Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

362results about How to "Reduce the driving force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

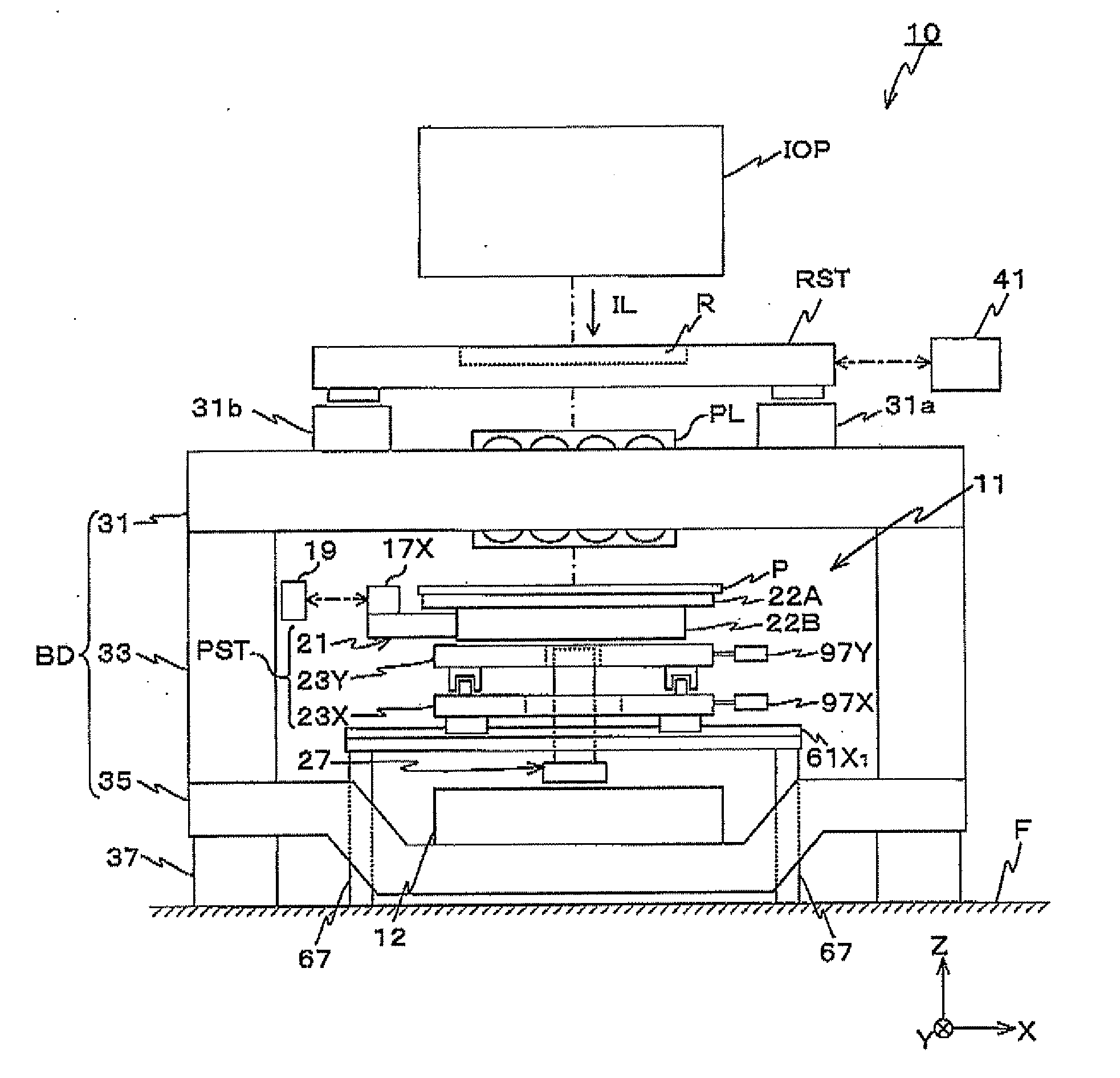

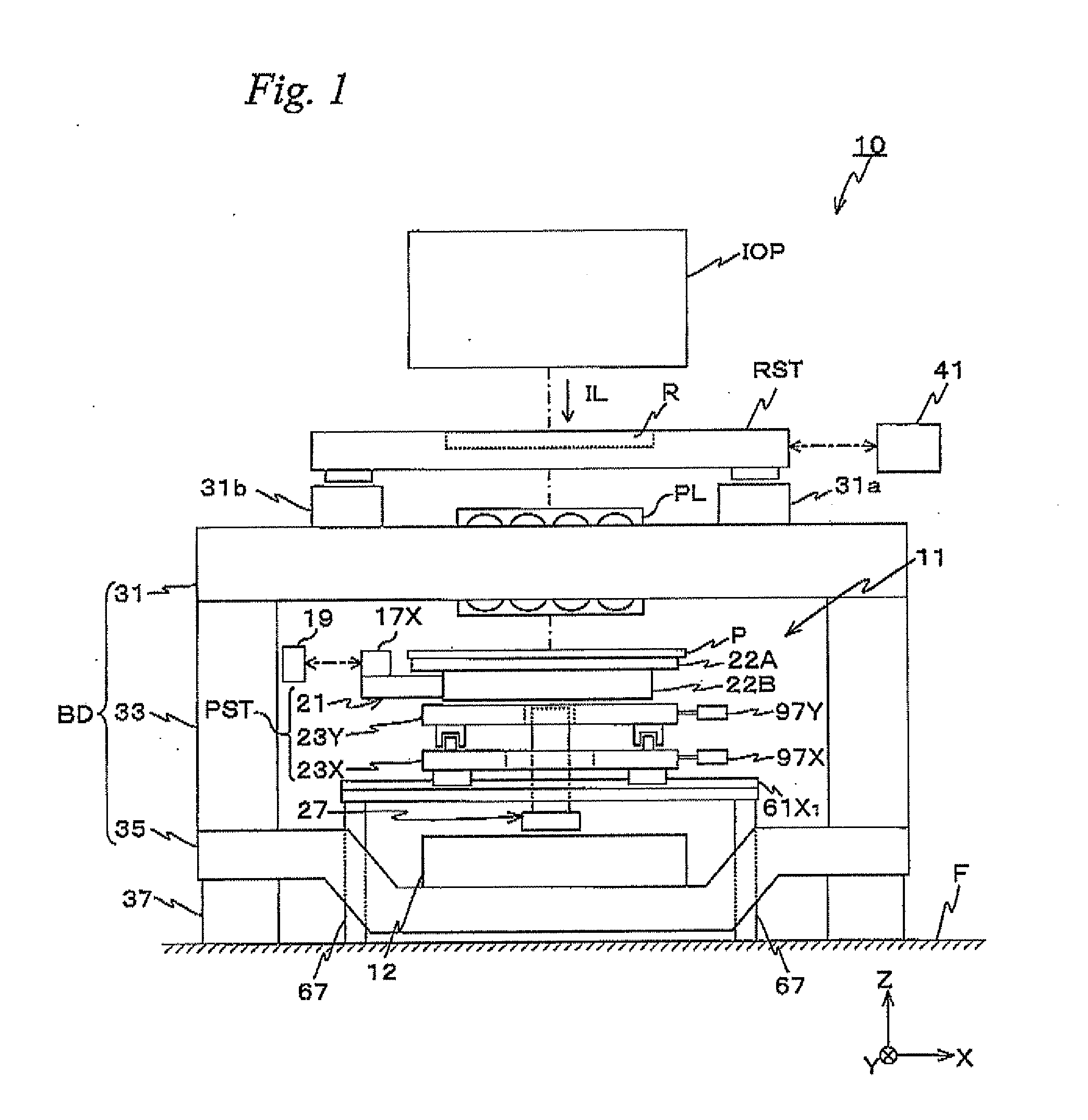

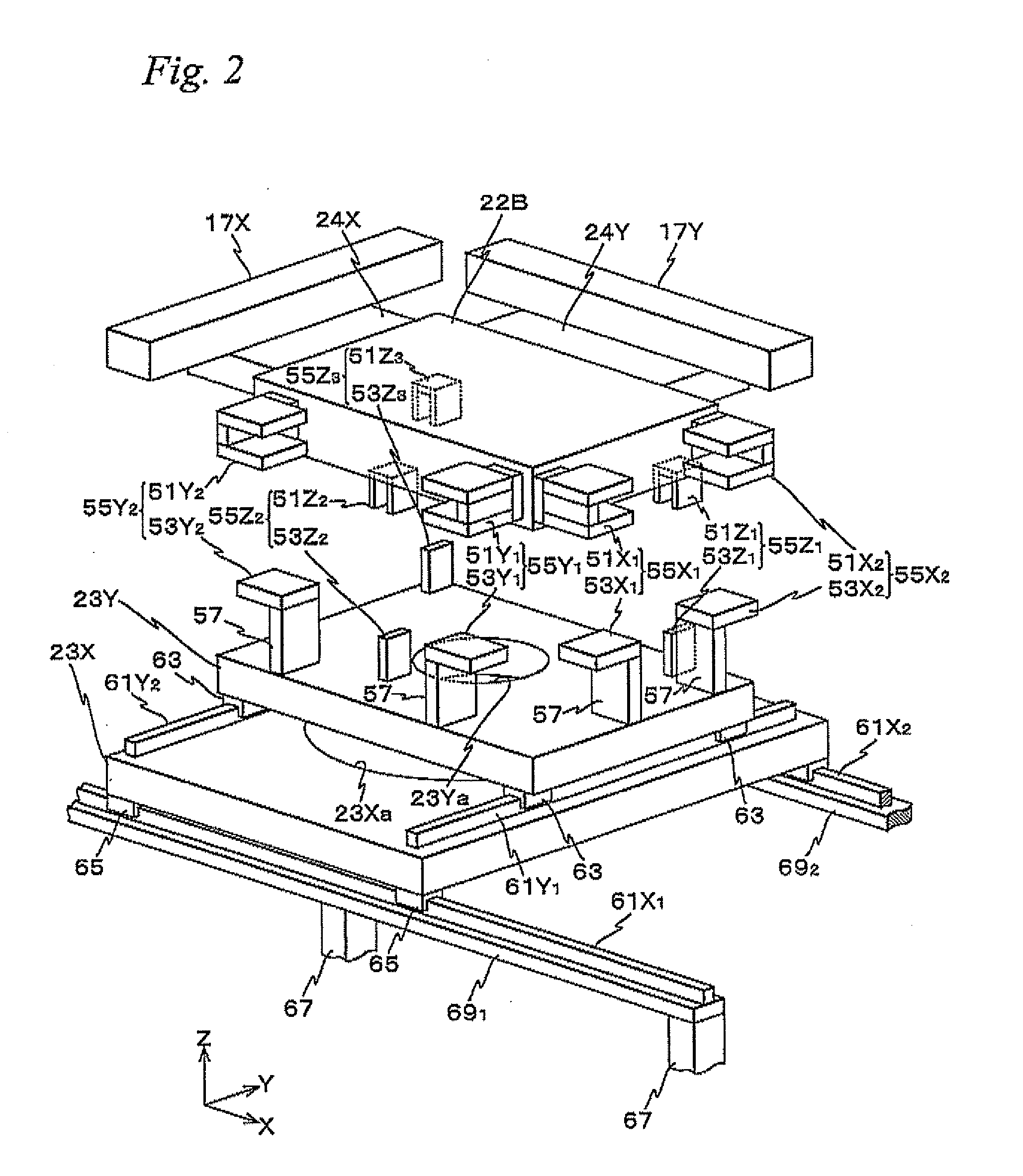

Movable body apparatus, pattern forming apparatus and pattern forming method, device manufacturing method, manufacturing method of movable body apparatus, and movable body drive method

ActiveUS20100018950A1Position controllability is improvedWell formedDecorative surface effectsPhotomechanical apparatusMechanical engineeringEngineering

Owner:NIKON CORP

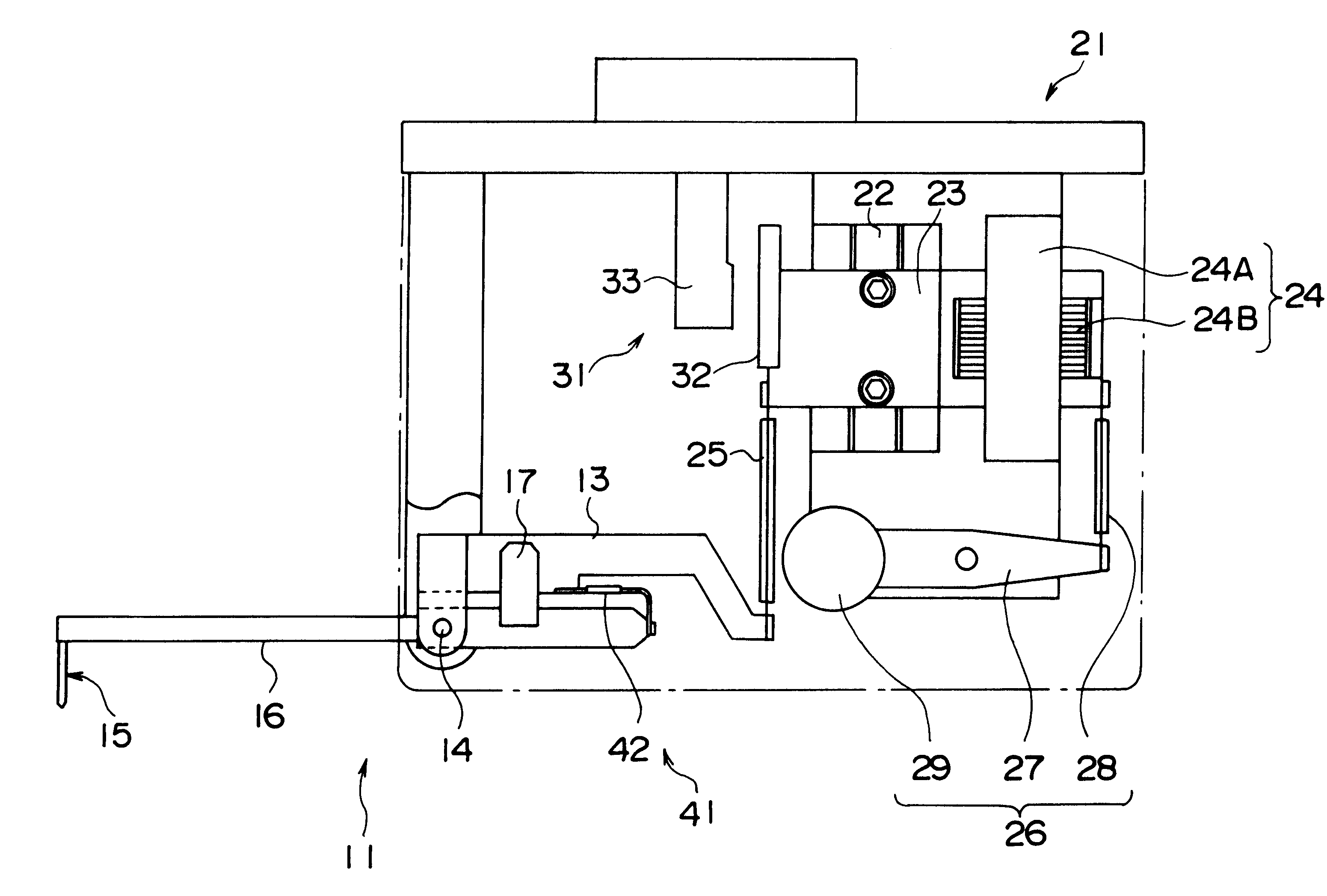

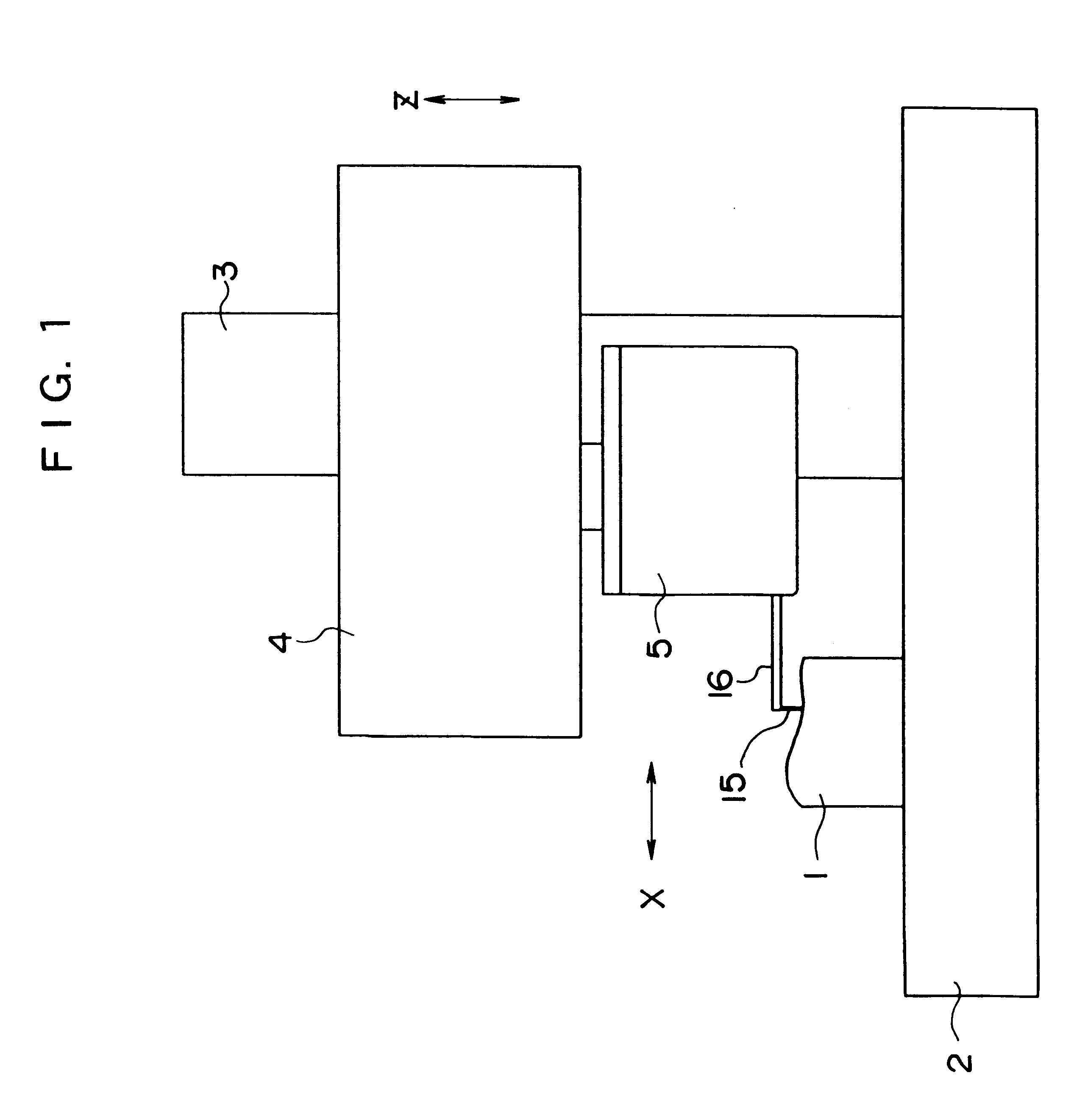

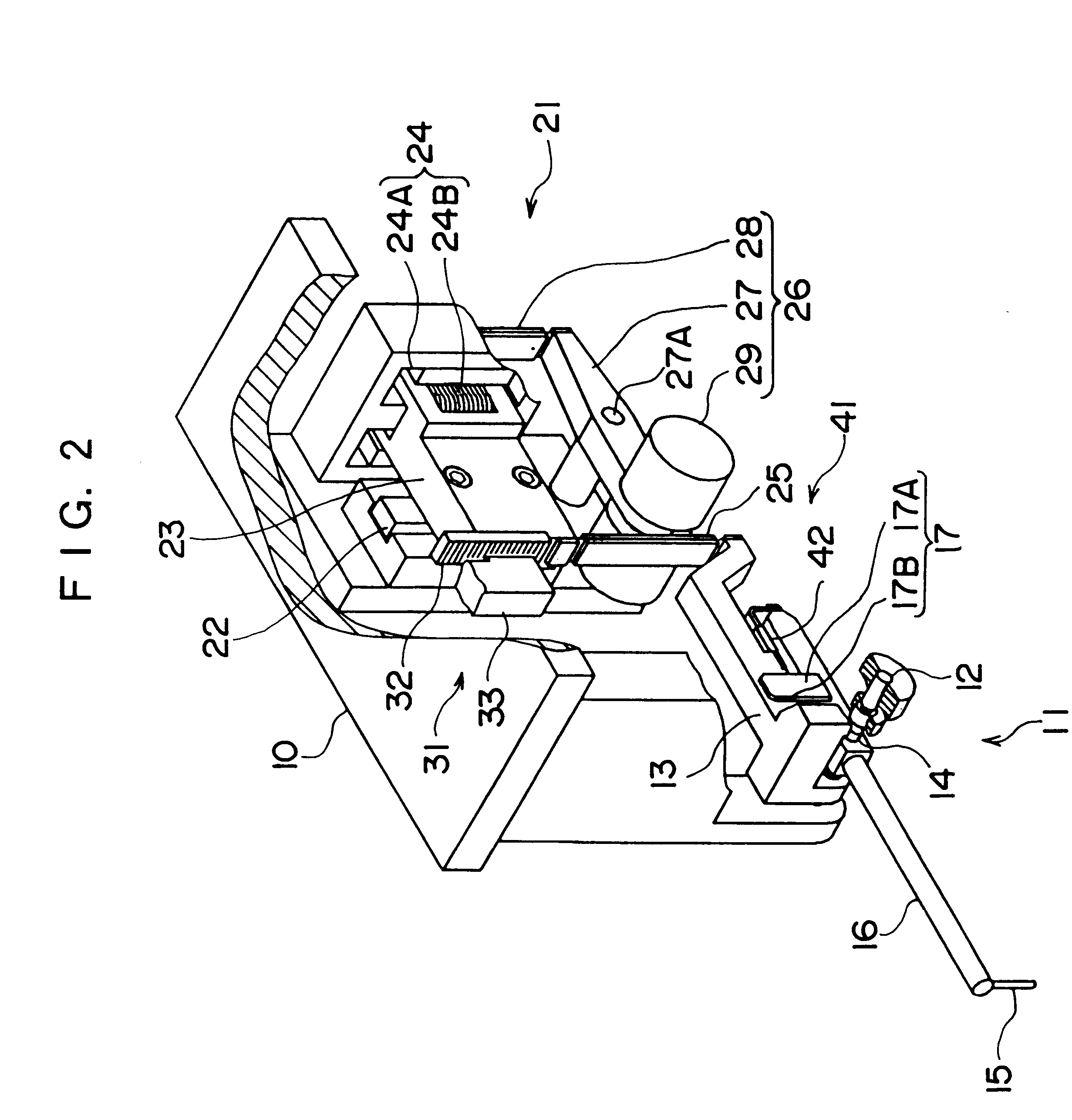

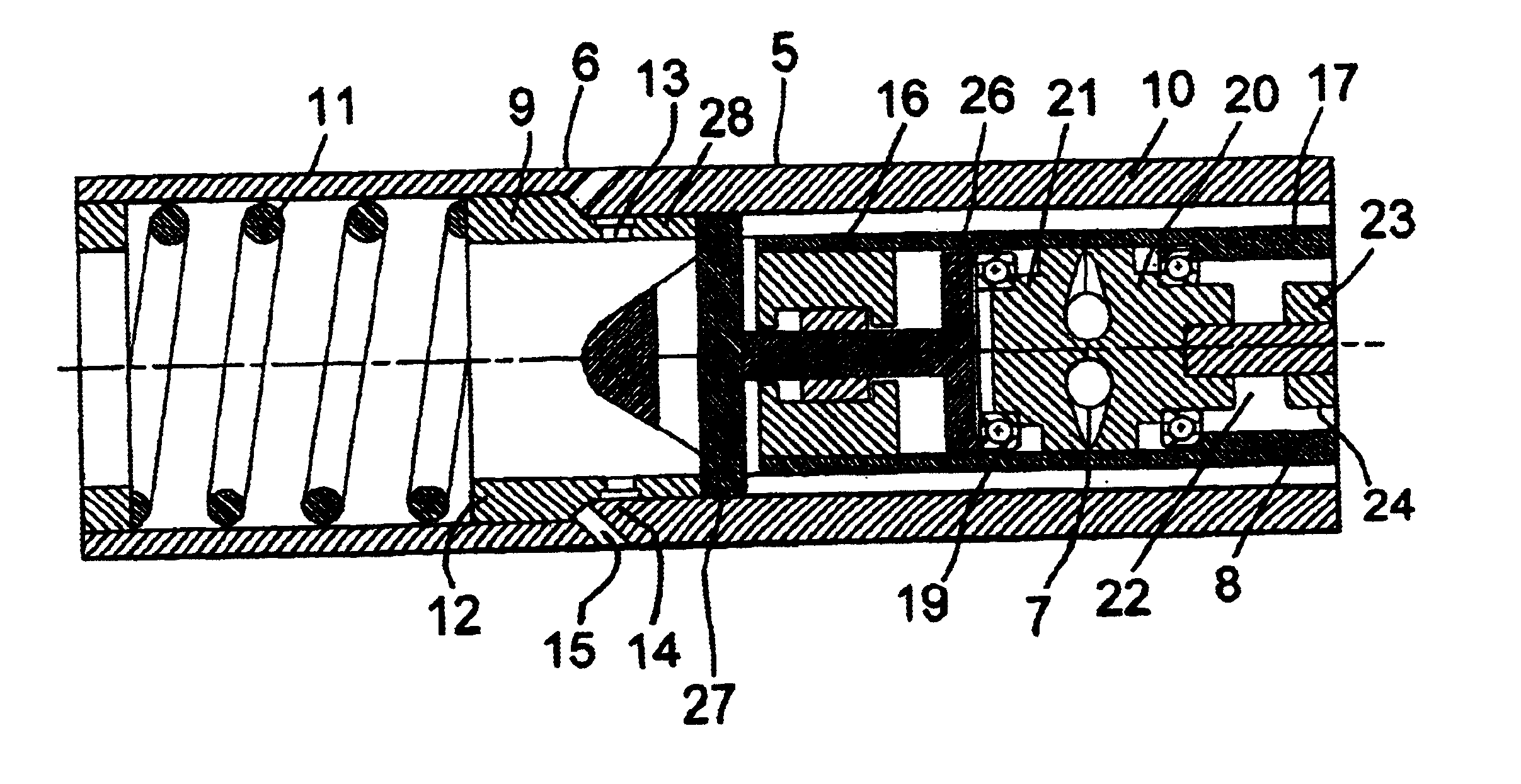

Surface-tracking measuring machine

InactiveUS6295866B1Accurate detectionReduce sensitivityCompasses with pivoted armsMechanical counters/curvatures measurementsResponsivityClassical mechanics

A surface-tracking measuring machine is provided, in which measurement range is enlarged while keeping a measuring force, responsivity, resolution thereof. For the object, the surface-tracking measuring machine has a frame (10), a probe (11) swingably supported by the frame (10) and having a tracer (15) at an end thereof, a measuring force controller (21) for controlling the measuring force applied to the probe, a displacement detector (31) for detecting a displacement of the probe, a measuring force detector (41) for detecting the measuring force applied to the probe, and a controller (51) for comparing a measuring force detected value detected by the measuring force detector and a previously commanded measuring force command value and to control the measuring force controller so that the measuring force detected value is equal to the measuring force command value.

Owner:MITUTOYO CORP

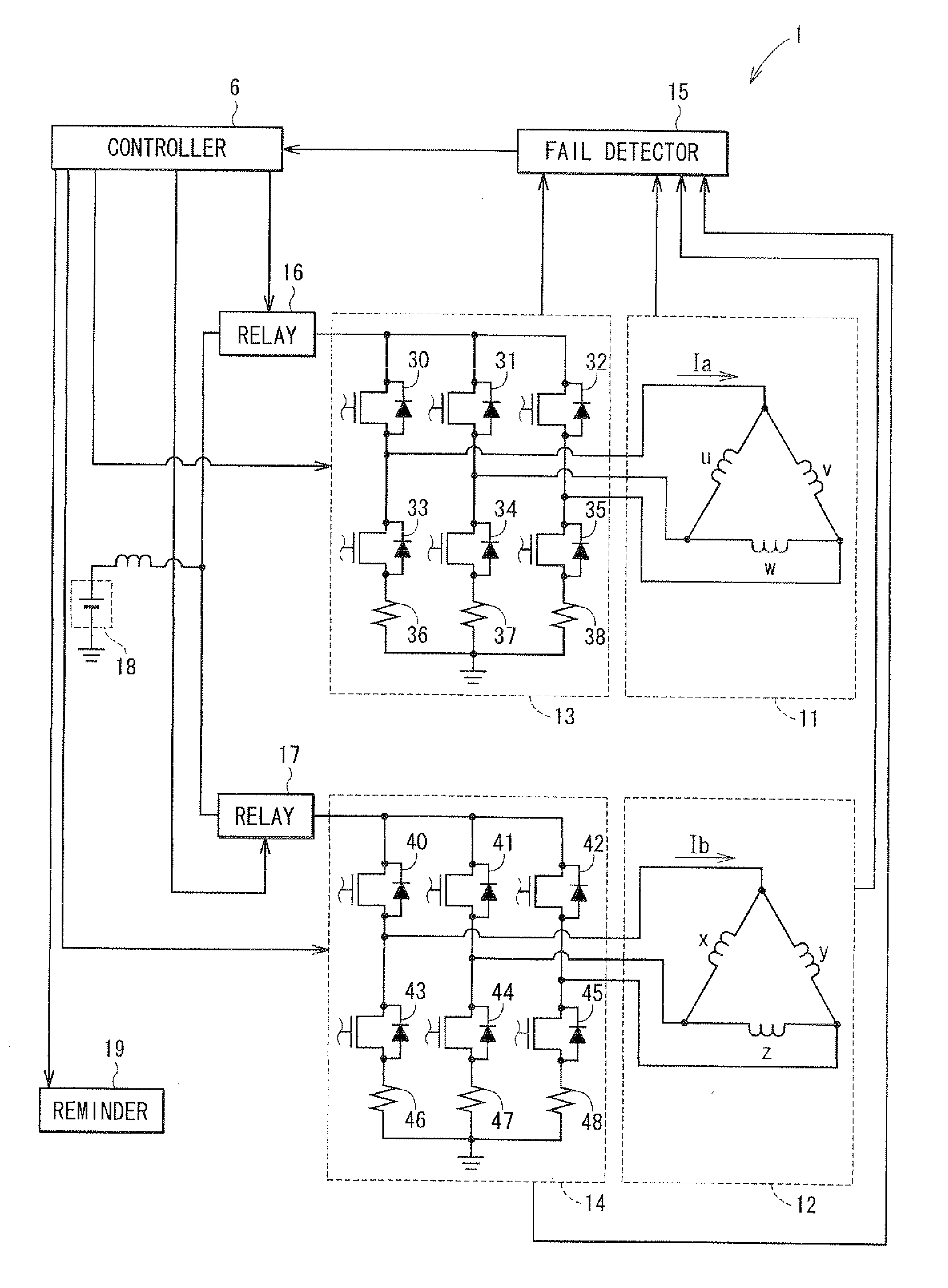

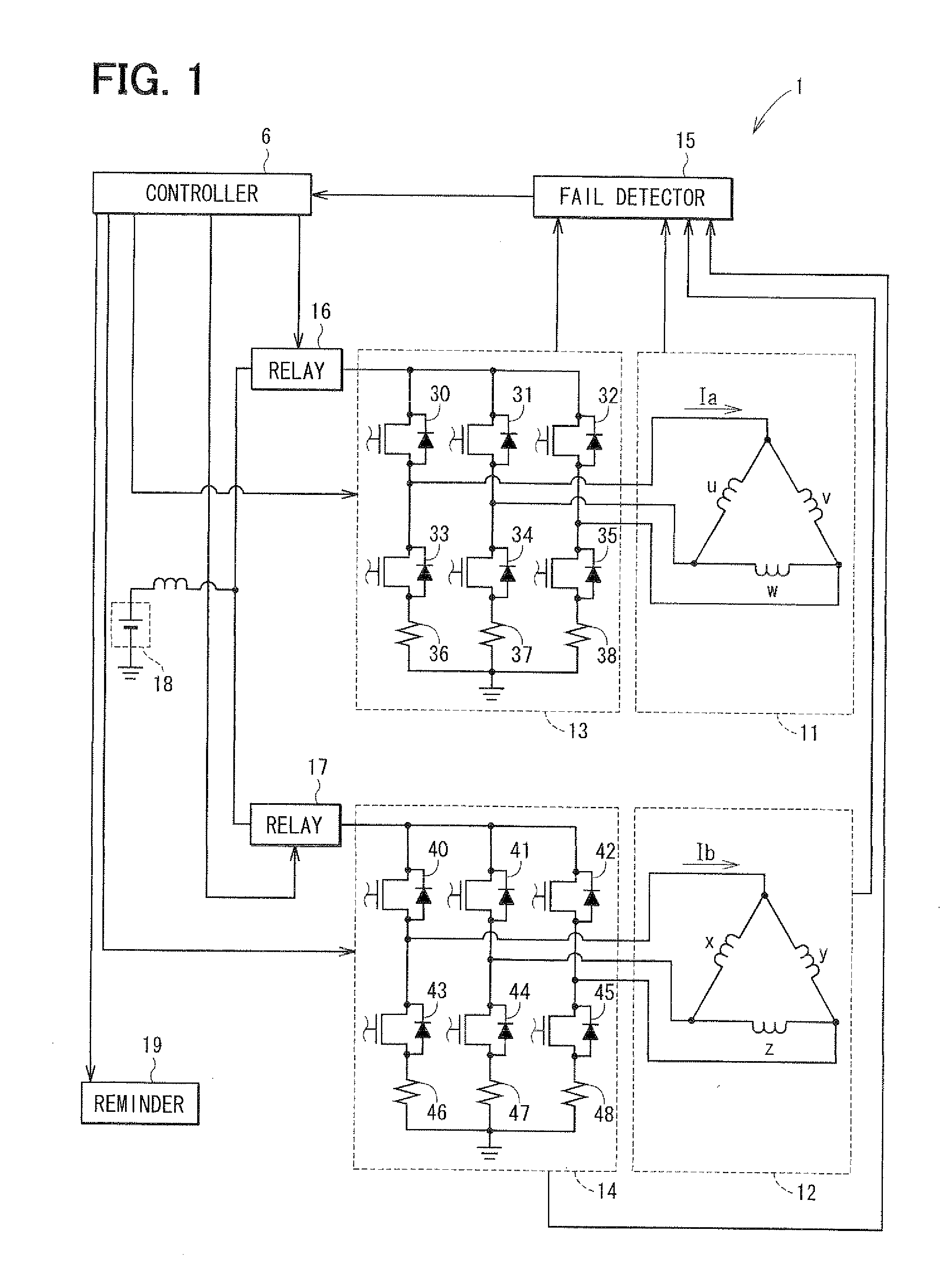

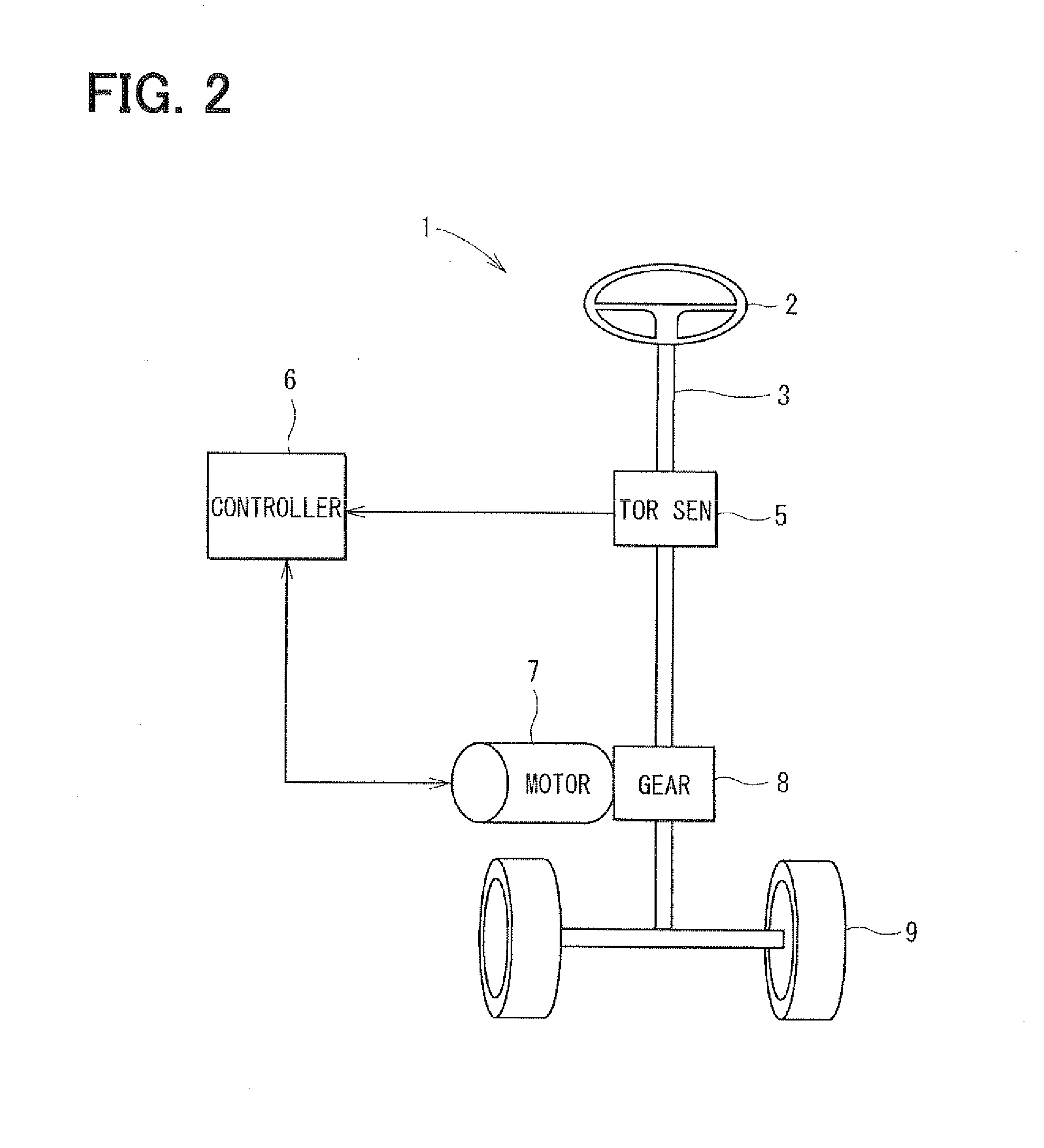

Electric power steering device

ActiveUS20110156629A1Reduce the driving forceMotor/generator/converter stoppersDC motor speed/torque controlElectric power steeringElectric power system

An electric power steering device includes: an electric power source for supplying first current; a controller for setting a current instruction value; multiple electric power converters for converting the first current to second current corresponding to the current instruction value; multiple pairs of windings for generating a driving force of a motor; and a failure detection element for detecting failure of the electric power converters and the windings. The controller reduces the current instruction value to be equal to or smaller than a predetermined instruction value of a normal operation when the failure detection element detects the failure. The controller controls the electric power converter in a normal state to supply the second current to a corresponding winding.

Owner:DENSO CORP

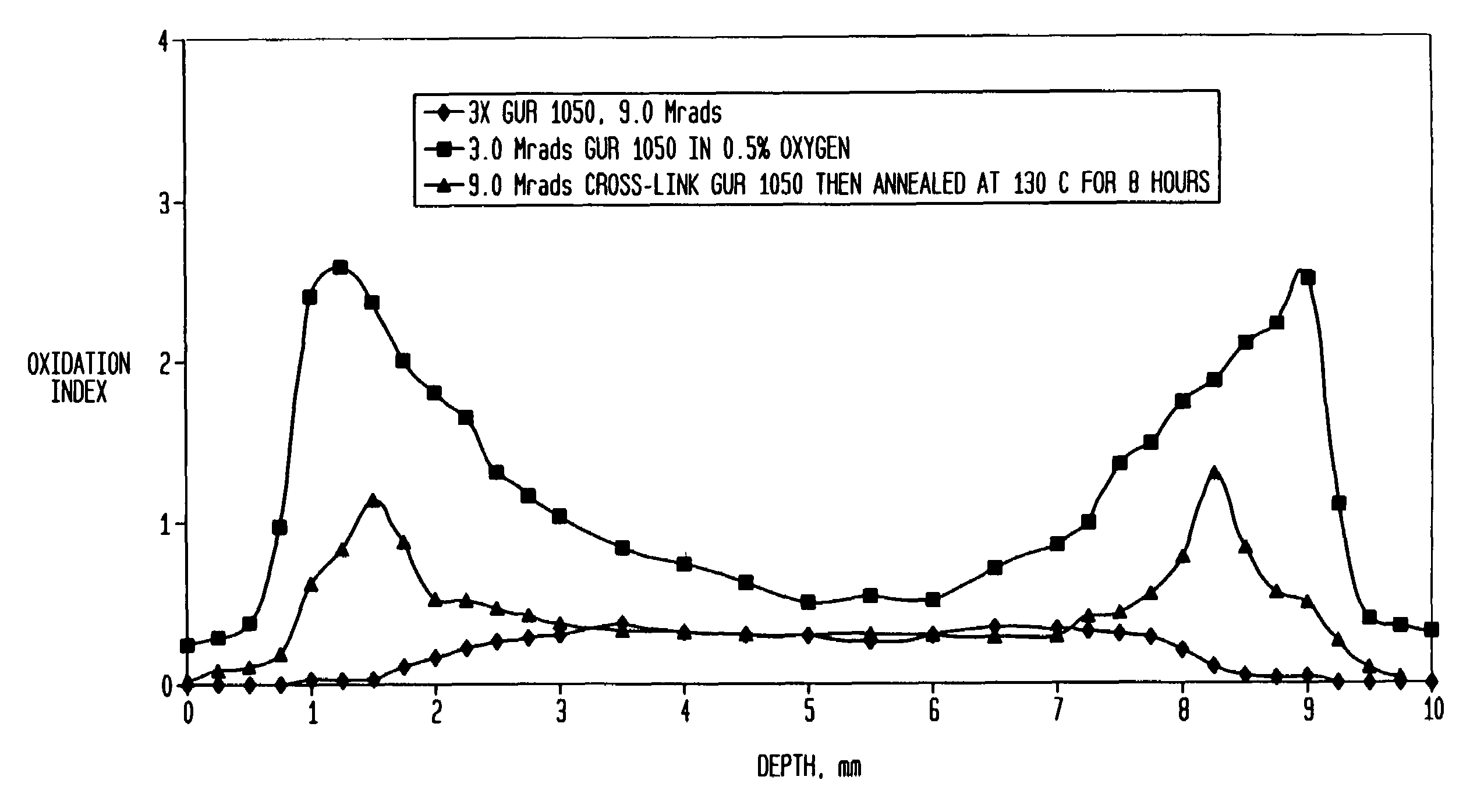

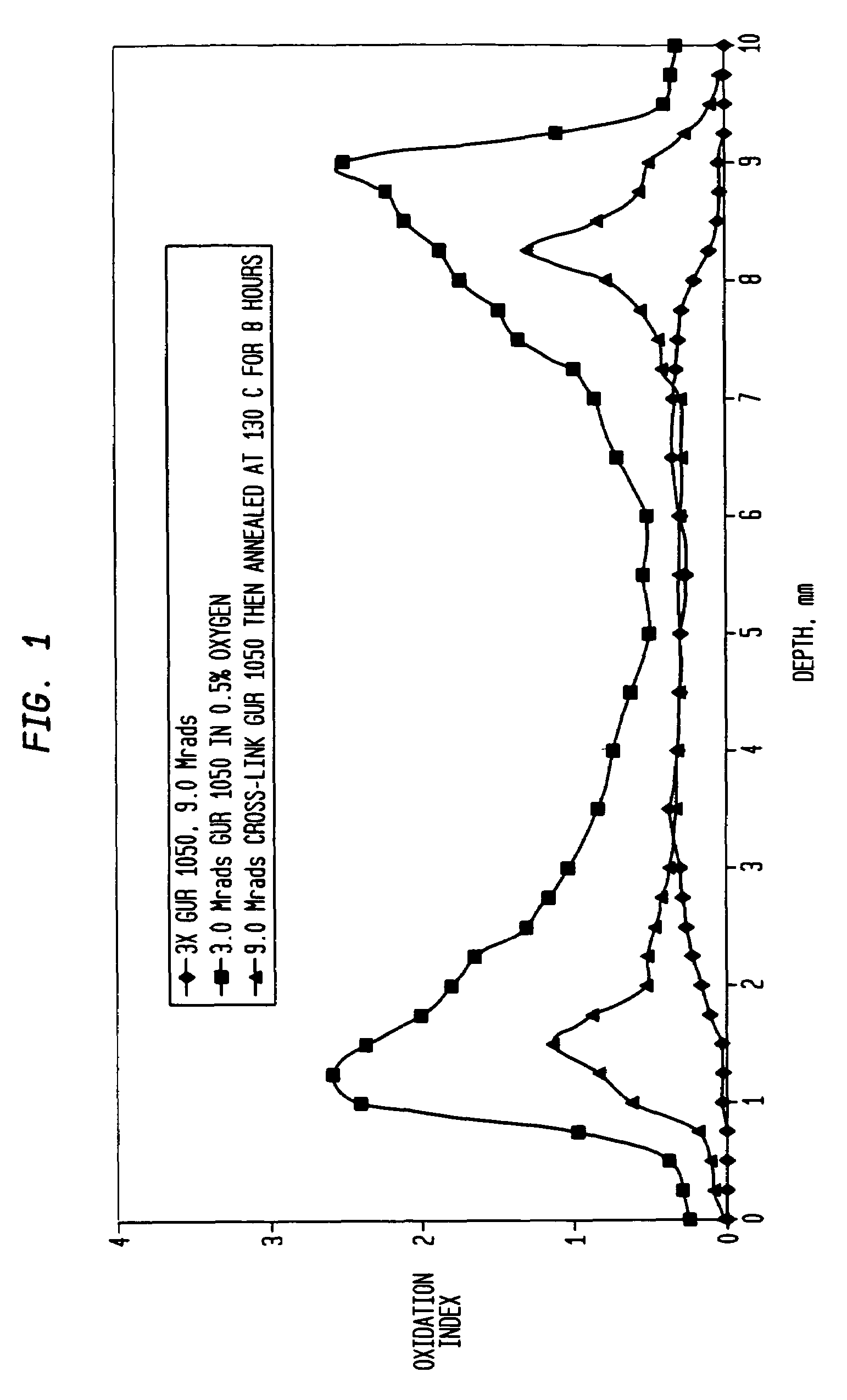

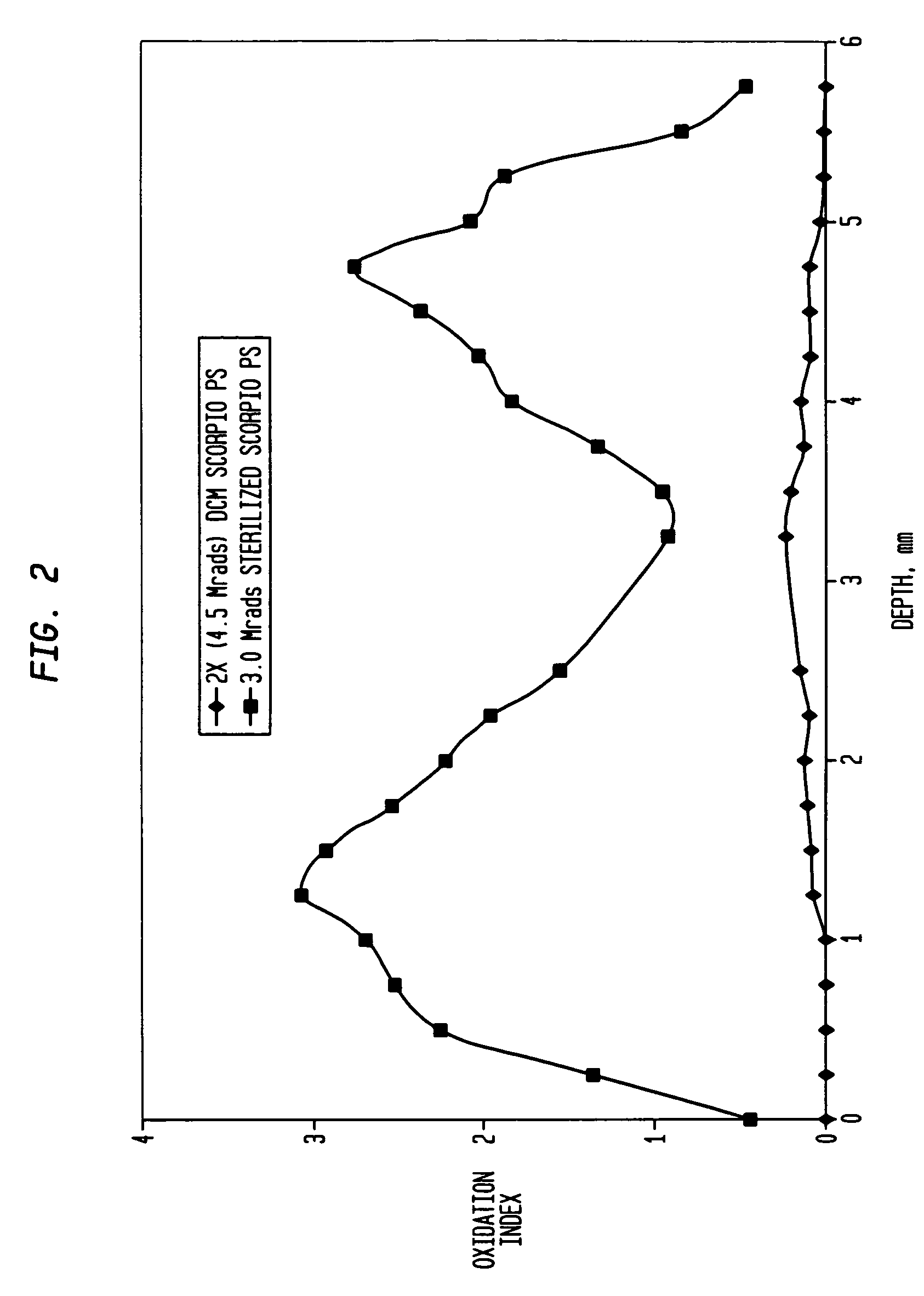

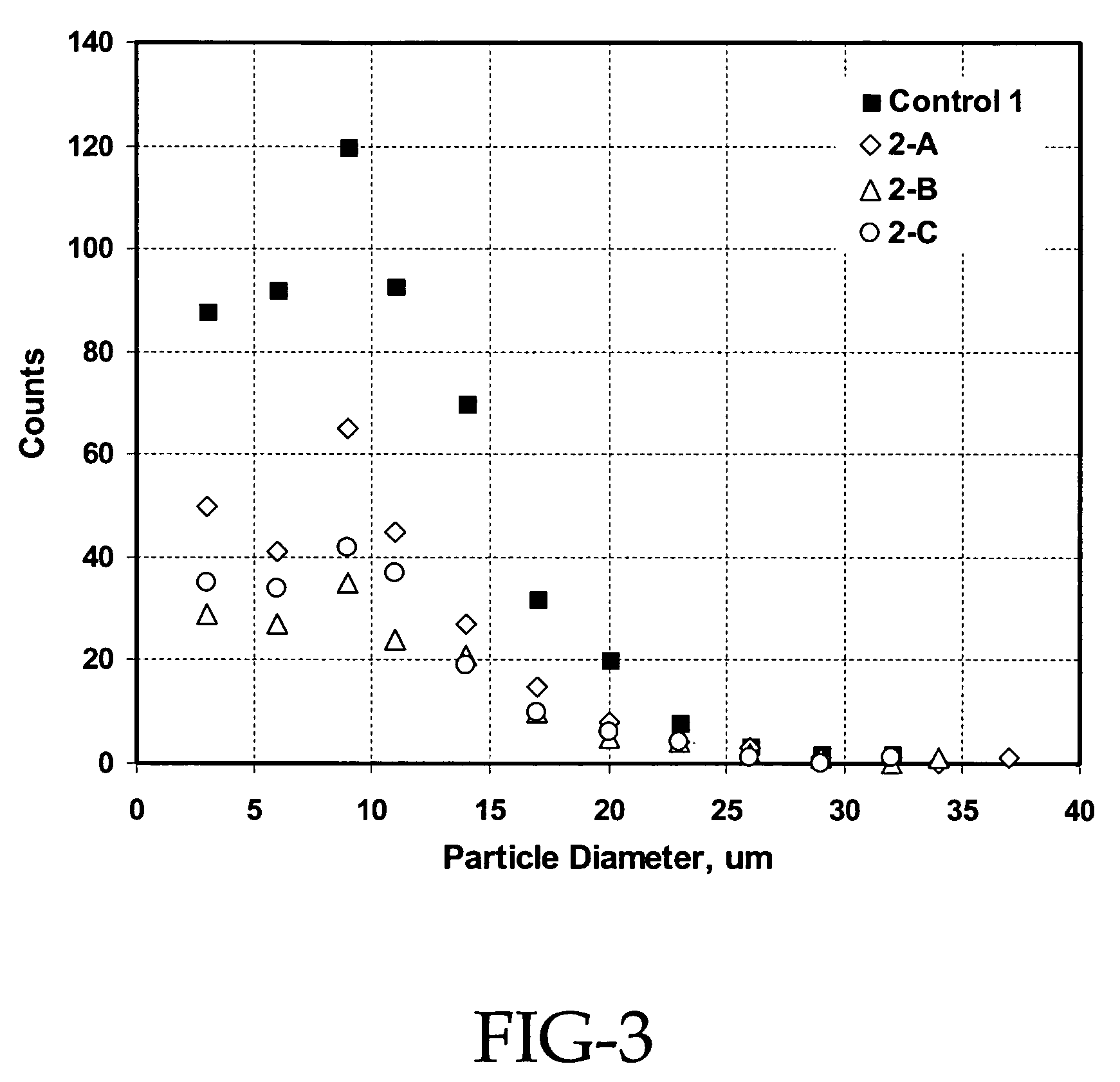

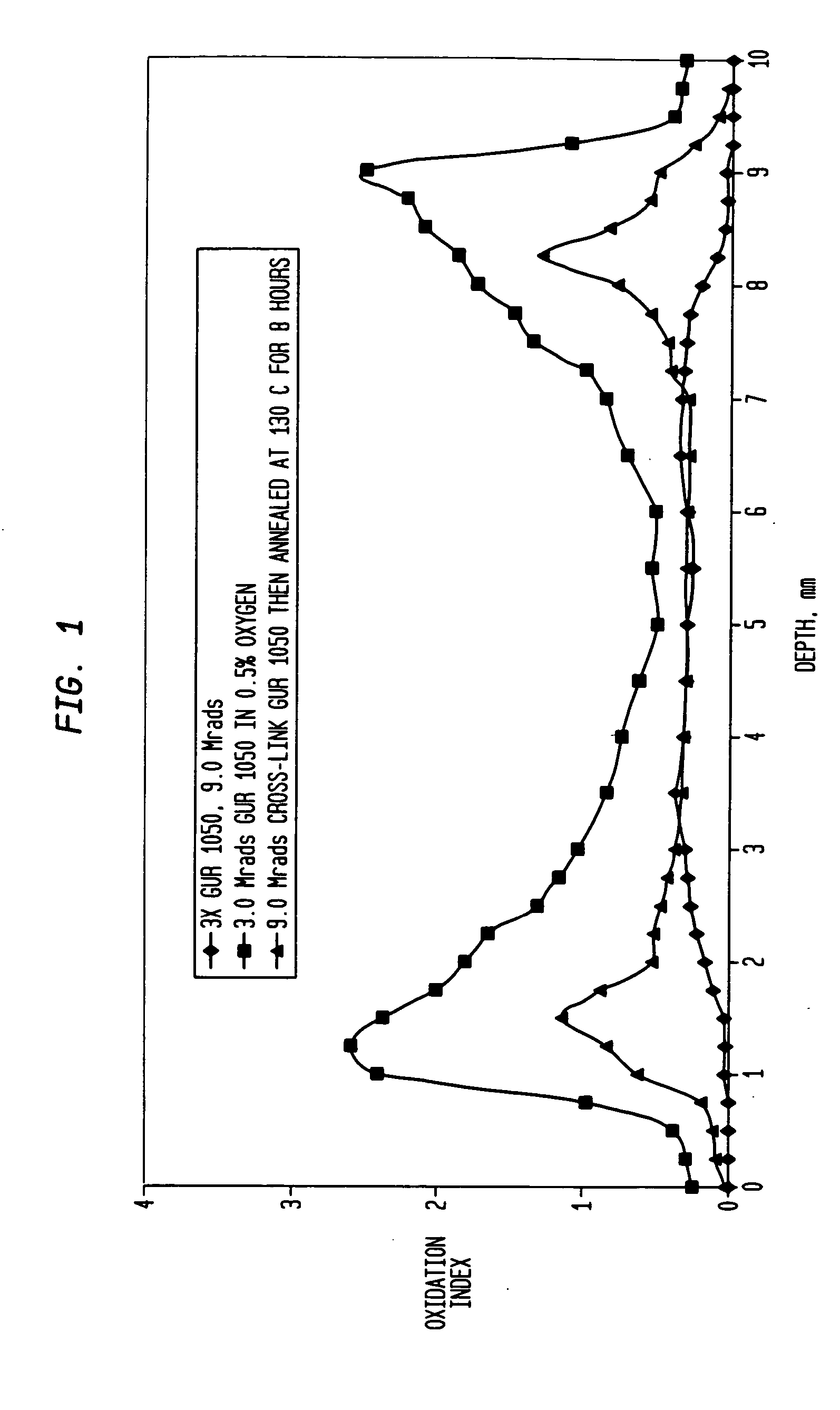

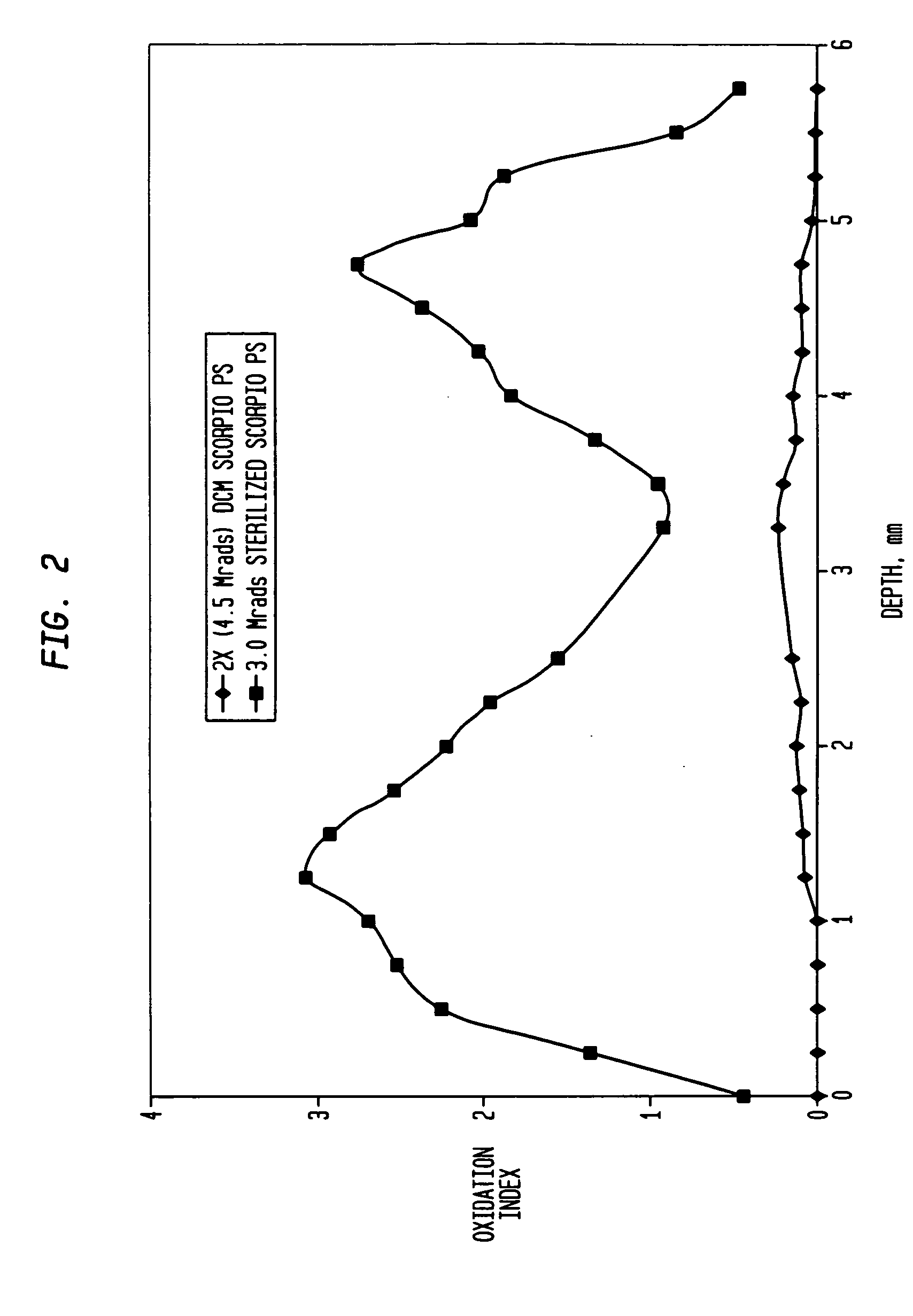

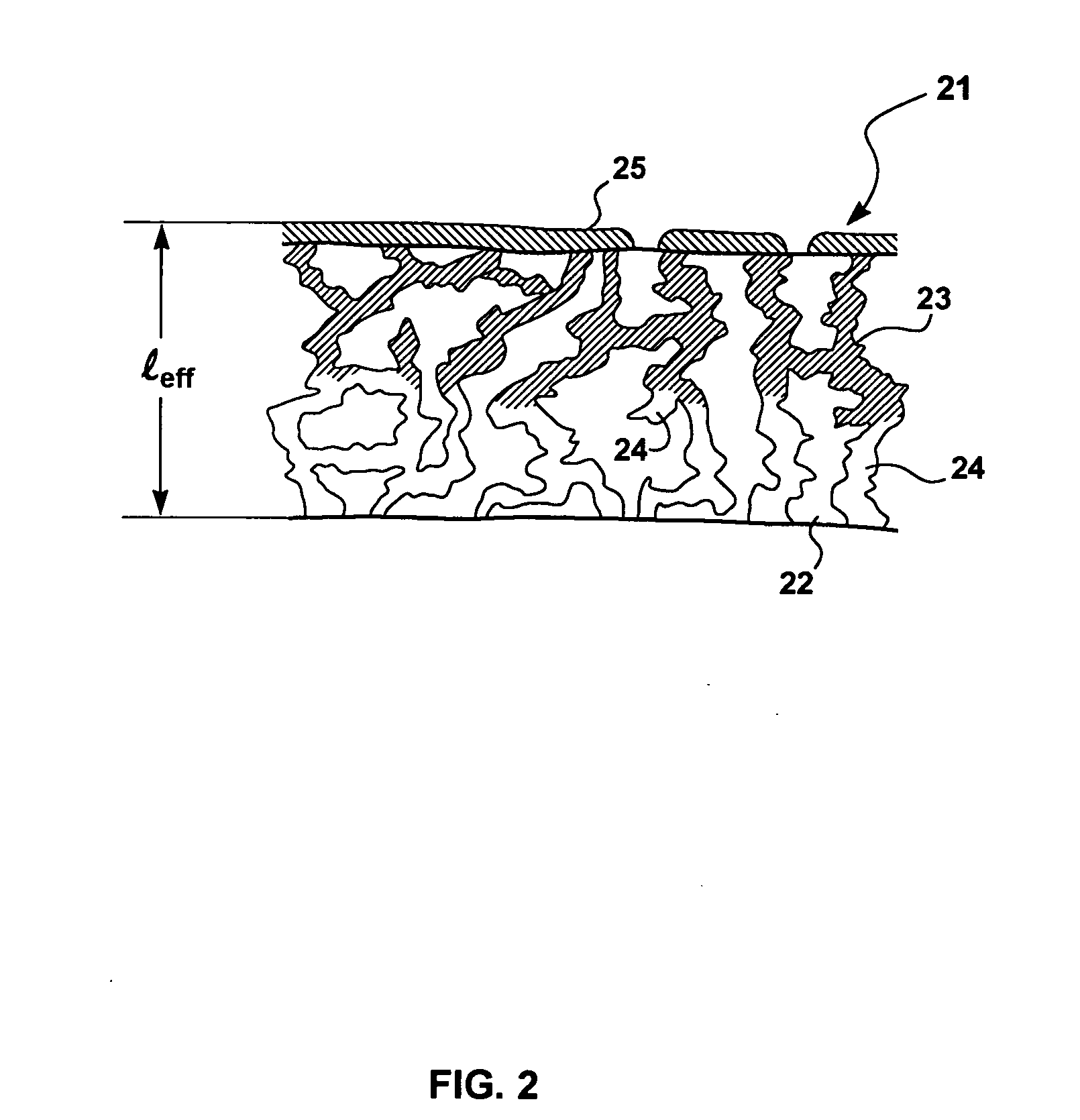

Sequentially cross-linked polyethylene

A method of producing an improved polyethylene, especially an ultra-high molecular weight polyethylene utilizes a sequential irradiation and annealing process to form a highly cross-linked polyethylene material. The use of sequential irradiation followed by sequential annealing after each irradiation allows each dose of irradiation in the series of doses to be relatively low while achieving a total dose which is sufficiently high to cross-link the material. The process may either be applied to a preformed material such as a rod or bar or sheet made from polyethylene resin or may be applied to a finished polyethylene part. If applied to a finished polyethylene part, the irradiation and annealing must be accomplished with the polyethylene material not in contact with oxygen at a concentration greater than 1% oxygen volume by volume. When applied to a preform, such as a rod, the annealing of the bulk polymer part of the rod from which the finished part is made must take place on the rod before the implant is machined therefrom and exposed to oxygen.

Owner:HOWMEDICA OSTEONICS CORP

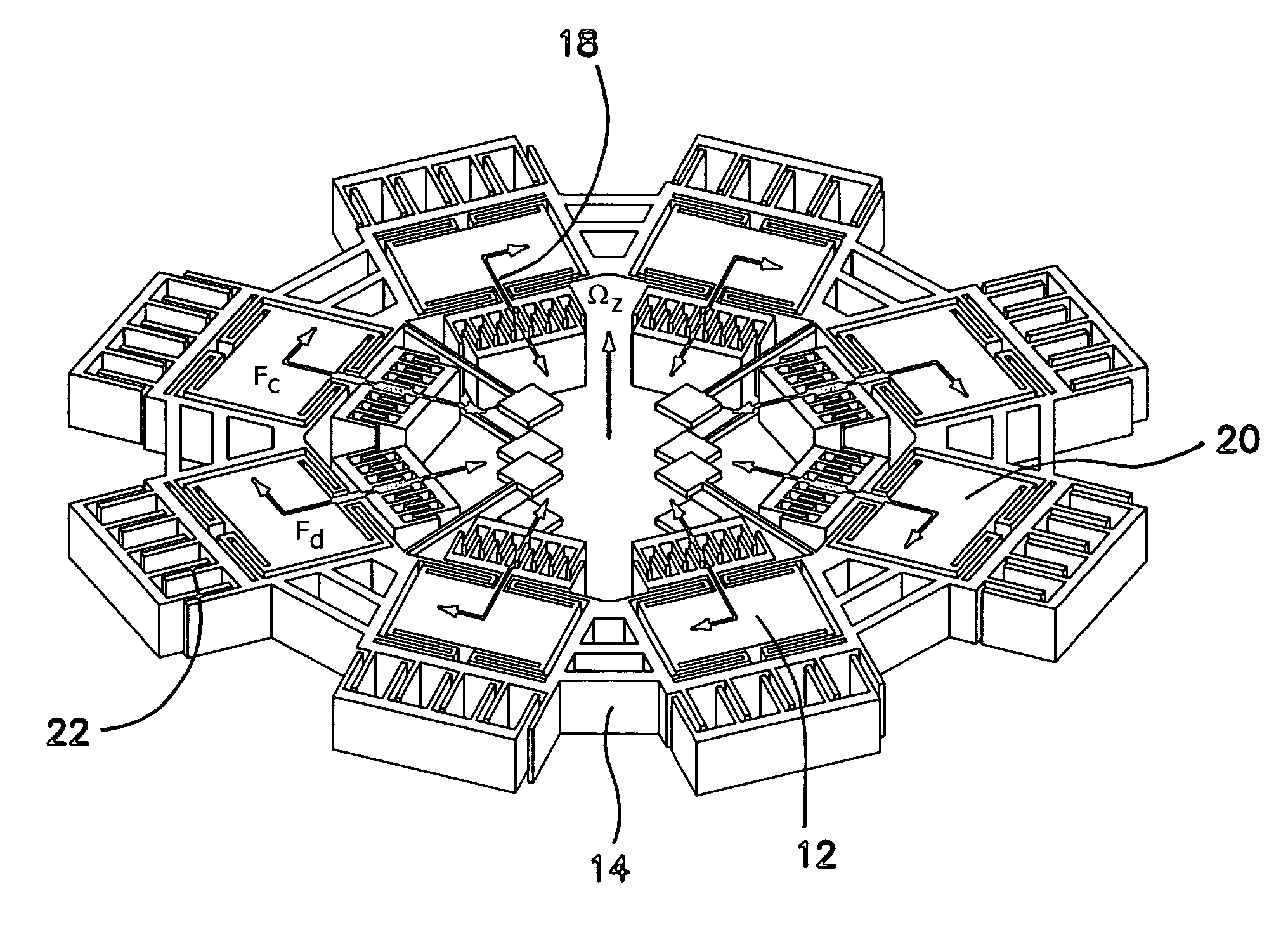

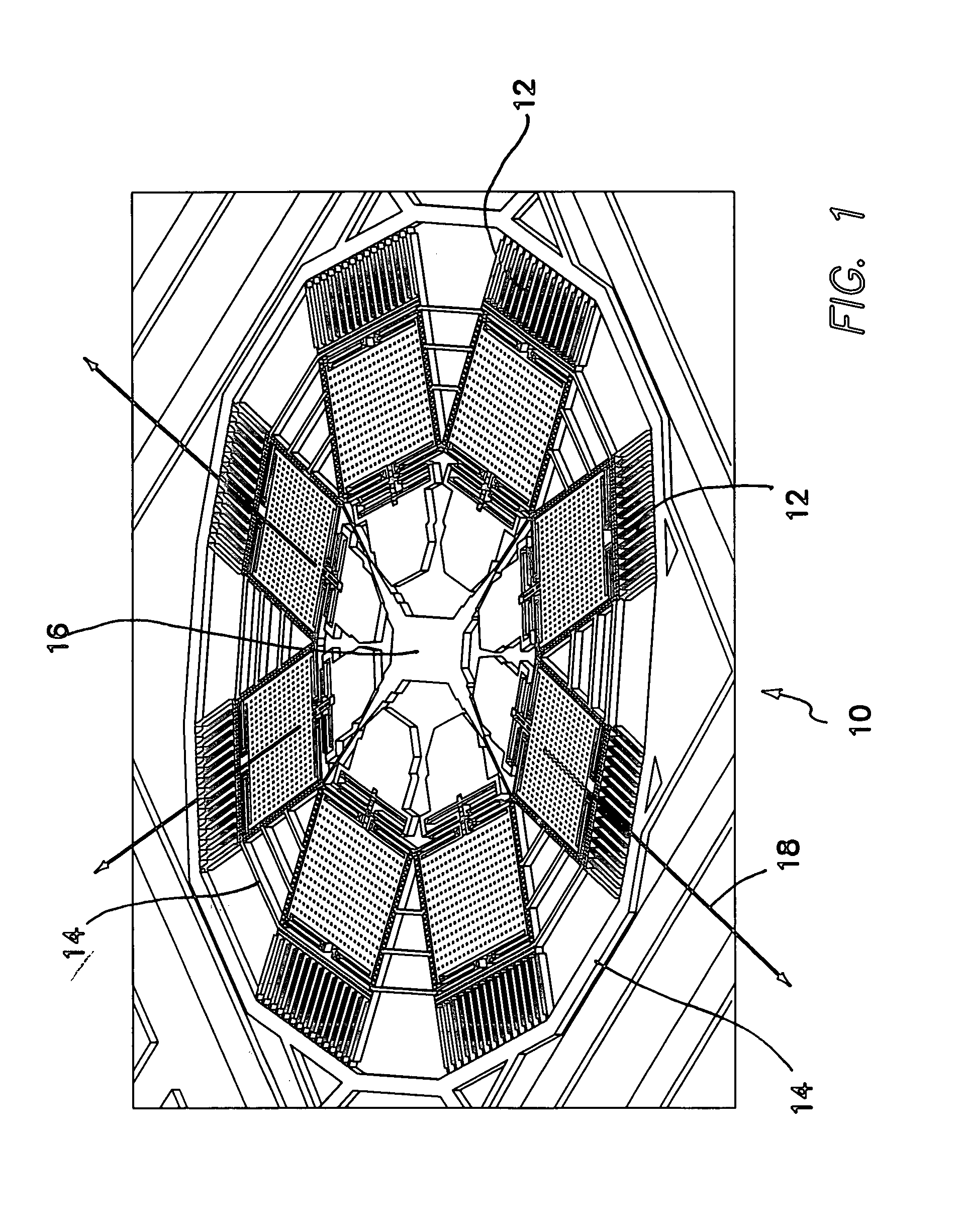

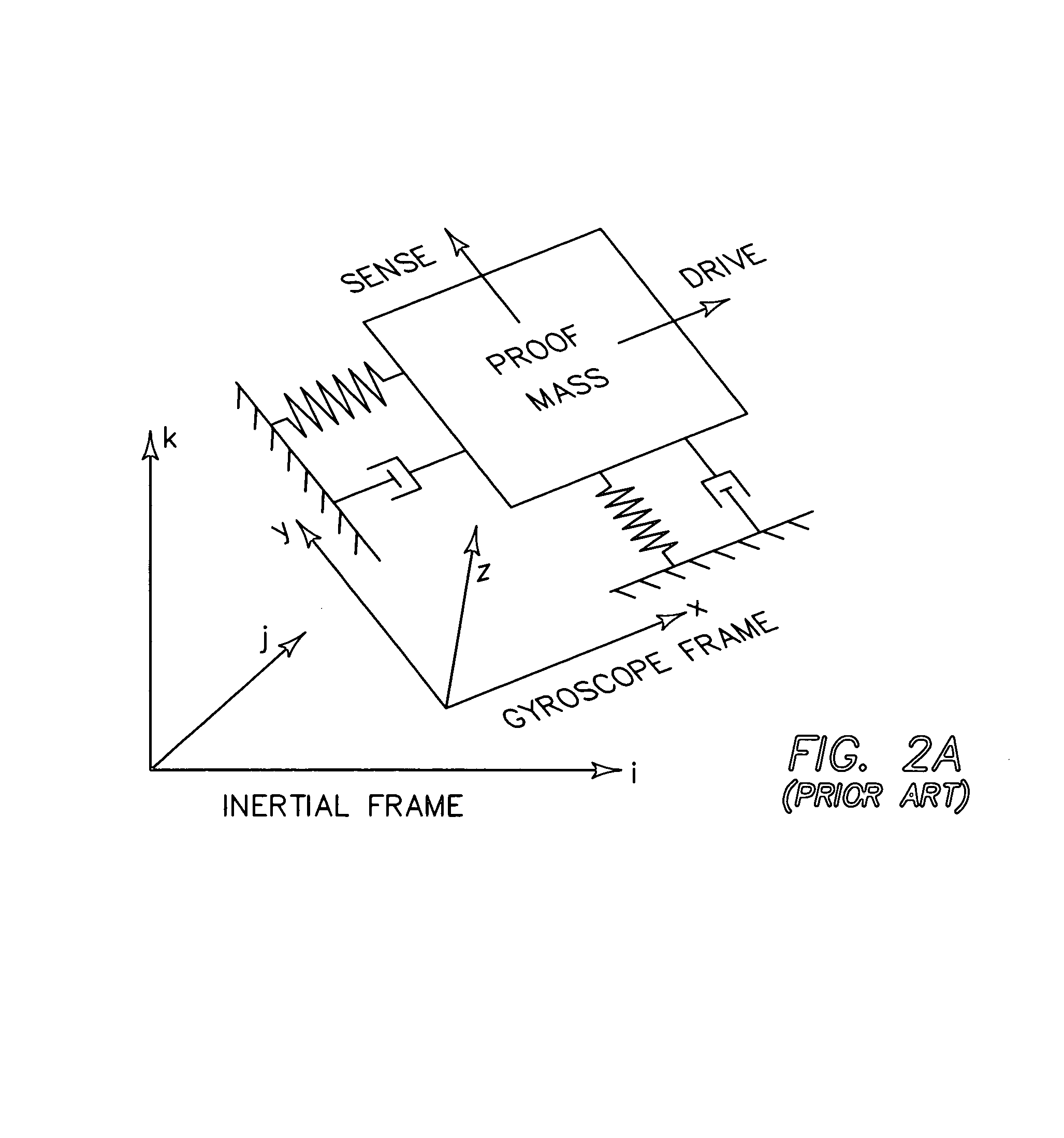

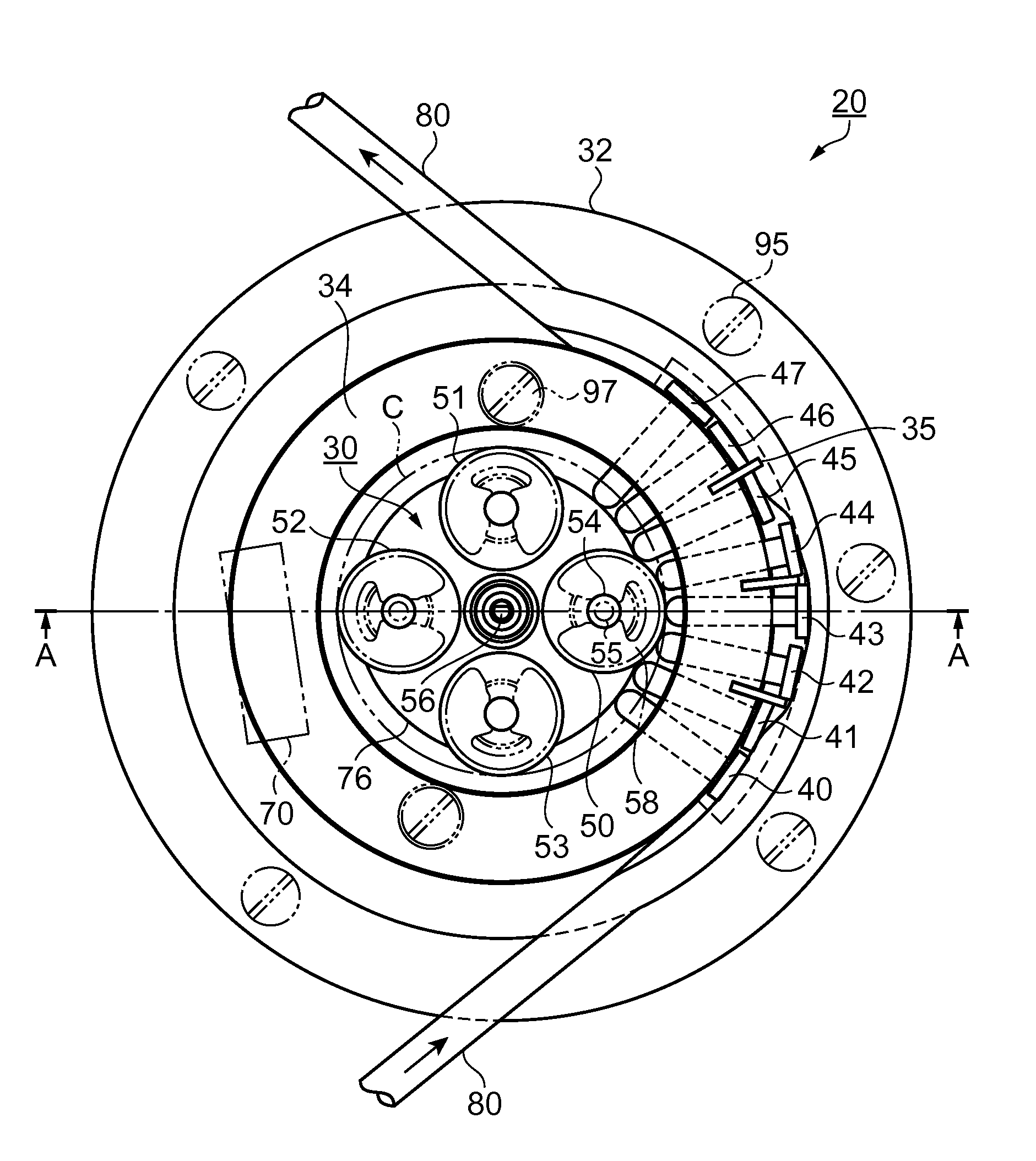

Distributed-mass micromachined gyroscopes operated with drive-mode bandwidth enhancement

ActiveUS7100446B1Reduce the driving forceFluctuations achievedAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsResonanceEngineering

A micromachined z-axis rate gyroscope with multidirectional drive-mode has an increased drive-mode bandwidth for relaxing mode-matching requirement in which the drive and sense modes are completely decoupled. By utilizing multiple drive-mode oscillators with incrementally spaced resonance frequencies, wide-bandwidth response is achieved in the drive-mode, leading to reduced sensitivity to structural and thermal parameter fluctuations. Quadrature error and zero-rate-output are also minimized, due to the enhanced decoupling of multi-directional linear drive-mode and the torsional sense-mode. Bulk-micromachined prototypes have been fabricated in a one-mask SOI-based process, and is experimentally characterized.

Owner:RGT UNIV OF CALIFORNIA

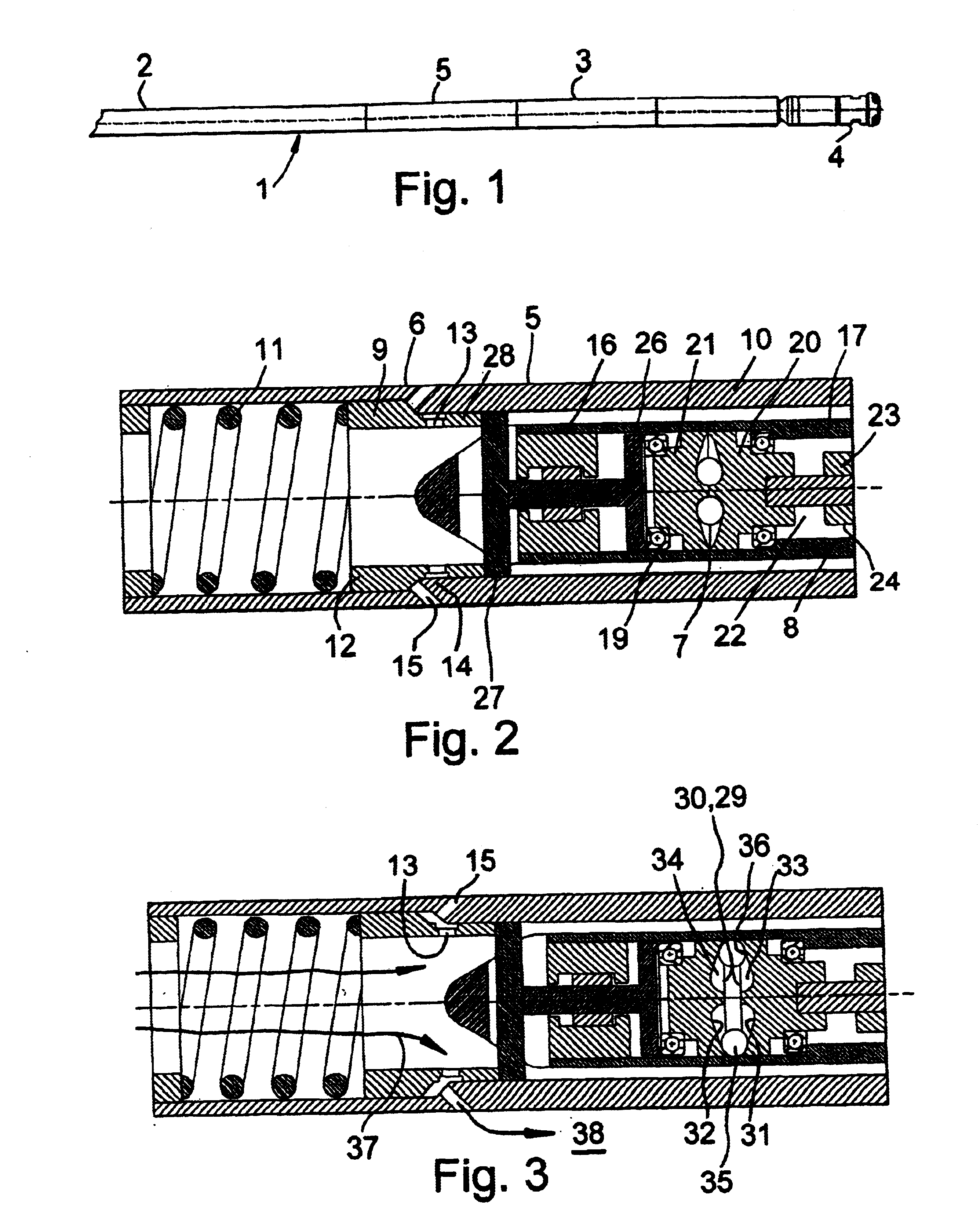

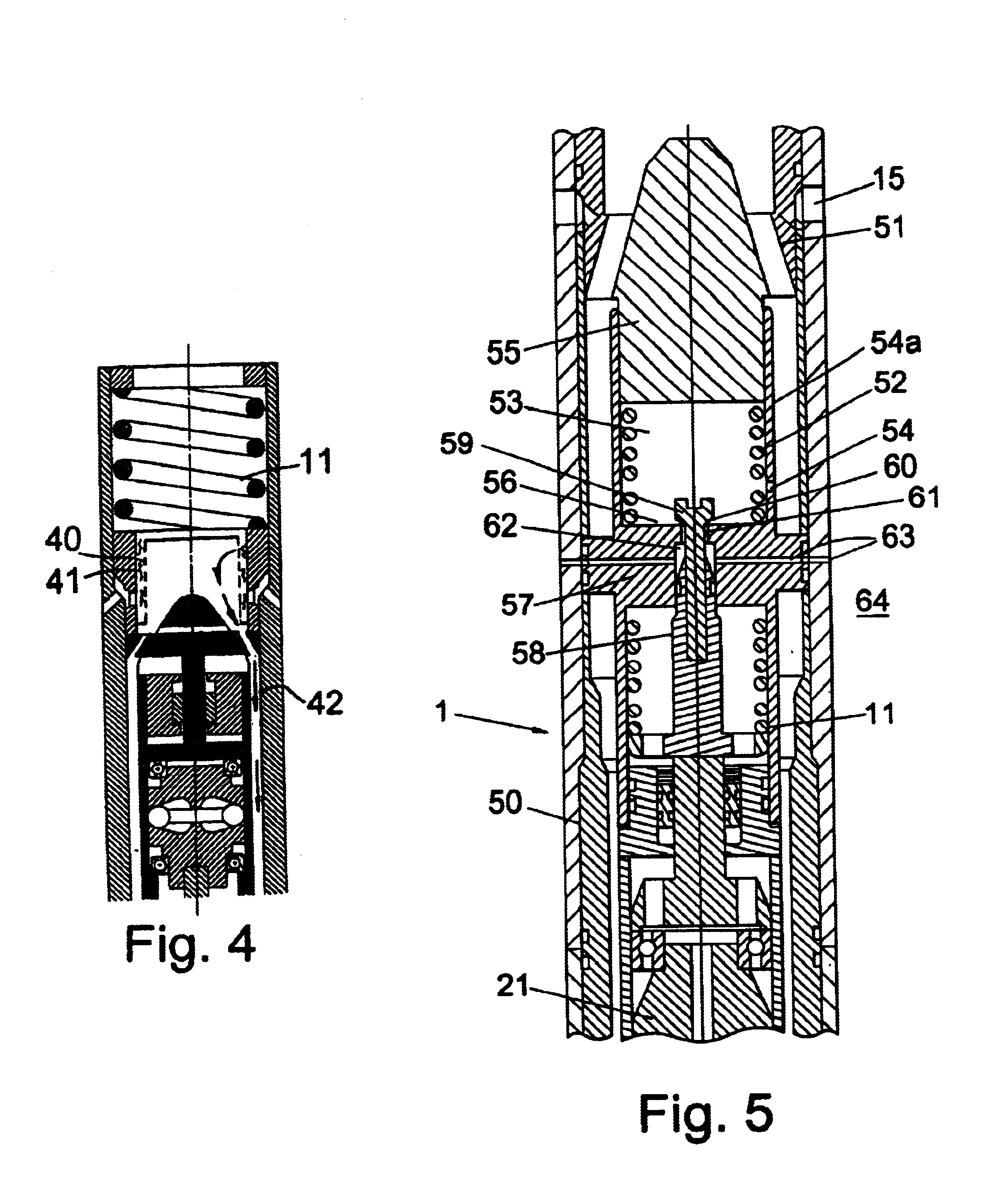

Speed governor

InactiveUS6854953B2Convenient and efficient mannerPrevent speedingWind motor controlServomotorsActuatorControl valves

The present invention provides a speed governor (5) suitable for use in a fluid driven down-hole tool (3). The speed governor comprises an actuator (7) operatively coupled to a motive fluid flow control valve (6). The actuator is and arranged so as to be activatable, directly or indirectly, in response to the running speed of the tool (3), for opening of the control valve (6) with increasing rotational speed of the motor (3) above a predetermined speed limit thereby to limit the rotational speed of the downhole tool (3).

Owner:ROTECH GROUP

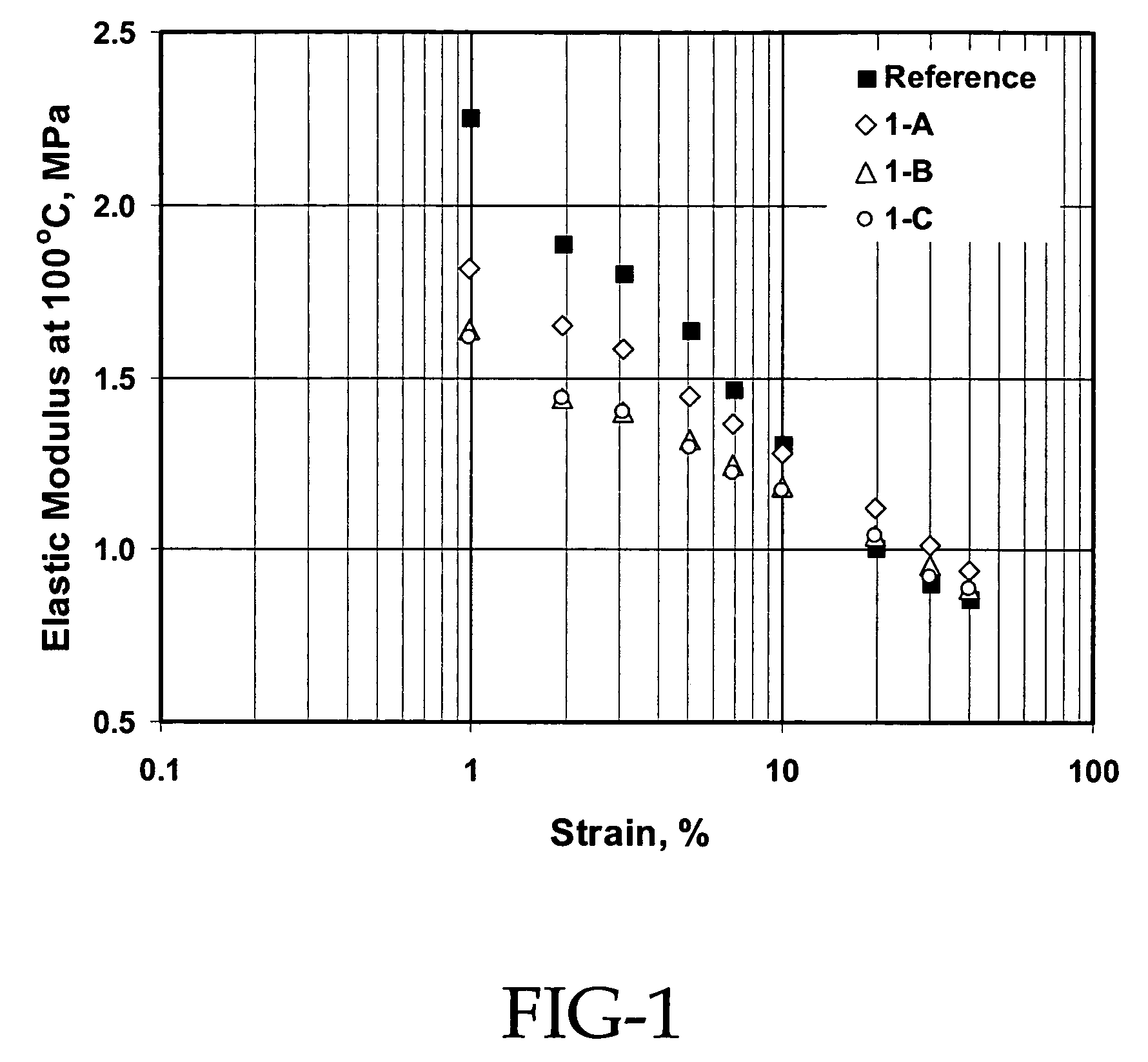

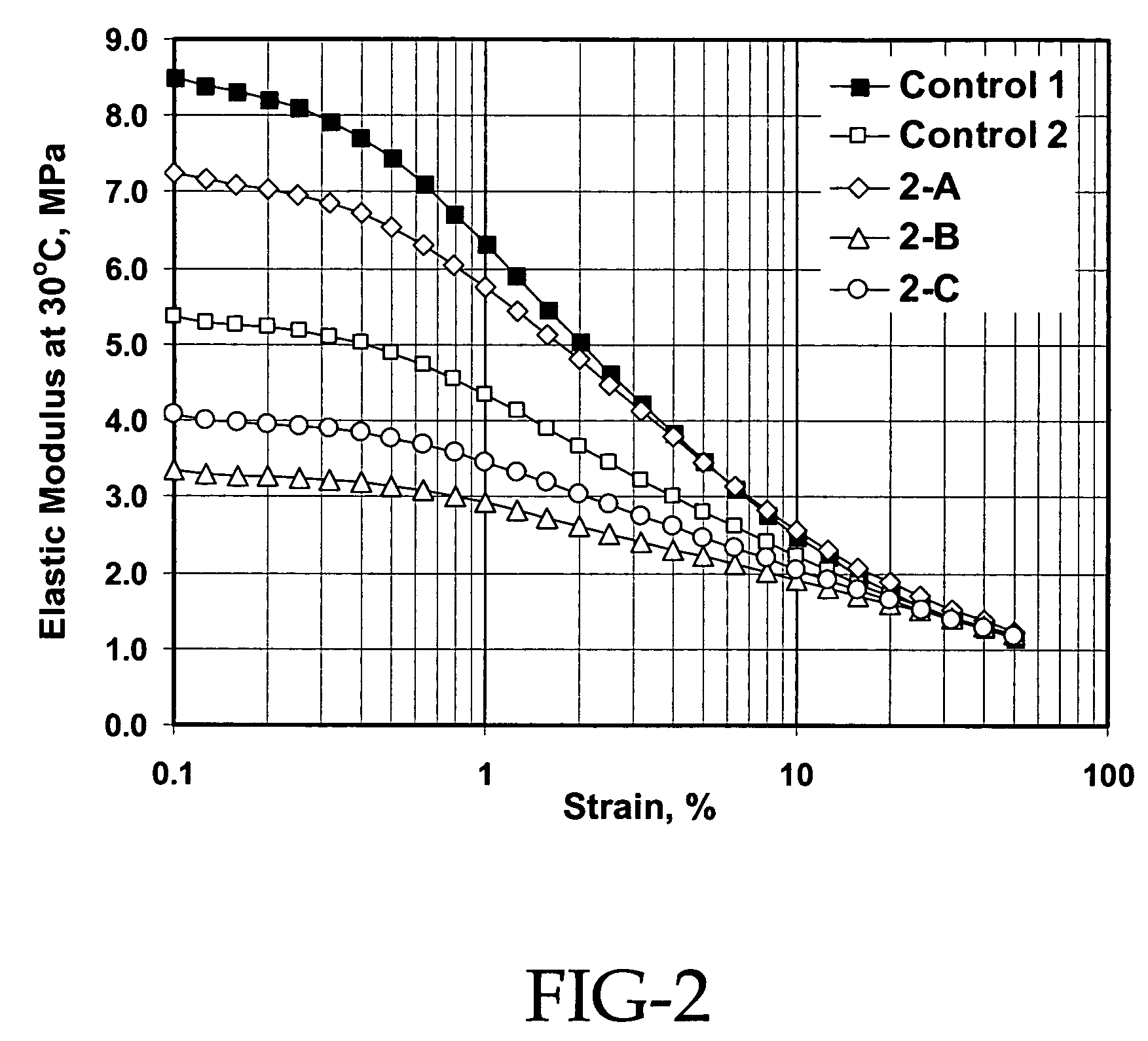

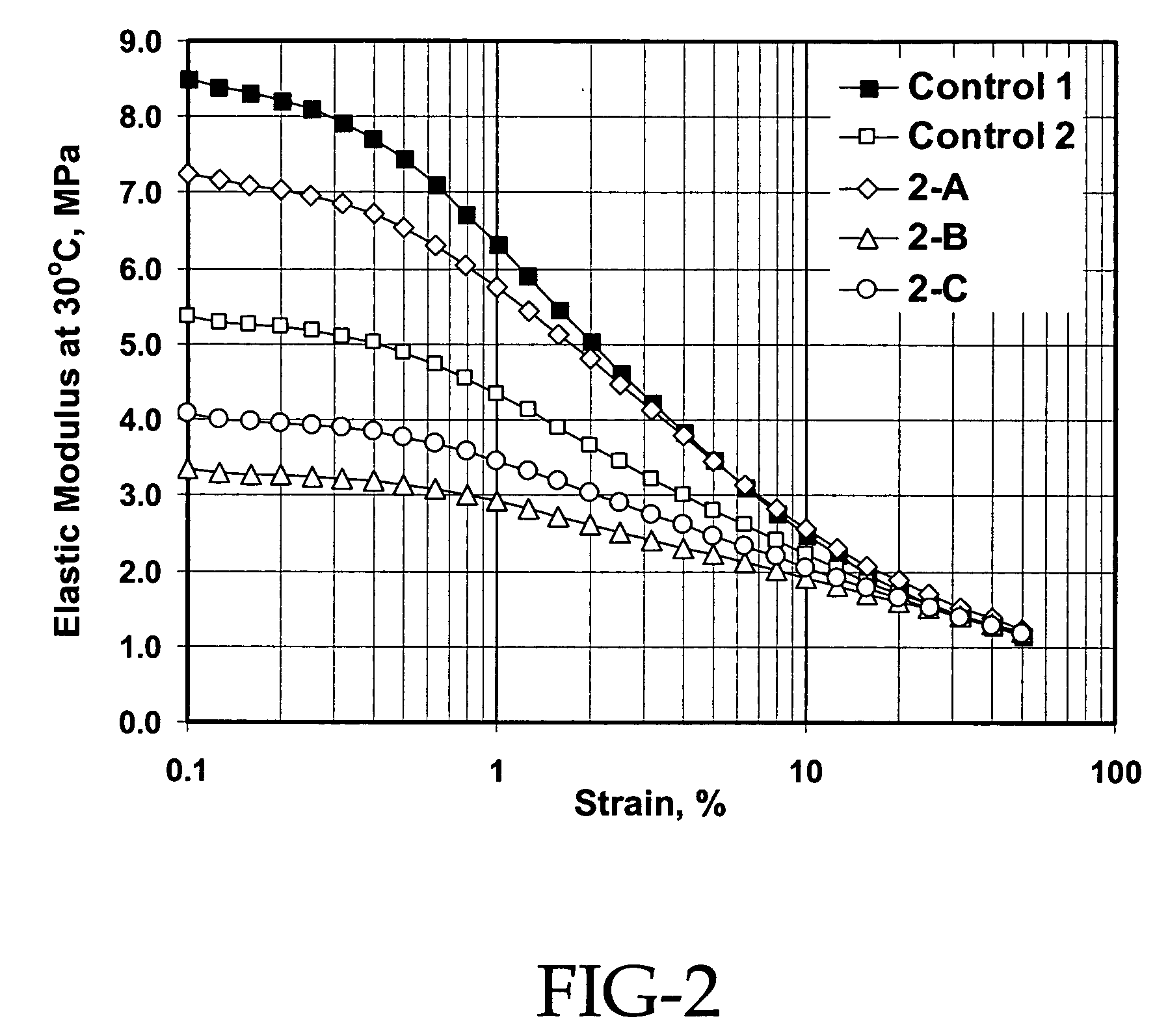

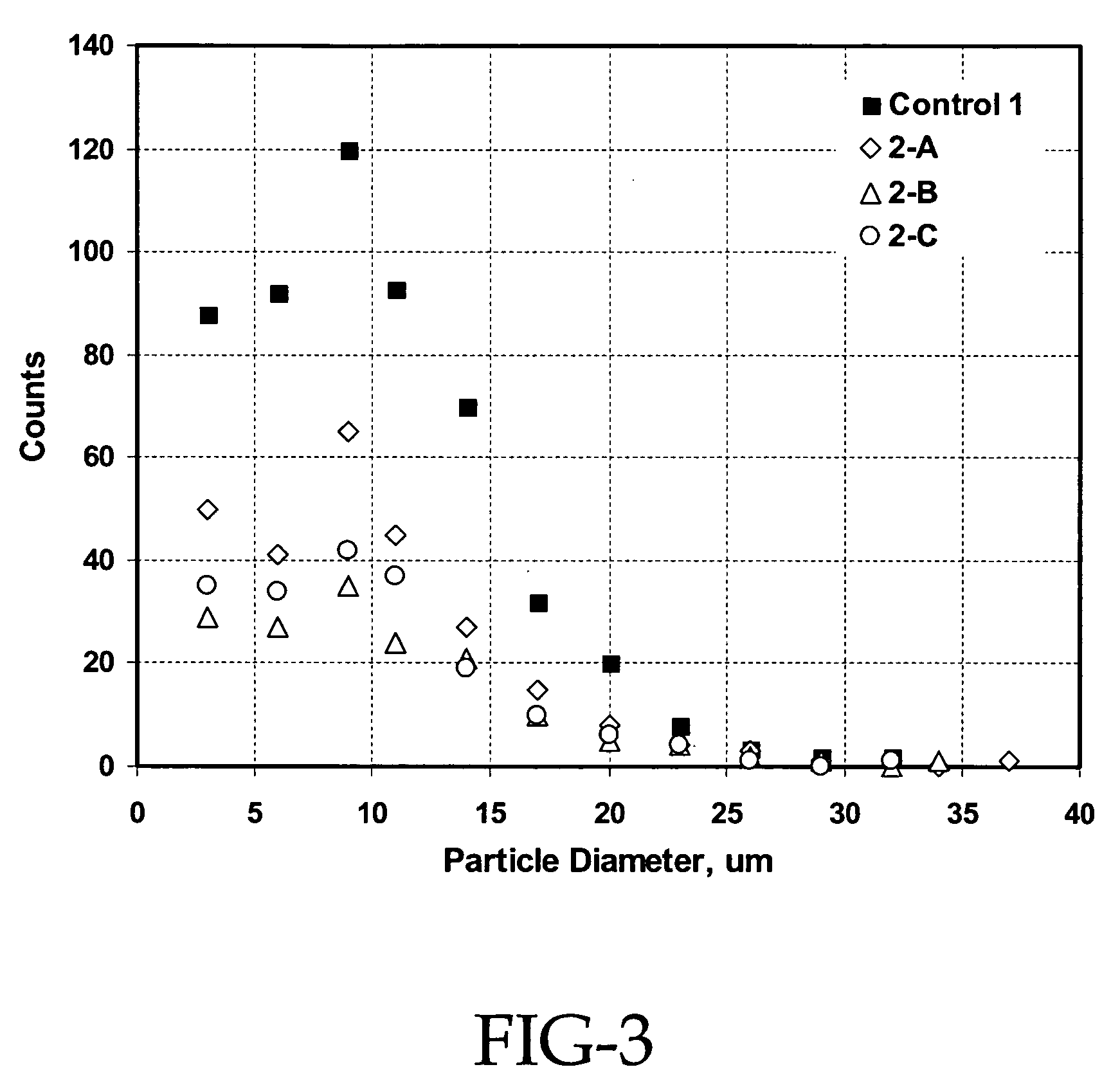

Silica containing rubber composition

InactiveUS7307121B2Great tractionReduce rolling resistanceSpecial tyresPretreated surfacesElastomerHysteresis

This invention discloses a method for preparing rubber compositions that exhibit unique combinations of properties that are desirable for tire tread applications for enhanced snow / ice and wet traction, low rolling resistance and increased treadwear performance in comparison with conventional silica compounds. Specifically, a high reactively silane coupling agent, such as a mercaptosilane, is used in combination with a silane coupling typically used for silica tread compounds such as bis(triethoxylsilylpropyl)disulfide to treat silica pellets in a hydrocarbon solvent at elevated temperatures. The treated silica is then blended with solution elastomer cement in a hydrocarbon solvent. The deposited reactive silanes partially react with the elastomer molecules forming a layer of polymer grafted on the silica surfaced. This structure significantly improves the silica retention during the steam stripping operation. Almost 100% (99+%) silica retention has been achieved by this invention. After solvent removal from steam stripping, the treated silica / elastomer mixer is dewatered and dried using conventional equipment such as shaker screens, expellers and expanders to form a well-dispersed silica masterbatch. This technique results in silica compounds with excellent silica dispersion and increased filler-polymer interaction, hence enhanced compound performance such as better physical properties, more desirable dynamic properties (low hysteresis at high temperatures and high hysteresis at low temperatures) and increased abrasion resistance.

Owner:THE GOODYEAR TIRE & RUBBER CO

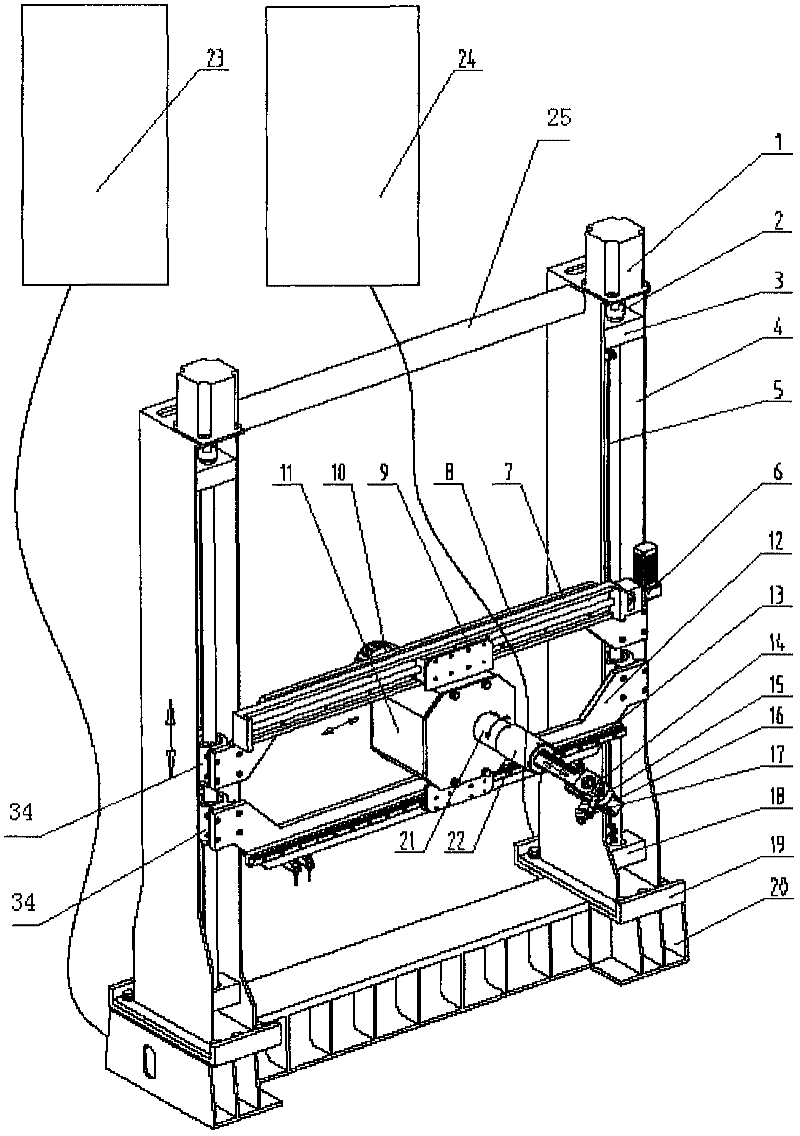

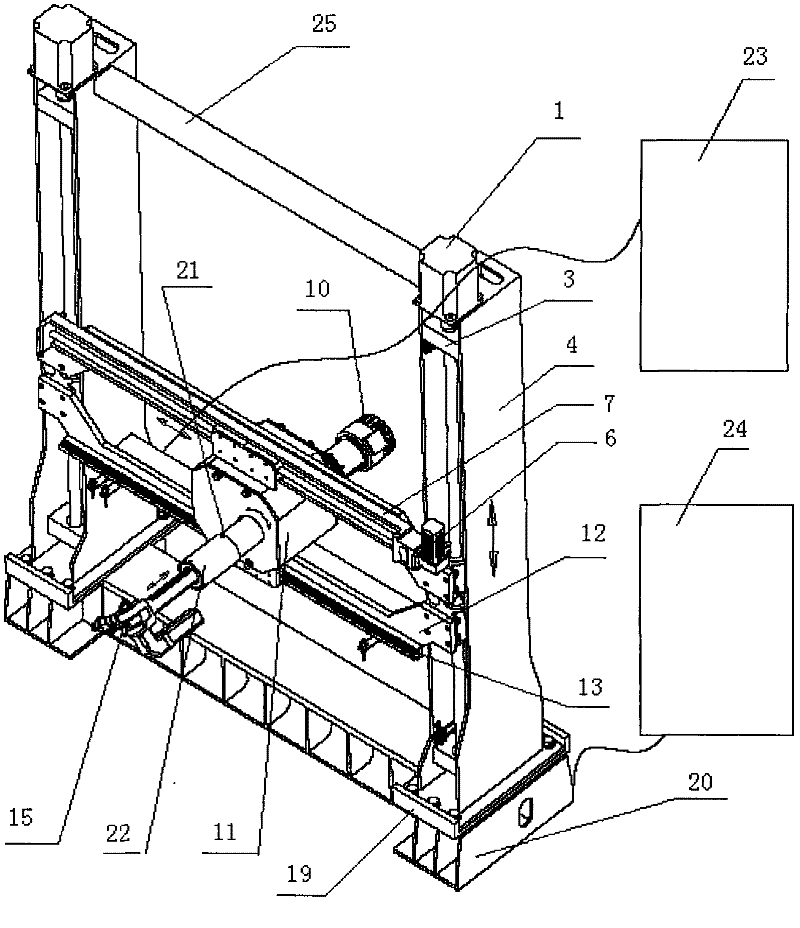

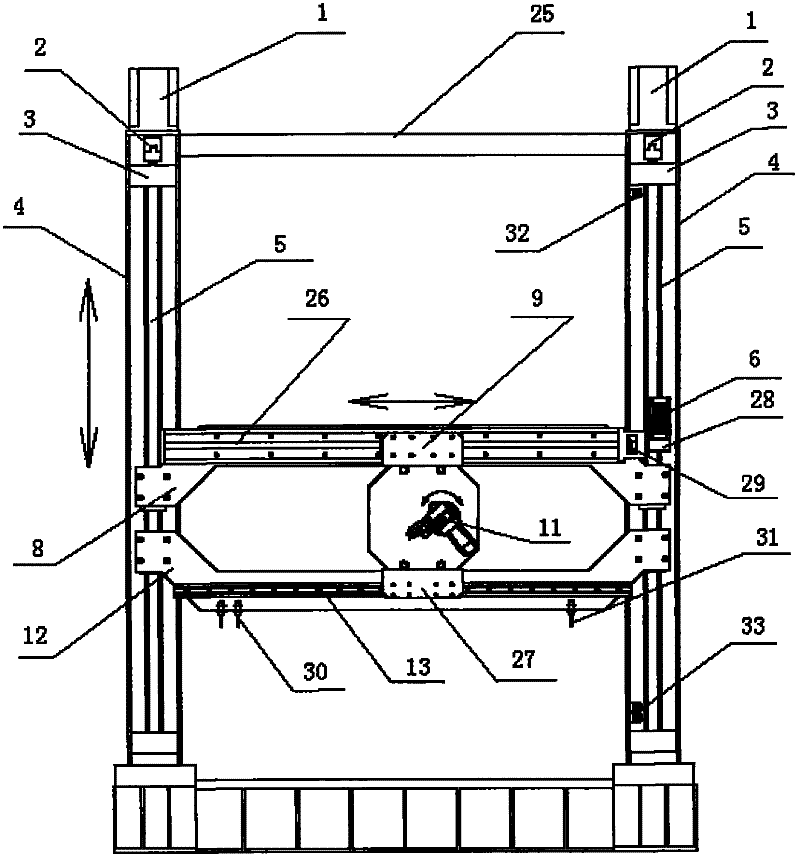

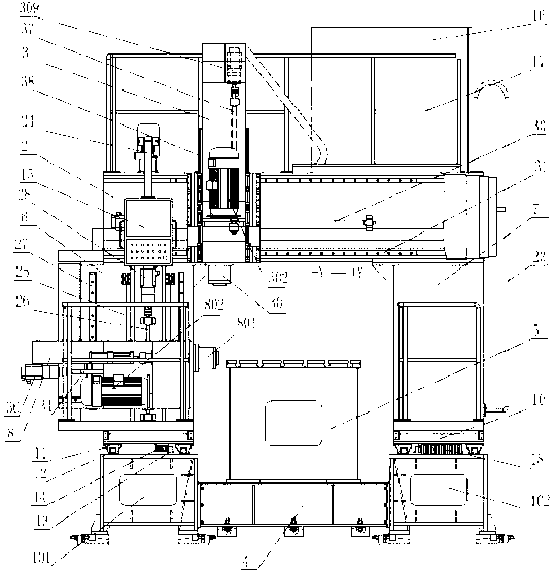

Spraying robot driving device

The invention relates to a robot driving device, comprising a planar intraframe driving device and a mechanical arm driving device, wherein the planar intraframe driving device comprises an up-down lifting driving device and a left-right horizontal driving device. The left-right horizontal driving device drives a spraying robot to horizontally move right and left with a linear module sliding block by virtue of a servo motor, the up-down lifting driving device drives the left-right horizontal driving device to do lifting motion up and down with a ball screw by virtue of the servo motor; the mechanical arm driving device comprises an intermediate rotating driving mechanism, a telescopic driving mechanism and a swinging driving mechanism at the front end, the intermediate rotating driving mechanism drives a mechanical arm to rotate by virtue of the servo motor; the telescopic driving mechanism drives the mechanical arm to do telescopic motion by virtue of the servo motor; and the swinging driving mechanism at the front end drives a spray gun to swing and rotate around by virtue of the servo motor and a reducer.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD

Sequentially cross-linked polyethylene

A method of producing an improved polyethylene, especially an ultra-high molecular weight polyethylene utilizes a sequential irradiation and annealing process to form a highly cross-linked polyethylene material. The use of sequential irradiation followed by sequential annealing after each irradiation allows each dose of irradiation in the series of doses to be relatively low while achieving a total dose which is sufficiently high to cross-link the material. The process may either be applied to a preformed material such as a rod or bar or sheet made from polyethylene resin or may be applied to a finished polyethylene part. If applied to a finished polyethylene part, the irradiation and annealing must be accomplished with the polyethylene material not in contact with oxygen at a concentration greater than 1% oxygen volume by volume. When applied to a preform, such as a rod, the annealing of the bulk polymer part of the rod from which the finished part is made must take place on the rod before the implant is machined therefrom and exposed to oxygen.

Owner:HOWMEDICA OSTEONICS CORP

Silica containing rubber composition

InactiveUS20050209370A1Enhanced snow/ice tractionReduce rolling resistanceSpecial tyresOrganic dyesElastomerHydrocarbon solvents

This invention discloses a method for preparing rubber compositions that exhibit unique combinations of properties that are desirable for tire tread applications for enhanced snow / ice and wet traction, low rolling resistance and increased treadwear performance in comparison with conventional silica compounds. Specifically, a high reactively silane coupling agent, such as a mercaptosilane, is used in combination with a silane coupling typically used for silica tread compounds such as bis(triethoxylsilylpropyl)disulfide to treat silica pellets in a hydrocarbon solvent at elevated temperatures. The treated silica is then blended with solution elastomer cement in a hydrocarbon solvent. The deposited reactive silanes partially react with the elastomer molecules forming a layer of polymer grafted on the silica surfaced. This structure significantly improves the silica retention during the steam stripping operation. Almost 100% (99+%) silica retention has been achieved by this invention. After solvent removal from steam stripping, the treated silica / elastomer mixer is dewatered and dried using conventional equipment such as shaker screens, expellers and expanders to form a well-dispersed silica masterbatch. This technique results in silica compounds with excellent silica dispersion and increased filler-polymer interaction, hence enhanced compound performance such as better physical properties, more desirable dynamic properties (low hysteresis at high temperatures and high hysteresis at low temperatures) and increased abrasion resistance.

Owner:THE GOODYEAR TIRE & RUBBER CO

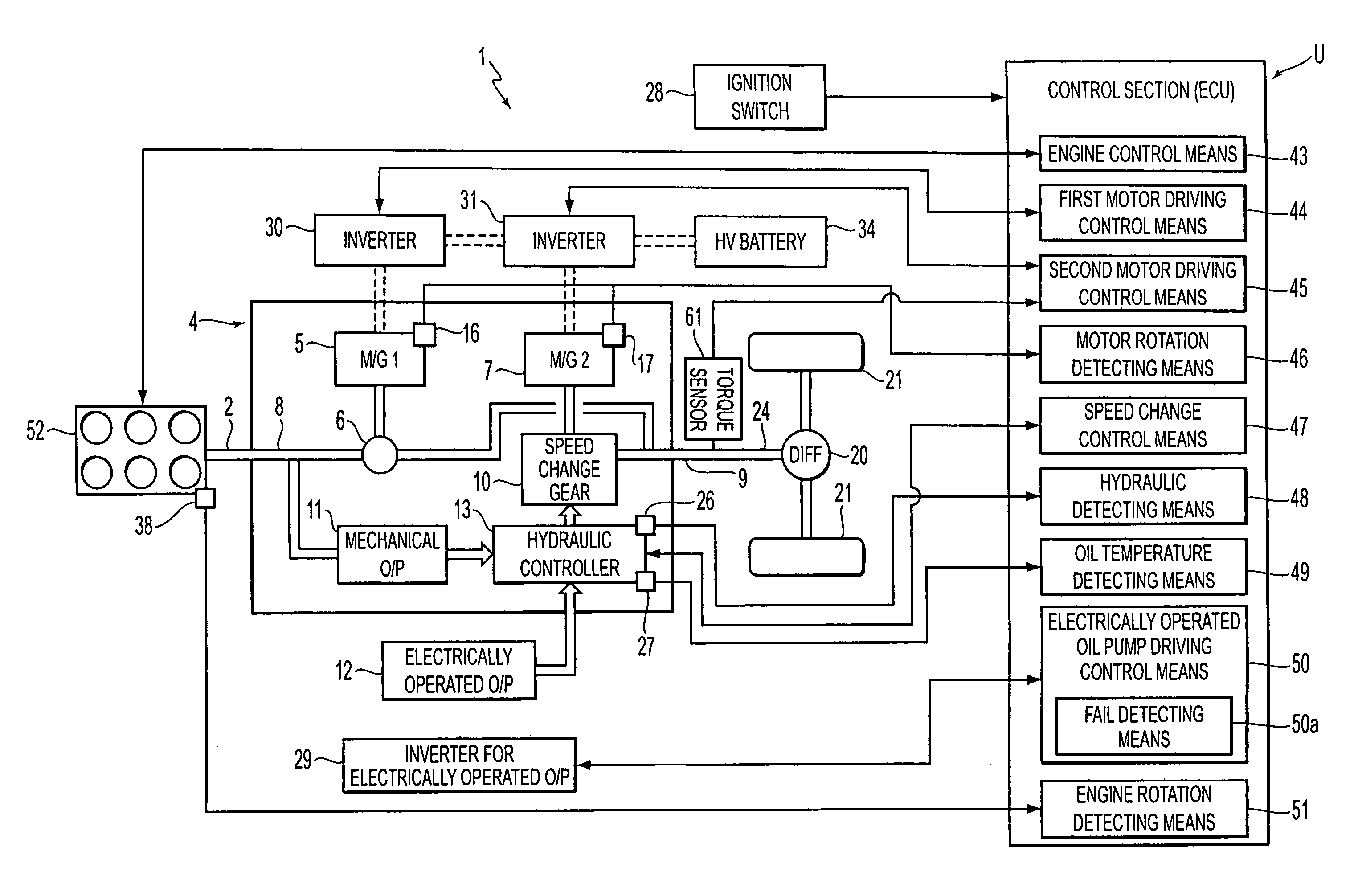

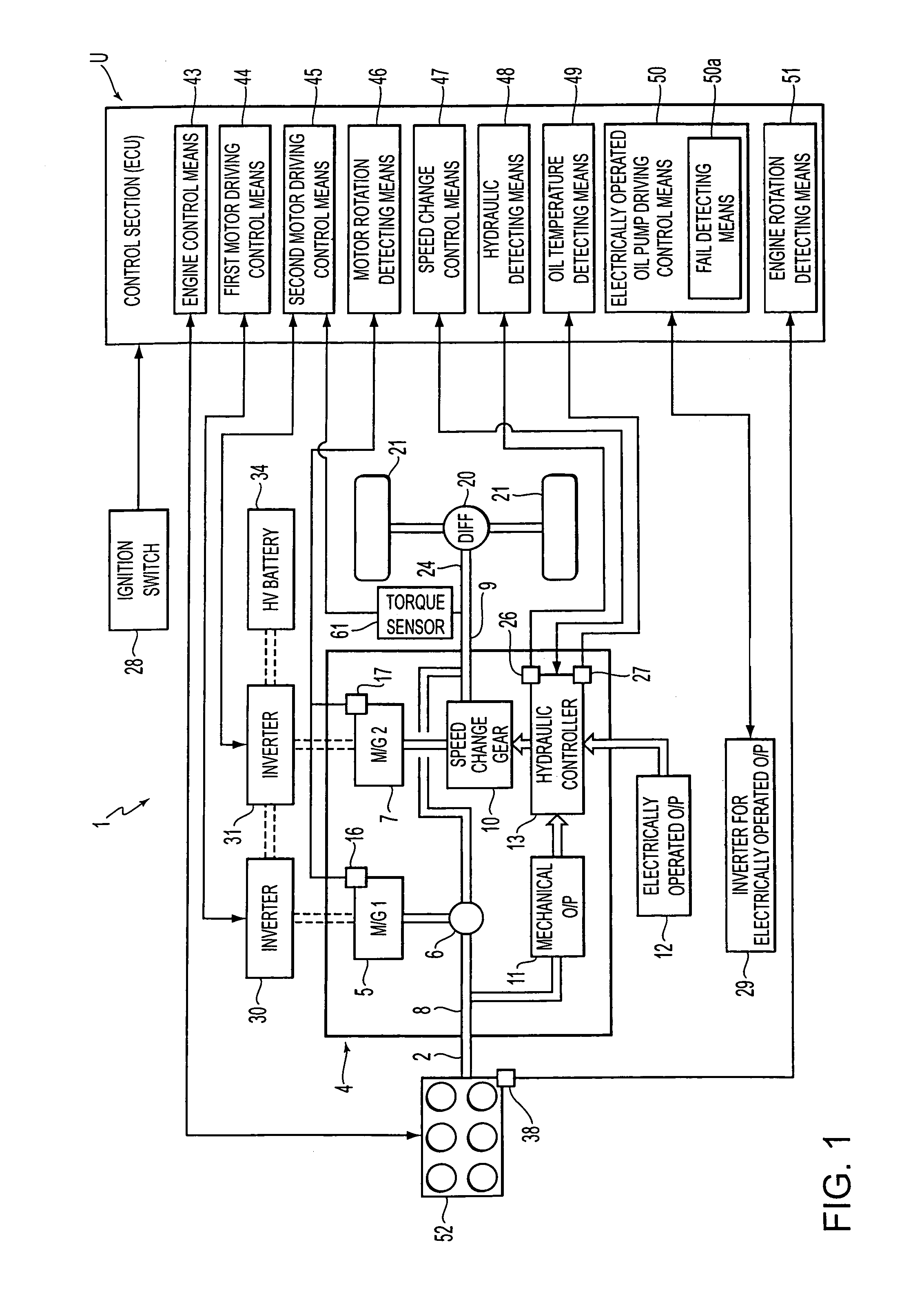

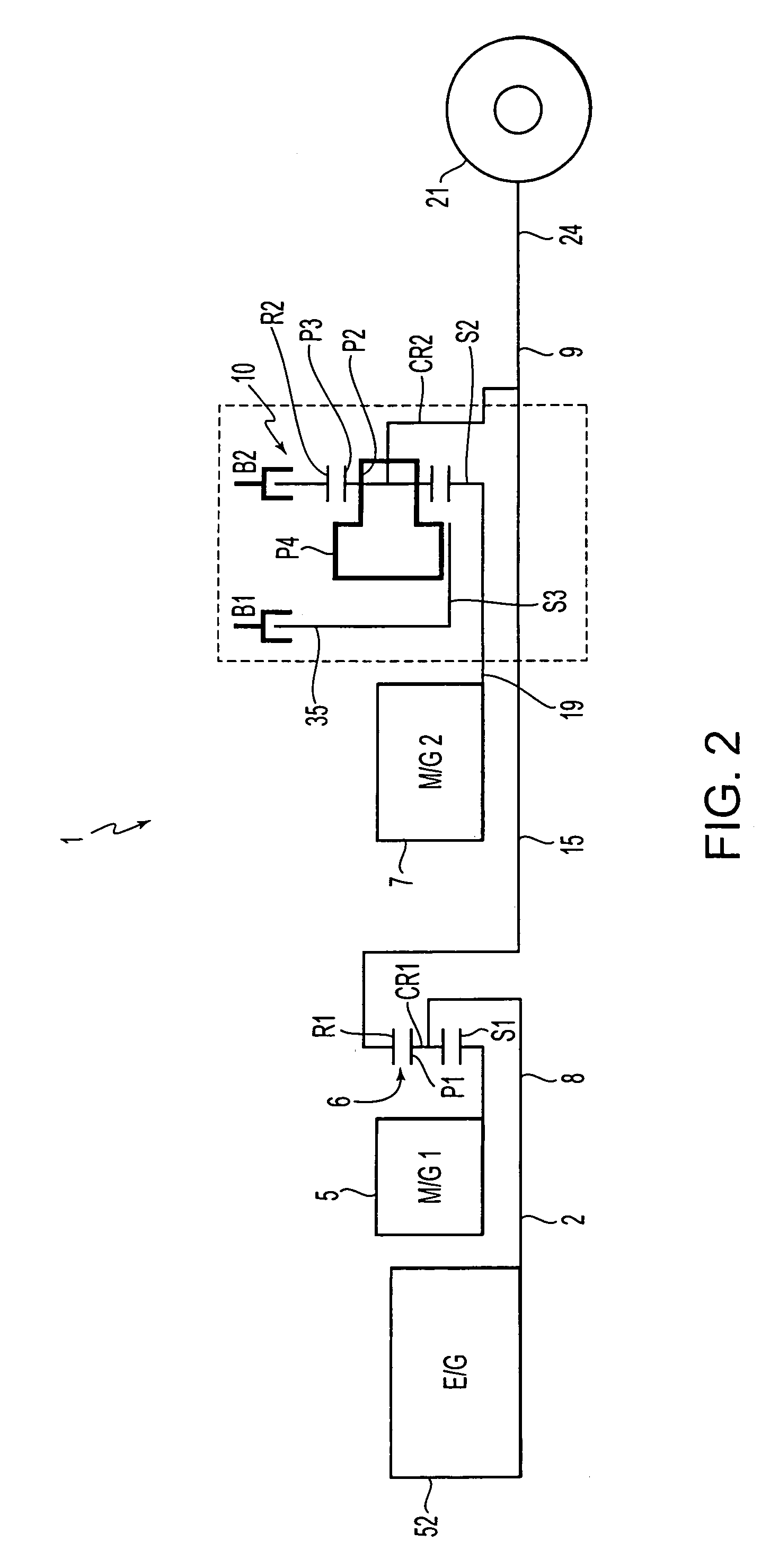

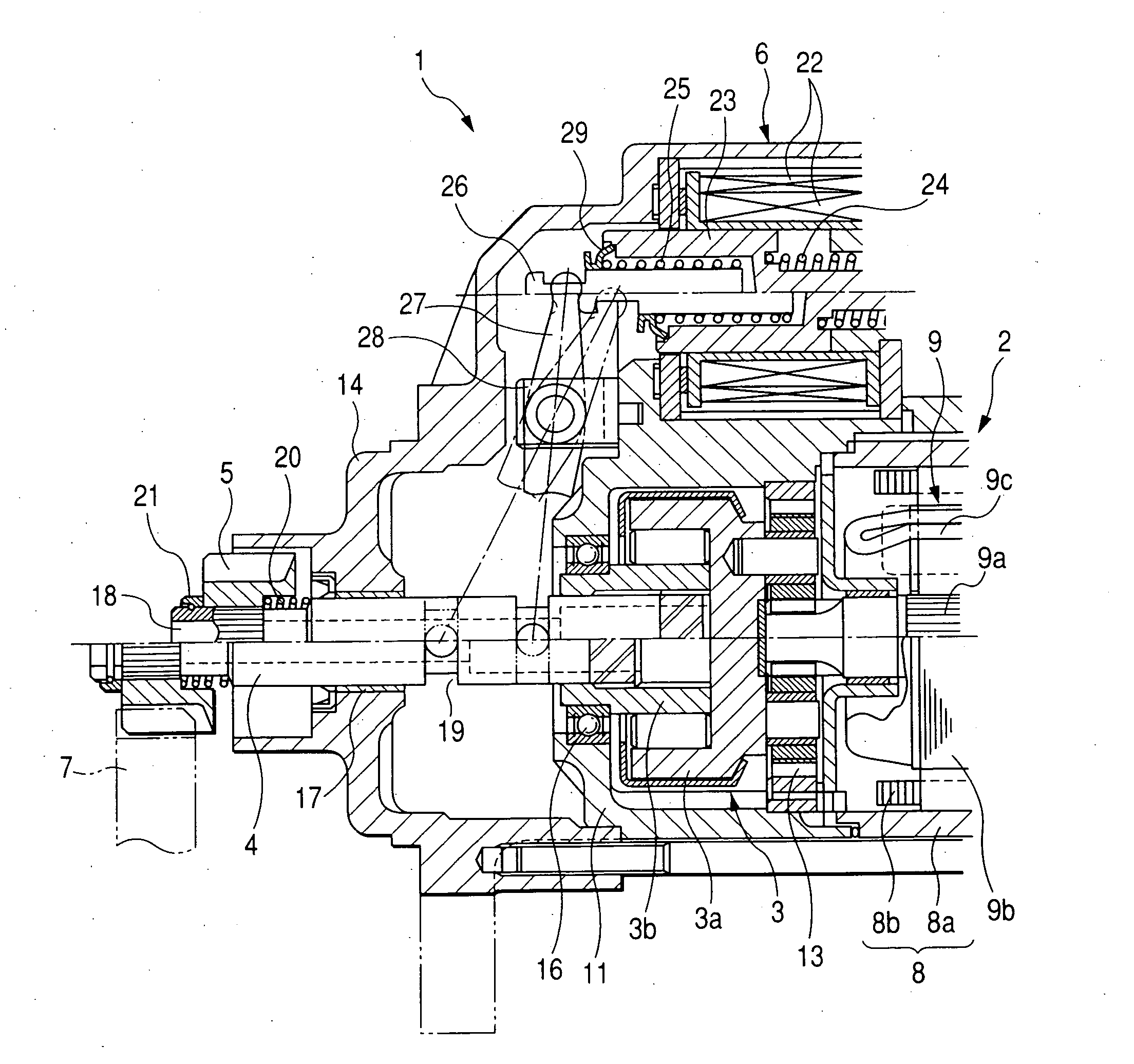

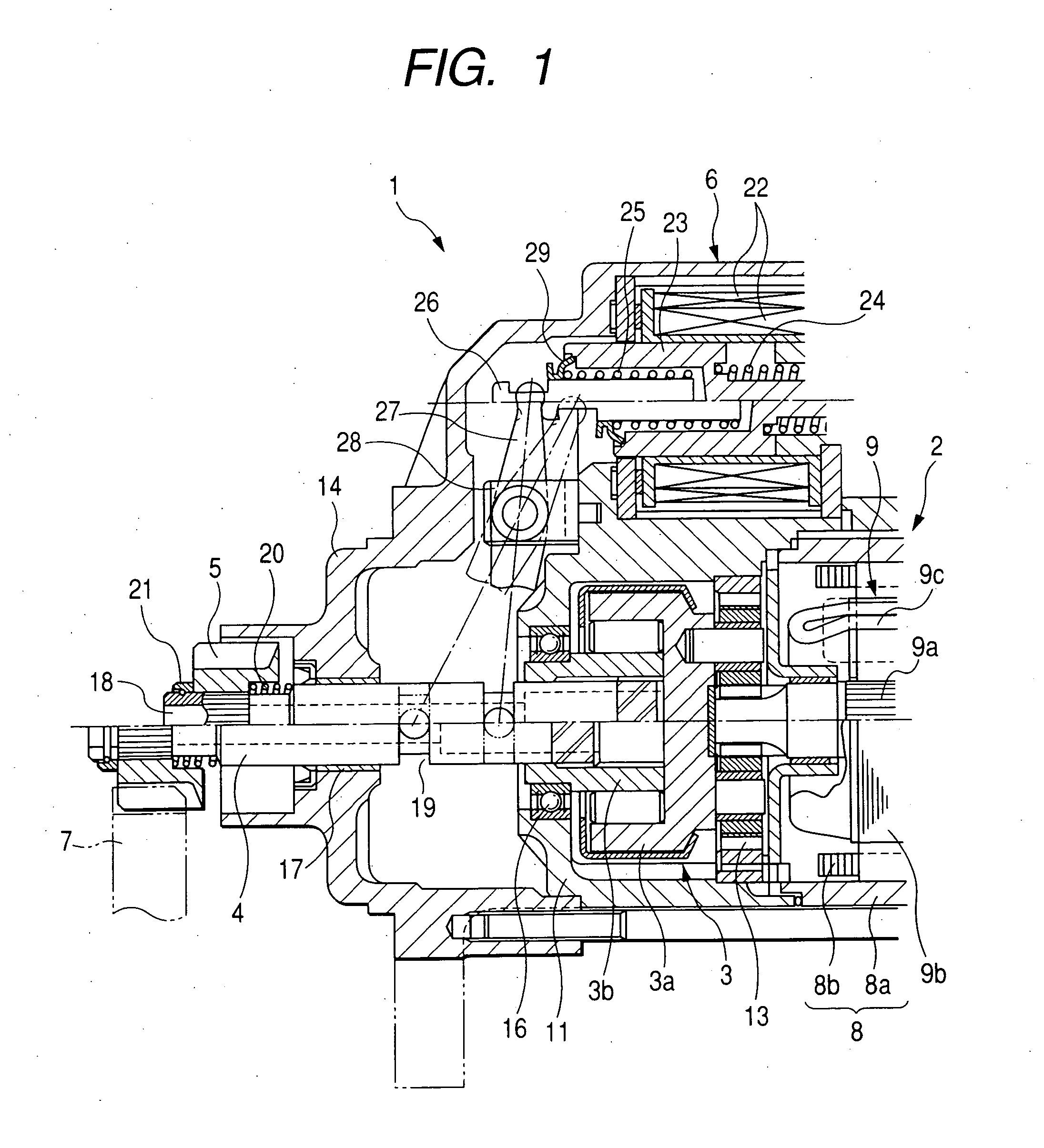

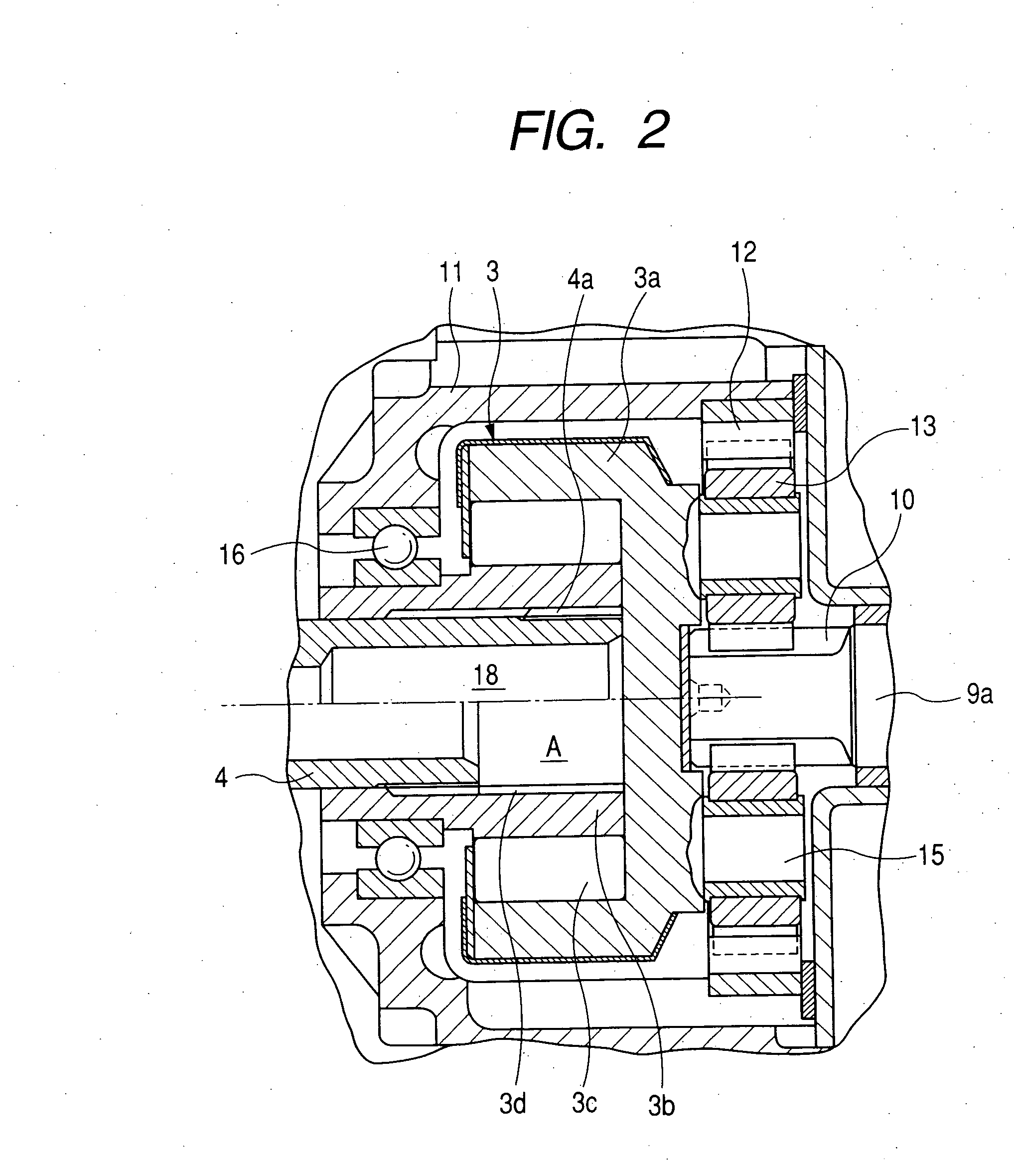

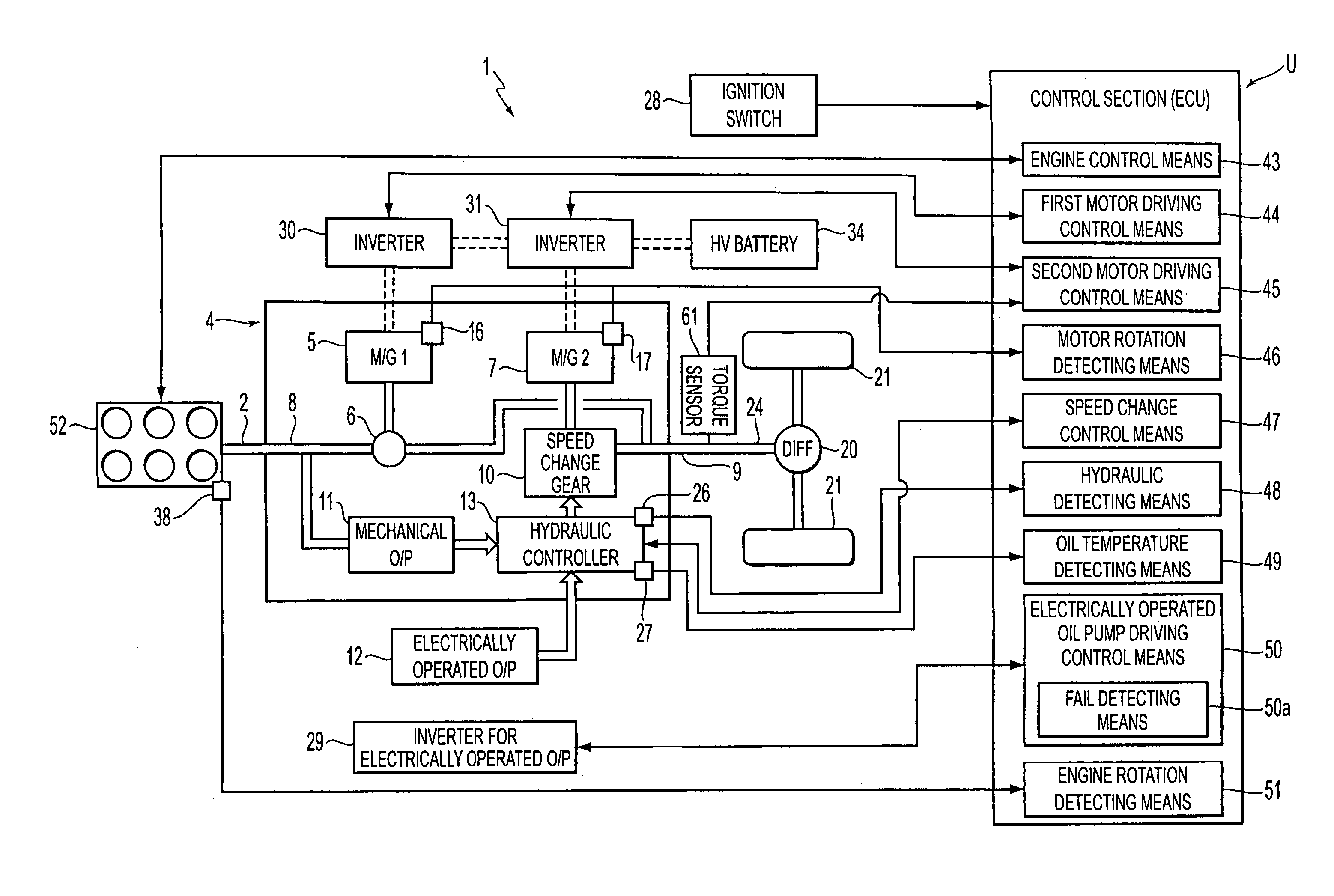

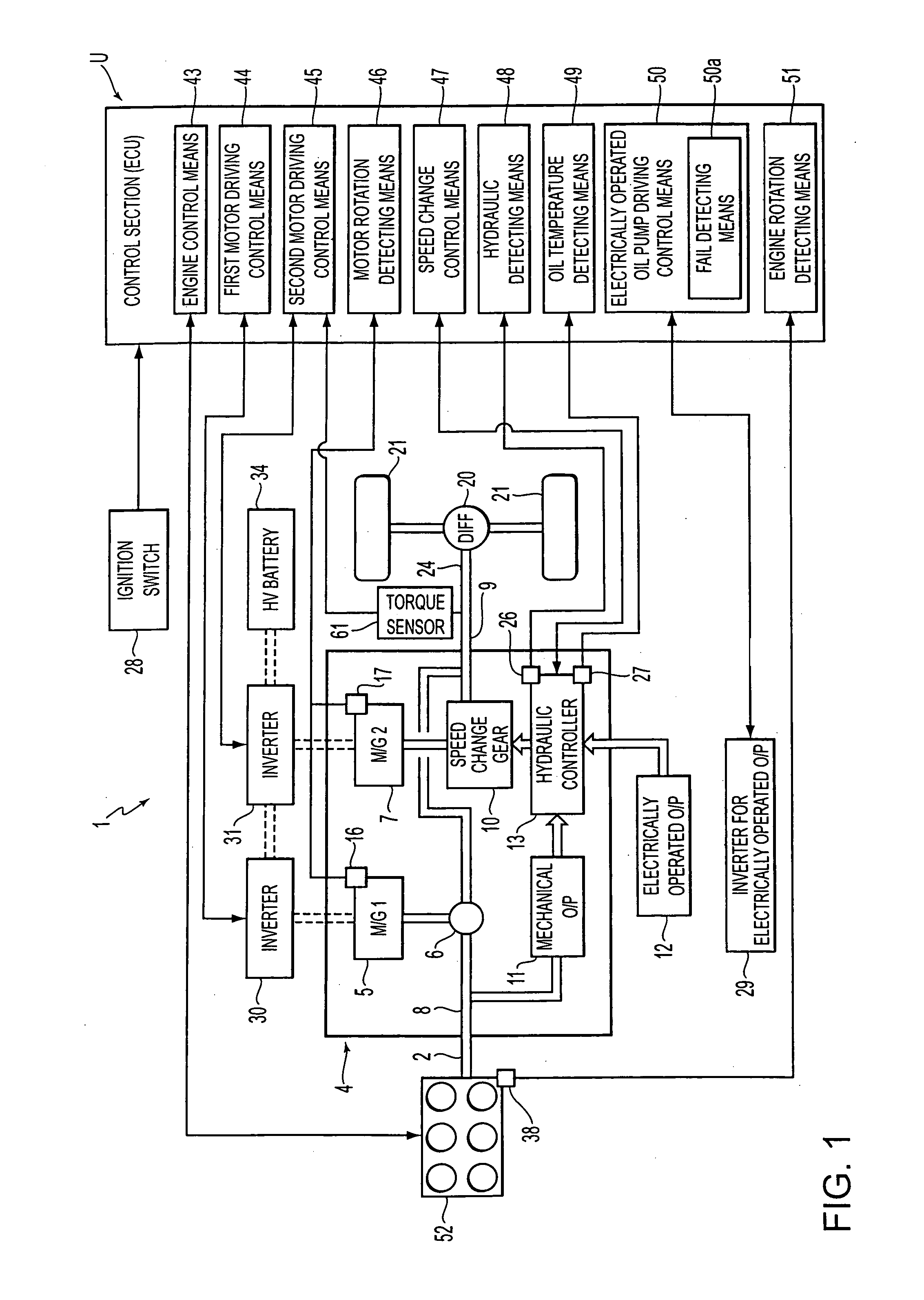

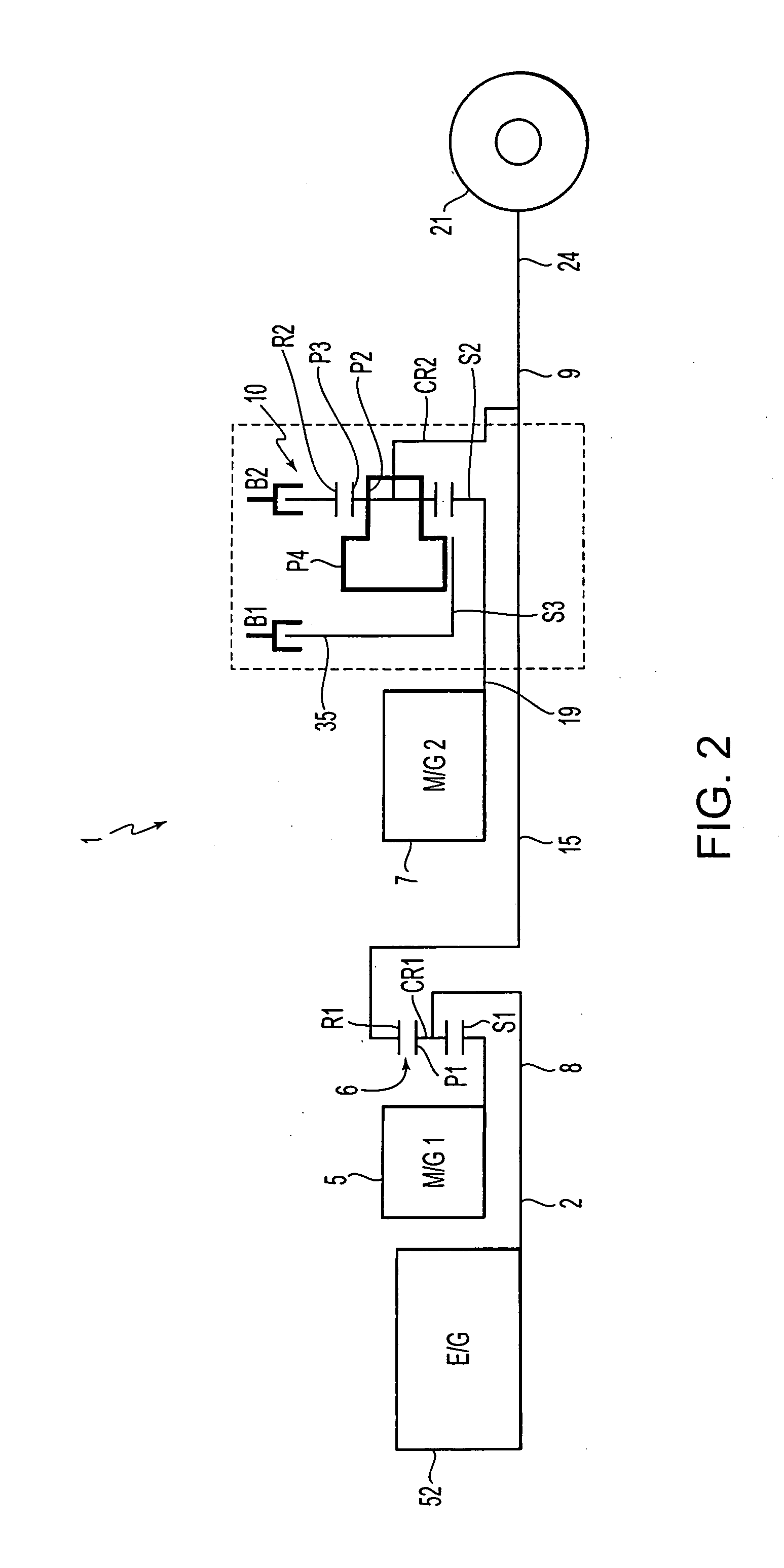

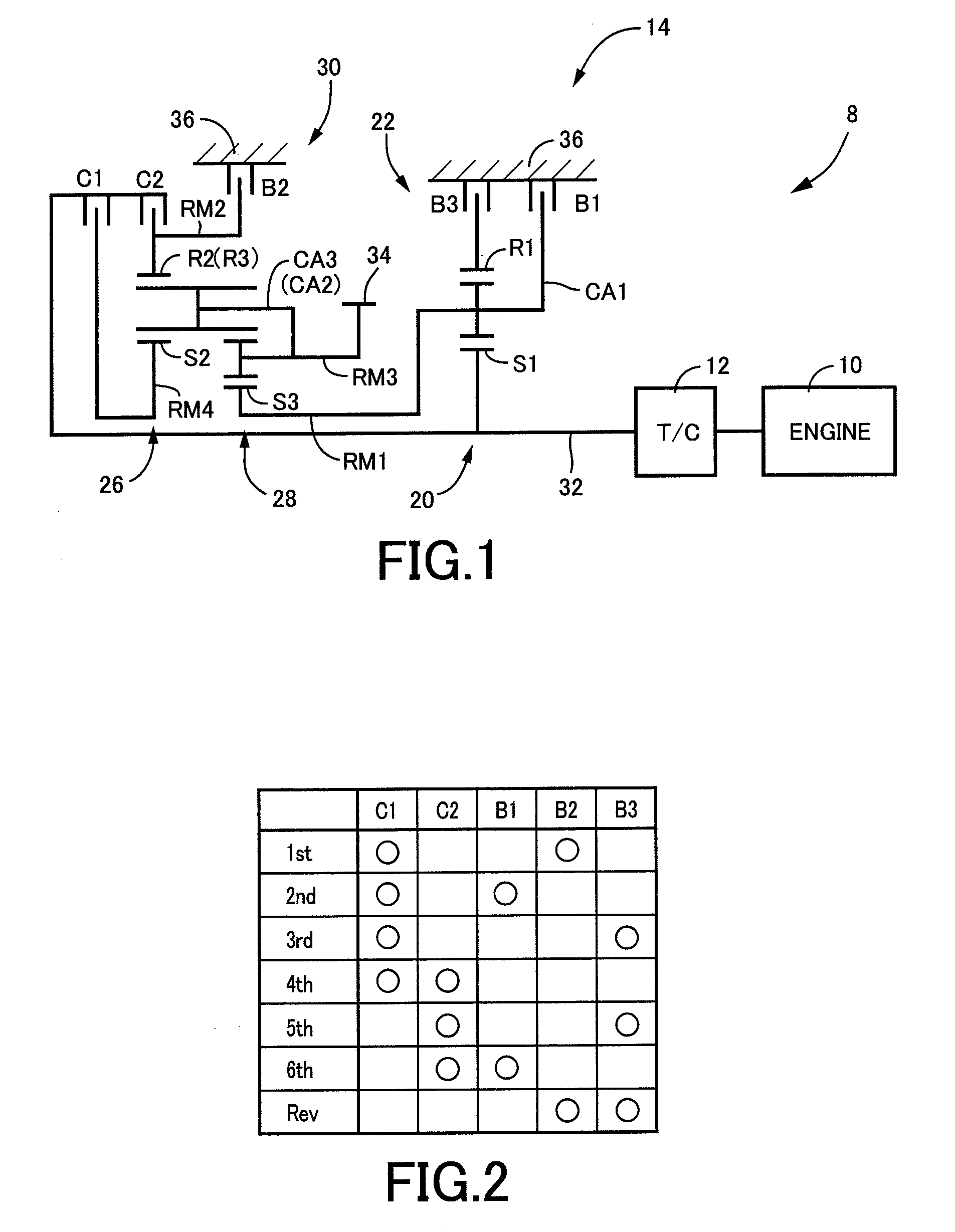

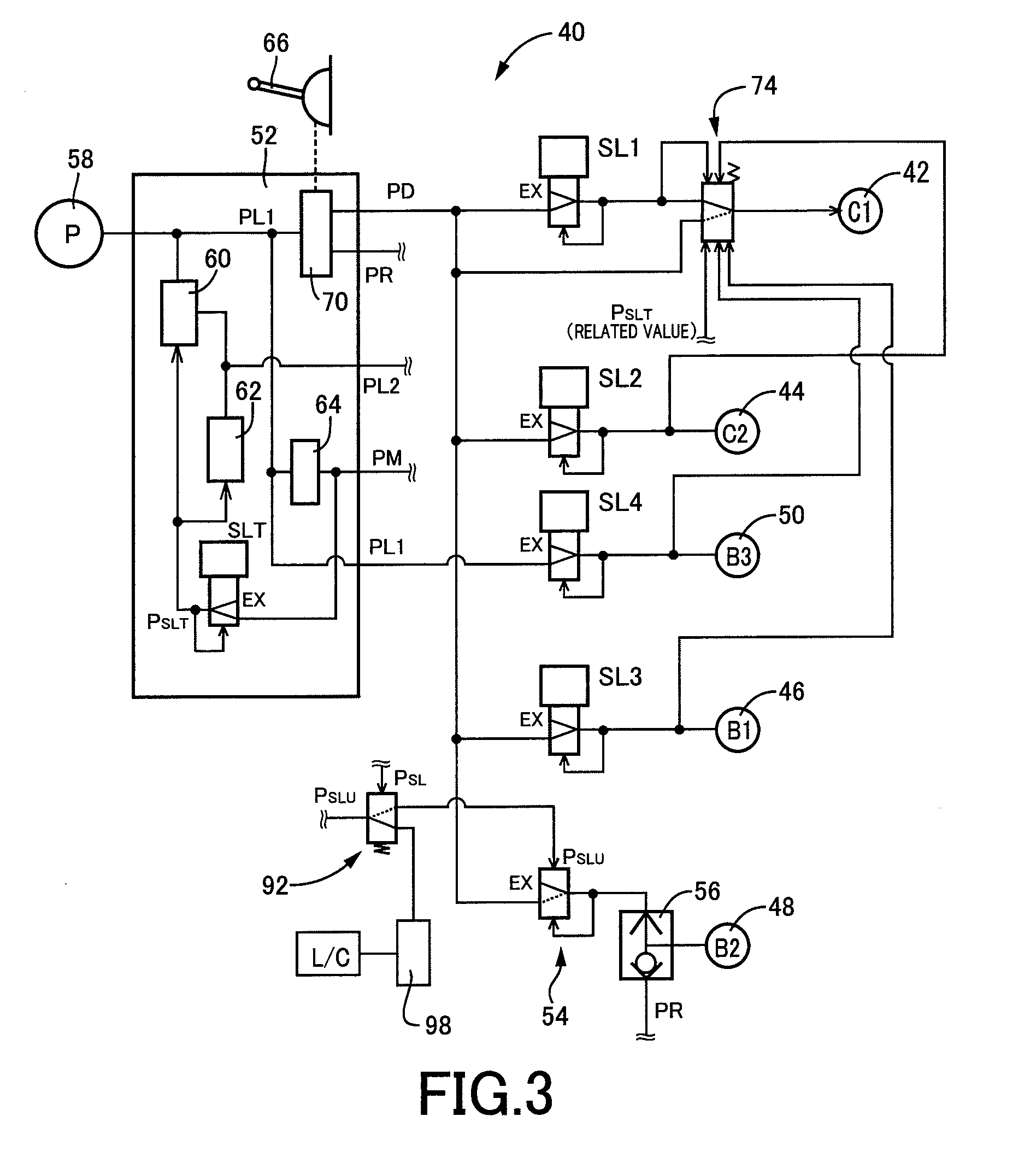

Drive unit for vehicle

ActiveUS7056260B2Reliable pressureAvoid feeling uncomfortableElectric propulsion mountingToothed gearingsOil pressureAutomotive engineering

The drive unit for a vehicle has an engine driving control element for driving a first motor on the basis of an engine driving signal, and driving a second motor so as to restrain a reaction force in a power distributing planetary gear due to the driving of the first motor in a state in which the stepped speed change gear connects the second motor and an output shaft by brakes. Further, the drive unit has an electrically operated oil pump for generating an operating oil pressure of the brakes, and also has a control section having an electrically operated oil pump operation control element for operating the electrically operated oil pump prior to the control of the engine driving control element on the basis of an engine starting signal outputted in a vehicle stopped state.

Owner:AISIN AW CO LTD +1

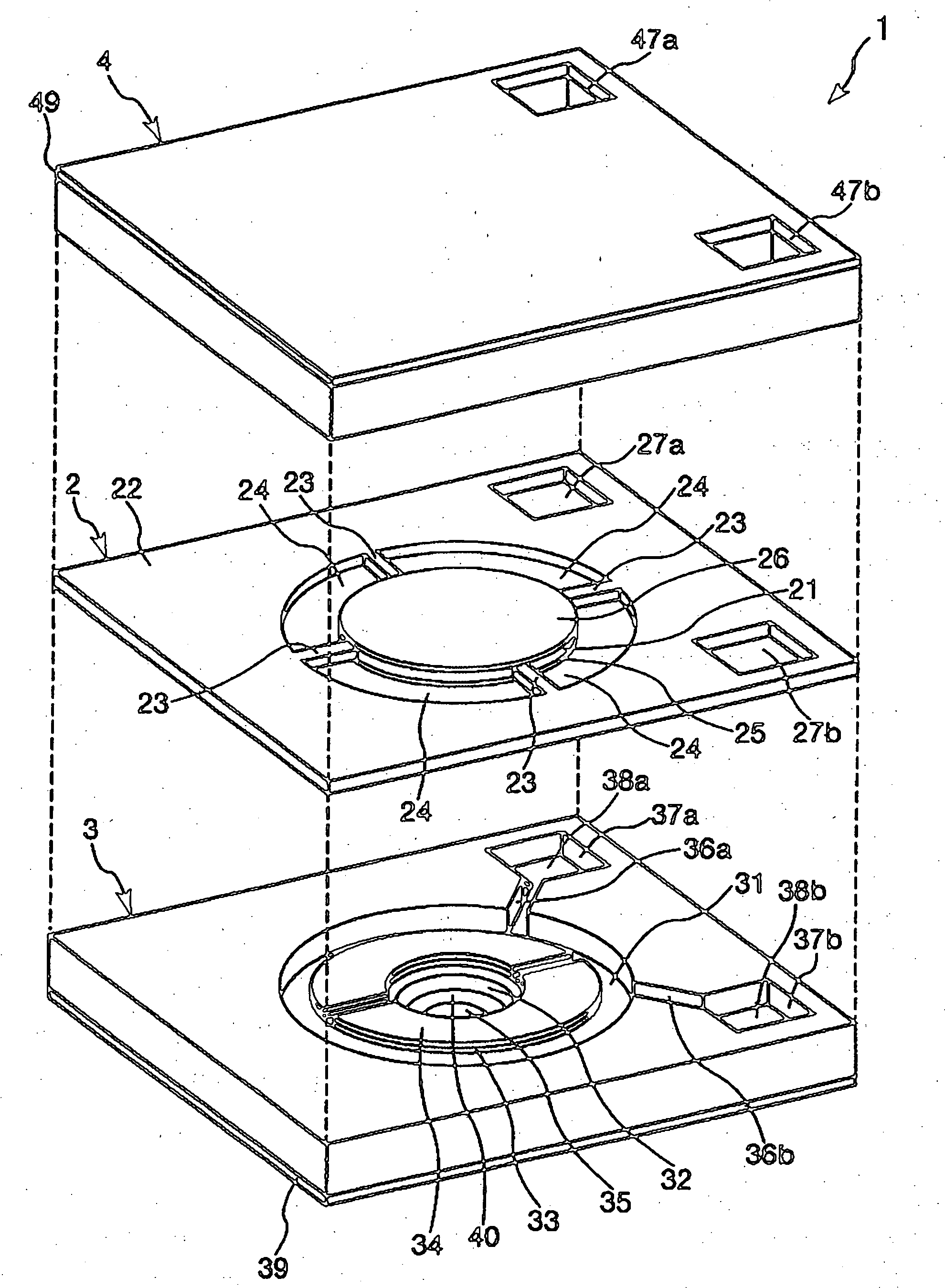

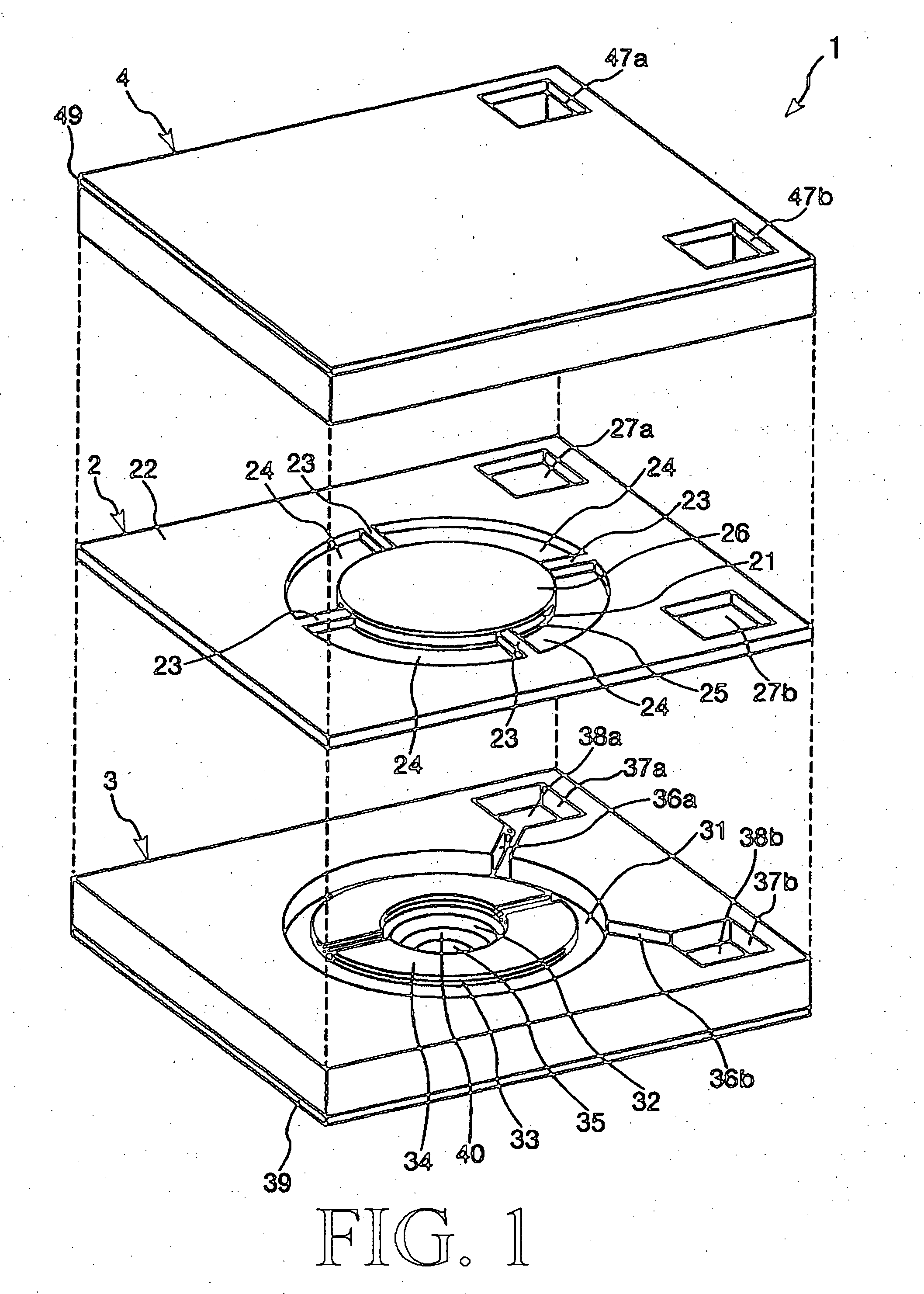

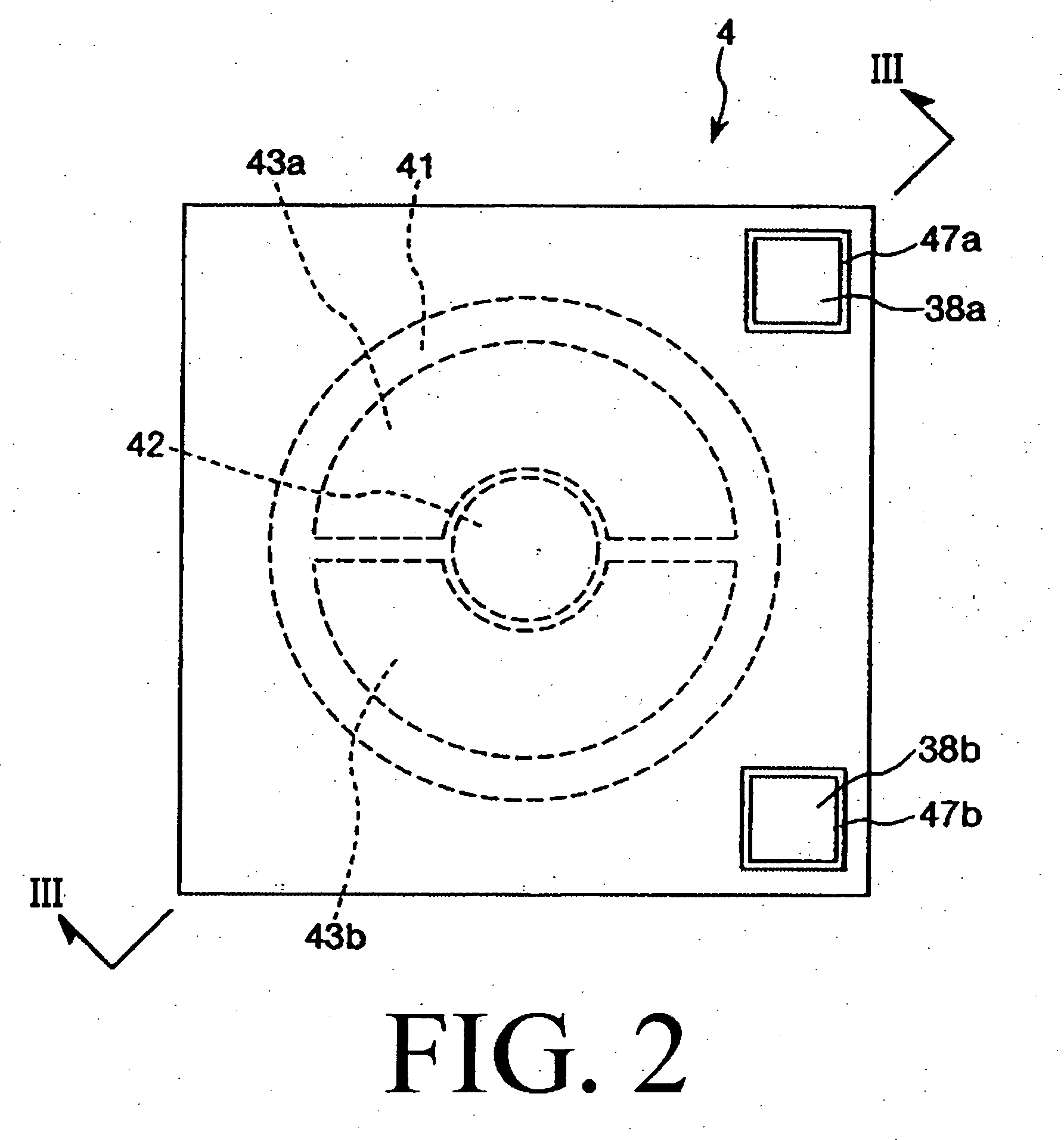

Optical device

InactiveUS20070171531A1Well formedImprove accuracyCoupling light guidesPiezoelectric/electrostrictive devicesPotential differenceLight reflection

An optical device includes a movable portion and a fixed portion having a first light reflection portion. The movable portion has a second light reflection portion facing the first light reflection portion with a first gap. The first and second light reflection portions are configured to reflect light repeatedly between the first and second light reflection portions so as to cause interference and emit light having a wavelength corresponding to a size of the first gap. The optical device includes a first drive electrode portion facing a surface of the movable portion near the first light reflection portion with a second gap between the movable portion and the first drive electrode portion. The optical device has a second drive electrode portion facing another surface of the movable portion with a third gap between the movable portion and the second drive electrode portion. The optical device also includes a circuit operable to generate a potential difference between the first and second drive electrode portions and the movable portion so as to generate an electrostatic attraction force therebetween for changing a position and / or a posture of the movable portion.

Owner:SEIKO EPSON CORP

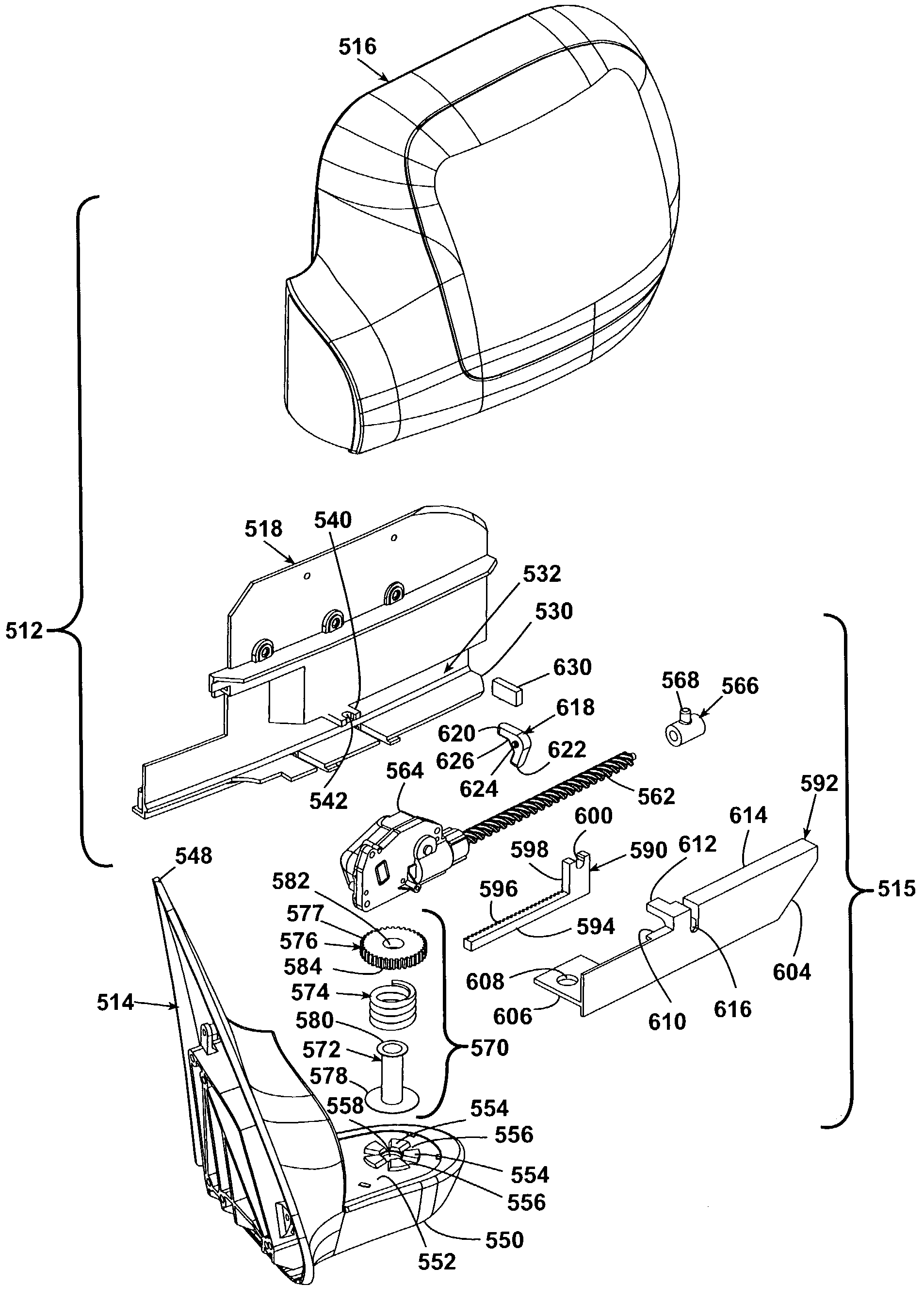

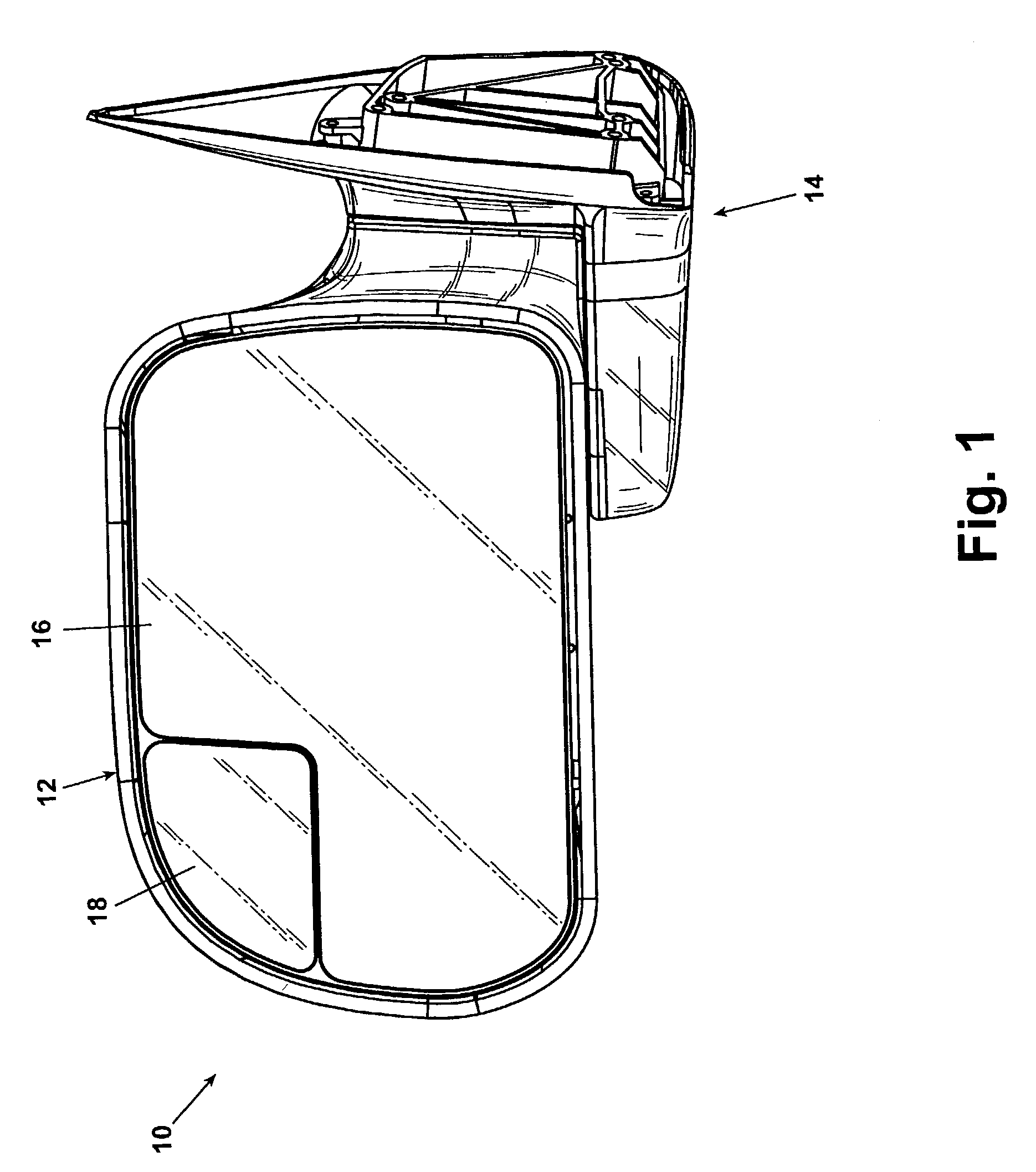

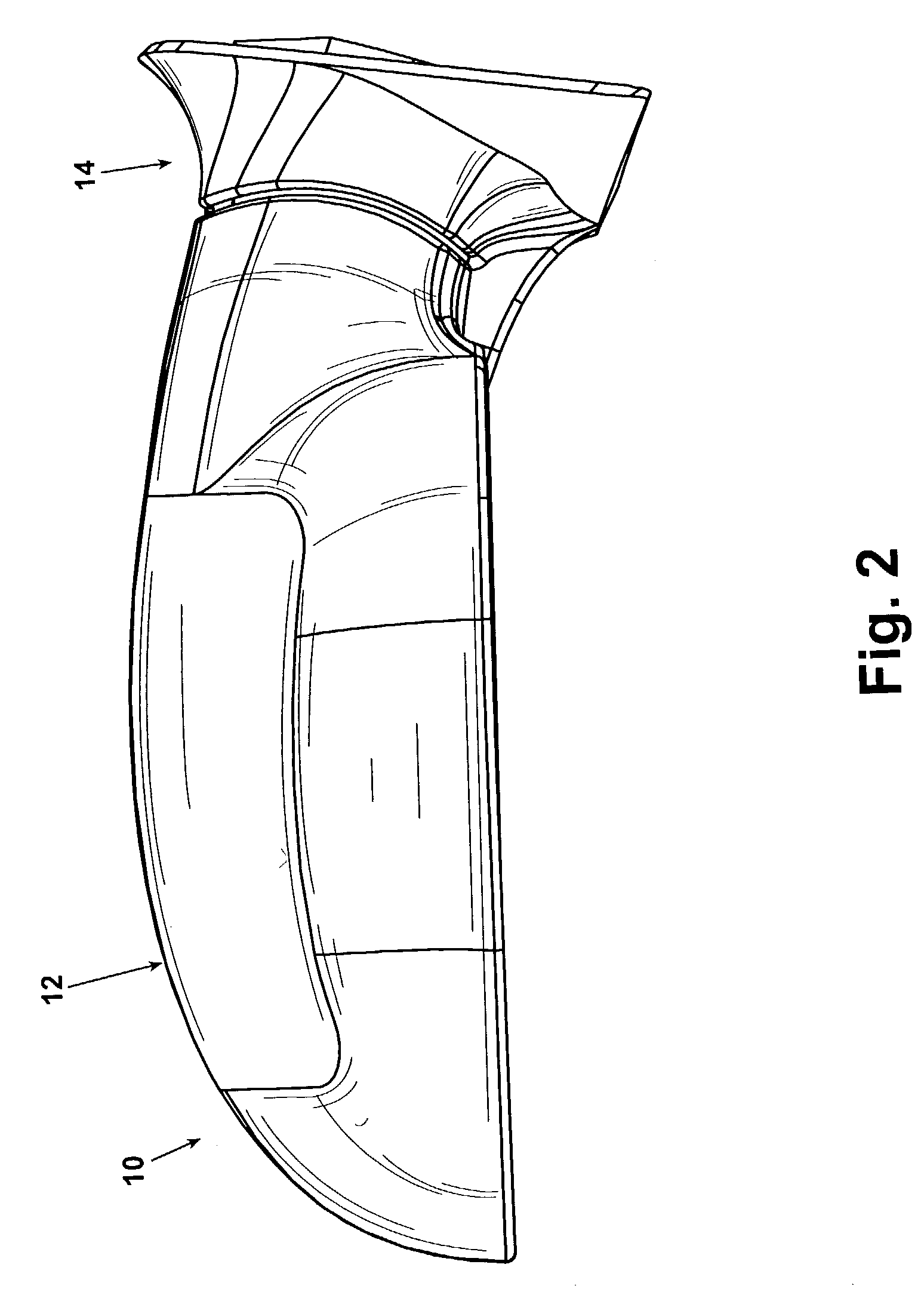

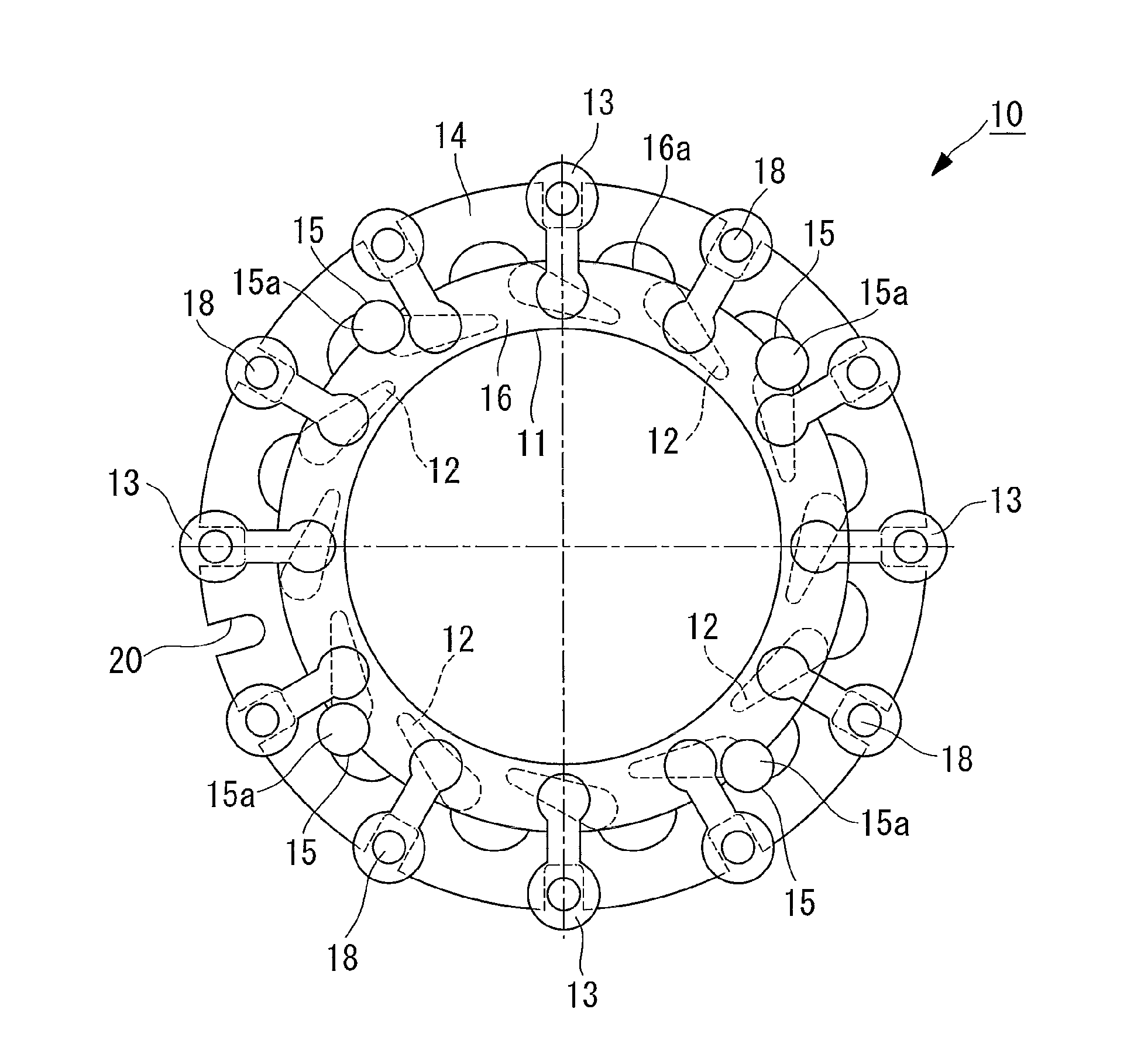

Vehicular mirror system with at least one of power-fold and power-extend functionality

A motorized pivoting and extending mechanism for a vehicular mirror assembly includes, alternatively, a force-reduction mechanism for reducing the friction within the mechanism, and a slip clutch mechanism for reducing overloading of the motor when the limits of mirror extension and retraction have been reached. Mirror power functions receive electrical power and control signals through a circular array of electrical contacts incorporated into the pivot connection irrespective of the pivotal orientation of the mirror. A motor shut-off circuit is able to shut off the motor within a predetermined period of time. The mirror can be angularly adjusted upon movement of the mirror between the retracted and the extended positions to maintain a common field of view for a driver of the vehicle to prevent the extension and / or retraction of the mirror from undesirably repositioning the field of view captured by the mirror.

Owner:MAGNA MIRRORS OF AMERICA INC

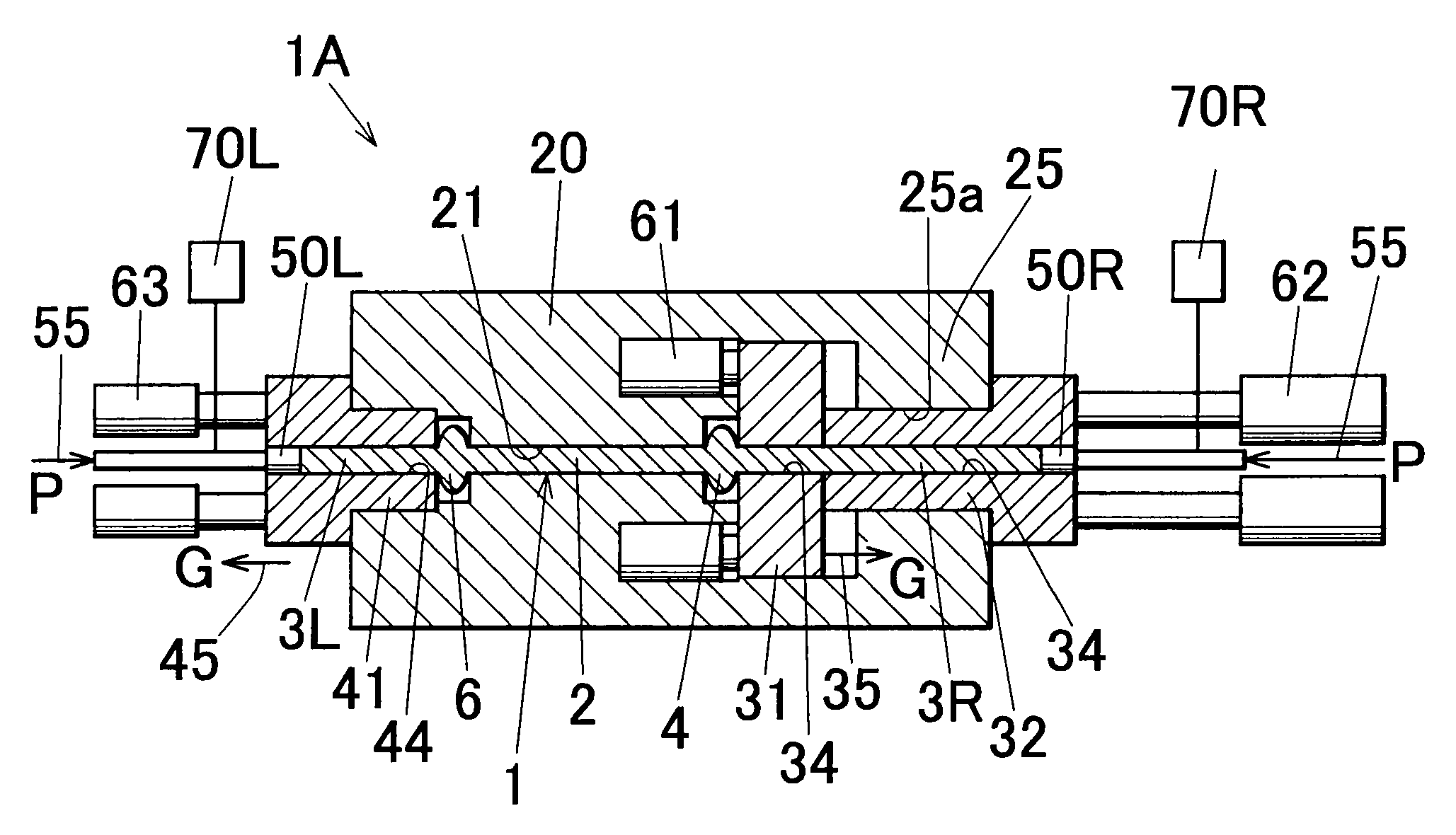

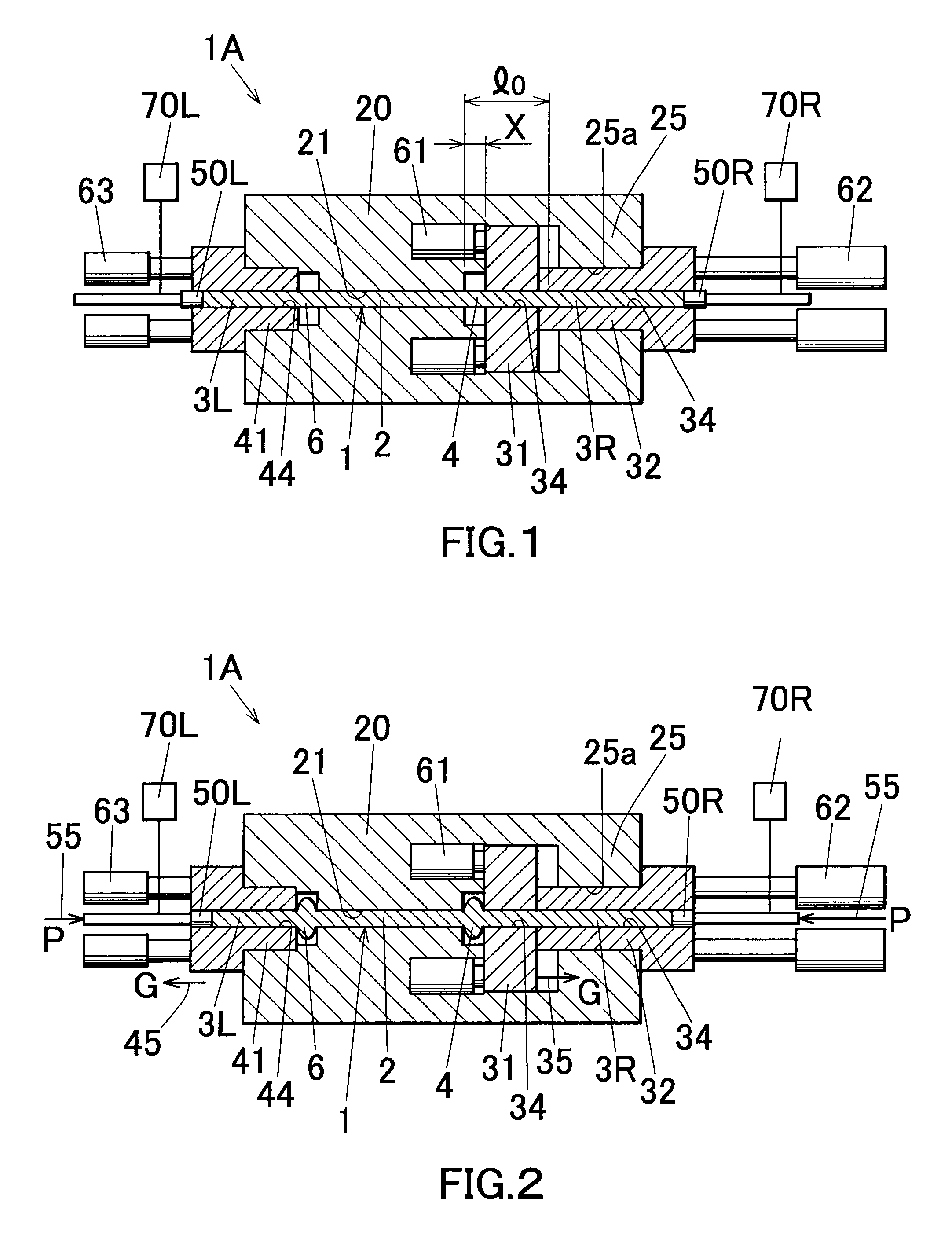

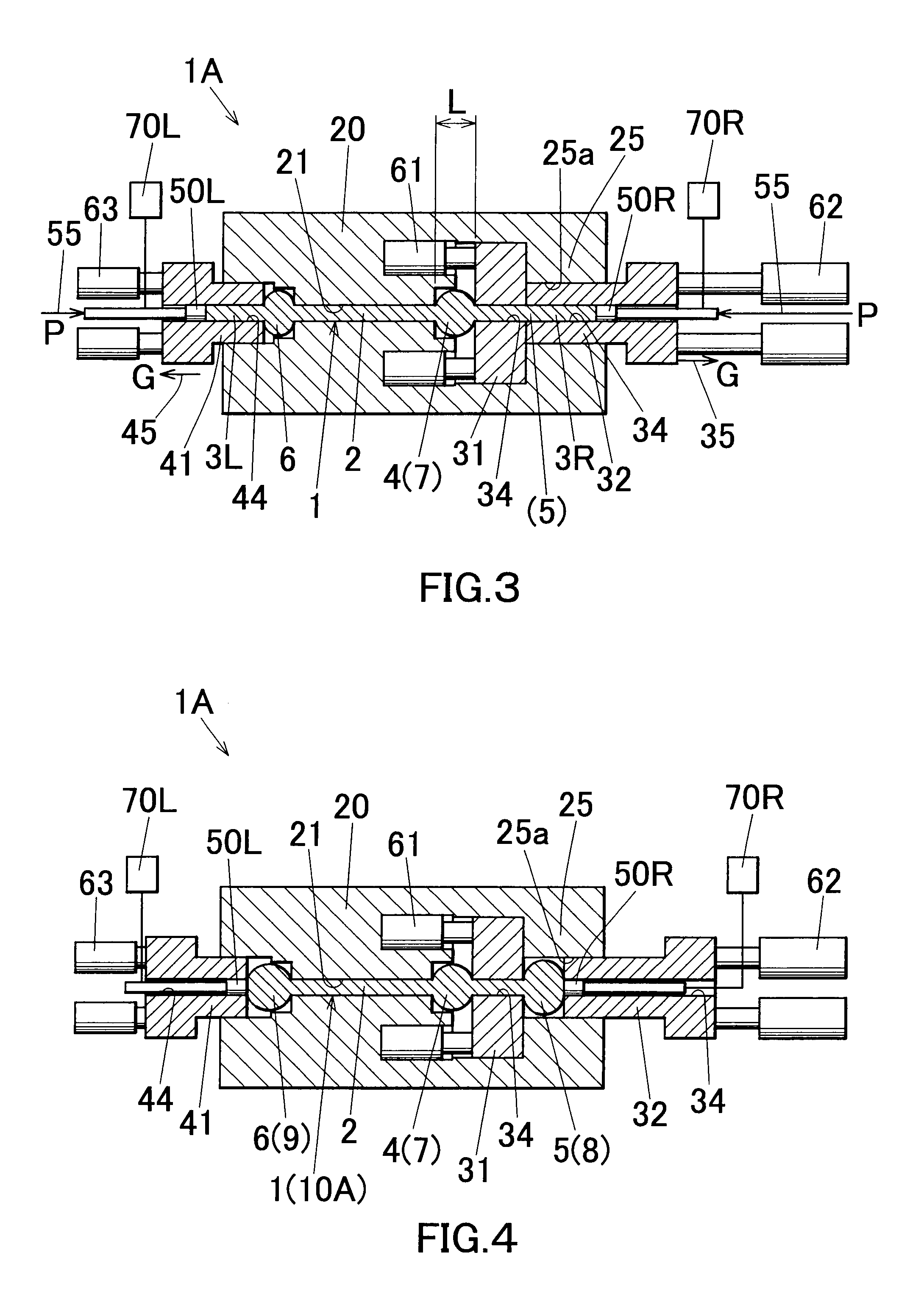

Upsetting method and upsetting apparatus

InactiveUS20080202189A1Efficient executionReduce the driving forceShaping toolsForging hammersMechanical engineeringRaw material

To provide an upsetting method capable of efficiently expanding a bar-shaped raw material at least two portions. A plurality of guides 31 and 32 each having an insertion hole 34 are prepared. The bar-shaped raw material 1 secured to a fixed die 20 is inserted and held in each insertion hole 34 of the plurality of guides 31 and 32 in order. Then, a first exposed portion 4 of the raw material 1 exposed between a first guide 31 located at the foremost side of the plurality of guides 31 and 32 and the fixed die 32 is expanded in diameter by moving the plurality of guides 31 and 32 in a direction opposite to a moving direction of the punch 50R in a mutually adhering manner while pressurizing the raw material 1 in the axial direction with the punch 50R. After completion of the movement of the first guide 31, a second exposed portion of the raw material 1 exposed between both the guides 31 and 32 is expanded in diameter by relatively moving the second guide 32 located behind the first guide 31 among the plurality of guides 31 and 32 in a direction opposite to a moving direction of the punch 50R.

Owner:RESONAC HOLDINGS CORPORATION

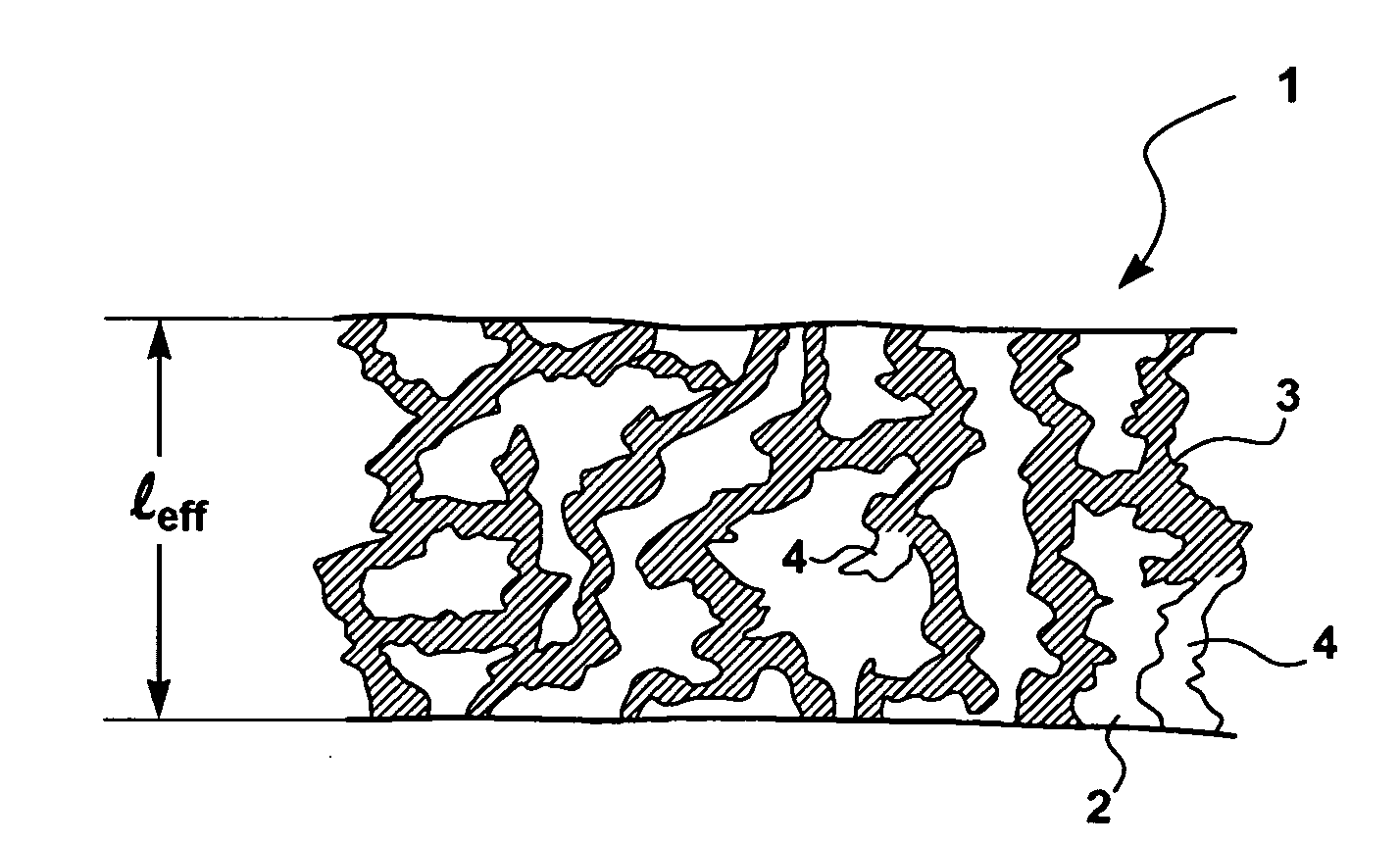

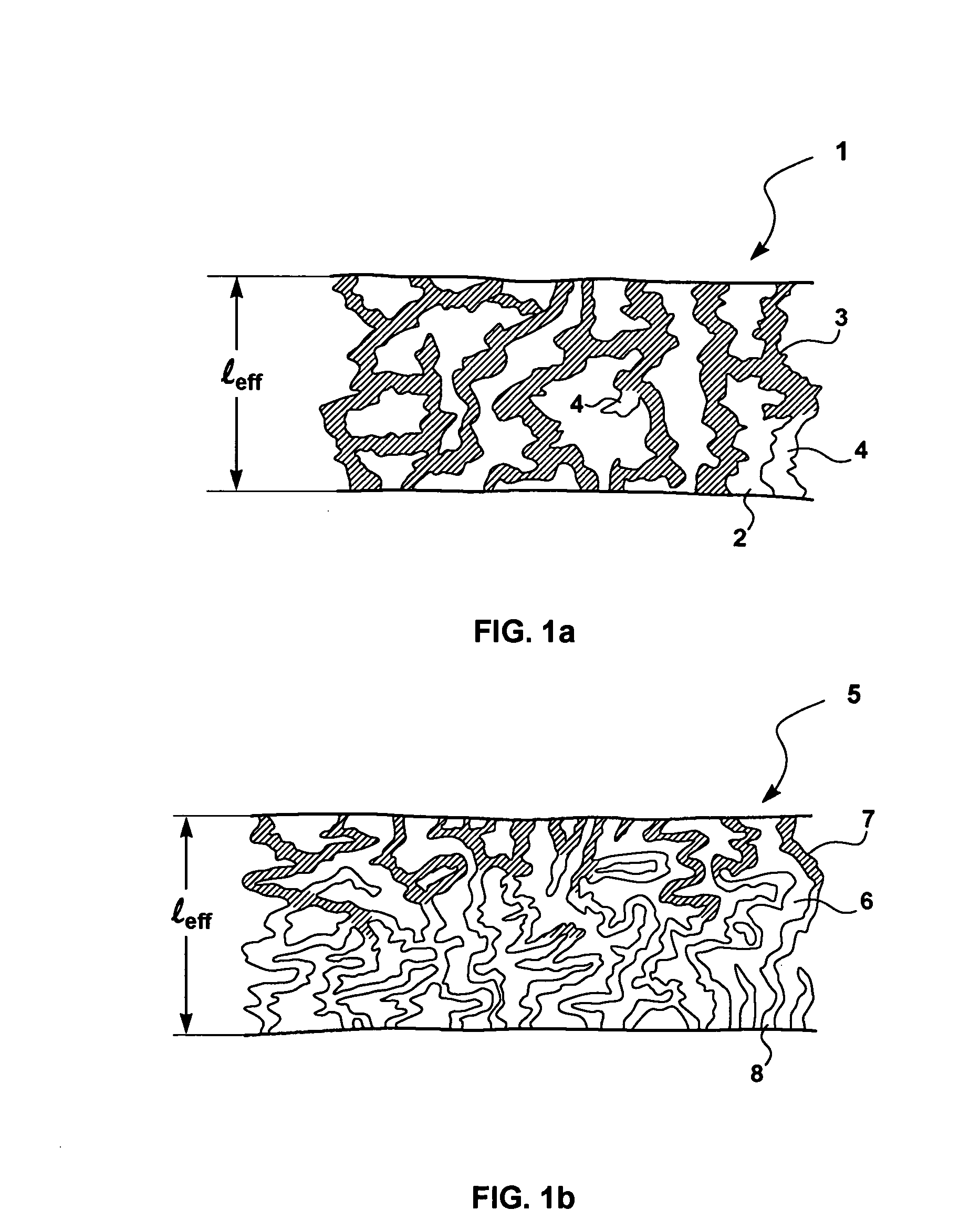

Gas separation membranes and processes for controlled environmental management

InactiveUS20070151447A1Maximum polarizationEasy to transportSemi-permeable membranesMembranesChemical physicsConcentration polarization

A gas-separation membrane, membrane module and membrane process for controlling humidity in an environment. The membrane has a porous support zone impregnated by a selective zone, a configuration that reduces concentration polarization within the membrane itself when the membrane is housed in the module and used in the process.

Owner:MEMBRANE TECH & RES

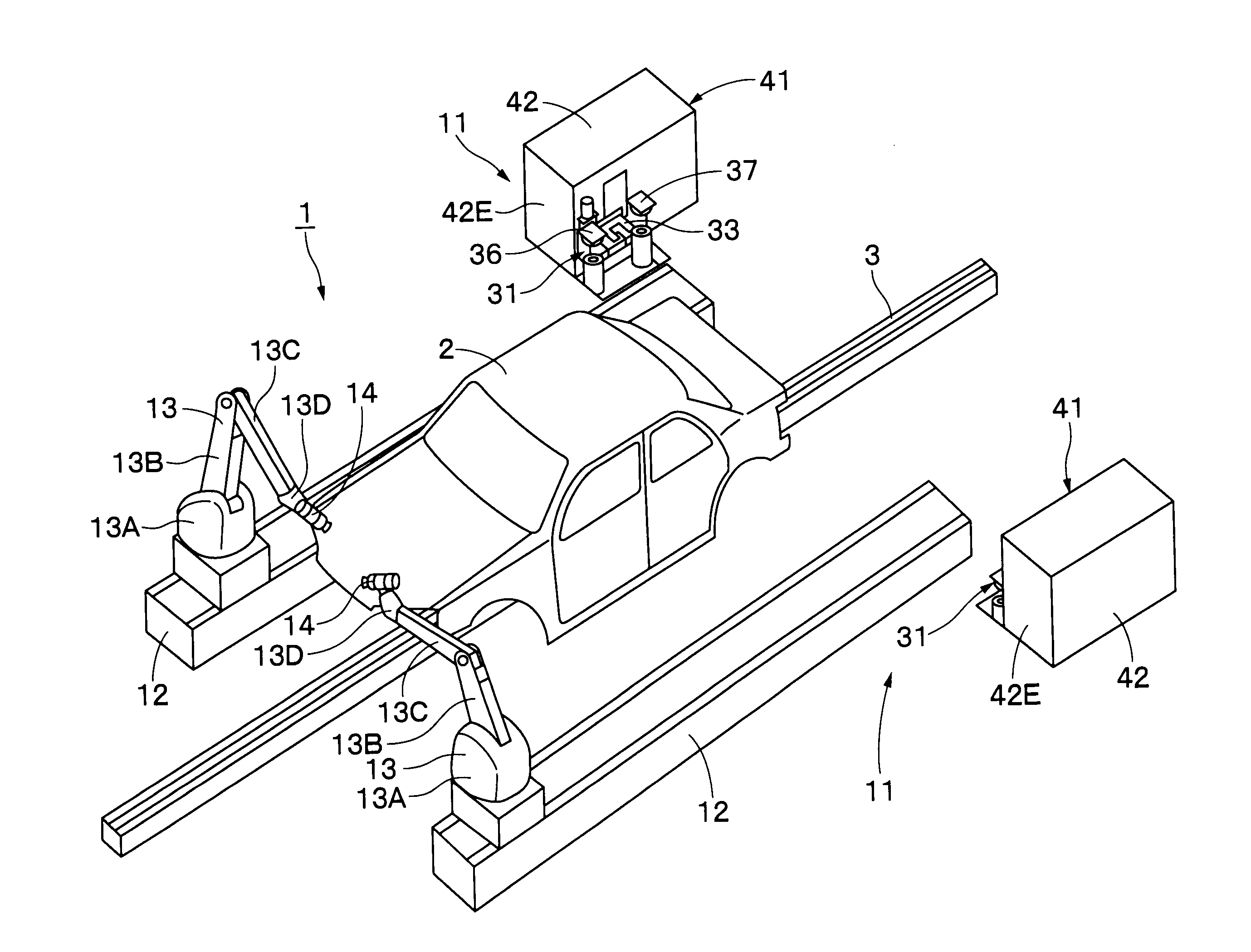

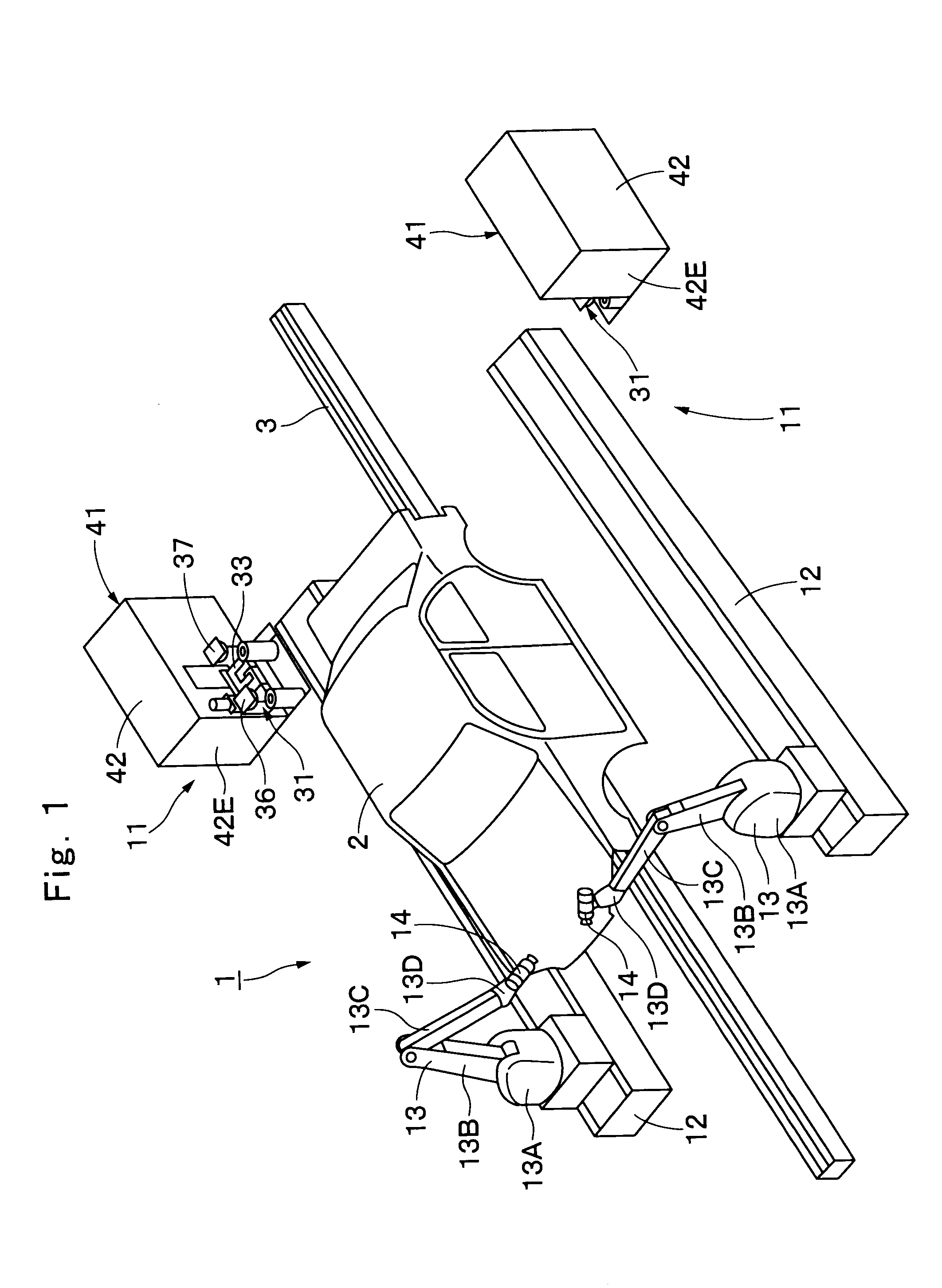

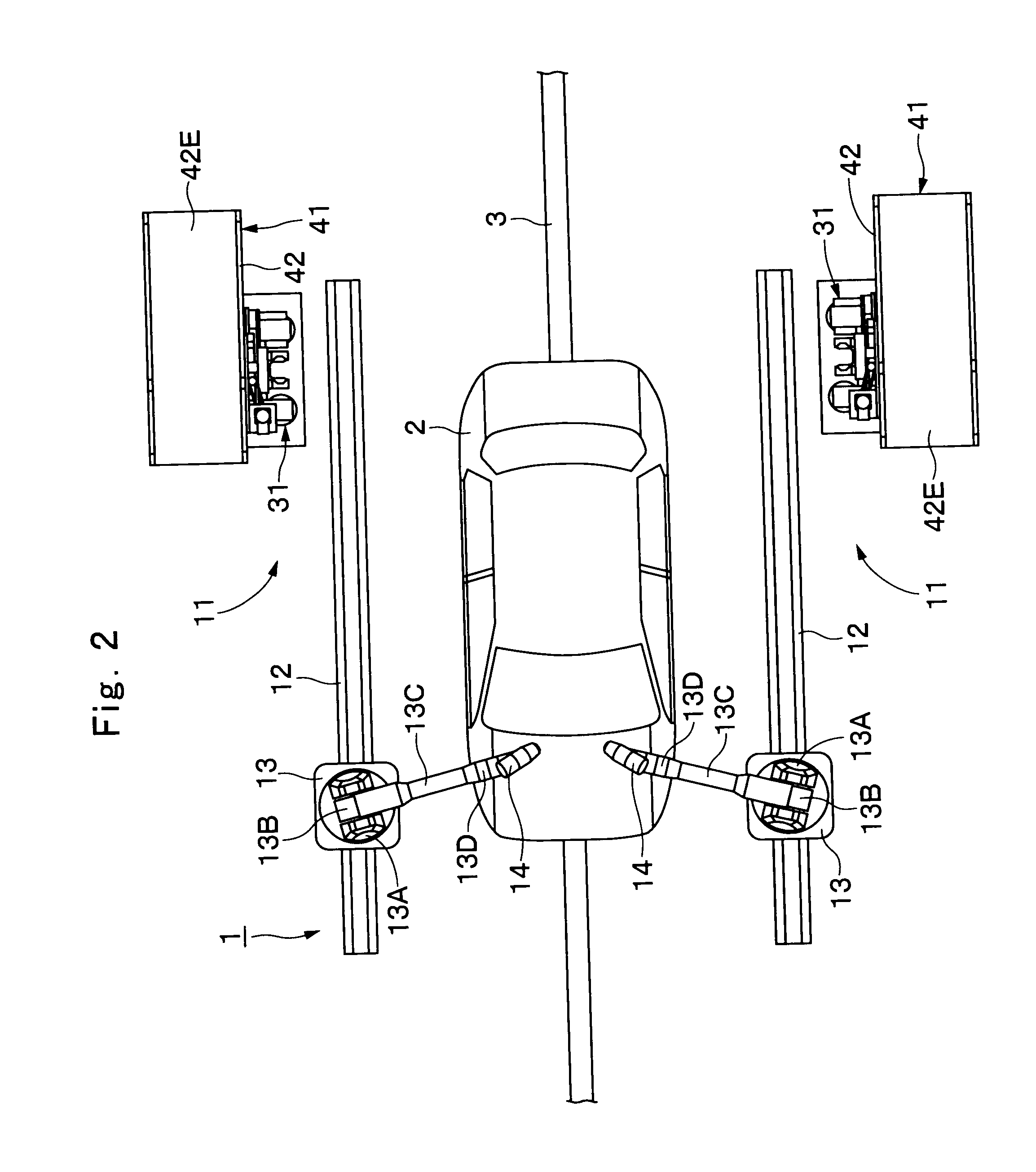

Paint coating system

InactiveUS20100230511A1Reduce total powerAccurate settingProgramme-controlled manipulatorLiquid surface applicatorsPower modeCoating system

A common body (15) of a coater unit (14) is mounted on a robot device (13). A common body gripper (33) is fixedly mounted on a fixed plate (32) of an atomizing head changing and washing device (31). At the time of replacing a used atomizing head (19′) and a used paint cartridge (24′) by a washed atomizing head (19) and a replenished paint cartridge (24), respectively, the common body (15) is gripped and located in a predetermined position by the common body gripper (33). When the common body (15) is gripped by the common body gripper (33), the robot device (13) is put in a reduced power mode attenuating driving forces to leave said common body (15) in a freely movable state by application of an external force.

Owner:ABB IND

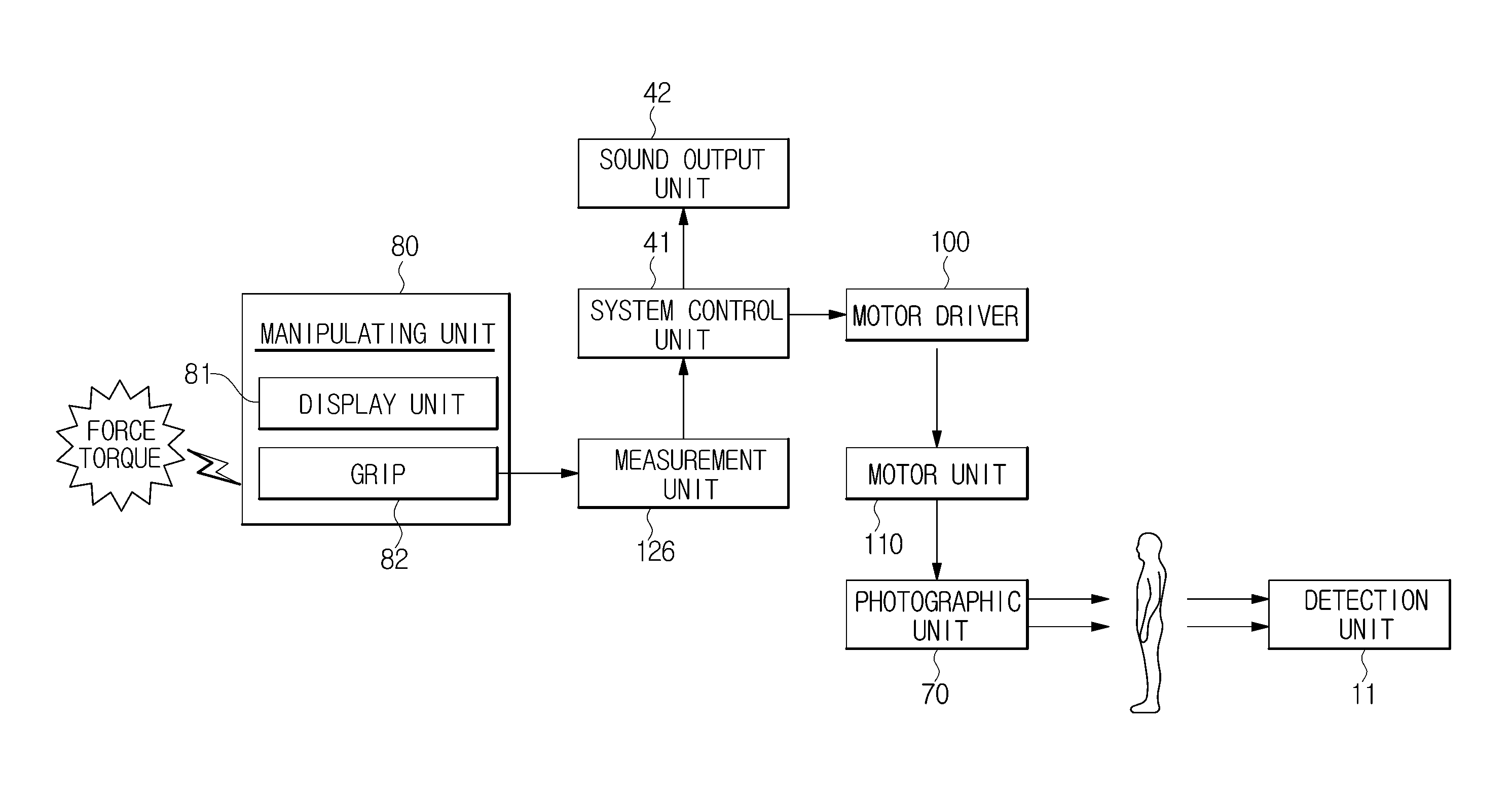

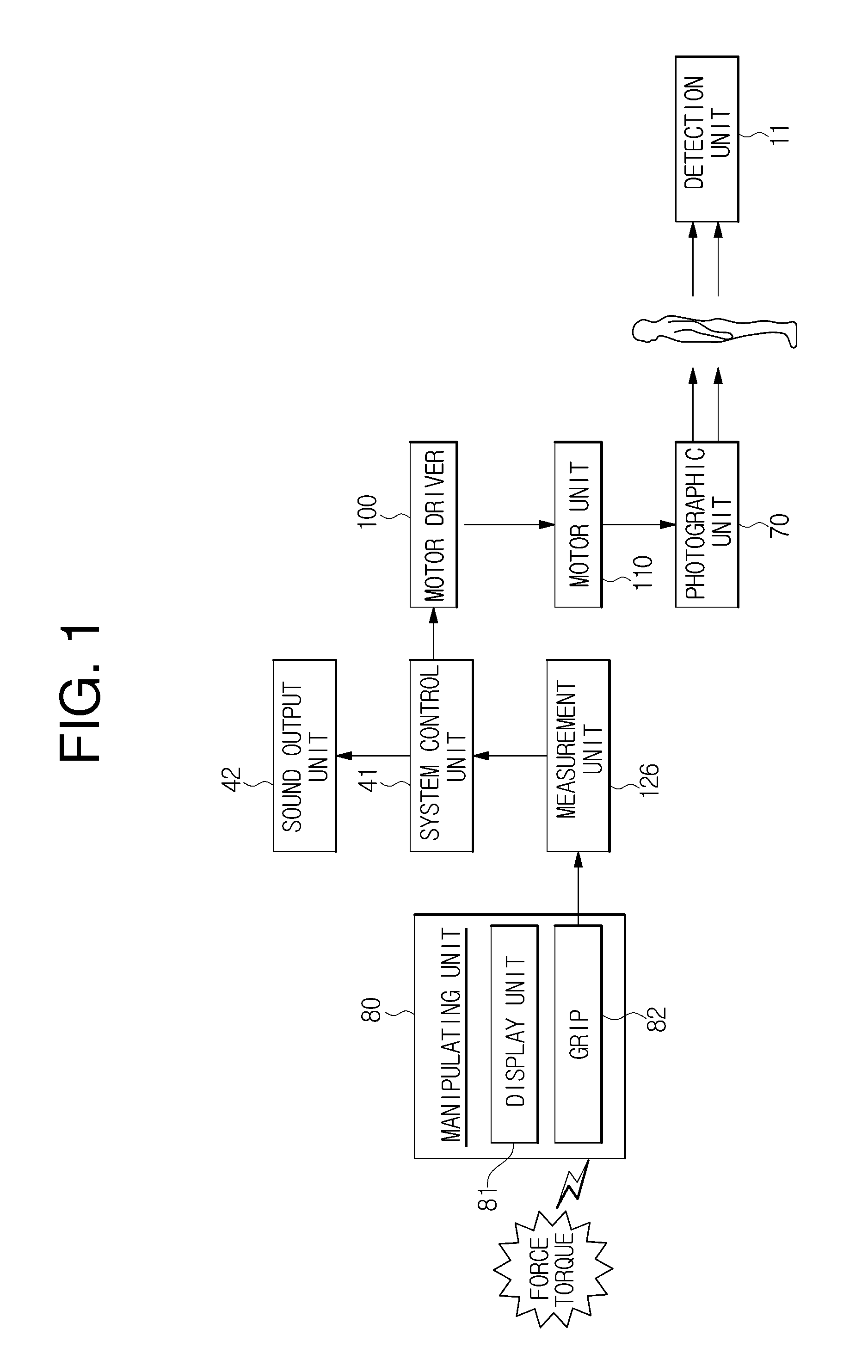

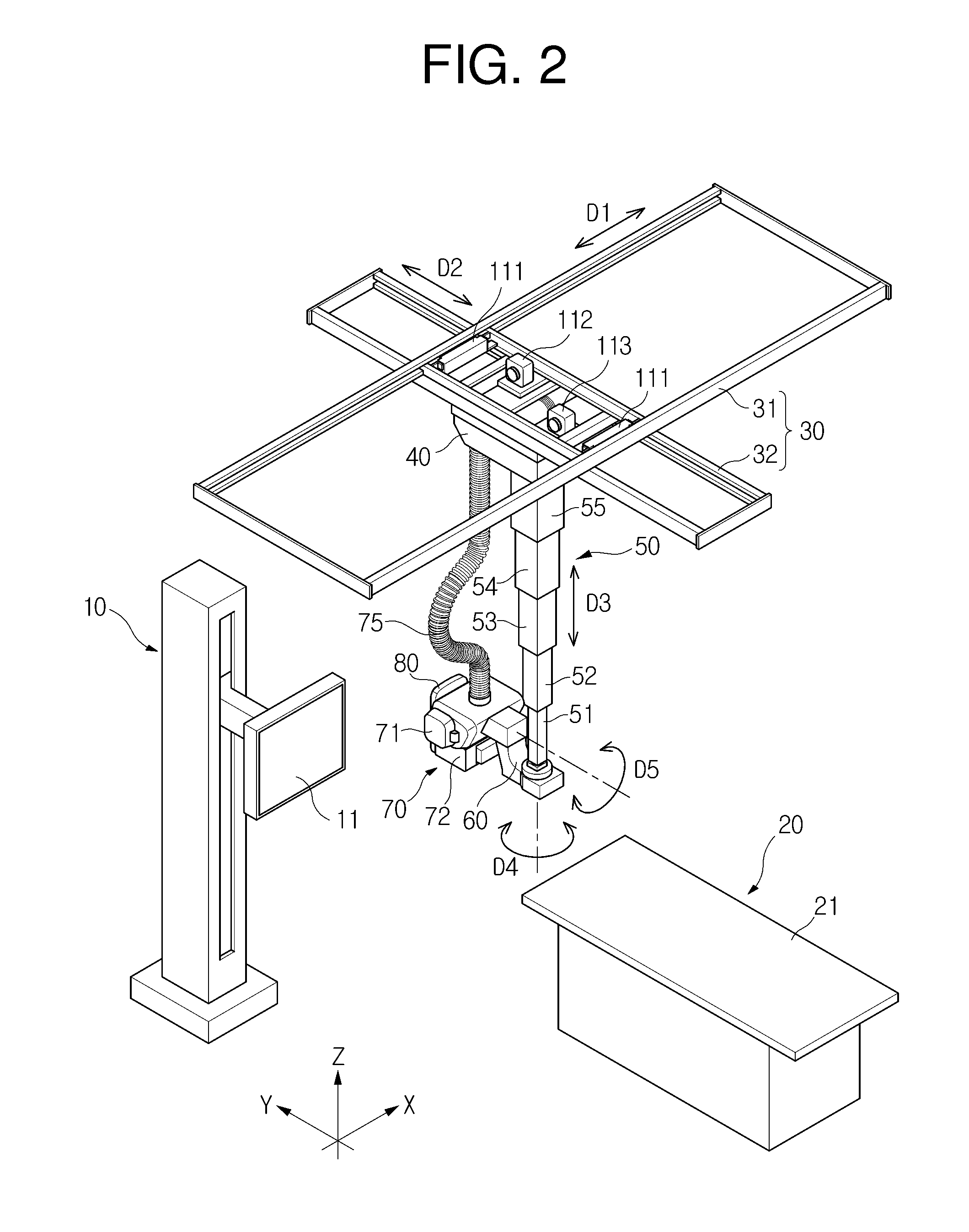

Radiographic system and control method thereof

ActiveUS20140328456A1Reduce the driving forceDuplicating/marking methodsSurgeryEngineeringElectrical and Electronics engineering

A radiographic system includes a photographic unit; an operating panel including a button configured to be pressed to indicate that a movement direction of the photographic unit is to be limited to a specific movement direction; a measurement unit provided between the operating panel and the photographic unit and configured to measure a magnitude and a direction of an external force applied to the operating panel; and a drive unit configured to move the photographic unit only in the specific movement direction based on the magnitude and the direction of the external force measured by the measurement unit in response to the button being pressed.

Owner:SAMSUNG ELECTRONICS CO LTD

Engine starter designed to have enhanced stability of engagement of pinion with ring gear

InactiveUS20060201266A1Reduce the total massDecrease torsional rigidityPower operated startersPlastic/resin/waxes insulatorsGear wheelEngineering

A starter for automotive engines is provided which is equipped with a pinion carrier which is shifted by a magnetic attraction, as transmitted from a solenoid switch through a shift lever, to establish engagement of a pinion with a ring gear jointed to the engine. If thrust acting on the pinion carrier to urge the pinion against the ring gear through when the pinion has been shifted and hit the ring gear, so that the pinion is placed in abutment with the ring gear is defined as N (Newton), and the mass of the pinion carrier is defined as g (gram), a relation of g / N≦6 is met. This improves the ability of engagement of the pinion with the ring gear, thus resulting in an increased life span of the starter.

Owner:DENSO CORP

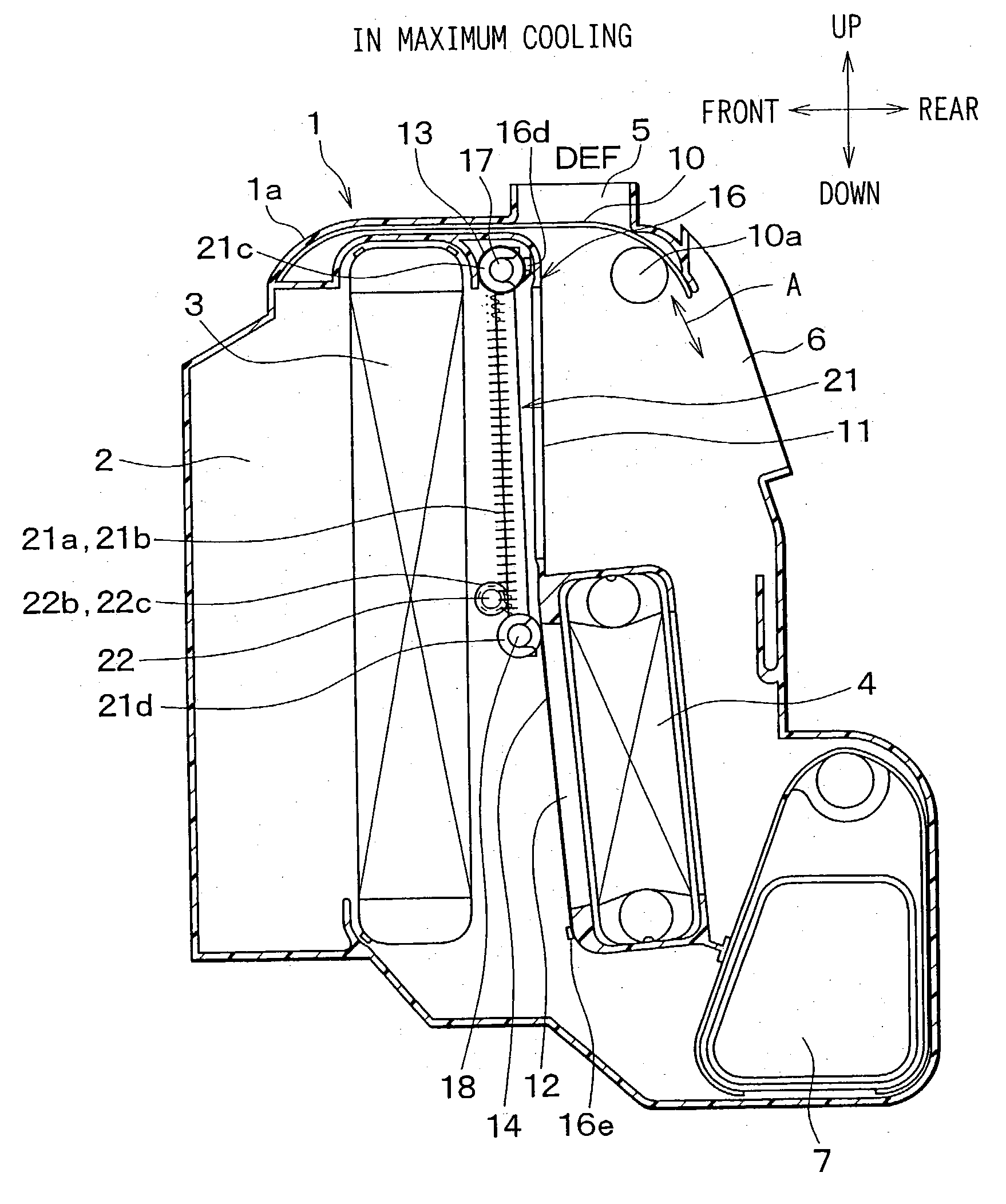

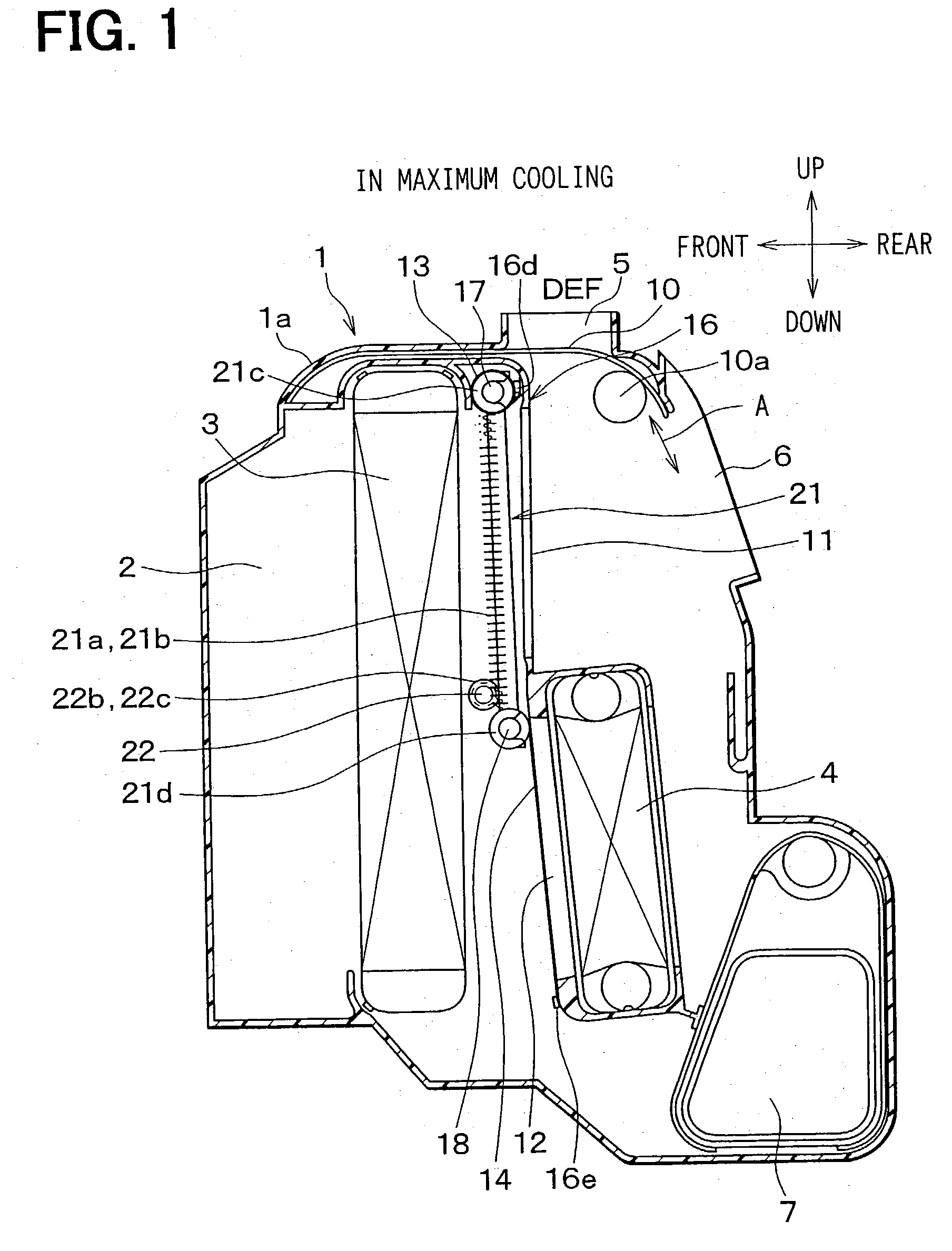

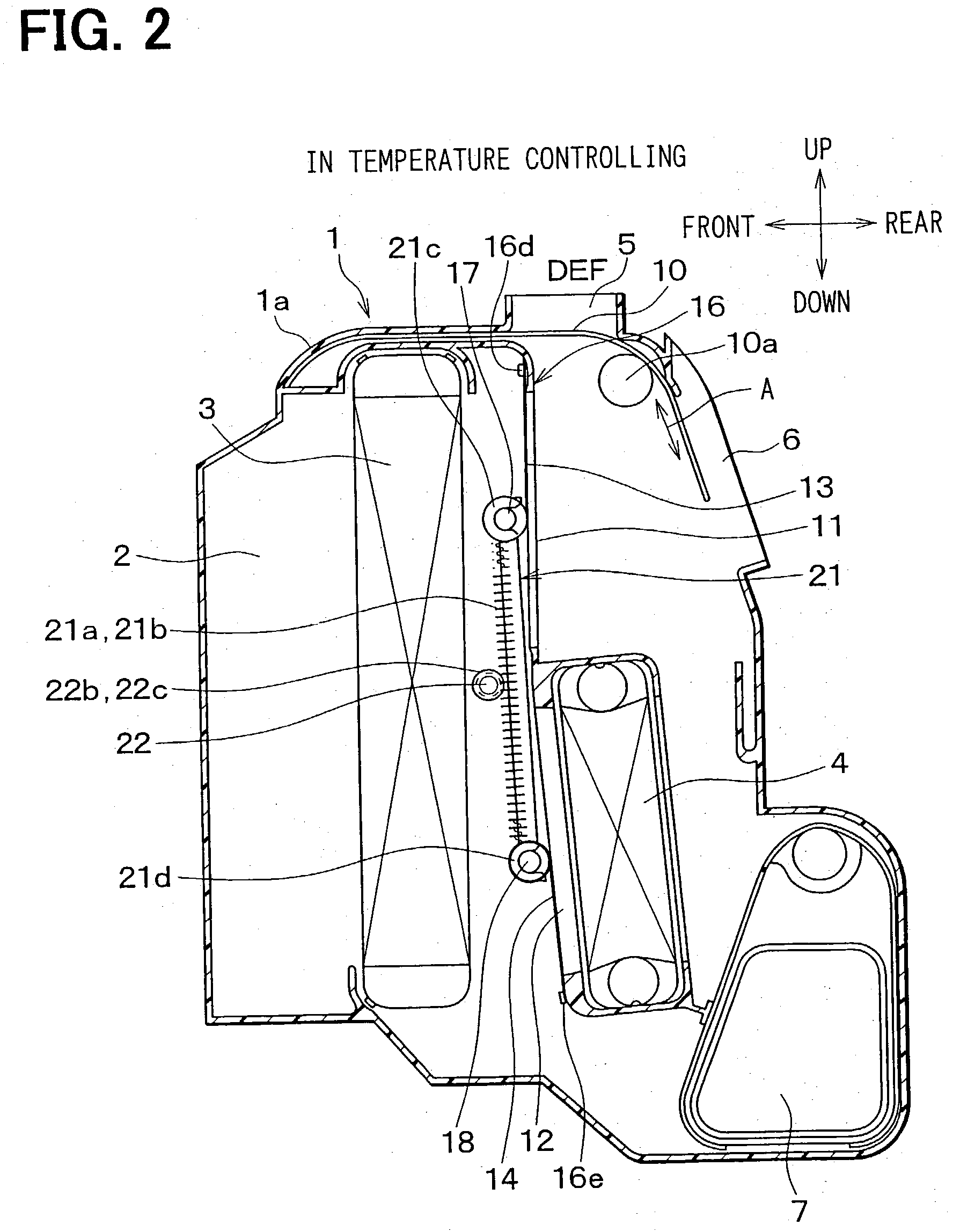

Air-passage opening/closing device

ActiveUS20030232590A1Avoid sliding frictionLow costAir-treating devicesOperating means/releasing devices for valvesDrive shaftEngineering

An air passage opening / closing device includes a film member for opening and closing an opening of an air passage of a case. One end of the film member is fixed to a fixing portion on an outer periphery of the opening of the air passage, and the other end thereof is connected to a film winding shaft. A moving member movable by rotation of a drive shaft is provided on the opening, and the film winding shaft is moved while being rotated by the movement of the moving member, so that the film member at the other end side is wound around and unwound from the film winding shaft. Accordingly, when the air passage is opened and closed by the film member, sliding friction can be prevented from being generated between the film member and the case.

Owner:DENSO CORP

Drive unit for vehicle

ActiveUS20050124457A1Inhibition is effectiveIncrease speedElectric propulsion mountingToothed gearingsOil pressureAutomotive engineering

The drive unit for a vehicle has an engine driving control element for driving a first motor on the basis of an engine driving signal, and driving a second motor so as to restrain a reaction force in a power distributing planetary gear due to the driving of the first motor in a state in which the stepped speed change gear connects the second motor and an output shaft by brakes. Further, the drive unit has an electrically operated oil pump for generating an operating oil pressure of the brakes, and also has a control section having an electrically operated oil pump operation control element for operating the electrically operated oil pump prior to the control of the engine driving control element on the basis of an engine starting signal outputted in a vehicle stopped state.

Owner:AISIN AW CO LTD +1

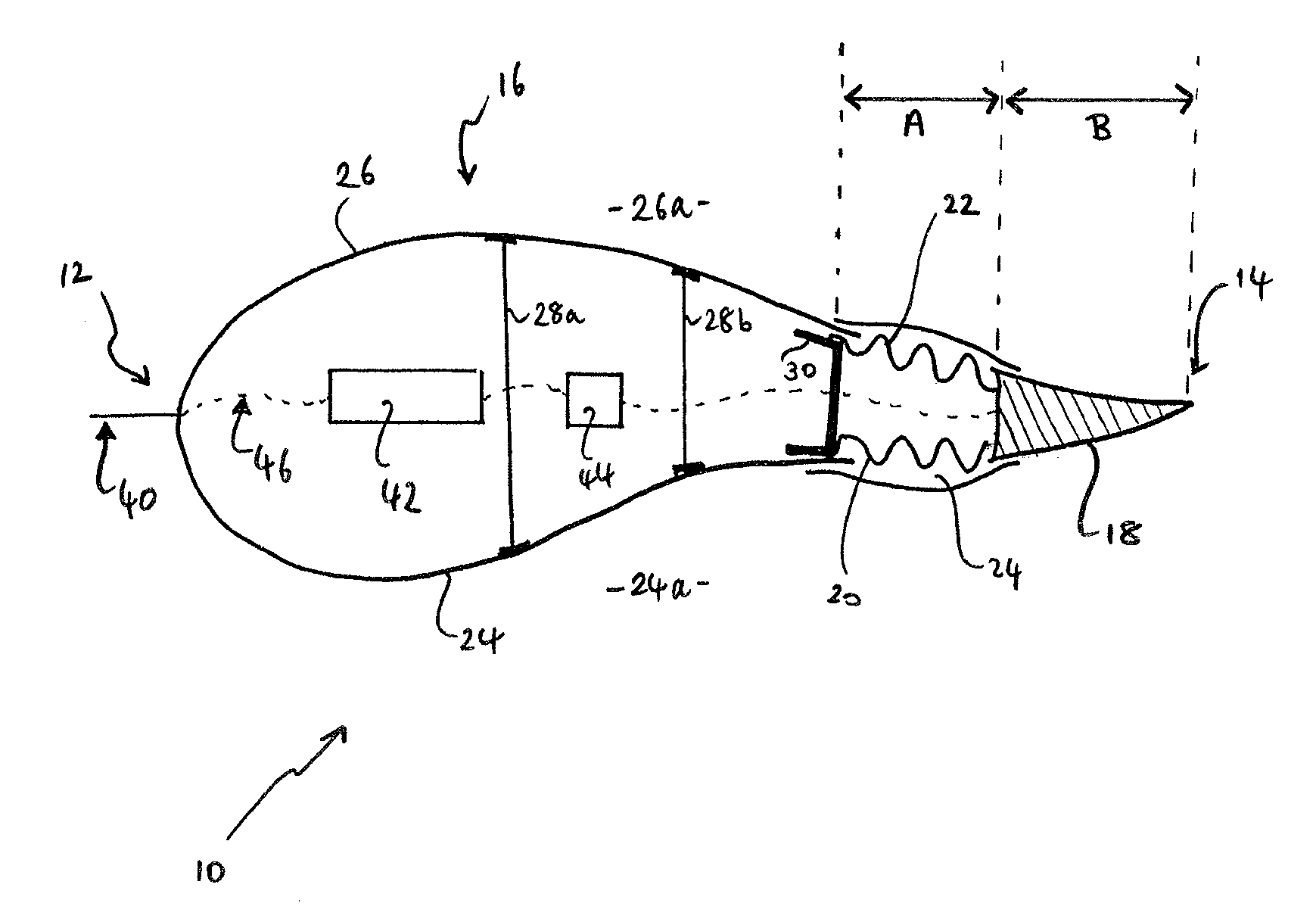

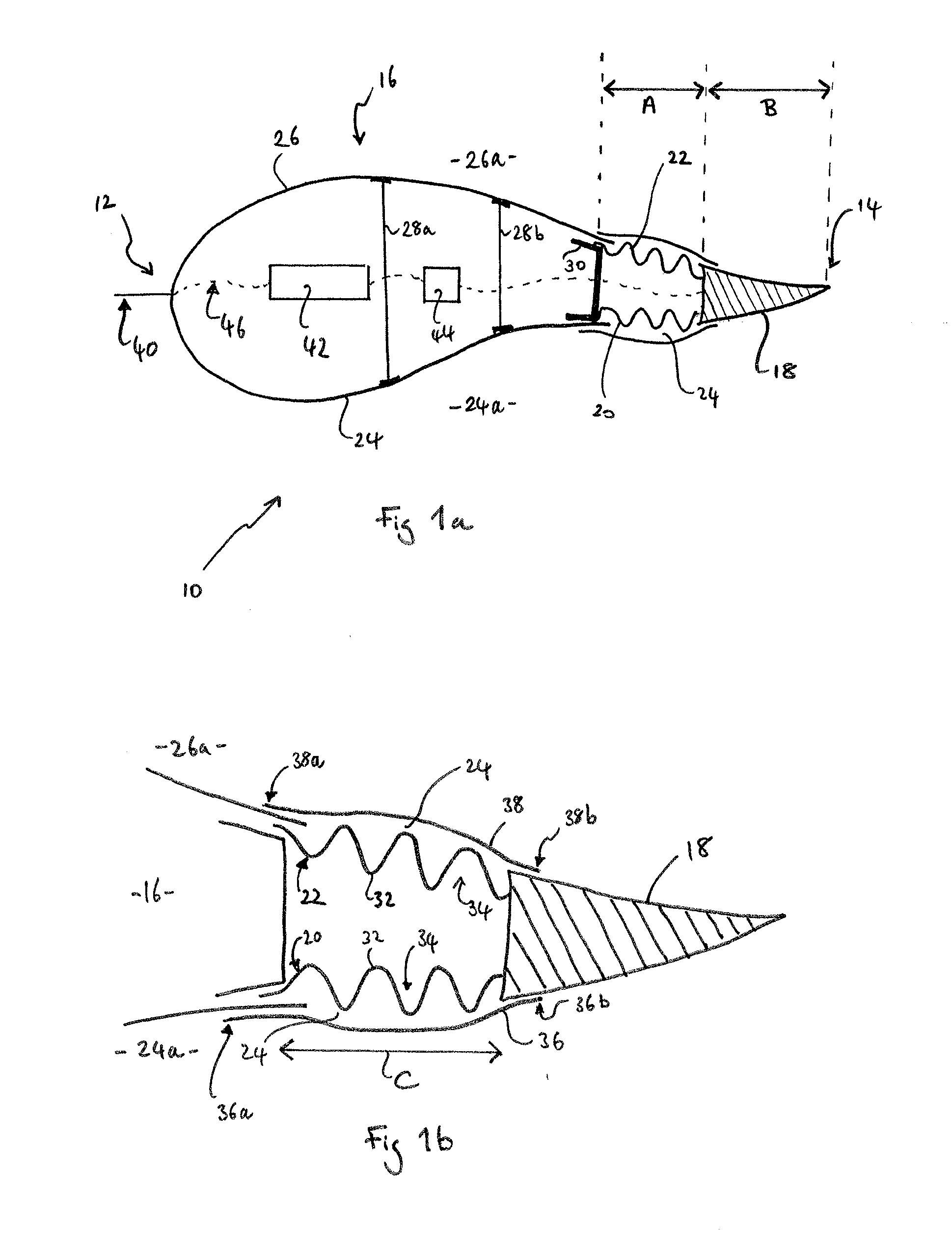

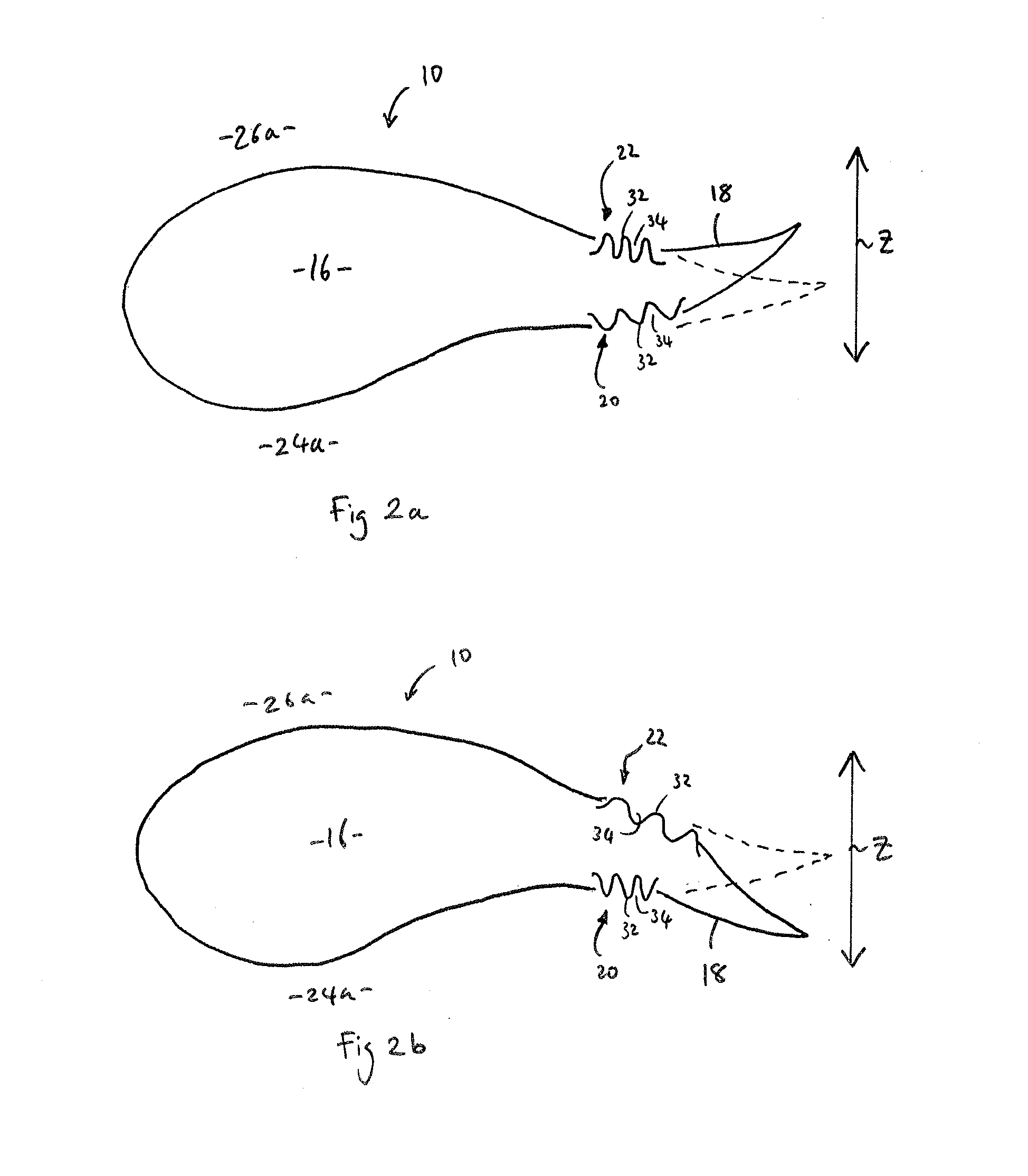

Wind turbine rotor blade

ActiveUS20120169060A1Improve aerodynamic performanceShort lifePropellersWind motor controlLeading edgeTurbine blade

A wind turbine blade is described, which extends in a spanwise direction from a root end to a tip end and defines an aerodynamic airfoil cross-section between a leading edge and a trailing edge in a chordwise direction transverse to the spanwise direction. The blade has a camber in the chordwise direction and includes a blade body and a moveable flap. The flap is moveable relative to the blade body to vary the camber of the blade. A deformable panel is located between the blade body and the moveable flap. The panel has an undulating profile comprising an alternating succession of ridges and troughs, which each extend in a first direction. The panel is formed of a material having anisotropic intrinsic stiffness with maximum anisotropic intrinsic stiffness being transverse to the first direction. In a preferred embodiment, the deformable panel is corrugated.

Owner:VESTAS WIND SYST AS

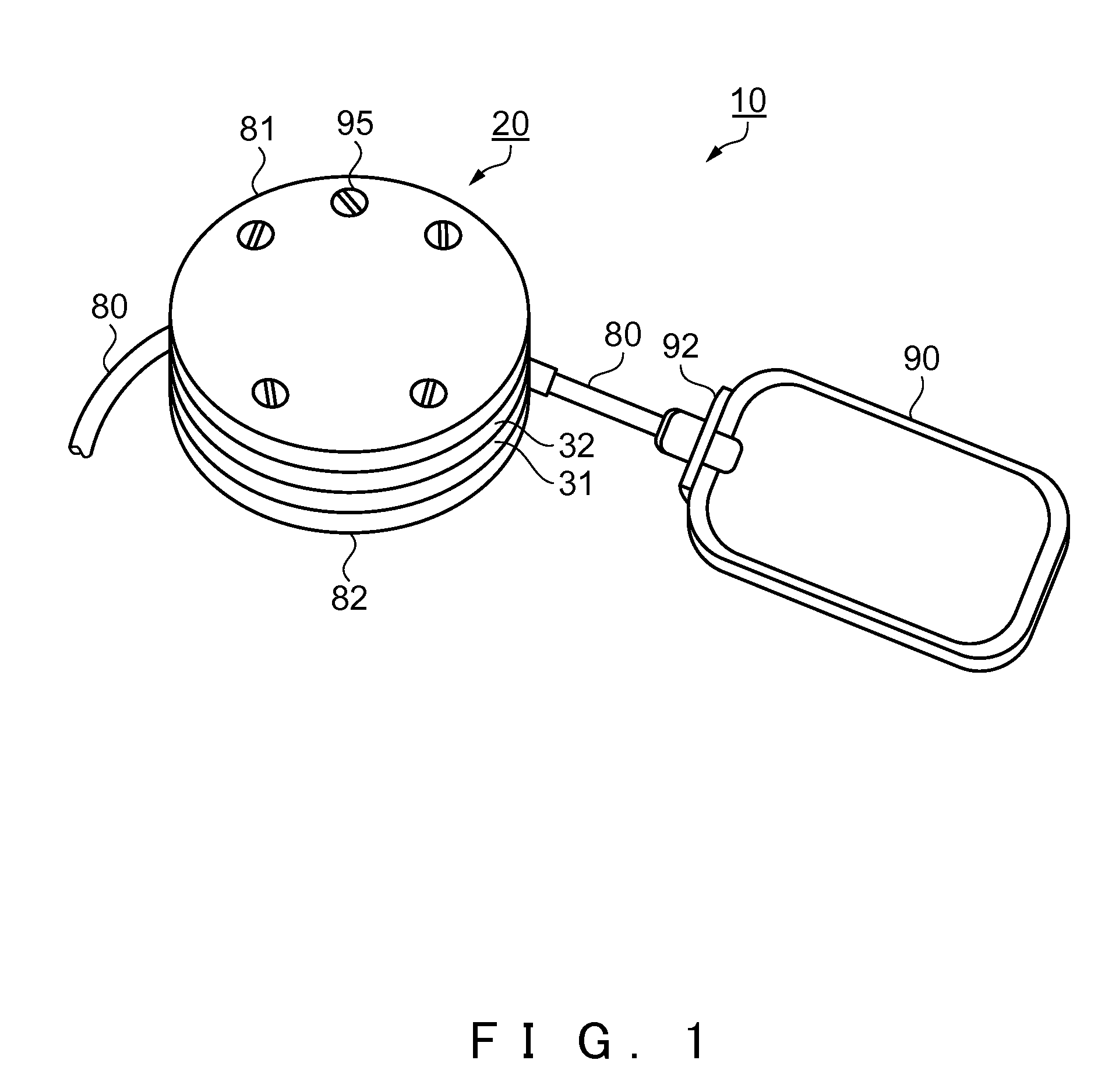

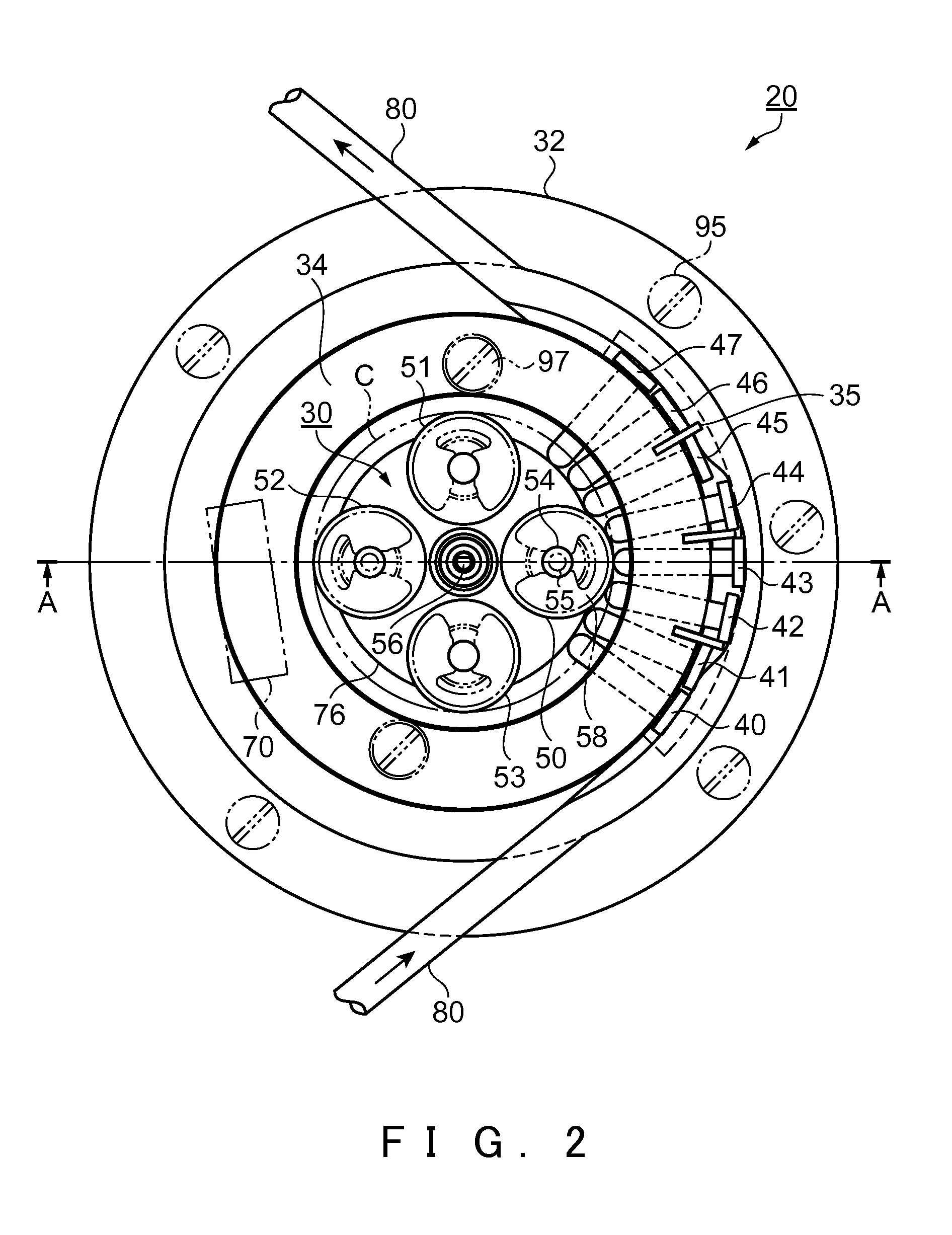

Fluid transporting device, and fluid transporter

InactiveUS20100074781A1Stable flow rateEasy to provideFlexible member pumpsPressure infusionFluid transportMechanical engineering

Owner:SEIKO EPSON CORP

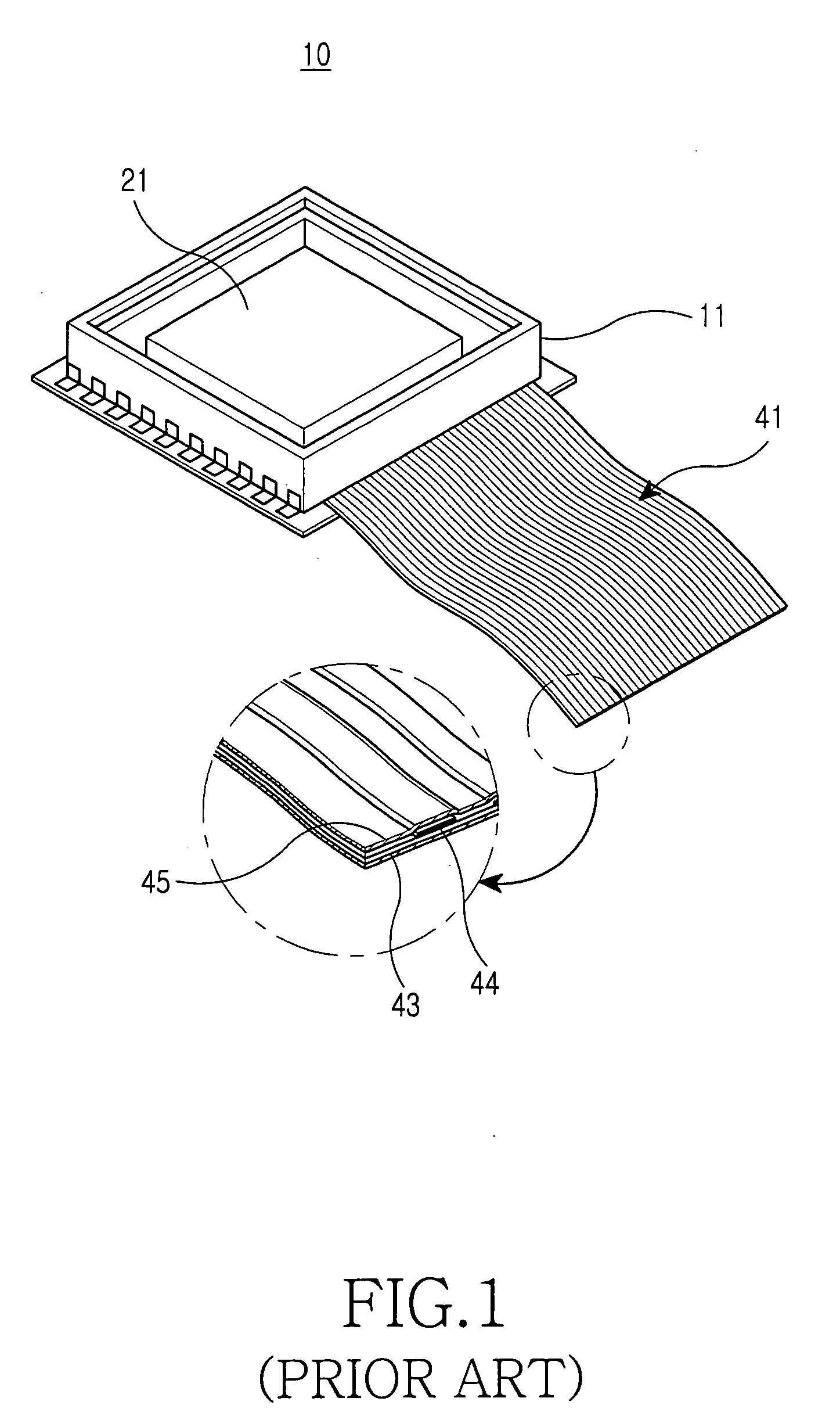

Optical image stabilizer for camera lens assembly

InactiveUS20070025710A1Reduce circuit loadReduce loadTelevision system detailsPrinted circuit aspectsCamera lensEngineering

An optical image stabilizer for use in a camera lens assembly includes: a main frame including a main circuit board; a driving frame installed so as to move on the main frame in at least one direction; a camera device including a sub-circuit board, the camera device being mounted on the driving frame; and a circuit connection for electrically connecting the main circuit board to the sub-circuit board, wherein the circuit connection includes both of its ends coupled to the main circuit board and the sub-circuit board, respectively, and a plurality of lead wires constructed so as to be moved separately with respect to the main circuit board and the sub-circuit board.

Owner:SAMSUNG ELECTRONICS CO LTD +1

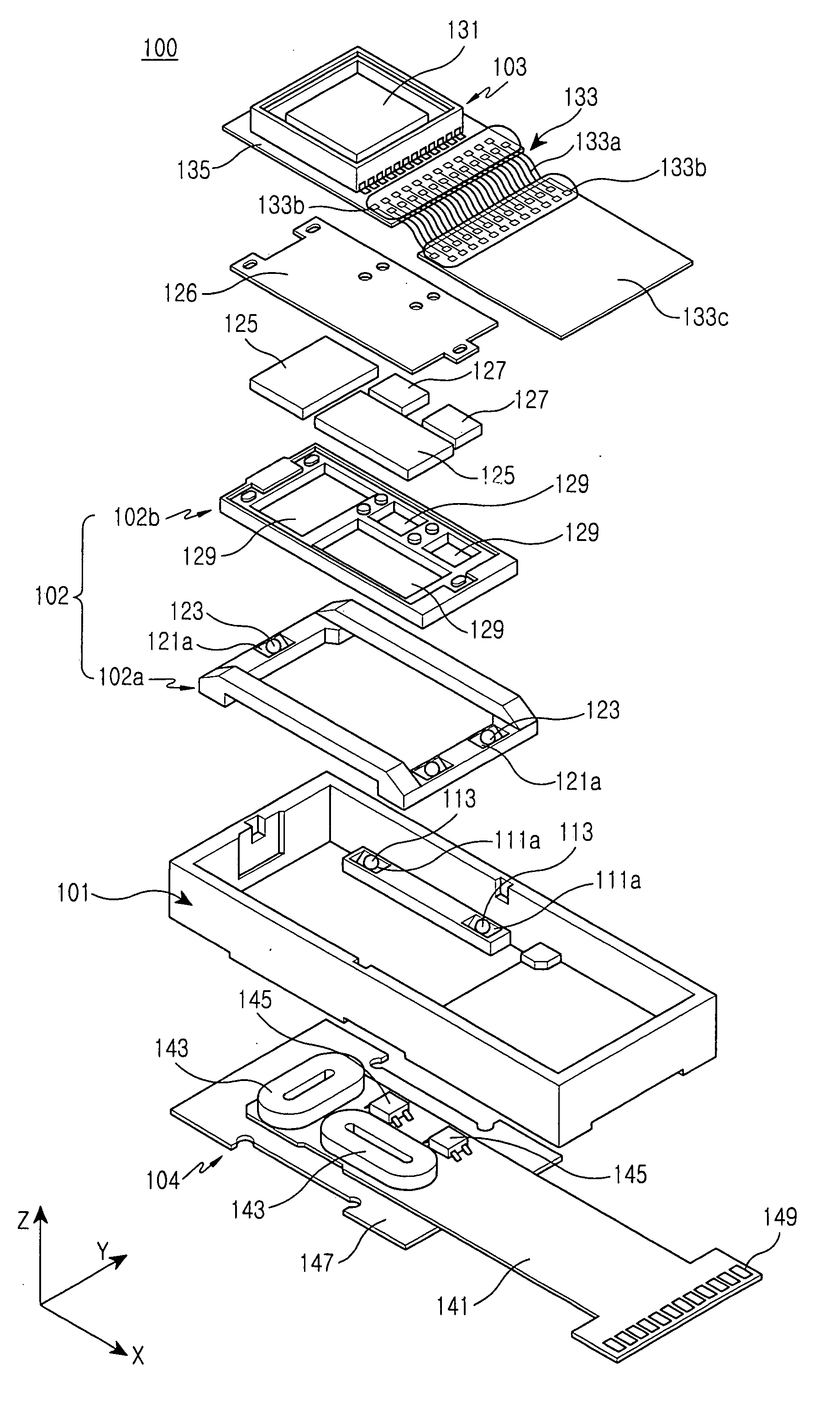

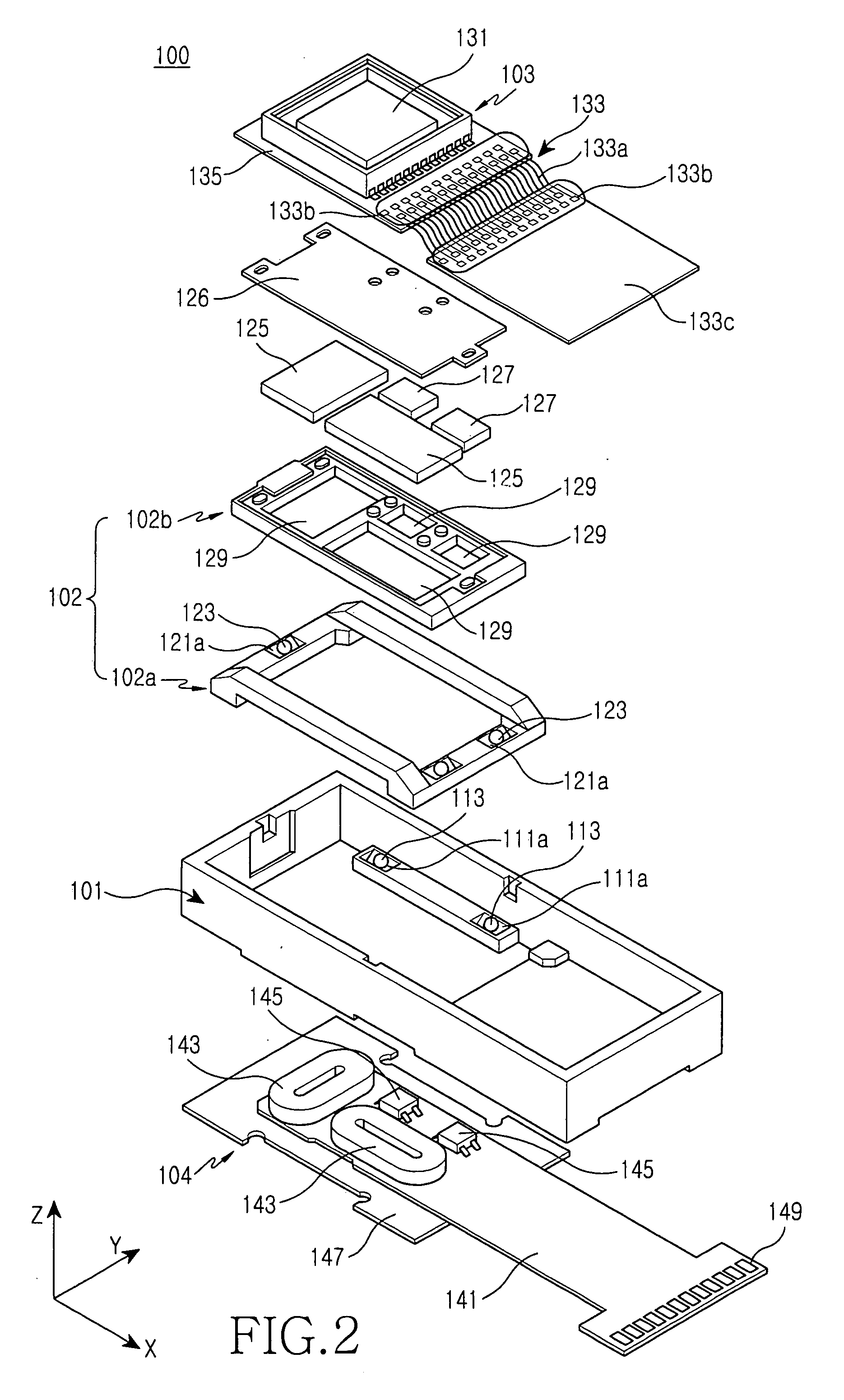

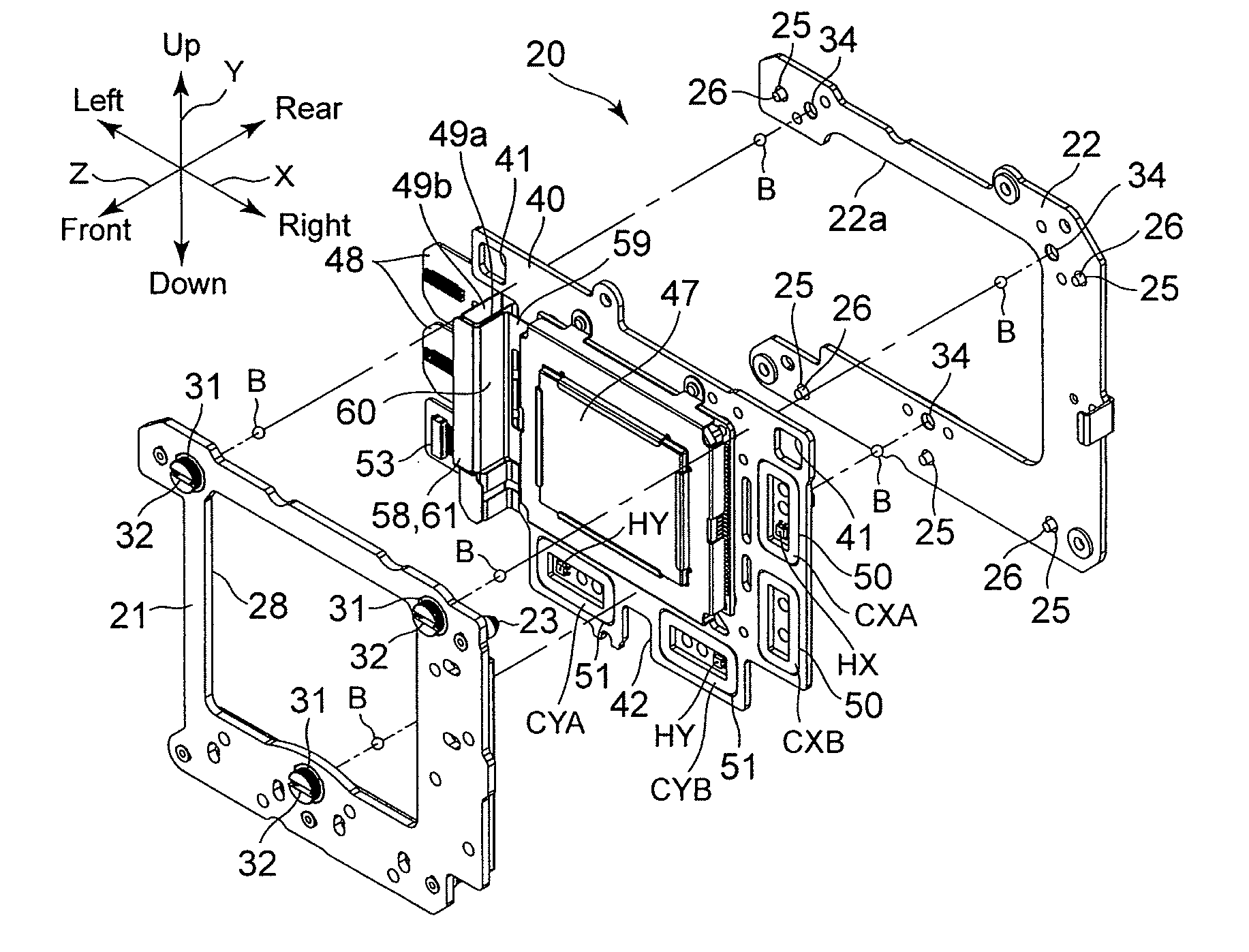

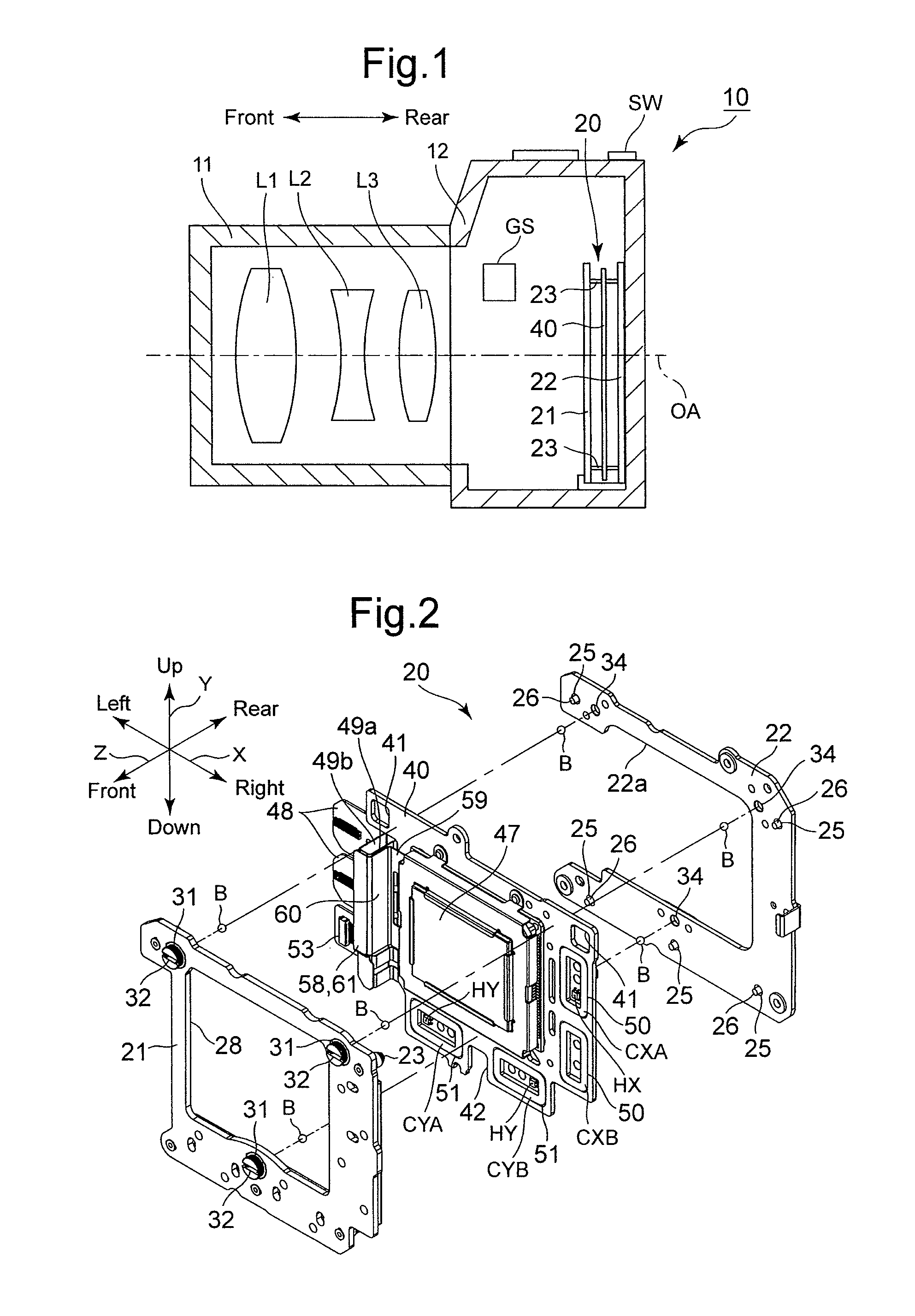

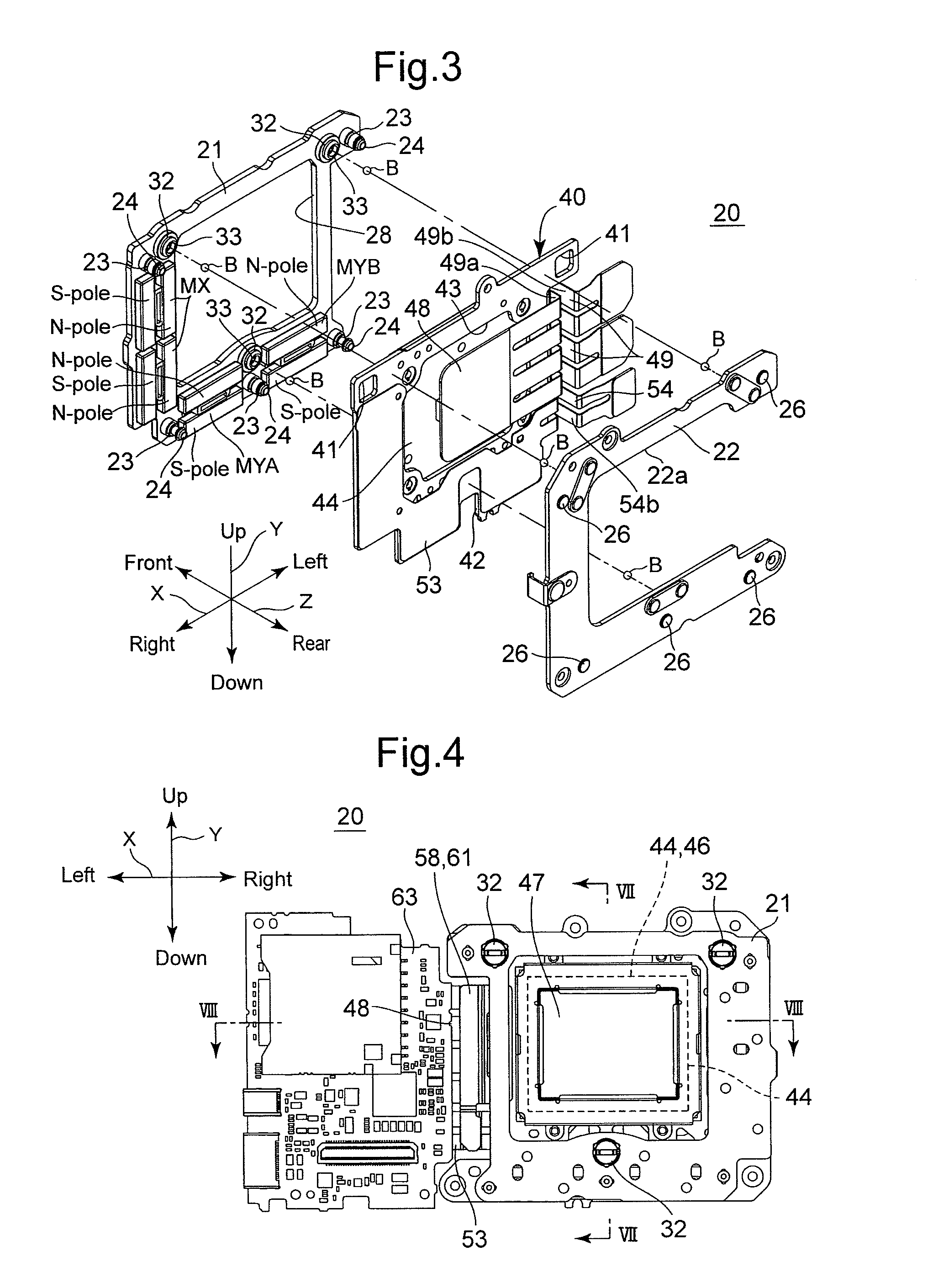

Stage apparatus and camera shake correction apparatus

ActiveUS20130194442A1Easy to touchProtection from damageTelevision system detailsColor television detailsEngineeringControl circuit

A stage apparatus includes a stationary support plate, magnetic force generators immovable relative to the stationary support plate, a stage member, an image sensor fixed to the stage member, a control circuit board connected to a side of the stage member, and coils which produce a driving force upon a supply of electric current thereto, the coils being fixed to the stage member at an opposite side of the center of the stage member with respect to the control circuit board, and a FPC board between the stationary support plate and the stage member. The stationary support plate is recessed, from a lateral edge of the stationary support plate at which the control circuit board is provided, in a direction toward the coils and includes an FPC board escape recess, in which said FPC board is partially positioned.

Owner:RICOH IMAGING COMPANY

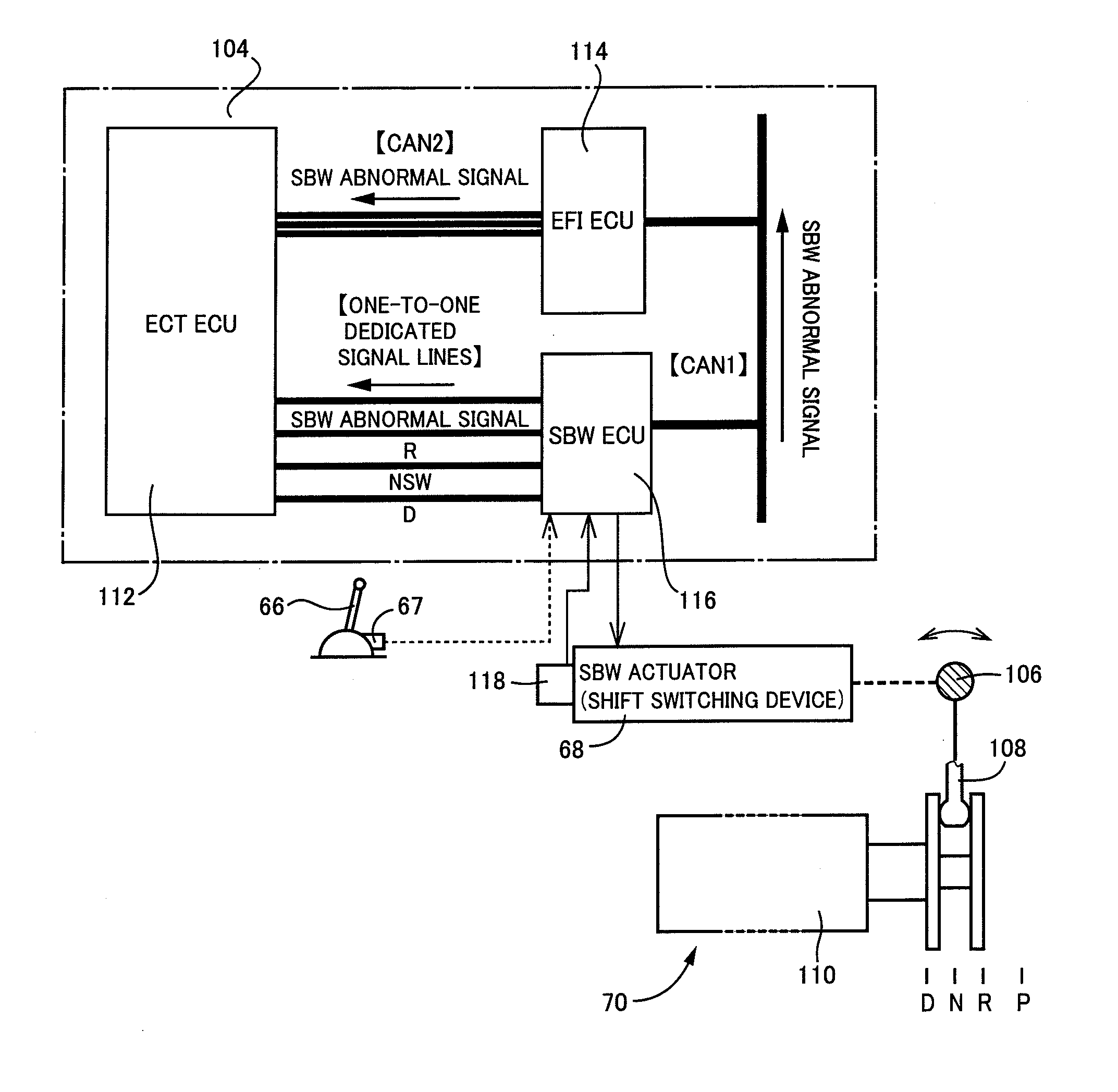

Vehicle control device

ActiveUS20110112736A1Prevent performanceReduce driving forceDigital data processing detailsAutomatic initiationsVariatorDriving range

A vehicle control device having a shift-by-wire system that switches a driving range of a vehicle transmission by inputting a range switching signal to a shift switching device, includes: an abnormality detecting means that detects an abnormality that the shift switching device cannot switch the driving range, of the shift-by-wire system; and a driving force suppressing means that suppresses a driving force of a vehicle when an abnormality is detected in the shift-by-wire system and when a vehicle stop is predicted, and the driving force suppressing means switching a gear stage of the vehicle transmission to a higher-speed gear stage.

Owner:TOYOTA JIDOSHA KK

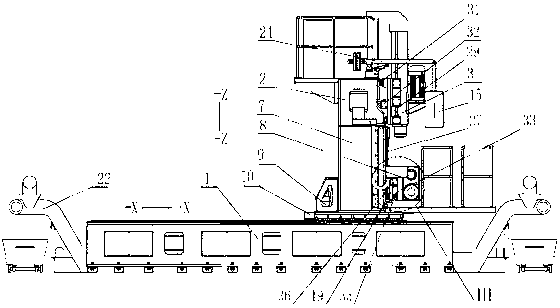

Gantry movable type multifunctional numerical-control drilling and milling machine

ActiveCN103203626AReduce labor intensityIncrease productivityFeeding apparatusOther manufacturing equipments/toolsNumerical controlEngineering

A gantry movable type multifunctional numerical-control drilling and milling machine comprises a machine body. Upright columns are slidably supported on the machine body, a crossbeam mechanism is fixedly arranged on the upright columns, an upper drilling and milling mechanism is slidably supported on the crossbeam mechanism, a left machine body is connected with a right machine body by a middle connecting frame, a workbench is fixedly arranged on the connecting frame, the left upright column and the right upright column are respectively slidably supported on the left machine body and the right machine body, the crossbeam mechanism crosses the left upright column and the right upright column and is fixedly arranged on the left upright column and the right upright column, the upper drilling and milling mechanism is slidably supported on the crossbeam mechanism, and a first spindle of the upper drilling and milling mechanism ascends and descends under control of a lifting mechanism and is driven by a first servo motor to rotate; and a lateral drilling and milling mechanism is slidably supported on the left upright column by a moving frame, a second spindle of the lateral drilling and milling mechanism is driven by a second servo motor to rotate, and the lateral drilling and milling mechanism is slidably supported on the moving frame. The gantry movable type multifunctional numerical-control drilling and milling machine has the advantages that lateral surfaces and an upper plane of a part can be simultaneously milled and then are drilled, accordingly, the production efficiency is improved, the labor intensity of workers is reduced, and the machining precision is guaranteed.

Owner:WUXI HUALIAN SCI & TECH GROUP

Method of manufacturing resin molded product

Owner:YOSHIDA KOGYO KK

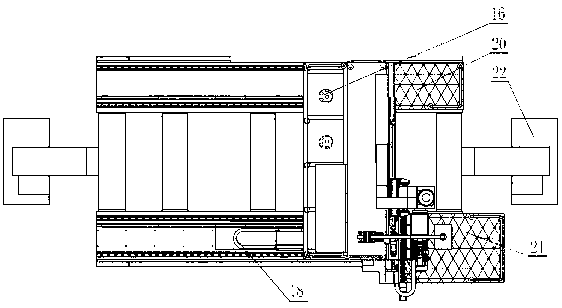

Variable nozzle mechanism

ActiveUS20100202874A1Reduce risk of damageReduce forceEngine manufactureWind motor controlEngineeringNozzle

When changing a nozzle blade angle by rotating a drive ring, a contact load generated between an inner circumferential surface of the drive ring and an outer circumferential surface of a mount can be reduced, allowing the drive ring to rotate smoothly and reducing the amount of wear and a driving force. It is also possible to reduce an impact force, such as engine vibrations, generated at the drive ring when an external force acts, reducing the risk of damage. A plurality of notches (19) are provided at an inner rim of the drive ring (14), and, among inner circumferential surfaces (14a, 14b, 14c, 14d, 14e, 14f, 14g, and 14h) located between the notches (19), when a driving force for rotating the drive ring (14) is applied, the inner diameters of the inner circumferential surfaces (14e, 14f, 14g, and 14h) where the contact load with the outer circumferential surface of a mount becomes large are made larger than the outer diameter of the outer circumferential surface.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

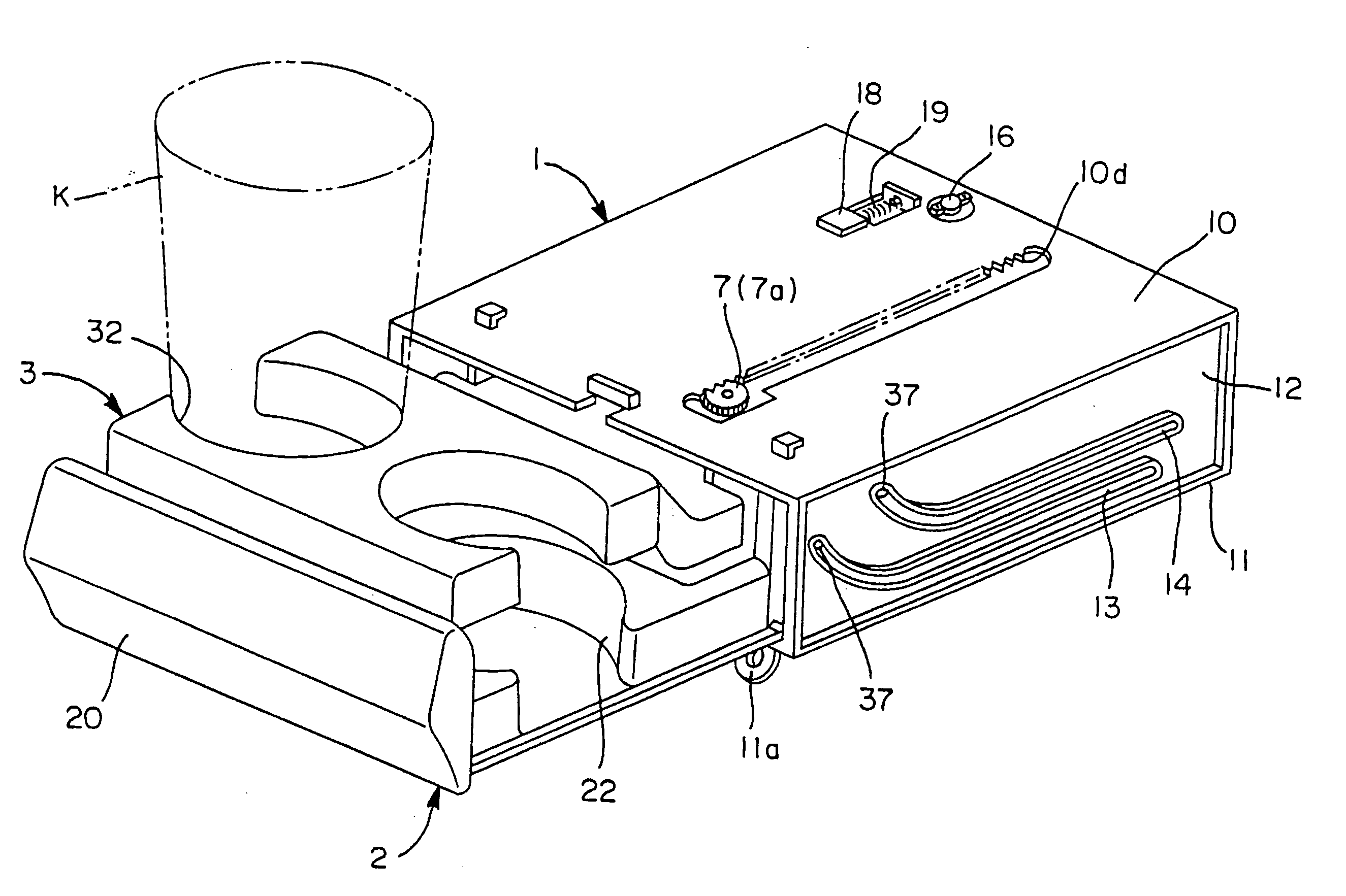

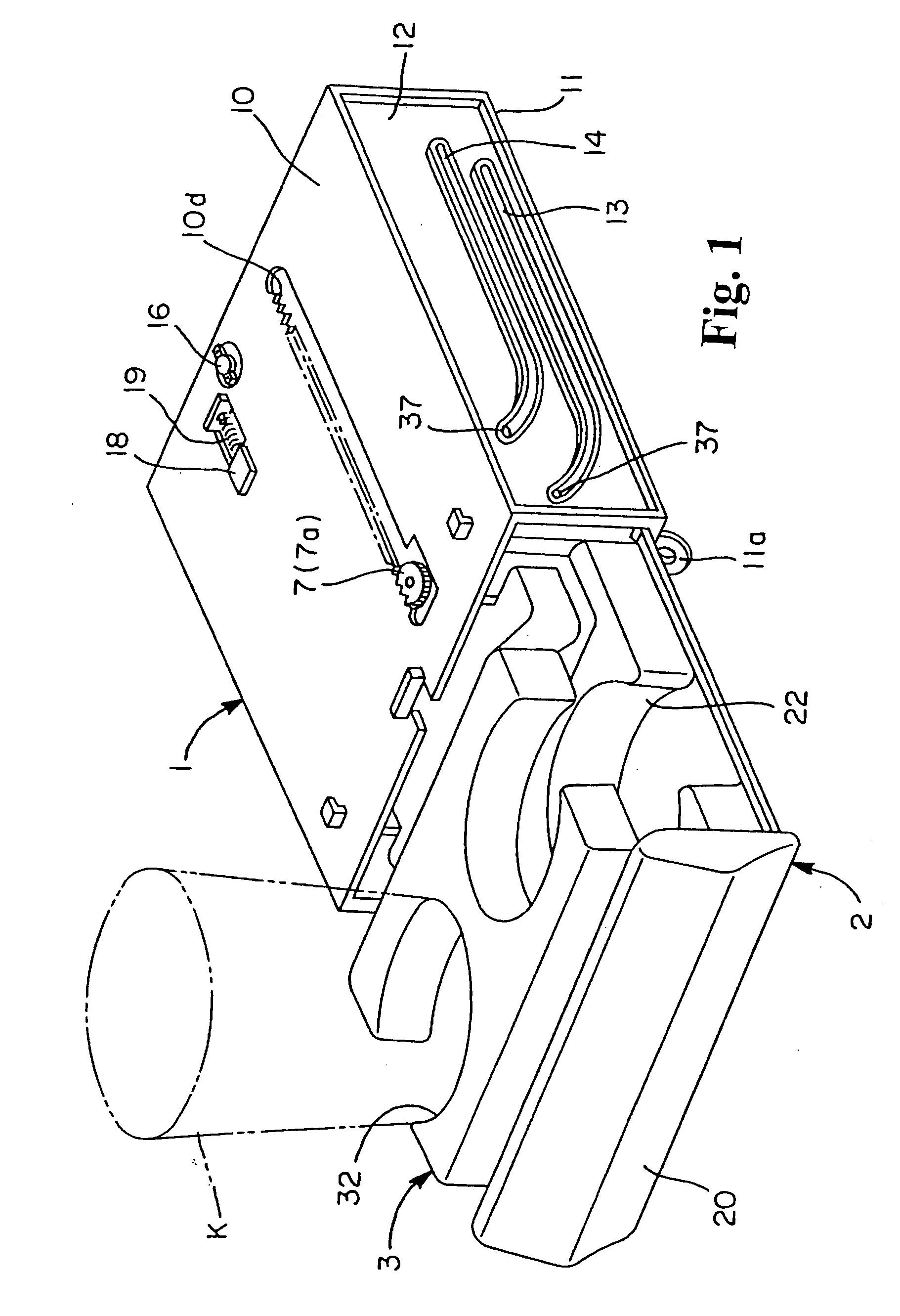

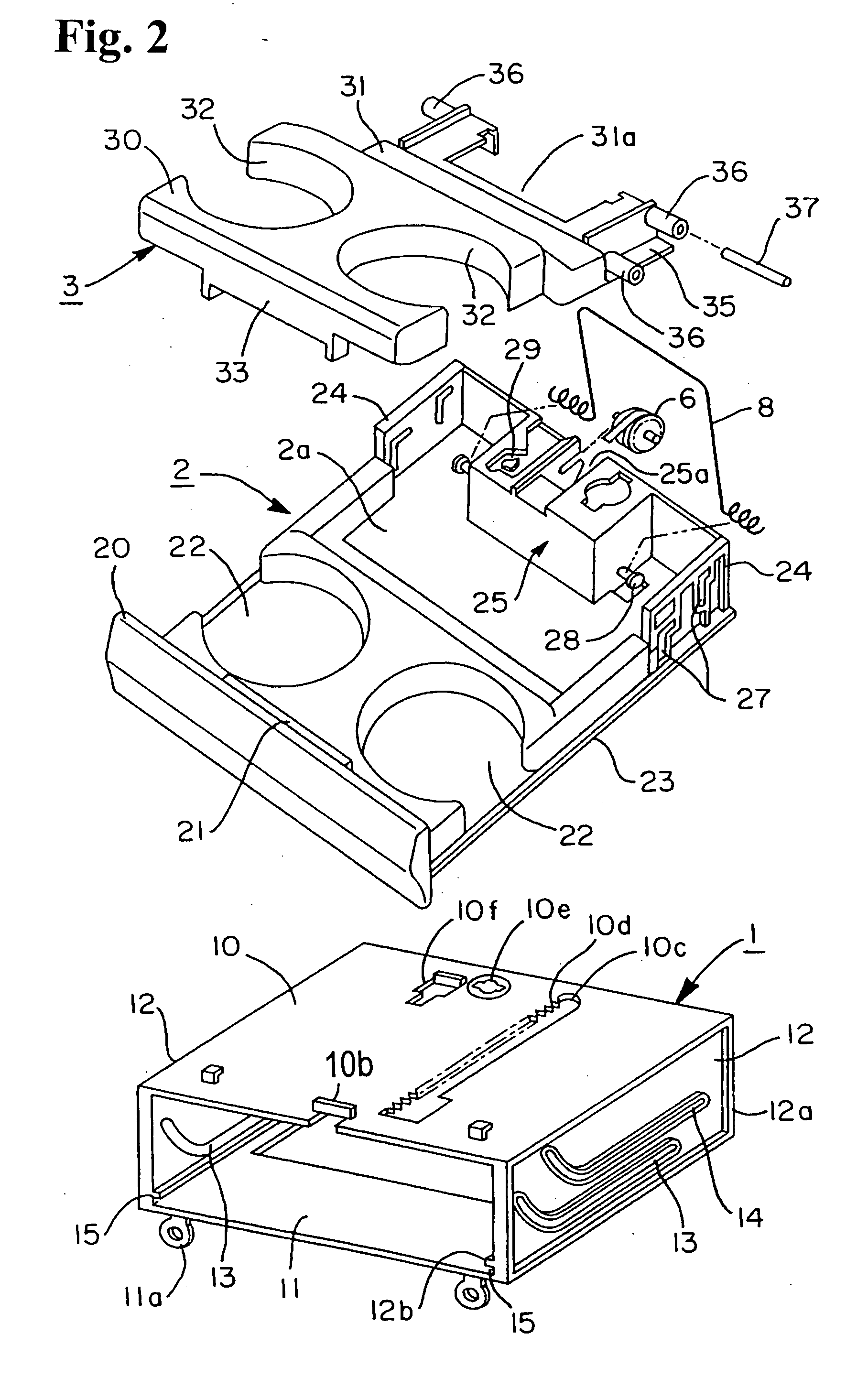

Cup holding device

ActiveUS20050000991A1Improve design flexibilityReduce the driving forcePassenger spaceVehicle arrangementsMechanical engineeringEngineering

A cup holding device includes a storage case having a front opening; a tray for placing a container movable between a drawn position where the tray is drawn forward from the storage case and a storage position where the tray is stored in the storage case; a holding member attached to the tray for holding the container and movable between a non-usable position where the holding member is retained in the tray and a usable position where the holding member rises above the tray; and a supporting rib. The rib is disposed at a forward end of the tray for supporting a forward end of the holding member when the tray moves forward to the drawn position and the holding member moves to the usable position, and is situated in a space formed in the holding member when the holding member is at the non-usable position.

Owner:NIFCO INC

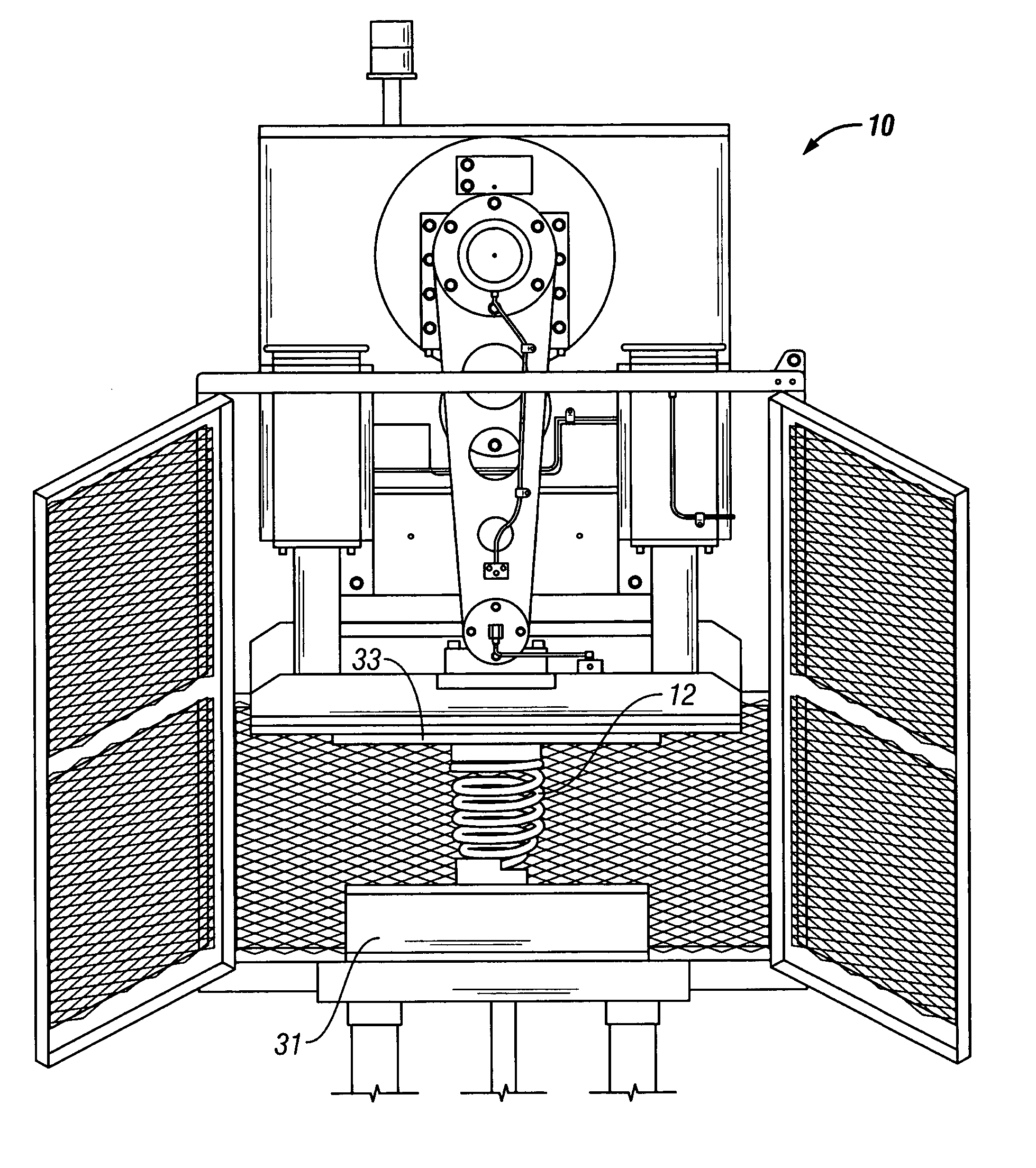

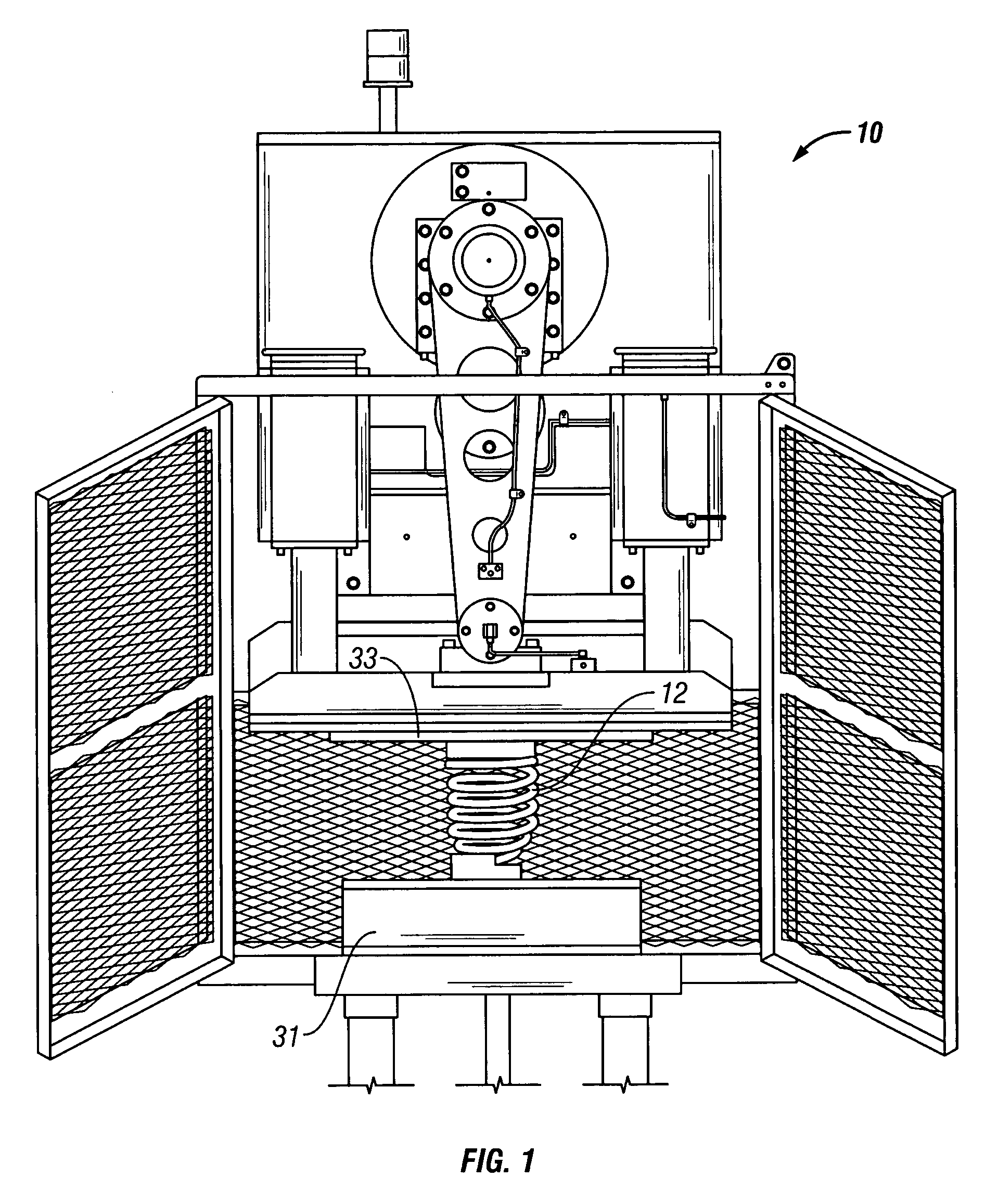

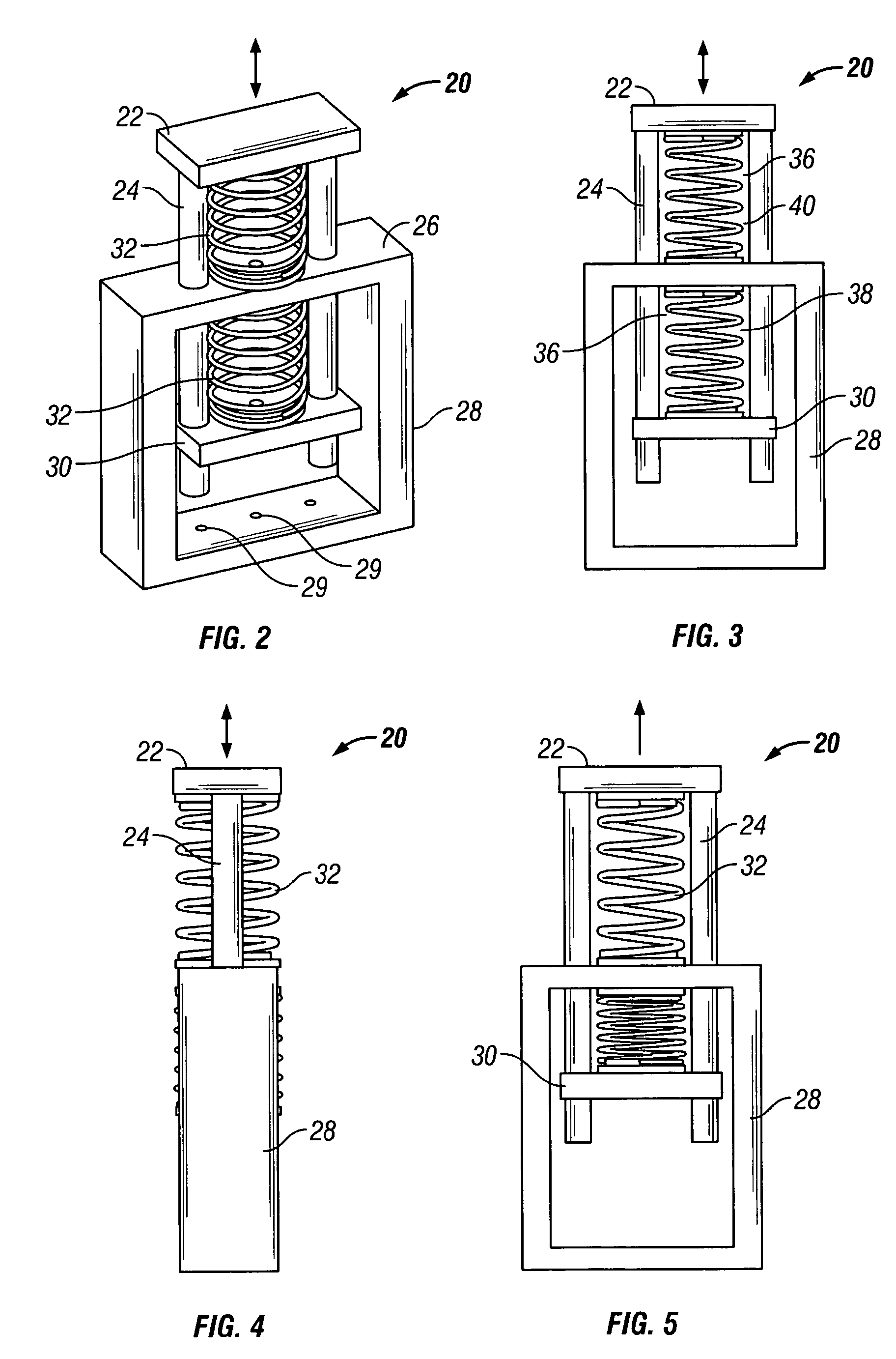

Method and apparatus for fatigue testing

ActiveUS20050050963A1Increase testing capacityIncreased capacity of testing compressionMechanical vibrations separationMaterial strength using repeated/pulsating forcesFatigue testingMechanical engineering

A fatigue test system includes a frame having top, intermediate and bottom supports each operatively interconnected by at least one extension, and the intermediate support being disposed between the top and bottom supports. The fatigue test system further includes a driving mechanism connectable to one of the supports to drive the support substantially along a longitudinal axis of the extension for fatigue testing at least one spring disposed between the top and intermediate supports, and at least one further spring disposed between the intermediate and bottom supports. In an alternative embodiment, the fatigue test system includes a frame including top and bottom supports each interconnected by an extension, and a driving mechanism disposed between the top and bottom supports for driving springs against the top and bottom supports, each spring being fatigue tested by being driven along a longitudinal axis of the extension or a central axis of the spring.

Owner:NHK SPRING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com