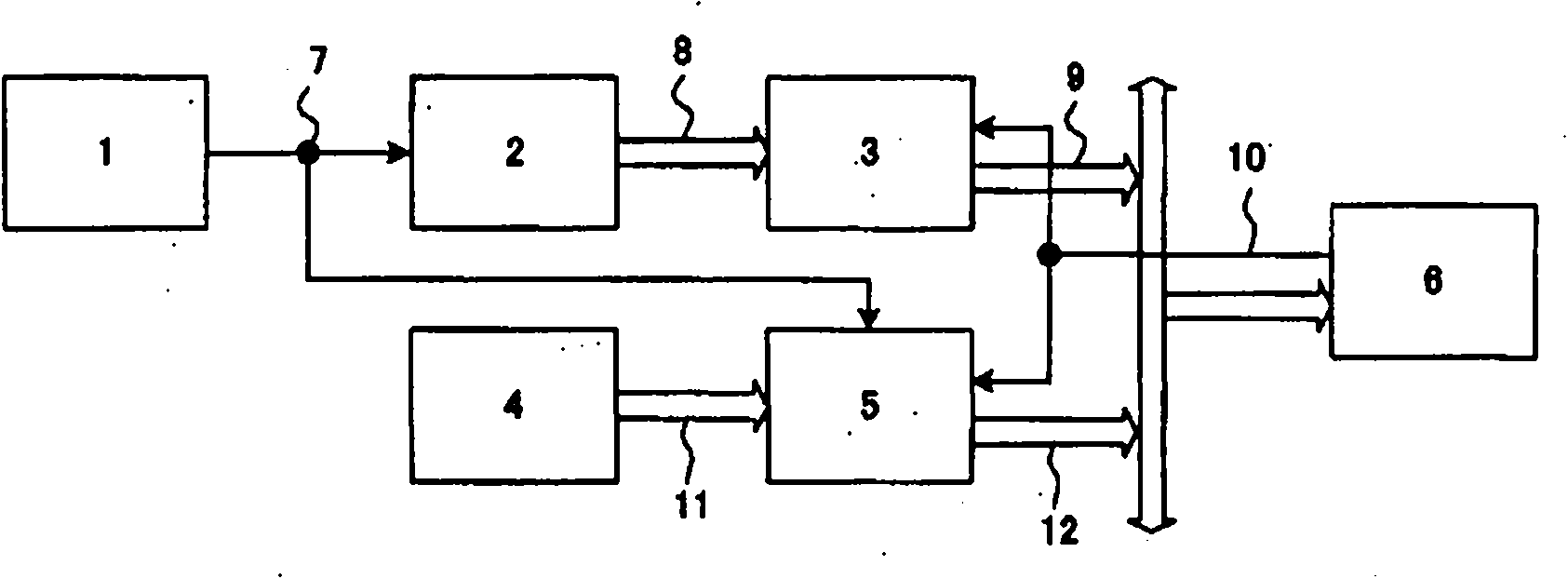

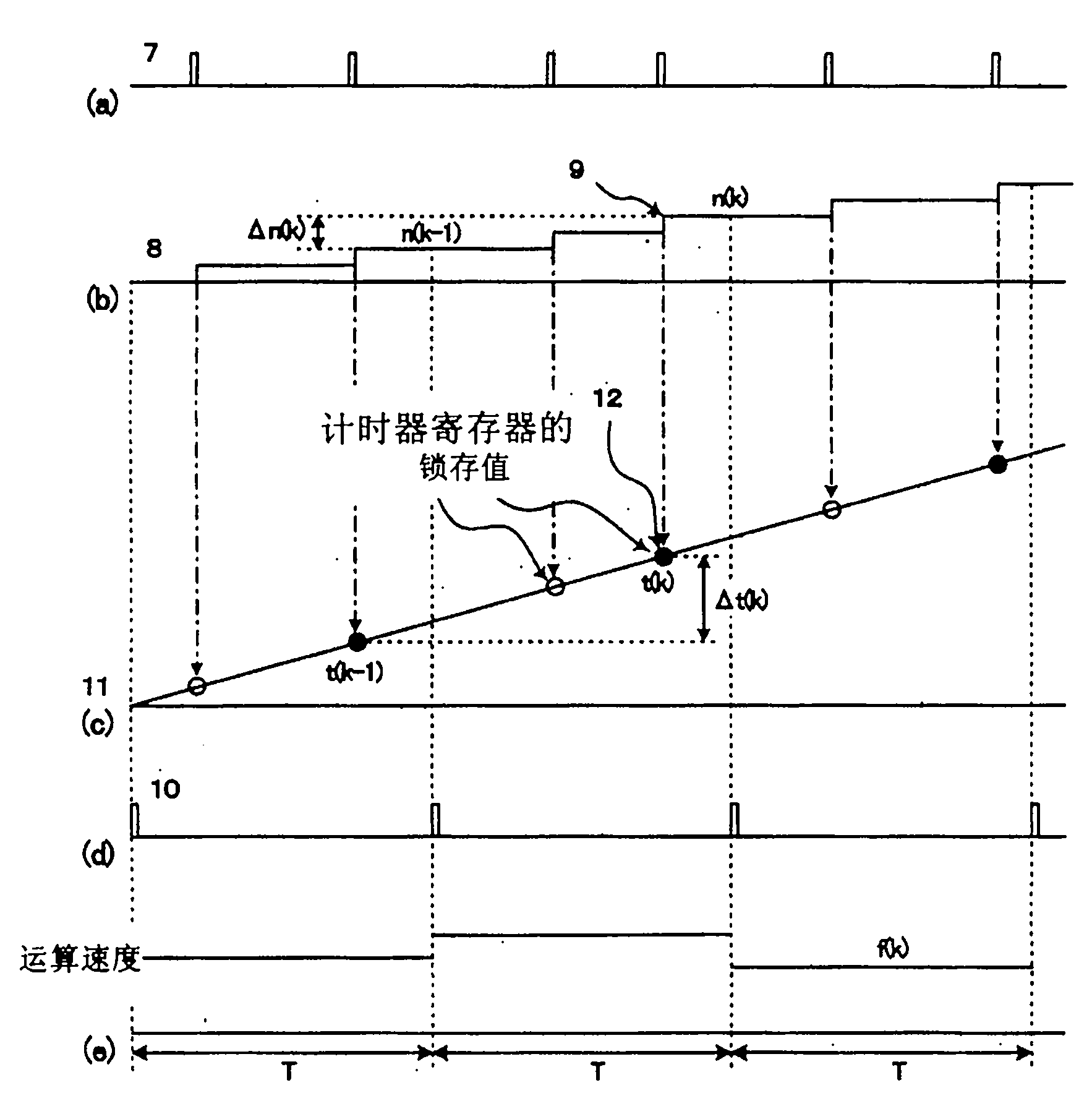

Velocity detection method and motor control device using the method

InactiveCN101784900AHigh precision and small fluctuationNo beatingLinear/angular speed measurementDynamo-electric machinesProcessor registerClassical mechanics

It is possible to provide a velocity detection method which can detect a highly-accurate and low-ripple velocity in a high-velocity region and can calculate a velocity without degrading the control performance even when a plenty of noises are contained in a low-velocity region. The velocity detection method uses a velocity detection device including: a pulse generation circuit (1) which outputs a position pulse; a counter (2) for counting the number of position pulses; a position register (3) which latches the value of the counter (2); a timer (4); a timer register (5) which stores the timer value by the up-down of the position pulse; and a velocity calculator (6) which issues a read-enable signal and reads the position pulse value from the position register (3) and the timer value from the timer register (5) so as to calculate a velocity. When the change pulse has reached a change pulse threshold value and the number of occurrences of the multi pulses has reached a multi-pulse continuous occurrence threshold value, the change pulse is divided by the change timer. Otherwise, the change pulse is divided by a sampling cycle to perform a velocity calculation process.

Owner:YASKAWA DENKI KK

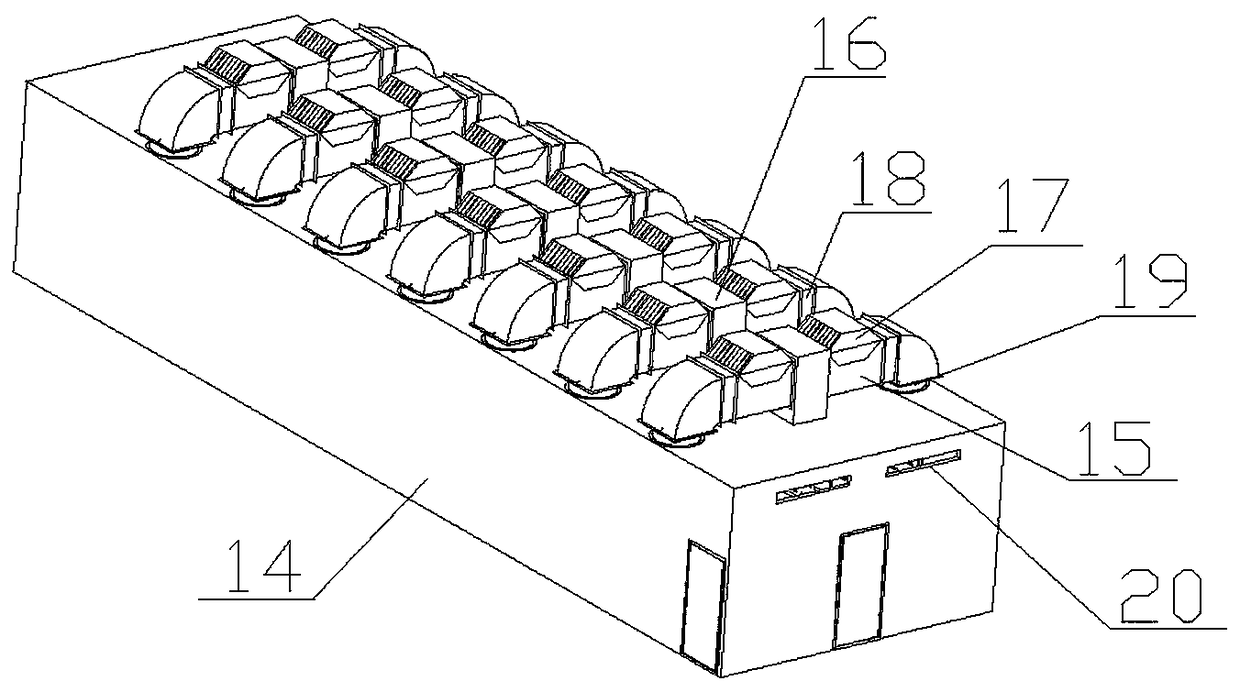

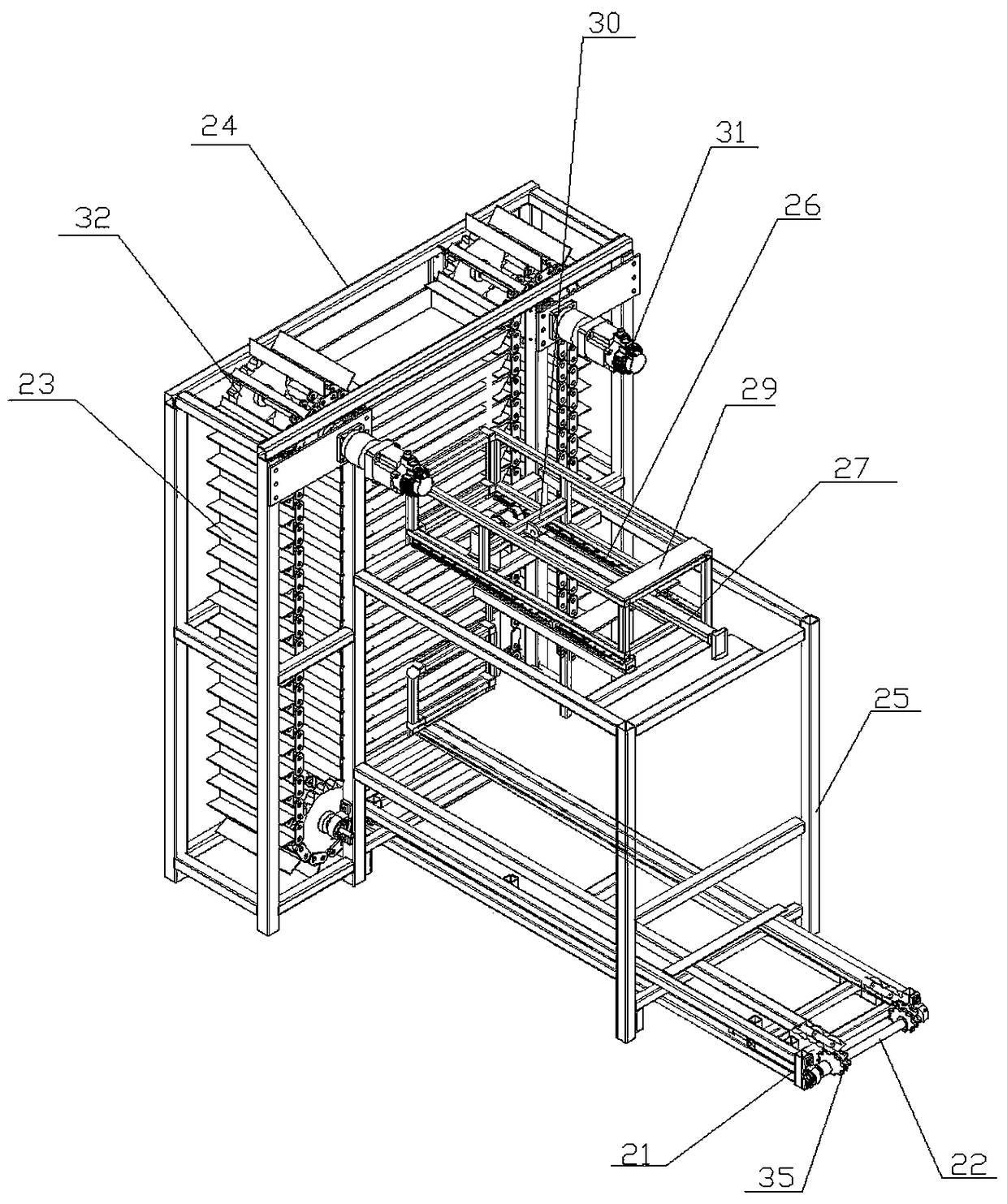

Hawthorn fruit drying device with charging machine

ActiveCN109170974AIncrease frictionImprove stabilityFood treatmentFood processingEngineeringMechanical engineering

The invention discloses a hawthorn fruit drying device with a charging machine. The hawthorn fruit drying device comprises a drying room, the charging machine, a plurality of heat transforming systemsand a conveying device, wherein the charging machine is arranged outside the drying room; the heat transforming systems are arranged in parallel above the drying room; the conveying device is positioned in the drying room; a material inlet is formed at the top of one end of the drying room, and a material outlet is arranged at the bottom of the drying room; the charging machine comprises a conveying part arranged at the bottom of one side of the material inlet of the drying room, a lifting part positioned at the end part of the inner side of the conveying part and a pushing part positioned atthe outer side of the lifting part; and the conveying device comprises a support frame, lifting mechanisms symmetrically arranged at both ends of the support frame, and a plurality of conveying mechanisms arranged in parallel on the support frame. The hawthorn fruit drying device with the charging machine has simple structure, energy conservation, environment friendliness, high drying efficiencyand good quality of hawthorn fruits, uniformity of operation in a transport process and no noise pollution, and can realize continuous transfer among transfer devices of different height.

Owner:河南中联热科工业节能股份有限公司

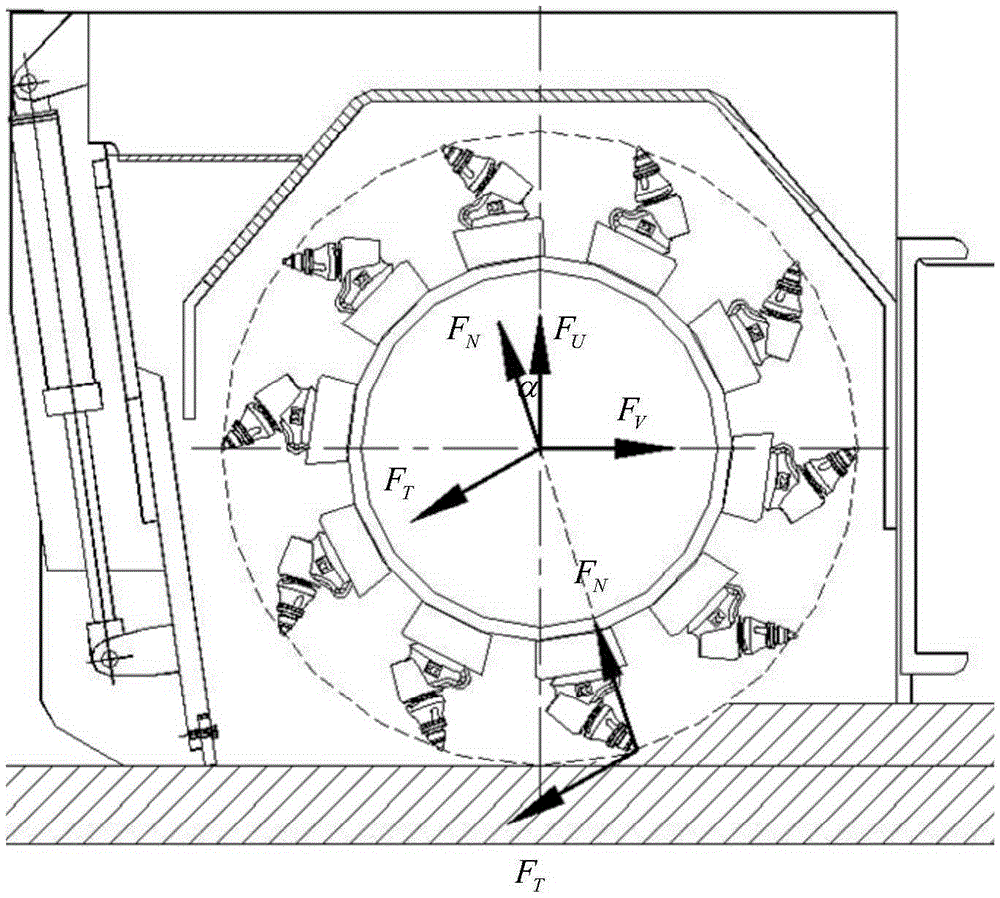

Road milling machine and milling flatness auxiliary control method

ActiveCN105386399AReduce the driving forceImprove flatnessRoads maintainenceHydraulic motorProgrammable logic controller

The invention discloses a road milling machine and a milling flatness auxiliary control method, which aim at solving a problem that the flatness of the milled road is poor in the prior art. The road milling machine comprises a pressure sensor (4) capable of detecting a walking pressure of the milling machine, wherein a programmable controller (9) and a walking hydraulic pump (8) are arranged on the milling machine (1); the pressure sensor (4) is connected with an input end of the controller (9); a walking hydraulic motor (2) is arranged on a walking crawler (7) of the milling machine; a liquid inlet of the walking hydraulic motor (2) is connected with a walking hydraulic pump (8); and an output end of the controller (9) is connected with a control end of the walking hydraulic pump (8).

Owner:CHANGAN UNIV

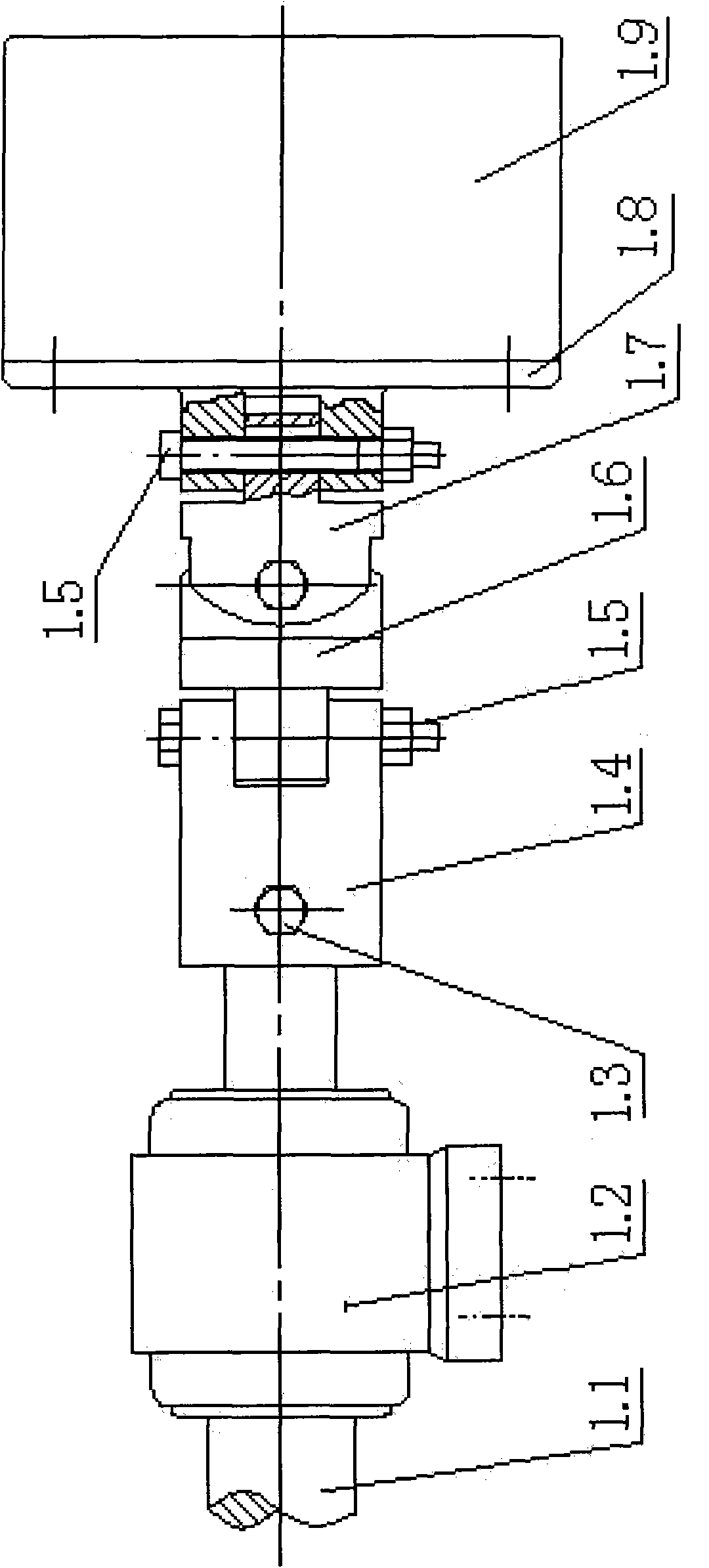

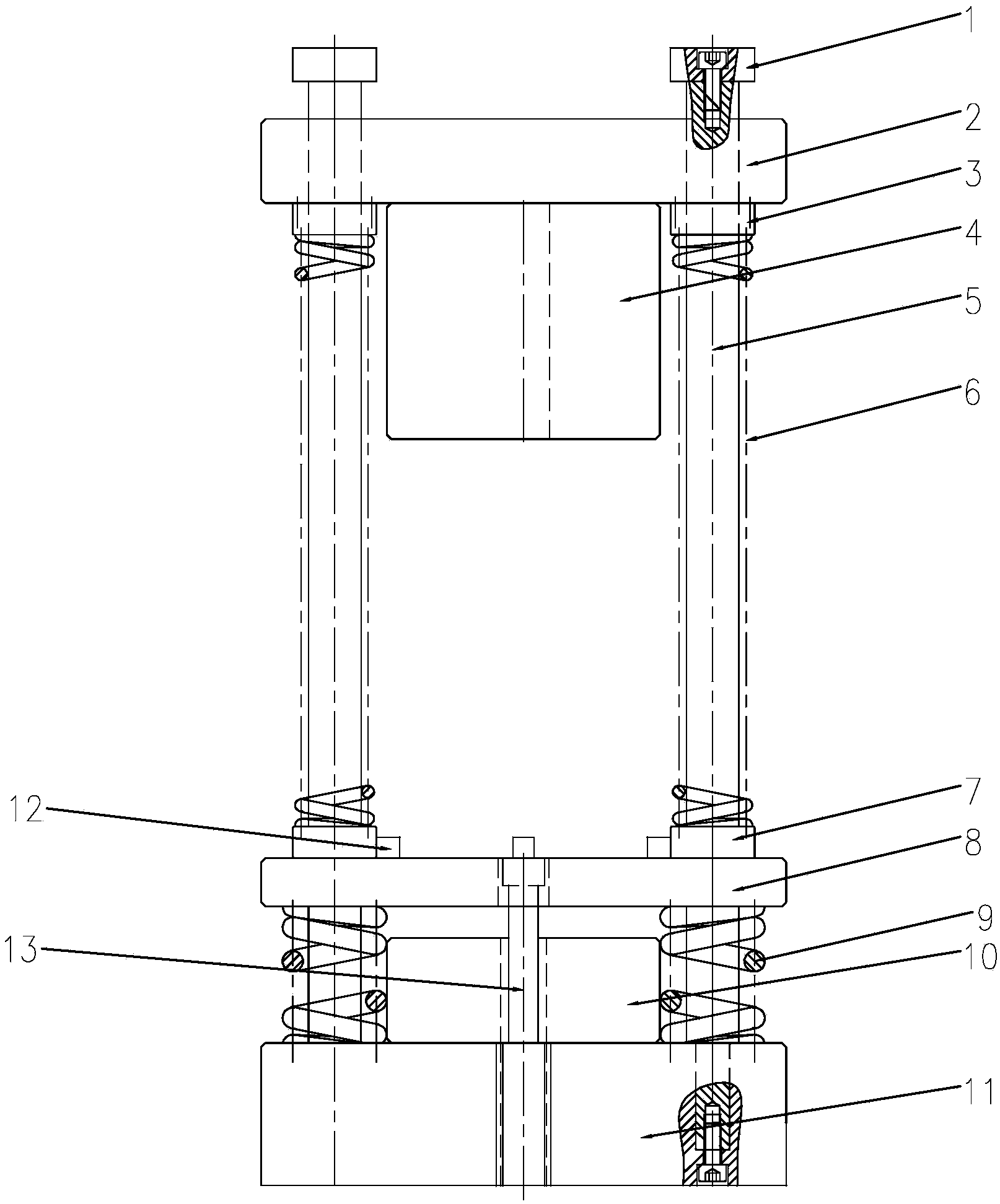

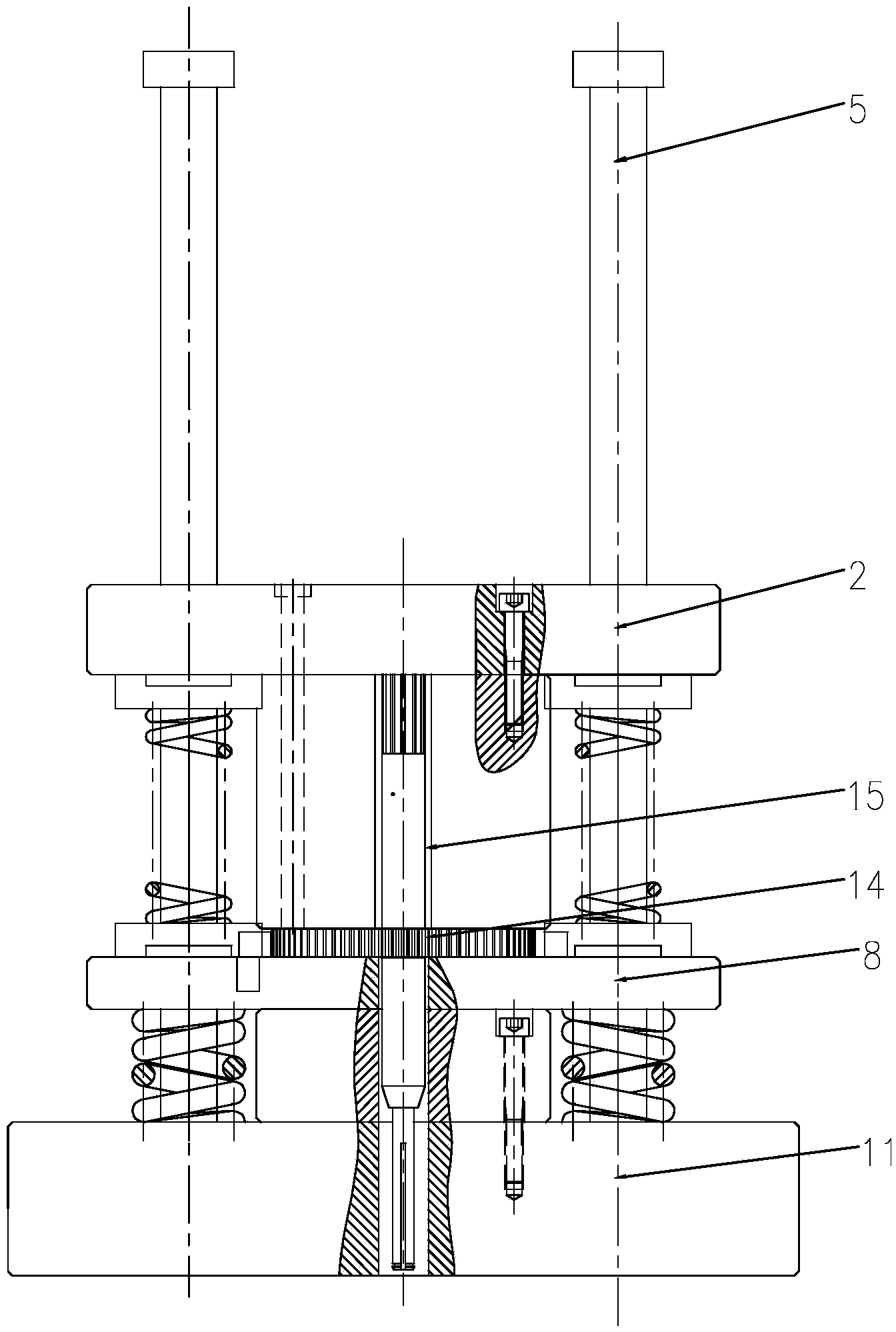

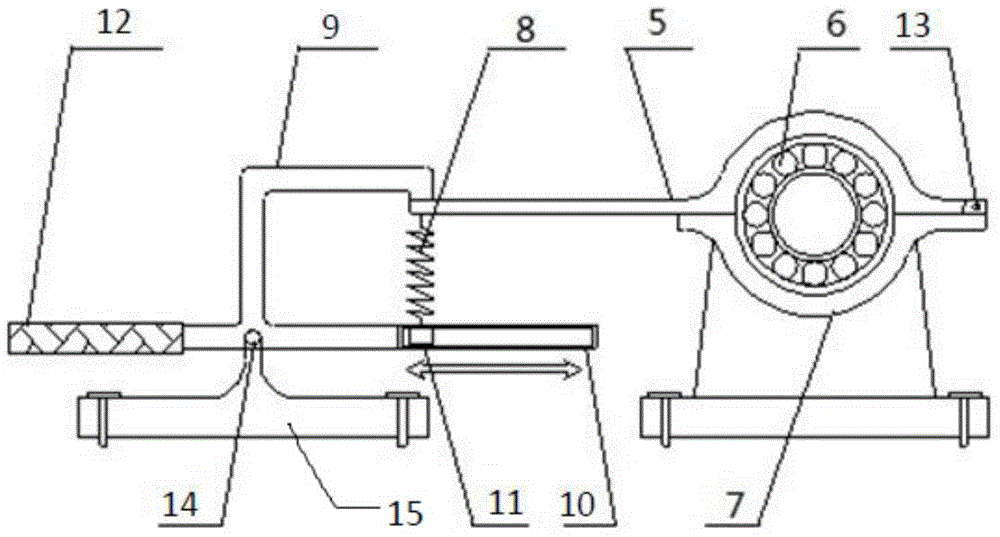

Gear and shaft assembling tooling

The invention relates to a gear and shaft assembling tooling, in particular to a tooling for accurate and quick assembling of a gear and a shaft, and belongs to the technical field of gear and shaft assembling. The gear and shaft assembling tooling comprises a base, wherein the center of the base is connected with a supporting block through bolts; an upper pressing plate and a lower pressing plate are jointly connected onto four sliding shafts, and the four sliding shafts are in sliding fit with the upper pressing plate and the lower pressing plate; the upper parts of the four sliding shafts are respectively provided with an upper restoring spring in a sheathing manner, the upper restoring springs are located between the upper pressing plate and the lower pressing plate and tightly press the upper pressing plate and the lower pressing plate, the lower parts of the four sliding shafts are respectively provided with a lower restoring spring in the sheathing manner, and the lower restoring springs are located between the lower pressing plate and the base and tightly press the lower pressing plate and the base. The gear and shaft assembling tooling has the advantages that the assembling is simple and quick to conduct, the production efficiency is improved, the tooling realizes accurate positioning, and the gear of a press-fit gear assembly is guaranteed not to run out during working; the lower restoring springs can prevent the workpiece and the tooling from being damaged due to compression, the overload protection is safe and parts are prevented from being damaged.

Owner:WUXI KAIXUAN MOTOR

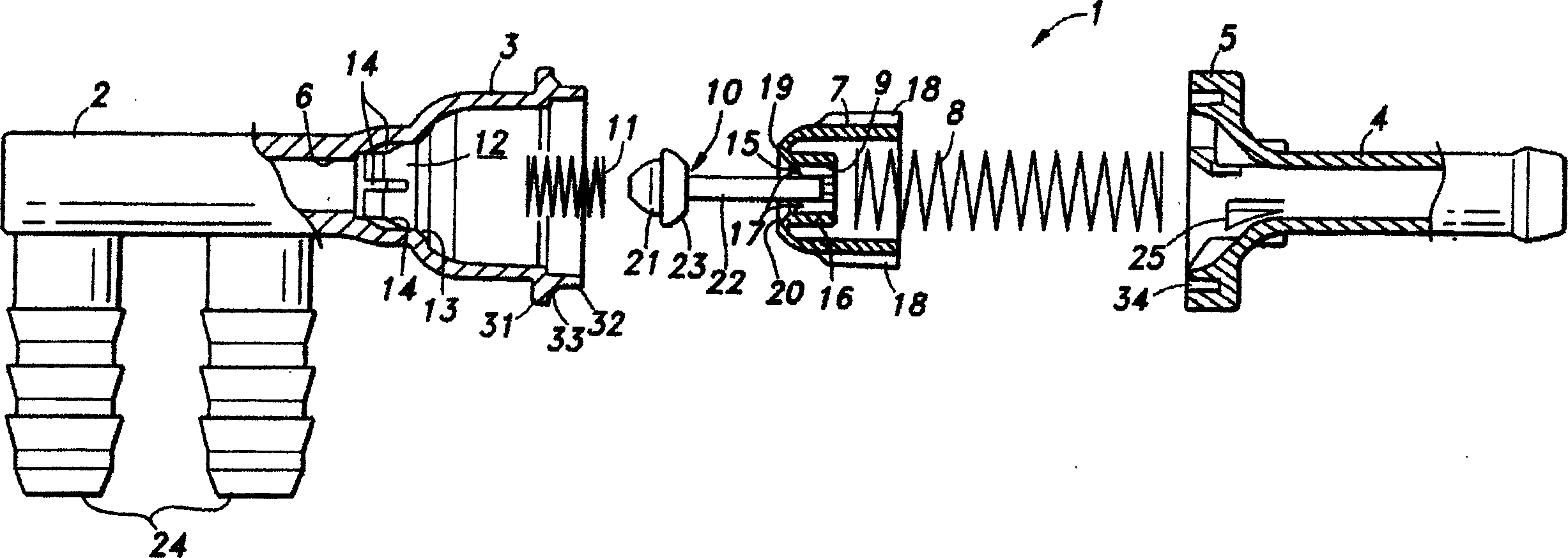

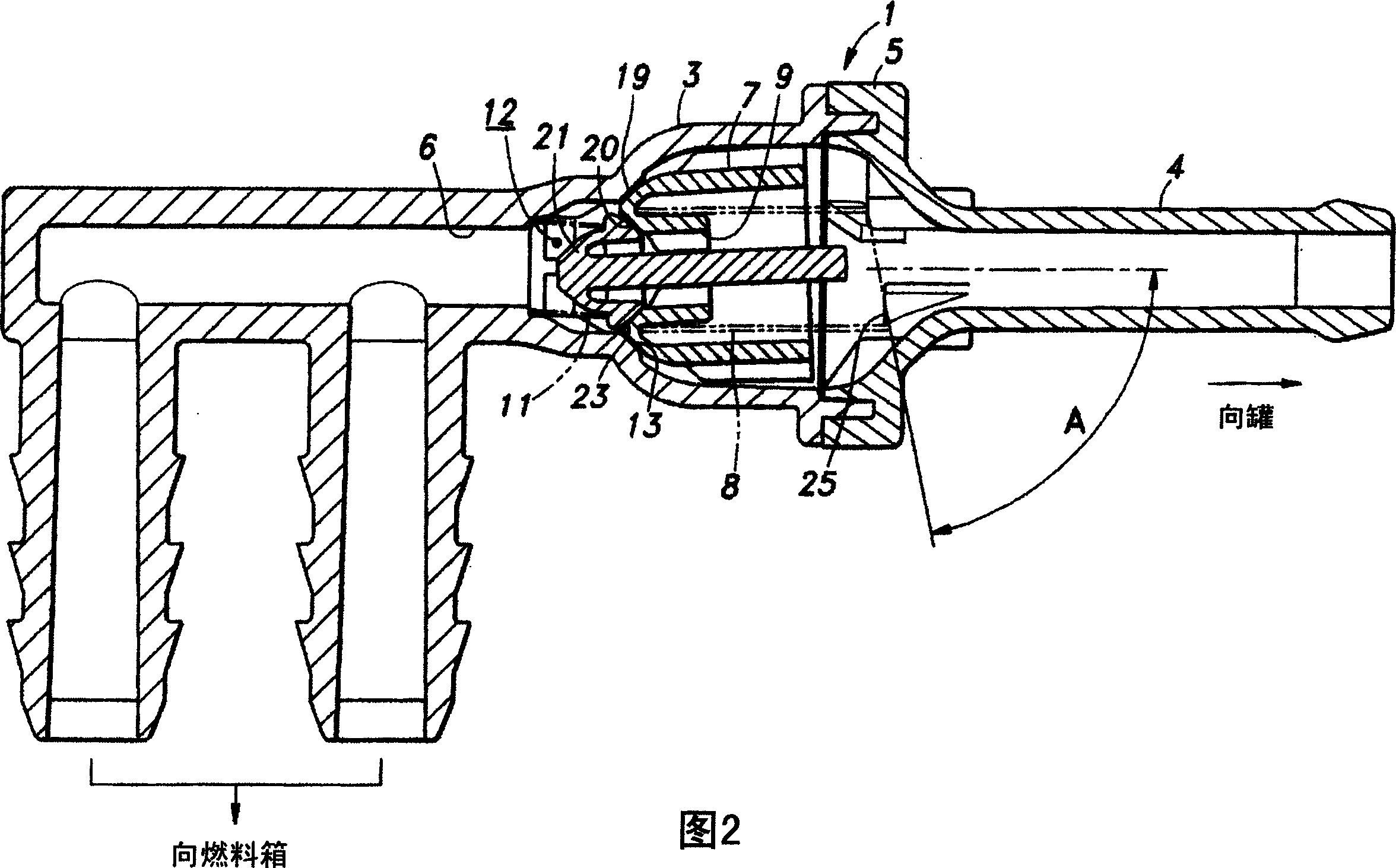

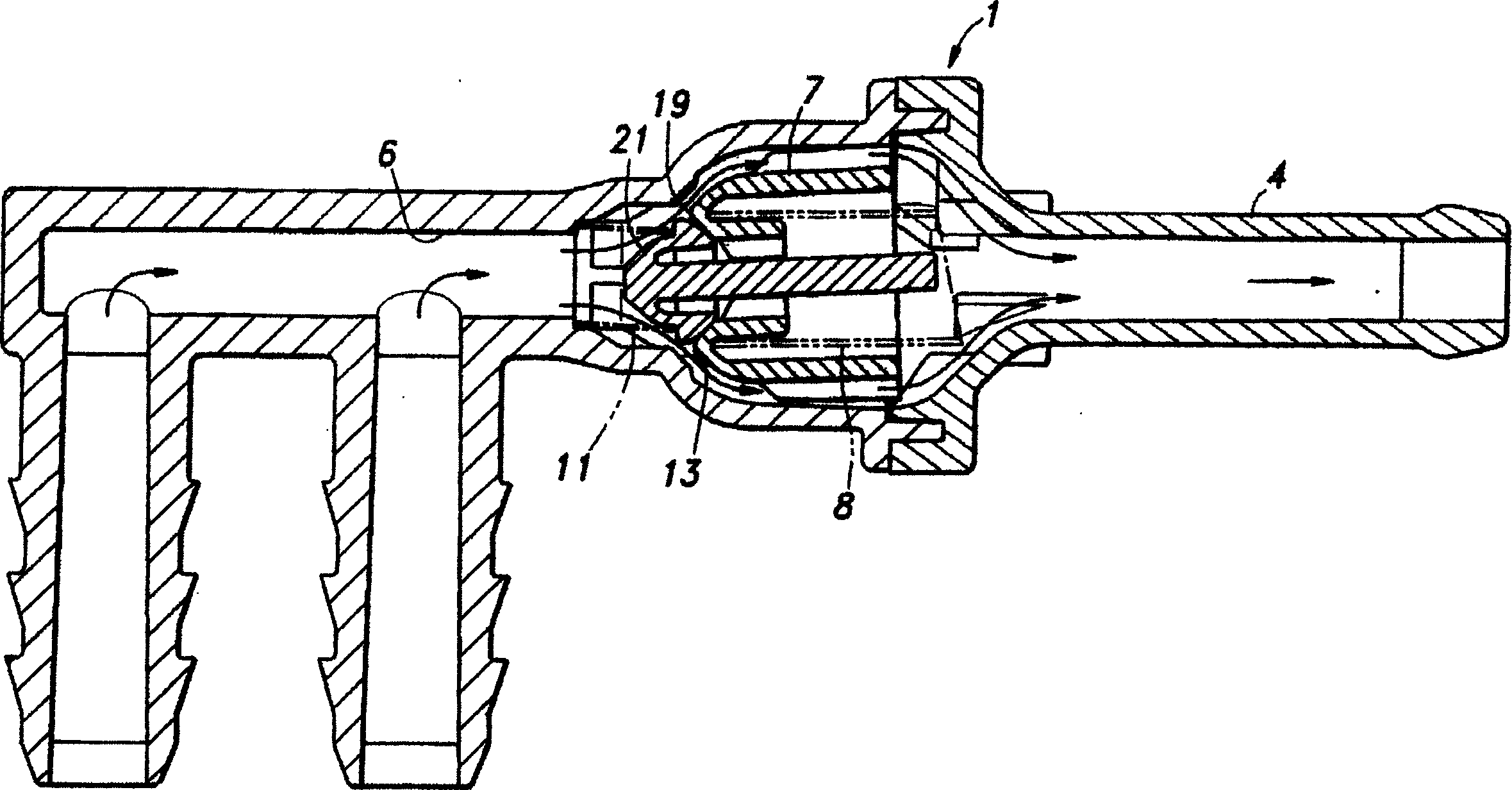

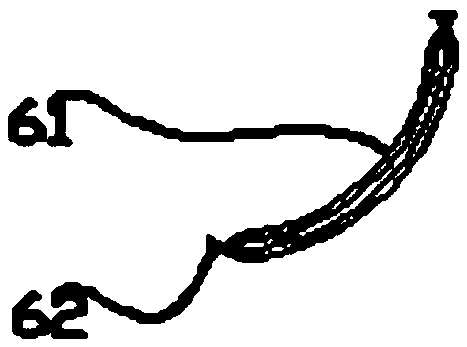

Pressure opening and closing valve

InactiveCN1590820ANo beatingIntentional contactNon-fuel substance addition to fuelEqualizing valvesPositive pressureDifferential pressure

To provide a pressure opening and shutting valve capable of controlling occurrence of beating noises without blocking smoothness of operation. The opening and shutting valve (1) comprises a housing (a housing body 3 and a housing cap 5) having first port (a fluid passage 6) and a second port (hose connecting nozzle 4), and a valve body (positive pressure valve body 7), which is housed in the housing, normally blocking the first port by urging with a spring (a coil spring 8 with a large diameter) and opening when differential pressure between the first port and the second port exceeds a designated value. An axis of urging force for closing a valve by means of the valve body is set to be non-parallel to an axis of a valve seat (a positive pressure valve seat 13) that brings into contact with the valve body.

Owner:NIFCO INC +1

Perforating device for aluminum alloy doors and windows

InactiveCN109702241AHigh positioning accuracyHigh precisionPositioning apparatusMetal-working holdersBidirectional transmissionEngineering

The invention discloses a perforating device for aluminum alloy doors and windows and belongs to the field of aluminum alloys. The perforating device comprises a bottom plate and a frame body; a substrate and a substrate driving mechanism are arranged on the frame body; a lifting driving mechanism is installed on the substrate; a drilling motor is installed at the output end of the lifting drivingmechanism; the drilling motor is connected with a drilling bit; clamping and fixing mechanisms are correspondingly installed at the parts, located on the two sides of the frame body, of the bottom plate; each clamping and fixing mechanism comprises a left and right rotary bidirectional transmission lead screw and two nuts; clamping substrates are installed on the nuts; the clamping substrates arein sliding connection with the bottom plate; pressing blocks and pressing block driving mechanisms are arranged on the clamping substrates; the sliding direction of the substrate is in parallel withthe direction of the left and right rotary bidirectional transmission lead screws; the sliding direction of the pressing blocks is in parallel with the direction of the drilling bit; and the sliding direction of the pressing blocks is perpendicular to the direction of the left and right rotary bidirectional transmission lead screws. The perforating device is convenient to operate and high in clamping and locating accuracy, and can be suitable for clamping operation of sectional materials in different heights.

Owner:安徽博安门窗有限公司

Glass panel polishing machine tool and polishing method

ActiveCN109227257AAvoid damageRealize automatic operationGrinding feedersPlane surface grinding machinesProduction lineEngineering

The invention discloses a glass panel polishing machine tool. The glass panel polishing machine tool comprises a cylindrical through hole formed in the center of a cover body, a polishing device penetrates through the through hole and makes the polishing device ascend and descend through a lifting mechanism, and the cover body is arranged above a conveying mechanism; the conveying mechanism comprises a support, two transmission rollers arranged at the left end and the right end of the support, a transmission motor and a conveying belt; the conveying belt sleeves the two transmission rollers atthe left end and the right end. The glass panel polishing machine tool is provided with a damping supporting device, so that the machine tool is particularly suitable for processing mobile phone panels and other glass panels with relatively high optical performance requirements; furthermore, an almost insulating environment is kept in the polishing operation process, and the interference of static electricity to the polishing process is reduced; furthermore, the machine tool is also suitable for being directly added into a production line to realize automatic operation in a processing environment.

Owner:SHANDONG CHUANGHUI TECH CO LTD

Cutting robot for aluminum alloy section and use method thereof

InactiveCN108637349AHigh precisionAvoid machining size deviationMetal-working feeding devicesShearing machinesAluminium alloyRobot

The invention provides a cutting robot for an aluminum alloy section and a use method thereof. The cutting robot for the aluminum alloy section comprises a working platform, a supporting rod and a second support, wherein a controller is arranged on the side surface of the working platform; an air pipe is arranged at the bottom part of the working platform, and a pedal plate is arranged at one end,far away from the working platform, of the air pipe; a feeding frame is arranged at one side of the working platform; a first supporting roller is arranged in the middle part of the feeding frame; adischarging frame is arranged at one side, far away from the feeding frame, of the working platform; and a second supporting roller is arranged in the middle part of the discharging frame. According to the cutting robot for the aluminum alloy section, the feeding frame is arranged, the aluminum alloy section is horizontally paved on the feeding frame and then pushed to the upper surface of the working platform; the aluminum alloy section is kept on one plane during the whole cutting process, so that the problem that the aluminum alloy section drops in cutting due to excessively high length, resulting in processing size deviation, can be avoided; and the aluminum alloy cutting accuracy can be improved.

Owner:冯建利

Five-cylinder electric magnetic engine

InactiveCN105375677ASimple and reliable control processQuality ratioMechanical energy handlingInterference fitEngineering

The invention discloses a five-cylinder electric magnetic engine, which comprises an engine body, support sleeves, connecting rods, an output shaft an a flywheel mechanism, wherein the engine body comprises a machine body and a machine cavity; the machine cavity is arranged in the machine body; the support sleeves are sleeved with the machine cavity in the machine body; permanent magnet groups are arranged between the machine body and the support sleeves; pistons are assembled in the support sleeves; a coil assembly winds one end of each piston and is fixed on each piston; the outer cylindrical surfaces of the support sleeves and the permanent magnet groups are in interference fit; the permanent magnet groups and an air cylinder body are in interference fit; the pistons and the inner cylindrical surfaces of the support sleeves are in interference fit; each piston is connected with one end of each connecting rod; the other end of each connecting rod is connected with the output shaft; the output shaft is located at the center of the machine body; the rotating center of the flywheel mechanism is connected with the output shaft; and off centers of the eccentric structure are distributed in a circumference array around the center. The five-cylinder electric magnetic engine is simple in structure, low in cost, simple and reliable in control principle, high in response speed, high in torque, environment-friendly and energy-saving; and consumption of the traditional fuel energy is reduced.

Owner:GUANGDONG UNIV OF TECH

Winding device for preventing pressing folds of textile fabric and operating method of winding device

The invention provides a winding device for preventing textile fabric from being pressed to wrinkle and an operating method of the winding device, and belongs to the technical field of textile fabric winding devices. The winding device overcomes the shortcomings that under the high-speed operation of an existing textile fabric winding device, and wound flocking textile fabric is uneven, transverse folds and pressing marks exist on the fabric. The winding device for preventing the textile fabric from being pressed to wrinkle comprises a rack, and a paper tube shaft roller and breadth adjusting arms are arranged on the rack; a paper tube is arranged on the paper tube shaft roller, and automatic adjusting mechanisms are arranged at the two ends of the paper tube shaft roller; each automatic adjusting mechanism comprises a bearing and a bearing bracket; the bearings are located on the bearing brackets, and the bearings are covered with single-arm bearing covers; the bearings are completely wrapped by the bearing brackets and the single-arm bearing covers; and each single-arm bearing cover comprises a bearing cover and a single arm, wherein a three-arm-rod automatic adjusting hasp arm is arranged at the tail end of the single arm, a spring is arranged at the position of a hasp of the three-arm-rod automatic adjusting buckle arm, and a three-arm-rod chute arm is connected to the other end of the spring.

Owner:HAINING JINYONGHE HOUSEHOLD TEXTILE

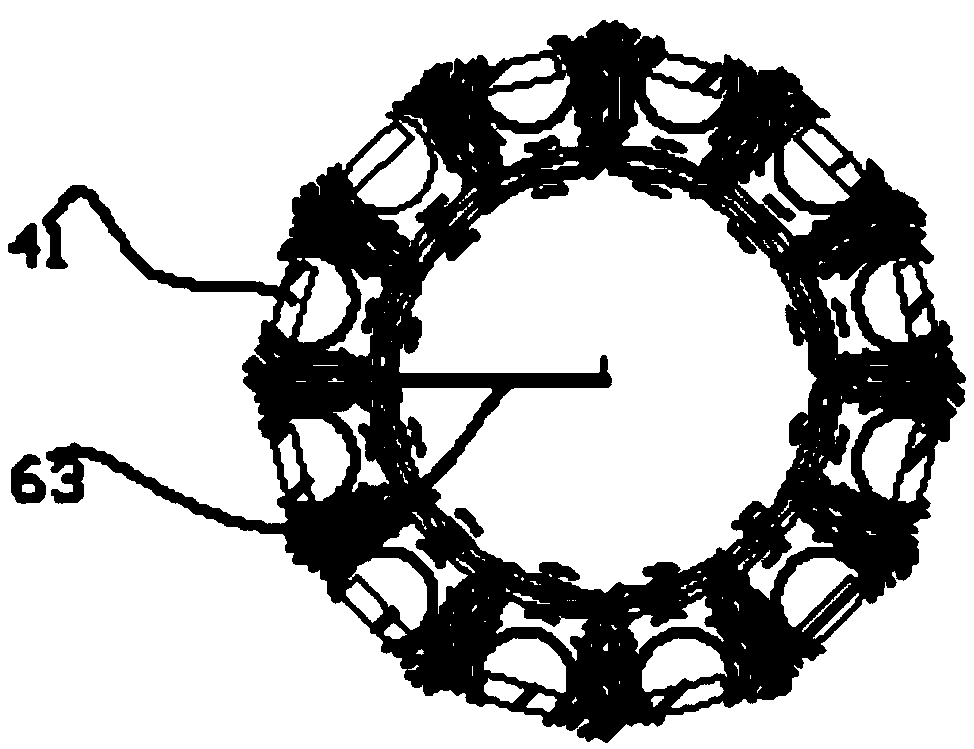

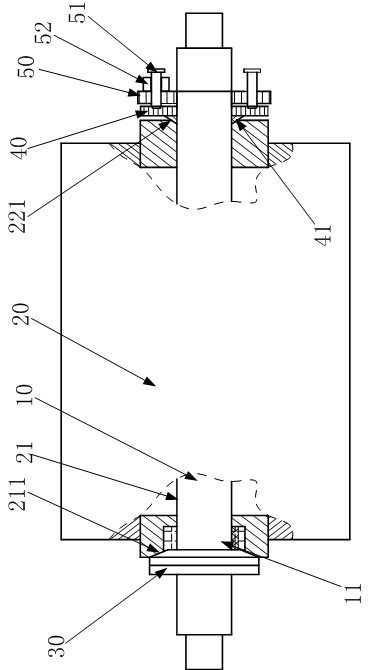

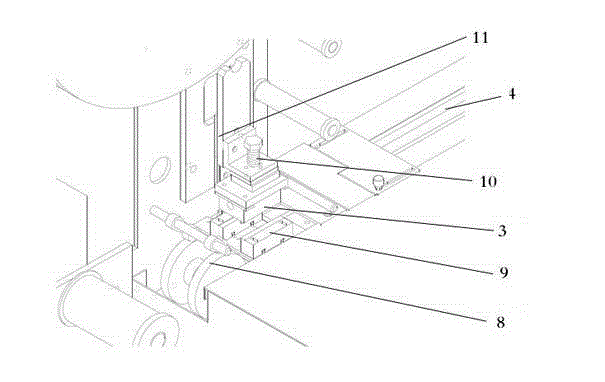

Fixing mechanism for brush roller of circuit board grinding machine

ActiveCN102581724AAvoid influenceGuaranteed uptimeGrinding machine componentsGrinding machinesDrive shaftEngineering

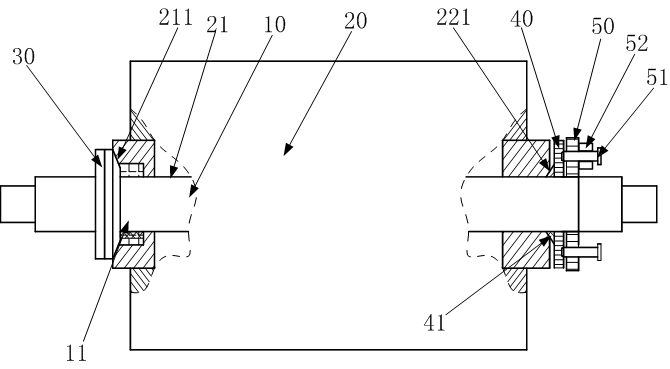

A fixing mechanism for a brush roller of a circuit board grinding machine comprises a transmission shaft (10) and a brush roller (20) sleeved on the transmission shaft (10). A positioning conical disk (30) is disposed at a positioning end (11) of the transmission shaft (10), and a first conical hole (211) matching with the positioning conical disk (20) in taper is disposed at a positioning end of a center hole (21) of the brush roller (20). The fixing mechanism further comprises a moving pressure disk (40) and a nut pressure disk (50), wherein the moving pressure disk (40) is movably sleeved to a fixed end (12) of the transmission shaft (10), the nut pressure disk (50) is in threaded connection with the fixed end (12) of the transmission shaft (10), and the nut pressure plate (5) jacks the moving pressure disk (4) to press the brush roller (20). According to the technical scheme, impact of opposite force of the brush roller upon the fixing mechanism is avoided, the brush roller is stable in operation without jumping and axial play, and quality of a ground board is guaranteed.

Owner:博罗县精汇电子科技有限公司

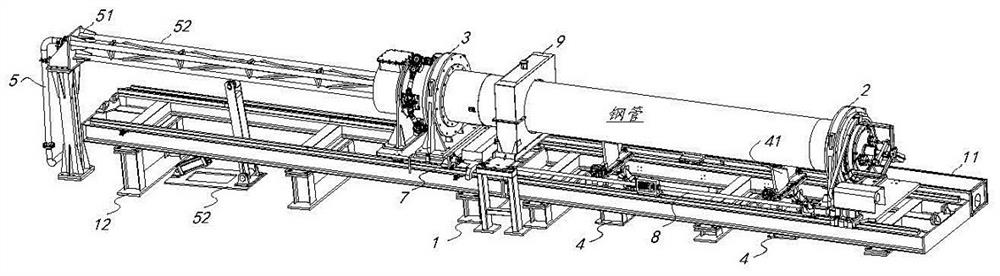

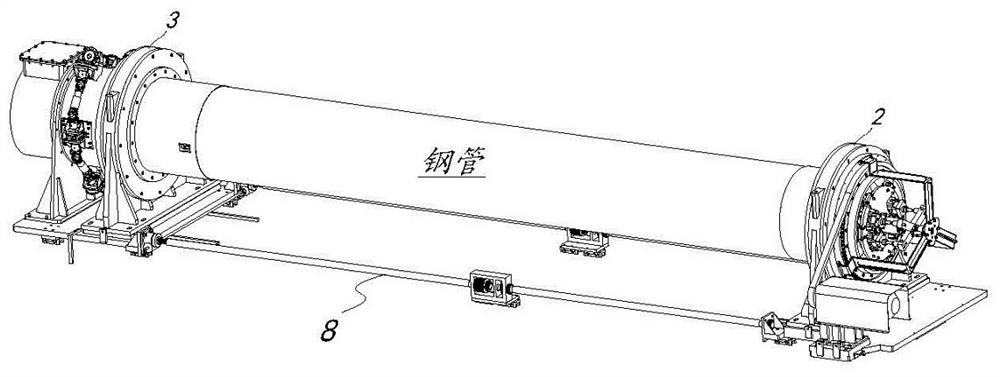

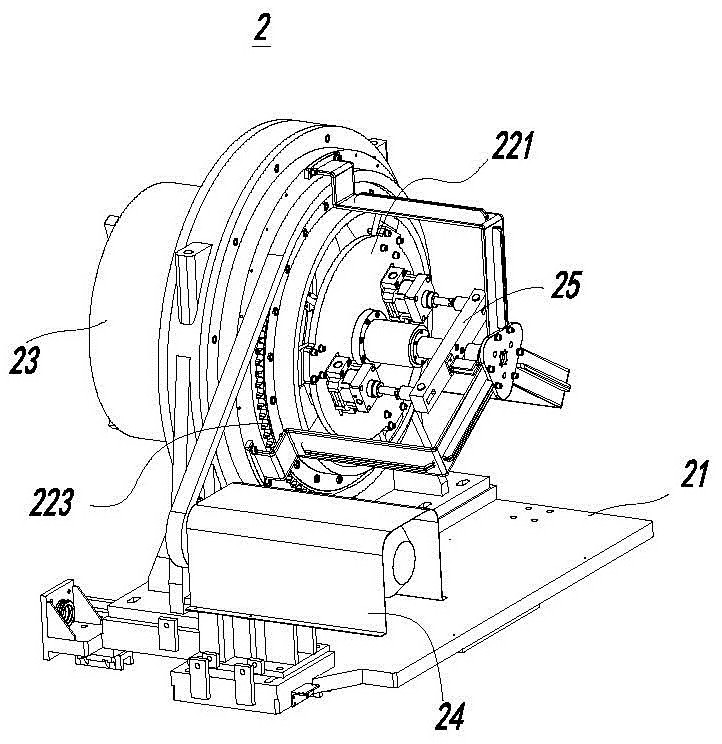

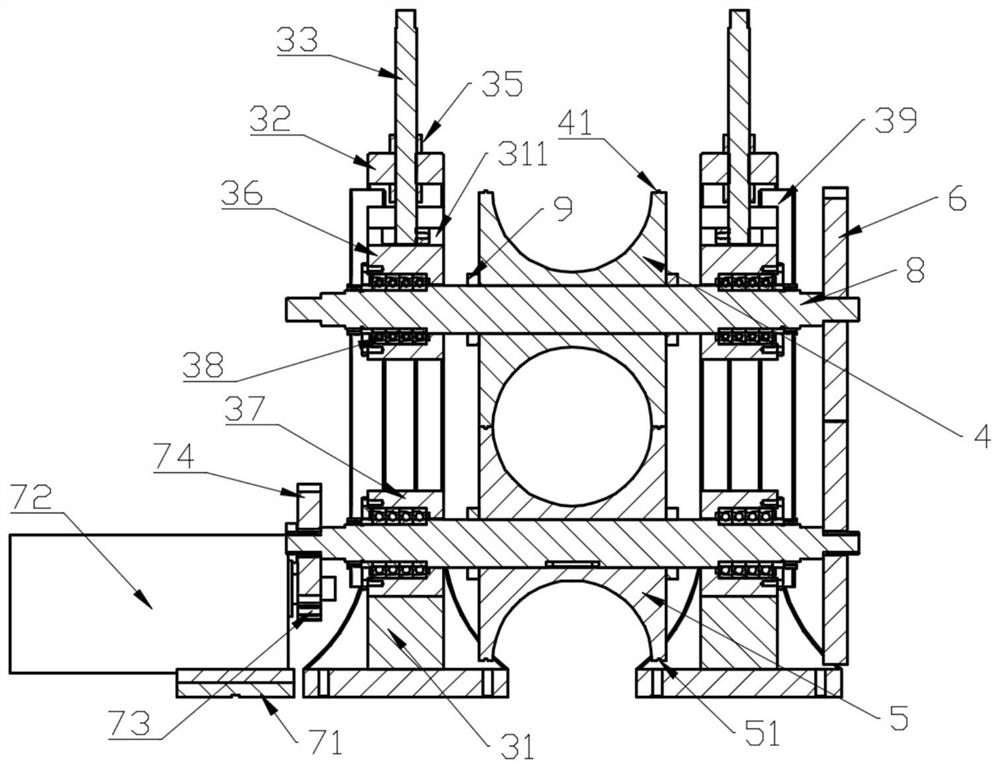

Steel pipe quenching clamping equipment

PendingCN112322860ASimple structureWalking smoothlyIncreasing energy efficiencyFurnace typesEngineeringMechanical engineering

The invention discloses steel pipe quenching clamping equipment. The steel pipe quenching clamping equipment comprises a base, a front end clamping mechanism, a rear end clamping mechanism, two lifting supports, a cooling water spraying device, a walking mechanism and a moving platform; the front end clamping mechanism and the rear end clamping mechanism are oppositely arranged on the upper surface of the moving platform, and a connecting rod is arranged between the front end clamping mechanism and the rear end clamping mechanism; the walking mechanism is arranged on one side of the rear end clamping mechanism and drives the rear end clamping mechanism to drive the front end clamping mechanism to move on the moving platform at the same time; the moving platform is mounted on the upper surface of the base; the lifting supports are oppositely installed on the front half section of the base; and the cooling water spraying device is mounted above the rear half section of the base. According to the steel pipe quenching clamping equipment provided by the invention, the functions of fixing, rotating and the like of steel pipes in the quenching process are ensured, the requirement for uniform induction heating is met, the steel pipes are radially cooled uniformly, and the quality of the steel pipes is improved.

Owner:SHANGHAI KINGS AUTOTECH

Material discharging and ejecting mechanism

The invention relates to a material discharging and ejecting mechanism which comprises a die seat (1). A material hole (2) of the die seat (1) is internally provided with a material ejecting rod (3) penetrating out of the lower portion of the material hole (2). A lever (4) is arranged on the lower portion of the material ejecting rod (3), the two sides of the lever (4) are free ends, and the middle portion of the lever (4) is provided with a fixed rotating point (5). One side of the lever (4) is arranged below the material ejecting rod (3) to make contact with the material ejecting rod (3), wherein the lower portion of the side of the lever (4) is provided with an eccentric mechanism (6). The upper portion of the other side of the lever (4) is provided with an air cylinder (6) which is fixedly arranged, and the air cylinder (6) is used for driving the other side of the lever (4). According to the material discharging and ejecting mechanism, due to the action of a material ejecting cam on the lever, material ejecting is achieved through the material ejecting rod; and meanwhile due to the air cylinder on the other side of the lever, the lever is restrained, the lever cannot jump in the movement process, the material ejecting rod cannot jump, and the material ejecting process can be stable.

Owner:YANGZHOU FORGING MACHINE TOOL

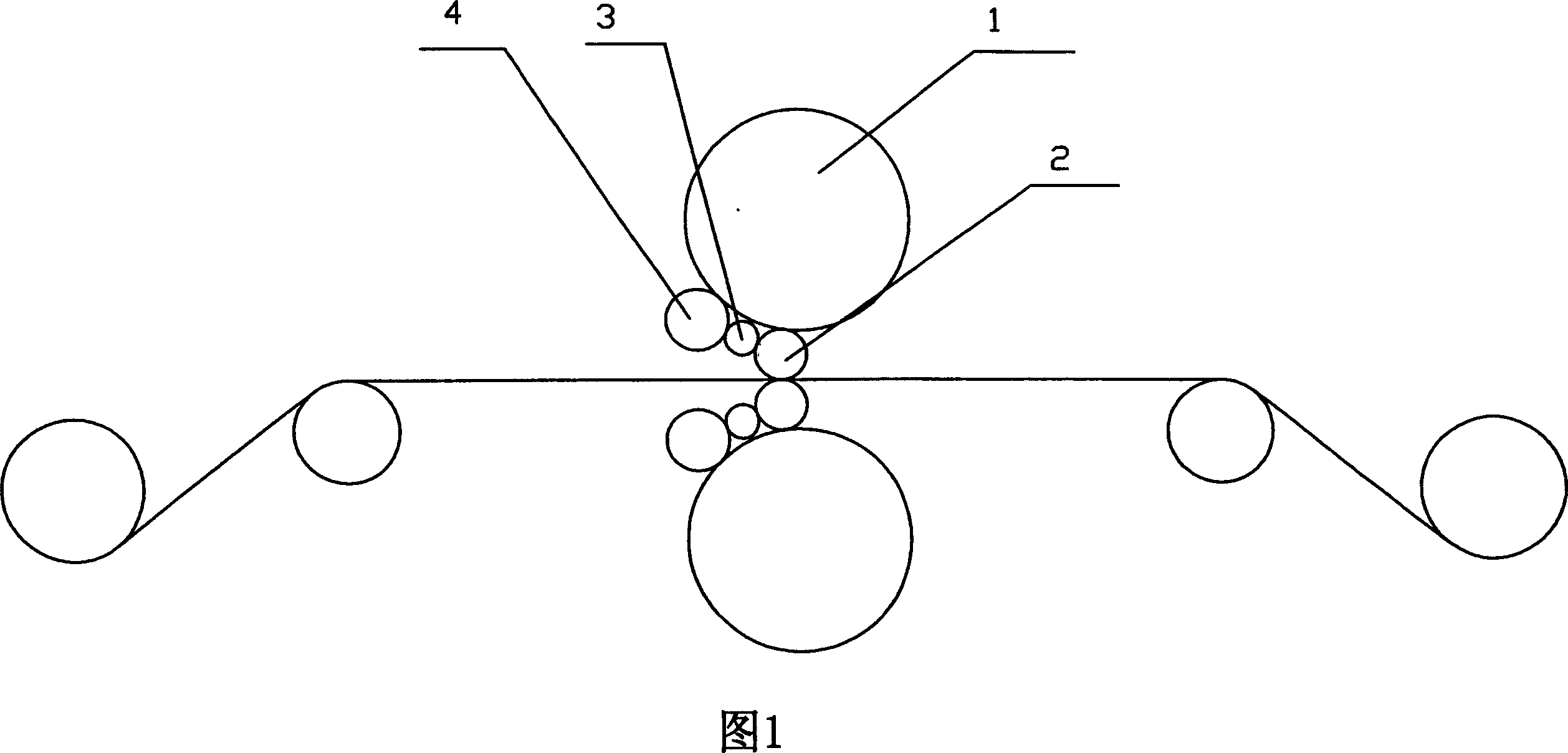

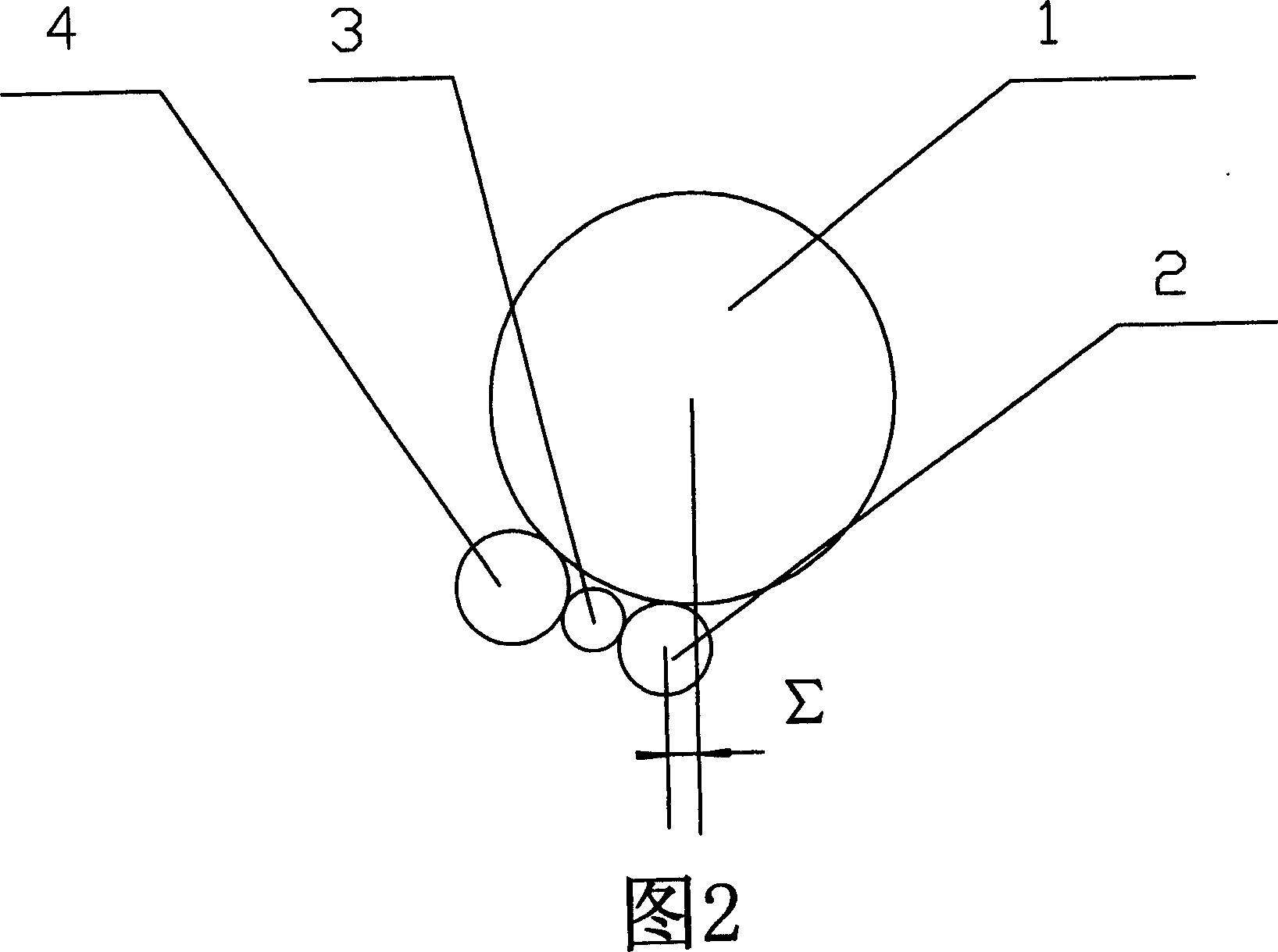

Eight slanting rollers shape structure of rolling mill of eight slanting rollers

The invention discloses a biased-eight-roll roll shape structure, which comprises the following parts: upper and lower bearing rolls, upper and lower working roll, upper and lower middle roll, upper and lower lateral support roll, wherein the upper and lower working roll and upper and lower lateral bearing roll are attached on the inner side of upper and lower bearing roll, the middle roll is set between working roll and lateral bearing roll, the center of working roll deviates the central line of bearing roll by 6-8% as bearing roll diameter, the roll radius and breadth of working roll, bearing roll, lateral bearing roll, middle roll adopts specific parameter.

Owner:何忠权

Efficient motor shaft

The invention relates to the technical field of motor devices, and in particular relates to an efficient motor shaft. The efficient motor shaft comprises a motor shaft body, wherein sleeves are respectively arranged on the positions, close to the front end and rear end of the motor shaft body, on the motor shaft body, and each sleeve is provided with a plurality of raised surfaces. The sleeves are made of elastic rubber. The sleeves are arranged on the shaft body in a sleeving manner and provided with the raised surfaces, so that a gear arranged on the motor shaft in the sleeving manner does not jump or shift during running and the working efficiency is greatly improved.

Owner:CHANGZHOU RIFA PRECISION MACHINERY PLANT

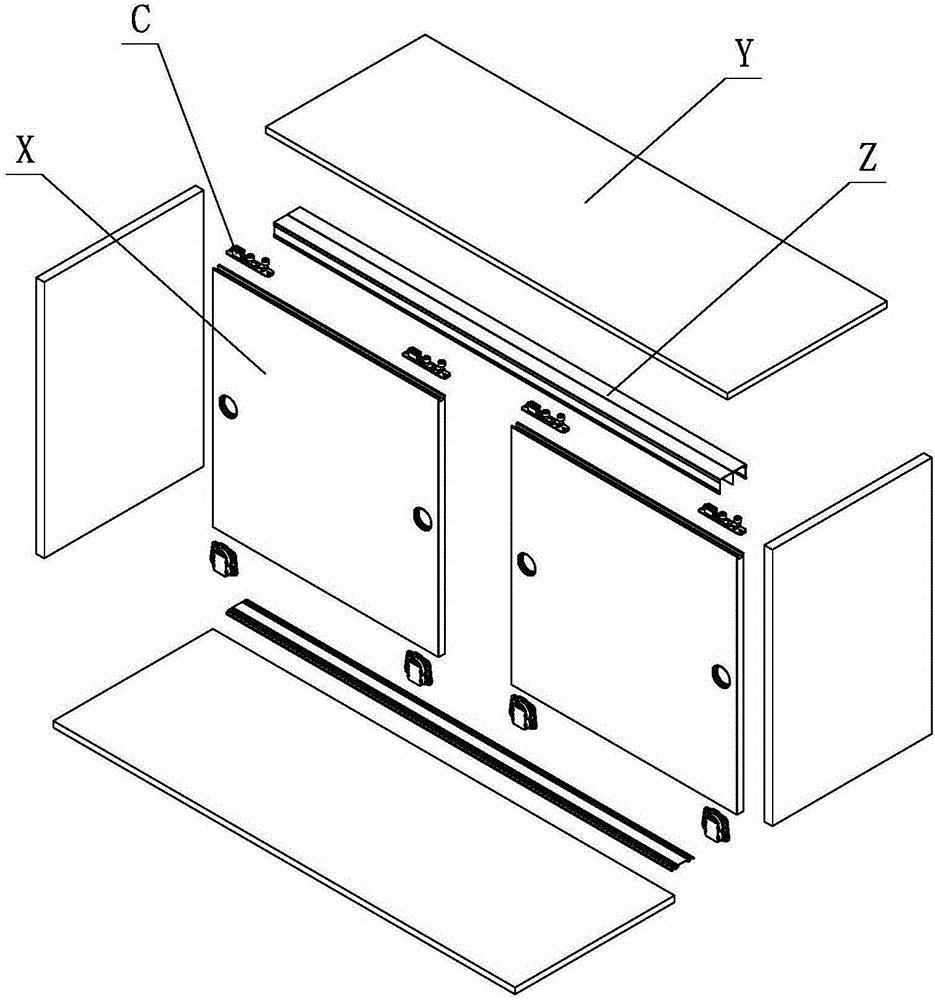

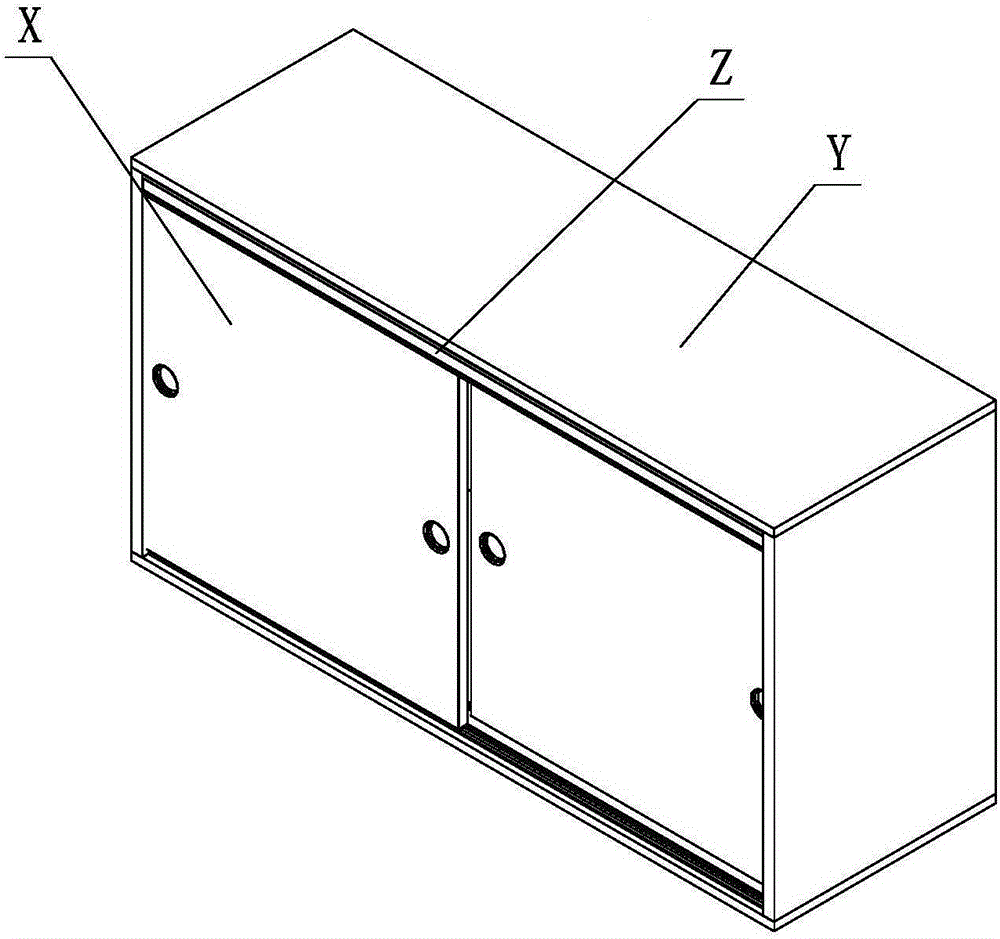

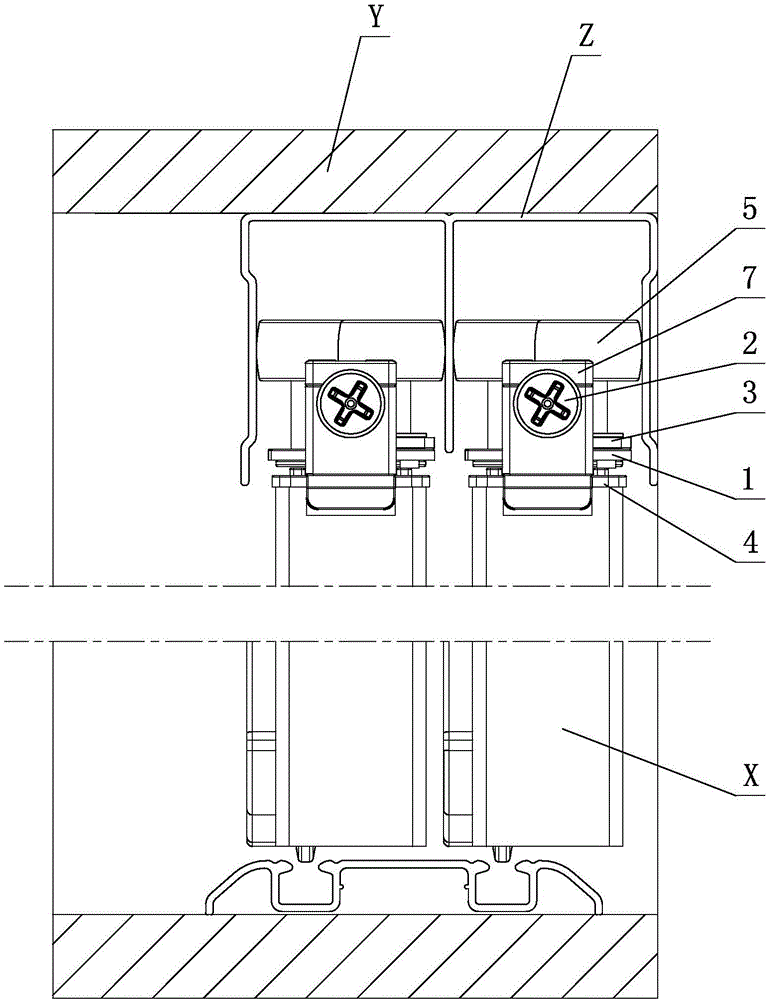

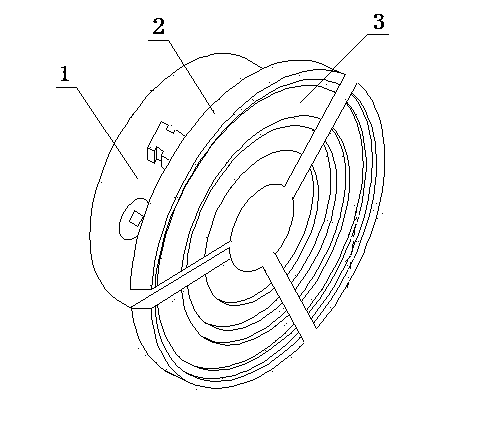

Rolling wheel linkage adjustment mechanism for sliding door of furniture

ActiveCN106837038ABeating noNo shakingWing arrangementsWing suspension devicesAdjustment ActionEngineering

A rolling wheel linkage adjustment mechanism for a sliding door of furniture comprises a rolling wheel adjustment device which comprises a rotating element, an adjustment element, a lever element and a support element; the rotating element is rotationally arranged on the support element, and rolling wheels are rotationally positioned at two ends of the rotating element; the adjustment element is rotationally positioned on the support element, and an adjustment acting part is arranged on the adjustment element; the lever element is arranged on the support element in a deflected manner, one end of the lever element is in linkage with the rotating element, and the other end is in linkage with the adjustment element. The adjustment element is positioned on the support element and can rotate by acting on the adjustment action part by hand or tool, and the lever element is driven to deflect on the support element and drives the rolling wheels at two ends of the rotating element to rotate simultaneously and / or synchronously clockwise or anticlockwise relative to the support element during deflection, so that the positions of the rolling wheels relative to the support element are adjusted. The rolling wheel linkage adjustment mechanism is high in practicability through structural improvement.

Owner:伍志勇

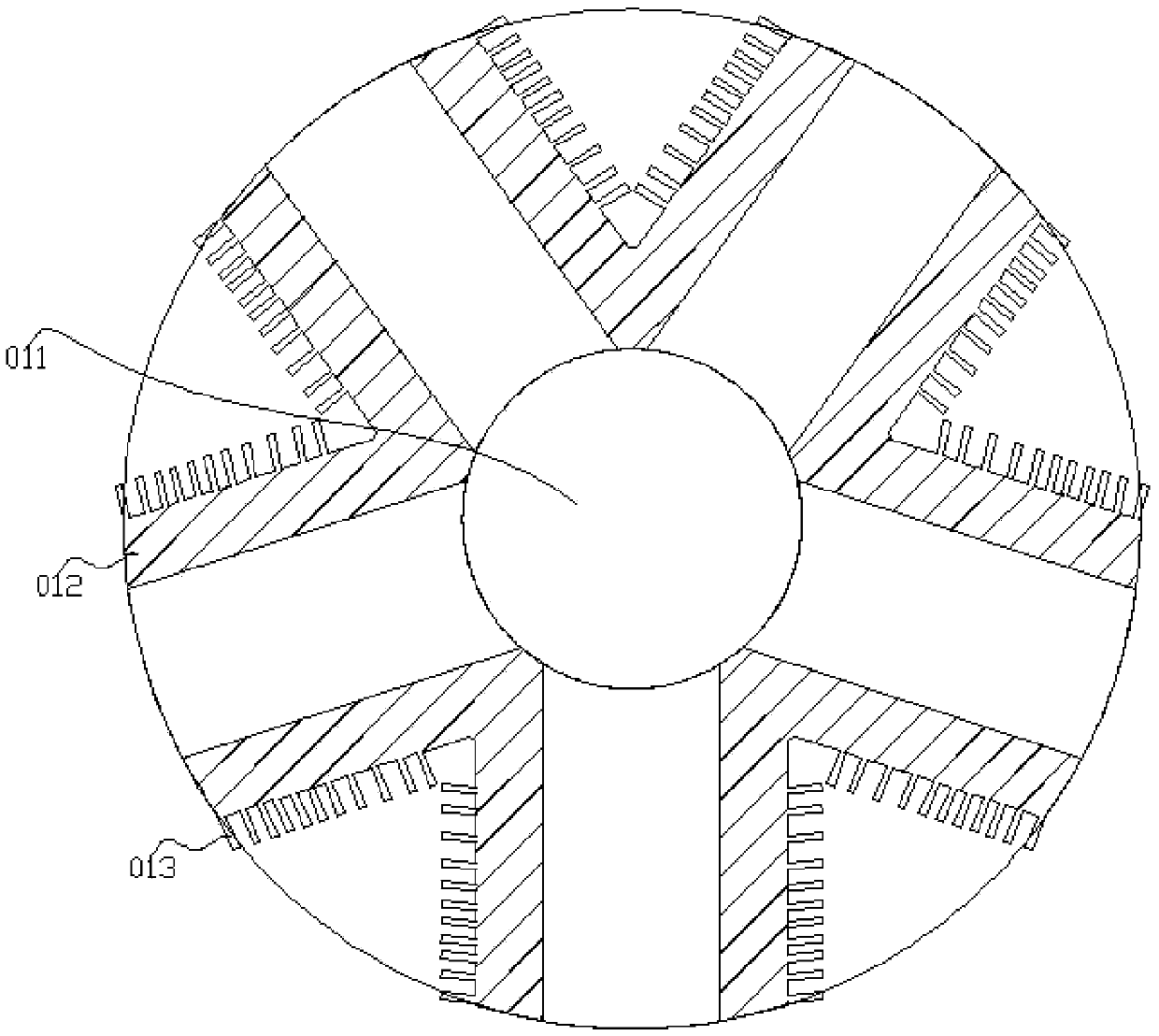

Metal winding gasket outer ring lathe groove chuck

InactiveCN103831448AReduce distortionNo beatingChucksStructural engineeringManufacturing engineering

A metal winding gasket outer ring lathe groove chuck comprises a three-jaw chuck and fan shaped paws, wherein the fan shaped jaws are three in number which are fixed on three jaws of the three-jaw chucks respectively; the three fan shaped jaws form a hollow circular ring shape and the intervals range from 8 mm to 13 mm; the fan shaped jaw upper lathe is provided with sequentially descending arc steps; the arc steps are 10 to 15 in number. According to the metal winding gasket outer ring lathe groove chuck, steps needed of various sizes are formed on the fan shaped jaws sequentially towards inner lathe, and outer rings of various models can be clamped through loosening or tightening the three-jaw chucks; when wingding gasket outer ring is processed, contact area of the fan shaped jaws and work pieces is increased, so that deformation of work pieces is reduced, the clamping is reliable, flexible and convenient, jumping do not occur on the end surface, speed of clamping parts is faster, time is saved greatly, and parts processing accuracy can be more guaranteed.

Owner:玉门金环密封材料有限公司

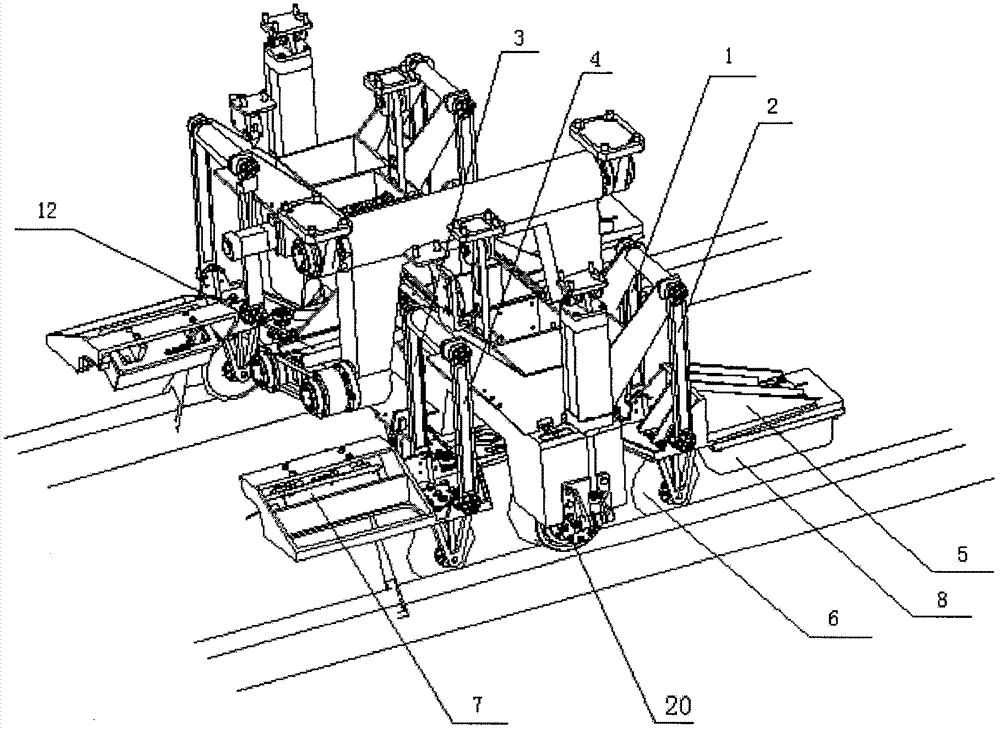

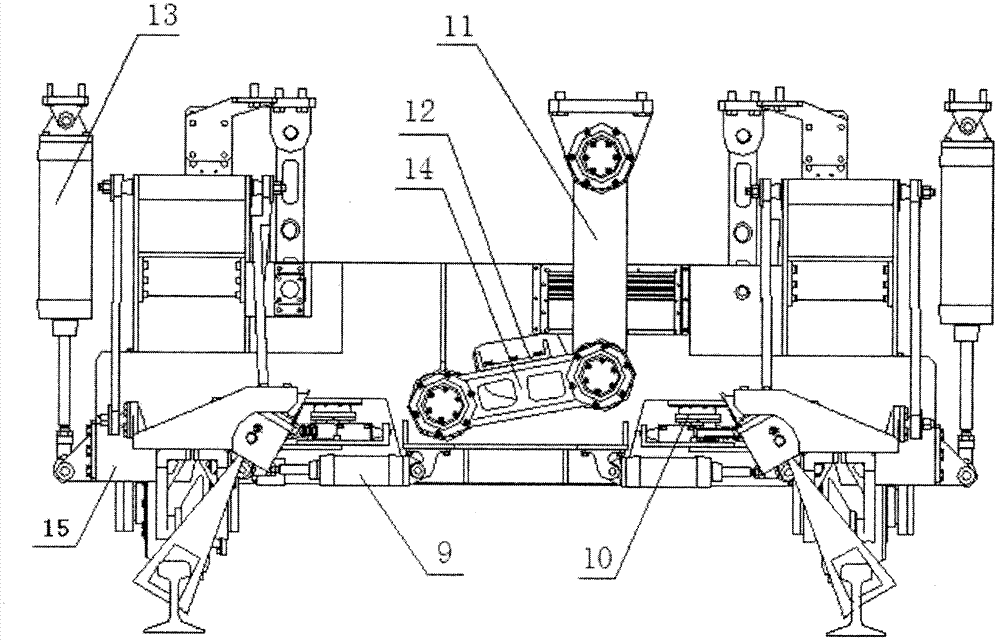

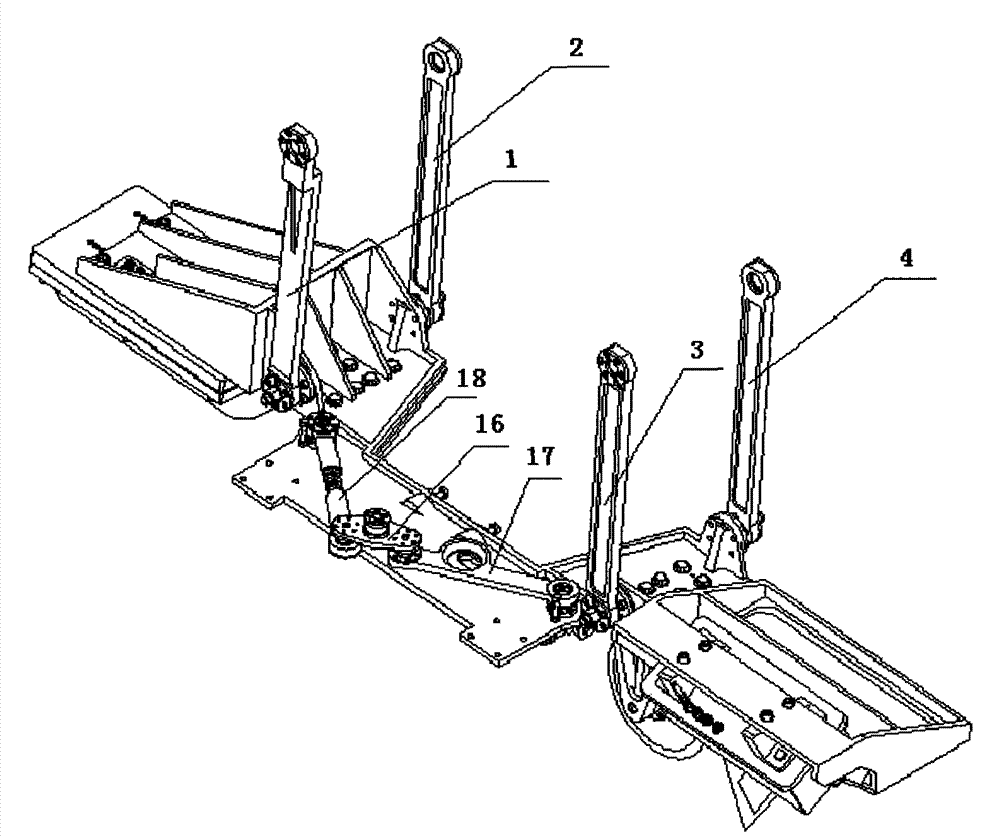

Rail outline and undulatory wear sensor positioning mechanism for tracking central line of top of steel rail

InactiveCN103029720BSolve the problem of swinging back and forthNo beatingRailway auxillary equipmentRailway profile gaugesEngineeringMechanical engineering

The invention discloses a rail outline and undulatory wear sensor positioning mechanism for tracking a central line of the top of a steel rail. The positioning mechanism is arranged on a detection vehicle chassis and stably moves along with a train; and four connecting rods of the positioning mechanism are driven through two main cylinders, so that the entire detection mechanism can be lifted or dropped. When not in work, the positioning mechanism is lifted and is fixedly arranged on the detection vehicle chassis; and when in work, a rail is tightly pressed by the positioning mechanism through the cylinder to keep in close contact with the rail face. A rail outline sensor and an undulatory wear sensor are arranged on two sides of a positioning wheel bracket respectively; and when in work, the positioning wheels are closely attached to the rail through a positioning wheel supporting cylinder. According to the positioning mechanism, a synchronous bracket is additionally arranged, so that the problem of back-forth swing during advancing of the front and rear positioning wheels is solved, and the front and rear positioning wheels can stably move along the center of the rail with the detection device.

Owner:CHINA NORTH VEHICLE RES INST

Electro-hydraulic torque power device for aviation engine

PendingCN110561321AImprove the level of automationImprove work efficiencySpannersWrenchesElectro hydraulicHigh torque

The invention discloses an electro-hydraulic torque power device for an aviation engine. The device comprises center ratchet wheels, a bearing, clamping jaws, drive blocks and a drive device; two drive rings are arranged on the bearing in parallel; openings for installing pawls are formed in inner rings of the drive rings, and sliding grooves are formed in the outer side faces of the drive rings;the pawls are connected with the drive rings through springs arranged in spring installing holes; the two center ratchet wheels are connected with oblique tooth pawls in the inner rings of the two drive rings; the clamping jaws are provided with U-shaped openings, and the two sides of the U-shaped openings are provided with connecting through holes; the drive blocks are arranged in the U-shaped openings; another clamping jaw pin is connected with the sliding grooves in the drive rings; the tail ends of the two clamping jaws are connected with the drive device; under the effect of the drive device, relative horizontal reciprocating motion can be performed. By adopting the dual-pawl wheel-ratchet engagement structure matched with the oblique tooth structure, clockwise and anti-clockwise high-torque output after one-time installation is ensured, counter-acting torque can be avoided, the mechanism does not bounce, and the clamping jaw pin has the overload self-turn-off function.

Owner:苏州慕天工业科技有限公司

Metal mesh screen pipe pressing molding equipment

PendingCN112170679ANo beatingAvoid misalignmentMetal-working feeding devicesShaping safety devicesGear wheelWorkbench

The invention discloses metal mesh screen pipe pressing forming equipment. The mesh screen pipe pressing forming equipment comprises a workbench and at least three pressing forming mechanisms sequentially arranged on the workbench, each pressing forming mechanism comprises two sets of supporting mechanisms which are symmetrically arranged, an upper rolling wheel, a lower rolling wheel, transmission gears and a driving mechanism, the upper rolling wheel and the lower rolling wheel are rotationally arranged between the two sets of supporting mechanisms through a rotating shaft wheel, the upper rolling wheel is arranged above the lower rolling wheel in a stacking mode, a circular channel is formed between the upper rolling wheel and the lower rolling wheel, the transmission gears are arrangedon rotating shafts of the upper rolling wheel and the lower rolling wheel respectively, the driving mechanism is arranged on the workbench, and the driving mechanism is utilized to drive the lower rolling wheel or the upper rolling wheel to rotate so as to synchronously drive the upper rolling wheel or the lower rolling wheel to rotate. An outer pipe and an inner pipe of a screen pipe are fully compacted and cannot be easily separated through extrusion of the multi-stage pressing molding equipment; a U-shaped support and an adjusting pressing plate form a sliding groove, the adjusting pressing plate is of a detachable structure, the situation of jamming during replacement of the upper rolling wheel and the lower rolling wheel is prevented, and therefore workers can carry out replacement on the upper rolling wheel or the lower rolling wheel conveniently.

Owner:TAICANG UNION TECH PRECISION MACHINERY

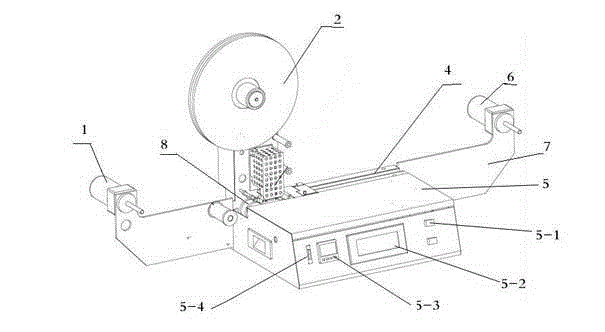

Inductance encapsulating machine

The invention discloses an inductance encapsulating machine, relating to the technical field of electronic machine manufacturing. The inductance encapsulating machine comprises a control box and a stand, wherein a band collecting shaft driven by a band collecting motor and a band feeding shaft driven by a band feeding motor, an upper paper reel and a carrier band guide wheel are arranged on the stand, a lower reel conveyor track is arranged between the band collecting shaft and the band feeding shaft, a carrier band guide groove is arranged on the lower reel conveyor track, a base is arranged on the tail end of the lower reel conveyor track, a hot end socket on a vertically arranged guide rail is arranged above the base, and an electromagnetic driver is connected between the stand and the hot end socket. According to the inductance encapsulating machine, the problem that a terminal user cannot correct take and use components due to encapsulated component polarity faults caused when inductance components on a carrier band jump because of instability in pull force of the encapsulating machine can be solved.

Owner:广西昭信平洲电子有限公司

Adjusting device of microwave antenna

A regulating device for a microwave antenna, comprising a supporting element hinged via a first hinge shaft, and a mounting element connected to the microwave antenna. The supporting element is provided with a first worm. The regulating device also comprises a first worm drive matching the first worm and fixed to the mounting element. The rotation axis of the first worm drive overlaps the axis of the first hinge shaft. The regulating device also comprises a first driver device for driving the first worm into rotation. In the regulating device, the worm drive-and-worm mechanism is used to drive the mounting element into rotation relative to the supporting element, thus driving into rotation the microwave antenna connected to the mounting element, allowing convenient operation. Also, as the worm drive-and-worm mechanism is transmitted linearly, the position of the microwave antenna is adjusted linearly, microwave signal transformations are continuous and pulse-free, and the regulation is of great precision. In addition, the worm drive-and-worm mechanism is provided with stable adjustment, compared to the prior art of threaded rod drive, the solution does not employ threaded rods, and obviates the need for the processing of an oversized through-hole, thus avoiding the generation of serial motion of signals when screws are fastened on two sides of the oversized through-hole.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com